Page 1

Instruction and

*1.039359ENG*

recommendation booklet

IE

AUDAX PRO

5 - 8 - 10

Page 2

Page 3

Dear Customer,

Our compliments for having chosen a top-quality Immergas product, able to assure well-being and safety for a long period of time. As an Immergas customer

you can also count on a qualied aer-sales service, prepared and updated to guarantee constant eciency of your heat pump. Read the following pages

carefully: you will be able to draw useful suggestions regarding the correct use of the appliance. By respecting these suggestions, you will no doubt be satised

with your Immergas product.

For assistance and scheduled maintenance, contact Authorised Immergas Aer-Sales centres: they have original spare parts and are specically trained directly

by the manufacturer.

General recommendations

All Immergas products are protected with suitable transport packaging.

e material must be stored in dry environments protected from bad weather.

e instruction book is an integral and essential part of the product and must also be given to the new user in the case of transfer or succession of ownership.

It must be stored with care and consulted carefully, as all of the warnings provide important safety indications for installation, use and maintenance stages.

is instruction manual provides technical information for installing the Immergas pack. As for the other issues related to pack installation (e.g. safety in the

work site, environment protection, injury prevention), it is necessary to comply with the provisions specied in the regulations in force and good practice rules.

In compliance with the legislation in force, the systems must be designed by qualied professionals, within the dimensional limits established by the Law.

Installation and maintenance must be performed in compliance with the regulations in force, according to the manufacturer's instructions and by professionally

qualied sta, intending sta with specic technical skills in the plant sector, as envisioned by the Law.

Improper installation or assembly of the Immergas appliance and/or components, accessories, kit and devices can cause unexpected problems for people, animals

and objects. Read the instructions provided with the product carefully to ensure proper installation.

Maintenance must be carried out by skilled technical sta. e Immergas Authorised Aer-sales Service represents a guarantee of qualications and

professionalism.

e appliance must only be destined for the use for which it has been expressly declared. Any other use will be considered improper and therefore potentially

dangerous.

If errors occur during installation, operation and maintenance, due to non-compliance with technical laws in force, standards or instructions contained in

this book (or however supplied by the manufacturer), the manufacturer is excluded from any contractual and extra-contractual liability for any damages and

the appliance warranty is invalidated.

For further information regarding legislative and statutory provisions relative to the installation of heat pumps, consult the Immergas site at the following

address: www.immergas.com

CE DECLARATION OF CONFORMITY

For the purpose and eects of the CE 2004/108 ''Electromagnetic Compatibility'' and CE 2006/95 Low Voltage Directives.

e Manufacturer: Immergas S.p.A. v. Cisa Ligure n° 95 42041 Brescello (RE)

DECLARES THAT: Immergas packs model:

Audax Pro 5 - 8 - 10

complies with the same European Community Directives

Signature:

Mauro Guareschi

Research & Development Director

Immergas S.p.A. declines all liability due to printing or transcription errors, reserving the right to make any modications to its technical and commercial

documents without prior notice.

Page 4

INDEX

1 Safety precautions ...............................................5

1.1 Hazard. ..........................................................5

2 Unit specications. .............................................6

2.1 Main dimensions..........................................6

2.2 Outdoor unit specications. ....................... 6

3 Unit installation. .................................................7

3.1 Selecting the installation position of the

outdoor unit. ........................................................7

3.2 Locations where the unit cannot be

installed. ...............................................................7

3.3 Minimum installation distances for

individual units. .................................................. 8

3.4 Minimum installation distances for more

than one unit. ......................................................8

3.5 Installing the outdoor unit. ...............................9

3.6 Outdoor unit mount structure. .................. 9

3.7 Drainage. .....................................................10

3.8 Installing the unit in harsh climates. .......11

4 Electrical connections. ..................................... 12

4.1 General connection conguration. ..........12

4.2 Power cable features. .................................12

4.3 Connection features between indoor and

outdoor units (commonly used). ....................12

4.4 Terminal board features. ........................... 13

4.5 Supply voltage cable connection. .............14

5 Installing the chiller lines. ................................15

5.1 Chiller line geometric limits and

installation examples. .......................................15

5.2 Pipe cutting and aring ............................. 16

5.3 Selecting chiller line insulation. ...............17

5.4 Insulating the chiller lines. ........................17

5.5 Welding the pipes. ...................................... 17

5.6 Using Nitrogen. ..........................................17

5.7 Pressure testing and leak check. ............... 18

5.8 Putting under drying vacuum. ................. 19

5.9 Topping up the coolant load. .................... 20

5.10 Adding coolant. ................................................. 20

5.11 Putting in the coolant. ...................................... 20

5.12 Important information on the coolant used .20

5.13 Topping up the load. .........................................21

5.14 Service valve ...................................................... 21

6 Checking the earthing connection ................. 22

7 Micro-switch setting and key function ..........23

7.1 Operating Test. ........................................... 23

7.2 Data display mode ..................................... 24

7.3 Micro-switch setting. ................................. 25

8 Pump down procedure. ....................................26

8.1 Purpose of pump down. ............................ 26

8.2 Precautions to take before performing

pump down. .......................................................26

8.3 Precautions to take before performing

pump down. .......................................................26

8.4 Transferring the coolant into an external

tank before performing pump down. .............26

8.5 Recovering large quantities of coolant. ...27

9 Completing installation. ..................................28

9.1 Checks at the end of installation. ............. 28

9.2 Final checks and operating test ................ 28

10 Yearly unit check and maintenance. ............... 29

11 Troubleshooting. ............................................... 30

11.1 Fault codes. ................................................30

Page 5

SAFETY

1

PRECAUTIONS

e following listed precautions must be taken

scrupulously, as they are essential in ensuring the

integrity of Immergas products.

HAZARD:

- Before servicing or accessing the inner parts,

the Air-Water Heat Pump supply voltage must

be disconnected.

- Only qualied personnel must do the installation and operating test.

- To prevent serious damage to the system and

serious accidents to users, all the precautions

and suggestions in this manual must absolutely

be taken.

1.1 HAZARD.

- This manual must be read carefully before

installation and then kept in a safe place, where

it can easily be found for future needs.

- For his/her own safety, the installer is required

to carefully read all the instructions contained

in this manual.

- e user installation and instructions manual

must be given to the user to keep in a safe place,

where it can be accessed for future needs or in

the event it needs to be handed over to a new

user following sale of the heat pump or of the

building in which it is installed.

- is manual explains the installation methods

of an Immergas Water-Air heat pump system.

Using unapproved components and/or different types of control systems automatically

invalidates any form of Warranty provided by

the manufacturer. In fact, the manufacturer

cannot be held liable for damages caused by

changes or methods of use that it did not previously authorise.

- This unit is compliant with the dictates of

the European Union Low Voltage Directive

(2006/98/CE) and Electromagnetic Compatibility Directive (2004/108/CEE).

- e manufacturer shall not be held liable for

any damage caused by changes that were not

previously authorised in writing or by errors

in connecting the hydraulic and/or electrical

lines. Failure to follow these instructions and/or

using the unit out of the limits in the "Operating

Limits" table automatically invalidates any form

of Warranty provided by the manufacturer.

- e warranty shall be automatically invalidated

in the event even just one of these instructions

was not followed and the unit was made to

operate outside the Operating Field (Central

heating: from -25 to 35°C/Cooling: from 10 to

45°C) shown in the Unit Specications on page

5 of this manual.

- e unit must not be used if it is damaged or

shows signs of faults; for example, excessive

noise or a burning smell.

- To prevent electrical shock, res and/or accidents, if the unit gives o smoke, the power

cable overheats and/or is damaged, and/or the

unit becomes very noisy, it is of fundamental

importance to open the protection switch and

contact the Immergas Customer Assistance.

- e unit, its electrical, hydraulic and refrigerant

connections, as well as its protections must be

regularly inspected. All these inspection operations must only be done by qualied personnel.

- e unit must be kept out of the reach of children, as it contains live electrical components

and moving parts.

- e unit must not be repaired, moved and/or

reinstalled by unauthorised personnel, as to do

so may cause damage to the unit and/or cause

electrical shock and/or res.

- ere must be no containers containing uids

or other objects on the unit.

- All the materials used to produce and package

the air-water heat pump are recyclable.

- e packaging materials and the remote control

(optional) batteries, when exhausted, must

be disposed of in compliance with the local

standards in force.

- At the end of its life cycle, the air-water heat

pump, which is special waste and contains

coolant, must be disposed of by bringing it

to an authorised centre or returning it to the

dealer where it was purchased.

- To prevent the risk of injury from contact with

the edges of the components, work gloves must

be worn when unpacking, handling, installing

and servicing the unit.

- The inner components (hydraulic pipes,

coolant pipes, heat exchangers, etc.) must not

be touched with bare hands when the unit is

operating. If they must be touched, the unit

must rst be switched o, waiting the amount

of time necessary for it to cool down and, in

any case, wearing protective gloves.

- In the event of coolant leaks, do not touch the

leaking coolant to avoid serious injury.

- If the heat pump is installed in a closed room,

any necessary forced ventilation devices must

be provided for. ey must be the proper size

so that, in the event of leaks, the level of coolant

in the air cannot exceed the allowed limits.

- Otherwise, the people in the room under these

circumstances would be subjected to serious

risks of suocation, with even fatal eects.

- e packaging material must be disposed of

safely. It may contain nails or pieces of wood

that could injure people.

- Upon receiving the machine, it must be inspected for any damages during transport. Should

such damages be found, it MUST NOT BE

INSTALLED and the damages found must be

immediately communicated in writing to the

courier or the dealer (in the event the unit was

picked up at a dealer).

- e unit must be installed respecting the spaces

indicated in the Installation Manual in order to

make it possible to access both sides of it and

carry out maintenance operations. Should it

be installed not respecting the procedures indicated in this Manual, any expenses due to the

need to use ladders, scaolding or other raised

systems for any warranty operations shall NOT

be considered covered by the warranty itself

and, therefore, shall be entirely charged to the

Customer.

- The supply voltage line must have all the

features required by the standards in force

regarding the installation site.

- Make sure the supply voltage mains voltage

and frequency are compatible with what the

unit requires and that the system has enough

power available to supply the unit and all the

other electrical utilities it supplies. Also make

sure that all the safety switches of this system

are of the proper dimension.

- Make sure that the entire electrical system

(cables, conductor cross-sections, protections,

etc.) are compliant with the standards in force

at the installation site and with the instructions contained in the wiring diagram. All

the connections must also be compliant with

the dictates of the local standards regarding

air-water heat pump installation. Devices that

can be disconnected from the electrical mains

must not be in overvoltage conditions.

- e earthing connection must not be done on

water or gas pipes, lightning protection systems

or telephone/intercom lines as, otherwise, there

would be serious risks of electrocution and/or

res.

- Both a circuit breaker switch and a safety differential switch must be installed, both with

a capacity compliant with the dictates of the

pertinent local standards in force.

- Otherwise, there would be serious risks of

electrocution and/or res.

- Defrost water must be able to drain normally

from the unit even when the outdoor temperature is very low. Ice plugs must not be

allowed to form on this line. Otherwise, the

resulting water may not be able to drain out of

the unit, causing large chunks of ice to form,

which could, in turn, stop the unit itself from

operating.

- e power cable and the communication cable

between the indoor and outdoor unit must run

at least 1 m away from any electrical devices.

- e unit must be protected from rodents and

other small animals. If allowed to access the

unit, such animals could cause malfunctions

and/or cause smoke emissions or res. e user

must also be given clear instructions to keep the

entire area around the unit clean and tidy.

55

Page 6

UNIT SPECIFICATIONS.

528

537

675

2

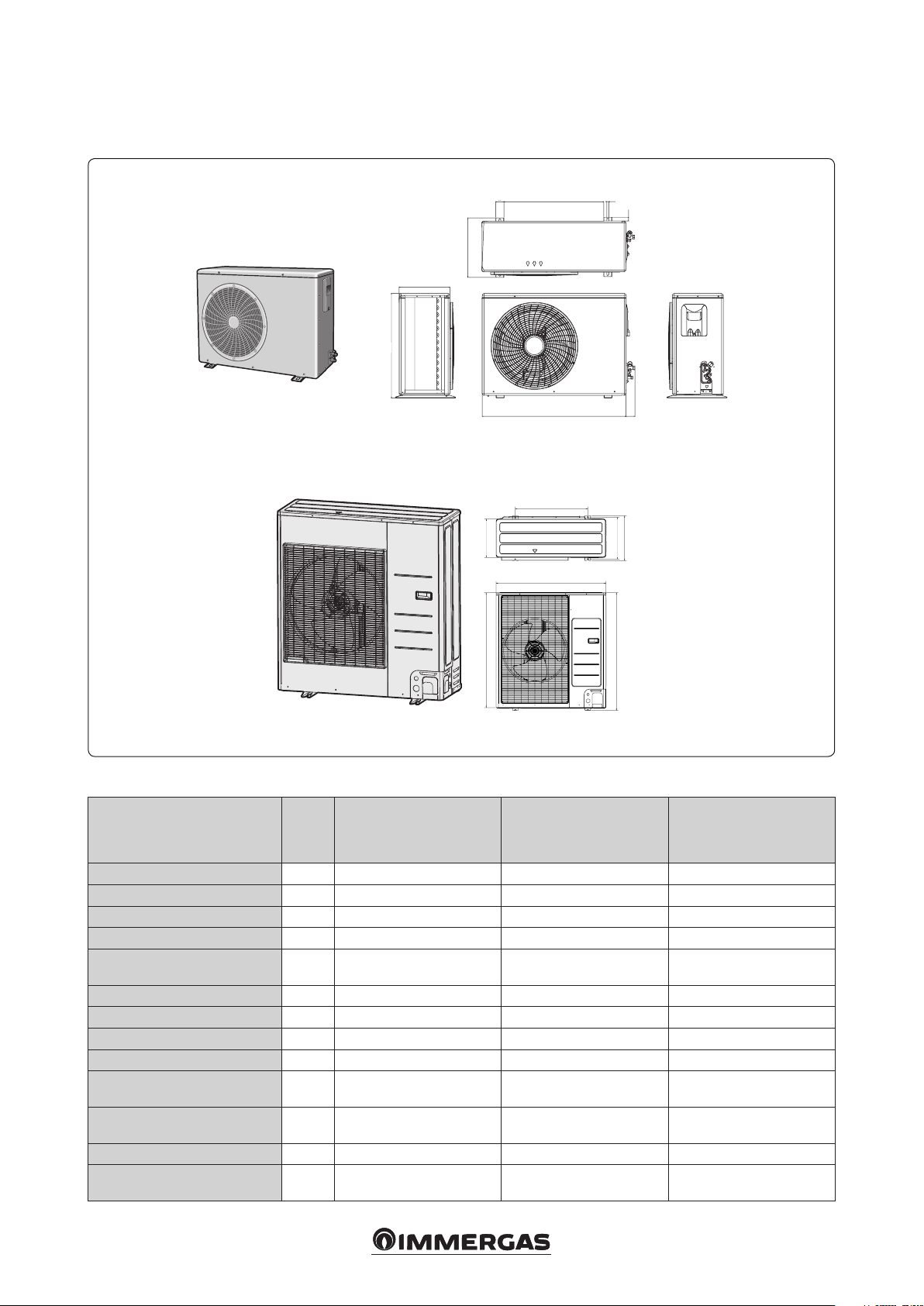

2.1 MAIN DIMENSIONS.

Audax Pro 5

Audax Pro 8 and 10

638

310

364

330973

61050

620

940

880

12

360

23

54.1

384

998

2-2

2.2 OUTDOOR UNIT SPECIFICATIONS.

Unit of

Typ e

Power Supply - 220 ~ 240 V AC / 1 F / 50 Hz 220 ~ 240 V AC / 1 F / 50 Hz 220 ~ 240 V AC / 1 F / 50 Hz

Compressor - Rotary inverter Rotary inverter Rotary inverter

Maximum input W 3200 4200 5100

Condenser - Ø 7, L 906 Ø 8, FP 1.5, L 950 Ø 8, FP 1.5, L 950

Motor fan -

Coolant load kg 1.2 2.0 2.0

Chiller line section - liquid phase 6.35 9.52 9.52

Chiller line section - gaseous phase 15.88 15.88 15.88

Sound power level dBA 62 66 66

Operating eld (central heating /

cooling)

Water output temperature °C

Weight (net / gross) kg 47.5 / 52.5 74.0 / 82.0 74.0 / 82.0

Dimensions (L x H x D, overall

clearance)

meas-

ure-

ment

°C - 20 ~ 35 / 10 ~ 46 - 20 ~ 35 / 10 ~ 46 - 20 ~ 35 / 10 ~ 46

mm 880 x 638 x 310 940 x 998 x 330 940 x 998 x 330

Audax Pro 5 Audax Pro 8 Audax Pro 10

Helicoidal, Ø420.3 with 3

blades, inverter BLDC

Cooling: 5 ~ 25

Central heating: 25 ~ 55

Helicoidal, Ø420.3 with 3

blades, inverter BLDC

Cooling: 5 ~ 25

Central heating: 25 ~ 55

Helicoidal, Ø420.3 with 3

blades, inverter BLDC

Central heating: 25 ~ 55

Cooling: 5 ~ 25

66

Page 7

UNIT INSTALLATION.

3

3.1 SELECTING THE INSTALLATION

POSITION OF THE OUTDOOR

UNIT.

e installation position must be identied in

agreement with the user and keeping the following in mind:

- e unit must not be installed upside down or

on its side, otherwise it would undergo serious damages because compressor lubrication

would be jeopardised, as the oil would spill

into the coolant circuit.

- e unit must be installed in a dry, ventilated

position but protected from sunlight and strong

winds.

- e space around the unit must be kept clean

and clear of any obstacles.

- e installation position must be such that the

noise from the unit and the air it discharges are

not of disturbance to anyone.

- e unit must be installed in a position in

which the pipes and cables can easily be connected.

- e installation position must have a stable, at

surface that can support the weight of the unit

without generating and/or amplifying noises

and vibrations.

- e unit must be installed in a position that

allows the air to be discharged outdoors with

no impediments.

- ere must be no trees near the installation

position and it must not be accessible to animals as, otherwise, the unit could have trouble

operating.

- All around the unit, there must be the space

necessary for air to circulate and there must

be no stereo, radio, television, computer, etc.

systems.

- If installed near the shoreline, the unit must not

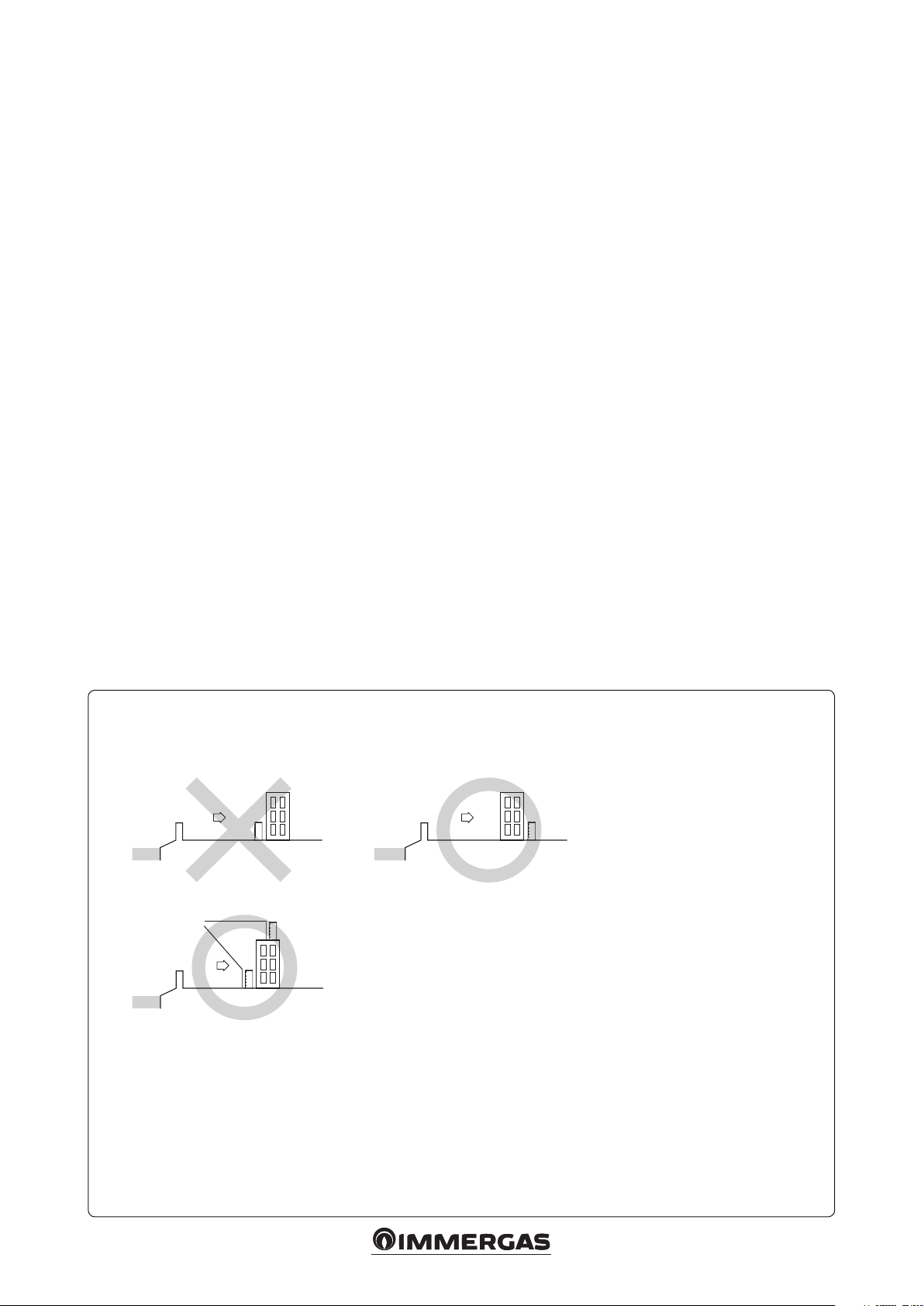

be directly exposed to salinity (see g.3-1).

3.2 LOCATIONS WHERE THE UNIT

CANNOT BE INSTALLED.

e unit must not be installed in sites where:

- ere are mineral oils or arsenic acids. Otherwise, the parts of the unit in resin could burn,

damaging it. e coolant-air exchanger could

also be damaged, which would have a very

negative impact on unit operation.

- ere are corrosive, sulphuric or acid gases like,

for example, those from chimneys or exhaust

air vents. Otherwise, the unit's copper pipes

could corrode, allowing the coolant to escape.

- ere is the risk of ammable gas leaks or there

are carbon bres or ammable dust. Petrol and/

or solvents are handled.

Attention: when the unit is installed in areas

exposed to snowfall or excessively harsh

temperatures (aka in areas with typically low

temperatures and high humidity - that is, with

temperatures below -7°C and relative humidity

above 85%), ice plugs could form in the defrosting water drainage outlets.

Any build-up of ice that forms on the unit can

damage it.

Attention: e unit must be installed respect-

ing local electrical standards.

Should the weight of the unit exceed 60 kg,

wall-mounted installation is not recommendable as it is preferable to install it on the ground

for safety reasons.

- If installed wall-mounted, the unit must be

securely attached to the structure supporting it.

- Water or condensate produced by the unit must

be able to drain out evenly and safely.

- Local regulations permitting, if it should be

installed on a road, the unit must be raised at

least 2 m from the pavement so as to prevent the

air it discharges from disturbing passers-by (to

be certain, consult the standard of town where

it is installed).

In the event of installation near the shoreline, as an alternative the unit can be positioned in a place where there is an obstacle (a

building, a wall, etc.) separating it from the sea breeze that could cover it in salinity.

Outdoor

Sea breeze

Sea

- If installed on the shoreline, the unit must always be protected by at least a wall.

Protective wall

Sea breeze

Sea

- e unit must be installed in a position in which the condensate it generates and the water resulting from defrosting can drain

out normally.

Do not hesitate to contact Immergas Customer Assistance if you are unable to satisfy all the above conditions. e coolant-air

exchanger must always be kept free of sand and sea water.

unit

Outdoor

unit

Sea breeze

Sea

e wall must be built with heavy materials like, for example,

concrete blocks and be able to stop the sea breeze. e height and

width of the protective wall must be at least 1.5 times the width

of the unit, which must be positioned at least 700 mm away from

the wall itself so as not to impede air expulsion.

Outdoor

unit

3-1

77

Page 8

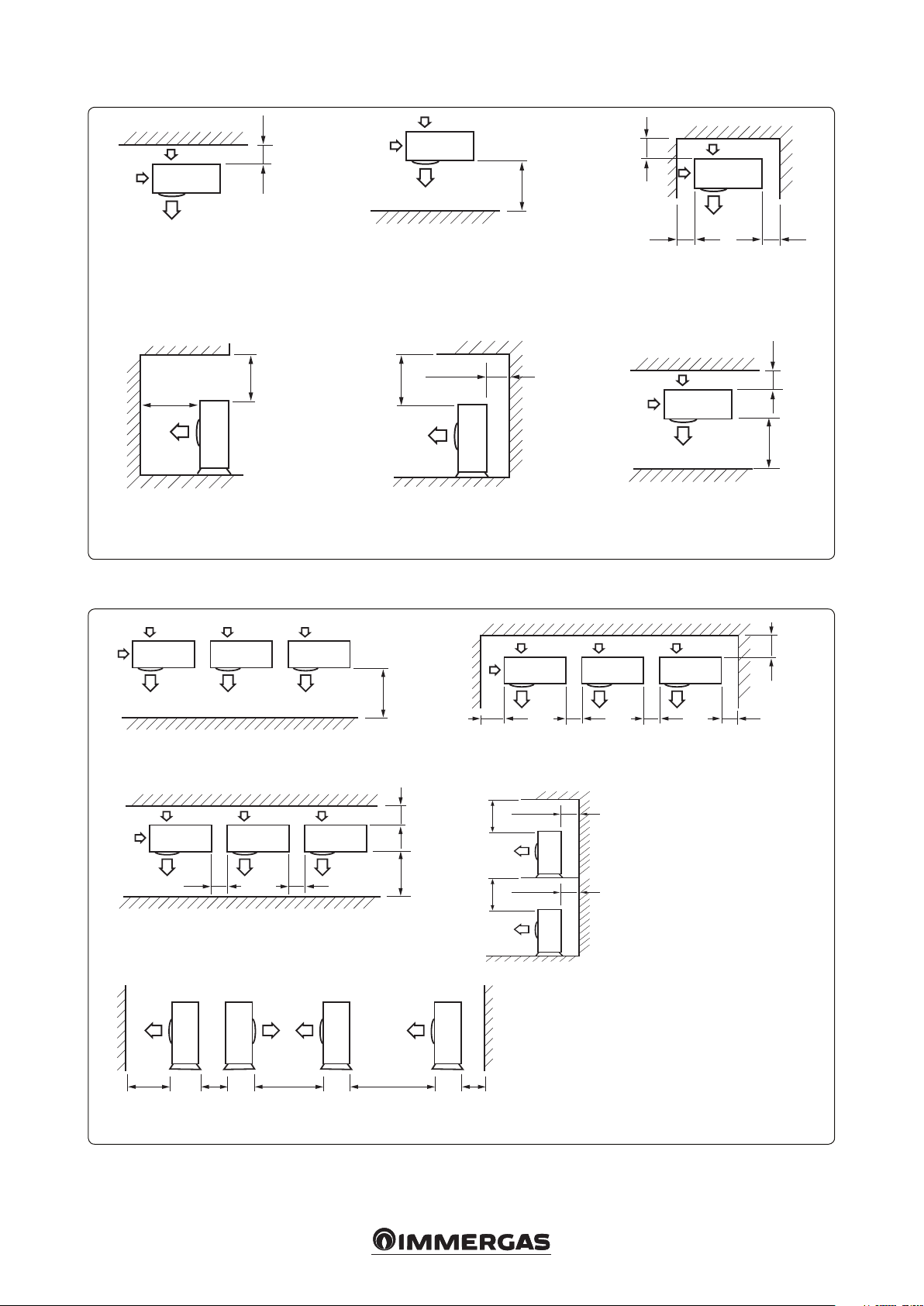

3.3 MINIMUM INSTALLATION DISTANCES FOR INDIVIDUAL UNITS.

300 min.

With the back side of the unit

facing a wall

2,000 min

1,500 min.

With the top and front sides of the

unit facing a wall

3.4 MINIMUM INSTALLATION DISTANCES FOR MORE THAN ONE UNIT.

With the front side of the unit

facing a wall

300 min.

600 min.

With the top and back sides of the

unit facing a wall

300 min.

1,500 min.

300 min. 600 min.

With three sides of the unit facing

a wall

300 min.

1,500 min.

With the front and back sides of

the unit facing a wall

3-2

1500 min.

the front side of the unit facing a wall

600 min.

With the front and back sides of the unit facing a wall

1500 min. 600 min. 3000 min. 300 min.3000 min.

With the units facing each other and with the front and back sides of the end

units facing a wall.

600 min.

300 min. 600 min. 600 min. 600 min.

With three sides of the unit facing a wall

300 min.1500 min.

500 min.

500 min.

300 min.

300 min.

300 min.

With the top and front sides of the

unit facing a wall

3-3

Attention: the spaces shown must be le free to allow air to circulate and to ensure accessibility for repairs or maintenance on every side of the units.

In fact, it must be possible to disassemble all the unit components under the utmost safety conditions (both for objects and for people).

88

Page 9

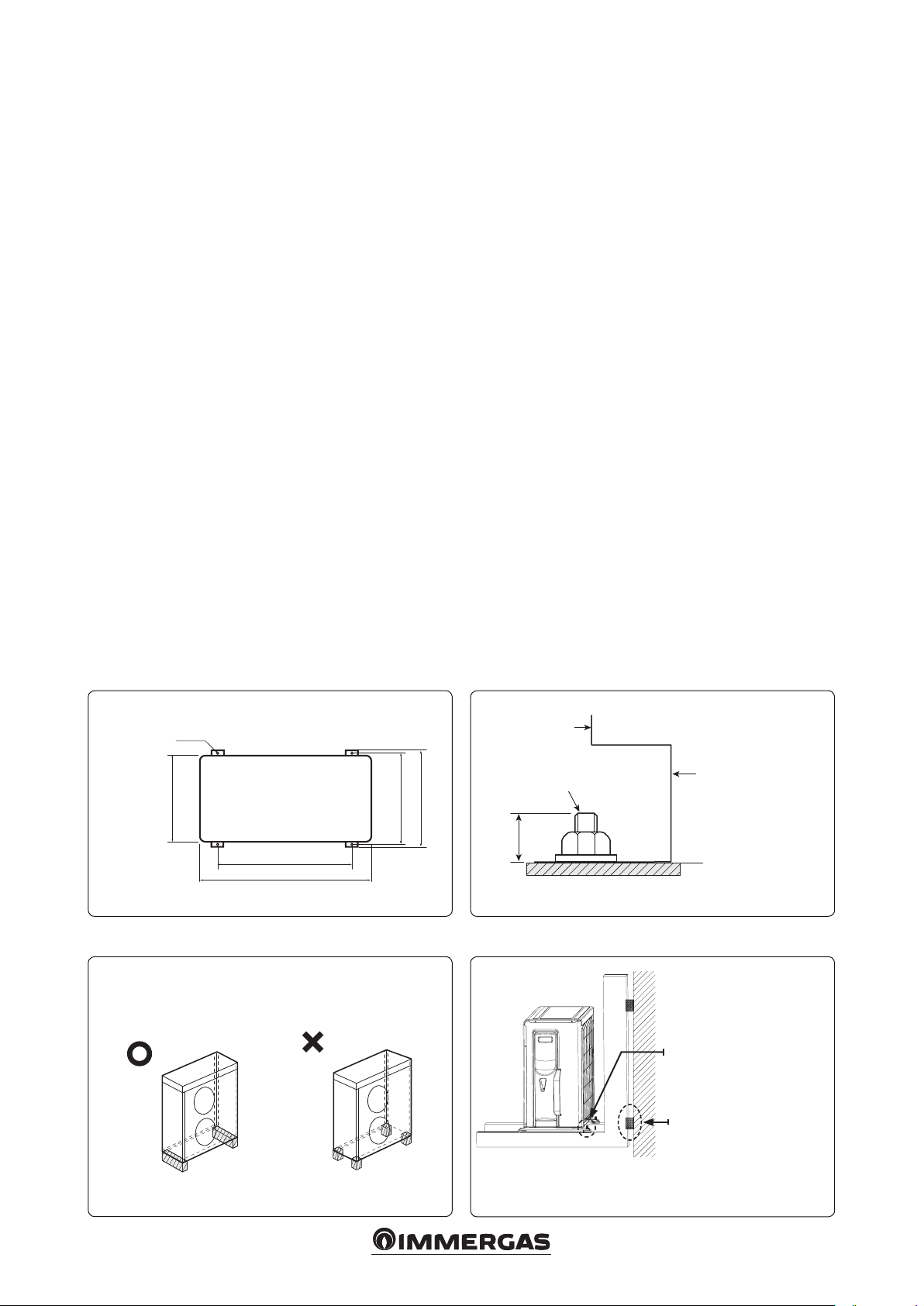

620

940

328

344

384

3.5 INSTALLING THE OUTDOOR UNIT.

20mm

To prevent the noise and vibrations it could

generate from being amplied, the outdoor unit

must be installed on a rigid base. Furthermore,

should it be installed in a position that is exposed

to strong winds or wall-mounted, it must be

solidly secured to the structure supporting it

(oor or wall).

e unit must be secured at the base with anchoring screws, using the anti-vibration pads

provided (g. 3-4).

N.B.: each anchoring screw must protrude

by at least 20mm from the base in which it is

embedded.

Attention:

- It is a good idea to insert rubber washers (not

supplied) between the tightening screw nuts

and the feet on the unit, as well as between

the latter and the supporting base to prevent

corrosion.

- A draining channel must be dug all around the

base of the unit that can appropriately drain the

water and condensate produced by the unit.

- When the unit must be installed on a roof, the

resistance of said roof must rst be checked.

Install the unit without damaging the roof itself

and/or its waterproong.

3.6 OUTDOOR UNIT MOUNT

STRUCTURE.

Figures 3-5 to 3-7 illustrate the instructions to

install the condensing unit mount structure.

When the outdoor unit is installed on a mount

structure attached to a wall, you must:

- Make sure the wall can support the weight of

the support structure plus the weight of the

device;

- Install the mount structure with the least

amount of overhang possible;

- Insulate the structure with respect to the wall

by inserting rubber dowels between them to

prevent vibrations from being transmitted to

the wall.

- Attention: the machines cannot be ducted.

Hole for anchoring screw

3-4

NO

OK

OK

3-6 3-7

NO

3-5

Outdoor

Unit

Anchoring Screws

Outdoor unit mount

structure

Base surfaces

Structure designed to eliminate

the residual vibrations that

the unit could transmit to the

outdoor unit mount structure

(not supplied by Immergas).

Rubber shock absorbers (not

supplied by Immergas) selected

to eliminate the vibrations that

the mount structure could

transmit to the wall.

99

Page 10

3.7 DRAINAGE.

During central heating, ice can deposit on the

outer surface of the coolant-air exchanger. To

prevent these deposits from becoming excessive,

the unit runs defrosting cycles to melt them. e

water resulting from this process is eliminated via

drainage holes to prevent it from re-solidifying

at the bottom of the unit when the outdoor

temperature is quite low.

• If, for whatever reason, this water cannot be

allowed to drain freely, you must:

- Leave a space of at least 50 mm (5 kW version)

and 100 mm (8 / 10 mm version) from the

support surface (Fig. 3-8).

- Insert the drainage tting in one of the three

drainage holes on the bottom of the unit and

plug the other three with the supplied drain

plugs.

- Connect the drainage tting to a hose that

conveys the water to the desired location.

- Prevent dust and debris from entering the

drainage hose.

Attention: if the water produced by the unit is

not properly drained, the performance of the

entire system will suer a negative impact and

the system itself could be damaged.

Warnings.

1 Dig a draining channel all around the base of

the unit that can appropriately drain the water

and condensate produced by the unit.

2 To facilitate drainage, you can install the unit

on a base of cement blocks so that it is at least

150 mm o the ground.

3 e unit must be raised at least 150 mm o the

ground to prevent it from being ooded in the

event of heavy rain.

4 If installed in a snowy area, the unit must be

raised o the ground by at least the height of

the heaviest foreseeable snowfall.

5 If wall-mounted (see gure), it is a good idea to

position a container (not supplied by Immergas) about 150 mm below the bottom of the

unit to collect and drain the condensate that

may drip from the unit.

3-8

3-10

≥ 50 mm (Audax Pro 5)

≥ 100 mm (Audax Pro 8 / 10)

3-9

Audax Pro 5 Audax Pro 8 and 10

Ø20 drainage hole (in 4 positions)Ø20 drainage hole

Air ow side

30 mm

Drainage tting (1)

Air ow side

1010

Page 11

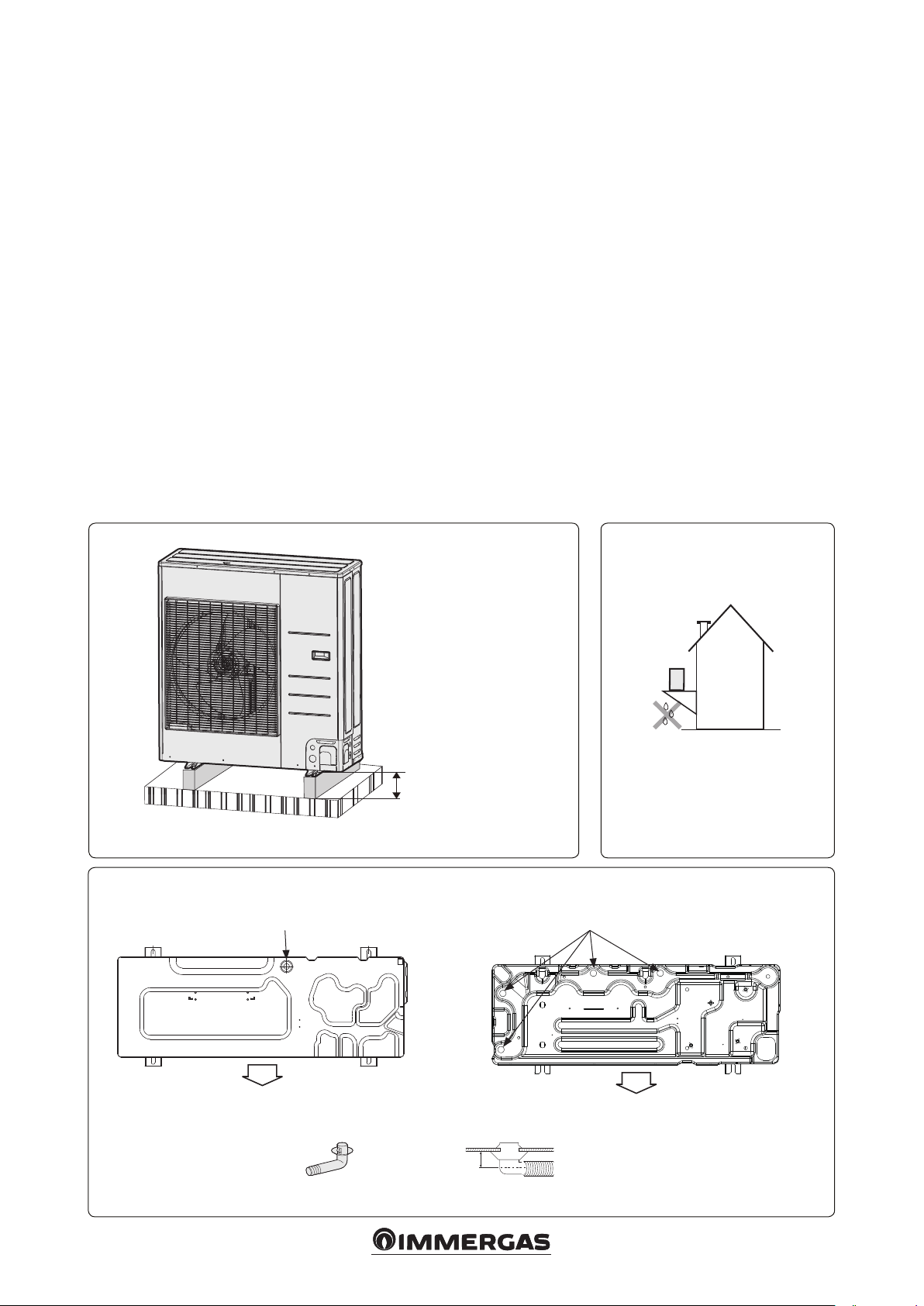

3.8 INSTALLING THE UNIT IN HARSH

CLIMATES.

N.B.: if installing the unit in harsh climates, you

must follow all the instructions below.

- e eects of the wind can be minimised by

installing the unit with the intake side facing a

wall.

- e unit must not be installed with the intake

side against the wind.

- e eects of the wind can be further minimised by installed a deector plate facing the

unit air ow side.

- e unit must be installed in a position protected from snow falling from above. If this is

not possible, you must at least prevent the snow

from clogging the air coolant exchanger (even

by constructing a small protective roof for the

unit, if necessary (Fig. 3-11)).

- e fan in the outdoor unit will work normally

with the K7 micro-switch on "ON" to prevent

snow from accumulating in the unit. (see parag.

7.3)

- e direction the unit faces depends on the

direction of the strongest winds. As it could

overturn with strong winds, the unit must be

oriented with one of its narrower sides against

the wind.

1

2

1 - Overall protective roof.

2 - Raised base.

e base must raise the unit

from the ground by at least the

height of the heaviest foreseeable

snowfall.

3-11 3-12

Strong wind

1111

Strong wind

Air ow

Page 12

ELECTRICAL

4

CONNECTIONS.

4.1 GENERAL CONNECTION

CONFIGURATION.

OUTDOOR UNIT

SUPPLY VOLTAGE

4-1

Mono-phase

2 230Vac

conductors

OUTDOOR

UNIT

PROTECTION

SWITCHES

Mono-phase

2 230Vac

conductors

COMMUNICATION

CABLE

UNIT SUPPLY

VOLTAGE

SYSTEM INTEGRATING RE-

SISTANCE SUPPLY VOLTAGE

Mono-phase

2 230Vac

conductors

INDOOR

UNIT

DOMESTIC

HOT WATER

TANK

4.2 POWER CABLE FEATURES.

- e power cable is not supplied with the unit.

- e outdoor unit power cable must be suitable for outdoor installation and must have at

least a exible polychloroprene sheath (Code

IEC:60245 IEC 57 / CENELEC:H05RN-F)

Attention:

should the connection

cable require an extension, do not use a circular

pressure terminal. Connection cables with connections that are not to code can be the cause of

electrical shock and res.

Mono-phase.

Maximum absorbed current

(MAC) in nor-

mal operation

MAC1.25

+ Additional

Load

Outdoor

Unit

Nominal Values

Field of

Tolerable

Voltage

Hz V V V. A A A

5 kW 50 220 - 240 198 264 20 25.0 30

8 and 10

kW

50 220 - 240 198 264 22 27.5 40

4.3 CONNECTION FEATURES

BETWEEN INDOOR AND

OUTDOOR UNITS COMMONLY

USED.

Use H07RN-F or H07RN-F class cables to power

the indoor unit.

When the indoor unit is installed in a room with

a computer or internet server, you must use a

double shielded FROHH2R class cable (Aluminium tape/Polyester + Copper braid).

Supply Voltage

Supply Voltage Max./Min.(V) Connection cable

Mono-phase,

220-240V, 50Hz

±10% 0.75 ~ 1.5mm², 3 wires 0.75 ~ 1.5mm², 2 wires

Communication cable

Fuse

capacity

necessary

for the unit

1212

Page 13

4.4 TERMINAL BOARD FEATURES.

Audax Pro 5 - Supply voltage in mono-phase AC.

M4 screw supply voltage M4 screw communica-

L

N

11.4 10.1

4-2

Audax Pro 8 and 10 - Supply voltage in mono-phase AC.

Electric supply voltage

M5 screw

L

N

15 12

4-3

tion bus

10.1

11.4

M3 screw communication bus

6.7

9.7

1313

Page 14

4.5 SUPPLY VOLTAGE CABLE

CONNECTION.

Attention:

- Aer connecting it to the terminal board, the

power cable must be secured using a cable

locking terminal.

- Voltage imbalance must not exceed 2% of

nominal voltage

With use of the mono-phase safety switch (ELB).

- Otherwise, condenser duration could be

jeopardised. Should imbalance exceed 4%, the

indoor unit would stop and an error would be

signalled

- To protect them from water and possible

mechanical trauma, the power and communication cables must run through a cable duct

(with an IP protection that is compliant with

the specic application requirements).

- e power cable must be connected to a 230V

±10% / 50Hz mains, respecting L-N polarity

and the earthing connection

; this network

must have a multi-pole circuit breaker with

class III overvoltage category.

- In the event of overvoltage, all the units connected to the supply voltage line must automatically disconnect.

- e communication cable must run at least 50

mm away from the power cable.

Depending on the model, the actual

appearance of the unit may dier from the

one shown in the gure.

Electrical panel

MCCB

ELB

MCCB

Hydro Unit

4-4

Connection to the supply voltage terminal

board.

- e connection must be made aer having secured the wires to ring compression terminals.

- Only use the types of cables specied.

- For the connection, you must only use screwdrivers that can give the screws the prescribed

tightening torques.

- Should the connection be loose, voltaic arcs

could be triggered, which could, in turn,

cause res. Instead, should the connection be

excessively tightened, the terminal could be

damaged.

Tightening torques (kgfcm) for terminal board

screws:

- M4 12.0 ÷ 14.7

- M5 24.4 ÷ 29.8

Connecting the earth cable.

- Only use the types of cables specied among

the features of outdoor unit cables.

- For the earthing connection, use a type of cable

specied for the outdoor unit.

Power cable earthing connection.

- e connection method depends on the nominal voltage and the site in which the Heat Pump

is installed.

- In any case, the features of this connection must

the following:

Key:

ELB - Safety Switch

MCCB - Circuit breaker switch

L

N

clamping

Main power

cable

Earthing connection.

- e earthing connection must be done by a

specialised electrician.

- Make sure the resistance to earth is < 100 Ohm.

If there is a circuit breaker switch to interrupt

the circuit in the event of a short circuit, the

resistance to earth can be 30 ÷ 500 Ohm.

Cable

clip

Communication

cable

Fairlead

terminal

1414

Page 15

INSTALLING THE CHILLER

H1

5

LINES.

- e length of the pipes between the outdoor

and indoor units and the dierence in the pipe

lengths aer the rst junction and the drop

must not exceed the indicated limits.

- R-410A is a high pressure coolant.

- Only use pipes that are certied for chilling and

follow the installation methods below.

- Only use clean pipes with no harmful ions,

oxides, dust, traces of iron or moisture.

- Only use equipment and ttings for R-410A.

Manometric unit. Use an R-410A manometric

unit to keep foreign objects from getting into the

chiller lines and prevent reading errors.

Vacuum pump. Only a vacuum pump with a

non return valve must be used to prevent the

oil inside it from getting into the chiller circuit

when it stops. is pump must be able to create

a vacuum of up to 500 mTorr (66 Pa).

Flare nuts. Only use the flare nuts supplied

with the unit.

5.1 CHILLER LINE GEOMETRIC LIMITS

AND INSTALLATION EXAMPLES.

e maximum lengths of the chiller lines are

listed below, based on the condensing unit model

and the type of installation (g. 5-1).

A

Audax Pro 5

A ≤ 30 m ≤ 50 m

H1 ≤ 20 m ≤ 30 m

H2 ≤ 20 m ≤ 15 m

N.B.: it is recommendable to provide for a siphon

in the immediate vicinity of the condensing unit.

If the length of the chiller line is greater than

the one given in the machine pre-load, it is

recommendable to provide for a siphon halfway.

A siphon is also recommendable in the event of

installation with drops between the condensing

unit and the hydronic unit.

Audax Pro

8 and 10

H2

A

5-1

1515

Page 16

5.2 PIPE CUTTING AND FLARING

1 Make sure you have all the equipment neces-

sary: pipe cutter, deburring tool, aring tool,

clamp, etc.

2 If the pipe needs to be shortened, it must be

cut with a pipe cutter, being careful to keep the

cutting angle at 90° with the pipe axis. Figure

5-2 shows some examples of correctly and

incorrectly made cuts.

3 To prevent coolant leaks, cutting burrs must

absolutely be eliminated using a deburring tool.

Attention: during deburring, the pipe must

be facing downward to prevent shavings from

getting into it (see g. 5-3).

4 Insert the nut in the pipe, then are it according

to the features indicated in gure 5-4

5 Make sure flaring has been done properly.

Figure 5-5 shows some examples of correctly

and incorrectly done aring.

6 Align the pipes to make connection easier.

Tighten the are nut by hand at rst, then denitively, using a dynamometric key calibrated

to the torque shown in gure 5-6.

N.B.: tightening to an excessive torque can

cause coolant to leak.

Attention: any welding must be done in a

Nitrogen atmosphere.

90°

5-2 5-3

Pipe

5-4

Flare

Obliquity

Roughness

Outside diameter

[D (mm)]

Burr

Overhang

[A (mm)]

Ø 6.35 1.3 9.0

Ø 9.52 1.8 13.0

Ø 12.70 2.0 16.2

Ø 15.88 2.2 19.3

Ø 19.05 2.2 22.5

Pipe

Burr

Pipe cutter

Collar diameter

[B (mm)]

Correct Obliquity CrackingDamage to the

5-5

Lubricate with coolant oil

Indoor unit coupling

5-6

Flare nut

Pipe to connect

seal surface

Unevenness in the

thickness

External diameter (mm) Tightening torque (Nm)

Ø 6.35 12 ÷ 17

Ø 9.52 30 ÷ 35

Ø 12.70 40 ÷ 45

Ø 15.88 50 ÷ 60

Ø 19.05 60 ÷ 70

1616

Page 17

5.3 SELECTING CHILLER LINE

INSULATION.

- e gas and liquid chiller lines must be insu-

lated with materials selected based on their

respective diameters.

- Standard insulation is required at a temperature

of 30°C with 85% relative humidity. Should the

thermohygrometric conditions of the air be

harsher, you must use insulations that can be

selected from the table in gure 5-7

- Attention:

- e insulation cannot be interrupted and for

this reason, its junctions must be sealed with

adhesive to prevent moisture from getting in.

- Should the insulation be exposed to sunlight,

it must be protected by wrapping it with electrical tape or material suitable for this type of

application.

- e insulation must be laid without its thick-

ness being reduced in the bends and supports

of the pipes.

Line

Liquid

Gas

5-7

Pipe diameter

(mm)

Ø 6.35 ÷ 19.05 9 9

Ø 12.70 ÷ 19.05 13 13

Ø 6.35 13 19

Ø 9.52

Ø 12.70

Ø 15.88

Ø 19.05

5.4 INSULATING THE CHILLER LINES.

- e insulation must only be laid aer having

made sure that there are no coolant leaks on

the lines.

- Use EPDM insulation with the features described in the table in gure 5-8.

- e chiller lines, the junctions and the connections must be insulated with class "0" (zero)

material.

- Proper insulation prevents condensate from

forming on the surface of the pipes and protects

heat pump performance and the level of user

satisfaction.

- Make sure that the insulation is not broken and/

or interrupted in the pipe bends (Fig. 5-9).

Insulation thickness

Standard conditions

(Less than 30°C, RH

85%)

EPDM, NBR

19 25

High humidity condi-

tions

(Over 30°C, RH 85%)

5.5 WELDING THE PIPES.

- Make sure there is no moisture inside the pipes

- Make sure there are no foreign objects inside

the pipes.

5.6 USING NITROGEN.

1 Welding must be done in a nitrogen atmos-

phere, that is, insufflating the pipes with

nitrogen as shown in gure 5-10.

2 Should welding be done without insuating

nitrogen, flakes of rust would form inside

the pipes. In coming loose, these akes could

damage the compressor and the valves.

3 e ow of nitrogen must be controlled, cali-

brating the pressure regulator so as to obtain a

ow of at least 0.05 m3/h.

4 e valves must be protected from heat while

they are being welded.

Notes

e pre-selected

material must be able to

withstand temperatures

exceeding 120°C.

5-8

Insulation

Gas pipe

Liquid pipe

Item Unit Standard Value Notes

Density g/cm² 0.048 ÷ 0.096

Dimensional variation due to temperature changes

Moisture permeability g/cm² ≤ 0.005

ermal conductance kcal/m·h·˚C ≤ 0.032 KSL 9016-95

Moisture transpiration factor ng/(m²·s·Pa) ≤ 15 KSM 3808-03

Moisture transpiration degree {g/(m²·24h)} ≤ 15 KSA 1013-01

Formaldehyde release mg/L - KSF 3200-02

Oxygen rate % ≤ 25 ISO 4589-2-96

Clip

Indoor

Indoor

unit

unit

% ≤ -5

Insulation

Overlapped

e insulation must completely overlap the pipes

KSM 3014-01

Tap ing

Part to

weld

Nitrogen

Pressure

regulator

1/4" copper

pipe

Valve stem

5-9

5-10

1717

Page 18

5.7 PRESSURE TESTING AND LEAK

CHECK.

- To prevent foreign substances from getting into

the circuit and to ensure the essential resistance

to the pressures in play, it is fundamental that

only an R-410A manometric unit be used.

- e pressure test must only be done using dry

nitrogen.

Pressurise with dry nitrogen at 4.1 MPa via the liquid and gas pipe.

Leave everything alone for at least 24 hours to check whether the

If pressure decreases, it means there are leaks.

Maintain a pressure of at least 1.0 MPa and check for leaks again before

putting the circuit under vacuum and drying it.

Audax Pro 5 Audax Pro 8 and 10

Low pressure

pressure falls.

Manometric unit

side

High pressure side

Should the unit be pressurised with nitrogen at more than 4.1 MPa,

the pipes could be damaged. Pressing must be done using a pressure

Pressure variations that can occur aer pressurising with nitrogen must

Should pressure decrease, a foaming solution must be applied to all the

junctions to locate the leaks. Bubbles forming in the foaming solution

pinpoint the location of the leaks, which must be eliminated before

Aer having repaired any leaks, you must maintain pressure at 1.0 MPa

Low pressure side

Service

coupling

regulator.

be checked using a pressure regulator.

re-pressurising with nitrogen.

at least and check for leaks again.

Manometric unit

High pressure side

Pressure regulator

(indispensable)

Service

door

5-11

To check for leaks, you must use an approved

foaming solution. Using a solution of water and

normal soap risks damaging the are nuts or

triggering corrosive processes in the are joints.

Attention: should a coupling be disconnected,

the gas that escapes could cause injuries when

coming into contact with people. Tighten the

couplings as required to prevent these accidents.

Pressure regulator

(indispensable)

Nitrogen

Gas pipe

Service coupling

Nitrogen

1818

Page 19

5.8 PUTTING UNDER DRYING

VACUUM.

- To prevent foreign substances from getting into

the circuit and to ensure the essential resistance

to the pressures in play, it is fundamental that

only an R-410A manometric unit be used.

- Only a vacuum pump with a non return valve

must be used to prevent the oil inside it from

getting into the chiller circuit when it stops.

- Use a pump that is able to create a vacuum of

up to 500 mTorr (66 Pa).

- Completely close the service valves on the gas

and liquid side.

Attention: if pressure increases aer an hour, this

means that there is residual water inside the pipe

and/or there are leaks.

Connect the manometric unit to the

liquid and gas pipes.

Audax Pro 5 Audax Pro 8 and 10

Manometric unit

Vacuum

pump

5-12

Manometric unit

Vacuum

pump

Using the vacuum pump, put the liquid

and gas pipes under vacuum and dry

them.

Putting under vacuum and drying must

last at least 2 hours and 30 minutes.

Close the valve once pressure drops to

500 mTorr.

Pressure increases

No

Put in the coolant

Make sure the vacuum pump is equipped with a non

return valve as, otherwise, when it stops, the oil inside of

it would be sucked back into the coolant circuit.

e time necessary to put under vacuum and dry varies, as

it depends on the length and diameter of the pipes, as well as

on the outdoor air temperature. Drying and putting under

vacuum must, however, last at least 2 hours and 30 minutes.

Check the vacuum level using a vacuometer.

Check for leaks

Yes

e pressure increases due to residual

water in the pipes.

Put in dry nitrogen at a pressure of 0.05

MPa to dilute the moisture.

Put under vacuum and dry again, lowering the pressure down to 500 mTorr

(66Pa) for at least 2 hours

5-13

No

1919

Pressure increases

Yes

Page 20

5.9 TOPPING UP THE COOLANT LOAD.

Below is the default factory base load:

- Audax Pro 5: 1.2 kg

- Audax Pro 8 and 10: 2.0 kg

The top-up depends on the total length and

diameter of the pipes.

All the default factory loads are determined as

follows, depending on the standard length of

the pipes:

- Audax Pro 5: ≤ 5m

- Audax Pro 8 and 10: ≤ 15m

Should the pipes used be longer, the load must

be topped up as follows.

e top-up amount depends on the total length

of the liquid line.

(g) = {(L1 - n) x 20} + {(L2 - n) x 50}

Key:

L1 - Total length of the Ø 6.35 liquid pipe,

(m)

L2 - Total length of the Ø 9.52 liquid pipe,

(m)

n - standard pipe length, see previously

listed specic value

5.10 ADDING COOLANT.

As the outdoor unit comes already equipped with

the base load, the amount to top-up depends on

the total length and diameters of the liquid pipes.

Liquid line Ø 6.35 Ø 9.52

Top-up (g) 20 g/m 50 g/m

Calculating the amount to top-up:

(Total length (m) of the Ø 9.52 pipes) × 50 g

+ (Total length (m) of the Ø 6.35 pipes) × 20g

Example:

20 m × 50 g/m + 20 m × 20 g/m = 1,400 g

5.11 PUTTING IN THE COOLANT.

R-410A is a blend of several coolants. For this

reason, it must be put into the chiller circuit only

in its liquid phase.

e amount of coolant to put in depends on the

length and diameters of the liquid pipes. Using

a scale is recommendable to put in the required

amount of coolant.

5.12 IMPORTANT INFORMATION ON

THE COOLANT USED

The coolant contained in this unit contains

uorinated greenhouse gases subject to the Kyoto

Protocol. erefore, it must not be released into

the atmosphere.

Attention:

- Inform the user if the chiller circuit contains

more than 5 tonnes of CO2 equivalents of

uorinated greenhouse coolant. In this case,

the system must undergo a leak check every 12

months, as required by regulation no. 517/2014.

Example: Audax Pro 2.0 kg of R-410A gas =

2.0 x 2088 (GWP) = 4.18 tonnes of CO

2

N.B.: if there is a leak detection system, the

minimum frequency of checks extends to every

24 months.

Checking for leaks must be done only by spe-

cialised personnel.

Introducing a load from a tank

with oat

Liquid loading can be done

keeping the tank upright with the

coupling facing upwards.

- In the previous situation (R-410A content

greater than 5 tonnes of CO2 equivalents), the

installer (or the person responsible for nal

checks) must provide the user with a "unit

record", on which to record all the information

required by EU regulation 517/2014 of the

European Parliament and Council dated 16

April 2014 on greenhouse gas management.

- Before putting in the coolant, you must check

whether the tank in which it is contained has

a oat or not, and consequently position the

tank itself (see g. 5-14).

Introducing a load from a tank

without oat

Liquid loading can be done turning

the tank upside down and keeping

it upright with the coupling facing

downwards.

Contains uorinated greenhouse gases subject

to the Kyoto Protocol

Indoor unit

2

d

1

Outdoor

Unit

a

1 = ( ) kg

2 = ( ) kg

b

1 + 2

= ( )

c

kg

5-14

Fill out with permanent ink.

1 Coolant load put into the unit at the factory.

2 Load top-up on-site.

1 + 2 Total coolant load.

On the coolant load identication label supplied with the unit.

a - Coolant load put into the unit at the factory: shown on the identication plate.

b - Load top-up on-site. (See the information provided regarding how to calculate the

top-up amount.)

c - Total coolant load.

d - Coolant tank and pressure gauge load manifold.

Coolant type GWP* value

R-410A 2088

GWP = Global Warming Potential

*) Based on 4

a

Assessment report of the

Intergovernmental Panel on Climate Change

- IPCC. Check for any updates.

5-15

2020

Page 21

5.13 TOPPING UP THE LOAD.

R-410A is a blend of several coolants. For this

reason, it must be put into the chiller circuit only

in its liquid phase.

e amount of coolant to put in depends on the

length and diameters of the liquid pipes. Using

an electronic scale is recommendable to put in

the required amount of coolant.

Top-up must be done while the unit is operating

in cooling

- Connect the manometric unit and bleed the air

contained inside it.

- Open the service valve on the manifold liquid

side and put in the coolant in liquid phase.

- If it is not possible to carry out or complete the

top-up while the unit is not operating, using a

button located on the outdoor unit PCB, you

can complete the top-up.

- Topping up during operation in cooling (Fig.

5-16):

Manometric unit

1 Open the valve on the gas side aer 20 min-

utes of operation.

2 Open the valve on the pressure gauge mani-

fold low pressure side to complete the top-up.

-Topping up during operation in central heating

(Fig. 5-17):

1 Connect the manometric unit low side to the

intake load coupling.

2 Press the top-up in central heating mode

button.

3 Open the intake load coupling valve aer 20

minutes of operation

4 Open the manometric unit low pressure side

valve to complete the top-up

Attention: aer having put in the coolant, you

must completely open the liquid side valve and

the gas side valve. (Allowing the system to operate when one of these valves is not completely

open could damage important components).

Intake load coupling

5.14 SERVICE VALVE

• Closing the valve.

1 Remove the valve cover and turn the stem

clockwise, using a hex key.

2 Tighten the stem until it is completely closed.

N.B.: do not force the stem and only use

suitable tools. Otherwise, the contact surface

between the shutter and its housing could be

damaged, with subsequent coolant leakage.

If you notice coolant leaking, you must open

the valve slightly, close it again and make sure

there is no more leaking. If that is the case,

the stem can then be tightened denitively.

3 Put the valve cover back on and tighten it as

required.

• Opening the valve

1 Remove the valve cover.

2 Turn the stem anticlockwise, using a hex key.

3 Tighten the stem until it is completely closed.

4 Put the valve cover back on and tighten it as

required.

Attention:

When you use the service coupling, you must

also use a loading hose.

Aer tightening the cover, make sure no coolant

leaks from it.

When opening/closing the valve, you must use

a key and a counter key.

Low pressure

Scale

Manometric unit

Low pressure

side

side

High pressure side

High pressure side

Gas side

Gas side

Outdoor unit

Liquid side

Service valve

Intake load coupling

Outdoor unit

Liquid side

5-16

Cover

Stem

Service

coupling

Scale

Service valve

2121

5-17

Seal

surface

5-18

Page 22

CHECKING THE EARTH

6

ING CONNECTION

Create a legally compliant earthing connection

if the building does not have one or the one it

has is not compliant. Whatever is needed to

earth the electrical system is not included in the

Immergas supply.

1 Get an earthing rod with the features shown in

gure 6-1.

2 Connect the hose to the corresponding cou-

pling.

- Moist, compact ground is preferable to sandy

or gravelly terrain, as the latter has a greater

electrical resistance.

- e earthing rod must be put in far from

the mains or underground water or gas

distribution structures, telephone networks

or underground cables

- e earthing rod must be put in at least two

metres away from connection cables and

lightning rods.

- N.B.: the unit's earthing connection must not

be made on telephone line earth connection

cables.

3 Completely wrap the connection lines to the

outdoor unit with electrical tape.

4 Connect a yellow/green cable to the earthing

rod:

- If necessary, the cable can be extended,

welding it to an extension cord and carefully

taping the junction (which, in any case, must

never be buried).

- Fasten the cable securely with hooks and clips

- N.B.: the heavier the trac in the area where

the cable runs, the more securely fastened it

must be.

5 Check earthing connection eciency using a

tester. If the resistance exceeds the necessary

value, you must push the earthing rod further

into the ground or add other earthing rods.

6 Connect the cable to the outdoor unit earthing

terminal.

Carbon fibrereinforced plastic

6-1

Steel core

M4 terminal

Cable with yellow/green

insulation in PVC

To the earthing

connection screw

50cm

30cm

2222

Page 23

7 MICROSWITCH SETTING

AND KEY FUNCTION

7.1 OPERATING TEST.

1 Check the supply voltage line between the units

and the circuit breaker switch

- Mono-phase supply voltage: L, N

2 Check the CONTROL KIT.

- Make sure the power cables are connected

properly (otherwise, the PCB could be seriously damaged).

- Make sure the temperature sensors, the drainage pump/hose and display are connected

proper ly.

3 Use the K1 or K2 button on the outdoor unit

PCB to start/stop the operating test.

KEY Using the BUTTON 7-segment display

K1

Pressing it once: Operating test in Central heating

Pressing it twice: Operating test in Defrost

" " " "BLANK" "BLANK"

"

" " " "BLANK" "BLANK"

"

Pressing it 3 times: Completes the Operating Test -

K2

Pressing it once: Operating test in Cooling

" " " "BLANK" "BLANK"

"

Pressing it twice: Completes the Operating Test -

K3 Reset

K4 Data display mode Refer to the instructions that appear for the data display mode

Audax Pro 5 Audax Pro 8 and 10

ON

ON

1 2 3 4

5 6 7 8

7-1

ON

ON

1 2 3 4

5 6 7 8

2323

Page 24

7.2 DATA DISPLAY MODE

Pressing the K4 button provides the information

on the system status shown in gure 7-2.

No. of times it is

pressed

0

1

2

3

4

5

6

7

8 Current 8 Tens Unit First decimal A

9 Fan speed 9 ousands Hundreds Ten s Rpm

10 Target ow temperature A Hundreds Tens Unit °C

11 EEV valve B ousands Hundreds Tens pulses

12

13 Protection controls D

14

15

long-1 Main Micom version Year (Hex) Month (Hex) Day (tens) Day (unit) -

long-1and 1 Inverter Micom version Year (Hex) Month (Hex) Day (tens) Day (unit) -

long-1and 2 EEPROM version Year (Hex) Month (Hex) Day (tens) Day (unit) -

Meaning of the instruc-

Communication status Tens of Tx Tx Unit Tens of Rx Rx Unit

tion

Controlled frequency 1 Hundreds Te n s Unit Hz

Current frequency 2 Hundreds Te ns Unit Hz

Type of Outdoor Unit

(Mono/Split)

Outdoor air sensor 4 + / - Tens Unit °C

Flow sensor 5 Hundreds Tens Unit °C

PHE sensor (Eva) 6 + / - Tens Unit °C

Condenser sensor 7 + / - Te ns Unit °C

Exchange power (not

used)

PBA board heat sink

temperature

Number of connected

indoor units

Segment 1 Segment 2 Segment 3 Segment 4

3 0 0

C 0 0 0 kW

0 : cooling

1 : central heating

E Hundreds Tens Unit °C

F Hundreds

Instructions

Protection control

0 : none

1 : antifreeze

2 : non-stop defrosting

3 : overload

4 : ow

Tens Unit set

0 : split

1 : block

Frequency status

0 : Normal

1 : Maintaining

2 : Lowering

3 : Upper limit

4 : Lower limit

Unit

-

7-2

2424

Page 25

7.3 MICROSWITCH SETTING.

Editing the micro-switch setting on the board,

there are various operating modes available, as

per gure 7-3 for Audax Pro 5 and gure 7-4 for

Audax Pro 8 and 10.

KEY ON (default) OFF Notes

Automatic Orientation

K5

(the outdoor unit recognises the indoor

unit address for random access).

K6 Anti-snow accumulation mode: ON Anti-snow accumulation mode: OFF

K7 Not used

K8 Not used

7-3

KEY ON (default) OFF Notes

Automatic Orientation

K5

(the outdoor unit recognises the indoor

unit address for random access).

K6 Base electric heater operation time: 15 min. Base electric heater operation time: 20 min.

K7 Anti-snow accumulation mode: ON Anti-snow accumulation mode: OFF

K8 Base electric heater enabled Base electric heater disabled

Silent Operation K9 K10 Mode

K9

K10

ON ON Silent operation disabled

ON OFF Silent operation: Step 1

OFF ON Silent operation. Step 2

OFF OFF Silent operation: Step 3

Manual Orientation

(the outdoor unit recognises the indoor unit address

depending on the setting of the indoor unit rotary

switch).

Manual Orientation

(the outdoor unit recognises the indoor access address

depending on the setting of the indoor unit rotary

switch).

e base electric heater works

K5 must be ON

K5 must be ON

below 0°C.

K11 X Not used

K12 X Not used

Total current absorp-

K13

tion control

K14

K15 X Not used

K16 X Not used

7-4

K13 K14 Mode

ON ON Total absorption limit: 1_Down

ON OFF Total absorption limit: 1_Down_OP1

OFF ON Total absorption limit: 1_Down_OP2

OFF OFF Total absorption limit: 1_Down_OP3

2525

Page 26

8 PUMP DOWN PROCE

DURE.

8.1 PURPOSE OF PUMP DOWN.

Pump down is used to accumulate coolant

in the outdoor unit before disconnecting the

chiller lines.

8.2 PRECAUTIONS TO TAKE BEFORE

PERFORMING PUMP DOWN.

Due to the compact nature of its shape, the unit

contains a small load of coolant

Before performing pump down, most of the load

can be transferred to an empty tank.

Attention: the maximum amount of coolant that

can be accumulated in the outdoor unit is 5 kg.

Accumulating larger quantities of coolant risks

causing the compressor to stop or burn out.

8.3 PRECAUTIONS TO TAKE BEFORE

PERFORMING PUMP DOWN.

1 Close the manometric unit.

2 Close the liquid service valve.

3 Press the K2 button on the outdoor unit PCV

three times; this makes the ( ) indication

appear on the board LED display

4 Keep an eye on the manifold low pressure gauge

while the compressor is running.

5 When the indication on said pressure gauge

goes below 0 MPa (0 kgf/cm²) e., close the gas

service valve and abandon pump down (pump

down can be abandoned by pressing the K2

button again or by pressing the K3 button to

reset).

Attention: Coolant can only be transferred to

appropriate tanks. Otherwise, explosions can

occur with subsequent damage to things and

injury to people.

N.B.: Repositioning the Air-Water heat pump.

- If the unit must be repositioned, do as follows:

- Perform pump down (put the above procedure

in action).

- Transfer as much coolant as possible to an

external tank in order to accumulate no more

than 5 kg in the outdoor unit (see parag. 8.4 for

details on coolant loads)

- Disconnect the power cable.

- Disconnect the connection cable between the

outdoor and indoor unit.

- Disconnect the pipes from the indoor unit

ared couplings.

- To prevent foreign objects from getting in,

immediately plug the indoor unit couplings

and the pipes they were connected to with vinyl

caps.

- Disconnect the pipes from the external unit

ared couplings. To prevent foreign objects

from getting in, immediately plug the outdoor

unit couplings and the pipes they were connected to with vinyl caps.

- Be careful not to damage the couplings and the

terminal boards.

- Move the indoor and outdoor units to their

respective new positions.

- Disassemble the indoor unit securing devices

and reassemble them in the new position.

8.4 TRANSFERRING THE COOLANT

INTO AN EXTERNAL TANK BEFORE

PERFORMING PUMP DOWN.

Do as follows before performing pump down if

the load quantity exceeds the maximum quantity

that can be accumulated in the outdoor unit.

1 Get an empty tank for R-410A, a scale and a

pressure gauge manifold.

2 Identify the load quantity contained in the

chiller circuit.

3 Connect the tank to the outdoor unit and

run approximately 50% of the indoor unit in

cooling.

4 Aer about 10 minutes, check the pressure on

the high side on the manifold pressure gauge.

If it exceeds 3.0 MPa (30.59 kgf/cm²) e., you

must reduce the quantity of the indoor units

in order to bring it back under 3.0 MPa (30.59

kgf/cm²).

5 As soon as the pressure goes below 3.0 MPa

(30.59 kgf/cm²) e., open the manometric unit

2 tap, connected to the liquid side. en open

the receiving tank valve to allow the coolant to

ow.

6 Using the scale, check the quantity of coolant

that has been transferred to the tank. Close the

liquid valve and disconnect the pressure gauge

manifold as soon as the desired quantity has

been reached.

7 The quantity of transferred coolant should

correspond to 50% of the entire load contained

in the chiller circuit.

8 e amount of the load remaining in the cir-

cuit must not exceed the quantity that can be

accumulated in the outdoor unit.

8-1

R-410A

Scale

Tank valve

Valve 2

Valve 1

Gas side

unit

Outdoor unit

Liquid side

Service valveManometric

2626

Page 27

8.5 RECOVERING LARGE QUANTITIES

OF COOLANT.

Should recovering the coolant be dicult due to

the large amount in play:

1 Get an empty tank for R-410A, a scale and a

manometric unit.

2 As shown in the gure, connect the central

coupling of the manometric unit to the coolant

tank and the side couplings of the manifold

itself to the outdoor unit service valves (leaving

the tank valve and the low side service valve

closed and leaving the high side service valve

open).

3 Start the coolant transfer procedure by pressing

the K2 button three times.

4 Aer 10 minutes, open the tank valve to trans-

fer the coolant.

5 Close the tank valve as soon as the desired

quantity of coolant has been transferred.

6 Immediately close the liquid side service valve.

Also close the gas service valve as soon as the

low side pressure goes below 0.

7 Press the reset button to abandon the Stop

procedure.

8-2

Audax Pro 5 Audax Pro 8 and 10

Manometric unit

Low pressure

side

Service coupling

High pressure side

Empty

tank

Low pressure

Service coupling

scale

Manometric unit

side

Liquid pipe

Gas pipe

High pressure side

Empty

tank

scale

2727

Page 28

9 COMPLETING

INSTALLATION.

9.1 CHECKS AT THE END OF

INSTALLATION.

Once installation is complete, check the following:

Outdoor unit

Installation

Indoor unit

Coolant pipes

Check the conditions of the inner and outer surface.

Can there be short circuits?

Is the installation position well-ventilated and are the required spaces free?

Are the units secured well?

Check the conditions of the inner and outer surfaces.

Is the installation position well-ventilated and are the required spaces free?

Check installation fastening and horizontality.

Are the pipe lengths and drops between the units within the required limits?

Are the pipes duly insulated?

Was the load top-up correctly weighed?

Condensate drain pipes

Electrical connections

9-1

9.2 FINAL CHECKS AND OPERATING

TEST

Before starting the checks and operating tests,

the outdoor unit must be powered at least three

hours before the operating test begins in order

to appropriately pre-heat the compressor. If the

compressor is not adequately pre-heated, 'CH'

may appear on the outdoor unit PCB display.

Checks to carry out before the operating test.

1 Check the indoor and outdoor unit power and

communication cables

2 Check the supply voltage between the outdoor

unit and the electrical panel.

3 Using a voltmeter, make sure the supply voltage

is at 220 V – 240 V~ or at / 380-415V~.

4 Once enabled, the outdoor unit searches for

the connected indoor units and the options.

Operating test

1 Activate the unit using the MODE button or

the control system.

- Activate all the indoor units using the MODE

BUTTON located on the printed circuit

Check the drain pipes on the indoor and outdoor units.

Has drainage system operation been checked?

Are the drain pipes duly insulated?

Has the earthing connection been made using procedure 3 and in compliance with the dictates

of the standards in force in the installation site?

Were 2-conductor cables used?

Are the cable lengths within the required limits?

Is the cable layout correct?

board on the outdoor unit control board.

- Using the control system, activate all the

indoor units separately.

- Observe how the compressor behaves at

start-up. If it emits a rumbling sound, stop

operation immediately.

2 Check the operating status of the indoor and

outdoor units.

- Check the air ow from the indoor units in

central heating and cooling.

- For every internal unit, check: air ow direction and speed.

- Check for any strange noises from the internal

units and/or outdoor unit.

3 Abandon the operating test.

4 Explain the heat pump management modes to

the user according to the instructions in the

user manual.

2828

Page 29

YEARLY UNIT CHECK

10

e following checks and maintenance should

be performed at least once a year.

- Visually check for water leaks or oxidation

- Visually check that the safety and control

- Check the condition and integrity of the elec-

- power cables must be inside the fairleads;

- there must be no traces of blackening or

- Check ignition and operation.

- Check the operation of the appliance control

- system regulation probes intervention;

- Clean the coil.

IMPORTANT NOTE: in addition to yearly

maintenance, you must also check the thermal

system and energy eciency, with the frequency

and procedures that comply with the technical

regulations in force.

AND MAINTENANCE.

from/on connections.

devices have not been tampered with and/or

short-circuited.

trical system and in particular:

burning.

and adjustment devices and in particular:

2929

Page 30

TROUBLESHOOTING.

11

Attention:

- Incorrectly managing thermostats, safety valves

and/or other types of valves can cause the tank

to break. Every operation on the unit must be

done scrupulously following the instructions

that concern it.

- e electrical supply voltage must always be

cut o before cutting o the hydraulic supply.

- Regularly check safety valve operation, making

it open to make sure water ows out with no

problem.

Code Explanation

101 CONTROL KIT/OUTDOOR UNIT wiring error

201 CONTROL KIT/OUTDOOR UNIT communication error (coupling error)

202 CONTROL KIT/OUTDOOR UNIT communication error (3 min.)

203 Communication error between INVERTER and MAIN MICOM (6 min.)

221 OUTDOOR UNIT temperature sensor error

231 Condensation temperature sensor error

251 Flow temperature sensor error

320 OLP sensor error

403 Ice detected on the compressor during operation in cooling

404 OUTDOOR UNIT overload prevention trip (at Safety device start-up, operation ? normal)

416 Compressor ow overtemperature

419 OUTDOOR UNIT EEV operation error

425 One of the supply voltage phases has fallen (only for three-phase models)

440 Operation in central heating stopped (outdoor temperature > 36°C)

441 Operation in cooling stopped (outdoor temperature < 9°C)

458 OUTDOOR UNIT fan 1 error

461 Compressor start-up error [Inverter]

462 Absorption error [Inverter]/PFC overcurrent error

463 OLP overheating

464 IPM overcurrent error [Inverter]

465 Compressor voltage limit error

466 LINK in CC Over/Undervoltage error

467 Compressor rotation error [Inverter]

468 Current sensor error [Inverter]

469 LINK in CC voltage sensor error [Inverter]

470 EEPROM reading/writing error

471 OTP error [Inverter]

474 IPM (IGBT Module) or PFCM temperature sensor error

475 OUTDOOR UNIT fan 1 error

484 PCF overload error

485 Incoming current sensor error

500 IPM overload

554 Coolant leak error

- e electrical connections and any work on the

electrical components must be done solely by

qualied electricians.

- e hydraulic connections and any work on the

hydraulic components must be done solely by

qualied installers.

- e components used as spare parts must be

approved by Immergas

11.1 FAULT CODES.

Every problem that presents itself during operation is highlighted by an error code that appears

on the main board of the outdoor unit or on the

hydronic unit display.

3030

Page 31

3131

Page 32

Follow us

Immergas Italia

immergas.com

Immergas S.p.A.

42041 Brescello (RE) - Italy

Tel. 0522.689011

Fax 0522.680617

Certied company ISO 9001

is instruction booklet is made of ecological paper Cod. 1.039359ENG - rev. ST.002324/000 - 01/16 - Inglese per IRLANDA (IE)

Loading...

Loading...