Immergas ARES 440 TEC ERP, ARES 660 TEC ERP, ARES 770 TEC ERP, ARES 900 TEC ERP, ARES 550 TEC ERP Instructions And Warnings

Page 1

*1.039293ENG*

Instructions and warnings

Installer

Maintenance technician

IE

ARES 440 TEC ERP

ARES 550 TEC ERP

ARES 660 TEC ERP

ARES 770 TEC ERP

ARES 900 TEC ERP

Modular condensing boiler

Page 2

Page 3

Warning this manual contains the exclusive instructions for use for professionally qualied

installers and/or maintenance technicians, in compliance with laws in force.

e individual in charge of the system is NOT authorised to work on the boiler.

e manufacturer will not be held liable in the case of damage to people, animals or property

due to the failure to observe the instructions contained in the manuals supplied with the boiler.

INDEX

1 General information ...................................................................4

1.1 Symbols used in the manual ........................................................4

1.2 Compliant use of the appliance ...................................................4

1.3 Information to be provided to the user .....................................4

1.4 Safety warnings .............................................................................5

1.5 Regulations for installation..........................................................6

1.6 Installation .....................................................................................6

1.7 Water treatment ............................................................................7

1.8 general warnings ...........................................................................8

2 Technical characteristics and dimensions .................................9

2.1 Technical characteristics .............................................................. 9

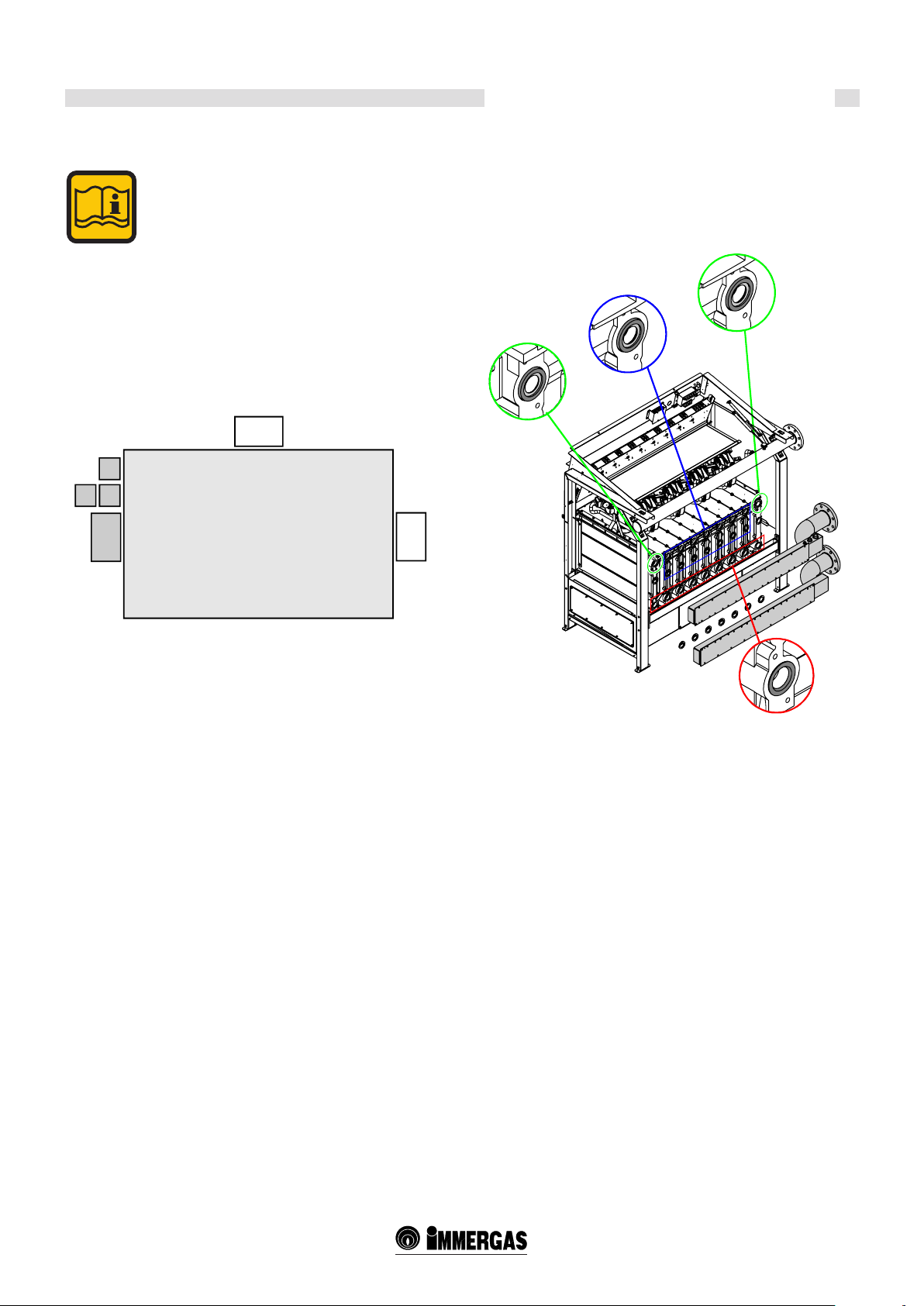

2.2 View of main parts ......................................................................10

2.3 Dimensions ..................................................................................11

2.4 Operating data / general characteristics ..................................12

3 Instructions for installation .....................................................13

3.1 General recommendations ........................................................13

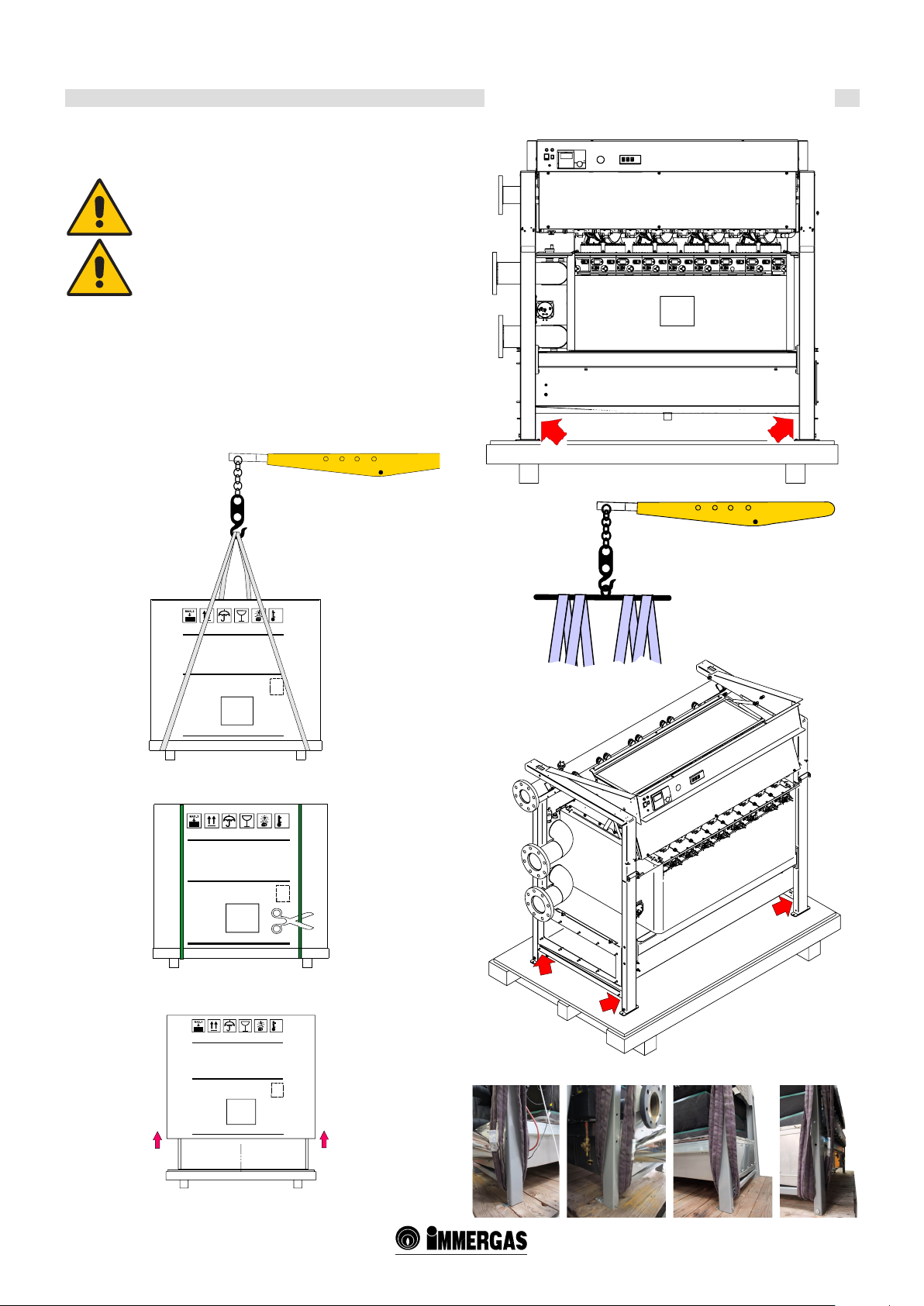

3.2 Packaging .....................................................................................14

3.3 Operation to unload and remove the packaging ...................15

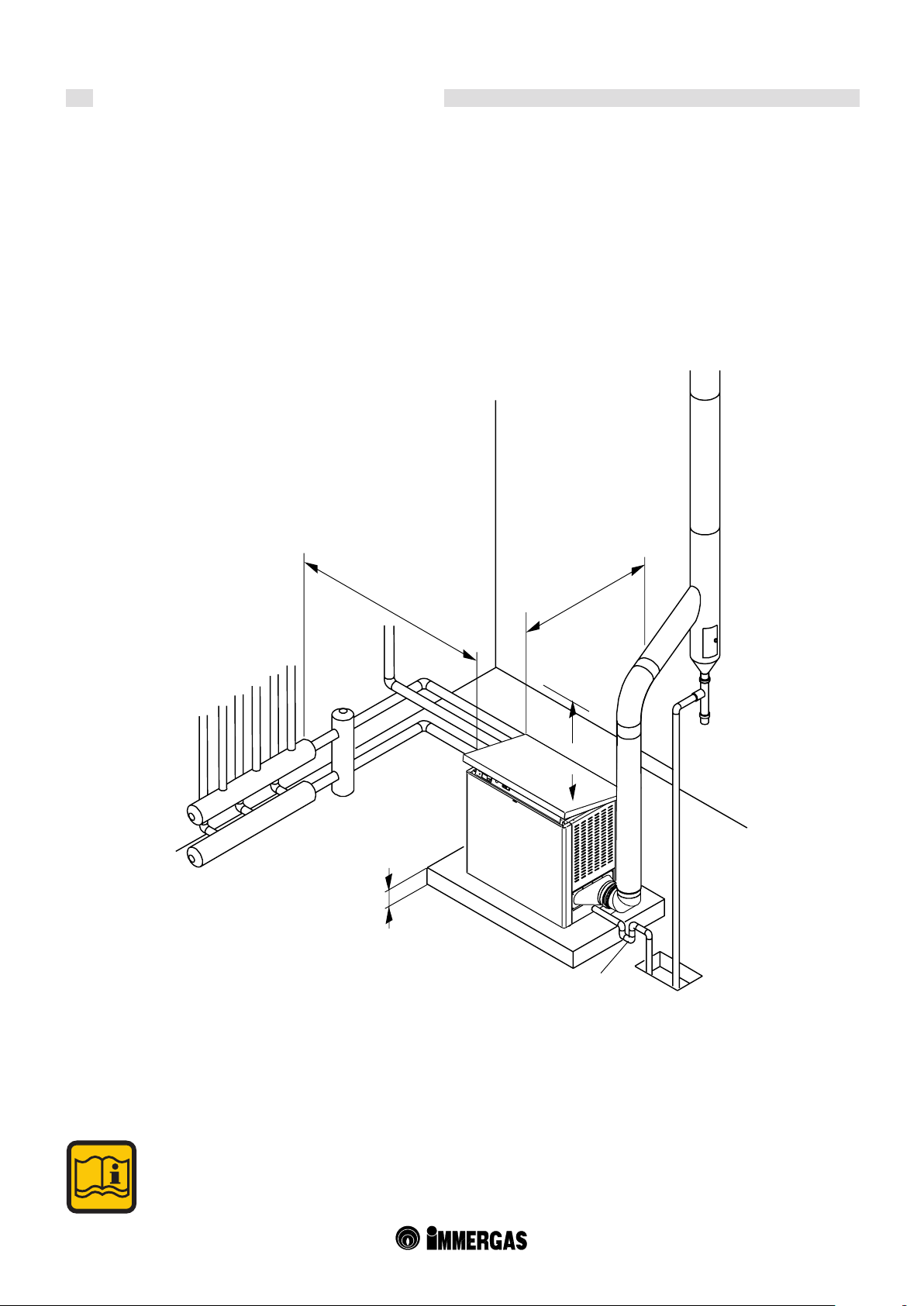

3.4 Positioning the heating control unit.........................................16

3.5 Connecting the boiler ................................................................17

3.6 Gas connection............................................................................18

3.7 System ow and return pipe connection .................................19

3.8 Additional safety, protection and control devices ..................20

3.9 Hydraulic separator ....................................................................21

3.10 Hydraulic system lter ...............................................................21

3.11 Determining the primary circuit pump or boiler pump .......22

3.12 Ball valves .....................................................................................22

3.13 complete optional kits ................................................................23

3.14 condensate drain .........................................................................24

3.15 Connecting the ue ....................................................................25

3.16 Flue exhaust manifold connection ...........................................25

3.17 Electrical connections ................................................................27

General recommendations ........................................................27

230V electrical supply connection ...........................................28

3.18 Connection diagram ..................................................................29

Power supply, gas electrovalve, INAIL, ON/OFF

pump, external probe, ow switch. ...........................................29

Power supply, gas electrovalve, INAIL, modulating pump,

external probe, ow switch. .......................................................29

INAIL safety connection

(supplied with modulating pump). .......................................... 30

ON/OFF thermostat connection. .............................................30

Modulating room thermostats connection. ............................31

Modulating zone manager connection. ...................................31

3.19 Practical connection diagram ...................................................32

3.20 Connections and management diagram ..................................34

3.21 Examples of installation (functional diagram and

description of connections) .......................................................36

3.22 System lling and emptying ......................................................41

3.23 Boiler frost protection ................................................................41

3.24 Check the adjustment of the pressure to the burner .............. 42

Nozzles - pressures. ....................................................................44

3.25 Emergency and safety operations ............................................46

3.26 First ignition ................................................................................47

4 Inspections and maintenance ..................................................48

CE DECLARATION OF CONFORMITY

(according to ISO/IEC 17050-1)

e company IMMERGAS S.p.A., with registered oce in via Cisa Ligure 95 42041 Brescello (RE) whose design, manufacturing, and aer sale

assistance processes comply with the requirements of standard UNI EN ISO 9001:2008,

DECLARES that:

e ARES 440 TEC ERP, ARES 550 TEC ERP, ARES 660 TEC ERP, ARES 770 TEC ERP, ARES 900 TEC ERP model boilers comply with the

following European Directives and Delegated European Regulations:

“Eco-design” Directive 2009/125/EC, “Energy labelling” Directive 2010/30/EC, “Gas Appliance” Directive 2009/142/EC, “Electromagnetic Compatibility” Directive 2004/108/EC, “Performance” Directive 92/42/EC and “Low Voltage” Directive 2006/95/EC.

Mauro Guareschi

Research & Development Director

Signature:

Immergas S.p.A. declines all liability due to printing or transcription errors, reserving the right to make any modications to its technical and

commercial documents without prior notice.

Page 4

General information

GENERAL

1

INFORMATION

1.1 SYMBOLS USED IN THE MANUAL

When reading this manual, pay special attention to the parts marked with these symbols:

DANGER!

Serious danger to

safety and life

for the product and environment

ATTENTION!

Possibly dangerous situation

1.2 COMPLIANT USE OF THE APPLIANCE

e ARES Tec appliance was built based on the current technical level and recognised technical safety rules.

Nevertheless, following improper use the safety and life of the user or other people may be exposed to danger, i.e. damage

to the appliance or other objects.

e appliance is designed for operation in hot water circulating heating systems.

Any other use is considered improper.

Immergas will not be held liable for any damage resulting from improper use.

Any use in accordance with the envisioned purposes includes the strict observance of the instructions in this manual.

1.3 INFORMATION TO BE PROVIDED TO THE USER

e user must be instructed in the use and operation of his/her heating system, in particular:

- Deliver these instructions to the user, as well as the other documents relative to the appliance contained in the packaging in

an envelope. e user must keep this documentation safe so that it is available for future consultation.

- Inform the user of the importance of aeration vents and the ue exhaust system, highlighting how essential they are and how

it is strictly forbidden to change them.

- Inform the user on how to control the water pressure in the system as well as the operations required to restore it.

- Inform the user on how to correctly regulate the temperature, control units/thermostats and radiators in order to save energy.

- Remember it is compulsory to carry out regular maintenance on the system once a year and a combustion analysis every two

years (as per national legislation).

- If the appliance is sold or transferred to another owner or if the owner moves, leaving the appliance behind, always ensure the

handbook accompanies the appliance so that it may be consulted by the new owner and/or installer.

NOTE!

Tips for the user

e manufacturer will not be held liable in the case of damage to people, animals or property due to the failure to observe the instructions

contained in this manual.

4

Page 5

1.4 SAFETY WARNINGS

ATTENTION!

e appliance must not be used by people with reduced physical, mental and sensorial capabilities, without experience and

knowledge. ese people must be duly instructed and supervised during manoeuvring operations.

ATTENTION!

Installation, adjustment and maintenance of the appliance must be carried out by professionally qualied sta, in compliance

with regulations and provisions in force, as incorrect installation can cause damage to people, animals and property, for

which the manufacturer will not be held liable.

DANGER!

Maintenance or repair work on the boiler must be carried out by professionally qualied sta, authorised by Immergas;

it is advisable to sign a maintenance contract.

Poor or irregular maintenance can compromise the operational safety of the appliance and cause damage to people, animals

and property for which the manufacturer will not be held liable.

Changes to parts connected to the appliance

Do not make changes to the following elements:

- to the boiler

- to the gas, air, water and power supply lines

- to the ue pipe, safety valve and exhaust pipe

- to the constructive elements that aect the operational safety of the appliance.

General information

Attention!

To tighten or loosen the screw-attached ttings, use suitable wrenches only.

Improper use and/or unsuitable tools can cause damage (for ex. water and gas leaks).

ATTENTION!

Instructions for appliances running on propane gas

Make sure that the gas tank has been deaerated prior to installing the appliance.

For a thorough deaeration of the tank contact the liquid gas supplier and in any case authorised sta, in accordance with the law.

Ignition problems can arise if the tank is not thoroughly deaerated.

In this case contact the liquid gas tank supplier.

Smell of gas

In case of the smell of gas observe the following safety instructions:

- do not use electric switches

- do not smoke

- do not use the telephone

- shut o the gas cut-o valve

- aerate the room where the gas leak occurred

- notify the gas supply company or a company specialised in the installation and maintenance of heating systems.

Explosive and easily ammable substances

Do not use or deposit explosive or easily ammable materials (for ex. petrol, paints, paper) in the room where the appliance is

installed.

ATTENTION!

e heat unit must be installed so as to avoid, under the envisioned operating conditions, the liquid contained in it from freezing

and avoid exposing the command and control parts to temperatures below -15°C and over +40°C.

e heat unit must be protected from climatic/environmental variations by:

- insulating the hydraulic and condensation exhaust pipes

- adopting specic anti-freeze products in the hydraulic system.

5

Page 6

General information

1.5 REGULATIONS FOR INSTALLATION

ARES Tec is a gas category II

e appliance must be installed in accordance with the instructions

contained in this manual.

Installation must be carried out by an authorised professional

technician, who is in charge of enforcing observance of all local

and/or national laws published in the Ocial Gazette, as well as all

applicable technical regulations.

It is necessary to observe the standards, regulations and requirements

for installation provided below, constituting a rough and non-exhaustive

list, in order to follow the evolution of the "state of the art". We

would like to underline that updating the list of standards is the

responsibility of the technicians authorised to carry out installation.

heat unit.

2H3P

Also observe the standards regarding the heating control unit,

construction regulations and requirements on combustion heating in

the country of installation.

The appliance must be installed, commissioned and subject to

maintenance in accordance with the current "state of the art". is also

applies to the hydraulic system, the ue exhaust system, the installation

room and the electrical system.

Failure to observe the above regulations will void

the warranty.

1.6 INSTALLATION

When the appliance is installed on existing systems, make sure that:

- e ue is suitable for condensation appliances, for the temperatures

of the combustion products, calculated and built in accordance with

regulations in force. at is it a straight as possible, water-tight and

insulated and does not have any obstructions or constrictions.

- e ue is equipped with an attachment to evacuate the condensation.

- e heating control unit is equipped with a pipe for the evacuation

of the condensation produced by the boiler.

- e electrical system is built in accordance with specic regulations

and qualied technical personnel.

- e ow rate, head and direction of ow of the circulation pumps is

appropriate.

- e fuel feed line and any existing tanks are set up in accordance with

regulations in force.

- e expansion vessels ensure complete absorption of the dilation of

the uid contained in the system.

- Slurry and build-up have been cleaned out of the system.

If ARES Tec is being installed on existing Systems:

If it is possible to schedule the replacement, it is necessary to wash

the system preventively, with alkaline dispersants. Washing must be

carried out four weeks prior to replacement, with a system operating

between 35°C - 40°C.

Attention!

If the new boiler has been replaced in an old system

without having preventively washed it as described

above, do not wash the system, as any residues of

the product in the circuit may ll the generator with

residues aer replacement.

It is advisable to contact a company specialised in

water treatment.

Otherwise, if ARES Tec is being installed on a new system it is advisable

to wash it thoroughly in any case, using products that are suitable for

the entire system, and install a Y-strainer with two cut-o valves on the

return pipe to the boiler, so that it can be cleaned as needed.

is lter will protect the boiler from sediments coming from the

heating system.

In both cases it is necessary to keep the head losses localised in the

primary circuit, for the correct sizing of the pump.

6

Page 7

General information

1.7 WATER TREATMENT

Treating the supply water allows you to prevent problems and

maintain the functionality and eciency of the generator over time.

e purpose of this treatment is to eliminate or signicantly reduce

problems that can be outlined as:

build-up

corrosion

sediments

biological growth (mould, fungus, algae, bacteria, etc.)

e chemical analysis of the water provides a lot of information on the

state and "health" of the system.

e pH level is a numerical indication of the acidity or alkalinity of

a solution.

e pH scale goes from 0 to 14, where 7 corresponds to neutral.

Values below 7 indicate acidity, values above 7 indicate alkalinity.

e ideal pH value in heating systems with aluminium boilers is

between 6.5 and 8, with a hardness of 15°F.

Water in a system with a pH value outside of this range considerably

accelerates the destruction of the protective oxide layer which forms

naturally inside the aluminium bodies, and would not occur naturally:

if the pH level is lower than 6 it contains acid, if it is above 8 the water is

alkaline, either due to an alkaline treatment (for example phosphates or

glycols operating as antifreeze) or in some cases the natural generation

of alkalis in the system.

Vice versa, if the pH value is between 6.5 and 8, the aluminium surfaces

in the body are passivated and protected from further corrosive attacks.

To minimise corrosion, it is essential to use a corrosion inhibitor.

In order for it to work eciently, however, the metal surfaces must

be clean.

The best inhibitors on the market also contain an aluminium

protection system that stabilises the pH levels of the ller water,

preventing sudden changes (buer eect).

It is advisable to systematically check (at least twice a year) the

pH value of the water in the system. In order to do so a chemical

laboratory analysis is not required, but a simple check using a

analysis "kit" contained in a carry cases, easily available on the

market.

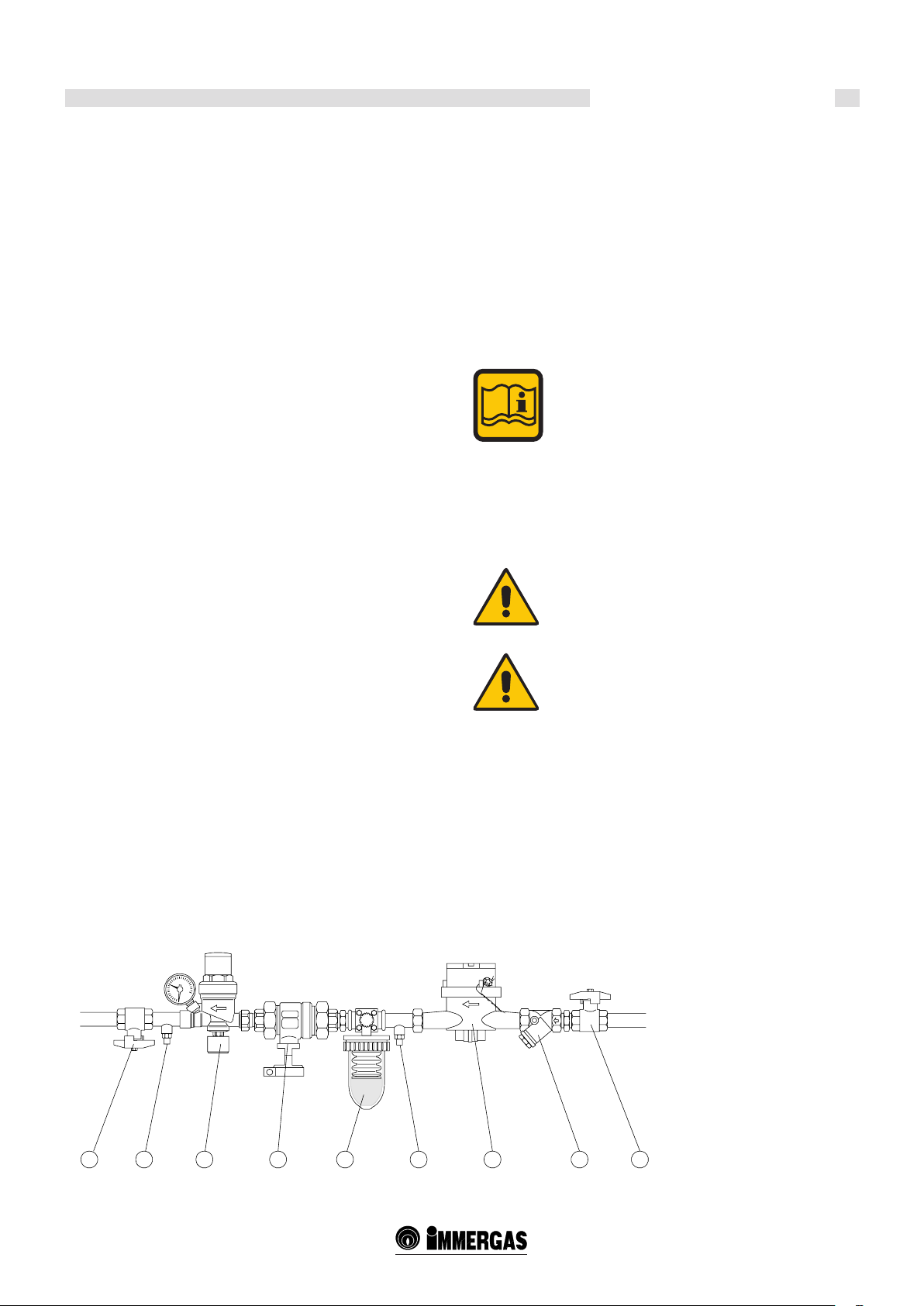

It will therefore be necessary to set up the devices shown in the gure

in the heating system.

THE COUPLING MUST BE SET UP ON THE

RETURN PIPE TO THE PRIMARY CIRCUIT

DOWNSTREAM OF THE PUMP.

All of the precautions required to avoid the formation and localisation of

oxygen in the water of the system. For this reason the plastic pipes used

in the under-oor heating systems must not be permeable to oxygen.

Make sure that any anti-freeze products are compatible with aliminium

and any other parts and materials in the system.

ATTENTION!

Any damage caused to the boiler, due to the formation

of build-up or corrosive water, will not be covered by

the warranty.

Example of water treatment unit

ATTENTION!

These appliances are designed and developed to

transfer heat to a heat carrying uid possessing the

characteristics described here, they are not suitable to

directly heat water intended for human consumption.

Key:

1 - Ball valve

2 - Sample trap

3 - Filling unit

4 - Cut-o device

5 - Water treatment unit

6 - Litre meter (recommended)

7 - "Y" strainer

1 2 3 4 5 2 7 16

7

Page 8

General information

1.8 GENERAL WARNINGS

e instruction handbook is an integral and essential part of the product

and must be kept safe by the individual in charge of the system.

Read the warnings contained in the handbook carefully, as they provide

important instructions regarding installation, user and maintenance

safety.

Keep the handbook safe for future consultation.

e appliance must be installed and maintained in accordance

with regulations in force, pursuant to the instructions of the

manufacturer, the state of the art and by authorised and qualied

personnel, in accordance with the law.

Professionally qualied personnel means sta with specic technical

skills in the sector of heating system parts for civil use, hot water

production for domestic use and maintenance. is personnel must

have the authorisations required by legislation in force.

Incorrect installation or poor maintenance can cause injury to persons

and animals and damage to objects, for which the manufacturer is

not liable.

Before carrying out any cleaning or maintenance operations, cut the

appliance o from the power mains by acting on the switch on the

system and/or using the cut-o devices.

Any repairs to the products must be carried out by authorised Immergas

personnel only, using original spare parts only. Failure to observe

the above can jeopardise the safety of the appliance and will void the

warranty.

e guarantee the eciency of the appliance and its correct operation it

is essential for authorised personnel to carry out annual maintenance.

If the appliance is put out of use for downtime, any part that is

susceptible to posing a potential source of danger must be made safe.

Before re-commissioning an appliance that has been put out of use,

proceed to washing the domestic hot water production system, making

water ow through it for the amount of time required to change the

water completely.

If the appliance is sold or transferred to another owner or if the owner

moves, leaving the appliance behind, always ensure the handbook

accompanies the appliance so that it may be consulted by the new

owner and/or installer.

All appliances with optionals or kits (including electric) must only use

original spare parts.

e appliance must only be employed for its expressly foreseen use.

Any other use must be considered improper and therefore dangerous.

Do not obstruct the intake/exhaust pipe terminals.

In case of breakdown and/or poor operation of the appliance, switch it

o, and do not attempt in any way to repair it or intervene directly. Only

contact personnel that has been authorised in accordance with the law.

8

Page 9

Technical characteristics and dimensions

TECHNICAL

2

CHARACTERISTICS AND

DIMENSIONS

2.1 TECHNICAL CHARACTERISTICS

- Heat generator, to heat Low Nox condensation gas

- Comprised of a heat module designed to operate on its own or in a

set

- Can be set up directly outside (IP X5D)

- Low water content

- High response speed to load changes

- Single ue exhaust that can be positioned on 3 sides

- Unied ow and return hydraulic manifolds

- Comprised of 4 or more heating elements (between 4 and 8),

aluminium/silicon/magnesium casting

- Including total irradiation premixing modulating burners

- None of the heating elements have hydraulic cut-o devices

- Single gas supply pipe

- Modulated power between 22 ÷ 108 kW/element.

TEMPERATURE CONTROL DEVICES:

- ROOM NTC sensor (every heating element)

- Room Limit ermostat (every heating element)

- Flow NTC sensor (General)

- Return NTC sensor (General)

- Approved safety thermostat (To be ordered and installed on INAIL

section in parag. 3.8)

- GCI global ow probe.

OTHER SAFETY DEVICES according to the R COLLECTION

see parag. 3.8

POP-UP control panel composed of:

- ON-OFF switch see parag. 3.25

- TGC boiler thermoregulation/manager

- GCI (internal cascade management board)

- Protection fuses

- Any limit thermostats

- Fan air pressure switch

- Condensation water level sensor

- Gas pressure switch

- Exhaust pressure switch (anti-obstruction).

- e entire heating unit is equipped with global temperature control

NTC sensors on the ow and return manifolds.

- Integral insulation with non-allergenic synthetic wool.

- Total premix burner, modulating, with "metal foam" radiation

combustion chamber. Premixing in the fan. Automatic separating

backow diaphragm from the combustion chamber.

- Sound emissions at maximum power below 49 dBA.

- Operation during heating: determining the instantaneous power

through a control microprocessor, with preset comparison parameters

between requested temperature (or calculated by the outdoor

thermoregulation) and global ow temperature.

- Logic of operation:

- Possibility of controlling the power of the single heating elements

for calibration and/or assistance with reserved access code.

- D.H.W. production through priority NTC probe, to control the

storage tank load through a pump or three-way deviator valve

through the supplied TGC thermoregulator.

- Possibility of controlling the power of the single heating elements.

- Heat request control: temperature setpoint and modulation level.

- Monitoring the state of operation and temperatures.

- Alarm notication.

- Parameter setting.

- Control relay to switch on a pump at a xed speed.

- Analogue 0÷10V output to control a modulating pump.

- Emergency operation: this allows you to avoid the system from

stopping due to an interruption in communication with the adjusting

system or possible remote management of the control unit:

- e possibility of selecting the emergency temperature through

supplied "Constant Setpoint" heating elements: 70°C, maximum

power 50%.

- Alarm management.

- Alarm reset input.

- Alarm notication Relay.

- Condensation collection tray with stainless steel exhaust trap.

- Easily removable integral panelling comprised of oven-painted steel

panels suitable for outdoor installation.

- Condensation collection tray with stainless steel exhaust trap and ue

chamber.

- Incorporated deaerator.

e request for heat can be generated by the TGC thermoregulation/

manager or alternatively by the GCI (internal cascade management

board).

The management logic envisions simultaneous operation of the

maximum number of heat elements, so as to always obtain the

maximum eciency. Since it guarantees the maximum exchange area

based on the delivered power. e elements are made to operate so as

to equally divide the operating time.

e hot water that is produced is pushed by the pump located on the

return of the primary ring to the ow of the hydraulic separator. From

here a second pump (system - see suggested diagrams) will distribute to

the various utilities. From the system, return the cooled water is taken

in by the pump on the return, through the hydraulic separator, to start

the cycle towards the generator again.

9

Page 10

Technical characteristics and dimensions

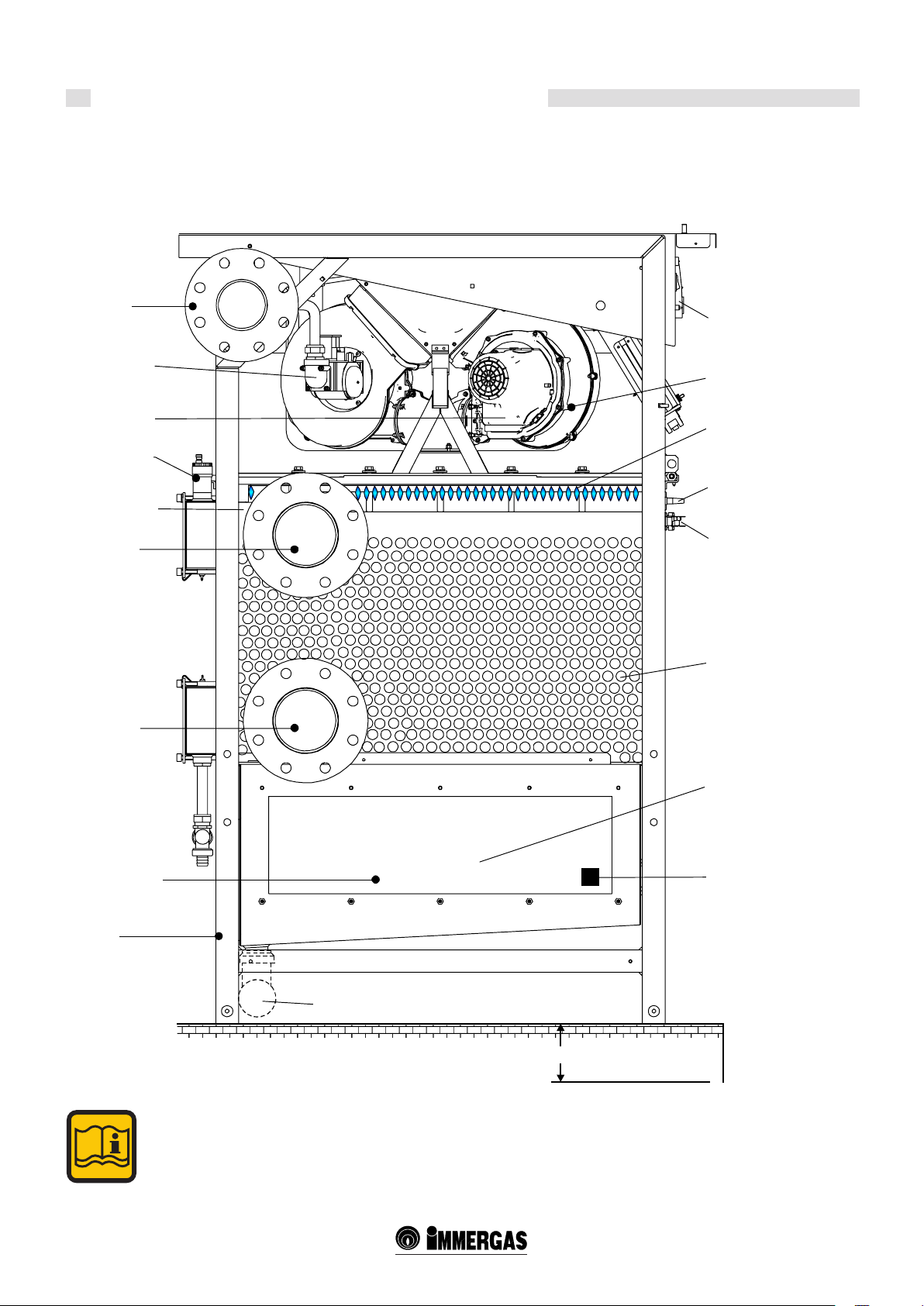

2.2 VIEW OF MAIN PARTS

GAS PIPE

TUBO GAS

Valvola gas

GAS VALVE

FAN

Ventilatore

AUTOMATIC

SFIATO ARIA

AIR BLEED

AUTOMATICO

VALVE

Camer a

COMBUSTION

di

CHAMBER

comb ustione

MANDATA

HEAT. FLOW

RISCALD AM.

Pannello

PANEL

BURNER

COPERCHIO

BR UCIATORE

COVER

Bruciatore

BURNER

Elettrodo

IGNITION

ELECTRODE

di accensione

Te rmostato

SAFETY

THERMOSTAT

di sicurezza

RITORNO

HEAT.

RISCALD AM.

RETURN

CONDENSATION

BACINELLA

COLLECTION

RACCOGLI

PAN

CONSENSA -

RACCORDO

FLUE FITTING

CAMINO

TELAIO

FRAME

TRAP

Sifone

Profondità min. 100 mm

Min. depth 100 mm

Elemento

STUDDED

ELEMENT

piolinato

CONDENSATE

Collettore

COLLECTION

raccogli condensa

MANIFOLD

LEVEL

Sensore di

SENSOR

livello

ue outlet LEFT, RIGHT, REAR side

ow LEFT side

return LEFT side

Gas inletLEFT side

GCI: under the front casing

10

Page 11

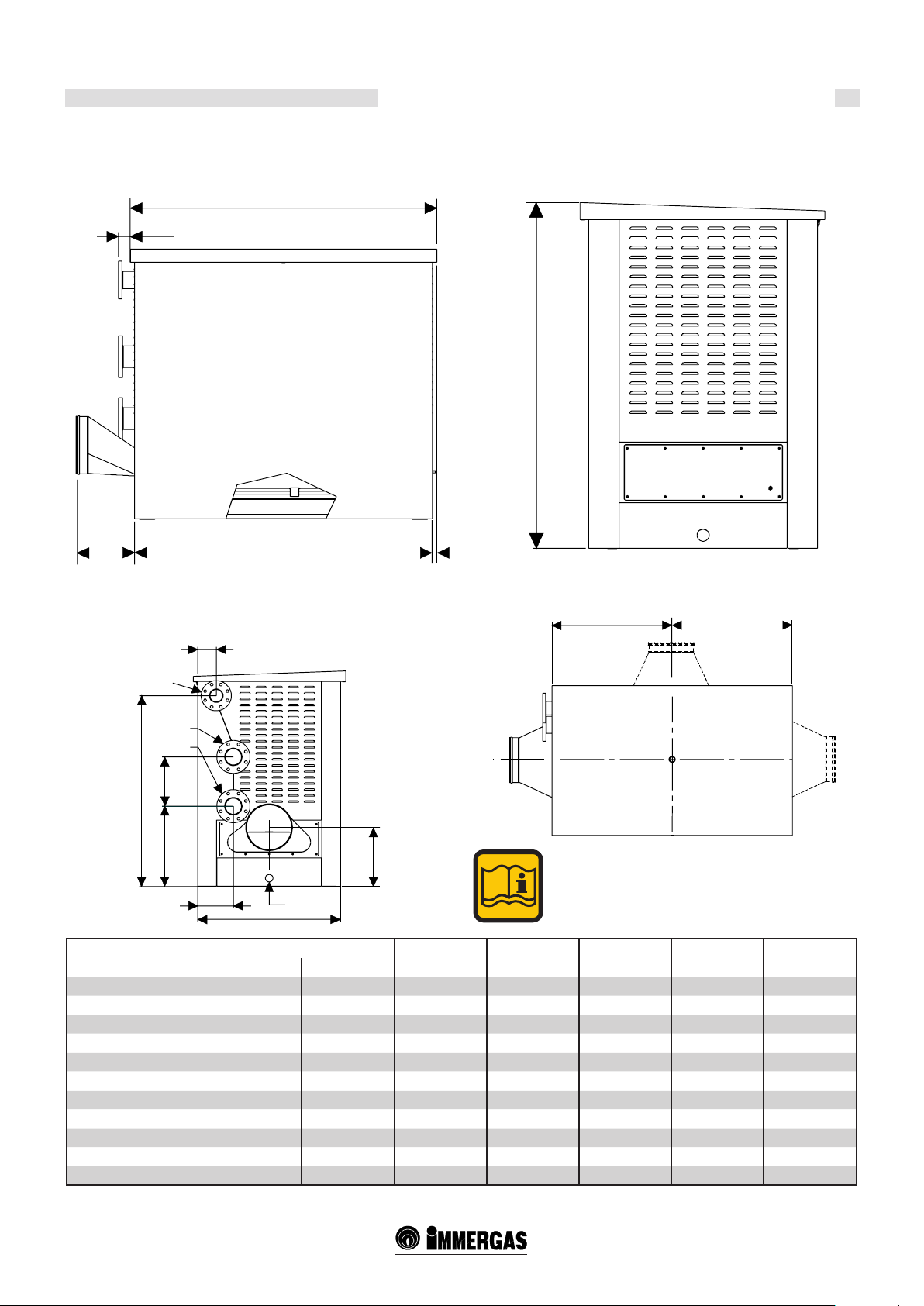

2.3 DIMENSIONS

62,5

Technical characteristics and dimensions

FRONT VIEW RIGHT SIDE VIEW

(Supply condition for le side attachments)

L

1448

S

287

L1

24

TOP VIEW

LEFT SIDE VIEW

122

G

M

R

327

1267

534

235

S

946

39 5

Flue outlets:

Le side (supply condition)

Right side

Rear side

=

=

ARES Tec 440 550 660 770 900

Dimensions Unit

Heating elements n° 4 5 6 7 8

Height mm 1448 1448 1448 1448 1448

Width "L" mm 1087 1355 1355 1623 1623

Width "L1" mm 1039 1307 1307 1575 1575

Depth mm 946 946 946 946 946

Attachment sizes

G Gas tting mm (inch) 80 (3) 80 (3) 80 (3) 80 (3) 80 (3)

F System ow mm (inch) 100 (4) 100 (4) 100 (4) 100 (4) 100 (4)

R System return mm (inch) 100 (4) 100 (4) 100 (4) 100 (4) 100 (4)

Flue tting mm 250 250 300 300 300

Condensate drain mm 40 40 40 40 40

11

Page 12

Technical characteristics and dimensions

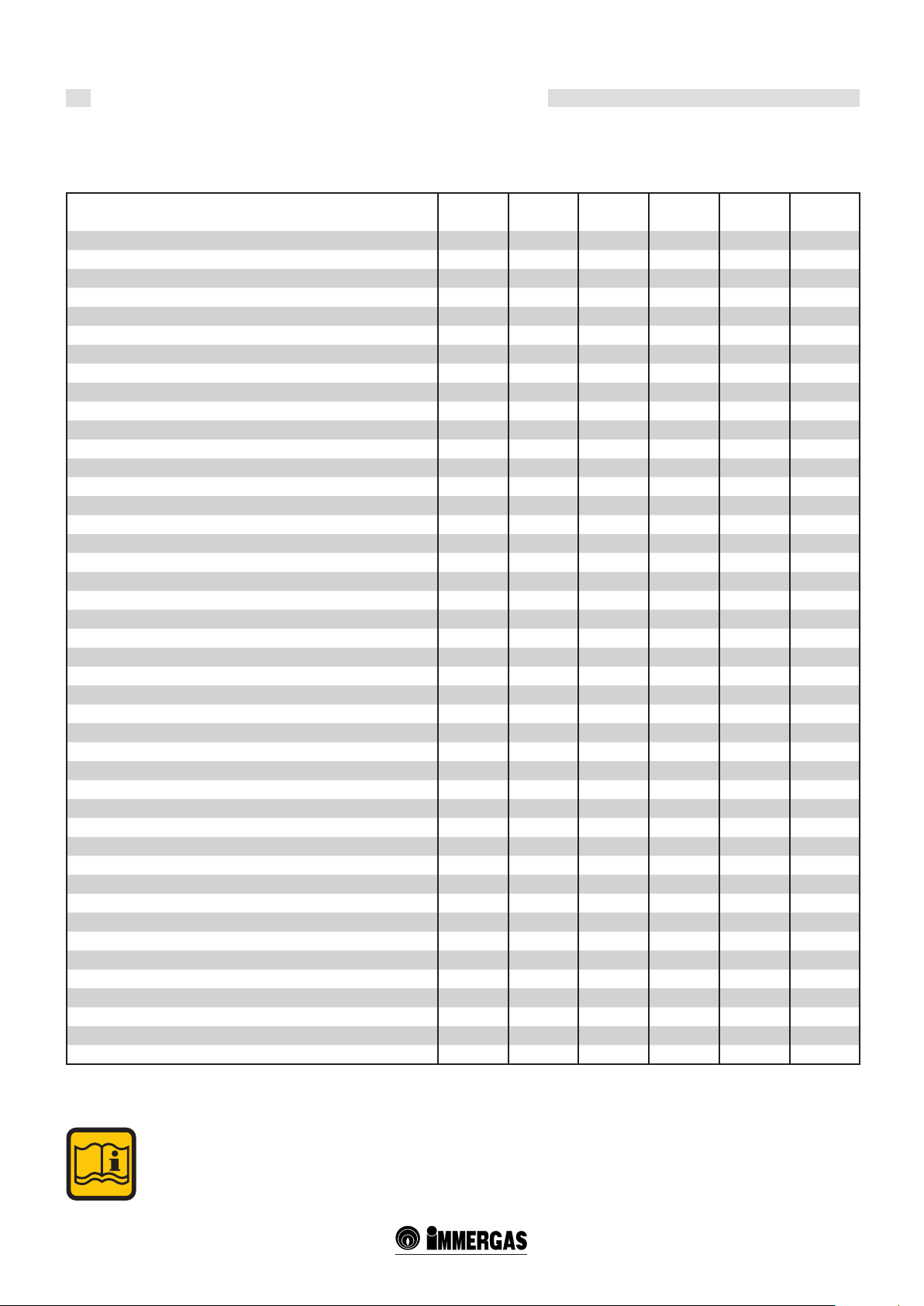

2.4 OPERATING DATA / GENERAL CHAR

ACTERISTICS

ARES Tec 440 550 660 770 900

Boiler category II

2H3P

Nominal heat input on L.V.C. Qn kW 432 540 648 756 864

Minimum heat input on L.C.V. Qmin kW 22 22 22 22 22

Nominal eective power (Tr 60 / Tf 80°C) Pn kW 424,27 530,33 636,40 742,47 848,53

Minimum eective power (Tr 60 / Tf 80°C) Pn min kW 20,57 20,57 20,57 20,57 20,57

Nominal eective power (Tr 30 / Tf 50°C) Pcond kW 445,39 557,82 670,03 783,22 900,29

Minimum eective power (Tr 30 / Tf 50°C) Pcond min kW 23,94 23,94 23,94 23,94 23,94

Eciency at nominal power (Tr 60 / Tf 80°C) % 98,21 98,21 98,21 98,21 98,21

Eciency at minimum power (Tr 60 / Tf 80°C) % 93,5 93,5 93,5 93,5 93,5

Eciency at nominal power (Tr 30 / Tf 50°C) % 103,1 103,3 103,4 103,6 104,2

Eciency at minimum power (Tr 30 / Tf 50°C) % 108,8 108,8 108,8 108,8 108,8

Eciency class according to directive 92/42 EEC -- 4 4 4 4 4

Combustion eciency at nominal load % 98,28 98,28 998,28 98,28 98,30

Combustion eciency at minimum load % 98,45 98,45 98,45 98,45 98,45

Losses from operating burner casing % 0,1 0,1 0,1 0,1 0,1

Losses from burner casing when switched o -- 0,1 0,1 0,1 0,1 0,1

Chimney losses with burner on % 1,55 1,55 1,55 1,55 1,55

Flue temperature at net of Tf-Ta (max) °C 45,4 45,5 45,5 45,5 45,3

Maximum ue ow rate (max) kg/h 706,0 882,5 1059,1 1235,6 1412,1

Air excess % 25,5 25,5 25,5 25,5 25,5

(**) CO2 (min/max) % - - - - NOX (weighted value according to EN 15420)

mg/kWh

47 47 47 47 47

NOX class -- 5 5 5 5 5

Water ow rate at nominal power (∆T 20°C) l/h 18243,5 22804,4 27365,2 31926,1 36487,0

Minimum pressure of heating circuit bar 0,5 0,5 0,5 0,5 0,5

Maximum pressure of heating circuit bar 6,0 6,0 6,0 6,0 6,0

Water content l 73 88 103 118 133

Methane gas consumption G20 (supp.press. 20 mbar) at Qn m3/h 45,68 57,10 68,52 79,94 91,36

Methane gas consumption G20 (supp.press. 20 mbar) at Qmin m3/h 2,33 2,33 2,33 2,33 2,33

Gas consumption G25 (supp.press. 20/25 mbar) at Qn m3/h 53,13 66,41 79,69 92,97 106,25

Gas consumption G25 (supp.press. 20/25 mbar) at Qmin m3/h 2,71 2,71 2,71 2,71 2,71

Propane gas consumption (supp.press. 37/50 mbar) at Qn kg/h 33,53 41,92 50,30 58,68 67,07

Propane gas consumption (supp.press. 37/50 mbar) at Qmin kg/h 1,71 1,71 1,71 1,71 1,71

Maximum pressure available at ue base Pa 100 100 100 100 100

Max condensate production kg/h 69,5 86,9 104,3 121,7 139,1

Emissions

CO with 0% of O2 in the exhaust ppm <95 <95 <95 <95 <95

NOx with 0% of O2 in the exhaust ppm <30 <30 <30 <30 <30

Sound dBA <49 <49 <49 <49 <49

Electrical data

Power supply voltage / Frequency V/Hz 230/50 230/50 230/50 230/50 230/50

Supply fuse A (F) 4 4 4 4 4

Maximum power W 626 783 940 1096 1252

(***) Degree of protection IP X5D X5D X5D X5D X5D

Consumption in stand-by W 20 20 20 20 20

II

2H3P

II

2H3P

II

2H3P

II

2H3P

(*) Room Temperature = 20°C

(**) See "NOZZLES - PRESSURES" table

(***) e IP X5D degree of protection is obtained with

the lid lowered.

12

Page 13

Instructions for the installer

INSTRUCTIONS FOR

3

INSTALLATION

3.1 GENERAL RECOMMENDATIONS

ATTENTION!

is boiler must only be employed for its explicitly

intended use. Any other use must be considered

improper and therefore dangerous.

is boiler is used to heat water to below boiling

temperature in atmospheric pressure.

ATTENTION!

These appliances are designed exclusively for

installation inside suitable technical compartments.

Before connecting the boiler, have professionally

qualied personnel:

a) Accurately washing all of the pipes in the system

to remove any residues or sediments could stop

the boiler form running eciently, even in terms

of health and hygiene.

b) Making sure the boiler is set up to operate with the

available type of fuel. e type of fuel is stated on the

packaging and technical characteristics plate.

c) Make sure that the chimney/ue has an adequate

draught, that it is not choked, and that there are no

other exhausts for other appliances, unless the ue

is designed for multiple utilities, in accordance with

standard specications and requirements in force.

Only once this check has been carried out can the

tting between boiler and chimney/ue be set up.

ATTENTION!

In rooms with aggressive vapour or dust, the

appliance must operate independently of the air in

the room of installation!

ATTENTION!

The appliance must be installed by a qualified

technician possessing professional-technical

qualications in accordance with the law, who, under

his/her own responsibility, enforces the observance of

regulations according to the rules of good practice.

ATTENTION!

Assemble the appliance in observance of the minimum

required distances for installation and maintenance.

e boiler must be connected to a heating system

compatibly with its specications and power.

13

Page 14

C

Instructions for the installer

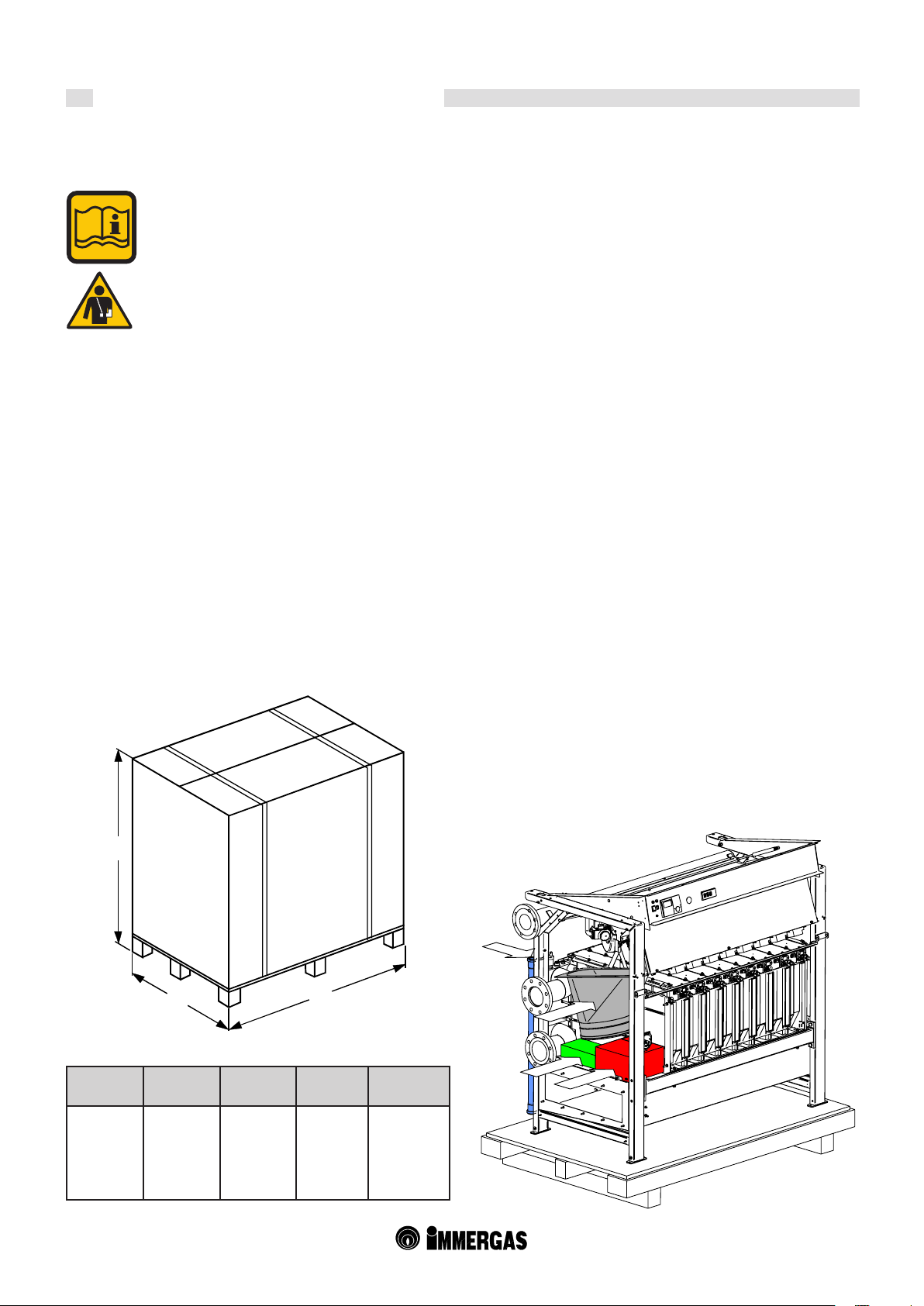

3.2 PACKAGING

e ARES Tec boiler is supplied assembled in a sturdy cardboard box.

Once the two straps have been removed, slide the box

o from the top and make sure the contents are intact.

Packaging materials (cardboard box, straps, plastic bags,

etc.) constitute a potential hazard and must be kept

out of the reach of children.

Immergas will not be held liable in case of damage

caused to people, animals or property due to failure to

observe the above.

To take the boiler o of the pallet it is necessary to use a jib crane, to

avoid damaging it.

- Remove the casings and harness it using slings "A" g. 3 being careful

to pass the slings through the load bearing crossbeams of the frame

- Tie the slings to the jib "B". Perform these operations with caution.

Composition of packaging:

on the le side of the boiler:

- e ue exhaust manifold.

- A cardboard box containing:

- Gasket between pan and terminal

- Collar gasket (Ø 250) Ø 300

- Two bends + one T + plastic cap for condensate drain

- Screws required to secure the ue terminal

- e probes: external, ow, storage tank.

- Flue inspection cap.

- Kit of resistances.

- Plate and fairlead for power output.

- A cardboard box containing:

- Flanges

Inside the rear side of the casing:

- Condensate drain trap pipes (1 m).

Above the boiler cover:

- A plastic bag containing:

- Installer and maintenance technician instructions handbook

- System manager instructions handbook

- TGC control unit user handbook

- Warranty certicate

- Hydraulic test certicate

- Control unit handbook

- Spare parts stub

B

Model A (mm) B (mm) C (mm)

440

550

660

770

900

1263

1531

1531

1799

1799

1120

1120

1120

1120

1120

A

1515

1515

1515

1515

1515

Gross

Weight (kg)

585

643

707

806

858

14

Page 15

3.3 OPERATION TO UNLOAD AND

REMOVE THE PACKAGING

ATTENTION!

Handle using forkli or hoist and sling.

ATTENTION!

Sling slotting points for liing. e slings must be

assembled on the load bearing crossbeams.

Instructions for the installer

To take the boiler o of the pallet it is necessary to use a jib crane, to

avoid damaging it.

- Remove the casings and harness it using slings, being careful to pass

the slings through the load bearing crossbeams of the frame.

- Tie the slings to the jib. Perform these operations with caution.

T max

50°C/122°F

T min

Max. admitted boilers

Do not turn upside down Do not expose to rain Fragile Do not expose to sunlight Do not store at

stacked

-5°C/23°F

temperature:

lower than - 5 ° C / 23 °F

superior than 50 °C / 122 °F

1

4

Max. admitted boilers

Do not turn upside down Do not expose to rain Fragile Do not expose to sunlight Do not store at

stacked

2

Max. admitted boilers

Do not turn upside dow n Do not expose to rain Fragile Do not expose to sunlight Do not store at

stacked

3

T max

50°C/122°F

T min

-5°C/23°F

temperature:

lower than - 5 ° C / 23 °F

superior than 50 °C / 122 °F

T max

50°C/122°F

T min

-5°C/23°F

temperature:

lower than - 5 ° C / 23 °F

superior than 50 °C / 122 °F

15

Page 16

Instructions for the installer

3.4 POSITIONING THE HEATING

CONTROL UNIT

Special attention must be paid to local standards and regulations

regarding heating control units, especially the minimum distances

that must be observed.

Installation must be comply with the requirements contained in the

most recent standards and legislation regarding heating control units,

heating system installation and hot water production, ventilation, ues

suitable for condensation boiler combustion product exhaust, and any

other applicable regulation.

A

e boiler can be placed on a at platform that is suciently sturdy

in size, in plan, no smaller than the boiler measurements and with a

minimum height of at least 100 mm so that the trap for condensate

drainage can be installed. Alternatively, a trap can be built from this

platform, next to the boiler, at a depth of 100 mm so that the trap can

be placed in it (Parag. 3.16).

When installation is complete the boiler should be perfectly horizontal

and rmly stable (to reduce vibrations and noise).

B

A > 400 mm

C

B > 400 mm

C = 100 mm

D= 500 mm

Observe the minimum clearance distances required to

perform normal maintenance and cleaning operations.

D

Sifone

Tra p

16

Page 17

Instructions for the installer

3.5 CONNECTING THE BOILER

e ARES Tec boiler leaves the factory set up for

the hydraulic (ow and return) and gas connections

located on the le side of the boiler.

To fasten the ue exhaust manifold use the screws

and gaskets contained in the accessory kit box and a

10 mm socket key.

e ue exhaust manifold is set up on the LEFT SIDE.

It is also possible to set up the outlet on the RIGHT

and REAR SIDE.

F

G

RM

F

Diaphragms and gaskets.

Diaphragm installed on the rst and last element of the ow manifold

Ø 18 (A), internal Ø 27 (B).

Gaskets installed on all of the other elements (C).

A

B

A

F

C

17

Page 18

Instructions for the installer

3.6 GAS CONNECTION

e gas intake pipe must be connected to the boiler using the respective

G 3" tting as indicated in parag. 2.3.

e supply pipe must have a section equal to or larger than the one used

in the boiler and must nevertheless provide the correct gas pressure.

It is nevertheless advisable to adhere to the standard specications

and requirements in force, setting up a cut-o valve, gas lter, antivibration joint, etc.

Before commissioning an internal gas distribution system and therefore,

before connecting it to the meter, it is necessary to thoroughly check

the seal.

If any part of the system is not in view, the sealing test must be carried

out before covering the pipe.

Danger!

e gas connection must be set up by an authorised

installation technician who must observe and apply

the contents of the legislation in force and the local

requirements of the gas supply company, as incorrect

installation can cause damage to people, animals

and property, for which the manufacturer will not

be held liable.

Before installation it is advisable to clean the inside

of the fuel intake pipe thoroughly, in order to remove

any residues that could stop the boiler from operating

sm oot hly.

If you notice the smell of gas:

a) Do not work the electrical switches, the telephone

or any other object that can generate sparks;

b) Immediately open doors and windows to create an

air current that puries the room;

c) Close the gas valves;

d) Seek the assistance of professionally qualified

personnel.

In order to prevent any gas leaks it is advisable to install

a surveillance and protection system composed of a gas

leak detector combined with a cut-o electrovalve on

the fuel supply line.

1 2 3 4 5 66

Key:

1 - Fuel shut-o valve

2 - Double membrane regulator

3 - Gas lter

4 - Anti-vibration joint

5 - Gas electrovalve

6 - Cut-o valve

EXAMPLE OF GAS INTAKE SYSTEM

INTERNO

INTERIOR OF

CENTRALE

THE HEATING

TERMICA

CONTROL UNIT

ESTERNO

EXTERIOR OF

CENTRALE

THE HEATING

TERMICA

CONTROL UNIT

18

Page 19

Instructions for the installer

3.7 SYSTEM FLOW AND RETURN PIPE

CONNECTION

e heating ow and return must be connected to the boiler by the

respective 4" ttings F and R as indicated in parag. 2.3.

For heating circuit pipe sizing it is necessary to take into account

the head losses induced by the components of the system and its

conguration.

e layout of the pipes must be set up taking every necessary precaution

to avoid air pockets and to facilitate continuous degassing of the system.

ATTENTION!

Before connecting the boiler to the system proceed

by thoroughly washing the pipes terminating at the

boiler with a suitable product, in compliance with

standards, in order to eliminate metal residues from

machining and welding, any oil and grease that could

aect its operation.

Do not use solvents to wash the system, as they might

damage the system and/or its components.

Failure to observe the instructions in this manual

can cause damage to people, animals and property,

for which the manufacturer will not be held liable.

Make sure the pipes in the system are not used as

earthing connections for the electrical or telephone

system. ey are absolutely not suitable for this purpose.

Serious damage to pipes, boiler and radiators could

occur in a short amount of time.

ATTENTION!

IT IS ABSOLUTELY FORBIDDEN TO SET UP CUTOFF DEVICES ON THE GENERATOR BEFORE

THE SAFETY DEVICES.

G

M

R

GCI

19

Page 20

Instructions for the installer

3.8 ADDITIONAL SAFETY, PROTECTION

AND CONTROL DEVICES

Certicate of additional safety devices: closely consult the legislative

regulations and safety provisions in force in the country of installation

of the appliance.

Use the fuel safety and cut-o valves suitable for application and

compliant with provisions in force.

e boiler is not equipped with an expansion vessel on the system. It

is mandatory to install a closed expansion vessel to guarantee correct

boiler operation. e expansion vessel must be compliant with standard

requirements in force. e dimensions of the expansion vessel depend

on the data for the central heating system. Install a vessel with a capacity,

determined by an authorised designer, that responds to the requisites

of the standards in force.

Safety devices.

1 Gas cut-o valve: this has the function of directly cutting-o the

gas supply if the limit value of the water temperature is reached.

e detection element must be installed as close as possible to the

generator output (ow pipe) at a distance of < 500 mm, and must

not have a cut-o device installed on it. Not supplied by Immergas.

2 Safety valve: this has the function of unloading the uid contained

in the generator into the atmosphere when it reaches the maximum

operating temperature for any reason. Not supplied by Immergas.

2a Visible draining funnel. Not supplied by Immergas.

Set up a safety valve, on the ow pipe, sized for boiler capacity, within

0.5 m of the boiler, and in compliance with regulations in force.

Attention!

Remember it is forbidden to set up any type of cut-o

device between the boiler and the safety valve, and it

is also advisable to use valves for operation that does

not exceed the maximum allowed operating pressure.

Protection devices.

10 Safety thermostat: this is designed to stop the generator if the safety

thermostat installed on the boiler fails to operate correctly. It must

have an IMMOVABLE calibration of < 100°C.

15 Minimum pressure switch: this is designed to stop the generator if

the minimum operating pressure drops (can be calibrated between

0.5 ÷ 1.7 bar). It must be manually re-armed.

16 Extra sleeve G1".

18 Safety pressure switch: this is designed to stop the generator if the

maximum operating pressure is reached (can be calibrated between

1 ÷ 5 bar).

Control devices.

13 (Pressure indicator - not supplied by Immergas) with (12) damper

pipe and (11) pressure gauge valve: it indicates the existing eective

pressure in the generator, it must be graduated in "bar", its full scale

must match the maximum operating pressure and be equipped with

a three-way valve with an attachment for the control pressure gauge.

14 ermometer: this indicates the eective temperature of the water

contained in the generator, it must be graduated in centigrade with

a full scale of no more than 120°C.

17 Inspection traps: approved for the inclusion of control devices.

19 G1 ¼" stub pipes: for the inclusion of safety valves.

20 Flow switch: this is designed to stop the generator in case of poor

water circulation inside the primary ring.

3 Approved expansion vessel: this absorbs the increase in volume

of water in the system following an increase in temperature. Not

supplied by Immergas.

8 Y strainer.

7 Modulation pump (Not included in the kit).

5 Hydraulic separator (Not included in the kit).

4 Bleeder valve. Not supplied by Immergas.

6 Draining valve. Not supplied by Immergas.

Attention!

Set up a runo pipe with funnel and trap on the

heating safety valve, that lead to a suitable drain. e

drain must be visually controlled.

e manufacturer will not be held liable in the case of

failure to observe this precaution, where any work on

the safety valve may cause damage to people, animals

and property.

20

Page 21

Recommended installation

Instructions for the installer

3

4

6

2

2a

15

17

19

111214

3.9 HYDRAULIC SEPARATOR

1a

GCI

13

18

16

10

1

3.10 HYDRAULIC SYSTEM FILTER

To ensure good operation it is necessary to use a hydraulic separator

that guarantees:

- separation and collection of impurities in the circuits

- optimal deaeration

- hydraulic decoupling between the two hydraulic circulation rings

- balancing the circuits

Circuito

Primary

Primario

Boiler

Caldaia

Circuit

F

M

F

M

R

Circuito

Secondary

Secondario

System

R

Impianto

Circuit

It is advisable to install a Y strainer in the boiler return

pipe.

This filter will protect the boiler from sediments

coming from the heating system.

mod. Ø

ARES Tec 440 ÷ 900 kW DN 100

17

Hydraulic separator 440 ÷ 900 kW

F = DN 100 - (G 4")

R = DN 100 - (G 4")

21

Page 22

Instructions for the installer

3.11 DETERMINING THE PRIMARY

CIRCUIT PUMP OR BOILER PUMP

Immergas provides a series of primary rings complete with an accurately

sized pump, if alternative solutions are being used, the boiler pump

must have a head that is capable of ensuring the ow rates represented

in the "Water side head losses" graph.

e pumps must be determined by the installer or

designer based on the data for the boiler and system.

e resistance curve on the water side of the boiler is

represented in the table provided below.

e pump is not an integral part of the boiler.

It is advisable to choose a pump with a ow rate and

head of approximately 2/3 of its typical curve.

e table below roughly indicates the ow rates of the pump based

on the Δt of the primary circuit if the installation is equipped with a

hydraulic separator.

Power in kW 440 550 660 770 900

Maximum ow rate in l/h (Δt = 15 K) 24326 30404 36487 42570 48647

Nominal requested ow rate in l/h (Δt = 20 K) 18243 22804 27365 31926 36487

6

5,8

5,6

5,4

5,2

4,8

4,6

4,4

O

2

4,2

3,8

O)

2

3,6

3,4

ico (m/H )

3,2

2,8

2,6

2,4

2,2

Head loss (m/H

1,8

1,6

Pe rdite d i c ar

1,4

1,2

0,8

0,6

0,4

0,2

5

4

3

2

1

0

0

4000 6000 8000 10000 12000 14000 16000 20000 22000 24000

2000

Flow rate (l/h)

Portata (l/h)

28000 30000 32000 34000 36000 38000 40000 42000 44000 46000 48000 50000 52000 5400018000

440

550

660

770

900

EXAMPLE:

For a T 20K, of an ARES 900 Tec the maximum

required ow rate is 36,289 l/h.

From the head loss graph it is possible to deduce that

the pump must ensure a head of at least 1.8 m/H2O.

3.12 BALL VALVES

It is advisable to install cut-o ball valves on the ow and return pipes

of the system.

ATTENTION!

NEVER CUT OFF SAFETY DEVICES FROM THE

GENERATOR, such as the safety valve and expansion

vessel.

In this way the boiler, during scheduled/unscheduled

maintenance, can be disconnected or emptied without

emptying the entire system.

NOTE: It is always advisable to set up a hydraulic compensator

between the boiler circuit and the system circuit. It becomes

ESSENTIAL if the system requires greater flow rates than the

maximum allowed by the boiler, i.e. ∆t below 15K.

Secondary circuit

22

Page 23

3.13 COMPLETE OPTIONAL KITS

Instructions for the installer

Safety kits including pump and plate exchanger.

Safety kits including pump and hydraulic separator.

External covering kit for plate exchanger kit.

External covering kit for hydraulic separator.

23

Page 24

Instructions for the installer

3.14 CONDENSATE DRAIN

e condensate drain into the sewer must be:

- built to avoid gaseous combustion products from leaking out into the

environment or the sewer (trap).

- sized and built to allow liquid discharge to runo correctly, preventing

any leaks (gradient of 3%).

- installed to avoid the liquid contained in it from freezing, under the

envisioned operating conditions.

- can be easily inspected from the relative trap

- mixed with household wastewater, for example, (washing machine

and dish washer drains etc.) with a mainly alkaline pH so as to form

a buer solution to send it into the sewers.

e condensate must not be le to stagnate in the combustion product

drainage system (for this very reason the evacuation pipe must be set

up at an inclination of at least 30 mm/m, running towards the drain)

except for any liquid head, in the drain trap of the combustion product

evacuation system (which must be lled aer installation and at a

minimum height with all of the fans operating at maximum speed of

at least 25 mm) - see gure.

It is forbidden to drain the condensate towards rain pipes, given the

risk of ice and degradation of materials normally used to build the rain

pipes themselves.

e drain tting must be visible.

Given the degree of acidity of the condensate (pH between 3 and 5)

suitable plastic materials must be used to build the drain pipes.

e condensate drain pipe outlet is set up towards the connection

side of the ue box manifold, removing the pre-sectioned part on the

cover panel.

e recommended material for use must be PE (polyethylene) or PPI

(polypropylene).

Before igniting the generator, ll the trap through

the relative cap.

INITIAL TRAP FILLER CAP

150

FLOOR OF THE

PAVIMENTO

H.C.U.

DELLA C.T.

PLATFORM (H min 100 mm)

* Minimum safety trap enforced by regulation

** Minimum head with boiler operating at maximum power.

If you do not want to or are able to create a platform, it is possible to

install the boiler on the oor and set up the trap at a depth of 100 mm.

La generatrice superiore del tubo di scarico

e top generator of the drain pipe must not

non dovrˆ trovarsi ad un livello superiore

be higher than the bottom of the

al fondo della bacinella.

pan

TO THE

150

CONDENSATION

DRAIN

24

Page 25

Instructions for the installer

3.15 CONNECTING THE FLUE

Exhaust is discharged at very low temperatures (Max 84°C approx) in

condensation boilers. It is therefore necessary for the ue to be perfectly

impermeable to combustion product condensate and built with suitable

corrosion-resistant materials.

e various slip on joints must be well-sealed and equipped with suitable

gaskets to stop condensation from leaking out and air from getting in.

In terms of ue section and height, it is necessary to refer to national

and local regulations in force.

Refer to regulations in force for sizing.

In order to avoid the formation of ice during operation, the temperature

of the inside wall at every point in the combustion product evacuation

system, for its entire length, must not drop below 0°C.

For condensation operating conditions of the appliance at project

outdoor temperatures, it will be necessary to build a confluent

condensate drainage system, based on the installation conditions, either

to the boiler collection tank or separate from it.

The flue exhaust pipe must comply with local and national

regulations.

e evacuation pipe must be built using materials that are resistant

to the combustion products, typically class W1 certied stainless

steel or plastic materials.

Such as PVDF (polyvinyldimethyluoride) or PPS (simple translucent

polypropylene) or aluminium or other materials with the same features,

in observance of regulation in force.

e supplier is excluded from any contractual and

extra-contractual liability for damage caused by

errors in installation and use and nevertheless due

to failure to observe the instructions provided by

the manufacturer.

Model Modules Ø Attachment

440 4 250

550 5 250

660 6 300

770 7 300

900 8 300

3.16 FLUE EXHAUST MANIFOLD

CONNECTION

To secure the ue exhaust manifold use the 10 nuts +

CH 10 washers contained in the bag.

e ue point must be positioned on the rst straight

section, within 1 meter of the boiler.

To set up the ue inspection point, cut a Ø 21 mm hole

in the ue exhaust pipe, and install the inspection point

following the sequence provided.

Ø21 mm

25

Page 26

Instructions for the installer

Dimensionamento camini

Flue sizing

secondo DIN 4705

according to DIN 4705

Po rtata fum i

Flue ow rate

2520

2160

1800

1440

1260

1080

900

720

606

540

0,700

0,600

0,500

0,400

0,350

0,300

0,250

0,200

0,150

Tenore di CO

CO2 content

6%

778

667

555

445

389

333

277

222

167

1037

889

741

668

593

519

444

370

296

222

8%

1400

1200

1000

900

800

700

600

500

400

300

kg/skg/h 10%

2

5

ERRATA CORRIGE

Temperatura fumi

Flue temperature 40°C

Pressione disponibile

Available pressure 40 Pa

10 15 20 25 30

d400

a

d315

a

d250

a

40°C

40 Pa

1400

1200

1000

900

800

700

600

500

400

300

360

324

288

252

216

180

144

126

108

14,4

12,0

10,8

0,100

0,090

0,080

0,070

0,060

0,050

0,040

0,035

0,030

90

72

0,020

54

0,015

111

100

148

180

133

160

119

89

140

104

78

120

89

67

100

74

56

50

44

39

34

28

22

17

90

66

80

59

70

52

60

44

50

37

40

30

30

22

d200

d160

d125

d110

a

a

a

a

200

180

160

140

120

100

90

80

2

70

content at 10%

60

50

40

30

2

co n teno re di CO al 10 %

200

W)

36

0,010

32

0,009

29

0,008

25

0,007

22

0,006

0,005

0,004

0,003

0,002

9,0

0,001

11

9

8

7

5,6

5,0

4,4

3,9

3,4

Portata termica nomina le (kW)

Nominal heat input (kW)

20

18

16

12

14

10

12

9

10

8

7,4

6,6

5,9

4,4

9

8

7

6

5 1 0 1 5 2 0 2 5 3 0

d75

a

20

18

16

14

12

10

9

8

7

Portata termica nomina le (k

6

Nominal thermal ow rate (kW) with CO

Table of max ue ow rate

ARES Tec Max ue ow rate (max) kg / h

440 706,0

550 882,5

660 1059,1

770 1235,6

900 1412,1

Example:

ARES 660 Tec

Maximum ue ow rate = 1040 Kg/h

Height of ue = 25 m

Diameter = 315 mm

NOTE:

e diagram provides rough values: in any case, the

ue must be designed by a qualied professional in

compliance with legislation and technical standard

in force.

26

Page 27

Instructions for the installer

3.17 ELECTRICAL CONNECTIONS

Have professionally qualied personnel make sure the electrical system

is suitable for the maximum power absorbed by the appliance, as stated

GENERAL RECOMMENDATIONS

Electrical safety of the appliance is only ensured when it is correctly

connected to an ecient earthing system as specied by current safety

standards: gas, water and heating system pipes are not suitable in any

way whatsoever as earthing connections.

It is necessary to check this fundamental safety requirement; In case

of doubt, have an accurate inspection of the electrical system carried

out by professionally qualied personnel, as the manufacturer is not

responsible for any damage caused by the lack of a earthing connection

in the system.

on the plate, making sure in particular that the section of the system's

cables is suitable for the power absorbed by the appliance.

For the main power supply to the appliance, never use adapters, multiple

sockets and/or extension leads.

e use of components involving use of electrical power requires some

fundamental rules to be observed such as:

- do not touch the appliance with wet and/or moist parts of the body

and/or barefoot;

- do not pull the electric cables;

- the appliance may not be used by children or unskilled individuals.

TGC Terminal board (rear side) GCI Terminal board (rear side)

3

12345678910

12

VII

0-10 V

eBUS

FA

FB R

n

4M21 3

A8 A9 A10A11

IV

1 234 5

34

23

2

12

1

1

T3 T4

VI

12

12

F9 F8 F6 F5 F3 F2 F1

VF

AF KF /SPF

T1 T2

M

I

VF

A7

III

VIII

V

F14

F17

F13

F15

F1 2F11

0-10 V

LH

IMP

PT100 0

SP F

67891012345

3

1

FBR

NL1L1’

A1 A2 A3 A4 A5 A6

II

12 1NL1L1

IX

BUS

3

12

4567

Y2

Jp1

GCI

+ 24 V

eB US -

eB US +

Y1

45 6

12 3

12

3

12

4

Y4

Y3

DL1 DL2

DL3

A1

0

1

9

2

8

3

7

4

6

5

SW1

A

P

TGC

ow

L

A

R

UT

E

N

NS

O

I

T

C

E

NN

O

C

DE

I

S

R

A

E

R

GCI

ly

pp

u

s

r

e

27

Page 28

Instructions for the installer

230V ELECTRICAL SUPPLY CONNECTION

e electrical connections are illustrated in section "PRACTICAL

CONNECTION DIAGRAM".

e installation of the boiler requires an electrical connection to a 230

V - 50 Hz network: is connection must be set up by state of the art,

as envisioned by IEC regulations in force.

ATTENTION!

Also bear in mind that, upstream of the supply,

it will be necessary to set up a service relay (NOT

SUPPLIED) that, when the electrical safety devices

are triggered, cuts o the electrical supply to the fuel

cut-o valve installed on the gas supply circuit, but

not to electrical supply the boiler, so as to ensure

pump operation and therefore boiler cooling.

Danger!

Electrical installation must only be carried out by an

authorised technician.

Before setting up the connections or any operation on

the electrical parts, always cut-o the electrical supply

and make sure it cannot be accidentally re-connected.

Remember that it is necessary to install a bipolar switch on the electrical

supply to the boiler with a max distance between the contacts of 3

mm, easy to access, so that maintenance operations can be carried out

quickly and safely. e electrical supply to the boiler, 230 V - 50 Hz

single phase, must be carried out on point A, included, with a H05VV-F

(PHASE - NEUTRAL - GROUND) three-pole cable with a section

between 0.75 mm and 1.5 mm.

ATTENTION:

Cables carrying a voltage of 230 V must travel

separately from cables carrying a voltage of 24 V.

FL = Flow switch Connection

28

Page 29

3.18 CONNECTION DIAGRAM

POWER SUPPLY, GAS ELECTROVALVE, INAIL, ON/OFF

PUMP, EXTERNAL PROBE, FLOW SWITCH.

If the safety devices are

triggered, the ON/OFF pump

continues operating to lower

the high temperature.

Boiler supp.

Press. max

Instructions for the installer

GENERAL

ELECTRICAL

CONTROL

PANEL

ermostat

Press. min

NOT

SUPPLIED

Terminal

board on the

boiler panel

External

Probe

TGC

POWER SUPPLY, GAS ELECTROVALVE, INAIL,

MODULATING PUMP, EXTERNAL PROBE, FLOW SWITCH.

If the safety devices

are triggered, the

Boiler supp.

MODULATING pump is

placed on the minimum

speed and continues

operating to lower the high

temperature.

Flow switch

Press. max

Flow switch

RELAY

GCI

GENERAL

ELECTRICAL

CONTROL

PANEL

ermostat

Press. min

NOT

SUPPLIED

Terminal

board on the

boiler panel

External

Probe

Interface

board

IF-EXT.

MIN 0-10V

TGC

RELAY

GCI

29

Page 30

Instructions for the installer

INAIL SAFETY CONNECTION

SUPPLIED WITH MODULATING PUMP.

ermostat

Min pressure switch

INAIL SECTION

Max pressure switch

electrovalve

Gas

Interface board

IF-EXT.MIN 0-10V

External

Probe

Boiler supp.

Terminal

board on the

boiler panel

Flow switch

RELAY

RELAY

GENERAL

ELECTRICAL

CONTROL

PANEL

S

U

P

N

P

O

L

I

T

E

D

ON/OFF THERMOSTAT CONNECTION.

ON/OFF

24

18 6

12

1

2 3

Zona 1

Zone 1 Zone 2

12345678910123

12

VII

I

0

4

3

2

12

1

12

V

F9 F8 F6 F5 F3 F2 F1

III

VIII

F14F13

F12F11

IX

F1 7F15

E8

24

18

6

12

1

2 3

Zona 2

12 1NL1L1

II

A1 A2 A3 A4 A5 A6

TGC

67 89101234 5

ON/OFF

0

1234 5

12

VI

IV

A7

A8 A9 A10A11

NOT

SUPPLIED

START/STOP contact

12345678910123

12

VII

I

F9 F8 F6 F5 F3 F2 F1

12

V

TGC

2

1

VIII

F14F13

F12F11

12

4

3

III

IX

F17F15

30

Page 31

MODULATING ROOM THERMOSTATS CONNECTION.

Instructions for the installer

Zona 1

Zone 1

1

2

1234567891012

12

VII

I

F9 F8 F6 F5 F3 F2 F1

12

1

VIII

V

F12F11

Zona 2

Zone 2

NOT

SUPPLIED

1

2

12 1NL1L1

23

2

1

III

F14F13

34

IX

F17F15

E8

II

TGC

67 89101234 5

A1 A2 A3 A4 A5 A6

12

VI

A7

12345

IV

A8 A9 A10 A1 1

MODULATING ZONE MANAGER CONNECTION.

24

18 6

12

1

2 3

Zona 1

Zone 1

123456789101234

12

VII

I

12

V

F9 F8 F6 F5 F3 F2 F1

F11

24

18 6

12

1

0

123

12

III

VIII

F1 4F13

F12

IX

F17F15

E8

2 3

Zona 2

Zone 2

12 1NL1L1

II

67891012345

A1 A2 A3 A4 A5 A6

TGC

12

VI

A7

0

1 2345

IV

A8 A9 A10A11

NOT

SUPPLIED

31

Page 32

TR. ACC.1

E. ACC. 1

VG1

BLU

MARRONE

BLU

MARRONE

BLU

MARRONE

ROSS O

+ 24 V

eBUS +

eBUS -

ROSSO

MARRONE

NERO

connessione

con GCI

MARRONE

AZZURRO

GIALLO/VERDE

1° MODUL O

Instructions for the installer

3.19 PRACTICAL CONNECTION DIAGRAM

KF

PINK

ROSA

GRIGIO

GREY

2

12345678910

1

VII

0-10 V

eBUS

FA

n

4

TGC THERMOREGULATION

CENTRALINA DI

CONTROL UNIT

TERMOREGOLAZIONE TGC

I

F6 F5 F3 F2 F1

VF

FBR

T3 T4

M

1 3

2

A7

A8 A9

A10A11

VI

IV

12

12345

NEUTRAL

COLLEGAMENT O

CONNECTIONS (N)

NEUTRI (N)

M2

5L

MARRONE

BROWN

J21

J3

1

J4

1

J3

1

A

B

N

VT

L1

BLU

BLUE

BROWN

MARRONE

N

L1

BLU

BLUE

BROWN

MARRONE

BLU

BLUE

NERO

BLACK

BLUE

BLU

BROWN

MARRONE

BROWN

MARRONE

RED

ROSSO

BLACK

NERO

BLACK

NERO

ORANGE

ARANCIONE

BROWN

MARRONE

BLUE

BLU

BLUE

BLU

BLUE

BLU

BROWN

MARRONE

BROWN

MARRONE

BLACK

NERO

BLACK

NERO

1

J6

(IG1)

(IG2)

2N

C

1b 1a

F8

BLUE

4L

1N

2

RED

1

F9

AF KF / SPF

T1 T2

BLUE

BLU

BLUE

BLU

BLUE

BLU

BLUE

BLU

BLUE

BLU

BLUE

BLU

BLUE

BLU

BLUE

BLU

BLUE

BLU

BLUE

BLU

BLUE

BLU

BLUE

BLU

BLUE

BLU

BLUE

BLU

BLU

ROSSO

1

VF

M

IG

2

12

VIII

V

F12F11

SPF

A1 A2 A3 A4 A5 A6

67891012345

12 1NL1L1

TLG

LTLG

F10A

F6.3A

F14F13

PT1000

BLACK

NERO

123

1

BROWN

MARRONE

234

1

III

IX

F17F15

0-10 V

LH

IMP

BUS

3

FBR

NL1L1’

II

BLUE

BLUE

BLU

BLU

STGC/GCI

I

1b

1

O

1a

II

BROWN

MARRONE

SR

SRR

SR1

PG

WHITE

BIANCO

NERO

BLACK

BIANCO

WHITE

ROSSO

RED

ROSSO

RED

NERO

BLACK

BIANCO

WHITE

(1)

ext. probe

ingresso

sonda est.

or emergency

o set point

set point

emergenza

input

(3)

(External cascade

(Gestore di cascata

CONTROLLO

MODULATING

POMPA

MODULANTE

CONTROL

( - )

67

MARRONE

BROWN

WHITE

BIANCO

remote

remoto

esterno)

manager)

PUMP

0-10 V

+ 24 V

1

ROSSO

RED

eBUS

eBUS

( - )

45

Y2

eBUS -

23

( + )

3

eBUS +

PLC /

BMS

Modbus - B

Modbus - B

Y1

45 6

BLACK

NERO

BROWN

MARRONE

Modbus - A

Modbu s - A

12

Jp1

WHITE

BIANCO

GCI

WHITE

BIANCO

PF

BOARD

INSERTION

RELEASE

SB LOCCO

INSERIMENTO

SCHEDA

IG

PR

ALARM SIGNAL

MANIFOLD CIRCUIT

PUMP CONTROL

COMANDOPOMPA

CIRCUITOCOLL ETTORE

ALLARME

SEG NALAZIONE

BLACK

RED

BROWN

NERO

MARRONE

ROSSO

123

3

12

4

Y4

Y3

A1

ALIM.

ALIM. (SUPP.)

Only on

Solo su

Scheda

1st Module

1° modulo

Board

DL1 DL2 DL3

0

1

9

8

7

6

5

GIA/VER

YEL/GRN

BLU (N)

BLUE (N)

MARRONE (L1)

BROWN (L1)

230V

NERO (-)

BLACK (-)

BLU (TACHO)

BLUE (TACHO)

MARRONE (PWM)

BROWN (PWM)

ORANGE +

ARANCIO +

RIL./R EG.

RIL./REG. (DET./REG.) 230V

2

3

4

SW1

SMG

PINK

GREY

3

2

4

1

5

0

6

9

7

8

1st Module

1° Modulo

1 (nc)

c3)

(

MARRONE

BROWN

WHITE

BIANCO

LIGHT BLUE

AZZURRO

AZZURRO

AZZURRO

AZZURRO

BLUE

BROWN

YEL/GRN

YEL/GRN

LIGHT BLUE

LIGHT BLUE

LIGHT BLUE

TLTL1

BIANCO

WHITE

E.RIL. 1

POWER SUPPLY

ALIMENTAZIONE

230 V - 50Hz

230 V - 50Hz

Key:

E.ACC 1...8 - Ignition electrode

E.RIL 1...8 - Detection electrode

FL - Blade ow switch (optional)

IG - Main switch

KF - TGC global ow probe

LTGL - Limit thermostat lamp

YEL/GRN

PF - Flue pressure switch

PG - Gas pressure switch

PV1...8 - Fan pressure switch

SL - Condensate level sensor

SMG - GCI global ow probe

SR - Flow sensor

SR 1...8 - Local ow sensor

32

SRR - Heating return sensor

TL - Safety thermostat

TL 1...8 - Local safety thermostat

TLG - General limit thermostat

VG 1...8 - Gas valve

TRA.ACC 1...8 - Ignition transformer

VM 1...8 - Modulating fan

Page 33

Instructions for the installer

BROWN

RED

ROSSO

MARRONE

+ 24 V

eBUS +

connessione

Connection

con GCI

with GCI

BLU

BLUE

MARRONE

BROWN

BLUE

BLU

BROWN

MARRONE

1st MODULE LAST MODULEINTERMEDIATE MODULES

1° MODUL O

BROWN

MARRONE

YELLOW/GREEN

GIALLO/VERDE

BLUE

AZZURRO

BLACK

NERO

VG1

eBUS -

TR. ACC.1

VM (A)

ST 2

123

N

L1

ALLO /VERD E

MARRON E

GI

YELLOW/GREEN

BROWN

SR2...SR8

NERO

BLACK

SL

12345

BROWN

MARRONE

BLUE

BLU

MODULI INTERMEDI

VM (A)

12345

ST 2

123

N

L1

U

ALLO /VER DE

BLUE

YELLOW/GREEN

BROWN

BL

GI

MARRON E

FILTRO

FILTER FILTER

BLACK

BLUE

NERO

BLU

NERO

BLU

BLU

NERO

BLACK

BLUE

ULTIMO MODULO

VM (A)

12345

ST 2

123

N

L1

BLUE

YELLOW/GREEN

BROWN

BLU

GIALLO /VER DE

MARRON E

FILTRO

NERO

BLACKBLACK

BLU

BLUEBLUE

( )

3rd - 8th MODULE

3° - 8° MODULO

GIA/VER

YEL/GRN

BLU(N)

BLUE (N)

MARRONE (L1)

BROWN (L1)

ALIM.

230V

NERO (-)

BLACK (-)

BLU (TACHO)

BLUE (TACHO)

MARRONE (PWM)

BROWN (PWM)

ALIM. (SUPP.)

ORANGE +

ARANCIO +

RIL./R EG.

PINK

PINK

GREY

GREY

ROSA

GRIGIO

ROSA

GRIGIO

3

2

4

1

5

0

6

9

7

8

BLU

BLUE

MARRONE

BROWN

BLU

BLUE

MARRONE

BROWN

VG2...V G8

E. ACC. 2...E.A CC.8

CIONE

ORANGE

ARAN

RIL./REG. (DET./REG.) 230V

Optional

Optional

2nd - 8th Module

BIANCO

WHITE

WHITE

BIANCO

BROWN

MARRONE

NERO

BLACK

BIANCO

WHITE

Optional

FL

Optional

Solo sul

Only on the

2° modulo

2nd Module

BROWN

MARRONE

WHITE

BIANCO

ANCIONE

ORANGE

AR

2° - 8° Modulo

YEL/GRN

BLUE

BROWN

MARRONE

BLU

GIA/VER

RED

ROSS O

E. ACC. 1

Board / module selector

selettore schede/moduli

Posizionamento

positioning

Only on the

Solo sul

2° modulo

2nd Module

Module 1

Modulo 1

(Pos 0)

(Pos 0)

3

2

4

1

5

0

6

9

7

8

Module 2

Modulo 2

(Pos 1)

(Pos 1)