Page 1

Manual

TRIME-PICO 64/32

Page 2

Manual TRIME_PICO64-32 Version 2_0 2017-05-30

Page 2

Thank you for purchasing a IMKO instrument.

Should you have any queries please

don’t hesitate to contact your local

distributor or address directly to IMKO:

IMKO Micromodultechnik GmbH

Am Reutgraben 2

D-76275 Ettlingen

Germany

Phone: +49-7243-5921-0

Fax: +49-7243-90856

E-mail: info@imko.de

Internet: http://www.imko.de

Page 3

2017-05-30 Manual TRIME_PICO64-32 Version 2_0

Page 3

Manual for TRIME®-PICO 64/32

List of Contents

1 Functional Description .................................................................................................... 5

1.1 Operation modes ........................................................................................................ 5

1.1.1 Operation mode A (Bus communication) ................................................................. 5

1.1.2 Operation mode B (Single measurement) ................................................................ 6

1.1.3 Operation mode C (Cyclic measurement) ................................................................. 6

1.1.4 PC connection....................................................................................................... 6

1.2 External power supply.................................................................................................. 6

2 Technical Data ................................................................................................................ 7

2.1 TRIME-PICO64 ............................................................................................................. 7

2.2 TRIME-PICO32 ............................................................................................................. 7

2.3 Installation hints .......................................................................................................... 8

3 TRIME-PICO64/32 Versions:............................................................................................. 9

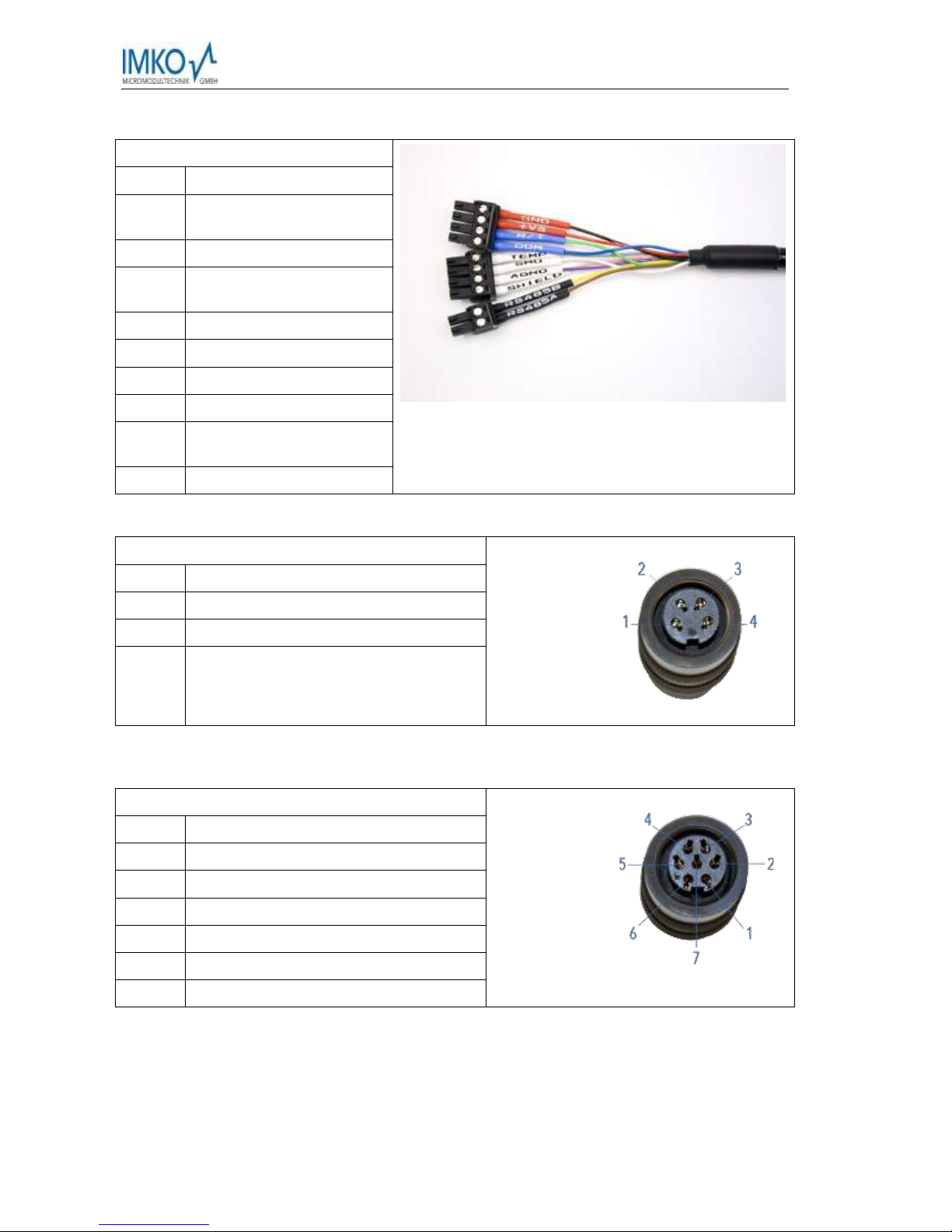

3.1 PICO DataLogger cable 5m with end splices (Item no.: 300082) ...................................... 10

3.2 PICO IMP-Bus cable 5m, 4-pin female connector (Item no.: 300080) ............................... 10

3.3 PICO BT+TRIME-HD cable 1,5m, 7-pin female connector (Item no.:300081) ..................... 10

3.4 Accessories ................................................................................................ ............... 11

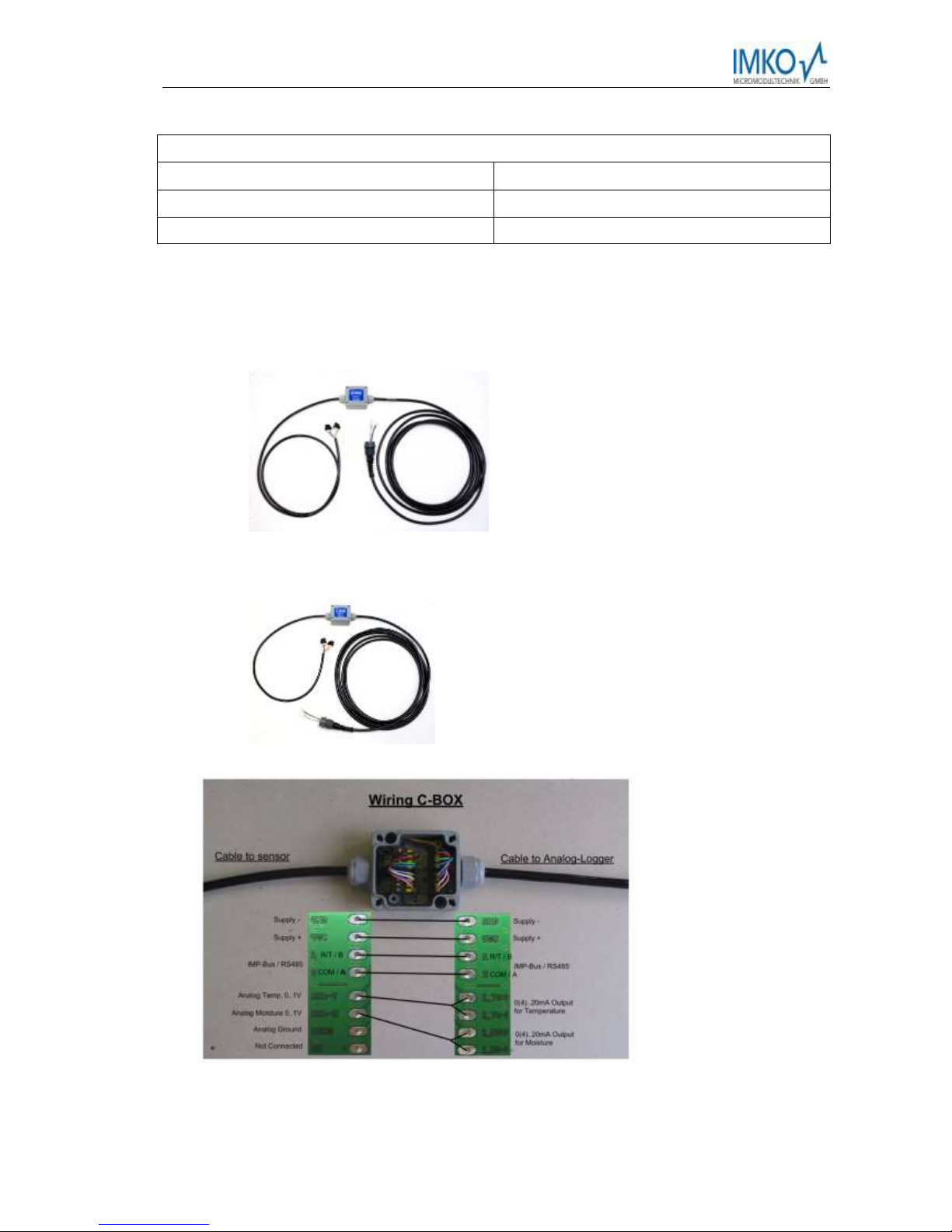

3.4.1 E-Box (Extension Box), (Item no.: 300092) .............................................................. 11

3.4.2 C-Box (Current Box), (Item no.: 300091) ................................................................ 11

3.4.3 SM-USB Serial Interface Module .......................................................................... 12

3.4.4 PICO-BT Bluetooth Module .................................................................................. 12

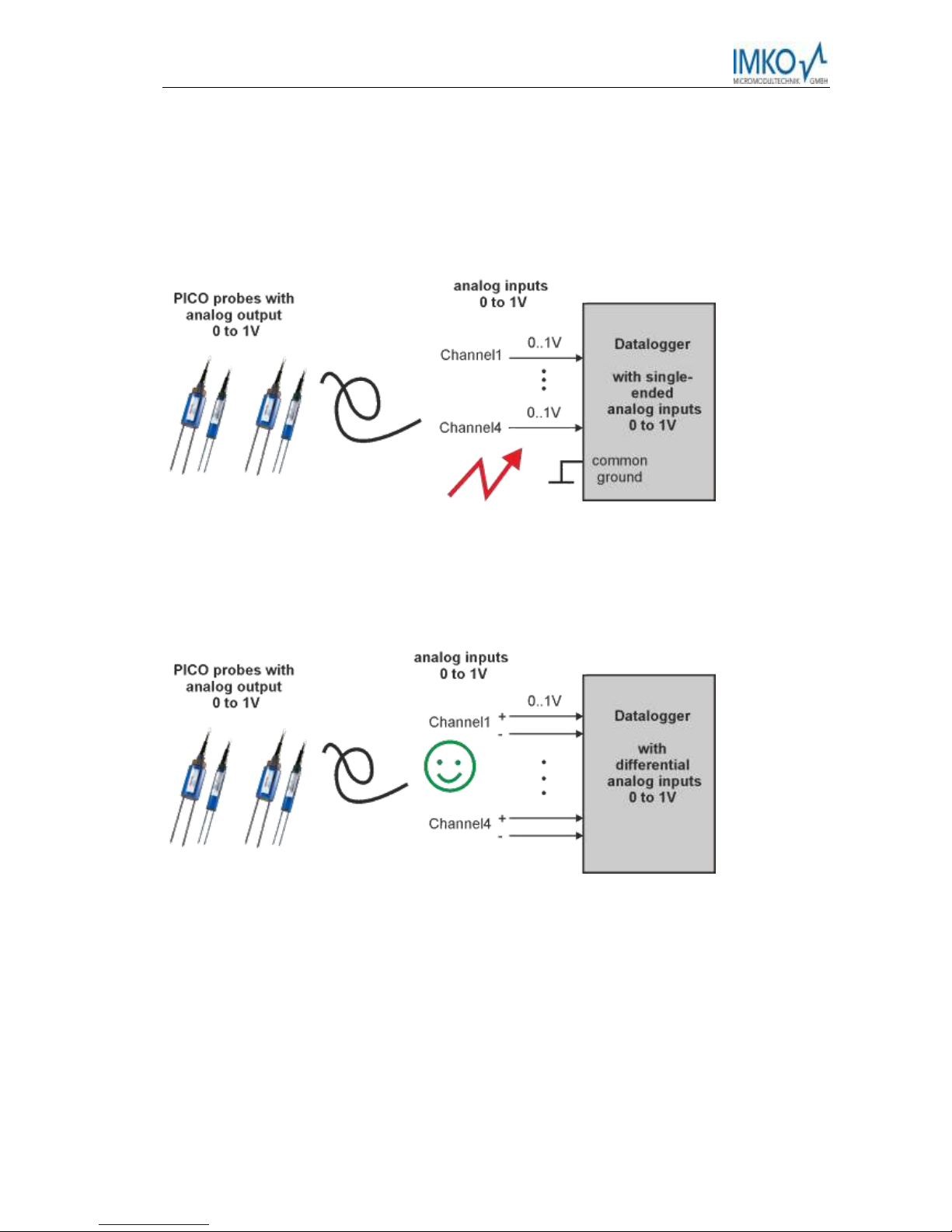

3.5 Datalogging with Differential Analog Inputs .................................................................. 13

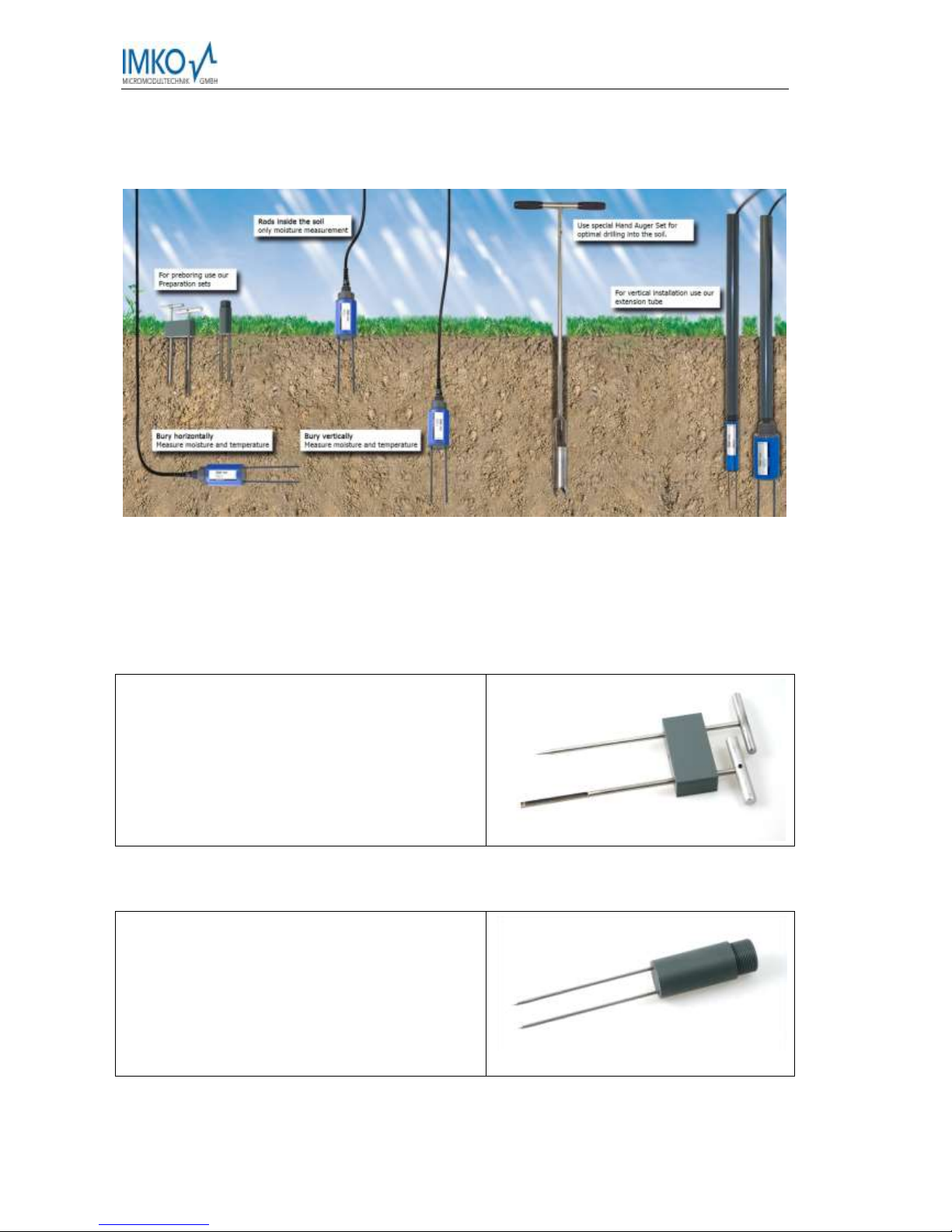

4 Installation details: ....................................................................................................... 14

4.1 Temperature measurement: ....................................................................................... 14

4.2 Installation equipment: .............................................................................................. 14

4.2.1 Preparation set for TRIME-PICO64, (Item no.: 302035) ............................................ 14

4.2.2 Preparation set for TRIME-PICO32, (Item no.: 302023) ............................................ 14

4.2.3 Extension tubes for TRIME-PICO64 & TRIME-PICO32 ............................................... 15

4.2.4 Hand Auger Set for TRIME-PICO64 & TRIME-PICO32 ............................................... 15

5 Remote Power Supply to TRIME-PICO ............................................................................ 16

6 Basic Calibration with the Calibration Set ....................................................................... 17

6.1 What is a basic calibration? ........................................................................................ 17

6.2 What are the benefits of the calibration set for the user? .............................................. 17

6.2.1 Calibration set for TRIME probes........................................................................... 17

6.3 How to perform a basic calibration? ............................................................................ 17

Page 4

Manual TRIME_PICO64-32 Version 2_0 2017-05-30

Page 4

6.3.1 Preparation of the glass beads .............................................................................. 17

6.3.2 Basic calibration procedure .................................................................................. 18

7 Material-Specific Calibration .......................................................................................... 19

7.1 Soil Density Correction with PICO Sensors .................................................................... 19

8 Mounting Spare Rods with O-ring Seals .......................................................................... 21

9 Information on Lightning Protection of the ENVIS Environmental Measurement System .... 22

9.1 Introduction .............................................................................................................. 22

9.2 Excess voltage protection on 110/220V mains supply .................................................... 22

9.3 Protection of modem and telephone lines .................................................................... 22

9.4 Excess voltage protection for network modules by "SM-Blitz"......................................... 22

9.5 Lightning protection on meteorological towers ............................................................. 22

9.6 Installation instructions for SM BLITZ lightning protection modules ................................. 22

9.7 Conclusion ................................................................................................................ 22

10 Datalogging configuration examples ............................................................................... 23

10.1 PICO probes connected to a PC under Windows ............................................................ 23

10.2 PICO probes connected to a SDI12 Datalogger .............................................................. 24

11 Quick guide for the Software PICO-CONFIG ..................................................................... 25

11.1 Connection of the RS485 or the SDI-12 and the IMP-Bus to the SM-USB Module .............. 25

11.1.1 RS485 or IMP-Bus Configuration and Probe Scan .................................................... 26

11.2 Scan of connected PICO probes on the RS485 or IMP-Bus .............................................. 27

11.3 Configuration of Measure Mode ................................................................................. 27

11.4 Analogue outputs of the PICO probe ............................................................................ 28

11.5 Simulate Analog Output ............................................................................................. 28

11.6 Selection of the individual Calibration Curves ............................................................... 29

11.7 Test Run in Measurement Mode A .............................................................................. 30

11.8 TRIME WIN MONITOR Datalogger Software .................................................................. 31

11.9 Calibration Curves ..................................................................................................... 32

11.10 Creating a linear Calibration Curve for a specific Material ............................................... 35

11.10.1 Calculation for a linear 2-point calibration curve ..................................................... 35

11.10.2 Calculation for a non-linear calibration curve ......................................................... 36

12 Measure Electrical Conductivity with TRIME Probes......................................................... 37

12.1 The analysis of Soils for Electrical Conductivity EC

TRIME

................................................... 38

12.2 EC

TRIME

Measurement Range for TRIME Probes ............................................................. 39

12.3 Measurement of Pore-Water-Conductivity or Salt-Content of Soils ................................. 39

12.4 Creation of a Moisture/ EC

TRIME

Diagram for a particular Soil .......................................... 42

13 Software Error codes ..................................................................................................... 43

13.1 Software Errors which will be coded with 4 digits. ........................................................ 43

13.2 PICO Errors (Firmware errors). The errors come from the firmware, from 1 to 255. .......... 44

14 Savety Notes ................................................................................................................ 45

Page 5

2017-05-30 Manual TRIME_PICO64-32 Version 2_0

Page 5

1 Functional Description

The intelligent and compact TRIME-PICO64/32 sensors are measurement devices for continuous and nondestructive determination of volumetric or gravimetric material moisture, material temperature and material

conductivity. They are designed for stationary subterranean field use. A variety of installation options (greater

depth, vertical or horizontal orientation) offer a wide range of applications.

TRIME-PICO64/32 systems require an external 7-24V/DC power supply. They are designed for connection to a

data logger or a PC for monitoring and data logging purposes.

Your sensor is supplied ready for use and works in a wide range of standard soils. For further information

please check the details under Section 6!

1.1 Operation modes

TRIME-PICO64/32 systems are supplied with an IMP-Bus interface and analogue output of 0..1V for soil moisture and temperature.

TRIME-PICO64/32 sensors can be easily connected (in operation modes A) to SDI12 datalogger and conventional analogue data loggers (in operation modes B and C).

A detailed description of how to select a specific operation mode for your application can be found below.

PLEASE NOTE: Analogue dataloggers require differential inputs!

1.1.1 Operation mode A (Bus communication)

TRIME-PICO64/32 systems can be connected directly to the IMP-Bus (4-wire bus system), either via SDI12 datalogger or via the SM-23U level converter module for use in conjunction with the EnvisLog data-logging software.

If multiple sensors are to be wired as a network, IMKO offers 3-port, 6-port and 12-port distribution modules.

Please note that the IMP-Bus cable length and cable diameter must be properly matched as otherwise the

energy consumption of the TRIME sensors (100mA @ 12V/DC for 2..3s) may cause a drop in voltage. More

information is available in Section 5.

Benefits:

Low power consumption in field installations (with SDI12 datalogger)

Straightforward installation and simple wiring by virtue of pre-configured standard compo-

nents (e.g. lightning protection, distribution modules…)

Attachment of any other analogue sensors to IMP-Bus (via SM-Modules)

Systems are supplied ready for use

Cable length >1000m (with only 4 wires for all sensors)

For use with:

SDI12 Datalogger

EnvisLog (PC-Software for Microsoft Windows) only with converter module SM-USB

IMKO calibration and test software PICO-CONFIG (see page 27, Software download:

www.imko.de) only with converter module SM-USB

Page 6

Manual TRIME_PICO64-32 Version 2_0 2017-05-30

Page 6

1.1.2 Operation mode B (Single measurement)

TRIME-PICO64/32 will perform a single measurement when the power is switched on. Once the measurement

has been taken (2..3s) the readings are supplied as analogue output signals until the power is switched off. The

probe switches to the energy-saving mode (>1mA) and takes no more measurements until the power has been

switched off.

Benefits:

Low power consumption in field installations

Easy control of the measurement rate from an external source

No implementation of commands necessary

For use with:

Switched power supply

Analogue data loggers with relay

PC A/D converter boards with relay

1.1.3 Operation mode C (Cyclic measurement)

TRIME-PICO64/32 takes measurements at a freely configurable measurement rate (from 8s..24h). Once the

measurements have been taken (2..3s) the measured values are supplied as analogue output signals. Until the

next measurement is finished, the values of the previous measurement are available as analogue signal. In

standby until the next measurement is executed the probe consumes 8..10mA @ 12V/DC, if the communication is set to standby (can be changed in PICO-CONFIG software) 2..3mA @ 12V/DC.

Benefits:

Probe can be supplied with mains power

Measurement rate can be specified as required (even independent from logging rate of analogue

logger)

No implementation of commands necessary

Non-intelligent logger can be used (without power management)

For use with:

Mains power

Analogue data loggers with mains power

PC A/D converter boards

The operation mode is preset to customer specifications prior to despatch. Reconfiguration is possible using

the complementary software PICO-CONFIG (download under http://www.imko.de).

1.1.4 PC connection

The TRIME-PICO64/32 can be connected to a PC via:

SM-23U IMP-Bus RS232 converter module

BT-Module RS485 Bluetooth converter module

SM-USB IMP-Bus/RS485 USB converter module

1.2 External power supply

In the IMP-Bus the power to sensors can be supplied by battery, a complete solar system or mains power. For

serial connection of a large number of sensors or long IMP232-bus cables it is advisable to use a power amplifier module (SM-23LV) or decentralised power supply.

Page 7

2017-05-30 Manual TRIME_PICO64-32 Version 2_0

Page 7

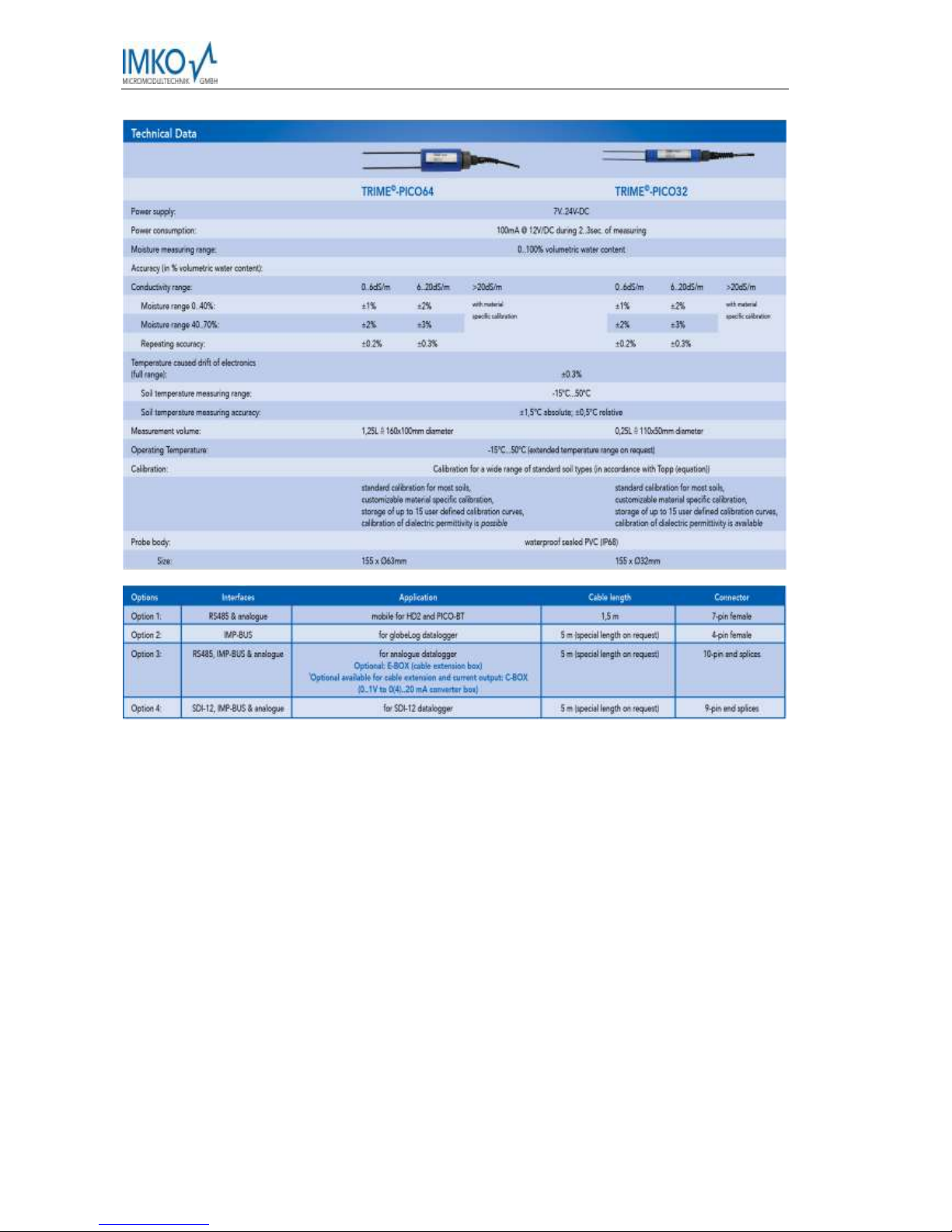

2 Technical Data

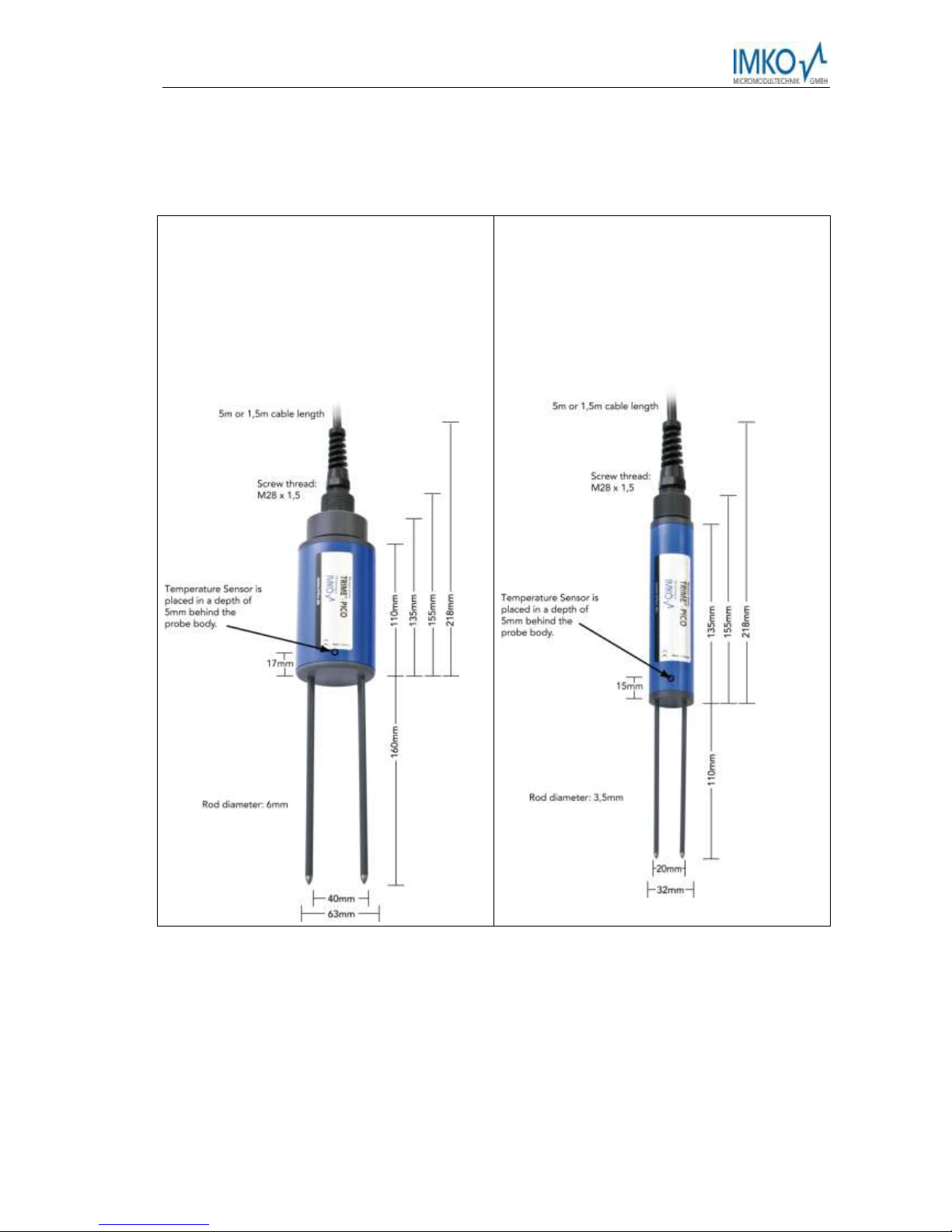

2.1 TRIME-PICO64

For in situ monitoring of volumetric moisture in soils.

The large measuring volume is particularly suitable

for applications in heterogeneous and skeletal media.

Burying capability for both horizontal and vertical

orientation.

2.2 TRIME-PICO32

For in situ monitoring of volumetric moisture in soils.

The small measuring volume permits high spatial

resolution. Burying capability for both horizontal and

vertical orientation.

Page 8

Manual TRIME_PICO64-32 Version 2_0 2017-05-30

Page 8

2.3 Installation hints

Please assure careful installation of the probes with close contact between rod and soil. It is important to avoid

air pockets around the rods as the highest measuring sensitivity is directly around them.

Air pockets around the probe rods can reduce the measured moisture reading. Where saturated soils are involved, water-filled air pockets will result in an exaggerated reading.

IMKO supplies pre-drilling sets for an optimal preparation of the installation point avoiding compaction of soil

otherwise caused by the insertion of the rods.

Page 9

2017-05-30 Manual TRIME_PICO64-32 Version 2_0

Page 9

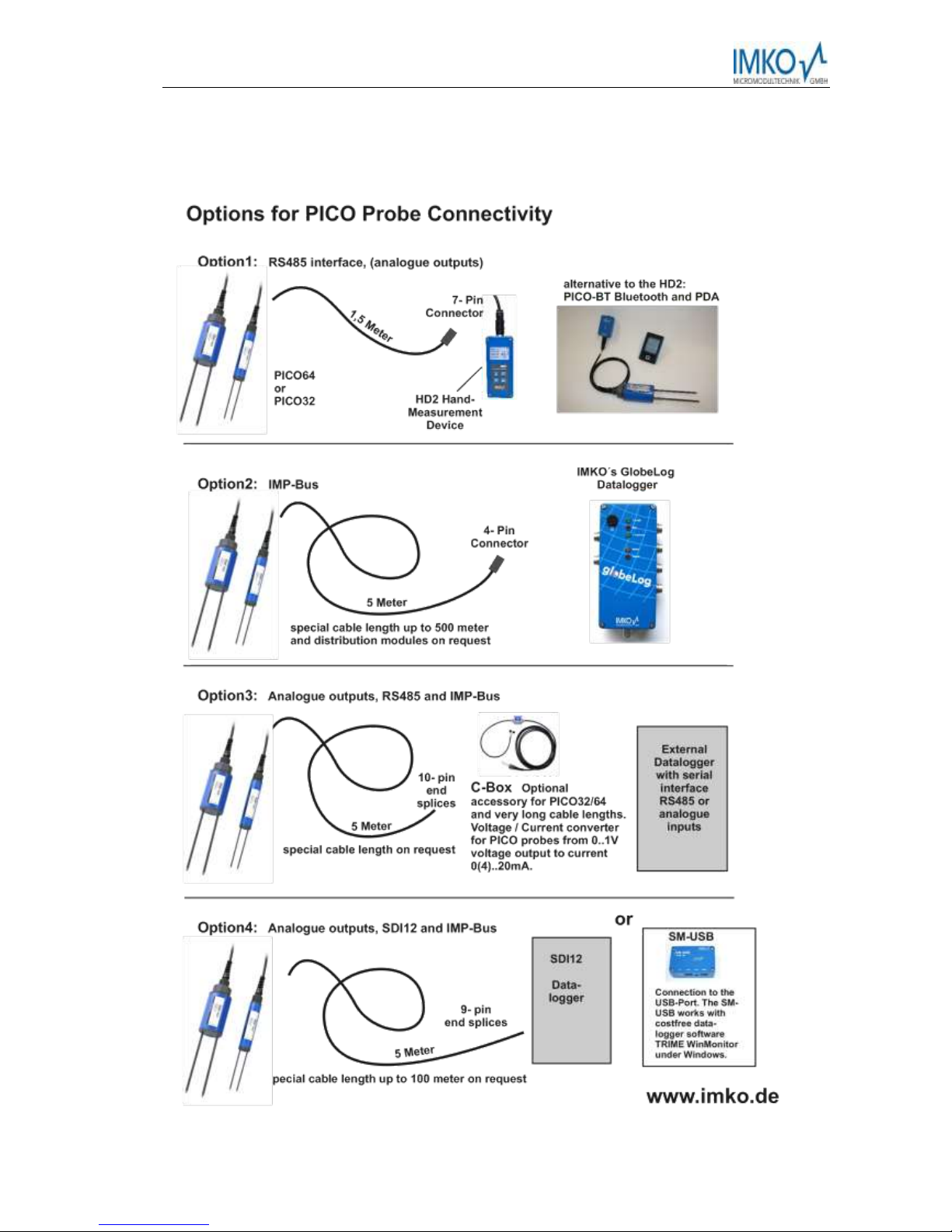

3 TRIME-PICO64/32 Versions:

Page 10

Manual TRIME_PICO64-32 Version 2_0 2017-05-30

Page 10

3.1 PICO DataLogger cable 5m with end splices (Item no.: 300082)

Wiring:

Pink:

Shield

Grey:

0..1V = -40..+70°C soil temperature

Violet:

AGND

White:

0..1V = 0..100% vol. water content

Blue:

COM (IMP-Bus)

Green:

R/T (IMP-Bus)

Black:

GND; (SDI-12 GND)

Red:

+Vs; (SDI-12 +Vs)

Yellow:

RS485B; (SDI-12 Data if

SDI-12 version)

Brown:

RS485A

3.2 PICO IMP-Bus cable 5m, 4-pin female connector (Item no.: 300080)

Pin layout:

Pin 1:

+Vs

Pin 2:

R/T (IMP-Bus)

Pin 3:

GND

Pin 4:

COM (IMP-Bus)

3.3 PICO BT+TRIME-HD cable 1,5m, 7-pin female connector (Item

no.:300081)

Pin layout:

Pin 1:

+Vs

Pin 2:

RS485-B

Pin 3:

GND

Pin 4:

RS485-A

Pin 5:

0..1V = 0..100% vol. soil water content

Pin 6:

AGND

Pin 7:

0..1V = -40..+70°C soil temperature

Page 11

2017-05-30 Manual TRIME_PICO64-32 Version 2_0

Page 11

List of abbreviations:

+Vs: + Voltage supply (7..24V/DC)

COM: Common (ground for IMP-Bus)

GND: Ground (for voltage supply)

AGND: Analogue ground

R/T: Receive/Transmit (on IMP-Bus)

3.4 Accessories

3.4.1 E-Box (Extension Box), (Item no.: 300092)

For extending the cable length of the TRIME-PICO

with DataLogger cable (see 3.1) up to 35m with

0..1V output signal.

3.4.2 C-Box (Current Box), (Item no.: 300091)

For extending the cable length of the TRIME-PICO with

DataLogger cable (see 3.1) and converting the 0..1V signal into 0(4)..20mA (cable length >100m possible).

Page 12

Manual TRIME_PICO64-32 Version 2_0 2017-05-30

Page 12

3.4.3 SM-USB Serial Interface Module

For connecting any of the TRIME-PICO (see 3.1 to 3.3, for 3.2 & 3.3 adapter required) via the

USB-Interface to a PC. The module offers 2 Sensor-Interfaces, IMP-Bus (IMKO specific) and

RS485 (industrial standard). One sensor can be powered out of the USB-Interface, if multiple

sensors are connected external power supply is required!

3.4.4 PICO-BT Bluetooth Module

For connecting the TRIME-PICO with PICO BT+TRIME-HD cable (see 3.3) to a PDA/PC via

Bluetooth interface. Module contains a internal rechargeable battery, which enables >1000

measurements.

Page 13

2017-05-30 Manual TRIME_PICO64-32 Version 2_0

Page 13

3.5 Datalogging with Differential Analog Inputs

Using a datalogger with a common ground will produce considerable problems, due to earth loops.

The higher the length of the cable the higher the problems with earth loops. Earth loops can produce

considerable fluctuations at the measurement signal 0 to 1V !

IMKO recommends to use a datalogger with differential inputs as shown in the following picture. With

differential inputs the problems with earth loops are eliminated.

Page 14

Manual TRIME_PICO64-32 Version 2_0 2017-05-30

Page 14

4 Installation details:

4.1 Temperature measurement:

Conclusion: the probes should be permanently buried in the soil for optimum

temperature measurement!

4.2 Installation equipment:

4.2.1 Preparation set for TRIME-PICO64, (Item no.: 302035)

For preboring the soil prior to probe insertion.

1 x spike

1 x core drill

1 x PVC block

Item no.: 302035

4.2.2 Preparation set for TRIME-PICO32, (Item no.: 302023)

For preboring the soil prior to probe insertion. Rod length:

110mm.

Item no.: 302023

Page 15

2017-05-30 Manual TRIME_PICO64-32 Version 2_0

Page 15

For compacted, coarse or stony soil use the preparation set to bore a pilot

hole!

Preboring using the preparation rods for PICO32 and PICO64 avoids

compaction of soil (which would impair measurement accuracy)

damaging the probe’s rods or rod tips. A defective PVC rod coating or a blank rod is sensitive to elec-

tromagnetic charge and may destroy the electronics of sensor.

4.2.3 Extension tubes for TRIME-PICO64 & TRIME-PICO32

Length 0.5m: Item no.: 302014

Length 1.0m: Item no.: 302015

4.2.4 Hand Auger Set for TRIME-PICO64 & TRIME-PICO32

Please contact us for further details.

Page 16

Manual TRIME_PICO64-32 Version 2_0 2017-05-30

Page 16

5 Remote Power Supply to TRIME-PICO

The operation of TRIME sensors may cause problems when power has to be supplied via long cables. There are

limitations to the maximum cable length depending on the cable diameter.

When power is supplied over long distance the maximum cable length depends on the cable cross section A,

the supply voltage Vs and the number n of the sensors measuring simultaneously. Device-specific data also be

applied to the formula:

Power consumption during measurements: I

norm

= 100mA @ 12V/DC

Power consumption at min. voltage: I

max

= 175mA @ 7V/DC

Supply voltage: V

s =

12V

Minimum sensor voltage at circuit end: V

min

= 7V

Wire cross section: A = 0,34mm²

Specific electrical resistance of copper:

= 0.0178Ω x mm² / m

Number of sensors: n = 1…

The maximum possible circuit length I

max

can then be calculated in the following manner:

max

min

max

2

)(InVVA

l

s

Please see the following the following example:

In the IMP232 environmental measurement system a bus cable with a wire cross section of A = 0.34 mm2 is

normally used. We further assume that the power supply voltage is Vs =12 V and only one sensor is designated

to measure. Thus n = 1.

m

A

m

mm

VVmm

l 270

175.010356.0

)712(34.0

2

2

max

In the above calculation, no tolerance is included; for security reasons the calculated cable length should be

reduced by 10% to obtain a realistic value. In order to increase the maximum possible cable length several

solutions are feasible.

1. Using cables with larger conductor diameters

By using 6-core conductor cables instead of 4-core, the cable length can be doubled as two extra

cores can be used for power supply. Cables with conductors of larger diameters will further increase the maximum cable length possible.

2. Increasing the power supply voltage

Power supply voltage can be increased up to 17V, thereby raising the maximum length from 270m

to 540m in the example calculation above.

3. Installation of buffer batteries in the distributor

Additional storage batteries close to the TRIME sensors, e.g. in the distributor, allow cable lengths

up to 1km and enable simultaneous measurement of several sensors. However, this method requires an additional charging circuit for the buffer storage battery.

4. Installation of a voltage regulator at the distributor

Voltage loss in the cable can be reduced with a 30V power supply and an installation of a voltage

regulator directly in front of the TRIME sensor, thus allowing circuit lengths of up to 1km.

Which solution is best suited mainly depends on the nature of the power supply of the measurement system:

Battery supply: solution 1 and possibly solution 3 should be considered, the latter being relatively ex-

pensive.

Mains supply: solutions 1 and 2 could be combined, or, more expensive, solutions 2 or 4 could be cho-

sen.

Page 17

2017-05-30 Manual TRIME_PICO64-32 Version 2_0

Page 17

6 Basic Calibration with the Calibration Set

6.1 What is a basic calibration?

Basic calibration serves to compensate the cable length and tolerances of the probe mechanics (thickness of the rod coating, rod length, etc.). After two measurements, one in dry and one in water- saturated glass beads, the calibration data is calculated and stored in the TRIME sensor.

Every TRIME-PICO64/32 sensor must be calibrated before it can supply proper measurement results.

Basic calibration is carried out by IMKO in the factory prior to shipment.

6.2 What are the benefits of the calibration set for the user?

With the calibration set you can easily carry out basic calibration of your TRIME sensor yourself.

If defective probe rods must be changed, you can perform the required basic calibration your-

self.

The calibration set cannot be used for establishing a material (soil) specific calibration. For this purpose a

measurement dataset must be created for the specific material. The complementary calibration program

TRIME-Tool is required to calculate the calibration data for this dataset and to download it to the TRIMEPICO-Probe.

6.2.1 Calibration set for TRIME probes

For basic calibration of TRIME probes.

- 2 x boxes (7 litres.)

- 28kg glass beads

Item no.: 305017

6.3 How to perform a basic calibration?

6.3.1 Preparation of the glass beads

The glass beads, supplied with the calibration set, have to be prepared first:

Fill up one bucket until the rods of the probe can be immersed completely. To obtain a consistent densi-

ty, knock the bucket on the ground several times.

Page 18

Manual TRIME_PICO64-32 Version 2_0 2017-05-30

Page 18

The density of the glass beads increases with frequent insertion of probes. Therefore the glass beads should be poured

out into another bucket and poured back to achieve the original density.

Now the second bucket has to be filled with water in order to be able to fill in the glass beads without

leaving air-bubbles. An additional precaution against air-bubbles is to stir slightly while filling in the glass

beads. The container must now be knocked on the ground several times to obtain a consistent density.

The surplus water must be poured out until the depth of the water film above the glass beads is less

than 2mm.

The water-saturated glass beads should be in a temperature range between 20°C and 25°.

Attention: Water dissolves Na2O and K2O from glass which causes a rising pH-value and higher electrical conductivity.

New glass beads have to be washed intensively with tap water!!!

1. Fill a bucket with water

2. Stir the beads under water to drive out all air bubbles

3. Pour out the water. This procedure should be done with new glass beads at least five times, each time

with fresh water. If the glass beads have been in use for a prolonged period, three times is sufficient.

Please note that the electrical conductivity of the water-saturated glass beads medium increases already after a few days storage. Therefore the glass beads must be washed again before the next calibra-

tion.

6.3.2 Basic calibration procedure

Basic calibration must be performed using the calibration program Pico-Config . Please read the information about basic calibration with Pico-Config in chapter 12 of this document.

Page 19

2017-05-30 Manual TRIME_PICO64-32 Version 2_0

Page 19

7 Material-Specific Calibration

Your TRIME measuring system operates with a universal calibration for mineral soils as a standard.

The following parameters limit the application range of the universal calibration:

Clay content: >50%

Organic content: >10%

Bulk density: <1.1kg/dm³ or >1.7kg/dm³

Exceeding these limits may cause the tolerances given on page 5 to be overstepped.

Material-specific calibration is advisable if your soil is listed above or if you require accuracy down to the last

digit. The PICO-CONFIG software is required for setting up a material-specific calibration (download under

www.imko.de).

A test series with reference values is necessary for performing material-specific calibration (e.g. Oven drying at

105°C until weight is constant). The test series –and consequently the calibration– should include minimum and

maximum moisture values. TRIME readings and reference values are compared in a table. The calibration coefficients must then be calculated and uploaded to the TRIME-device.

7.1 Soil Density Correction with PICO Sensors

One of the most important advantages of PICO sensors is, that it is possible to measure volumetric

moisture for all soil types with <50% clay and <10% organic with just one calibration. The only factor is

the offset caused by the differing soil density, which can be compensated by a formula which IMKO

offers at its homepage in an Excel-File “Soil Density Correction”.

Volcanic soils have normally lower densities, clayey soils can have higher densities.

It is possible to make an offset correction with Excel functions after datalogging of the stored moisture

values. But it is also possible to change the offset calibration parameter m0 inside the PICO probe

before installation and use of the PICO sensor. With help of the software tool PICO-CONFIG it is possible to load the “Universal Soil” calibration curve of the PICO sensor, to change it and store it back

to the sensor.

Necessary is to change the parameter m0 of the “Universal Soil” calibration curve inside the PICO

probe. If a soil has a lower density as 1,4 than the PICO senor measures a too low moisture value and

therefore the calibration parameter m0 has to be increased with an offset correction value.

E.g. if the soil density is 1,3 than the calibration parameter m0 has to be increased with +1,21.

If e.g. the calibration parameter m0 = -30 inside the PICO sensor than it has to be increased to

m0 = -30 + 1,21 = -28,79

If the soil has a density higher than 1,4 than the calibration parameter m0 of the “Universal Soil”

calibration curve has to be decreased with the appropriate offset correction value.

Page 20

Manual TRIME_PICO64-32 Version 2_0 2017-05-30

Page 20

The correction values for some soil density values are outlined below:

Soil

Density

Factor

Error in %

due to

deviating

Density

m0 Offset

Correction

Value

-0,3

1,10675

12,12

-17,05

-3,64

+3,64

-0,2

1,20675

12,12

-17,05

-2,42

+2,42

-0,1

1,30675

12,12

-17,05

-1,21

+1,21

0

1,40675

12,12

-17,05

0,00

DEFAULT

0,1

1,50675

12,12

-17,05

1,21

-1,21

0,2

1,60675

12,12

-17,05

2,42

-2,42

0,3

1,70675

12,12

-17,05

3,64

-3,64

0,5

1,90675

12,12

-17,05

6,06

-6,06

0,6

2,00675

12,12

-17,05

7,27

-7,27

0,7

2,10675

12,12

-17,05

8,48

-8,48

Load the Excel-file “Soil Density Correction” from IMKO´s homepage “Support” and “PICOCONFIG” and enter your soil density for getting the appropriate offset correction value.

Page 21

2017-05-30 Manual TRIME_PICO64-32 Version 2_0

Page 21

8 Mounting Spare Rods with O-ring Seals

NOTE!

Basic calibration must be performed after exchanging the rods.

Failure to do so will cause a deviation of +2% or more!

1) Prepare probe body, seals, rods

2) Insert the seals into the bore holes

3) Push the seals to the base of the bore holes where

the threads begin

4) Screw the rods into the probe body

Page 22

Manual TRIME_PICO64-32 Version 2_0 2017-05-30

Page 22

9 Information on Lightning Protection of the

ENVIS Environmental Measurement System

(IMP-Bus, Datalogger and integrated Sensors)

9.1 Introduction

Lightning strikes can cause considerable and costly damage to unprotected electronics. The equipment is often

totally destroyed. A good number of users are not or only partially insured. Customers who have lightning protection insurance must comply with defined clauses regarding lightning and excess voltage. Insurance companies only cover the damage when compliance with the defined clauses has been proven. IMKO strongly recommends adequate lightning / excess voltage protection equipment for ENVIS environmental measurement

systems.

9.2 Excess voltage protection on 110/220V mains supply

Lightning strikes in proximity to high-voltage transmission lines can cause excess voltage in the mains power

supply which may result in damage of electronic components. Environmental measurement systems with

110/220V mains supply are at risk from this excess voltage. It may affect the whole system through the power

supply unit and the SDI12 datalogger or SM-23U). Excess voltage can even enter the measuring system through

the data acquisition computer’s mains power supply. An excess voltage protection is highly recommended for

all 110/220V devices connected to the ENVIS system

9.3 Protection of modem and telephone lines

Telephone lines are at risk from excess voltage. If a modem is connected to the measurement system the telephone line should also be protected by a lightning protection module.

9.4 Excess voltage protection for network modules by "SM-Blitz"

Excess voltage caused by lightning strokes in close proximity to the environmental measurement test system

may enter the IMP-Bus transmission lines. Longer lines increase the risk of lightning strikes. Theoretically maximum protection is achieved by installation of a lightning protection module (SM-Blitz) in front of each SMModule. Lightning protection is not cheap but it is certainly worthwhile. A compromise should be found between costs and the maximum-affordable protection, i.e. interconnection of adjacent SM-Modules to lightning

protected groups.

9.5 Lightning protection on meteorological towers

SM-Modules installed on meteorological towers cannot be protected from lightning strikes. The field strength

resulting from the electromagnetic fields and the associated accumulated energy will cause damage to the

electronics. Two solutions to the problem:

Erect a higher lightning conductor close to the meteorological tower serving as a lightning conductor.

Install the measuring modules a number of metres away. Then all lines coming from the tower have to

be protected by lightning protection modules.

9.6 Installation instructions for SM BLITZ lightning protection modules

Basically, there are two potential sources of risk in the field of environmental measurement technology: transmission lines and sensors or network devices. Lightning protection modules should always be installed at the

beginning and at the end of a circuit in order to protect the electronics from excess voltage (Attention: SM-Blitz

modules have a protected and an unprotected side).

The SM-BLITZ lightning protection module has to be grounded using a ground conductor with a wire crosssection of at least 6 mm2 screwed to the long side of the module. A 2-metre long grounding rod may serve as a

ground conductor. Grounding is optimal when the grounding rod is in direct contact with ground water.

9.7 Conclusion

Only limited protection against excess voltage is possible where natural phenomenon such as lightning strikes

are concerned. Direct lightning strikes may cause damage nevertheless.

Page 23

2017-05-30 Manual TRIME_PICO64-32 Version 2_0

Page 23

10 Datalogging configuration examples

PICO probes offer the possibility to use three different options for serial communication:

The robust and secure (opto-isolated) IMP-Bus for large area monitoring networks with cable

length >500 meter,

the RS485 as an international standard serial interface for connection of PICO probes to

standard PC´s, PDA´s and other computers,

or the SDI12 interface for direct connection to SDI12 dataloggers.

10.1 PICO probes connected to a PC under Windows

With IMKO´s small software package TRIME WIN-MONITOR (cost free) it is possible to collect

measurement data from up to 60 PICO probes to a PC. TRIME WIN-MONITOR runs under Windows.

With the software PICO-CONFIG it is possible to configurate single PICO probes, e.g. to select a

special calibration curve inside the PICO probe. The connection to the PC can be configured via the

module SM-USB and a USB-port to the PC.

Page 24

Manual TRIME_PICO64-32 Version 2_0 2017-05-30

Page 24

10.2 PICO probes connected to a SDI12 Datalogger

Page 25

2017-05-30 Manual TRIME_PICO64-32 Version 2_0

Page 25

11 Quick guide for the Software PICO-CONFIG

11.1 Connection of the RS485 or the SDI-12 and the IMP-Bus to the SM-USB

Module

The SM-USB is available in two versions, for the RS485 or optionally for the SDI-12 interface (but not together!). The

SM-USB provides the ability to connect a PICO probe either to the standard RS485 interface (in special version the

SDI-12) and to the IMP-Bus from IMKO, which enables the download of a new firmware to the PICO probe. Both

connector ports are shown in the drawing below. The SM-USB is signalling the status of power supply and the

transmission signals with 4 LED´s. When using a dual-USB connector on the PC, it is possible to use the power supply

for the PICO probe directly from the USB port of the PC without the use of the external AC adapter.

How to start with the USB-Module SM-USB from IMKO

Install USB-Driver from USB-Stick.

Connect the SM-USB to the USB-Port of the PC and the installation will be accomplished auto-

matically.

Install Software PICOConfig-SetUp.msi from USB-Stick.

Connection of the PICO probe to the EX9531 via RS485A, RS485B and 0V.

Check the setting of the COM-Ports in the Device-Manager und setup the specific COM-Port with

the Baudrate of 9600 Baud in PICO-CONFIG with the button "Bus" and "Configuration" (COM1COM15 is possible).

Start “Scan probes” in PICOConfig.

The PICO probe logs in the window „Probe List“ after max. 30 seconds with its serial number.

Note 1:

In the Device-Manager passes it as follows:

Page 26

Manual TRIME_PICO64-32 Version 2_0 2017-05-30

Page 26

Control Panel System Hardware Device-Manager

Under the entry “Ports (COM & LPT) now the item

“USB Serial Port (COMx)” is found.

COMx set must be between COM1….COM9 and it

should be ensured that there is no double occupancy of the interfaces.

If it comes to conflicts among the serial port or the USB-SM has been found in a higher COM-port, the COM

port number can be adjusted manually:

By double clicking on "USB Serial Port" you can go into the properties menu, where you see "connection settings" – with "Advanced" button, the COM port number can be switched to a free number.

After changing the COMx port settings, PICO-CONFIG must be restarted.

11.1.1 RS485 or IMP-Bus Configuration and Probe Scan

With PICO-CONFIG it is possible to make process-related adjustments of individual parameters of the PICO

probe. Furthermore the measurement values of the PICO probe can be read from the probe via the RS485 or

IMP-Bus interface and displayed on the screen.

In the menu "Bus" and the window "Configuration" the PC can be configured to an available COMx-port with

the Baudrate of 9600 Baud.

Page 27

2017-05-30 Manual TRIME_PICO64-32 Version 2_0

Page 27

11.2 Scan of connected PICO probes on the RS485 or IMP-Bus

In the menu "Bus" and the window "Scan Probes" the RS485 bus can be scanned for attached PICO probes

(takes max. 30 seconds).

PICO-CONFIG reports founded PICO probes with its serial number in the window “Probe List“.

11.3 Configuration of Measure Mode

In "Probe List" with "Config" and "Measure Mode & Parameters” the PICO probe can be adjusted to the de-

sired mode A, B or C (see Chapter “Configuration Measure Mode”).

Page 28

Manual TRIME_PICO64-32 Version 2_0 2017-05-30

Page 28

11.4 Analogue outputs of the PICO probe

In the menu "Config" and the window "Analog Output" the analogue outputs of the PICO probe can be configured (see Chapter “Analogue outputs..”).

The conductivity range can be selected, depending on the specific soil which is measured. 0..20 dS/m should

be selected for soils with a very high salinity content.

11.5 Simulate Analog Output

By pressing the button “Simulate” in the window "Analog Output" the analog output 1 and 2 can be simulated

in 5 ranges from 0 to 100%. The %-value can be entered directly by hand and the analog output follows by

pressing the button “Set”.

Page 29

2017-05-30 Manual TRIME_PICO64-32 Version 2_0

Page 29

11.6 Selection of the individual Calibration Curves

In the menu "Calibration" and the window "Material Property Calibration" the calibration curves CAL1 to

Cal15 which are stored in the PICO probe are loaded and displayed on the screen (takes max. 1 minute). With

the mouse pointer individual calibration curves can be activated and tested with the PICO probe by activating

the button "Set Active Calib". Furthermore, the individual calibration curves CAL1 to Cal15 can be adapted or

modified with the calibration coefficients (see Chapter “Creating a linear calibration curve”).

The desired and possibly altered calibration curve (Cal1. .15) which is activated after switching on the probes

power supply can be adjusted with the button "Set Default Calib”.

The coefficients m1 = 0.0581 and m0 = -4.05 for individual calibration curves can be entered and adjusted directly by hand and are stored in the probe by pressing the “Set” button.

Page 30

Manual TRIME_PICO64-32 Version 2_0 2017-05-30

Page 30

11.7 Test Run in Measurement Mode A

In the menu "Test" and the window Test in Mode A, the measured moisture values “Moist” of the PICO probe

are displayed on the screen and can be parallel saved in a file.

Attention: for a test run in mode A it must be ensured that the PICO probe was also set to this mode. If this

is not assured, the probe returns zero values.

Following measurement values are displayed on the screen:

Moist Moisture Value

MatTemp Temperature

Conduct Bulk Electrical Conductivity EC

TRIME

TDRLevel TDR-Level (for special applications)

tp Radar time which corresponds to the respective moisture value.

The other values like Count, ASICCount, etc. are for special use.

By clicking „Save“ the recorded data is saved in a text file in the following path:

\PICO-CONFIG.exe-Pfad\MD\Dateiname

The name of the text file TestMeas+SN+yyyymmddHHMMSS.sts is assigned automatically with the serial

number of the probe (SN) and date and time.

The data in the text file can be evaluated with Windows-EXCEL.

Basic Balancing in Glass Beads

PICO probes are identical and manufactured precisely. After an exchange of a probe rod it is nevertheless ad-

visable to verify the calibration and to check the basic calibration and if necessary to correct it with a “Basic

Balancing”.

With a “Basic Balancing” two reference calibration measurements are to be carried out with known set-points

("RefValues"). For the reference media, dry and wet glass beads should be used.

Page 31

2017-05-30 Manual TRIME_PICO64-32 Version 2_0

Page 31

Attention: Before performing a “Basic Balancing” it must be ensured that the PICO probe was set to “Measure

Mode” A. If this is not assured, the probe returns zero values. After a “Basic Balancing” the PICO probe has to

be set to “Measure Mode” B or C again.

In the menu "Calibration" and the window "Basic Balancing" the two set-point values of the radar time tp are

displayed with 145ps and 625ps.

Reference set-point A: tp=145ps in dry glass beads.

The first set-point can be activated with the mouse pointer by clicking to No.1. By activating the button "Do

Measurement" the PICO probe determines the first reference set-point in dry glass beads. In the column

„MeasValues“ the measured raw value of the radar time t is displayed.

Reference set-point B: tp=625ps in wet glass beads. The PICO probe head has to be completely covered with

wet glass beads. The second set-point can be activated with the mouse pointer by clicking to No.2. By activating the button "Do Measurement" the PICO probe determines the second reference set-point in wet glass

beads. In the column „MeasValues“ the measured raw value of the radar time t is also displayed.

By activating the button „Calculate Coeffs“ and „Coeffs Probe“ the alignment data is calculated automatical-

ly and is stored in the PICO probe non-volatile. With a “Test run” (in Mode A) the radar time tp of the PICO

probe should be now 145ps in dry and 625ps in wet glass beads.

11.8 TRIME WIN MONITOR Datalogger Software

TRIME WIN MONITOR is a datalogger software for measurement data collection of TRIME sensors. TRIME WIN

MONITOR runs under Windows.

The software and the manual can be downloaded from IMKO´s homepage under the menu item “Support”,

“Software” and “TRIME WIN MONITOR”.

Page 32

Manual TRIME_PICO64-32 Version 2_0 2017-05-30

Page 32

11.9 Calibration Curves

PICO64/32 probes are supplied with different calibration curves.

Cal1 Universal Soil Vol. is a nonlinear calibration curve 5th order which is suitable for most soils.

Cal 2 to Cal7 (see next pages) can be selected for special applications. These are the calibration functions in-

stalled to the upgrade version of the Trime-PICO32/64 delivered together with the measurement of the Radar based Conductivity (RbC). If you want to have these Calibration functions for your current Trime-PICO

please contact IMKO GmbH (info@imko.de)

A maximum of 15 different calibration curves (Cal1 ... Cal15) can be stored inside the PICO probe and can optionally be activated via the program PICO-CONFIG.

A preliminary test of an appropriate calibration curve (Cal1. .15) can be activated in the menu "Calibration"

and in the window “Material Property Calibration" by selecting the desired calibration curve (Cal1...Cal15) and

with using the button “Set Active Calib”. The finally desired and possibly altered calibration curve (Cal1. .15)

which is activated after switching on the probes power supply will be adjusted with the button "Set Default

Calib”.

Nonlinear calibrations are possible with polynomials up to 5th grade (coefficients m0 to m5).

IMKO publish on its website more suitable calibration coefficients for different materials. These calibration

coefficients can be entered and stored in the PICO probe by hand (Cal14 and Cal15) with the help of PICOCONFIG.

Next page:

The following charts (Cal.1 .. 15) show different selectable calibration curves which are stored inside the PICO

probe.

On the y-axis the gravimetric moisture Moist (or Dielectric-Constant Epsilon) is shown. On the x-axis depending on the calibration curve the associated radar time tp in picoseconds is shown. With the software PICO-

CONFIG the radar time tp is shown on the screen parallel to the moisture value Moist.

Page 33

2017-05-30 Manual TRIME_PICO64-32 Version 2_0

Page 33

Page 34

Manual TRIME_PICO64-32 Version 2_0 2017-05-30

Page 34

Page 35

2017-05-30 Manual TRIME_PICO64-32 Version 2_0

Page 35

11.10 Creating a linear Calibration Curve for a specific Material

The calibration curves Cal1 to Cal15 can be easily created or adapted for a specific soil with the help of PICOCONFIG. Therefore, two measurement points need to be identified with the probe. Point P1 at dried soil and

point P2 at moist soil where the points P1 and P2 should be far enough apart to get a best possible calibration

curve. The moisture content of the soil at point P1 and P2 can be determined with laboratory measurement

methods (oven drying). It is to consider that sufficient material is measured to get a representative value.

Under the menu "Calibration" and the window "Material Property Calibration" the calibration curves CAL1 to

Cal15 which are stored in the PICO probe are loaded and displayed on the screen (takes max. 1 minute). With

the mouse pointer individual calibration curves can be tested with the PICO-probe by activating the button "Set

Active Calib". The measurement of the moisture value Moist with the associated radar time tp at point P1 and

P2 is started using the program PICO-CONFIG in the sub menu "Test" and "Test in Mode A".

Step 1: The radar pulse time tp of the probe is measured with dried soil. It is recommended to detect multiple

measurement values for finding a best average value for tp. The result is the first calibration point P1 (e.g.

70/0). I.e. 70ps (picoseconds) of the radar pulse time tp corresponds to 0% moisture content of the material.

But it would be also possible to use a higher point P1´ (e.g. 190/7) where a tp of 190ps corresponds to a moisture content of 7%. The gravimetric or volumetric moisture content of the material, e.g. 7% has to be determined with laboratory measurement methods (oven drying).

Step 2: The radar pulse time tp of the probe is measured with moist material. Again, it is recommended to

detect multiple measurement values of tp for finding a best average value. The result is the second calibration

point P2 with X2/Y2 (e.g. 500/25). I.e. tp of 500ps corresponds to 25% moisture content. The gravimetric or

volumetric moisture content of the material, e.g. 25% has to be determined with laboratory measurement

methods (oven drying).

Step 3: With the two calibration points P1 and P2, the calibration coefficients m0 and m1 can be determined

for the specific soil (see next page).

Step 4: The coefficients m1 = 0.0581 and m0 = -4.05 (see next page) for the calibration curve Cal15 can be entered directly by hand and are stored in the probe by pressing the button “Set”. The name of the calibration

curve can also be entered by hand. The selected calibration curve (e.g. Cal15) which is activated after switching

on the probes power supply will be adjusted with the button "Set Default Calib”.

Attention: Use “dot” as separator (0.0581), not comma !

11.10.1 Calculation for a linear 2-point calibration curve

1. Download the Excel-Sheet „SONO 2-Point LinearCalibration_Calculation“ from IMKO´s

Homepage under „Support Software“.

2. Enter into the Excel-Sheet both TP-values with the respective reference moisture values.

3. Read out both parameters m0 and m1 from the Excel-Sheet.

4. Enter, set and save both parameters m0 and m1 with help of the software „SONO-CONFIG“

in the menu „Calibration“ in the window „Material Property Calibration“ in the selected calibration curve.

Page 36

Manual TRIME_PICO64-32 Version 2_0 2017-05-30

Page 36

11.10.2 Calculation for a non-linear calibration curve

PICO probes can work also with non-linear calibration curves with polynomials up to 5th grade.

For a non-linear calibration it is necessary to calibrate with 4…8 different calibration points with different Tp values and the related moisture values in %. To calculate nonlinear coefficients for polynomials up to 5th grade, an EXCEL software tool from IMKO can be used.

1. Download the Excel-Sheet „SONO_NonlinearCalibration_Calculation“ from IMKO´s

Homepage under „Support Software“.

2. Enter the TP-values with the respective reference moisture values into the Excel-Sheet.

3. Read out the parameters m0 to m5 from the Excel-Sheet.

4. Enter, set and save the parameters m0 to m5 in the selected calibration curve with help of the

software „SONO-CONFIG“ in the menu „Calibration“ under the window „Material Property Calibration“.

The following diagram shows a sample calculation for a linear calibration curve with the coefficients

m0 and m1 for a specific soil or material.

Page 37

2017-05-30 Manual TRIME_PICO64-32 Version 2_0

Page 37

12 Measure Electrical Conductivity with TRIME Probes

A reliable, practical and easy-to-use Determination of Soil

Conductivity and Salt Content with TRIME Probes

IMKO´s TRIME TDR-probes can now report soil EC as standard simultaneously with soil moisture

content percentage. A manual conversion based on researched curves for different soil types enables the user to derive a soil EC expressed in mg/l TDS (total dissolved salts).

TRIME TDR probes can do this very accurately because:

TRIME probes measure conductivity with the same large soil volume as it will be used for the TDR

moisture measurement. The contact of the probe rods inside the soil is far less critical as with "galvanic" EC probes with a point to point measurement where even small air gaps lead to significant

deviations.

TRIME probes use coated and therefore isolated rods which guarantee the non-appearance of galvanic accumulation along the rods allowing for long-run installations over many years. Unisolated

rods means there is a risk of galvanic reactions and possible influence on the sensor´s reading with

serious problems when the probes must be removed from larger depths due to a rod cleaning.

TRIME probes measure moisture and conductivity very precisely at a frequency of 1GHz with a better

and more exact separation of moisture and conductivity in comparison to capacitive probes with

lower frequencies. This means that in practice, a reliable determination of the pore water conductivity ECw and respectively TDS (mg of salt per liter water) is possible at different moisture levels.

All TRIME probes work with a concurrently basic calibration for moisture and conductivity. This allows a check of the limits of saline stress in soils according to standards of FAO2006 for specific soils.

Page 38

Manual TRIME_PICO64-32 Version 2_0 2017-05-30

Page 38

12.1 The analysis of Soils for Electrical Conductivity EC

TRIME

Notes and Disclaimer: The analysis of electrical conductivity is an immensely complex subject. This

resume is not intended as a study document in soil science nor does it discuss the technical complexities of the devices used.

For agricultural and horticultural soils, the measurement of Electrical Conductivity is an immensely

important measurement. Electrical Conductivity measures the amount of total dissolved salts (TDS)

or total dissolved ions in water. To complicate matters, some ions such as Sodium and Chloride will

contribute more to EC than others such as Phosphorus and Potassium.

Plants require nutrients such as Nitrogen, Phosphorus, Potassium, Magnesium in large quantities

hence they are called major nutrients and also smaller amounts of elements such as Iron, Manganese , Molybdenum and these are called micro nutrients or sometimes referred to as trace metals. Fertilisers are supplied to plants as compounds for example Ammonium Nitrate which supplies

Nitrogen in the form of Nitrate or Ammonium. Micro-organisms will break down these compounds

so they are more readily available for uptake by the plants. Levels of some ions such as Chlorides are

less desirable and in great quantities can be harmful to plant growth. The quantity of ions or salts in a

soil is of huge importance. Too much or too few nutrients will create a restriction in plant growth.

Measurement of EC in water is relatively straightforward. An EC probe (usually platinum) is inserted

in the water and a reading in mS/cm is reported on the meter’s display. This is relatively easy because water is a homogenous medium. Soil on the other hand is not and this has caused great difficulties when trying to measure its conductivity. To work around this, the analysis on agricultural and

horticultural soils has been carried out by mixing a volume of soil and a volume of water and measuring the EC on the suspension or filtered extract. Different countries and different regulatory bodies

have specified methodologies and in general results have been good enough to use for fertilisation

recommendations and programmes. This analysis was generally carried out by a laboratory and

whereas results were and are reliable the method is slow, time consuming and expensive.

Over the years manufacturers have tried to come up with solutions whereby an instrument could be

used directly in soils without having to resort to laboratories. The EC reported by these instruments is

referred to soil bulk electrical conductivity. Whereas there has been some success, there are so many

influential variables such as temperature, soil moisture and granular composition that results have

not been adequate for reliable fertilisation studies. Mostly soil bulk conductivity was of academic

rather than practical interest.

IMKO has studied the subject in detail and has come up with a breakthrough. By using coated rods

and measuring over the length of the probes, all TRIME probes can now accurately report what IMKO

calls EC

TRIME

. This measurement takes account of soil moisture and conductivity by volume. Because

soil moisture is so important in the calculation of EC, all different TRIME probes now incorporate TDR

calibration curves for a selection of soils. Special graphs have been constructed so that the user can

convert the EC

TRIME

reading to grams/litre of dissolved salt. So far curves are available for sandy and

loam soils and it is intended to produce a handful of curves to cover most situations. At this moment

in time, conversion of EC

TRIME

to mg/l TDS is done manually.

IMKO hopes that this breakthrough whereby a TDR instrument can be used to derive a true soil EC

measurement will become the new standard for soil fertilisation analyses.

Page 39

2017-05-30 Manual TRIME_PICO64-32 Version 2_0

Page 39

12.2 EC

TRIME

Measurement Range for TRIME Probes

All PICO probes work with a concurrently basic calibration for moisture and conductivity. This allows

a check of the limits of saline soils according to standards of FAO2006 for specific soils.

Measurement Range Conductivity for PICO64, PICO32, T3-IPH, PICO-PROFILE

0…10dS/m EC

TRIME

(here is, depending on moisture content ECw >20dS/m)

All TRIME probes have a linear EC

TRIME

calibration curve with two calibration points. This ensures an

equal behaviour of a TRIME probe type (e.g. PICO32).

Calibration Point1: Dry glass beads = 0dS/m EC

TRIME

Calibration Point2: Saturated glass beads with water ECw 5dS/m = 5dS/m EC

TRIME

With dry glass beads (not air!) it is ensured that the conductivity range of dry soils starts with nearly

0dS/m. The calibration at point2 was performed with glass beads and water which was adjusted with

salt to a pore water conductivity of ECw = 5dS/m at a temperature of 23°C.

12.3 Measurement of Pore-Water-Conductivity or Salt-Content of Soils

The possible salt stress depends on soil type and plant species and can be roughly classified:

Slight salinization: 1-3g of salt per liter

Average salinity: 3-5g salt / liter

Strong salinity: 5-10g salt / liter

Very high salinity: > 10 g salt / liter

The conversion of the salt content in grams of salt per liter water (TDS Total-Dissolved-Salts) into the

pore water conductivity of ECw happens with:

Salt content in grams of salt per liter of water TDS = 0.64 * ECw

An ECw = 5mS/cm result thus with 3.2 grams of salt per liter (pore) water

ECw can be determined with a laboratory conductivity meter. 1dS/m = 1mS/cm

A determination of the pore water conductivity or salinity of soils and sand at different moisture

values is possible by using a Moisture/ EC

TRIME

diagram for the PICO32 or PICO64. With measuring

moisture and EC

TRIME

, the pore water conductivity (or TDS salt content in grams salt per liter) of the

soil can be determined by using the individual pore water water curves.

The below displayed Moisture/ EC

TRIME

charts were created for sand and a loamy soil.

We recommend the creation of a separate Moisture/ EC

TRIME

diagram for the intended soil in the

designated ranges of salinity.

Page 40

Manual TRIME_PICO64-32 Version 2_0 2017-05-30

Page 40

The following diagram illustrates curve progressions of pore-water with four different salinity contents at different moisture contents for the PICO32.

Sand1 was mixed with 0,5dS/m pore water, sand2 mixed with water which had a conductivity of

5dS/m, sand3 with 10dS/m and sand4 with 20dS/m water. The PICO32 determines different EC

TRIME

conductivities in the different sands at one moisture level. The moisture range with the best resolution for the EC

TRIME

measurement lies between 10% and 30%, depending on the salt content.

How to determine the salt content

With both parameters, the moisture value (X-axis) and EC

TRIME

(Y-axis) it is possible to determine the

salt content in sand. With a moisture content of e.g. 17% and an EC

TRIME

of 4,6dS/m, the intersection

point lies on the blue curve which represents a salt content of 6,4g salt per liter water in the sand.

With 30% moisture content and an EC

TRIME

of 5,5dS/m the salt content would be 3,2g salt per liter

water in the sand.

The intersection point of „Moisture“ and „EC

TRIME

“ is representing the salinity curve ECW in the

sand-diagram.

This sand diagram shows four pore water curves. If intersection points lies between this four curves

(e.g. the yellow curve), the result of the salt content has to be interpolated.

Page 41

2017-05-30 Manual TRIME_PICO64-32 Version 2_0

Page 41

The following diagram illustrates curve progressions of EC

TRIME

for PICO32 for a loamy soil at different

salt contents. The PICO32 determines different EC

TRIME

conductivities in different soils at one mois-

ture level. The moisture range with the best resolution for the EC

TRIME

measurement for a loamy soil

is between 25% and 35%.

Also here the intersection point of „Moisture“ and „EC

TRIME

“ is representing the salinity curve

ECW in the soil-diagram.

Page 42

Manual TRIME_PICO64-32 Version 2_0 2017-05-30

Page 42

12.4 Creation of a Moisture/ EC

TRIME

Diagram for a particular Soil

The following description shows a possible way to create a Moisture/ EC

TRIME

diagram for a particular

soil:

Take a soil sample and determine the salt content with a laboratory method. (e.g. determine ECw of

the soil/water saturation extract).

Dry the soil sample to 0% moisture. Cut it into small pieces and grind the soil so that it can be mois-

tened by hand as evenly as possible (eg with a water spray pump).

Moisten the soil evenly with a pore water solution for example 2.56g of salt per liter (equivalent to

ECw= 4dS/m) to the first measurement point (e.g 2.5% moisture). Take into account, that the soil

already contains salt. I.e. were already 1g of salt per liter in the soil, you put a curve for a pore water

conductivity record of 2.56 g + 1g salt = 3.56g per liter (ECw= 5.5 dS/m).

Compact the soil in a plastic bowl (no metal and not too small!) so that it largely corresponds to the

natural density. Concerning the insertion of the PICO-probe rods for measurement, it is recommended to perform several measurements per point in order to form an average value for each moisture

and EC

TRIME

value. It is important to ensure that the measuring field is not disturbed around the rods,

eg by previous punctures.

Moisten the soil more, as homogeneous as possible with the pore water solution ECw= 4dS/m to eg

5% moisture. Again compact the soil in a plastic bowl so that it largely corresponds to the natural

density. Concerning the insertion of the PICO-probe rods for measurement, it is recommended to

perform several measurements per point in order to form an average value for each moisture and

EC

TRIME

value. It is important to ensure that the measuring field is not disturbed around the rods, eg

by previous punctures.

Take more moisture and EC

TRIME

values, up to soil saturation.

Create the pore-water curve for example for 3.56g salt/liter (ECw=5.5dS/m) with the added moisture

and EC

TRIME

values.

Take up several curves for different pore water contents.

If the soil sample is already too heavily loaded with salt, a washing out of the ions would be possible,

but without the lost of the fine fraction. After a subsequent drying and crushing of the soil, the Moisture/ EC

TRIME

diagram can be established with a lower salt content. It is also possible to use distilled

water for obtaining the lowest curve.

Note: The effort for a Moisture/ EC

TRIME

diagram is not negligible. IMKO has the hope to establish

with the EC

TRIME

process an easier, faster, better and generally accepted determination of the salt

contamination of soils. In future IMKO plans to provide or publish different Moisture/ EC

TRIME

curves

for standard soils. We expect to cover nearly most soils with about 4-5 diagrams.

Page 43

2017-05-30 Manual TRIME_PICO64-32 Version 2_0

Page 43

13 Software Error codes

13.1 Software Errors which will be coded with 4 digits.

Code

Explanation

Measurement

0101-0108,

0301

Serial Port errors

Check port's setting or if the port has

been opened. Then close and restart the

program.

0201

No answer

Check the power of PICO, the serial port

of PC and the connection between PC and

PICO.

0202-0212

Protocol errors

Check if PICO-CONFIG’s version passes

PICO’s version.

0302-0307

Protocol error, Parameter

setting false

Check if parameters are correct and if

PICO-CONFIG’s version passes PICO’s

version.

0401

Can not find config file PICOCONFIG.con

Look for the file in the exe path. If not

found, copy the file to the path.

0501-0508

Errors in Event & MeasureMode

Restart PICO and PICO-CONFIG

0601,0602,0604,

0605,0606,0607,

0609

Operation errors in Basic

Balancing

Operate correctly and try it again.

0603,0608,0610,

0611

Communication or protocol

errors in Basic Balancing

Restart PICO and PICO-CONFIG.

0701,0702

Read file errors in Material

Property Calibration

Check if the files are in the required path.

If not, copy the files to the path or

redefine the path under the menu

Bus/Configuration/Material Property

Calibration.

0703

Operation errors in Material

Property Calibration

Operate correctly and try it again.

0704, 0705,0706

Communication or protocol

errors in Material Property

Calibration

Restart PICO and PICO-CONFIG.

0801-0805,0901

Operation errors in Calibration

IDs and Names

Operate correctly and try it again.

1001,1101,1102

Read file errors in Calibration

IDs and Names

Check if the files are in the required path.

If not, copy the files to the path or

redefine the path under the menu

Bus/Configuration/Material Property

Calibration.

1201, 1203

Operation errors in Test

Operate correctly and try it again.

1202

Communication or protocol

errors in Test

Restart PICO and PICO-CONFIG.

Page 44

Manual TRIME_PICO64-32 Version 2_0 2017-05-30

Page 44

1301

Write file error in Test

Check file path and try it again. If failed,

restart PICO-CONFIG.

4001-4002,

4101-4106,4201

Read file or write file errors

Check the files and try again.

4301-4303

Intenal calculating errors

Restart PICO-CONFIG and try

again.Otherwise contact IMKO.

13.2 PICO Errors (Firmware errors). The errors come from the firmware, from

1 to 255.

Code

Explanation

Measurement

1-19

The serial communication errors due to

incorrect telegram, baud rate, timing etc.

Power off, power on PICO and try it again. Otherwise contact

IMKO.

20-39

incorrect command number, command

right or command parameters.

Power off, power on PICO and try it again. Otherwise contact

IMKO.

40-49

EEPROM is defect

Power off, power on PICO and try it again. Otherwise contact

IMKO.

50-59

ASIC is defect

Power off, power on PICO and try it again. Otherwise contact

IMKO.

60

Power voltage is too low

Check power voltage of PICO, it is minimal 6V.

100

TDR measurement parameter is incorrectly

set or the material conductivity is too high.

Adjust the TDR measurement parameters or contact IMKO

101

TDR measurement parameter is incorrectly

set

Adjust the TDR measurement parameters or contact IMKO

102

ASIC is defect

Power off, power on PICO and try it again. Otherwise contact

IMKO.

103

EC parameter is incorrectly set.

Power off, power on PICO and try it again. Otherwise contact

IMKO.

105

Tp is out of range for the standard calibration polynomial.

Check if PICO is inserted in the measured material correctly.

108

TDR measurement parameter is incorrectly

set or the material conductivity is too high.

Adjust the TDR measurement parameters or contact IMKO

120-129

Internal chip problem

Power off, power on PICO and try it again. Otherwise contact

IMKO.

130-199

Internal errors

Contact IMKO

200-254

Reserved

255

The data transmission is not finished.

Page 45

2017-05-30 Manual TRIME_PICO64-32 Version 2_0

Page 45

14 Savety Notes

In this documentation, text points are highlighted, which require special attention.

DANGER:

The Warning Triangle with the exclamation mark warns you against personal injury or property damage.

Intended Use

Sensors and measuring systems of IMKO GmbH may only be used for the purpose described, taking into account the technical data. Misuse and use of the equipment other than

for its intended purpose are not eligible. The function and operational safety of a sensor or

measuring system can only be guaranteed if the general safety precautions, national regulations and the special safety instructions in this operating manual are observed during use.

The moisture sensors and measuring systems of IMKO GmbH are used to measure moisture

according to the measuring purpose and measuring range defined and defined in the technical data. Only adherence to the instructions described in the manual is regarded as intended use. The manual describes the connection, use and maintenance of IMKO sensors and

IMKO measuring systems. Read the manual before connecting and operating a sensor or

measuring system. The manual is part of the product and must be kept close to the sensor or

measuring system.

Impairment of safety

The sensor or the measuring system has been designed and tested in accordance with EN 61010 safety regulations for electronic measuring instruments

and has left the factory in a safe and safe condition. If the sensor or the meas-

uring system can no longer be operated safely, it must be put out of operation

and secured by means of marking before further commissioning. In case of doubt, the sensor

or the measuring system must be sent to the manufacturer or his contractual partner for repair or maintenance.

Modifications

For safety reasons, it is not permitted to carry out any modifications or modifi-

cations to the sensor or the measuring system without the consent of the man-

ufacturer. The opening of the sensor or hand-held meter, adjustment and re-

pair work, as well as all maintenance work other than the work described in the

manual may only be carried out by a specialist authorized by IMKO. The sensor or the

measuring system must be disconnected from the power supply before installation or

maintenance work. Do not open or repair the hand-held unit and the power supply!

Page 46

Manual TRIME_PICO64-32 Version 2_0 2017-05-30

Page 46

Hazard Warnings

Danger due to improper operation. The sensor or the measuring system may

only be operated by instructed personnel. The operating personnel must

have read and understood the operating instructions.

Danger by electricity

The hand-held meter must not be immersed in water or other liquids. The

sensor is insensitive to moisture contained in the typically measured products. Only connect the hand-held meter to a properly installed outlet with the

supplied voltage supply cable, the voltage of which corresponds to the technical data. Make sure that the power outlet is well accessible, so that you can unplug the

power supply quickly if necessary. Use only the adapter that is suitable for your outlet.

Only operate the meter with the supplied original accessories. If you need additional accessories

or replacement, please contact the manufacturer.

Do not use the meter in following case:

- if the measuring instrument, sensor, plug-in power supply or accessories are damaged,

- the sensor or the measuring system does not operate as intended,

- the power cord or plug is damaged,

- the sensor or the measuring system has fallen down.

Unplug the power supply from the wall outlet in following case:

- if you do not use the sensor or the measuring system for an extended period of time,

- before cleaning, unpacking or changing the sensor or the measuring system,

- if you are working inside the sensor or measuring instrument, e.g. connect devices,

- if a fault occurs during operation,

- during thunderstorms.

Caution - Property damage

Ensure that there is a sufficient distance to strong heat sources such as heating plates, heating pipes. Disconnect the sensor or handheld device from other devices before relocating or transporting it. Disconnect the connectors on

the device.

Do not use aggressive chemical cleaning agents, scouring agents, hard sponges or the like.

Page 47

2017-05-30 Manual TRIME_PICO64-32 Version 2_0

Page 47

Notes:

Page 48

Precise Moisture Measurement

in hydrology, forestry, agriculture, environmental and earth science,

civil engineering, as well as individual applications!

Loading...

Loading...