Page 1

I:\publik\TECH_MAN\TRIME-GW\english\GW-MAN_e-Temperatur_Vers2_6.doc

Page 2

Thank y

ou for buying IMKO.

Should you have any queries, please

don’t hesitate to contact your local

distributor or contact IMKO direct:

IMKO Micromodultechnik GmbH

Im Stoeck 2

D-76275 Ettlingen

Germany

Phone: +49-7243-5921-0

Fax: +49-7243-90856

e-mail: info@imko.de

internet: http://www.imko.de

Operating instructions for TRIME

status November 2008

List of contents

®

-GW

1 Instrument description ...............................................................................................................................4

1.1 The method of measurement....................................................................................................................4

1.1.1 TRIME - The patented TDR method.................................................................................................4

1.1.2 TRIME compared to other methods..................................................................................................4

1.2 The operating principle .............................................................................................................................4

1.2.1 Measuring with floating mean-value..................................................................................................4

1.2.2 Temperature compensation..............................................................................................................4

1.2.3 The analogue output.........................................................................................................................5

1.2.4 Error display and error messages.....................................................................................................5

1.3 Configuration ............................................................................................................................................6

1.3.1 Product selection switch ...................................................................................................................6

1.3.2 Offset-correction...............................................................................................................................6

1.3.3 Averaging time..................................................................................................................................7

1.3.4 Calibration and temperature compensation exchange......................................................................8

1.4 Instrumentation.........................................................................................................................................9

1.5 Connections............................................................................................................................................10

1.5.1 Connector for strip terminals...........................................................................................................10

1.5.2 The probe connector (Probe)..........................................................................................................10

1.5.3 The configuration connector (Configuration)...................................................................................10

1.5.4 The RS232 connector (RS-232) .....................................................................................................10

1.5.5 The IMP-Bus connector (IMP-Bus).................................................................................................10

1.6 Connections TRIME®-GW ......................................................................................................................11

1.7 The probe...............................................................................................................................................12

1.7.1 The rod probe GR...........................................................................................................................12

1.7.2 The surface probe GS1 ..................................................................................................................12

2 Installation .................................................................................................................................................13

2.1 Probe installation....................................................................................................................................13

2.2 Instrument installation.............................................................................................................................14

2.3 Wiring .....................................................................................................................................................15

_____________________________________________________________________________

2

Page 3

2.3.1.1

Integration into the existing system-electronics................................................................ 15

3 Initial operation and handling ..................................................................................................................17

3.1 Adjustment guidelines.............................................................................................................................17

3.2 Adjustments for initial operation..............................................................................................................17

3.2.1 Adjustment for plants with several TRIME®-GW.............................................................................17

3.2.2 The product selector-switch............................................................................................................18

3.2.3 Selection and application of the reference method.........................................................................18

3.2.4 Initial operation................................................................................................................................18

3.2.5 Recording measurement data in trial operation ..............................................................................19

3.2.6 Setting the product selector-switch (adjustment) ............................................................................19

3.2.7 An example.....................................................................................................................................20

3.3 Practical application................................................................................................................................21

3.3.1 Monitoring during grain delivery......................................................................................................22

3.3.2 Manual control of the grain dryer ....................................................................................................22

3.3.3 Automatic control of the grain dryer................................................................................................22

4 Special functions.......................................................................................................................................23

4.1 Operating the TRIME®-GW measurement systems in an intermittent flow of material............................23

4.1.1 Behaviour upon detection of air around the probe rods ..................................................................23

4.1.2 Control via the internal time constants Queue-FillingTime and Queue-DischargeTime..................23

4.1.3 A side-effect when using the time constants Queue-FillingTime and Queue-DischargeTime.........24

4.1.4 Setting Queue-FillingTime ..............................................................................................................24

4.1.5 Control via an external, digital input signal HaltM ...........................................................................25

4.1.6 Electrical specification of the input signal HaltM / HaltM-In.............................................................25

4.2 Basis calibration after replacing system components .............................................................................26

4.2.1 General notes regarding basis calibration.......................................................................................26

4.2.2 Reference values of the calibration media used for the basis calibration........................................26

4.2.3 Preparatory measures ....................................................................................................................26

4.2.4 The procedure using the configuration plug “TRIME®-GW basis calibration”..................................26

5 Technical data ...........................................................................................................................................28

6 TRIME-GW adjustment protocol ..............................................................................................................30

_____________________________________________________________________________

3

Page 4

1 Instrument description

1.1 The method of measurement

1.1.1 TRIME - The patented TDR method

The TDR method (Time-Domain-Reflectometry) is based on a dielectric measurement method in

which the transit times of electromagnetic pulses are determined in order to measure the dielectric constant or the water content.

TRIME systems comprise a probe with parallel metallic rods that are inserted into the flow of grain

and a die-cast aluminium case with an integrated TDR measuring transformer. A high-frequency

TDR- pulse (1 GHz) generated in the instrument propagates along the wave guides inducing an

electromagnetic field around these guides and thus in the material around the probe. Using a

patented method, IMKO has succeeded in measuring the transit time of with a resolution of 10

seconds.

The determined moisture content can either be transmitted via an analogue output (0 or 4...20

mA) to a display in the process control room or fed directly into an automatic process control system. In addition, the TRIME systems can be easily networked and extended via a serial bus interface (RS232/V24).

-12

1.1.2 TRIME compared to other methods

In contrast to capacitive, infra-red- or resistance methods of measurement, the TRIME TDRtechnology shows greater indifference to the grain type, the temperature of the product and the

ionic conductivity. The remaining temperature dependency is compensated by means of a grain

temperature measurement in the probe.

3

The TRIME method fully penetrates a corn volume of 1..2 dm

about the moisture close to the surface (such as with the infra-red method) but also the water

content of the unground, whole corn. Complex and fault-prone bypass constructions, as required

by the disproportionately expensive microwave method or transmissive infra-red method, can be

dispensed with when using TRIME systems. The modular technology allows later system extensions with minimal expense. TRIME technology is also highly flexible in terms of probe design

thus making it adaptable to numerous applications.

. You thus not only obtain data

1.2 The operating principle

1.2.1 Measuring with floating mean-value

TRIME-GW constantly takes readings in cycles of 0.5 s and passes them on via the analogue

output. However, not the individual values just recorded are directly output, but the mean value of

a certain number of measurements thereby filtering out any temporary fluctuations that may occur. These fluctuations can be caused by an uneven distribution of moisture in the flowing grain.

The number of readings from which a final measurement is to be taken, or the averaging time,

can be set depending on the particular application (see page 6).

1.2.2 Temperature compensation

A built-in temperature sensor measures the grain temperature. Thus the measured water content

value is automatically corrected dependent on the grain temperature and the water content. It is

very important that the probe is in the colder exhaust air area of the dryer. It would measure the

air temperature instead of the grain temperature, it was in the heated inlet air zone.

_____________________________________________________________________________

4

Page 5

1.2.3 The analogue output

The measured value is conveyed via the analogue output in the form of electrical current. Two

versions of the instrument are available, 0..20 mA and 4..20 mA. The relationship between the

c

urrent,

I, at the analogue output and the grain moisture, (in %), arises from the following for-

mula:

0..20 mA: Fehler! Textmarke nicht definiert.

4..20 mA: Fehler! Textmarke nicht definiert.

I 5000 Example: 1 mA = 5%

I 6250 25 Example: 8 mA = 25%

The display units, available as optional extras, present the moisture readings directly as a percentage. The analogue port can also be used for connecting a line printer or a controller for regulating the dryer.

1.2.4 Error display and error messages

Errors occurring while measurements are being taken are displayed at the analogue output as

currents greater than 20 mA (see the table below). TRIME-GW, however, is very tolerant of errors. Malfunctions that occur during measurement don not appear at the analogue output until

25% of the readings are show discrepancies. If no more incorrect measurements occur, at least

80% of the values must be free of errors for a valid reading to appear at the analogue output. This

tolerance of errors allows trouble-free operation even when temporary faults occur, which is of

particular significance when used on controllers.

The only "error" that is permitted to appear in operation is error no. 66. It appears when the probe

is not immersed in grain.

The display instruments show occurring faults as "EE.E" or as values above 100% on the display

panel, dependent on the display type. When a line printer is connected, the fault is indicated by a

line at the upper limit or above 100%. To distinguish the type of fault the display instrument or the

line printer must be able to show values above 20 mA.

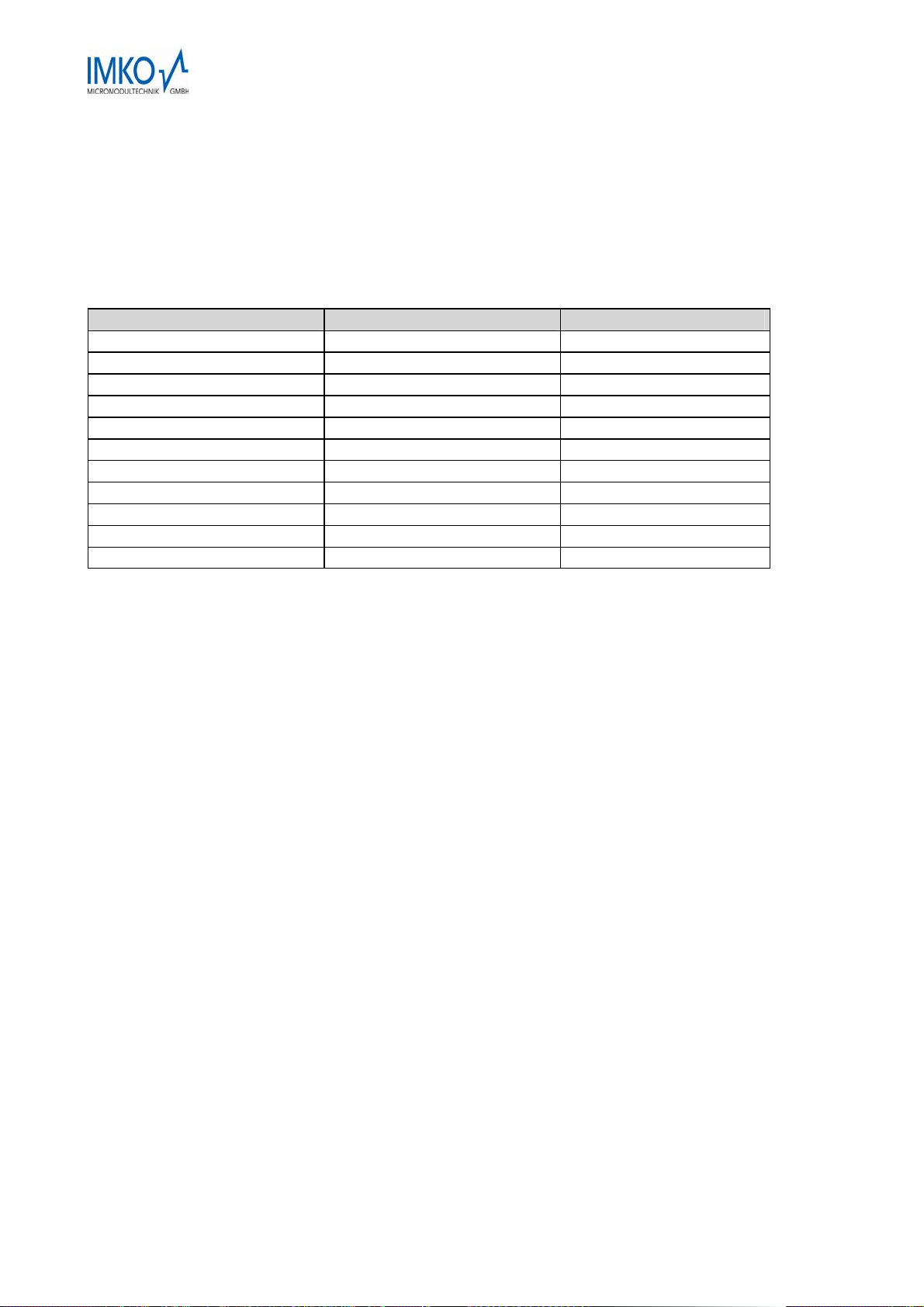

The following table shows the meanings of the individual faults and the corresponding currents.

Table 1

Fault

no.

30 26.0 mA 24.80 mA 130%

31 26.2 mA 24.96 mA 131%

Current

0..20 mA

Current

4..20 mA

Displayed

value

Possible cause

Coaxial cable missing or TDR-electronics defect

TDR-measurement incorrect (only in extremely saline

media)

33 26.6 mA 25.28 mA 133%

34 26.8 mA 25.44 mA 134%

35 27.0 mA 25.60 mA 135%

62 32.4 mA 29.92 mA 162%

Salinity too high

Data implausible or EEPROM defective

Power supply too low

Temperature sensor in the probe: temperature readings

implausible. Sensor faulty or detached from probe; EMC/

process faults; extremely rapid temp. fluctuations

63 32.6 mA 30.08 mA 163%

Temperature sensor in the probe: sensor not recognised

Sensor faulty; wiring broken; short circuit; switch on without probe

64 32.8 mA 30.24 mA 164%

Temperature sensor in the probe: communication problems

Sensor faulty; loose connection; EMC faults

66 33.2 mA 30.56 mA 166%

Probe not fully immersed in grain

_____________________________________________________________________________

5

Page 6

1.3 Configuration

The instrument configuration is set optimally at the factory prior to delivery of the TRIME-GW. In

some cases, further optimisation of these instrument-internal settings may be necessary.

The following TRIME-GW settings can be altered:

Product selection switch (0..F initially use switch setting 8)

Offset correction (shifting the measurements)

Averaging time (reaction speed of the readings)

Calibration and temperature compensation (when using a variety of materials)

Behaviour during filling/discharge, i.e. where material being measured is not always present

(e.g. in the discharge chute)

These functions are described in detail in Section 4.1 Operating the TRIME®-GW measure-

ent systems in an intermittent flow of material on page 23

m

Each of these settings remains unaltered even after the instrument is turned off, i.e. permanent

storage.

1.3.1 Product selection switch

After you wired up the system as described initially start with the switch setting 8, after the system

is running take samples close to the probe and compare the value of the TRIME-GW with the

result of your reference instrument.

Example:

The TRIME-GW shows an value of 18,0% the reference instrument shows an value of 15,0% so

you have to change the switch setting from initial setting 8 to the new switch setting B

The here shown values are for the use with the standard calibration set for the measurement in

grain (for use with maize, wheat, rye and barley), for other materials these values are specific:

Table 2

Switch position Switch (Offset

to raw value)

0 + 3 % Inactive (for testing)

1 +10 % Active

2 + 9 % Active

3 + 8 % Active

4 + 7 % Active

5 + 6 % Active

6 + 5 % Active

7 + 4 % Active

8 + 3 % Active

9 + 2 % Active

A + 1 % Active

B ± 0 % Active

C - 1 % Active

D - 2 % Active

E - 3 % Active

F - 4 % Active

Temperature compensation:

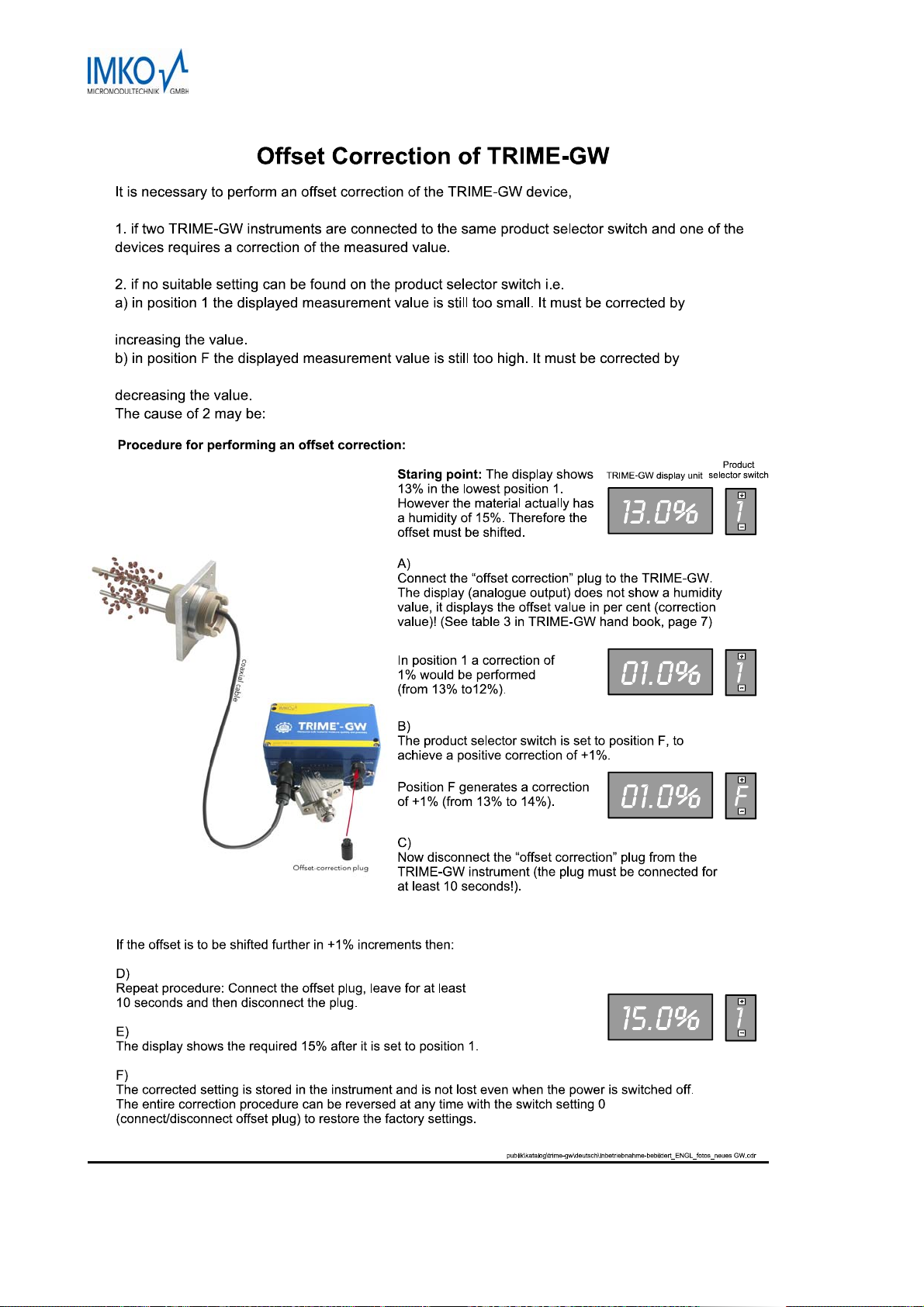

1.3.2 Offset-correction

The measurements taken by the TRIME-GW may vary slightly depending on the location of the

probe in the dryer because metallic components or hollow spaces (e.g. the dryer walls or baffle

structures inside the dryer) in the immediate vicinity of the probe may affect measurement. In

order to correct these installation-related but constant and reproducible errors, a so-called "offset-

_____________________________________________________________________________

6

Page 7

correction value" can be deposited in the TRIME-GW. This value is automatically added to every

measurement.

The offset-correction should only be done if the desired value can not be reached by using the

product selector switch!

The offset-correction value can be altered as follows by inserting the "TRIME-GW offsetcorrection" plug:

1.

Insert the plug into the TRIME-GW's configuration socket. The offset-correction value can now

be selected at the product selector-switch according to the following table. The selected value

is presented at the analogue output (or on the LED display in the measuring station). Each position of the product selector-switch corresponds to a particular offset-correction value.

Table 3

Switch position Offset-correction value

0 Restore to factory setting

1 -1.0 %

2 -0.8 %

3 -0.6 %

4 -0.4 %

5 -0.3 %

6 -0.2 %

7 -0.1 %

8 0.0 %

9 +0.1 %

A +0.2 %

B +0.3 %

C +0.4 %

D +0.6 %

E +0.8 %

F +1.0 %

2. As soon as the plug is removed, the value currently set at the product selector-switch is adopted. If the plug is removed when the switch is on 0 the offset-correction value is erased and the

factory setting restored.

3. After changing the offset value reset the setting of the product selection switch back to the

initial setting before aligning the Offset!!!

If it is necessary to enter correction values greater than 1% or intermediate values not shown in

the table, the process can be repeated a number of times. A shifting of 0.5% can, for example, be

achieved by 0.2% + 0.3%.

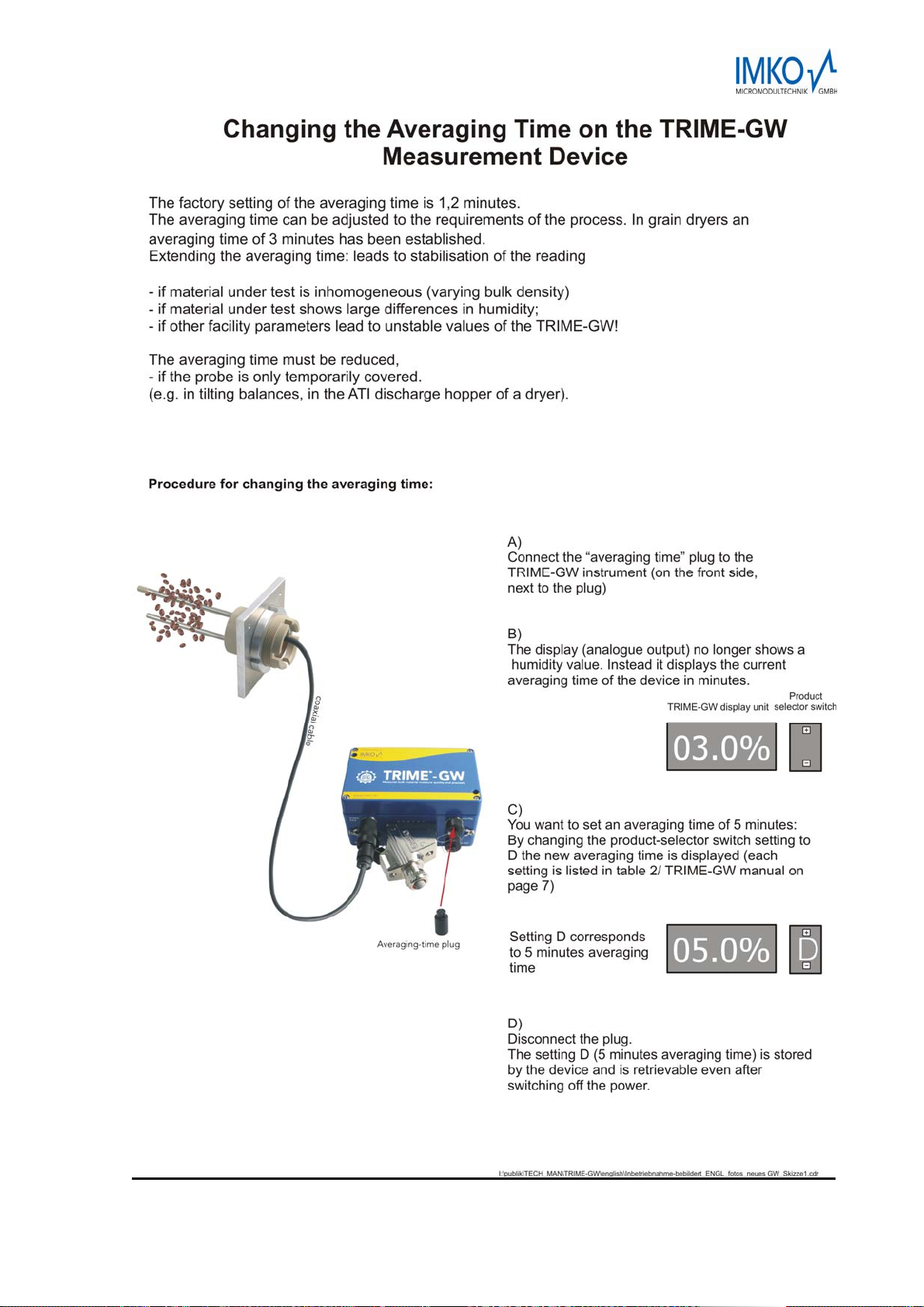

1.3.3 Averaging time

The TRIME-GW detects a new reading every half-second and, at the same intervals and via the

analogue port, outputs the appropriate mean value of the readings spanning a predetermined

period. The averaging time, therefore, is the equivalent of the TRIME-GW's "memory". The longer

the selected period, the more sluggish the reaction time when grain of varying degrees of moisture flows past the probe. A long averaging time thereby leads to a more stable reading as well.

This is of particular importance when operating the TRIME-GW in dryers so that fluctuations in

readings caused by the varying moisture in grain layers can be compensated for.

The factory setting of the averaging time is 3 minutes. This is a proven setting for grain dryers. If a

faster reaction in your application is necessary a lower value should be selected. Scattering of the

displayed moisture value can be prevented by a higher averaging value.

The averaging time can be changed as follows by connecting the "TRIME-GW averaging time"

plug:

Insert the plug into the TRIME-GW's configuration socket. As soon as the plug is connected,

1.

the prevailing measurement appearing at the analogue output (or on the LED display in the

_____________________________________________________________________________

7

Page 8

measuring station) is replaced by the currently set averaging time as per the following table.

Each position of the product selection switch corresponds to a particular averaging time. If the

configuration plug is now removed again, no alteration will be made to the averaging time

stored in the instrument.

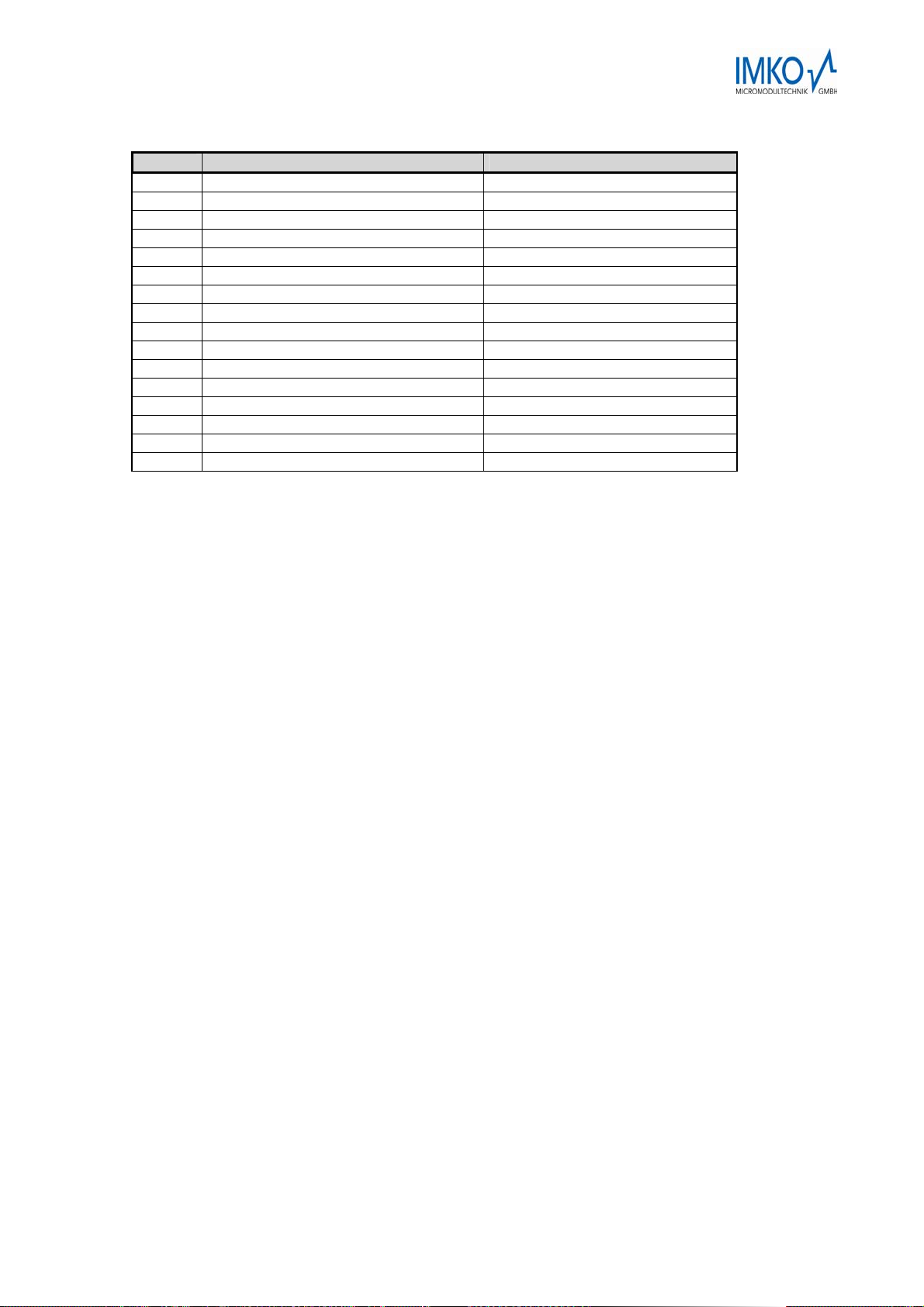

Table 2

Switch position Averaging time Field of application

0 previous setting remains unchanged

1 0.1 min = 0.5 s

2 0.1 min = 6 s Moisture measurement upon delivery

3 0.2 min = 12 s

4 0.3 min = 18 s

5 0.4 min = 24 s

6 0.6 min = 36 s

7 0.8 min = 42 s

8 1.0 min Moisture measurement in the dryer

9 1.2 min or in the grain silo

A 1.5 min

B 2.0 min

C 3.0 min (Factory setting)

D 5.0 min

E 10.0 min

F 20.0 min

2. As soon as the product selector-switch is changed for the first time, the corresponding averaging time can be read from the display.

3. As soon as the plug is removed, the value currently set at the product selection is adopted by

the instrument. If the plug is removed when the switch is on 0, the internal setting remains unaltered.

1.3.4 Calibration and temperature compensation exchange

The calibration for all 15 positions of the product selector-switch can also be replaced. This is,

however, only necessary for special materials. It can be done simply by inserting the appropriate

calibration plug. The plug must only remain connected for 10 to 15 seconds. The instrument extracts the data from the plug and transfers them to its internal memory.

The temperature compensation can also be changed or even deactivated by an appropriate calibration switch. If the probe must necessarily be installed in the heated inlet air zone a deactivation

of the temperature compensation can be necessary.

The calibration plugs are available as accessories. Alternatively, calibrations and temperature

compensation can be exchanged by a Windows95/98 software.

_____________________________________________________________________________

8

Page 9

1.4 Instrumentation

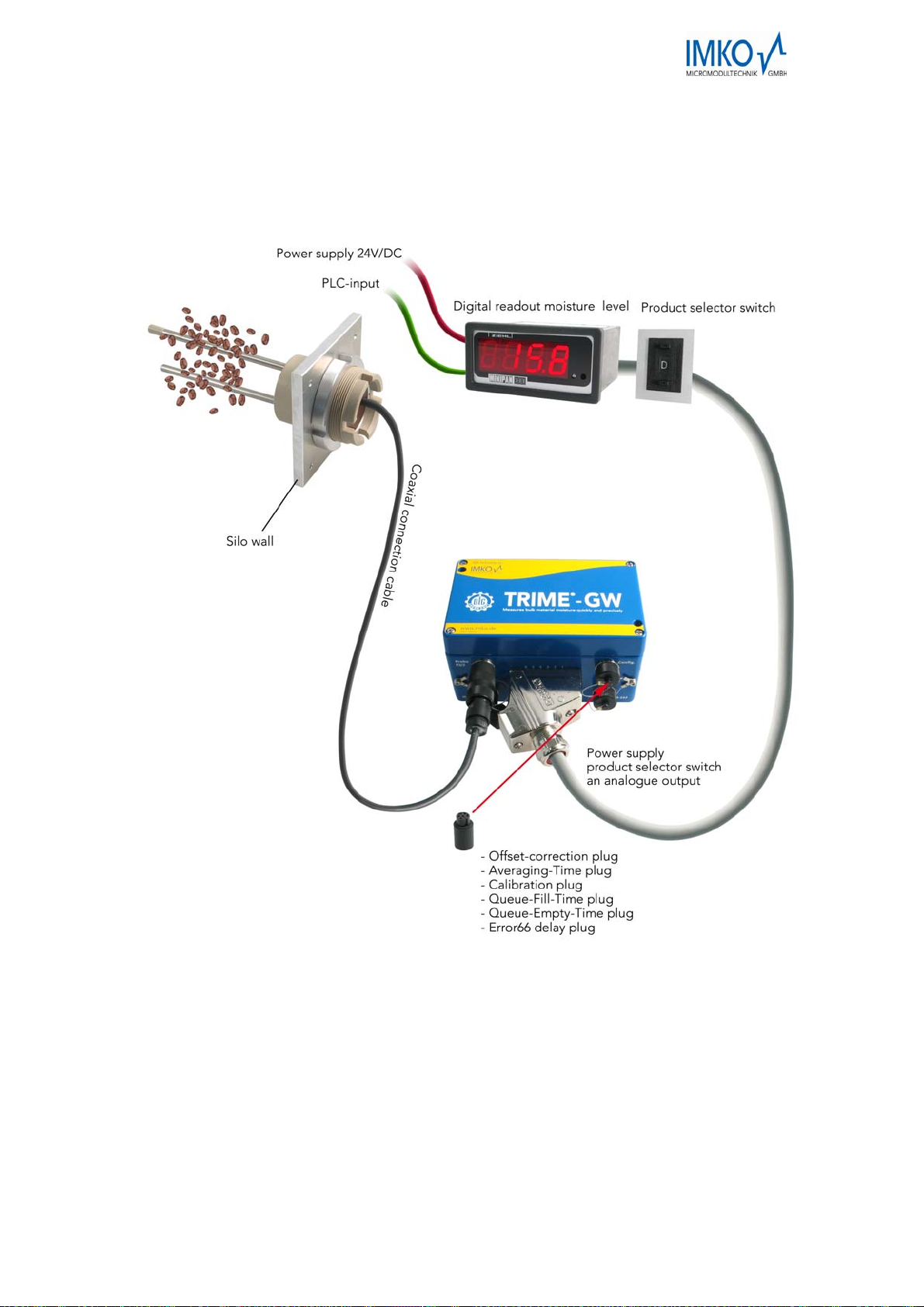

Figure 1: The TRIME®-GW components

®

The TRIME

-GW system comprises the actual measurement transformer in a aluminium die-cast

casing and the measuring probe that is connected to a coaxial cable over 2.5 m long. A display

unit that can include the product selector-switch is connected to present the readings.

Also available as an optional extra is the connection to a controller, a PLC, a PC or a line printer.

_____________________________________________________________________________

9

Page 10

1.5 Connections

1.5.1 Connector for strip terminals

The 12-pin connector (male) allow connection of the screw connector block to an SPS via the 12pin connector (female) and ensure the protection level IP65 (dustproof, splash-proof) once installed. A detailed pin assignment you’ll find on page Fehler! Textmarke nicht definiert.Fehler!

Verweisquelle konnte nicht gefunden werden..

Table 4

Contact Term Explanation

1 +Vs Positive pole for the power supply

2 R/T IMP-bus signal, for PC communication

3 0V Negative pole for the power supply

4 COM IMP-bus signal, for PC communication

5 SW Switch output for the product selector-switch

6 S0 Switch input for the product selector-switch (Binary digit 20, least significant bit)

7 S1 Switch input for the product selector-switch (Binary digit 21)

8 S2 Switch input for the product selector-switch (Binary digit 22)

9 S3 Switch input for the product selector-switch (Binary digit 23, most significant bit)

10 Ana GW + Positive pole analogue output, 0(4) .. 20mA

11 Ana GW - Negative pole analogue output, 0(4) .. 20mA

12 Halt M Input signal to stop the measurement

1.5.2 The probe connector (Probe)

A dust- and splashproof Binder-connector for connecting the coaxial cable to the measuring probe. Only the probe calibrated for this instrument can be connected. The number in the ca-

ble support sleeve must correspond to the serial number printed on the instrument. Probes and cables from different instruments are not to be interchanged.

1.5.3 The configuration connector (Configuration)

With the help of this connector, the application parameters of the instrument can be changed

without having to connect a PC (see page 6).

1.5.4 The RS232 connector (RS-232)

A PC can be hooked up to this connection via an RS232 cable (IMKO accessory) for configuration-, calibration and diagnosis purposes.

1.5.5 The IMP-Bus connector (IMP-Bus)

Electrical connection via Central Module SM-23U.

_____________________________________________________________________________

10

Page 11

1.6 Connections TRIME®-GW

Probe connector

Configuration

connector

Grounding

IMP-Bus connector

Pin 1

+Vs

2 R/T

3 0V

4 COM

RS232 connector

Pin 1 N.C.

2 TxD

3 RS GND

4 RxD

12-pin connector (male)

see detailed pin assign-

ment on page 16.

_____________________________________________________________________________

11

Page 12

1.7 The probe

1.7.1 The rod probe GR

The GR probe comprises a cylindrical probe-head made of a heat-resistant special-purpose plastic that has a threaded bore for mounting on silo- or housing walls. The actual measuring probe

consists of two parallel, steel prongs that are set into this probe head. The area relevant for moisture measurement surrounds the prongs.

Figure 2: TRIME®-GR

1.7.2 The surface probe GS1

The GS probe has been specially designed for use in areas where probe prongs cannot be inserted into the produce to be measured. The measuring electrodes in this probe are sunk into a

rectangular plastic panel. This enables it to be fitted in such a way that it practically becomes a

single entity with the vessel walls, without any protruding elements.

Figure 3: TRIME®-GS1

Probes and cables from different instruments are not to be interchanged as this may otherwise lead to discrepancies and deviations in measurements. Please note the serial number labels!

_____________________________________________________________________________

12

Page 13

v

2 Installation

The conditions for installation depend heavily on the characteristics of the plant. The optimum

location must be sought for each case individually. The following guidelines will be of assistance.

2.1 Probe installation

The probe must be fitted in such a way that the prongs protrude into the interior of the dryer or

silo. Reliable measurements can only be ensured when the prongs are fully immersed in grain.

Therefore, a location for installation must be chosen where ...

the full length of the prongs is covered by and in contact with grain.

hollow spaces cannot occur in the direct vicinity of the probe prongs (at least 5 cm from the

prongs).

the prongs are in the stream of exhaust (outlet) air. The temperature compensation fails in the

inlet (heated) air zone.

metallic objects, e.g. channelling panels in dryers, are at least 5 cm from the prongs. Meas-

urement anomalies caused by metallic objects can be eliminated by offset-correction (see

page Fehler! Textmarke nicht definiert.).

no temperatures above 120°C occur.

In continuous-flow dryers, the best place for optimum regulation is at the end of the drying

zone. Regulation can, of course, be further improved by installing additional probes in the drying

zone and at the end of the cooling zone. The final moisture content at the end of the drying process can be best monitored when a probe is fitted at the discharge point as well.

Exhaust

roof

s

u

r

a

e

m

grain flow

e

m

m

e

a

s

u

r

e

e

n

t

f

i

e

l

d

TRIME-GR

m

e

n

t

f

l

d

i

e

grain flow

entilation

roof

Figure 4: A schematic diagram of a roof-dryer (exhaust side !) with a fitted probe. The elliptical area

represents the measuring range of the TRIME

ishes the greater the distance from the probe.

Nevertheless, the measurement range can extend into the area of the ventilation roofs where

there is no grain. This means that the reading includes a proportion of air in the measurement

volume and thus the resultant relative water content is too low. This constant, location-specific

offset can be compensated for by offset-correction (see section Fehler! Verweisquelle konnte

nicht gefunden werden.).

®

-GW probe. The field of measurement dimin-

_____________________________________________________________________________

13

Page 14

In the c

veying speed is lowest. We recommend installation in the reservoir or close to the discharge

point.

Probe installation can be carried out in the following steps:

1. Drill a 72 mm – diameter hole in the container wall or cut out a square hole using an angle-

2. Secure the aluminium flange to the wall with four M5 screws (Cut M5 threads into the wall).

3. Screw the probe into the flange as far as possible.

4. Use the locknut to secure the probe in such a way that the prongs are set slight past vertical

ase of rotary dryers and delivery points, the probe should be fitted where the grain con-

grinder.

(10° to 15°).

Important: Under no circumstances is the probe to be connected to

the instrument while being installed as the electronics may

be destroyed otherwise!

2.2 Instrument installation

The TRIME®-GW must be installed in the vicinity of the probe as the length of the probe cable is

only 2.5 m for technical reasons. The temperature of the surroundings should, however, not exceed 60°C (ideal: outgoing-air end, external wall of dryer). The instrument can be mounted at a

suitable point with screws through the two diagonally-opposed holes in the casing. An aluminium

mounting-plate is available as an optional extra.

If the instrument is to be mounted on a surface whose temperature exceeds 60°C, it must be fitted using spacing bolts (min. 8 mm) to prevent the direct transfer of heat from the wall to the instrument casing.

The instrument should not permanently be exposed to direct precipitation, although it is specified

to IP65. For outdoor usage it should be mounted below a protection roof, e. g. a horizontal mounted plate.

Distance 8 mm

_____________________________________________________________________________

14

Page 15

2.3 Wiring

First of all, connect the probe to the instrument using the black coaxial connection lead. When

doing so, make sure that the serial numbers on the probe, the cable and the instrument are identical to each other to ensure reliable readings.

As shown in Figure 1 (Page 8), power is supplied via the screw connector block, the product selector-switch connected and the measurement extracted via the analogue output (0(4)..20mA).

The illustration shows how two instruments are connected in cascade. This method significantly

reduces the amount of wiring required if several (up to four) instruments are to be connected.

The two connection ports R/T and COM should also be wired up this point even if no computer

link is planned for the time being. Measurement extraction by PC or connection of a PC for the

purposes of diagnosis can be realised, later on too, by connecting a conversion module SM-23U.

2.3.1.1 Integration into the existing system-electronics

Instead of implementing the TRIME®-GW independently for monitoring purposes, it can also be

integrated into existing systems. For example, a programmable logical controller (PLC) can extract the readings from the current output 0(4)..20mA. The function of the product selector-switch

can also be taken over by another electronic system (e.g. PLC) that has relay outputs. Relay contacts between the connection SW and the inputs S0 to S3 allow product selection as per the following table:

Table 5

Product selection SW – S3 SW – S2 SW – S1 SW – S0

0 open open open open

1 open open open closed

2 open open closed open

3 open open closed closed

4 open closed open open

5 open closed open closed

6 open closed closed open

7 open closed closed closed

8 closed open open open

9 closed open open closed

A closed open closed open

_____________________________________________________________________________

15

Page 16

B closed open closed closed

C closed closed open open

D closed closed open closed

E closed closed closed open

F closed closed closed closed

Figure 5: Circuit diagram

Product monitoring switch

S0 (yellow)

S1 (white)

+

6

-

SW (pink)

S3 (black)

S2 (grey)

Ana + (purple)

Ana - (white/green)

12pin connector at

TRIME-GW case

+Vs (red)

R/T (green)

0V (brown)

COM (blue)

SW (pink)

S0 (yellow)

S1 (white)

S2 (grey)

S3 (black)

Ana + (purple)

Ana - (whi te/gre e n)

HALT-M (white/ yellow)

1

2

3

4

5

6

7

8

9

10

11

12

15.8%

Dis pl ay or

SPS-input

0(4)...20mA

Tapping point for

analogue input

or voltage input

via shunt resistor

to SPS control unit

Inp u t sign al to st op th e me a su re me n t,

if it is no or to less material in the

meas uring field of the GW probe.

E.g. Bz SPS control,

Z.B. durch SPS, level indicator.

Voltage > 4,5V= Stop meas urem ent

(adverse 0V = pin 3)

J:\dtp_prod\trimegw\an2xgw-Englisch-Neu-blaues Gehäuse.cdr

HALT-M

+Vs (red)

0V (brown)

Power

supply

+24V/DC

R/T (green)

COM (blue)

PC-connection

via SM- 23U

modul

(IMP-Bus)

for adjustment

parameters etc.

line c onf ig uratio n 12 or 18 wire

1 = +Vs (red)

2 = R/T (green)

3 = 0V (brown)

4 = COM (blue)

5 = SW (pink)

6 = S0 (yellow)

7 = S1 (white )

8 = S2 (grey)

9 = S3 (black)

10 = Ana + (purple)

1 1 = Ana - (white/green)

12 = HALT-M (white/yellow)

_____________________________________________________________________________

16

Page 17

3 Initial operation and handling

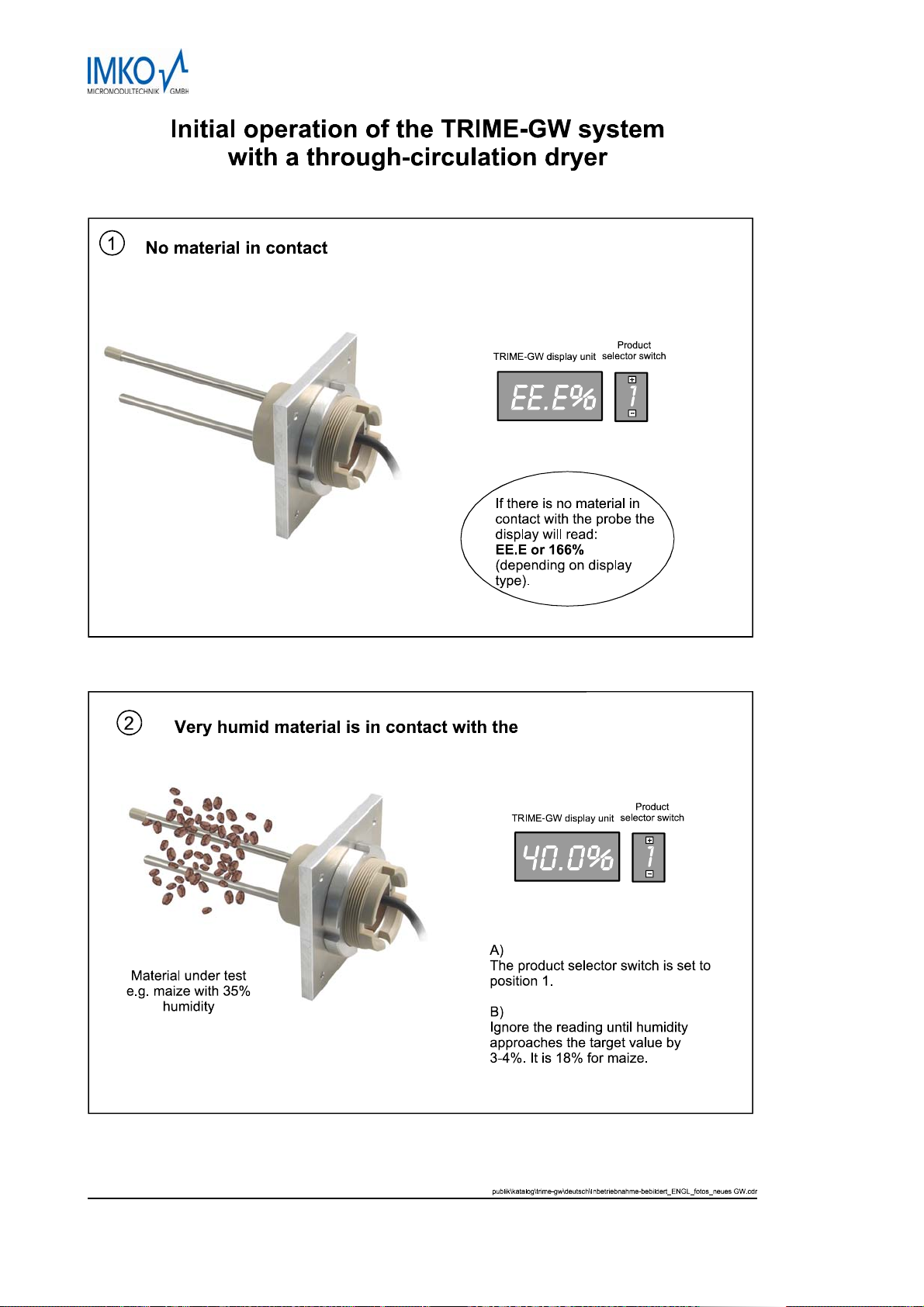

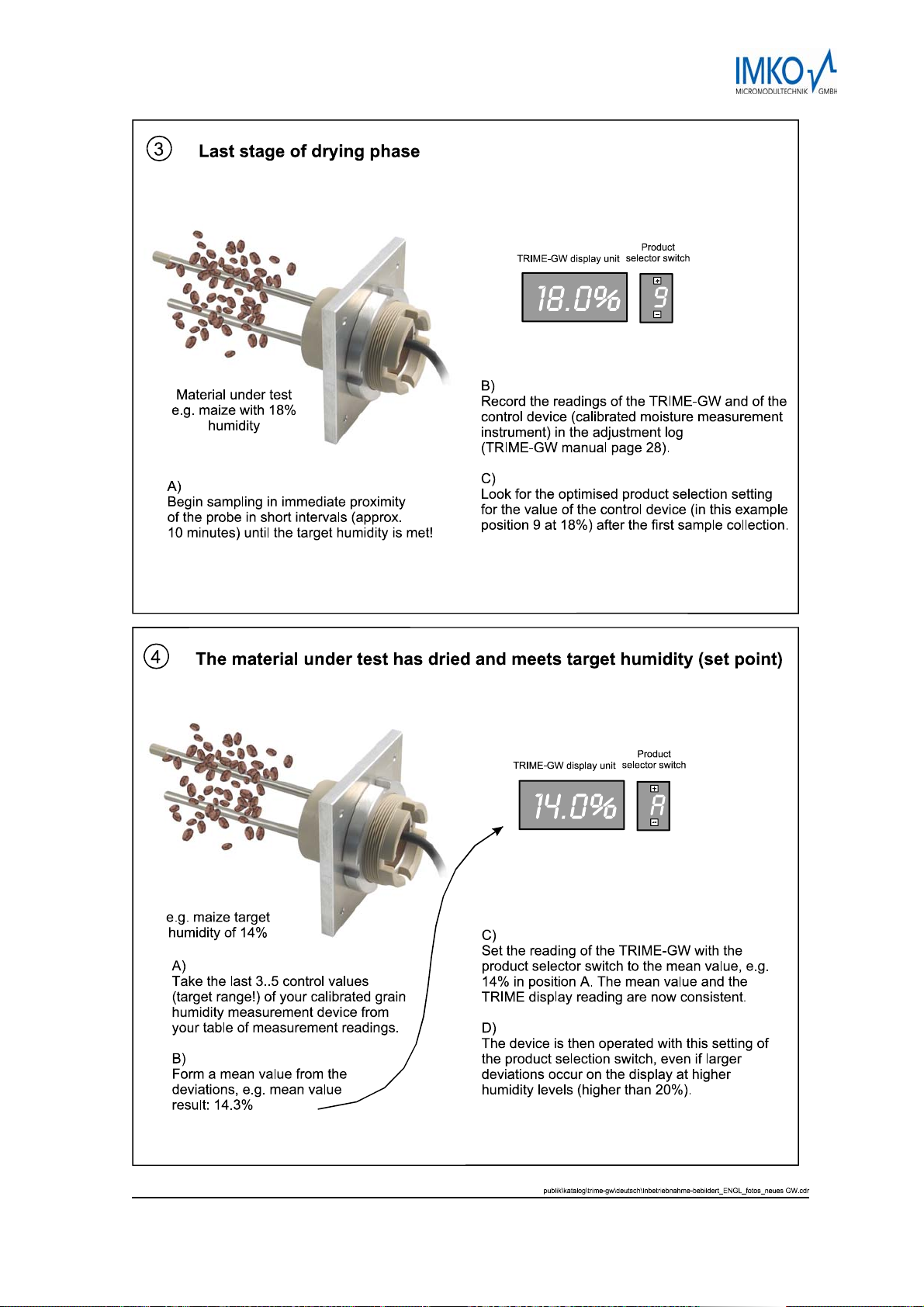

3.1 Adjustment guidelines

Please read the detailed description first and subsequently use these guidelines as a checklist for

adjustments.

Extract samples from as close as possible to the probe.

Select switch position 1 on the product selection switch and do not change the setting

from this position until the moisture is near the target moisture (e.g. 3% above)!

Start up the dryer for the trial run, extract reference samples continuously approx.

every half hour and enter the reading together with the switch position in the adjustment protocol (Page 30).

As soon as the grain moisture has fallen to 3%

above the target value (for continuousflow dryers when the start-up phase is finished), extraction of reference samples must

be stepped up to take place at 15 minute intervals.

When drying is finished, the correct setting on the product selection switch must be

determined from the last reference values (less than 3% above the target value).

3.2 Adjustments for initial operation

The TRIME®-GW can only be adjusted when installed in the plant as the location and the bulk density

of the grain have a significant influence on moisture measurement. Adjustment must be carried out

separately for every product. The term “adjustment” refers, in this case, to the correct setting of the

product selector-switch.

Moisture measurement is dependent on the following parameters:

Location (e.g. metallic objects within the field of measurement)

Bulk density of the grain

Type of grain (product)

As soon as one of these parameters changes, another adjustment must be chosen using the product

selector-switch. The setting only has to be adjusted during operation when the product changes because the influence of the location remains constant and the bulk density of a given product remains

more or less constant as well.

®

3.2.1 Adjustment for plants with several TRIME

When the plant is only equipped with one TRIME

®

-GW, adjustments are made for the installationrelated influences at the same time as those for the grain product. Exactly the same procedure can be

followed as described in the next sections (3 to 3.2.7).

In plants with several probes, it may also be necessary to correct the deviations between the TRIME

GWs themselves. This is good policy only when all the TRIME

urement. If the installation-related constant deviation of 1-2% presents no problem, it is sufficient to

make an adjustment using the most important probe, e.g. at the discharge point.

As usually only one product selector-switch is installed for all TRIME

taneously applies to all the TRIME

®

-GWs. To carry out the extended adjustment for all TRIME®-GWs,

three steps must be taken:

1. Firstly, the TRIME

®

-GW that is most important for the drying operation must be selected. The probe at the discharge point, for example, is a potential candidate. Whichever one is chosen, it must

be possible to extract samples directly at the point where this probe is located.

-GW

®

-GWs are to give an absolute meas-

®

-GWs, its setting always simul-

®

-

_________________________________________________________________________________

17

Page 18

2. This

TRIME

®

-GW must be set as described in section 3 to 3.2.7. Simultaneously, the measurement data for all the other instruments must be gathered, too (section 3.2.5). The samples for this

should be extracted from as near to the probe as possible.

Using the differences between the readings of each of the instruments, the TRIME

3.

®

-GW can be

adjusted using the offset-correction connector as set out in section Fehler! Verweisquelle konnte

nicht gefunden werden..

3.2.2 The product selector-switch

®

The TRIME

-GW is ideally suitable for relative measurements. It can measure differences in moisture

up to the nearest 0.1%. The product selector-switch must be correctly adjusted to be able to take absolute measurements. A selection can be made from 15 different levels (1 to F). Level 0 is reserved

for diagnosis purposes. The individual levels differ from each other by 1% with 20°C and standard

calibration for corn and cereal.

In Level 1, the highest measurement appears, suitable for the lowest possible bulk density.

Level F provides the lowest measurement, corresponding to the highest possible density.

The appropriate level on the product selector-switch must be selected depending on the grain to be

measured and its bulk density specific to the plant.

3.2.3 Selection and application of the reference method

®

In order to adjust the TRIME

-GW on-line, an off-line method of measurement must be available to

serve as a reference. It must provide a high degree of absolute precision and function with large sample volumes

Most commercially available grain-moisture measuring systems leave a great deal to be desired regarding both of these aspects!

®

The TRIME

-GW measures the average value continuously over a volume of 1-2 litres. In moving

grain, the measurement volume acquired in the averaging time increases many times over. It therefore requires a lot of time and effort to check this very representative value with a reference instrument

that shows a sample quantity in the millilitre range. There are also factors that can affect measurement, such as temperature and conductivity, that can be ignored when using TRIME

®

-GW because of

the TDR method of measurement.

Thus, the most suitable method for determining the exact moisture of the grain is to use a drying oven.

Here, too, the sample volume is of decisive importance and should be at 0.5 litres.

When extracting the sample and taking reference measurements, the following must be observed:

The samples for the reference measurements should be extracted from as close as possible

to the probe. The distribution of moisture in the grain dryer can vary greatly.

When using a calibrated instrument with small sample volumes, several samples must be ex-

tracted and their arithmetical average calculated.

Please note that calibrated instruments can also produce incorrect measurements that can lie

between 2% in the lower and even 5% in the upper moisture range.

3.2.4 Initial operation

e the TRIME

Onc

the display type) should appear on the display as long as the dryer is empty or the probe prongs are

not completely immersed in grain. The current output of the TRIME

®

-GW has been turned on and after a few seconds, “EE.E“ or 166% (dependent on

®

-GW signalises this with a current

of 33.2 mA (or 30.56 mA at 4..20 mA).

After the dryer or the silo has been filled, the display must show a valid reading. The output current of

the TRIME

®

-GW is between 0 and 20 mA.

________________________________________________________________________________

18

Page 19

3.2.5 Recording measurement data in trial operation

The product selector-switch can only be adjusted in real operation or in realistic trial operation. The

following description is based on the implementation of the TRIME

®

-GW in a grain dryer as this in-

volves more complex adjustment than in the delivery or storage area.

As a general rule, only the moisture range close to the reference input is of significance for trial opera-

tion, i.e. when determining the switch position for maize, checking should be done at about 15%. It is

more important that the TRIME

importance whether TRIME

®

-GW is exactly correct in the lower area of measurement. It is of less

®

-GW measures 26% instead of 28% in the upper range! When extracting

a sample or checking the lower reference input (e.g. 15% ), a single sample is of course insufficient. A

single sample, possibly even extracted from quite a different point than in the direct vicinity of the probe, is not at all representative, i.e. several samples must be taken directly at the probe and averaged!

At the start of trial operation, the product selector-switch can be set to Level 1.

When all the preparations for extracting samples and measuring them have been made, the grain

dryer can be started up. Now, a sample of grain must be taken continuously, ideally every 15 minutes.

The TRIME

®

-GW reading and the selected switch position are to be noted simultaneously with

every extracted sample. This is compared with the appropriate offline-determined reference value,

which is also to be noted. As soon as the moisture is near the target moisture, the product selectorswitch should be set to the best possible value, which is the nearest to the reference value.

On page 30 you will find a ready-to-use form for entering the measurements.

Where continuous-flow

dryers are concerned, at least 10 to 20 measurements should be

available in the range between the minimum and maximum permissible moisture content after

drying. The measurements from the still very damp discharged grain during the charge phase

should be noted but not used for the purposes of adjustment.

For rotary dryers, only the measurements take towards the end of the drying process are of

relevance to adjustment. Here, too, at least 10 measurements are to have been documented.

Density and moisture distribution effects in the grain can cause too low measurements during

the first one to two hours. These values should not be used for the adjustment.

3.2.6 Setting the product selector-switch (adjustment)

The appropriate setting of the product selector-switch should be determined on the adjustment protocol. Only the measurements near the target moisture should be taken into account.

_________________________________________________________________________________

19

Page 20

3.2.7 An example

A continuous-flow dryer is to be set for maize. A TRIME

®

-GW has been installed whose probe is located in the direct vicinity of the discharge point. To start with, the product selector-switch is set to

Level 1. The dryer is started up and measurement recording commences. It is not until the moisture at

the discharge point falls below 18% that the measurements become of real interest and can be used

for the adjustment process. Analysis can start as soon as about 10 to 20 measurements are available

in the range from 12% to 18%. The following table shows that the best setting for the product selectorswitch is 7.

Table 6

Reference measurement TRIME-GW, Level 1 TRIME-GW deviation

17.9% 24.6% 1

17.3% 17.6% 8

17.8% 17.3% 8

17.1% 16.8% 8

16.8% 16.2% 8

16.5% 15.8% 8

15.8% 16.0% 7

15.1% 15.6% 7

14.5% 14.7% 7

13.9% 14.0% 7

13.3% 13.5% 7

________________________________________________________________________________

20

Page 21

3.3 Practical application

There is a variety of applications for the TRIME®-GW. On the one hand, it can be used for monitoring

the moisture of delivered grain. On the other, it can assist or automate the grain-drying process.

The appropriate position of the product selector-switch must be selected depending on the grain in

question and its density.

In-line measurement

of grain moisture

during the drying

process directly inside

the drying chamber.

T

R

I

M

E

-

G

W

Continuous monitoring

and recording during

grain deliv ery with

protocol print-out log issue

Networking via PC via

RS232/V24-interface for

processing the acquired

data in a grain mo isture

management system

T

R

I

M

E

-

G

Central Module

SM23U

RS232/V24

T

R

I

M

E

-

G

W

T

R

I

M

E

-

G

W

W

Integration into existing

control panels or

systems via standard

analogue interfaces

0...20 mA or 4..20mA

Figure 6: Schematic diagram of a drying plant showing possible applications of the TRIME-GW.

_________________________________________________________________________________

21

Page 22

3.3.1 Monitoring during grain delivery

The TRIME

®

-GW presents a means of continually measuring the moisture of the grain while it is being

delivered. This provides a moisture profile that can be recorded by a PC or a line printer. A display unit

can be connected as well for showing the values at any given moment. Legal regulations prevent TRI-

®

-GW being used instead of instruments that have been officially calibrated and authorised for

ME

goods traffic. The single measurements, usually based on very small samples, from such instruments

are supplemented by the continual, considerably more representative range of measurements taken

by the TRIME

®

-GW. This results in better quality control and enhances transparency.

3.3.2 Manual control of the grain dryer

In the case of manual or semi-automatic dryer-control systems, using the TRIME TRIME

®

--GW in

conjunction with a display unit can significantly improve drying results. Connecting a line printer or a

PC allows, in addition, the progression of drying to be documented and provides further potential for

optimising drying.

3.3.3 Automatic control of the grain dryer

®

This involves connecting the TRIME

eral TRIME

®

-GW in this case. The highest level of drying efficiency can be achieved in automatic con-

--GW to the controller’s actual-value input. It is ideal to use sev-

trol systems. We would be glad to assist you in selecting the most suitable controller for your particular

application.

________________________________________________________________________________

22

Page 23

4 Special functions

The possible adjustments and special functions of TRIME®-GW described in this section are only

likely to be required very rarely. Altering these settings or effecting the special functions may cause

the device to behave incorrectly!

The settings mentioned hereafter in this context can be changed by using:

a special configuring connector (available as an special accessory).

TRIME®-WinGWData Software (free of charge). Downloadable from our website:

www.imko.de

4.1 Operating the TRIME®-GW measurement systems in an intermittent

flow of material

A classic example of intermittent material flow is the use of the probe in the discharge chute, where

material is only present for a brief period shortly after a discharge. For this and similar cases, two options exist for controlling the measuring process:

1. Control of the measuring process via the adjustable internal time constants Queue-

FillingTime and Queue-DischargeTime in conjunction with the similarly adjustable internal

time constant Error66-Delay.

2. Control of the measuring process via an external digital input signal HaltM which, for example, can be produced by an PLC or a fill-level indicator.

4.1.1 Behaviour upon detection of air around the probe rods

®

The TRIME

rods. When this situation arise, the measuring process is stopped immediately and the existing reading “frozen”. After the adjustable time constant Error66-Delay has expired (cf. Table 1

the error 66: "Probe not fully immersed in grain" (cf. Table 1

is transmitted through the analogue output as "166.0". This is shown on the display unit as “E.EE” or

“166.0”, depending on the model.

Requiring special attention is the case where the periods in which the probe’s field of measurement

volume is only partially filled with the subject material, i.e. when the fill level “passes through” the probe’s field of measurement during filling or discharge. During these periods, the device would record an

excessively low reading because a proportion of the field of measurement is occupied by air, which

contains only negligible amounts of water. The materials’ characteristics differ too in their “dielectricity”

upon which water-content measurement is based. Individual readings such as these must therefore be

discarded and prevented from inclusion in the calculation of the overall measurement value.

This overall measurement value or reading is still carried out in the manner described as “fluid mean

value” in Section Fehler! Verw

Textmarke nicht definiert.. All that now has to be assured is that the determination of the mean value

is continued whilst using the set averaging time throughout the empty periods, and not started anew.

All that is not available during the empty period (plus the Queue-DischargeTime and the Queue-

FillingTime) are individual measurements that could contribute to the determination of the mean value.

The set “averaging time” is thus only composed of blocks of time in which valid individual

measurements can be taken.

-GW measurement system can detect when there is no more material around the probe

eisquelle konnte nicht gefunden werden. on page Fehler!

4.1.2 Control via the internal time constants Queue-FillingTime and Queue-

DischargeTime

During discharge, not only the measurement must be frozen after air around the probe rods has been

detected, but the individual readings of the past Queue-DischargeTim

_________________________________________________________________________________

e seconds, where the field of

23

Page 24

measurement was already less than full, must be discarded as well. Also, after the first wave of subject material has been detected around the probe rods, the individual readings of the future Queue-

FillingTim

e seconds must be discarded as well until the field of measurement is fully replenished

again.

The two time constants Queue-DischargeTime and Queue-FillingTime are adjustable and must be

determined by observing the relevant process.

If direct observation is not possible, suitable time constants can also be found by experimentation.

This can be done, for example, by determining those time constants from which point onwards no

further change can be detected in the reading when the discharge period starts or finishes. A certain

waiting period should also be added to the ascertained time values to be on the safe side and to absorb process fluctuations.

When performing a trial such as this, the subject material should be as homogenous as

possible and the averaging time low, though not less than 24s as the full functionality is

otherwise restricted (cf. Table 2

on page Fehler! Textmarke nicht definiert.).

It must be assured that an adequate measuring time remains for each measuring cycle during which

no individual readings are discarded. This is the reason why the two time constants cannot, in general,

be permanently set at their maximum value. This remaining time should not be less than 10s; 5s is

conceivable in extreme cases.

4.1.3 A side-effect when using the time constants Queue-FillingTime and Queue-

DischargeTime

The option of being able to discard individual past readings where required demands that a current

individual reading must first of all be temporarily stored until it becomes clear whether it is to be discarded or is to contribute to forming the mean value.

The (analogue or digital via PC) output reading is therefore “a glimpse into the past”:

under normal operation, the shift Queue-DischargeTime is a matter of seconds. In the transi-

tion from the "empty

phase" to the "full phase", individual seconds-long Queue-FillingTime

measurements are discarded first and then followed by the loading of seconds-long Queue-

DischargeTime intermediate memory, producing in this case a shift in seconds of "QueueDischargeTime + Queue-FillingTime".

4.1.4 Setting Queue-FillingTime

The Queue-FillingTim

e can be altered as follows by plugging in the configuration plug “TRIME

®

-GW

Queue-FillingTime”:

1. Insert the plug into the TRIME

®

-GW’s configuration socket. As soon as the plug is in place, the

analogue output (or the LED panel in measuring station) do longer displays the current measurement, but the current Queue-FillingTime setting in seconds as per the following table. Each position of the product selection switch corresponds to a certain Queue-FillingTime. If the configuration plug is removed at this point, the Queue-Filling Time stored in the unit will remain unchanged.

2. As soon as the setting/position of the product selection switch is changed for the first time, the

appropriate Queue-FillingTime value can be read on the display.

3. As soon as the plug is removed again, the unit adopts the value set at the product selection

switch. If the plug is removed when the switch is in the [0] position, the internal setting remains

unchanged.

________________________________________________________________________________

24

Page 25

Table 7

Queue-FillingTime/ Queue-DischargeTime Error66 delay Switch

0 Retain former setting Retain former setting

1 0.0 s (factory setting) 0.0 min = 0s

2 0.4s 0.1 min = 4s

3 0.8s 0.3 min = 20s (factory setting)

4 1.2s 0.7 min = 44s

5 2.0s 1.0 min = 60s

6 3.0s 1.5 min = 92s

7 4.0s 2.0 min = 120s

8 5.0s 3.0 min = 180s

9 6.0s 4.0 min = 240s

A 8.0s 5.0 min = 300s

B 10.0s 7.5 min = 452s

C 12.0s 10.0 min = 600s

D 14.0s 20.0 min = 1200s

E 16.0s 30.0 min = 1800s

F 20.0s 60.0 min = 3600s

4.1.5 Control via an external, digital input signal HaltM

The measuring process can also be halted by means of the external, digital input signal HaltM. This

interruption is immediate and is independent of control by the time constants Queue-FillingTime/ -

DischargeTime (see above). It is therefore theoretically even possible to combine the two means.

The appropriate signal can , for example, be created by an existing PLC that simultaneously operates

the discharge unit and therefore “knows” when material is present. At least just as suitable is a capacitive fill-level detector.

4.1.6 Electrical specification of the input signal HaltM / HaltM-In

The signal for halting the measurement process (HaltM) is transmitted from the PLC (or fill-level detector, etc.) to pin 12 (white/yellow) and looped from there through all the connected measuring transducers, thus making it available at each one.

®

The digital input directly to the TRIME

-GW measurement transducer’s 12-pin flanged bushing called

“HaltM-In” is hi-active and runs into pin 12 (white/blue) of each transducer (see also fig.5 on pg.16).

If this input is idle or has less than 0.7V above 0V (pin 22) running through it, a measurement is being

taken. If more than 3.8V (up to 24V and more) is applied, the measuring process is halted. Pin 22 (0V)

is identical to pin 3 (0V), i.e. the reference mass of the power supply.

HaltM-In (pin 21) of the measurement transducer is not wired as standard in the wiring-loom connector. If the control of the measuring process via HaltM is to be activated for one or more measuring

transducers, a bridge between the stated pin 21 (white/blue) and pin 19 (white/pink) must be created

in at least one of the cable connectors of this/these connector/s.

_________________________________________________________________________________

25

Page 26

4.2 Basis calibration after replacing system components

4.2.1 General notes regarding basis calibration

System components directly involved in the measuring process (probe, probe lead, transducer) are

aligned with each another by means of the basis calibration. Manufacturing tolerances influencing the

measurement reading are compensated for. New instruments are supplied with the basis calibra-

tion already performed. The process must be repeated if one of the system components mentioned above has been repaired or replaced. Calibration at the factory is not possible unless

the unit has been sent in with all components stated above.

Basis calibration involves taking two reference measurements in media of a known value ("reference

value") correcting any divergence of the unit from these reference values where necessary. TRI-

®

-GW calculates the correction values required for this ("offset" and "slope") itself and stored in

ME

non-volatile form in the instrument, i.e. they remain intact even when the power supply is switched off.

Air and dry glass beads are used as reference media.

The procedure is carried out using the GW basis-calibration set available as an optional extra and

comprising:

dry glass beads,

RS232 cable

Software WinCal

4.2.2 Reference values of the calibration media used for the basis calibration

The reference values listed below apply for the appropriate calibration media.

Table 10

Calibration medi-

um

Air -11.0 %

Dry glass beads +12.7 %

Reference value

before material calibration

and offset correction

(pseudo-transit time)

Permissible tolerance for test

measurements

0.5%

0.2%

4.2.3 Preparatory measures

The “dry glass beads” and probe required for the basis calibration must themselves be around room

temperature (18..24°C).

®

4.2.4 The procedure using the configuration plug “TRIME

-GW basis calibration”

1. To set the first reference value “air” the probe must be positioned in such a way that within a field

of at least 15 cm only air surrounds the probe rods.

It is by no means sufficient to place the probe on a table or something similar. The probe

Note:

can either be laid on the table so that the probe rods are fully overhanging the edge and the first

2..3 cm of the probe body are overhanging it as well. Alternatively, hold the it your hand at the

very rear (!) of the probe body to ensure that the hand does not invade the field of measurement

which also registers the front 3..4 cm of the probe body.

2. If the measurement was erroneous, the value “E.EE” is displayed instead of the reference value

"39.0". If this occurs, basis calibration must be repeated from step 1.

If the basis calibration procedure is not continued to take the second reference measure-

Note:

ment (“dry glass beads”) once the first reference measurement has been taken, only an offset correction has been performed, the slope remains unaltered. A “single-point basis calibration” such

as this can be used as a stopgap if no “dry glass beads” are available. A “two-point basis calibration” should be carried out later on though. Please also refer to the notes at the end of the section

on performing the basis calibration.

________________________________________________________________________________

26

Page 27

3. To obtain the second reference value “dry glass beads”, set the probe vertically into the vessel of

dry glass beads up to the lower rim of the probe body. Make sure that the probe lead exerts no

noticeable load on the probe when doing so in order to prevent creating an air space between the

probe rods and glass beads. Tap the outside of the vessel lightly to ensure that the beads sit

tightly around the rods. The glass bead vessel and the probe themselves must not be in contact

with any metal objec

ts (e.g. a metal table top).

Use only the glass beads we supply with the “calibration set” as otherwise completely dif-

Note:

ferent results may be obtained if others are used. The glass beads must be dry and clean and at

room temperature (18-24°C).

The probe, too, must be at room temperature as otherwise condensation may form on the probe

rods and thereby serious distort the results.

The diameter of the vessel used must be at least 18-20 cm; where probe rods are immersed completely, at least 3-4 cm must remain between the tips of the rods and the bottom of the vessel.

Reason:

The single-point correction shifts the measurement value by only one offset, the slope remains unchanged. In other words: the measurement value has been corrected only by a single additive constant (positive or negative), the sensitivity remains unchanged so the scale of the deviation can differ

depending on the moisture range in which the measurement is being taken.

The main factor influencing the offset is a differing length of the probe lead. The main factor influencing the slope is a differing length of the probe rods. There are, however, other parameters as well that

can influence both.

The single-point offset correction is to be regarded as no more than a stopgap because – arising from

the dielectric constant of air compared to that of the other material – it is not carried out in the range of

the target moisture for the material to be dried (generally ~8-14%) , but with a theoretical moisture

value of -11% (air). Deviations in the slope (sensor sensitivity) therefore have a considerably greater

effect at approx. 20 % on either side of a given moisture range.

1. If the readings deviate excessively from the reference values (cf. table at the top of section 4.2.2

Reference values of the calibration media used for the basis calibration), the basis calibration

must be repeated using the affected TRIME

®

-GW instruments.

_________________________________________________________________________________

27

Page 28

5 Technical data

Figure 7: Sizes and dimensions

connecting plug / screw connector

block:

power supply,

analogue output 0(4)..20mA

product selector switch,

IMP232-network bus.

Dimensions: 160 x 100 x 81 mm

________________________________________________________________________________

28

Page 29

Table 11

Power supply:

Power consumption:

Measuring range:

Standard deviation:

Repeatability:

Measurement transformer temperature range:

Probe temperature range:

Measuring period / -interval:

Interface:

Analogue output:

Cable length of probe:

Housing protection:

Probe protection:

9V..24V-DC

Dependent on the power supply:

200mA@24V-DC or 350..500mA@12..9V-DC

5..45 by

weight (b.w.) on a wet mass basis

(depends on the used material)

range 5..20 % b.w.: 0.6 % b.w.

range 20..45 % b.w.: 1 % b.w.

(depends on the used material)

0.3 % b.w. (depends on the used material)

-10..60 °C, extended range on request

0..127°C; temporarily up to 150°C

floating average with adjustable time interval (0.5s..20 min)

IMP232 MICRONET and RS232/V24

0 or 4..20 mA = 0 .. 100% gravimetric moisture

(max. load: 300 )

Standard 2.5m

Aluminium diecasting IP65

IP68 watertight casting

_________________________________________________________________________________

29

Page 30

6 TRIME-GW adjustment protocol

Serial number: ___________________

Installation location: ___________________

Product: ___________________

Plant: ___________________

Place: ___________________

Date Time Reference value of

the extracted sam-

ple

TRIME-GW reading Position of the

product selector-

switch

Comments

________________________________________________________________________________

30

Page 31

Notes

_________________________________________________________________________________

31

Page 32

________________________________________________________________________________

32

Page 33

_________________________________________________________________________________

33

Page 34

________________________________________________________________________________

34

Page 35

_________________________________________________________________________________

35

Loading...

Loading...