Page 1

Model CS670A01

Echo® Wireless Vibration Sensor, Intrinsically Safe

Installation and Operating Manual

For assistance with the operation of this product,

contact PCB Piezotronics, Inc.

Toll-free: 800-959-4464

24-hour SensorLine: 716-684-0001

Fax: 716-684-3823

E-mail: imi@pcb.com

Web: www.imi-sensors.com

Page 2

Service, Repair, and Return

Policies and Instructions

The information contained in this document supersedes all similar information that

may be found elsewhere in this manual.

Service – Due to the sophisticated

nature of the sensors and associated

instrumentation provided by PCB

Piezotronics, user servicing or repair is

not recommended and, if attempted,

may void the factory warranty. Routine

maintenance, such as the cleaning of

electrical connectors, housings, and

mounting surfaces with solutions and

techniques that will not harm the

physical material of construction, is

acceptable. Caution should be observed

to ensure that liquids are not permitted

to migrate into devices that are not

hermetically sealed. Such devices

should only be wiped with a dampened

cloth and never submerged or have

liquids poured upon them.

Repair – In the event that equipment

becomes damaged or ceases to

operate, arrangements should be made

to return the equipment to PCB

Piezotronics for repair. User servicing or

repair is not recommended and, if

attempted, may void the factory

warranty.

Calibration – Routine calibration of

sensors and associated instrumentation

is recommended as this helps build

confidence in measurement accuracy

and acquired data. Equipment

calibration cycles are typically

established by the users own quality

regimen. When in doubt about a

calibration cycle, a good “rule of thumb”

is to recalibrate on an annual basis. It is

also good practice to recalibrate after

exposure to any severe temperature

extreme, shock, load, or other

environmental influence, or prior to any

critical test.

PCB Piezotronics maintains an ISO9001 certified metrology laboratory and

offers calibration services, which are

accredited by A2LA to ISO/IEC 17025,

with full traceability to SI through

N.I.S.T. In addition to the normally

supplied calibration, special testing is

also available, such as: sensitivity at

elevated or cryogenic temperatures,

phase response, extended high or low

frequency response, extended range,

leak testing, hydrostatic pressure

testing, and others. For information on

standard recalibration services or

special testing, contact your local PCB

Piezotronics distributor, sales

representative, or factory customer

service representative.

Returning Equipment – Following

these procedures will ensure that your

returned materials are handled in the

most expedient manner. Before

returning any equipment to PCB

Piezotronics, contact your local

distributor, sales representative, or

factory customer service representative

to obtain a Return Warranty, Service,

Repair, and Return Policies and

Instructions Materials Authorization

(RMA) Number. This RMA number

should be clearly marked on the outside

of all package(s) and on the packing

Page 3

list(s) accompanying the shipment. A

detailed account of the nature of the

problem(s) being experienced with the

equipment should also be included

inside the package(s) containing any

returned materials.

A Purchase Order, included with the

returned materials, will expedite the

turn-around of serviced equipment. It is

recommended to include authorization

on the Purchase Order for PCB to

proceed with any repairs, as long as

they do not exceed 50% of the

replacement cost of the returned

item(s). PCB will provide a price

quotation or replacement

recommendation for any item whose

repair costs would exceed 50% of

replacement cost, or any item that is not

economically feasible to repair. For

routine calibration services, the

Purchase Order should include

authorization to proceed and return at

current pricing, which can be obtained

from a factory customer service

representative.

Contact Information – International

customers should direct all inquiries to

their local distributor or sales office. A

complete list of distributors and offices

can be found at www.pcb.com.

Customers within the United States may

contact their local sales representative

or a factory customer service

representative. A complete list of sales

representatives can be found at

www.pcb.com. Toll-free telephone

numbers for a factory customer service

representative, in the division

responsible for this product, can be

found on the title page at the front of this

manual. Our ship to address and

general contact numbers are:

PCB Piezotronics, Inc.

3425 Walden Ave.

Depew, NY14043 USA

Toll-free: (800) 828-8840

24-hour SensorLineSM: (716) 684-0001

Website: www.pcb.com

E-mail: info@pcb.com

Page 4

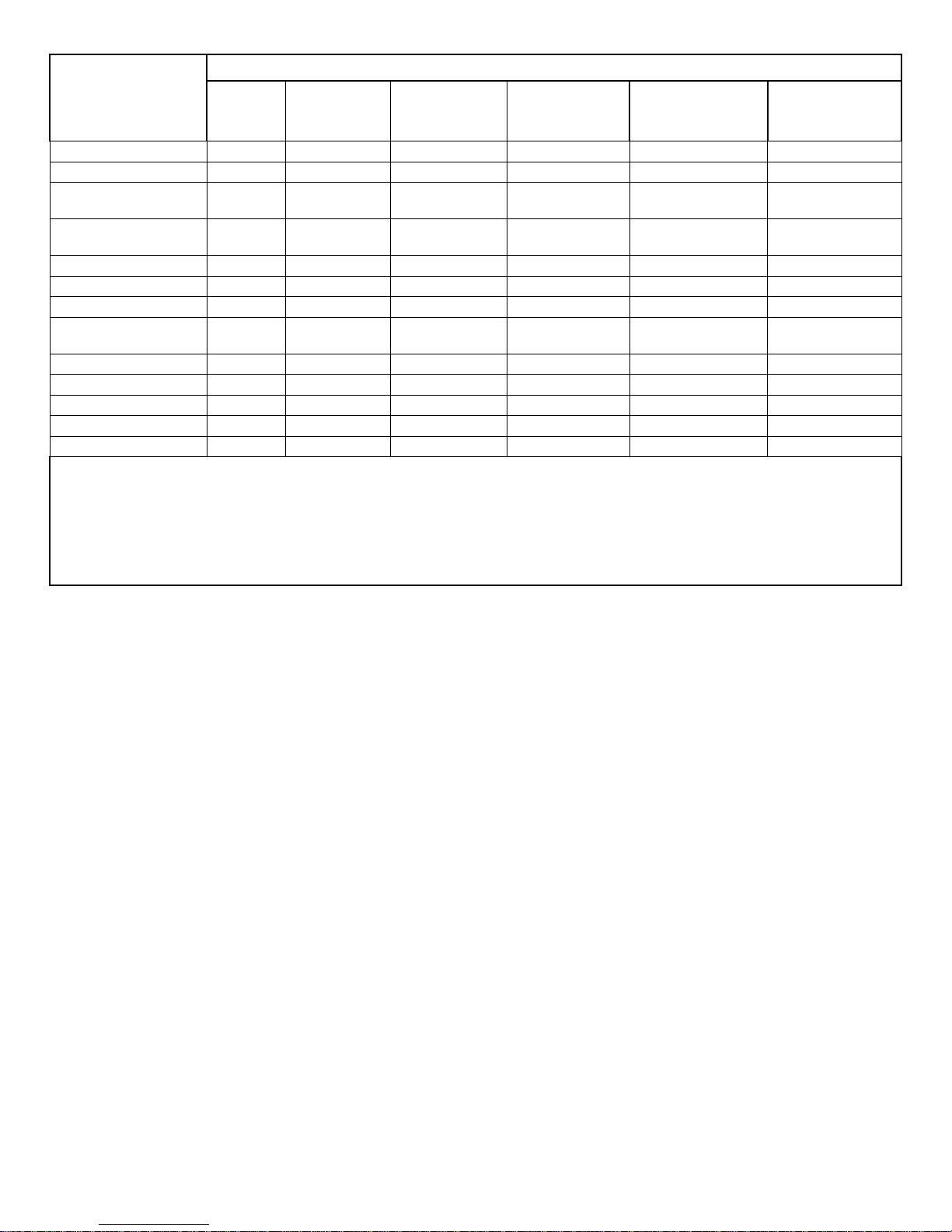

PCB工业监视和测量设备 - 中国RoHS2公布表

PCB Industrial Monitoring and Measuring Equipment - China RoHS 2 Disclosure Table

部件名称

有害物质

铅 (Pb)

汞

(Hg)

镉

(Cd)

六价铬 (Cr(VI))

多溴联苯 (PBB)

多溴二苯醚 (PBDE)

住房

O O O

O O O

PCB板

X O O

O O O

电气连接器

O O O

O O O

压电晶体

X O O

O O O

环氧

O O O

O O O

铁氟龙

O O O

O O O

电子

O O O

O O O

厚膜基板

O O X

O O O

电线

O O O

O O O

电缆

X O O

O O O

塑料

O O O

O O O

焊接

X O O

O O O

铜合金/黄铜

X O O

O O O

本表格依据 SJ/T 11364 的规定编制。

O: 表示该有害物质在该部件所有均质材料中的含量均在 GB/T 26572 规定的限量要求以下。

X: 表示该有害物质至少在该部件的某一均质材料中的含量超出 GB/T 26572 规定的限量要求。

铅是欧洲RoHS指令2011/65/ EU附件三和附件四目前由于允许的豁免。

CHINA RoHS COMPLIANCE

Page 5

Component Name

Hazardous Substances

Lead

(Pb)

Mercury

(Hg)

Cadmium

(Cd)

Chromium VI

Compounds

(Cr(VI))

Polybrominated

Biphenyls

(PBB)

Polybrominated

Diphenyl

Ethers (PBDE)

Housing O O O O O O

PCB Board

X O O O O

O

Electrical

Connectors

O O O O O

O

Piezoelectric

Crystals

X O O O O

O

Epoxy O O O O O O

Teflon O O O O O O

Electronics

O O O O O

O

Thick Film

Substrate

O O X O O

O

Wires O O O O O O

Cables X O O O O O

Plastic O O O O O O

Solder X O O O O O

Copper Alloy/Brass

X O O O O

O

This table is prepared in accordance with the provisions of SJ/T 11364.

O: Indicates that said hazardous substance contained in all of the homogeneous materials for this part is below the limit

requirement of GB/T 26572.

X: Indicates that said hazardous substance contained in at least one of the homogeneous materials for this part is above

the limit requirement of GB/T 26572.

Lead is present due to allowed exemption in Annex III or Annex IV of the European RoHS Directive 2011/65/EU.

DOCUMENT NUMBER: 21354

DOCUMENT REVISION: D

ECN: 46162

Page 6

Echo® Wireless Vibration Sensor

User’s Manual

Models: 670A01, RV670A01 and CS670A01

41967

Rev C

ECO#: 43669

Page 7

2

Table of Contents

FCC NOTICE ..................................................................................................................... 3

INDUSTRY CANADA (IC) NOTICE ............................................................................... 3

HAZARDOUS AREA USE ............................................................................................... 3

Introduction ......................................................................................................................... 4

Proper Handling .................................................................................................................. 4

Cap Material and Chemical Compatibility ......................................................................... 5

Magnet Switch and LED Status Indicator .......................................................................... 6

LED Status Messages ..................................................................................................... 6

Programming the Echo® Wireless Vibration Sensor .......................................................... 7

Programming................................................................................................................... 7

Connect the Echo® Programming Cable ........................................................................ 7

Connect to the Sensor with the Echo® Monitoring Software ........................................ 8

Click on Configuration on the menu bar. You should see a screen similar to the

following, and then click on Echo® EchoPlus® Sensors. .............................................. 8

Factory Defaults ............................................................................................................ 12

Explanation of Echo® Wireless Sensor Parameters ..................................................... 12

Parameters can be changed by using the up and down arrows or by typing the values in

the appropriate box. Click on the Set button by the parameter to actually program the

sensor. ........................................................................................................................... 12

Sensor ID ...................................................................................................................... 12

Transmission Interval.................................................................................................... 12

RVL (Residual Vibration Level) .................................................................................. 12

CF Report Threshold..................................................................................................... 12

Transmission Power ...................................................................................................... 13

Transmission Band........................................................................................................ 13

Saving Changes to the Echo® Sensor............................................................................ 13

Updating the Database to Match Sensor Programming ................................................ 14

RV (Raw Vibration) Option.............................................................................................. 15

Mounting ........................................................................................................................... 16

Outline Drawing (See Attachment) ..................................................................................

Preparing the Surface .................................................................................................... 17

Battery Pack ...................................................................................................................... 18

Battery Replacement Instructions ..................................................................................... 19

Echo® Wireless Vibration Sensor Manual

Version 1.2, 2011-12-07

Page 8

3

FCC NOTICE

FCC ID: ZOC-IMI670A01

This device complies with part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) This device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation.

Changes or modifications not expressly approved by the party responsible for compliance

could void the user's authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

INDUSTRY CANADA (IC) NOTICE

IC: 9732A-IMI670A01

Operation is subject to the following two conditions: (1) this device may not cause

interference, and (2) this device must accept any interference, including interference that

may cause undesired operation of the device.

HAZARDOUS AREA USE

Warning- Explosion Hazard- Do Not Disconnect or connect while circuit is live unless

area is known to be non-hazardous. Batteries must not be changed unless area is known

to be Non-Hazardous. Do not open when an explosive atmosphere may be present.

Substitution of components may impair suitability for Class I, Div 2.

Advertissment- Risque D’explosion – Ne pas debrancher ou brancher tant que le

circuitest sous tension. A moins qu’il ne s’agisse d’un emplacement non dangereux. Les

piles ne doivent pas etre remplacees a moins qu’il ne s’agisse d’un emplacement non

dangereux. N'ouvrez pas lorsqu'une atmosphère explosive peut être présente.

Remplacement de composants peut nuire à la conformité de Classe I Div 2.

Echo® Wireless Vibration Sensor Manual

Version 1.2, 2011-12-07

Page 9

4

Introduction

The Echo® Wireless Vibration Sensor, Model 670A01, is a stand alone, battery powered,

wireless, industrial vibration sensor. Its primary function is to monitor the vibration of

machinery in condition monitoring and predictive maintenance applications. The sensor’s

measurements are optimized to be sensitive to most common machinery faults such as:

unbalance, misalignment, looseness, bearing faults and gear faults.

Echo® contains a one-way wireless transmitter that is designed to “wake up” at

preprogrammed intervals, make a series of overall vibration measurements, transmit them

to a receiver for processing, and go back to sleep to conserve battery power. The sensor is

activated or deactivated using a magnet to operate a magnetic switch in the unit. When

activated, the sensor immediately makes and transmits a measurement set and then goes

to sleep until its next transmission time. The default transmission interval is 8-hours (3

times per day). An LED in the unit provides visual feedback on the state of the sensor: off,

on but in sleep mode, measuring, transmitting and changing states.

The transmitted data is received by an Echo® Receiver, decoded, and sent via Ethernet to

a computer or server running the Echo® Monitoring Software. For additional information

on the Echo® Receiver and the Echo® Monitoring Software, please refer to their

respective manuals.

The Model RV670A01 Echo® Wireless Vibration Sensor with RV (Raw Vibration)

Output operates identically to the standard model and additionally, provides the raw

vibration signal for detailed diagnostic analysis. The unit has a connector on the side and

can be used with an optional Model 070A86 Echo® RV Output Cable for analysis. See

the “RV (Raw Vibration) Option” section of this manual for additional information.

Proper Handling

Proper handling of the Echo® Wireless Vibration Sensor is critical to preventing damage.

The following should be avoided:

Dropping the unit.

Submersing the units in fluids of any kind.

Mounting the sensor by twisting the housing.

Exposing the unit to temperatures above 158° F.

Exposing the cap to any reactive chemicals.

Caution - The sensor cap is easily cross threaded. To avoid cross threading, press down

lightly on the cap to compress the battery securing foam. Turn the cap counter-clockwise

until a click is heard to line up the threads. Turn the cap slowly and carefully clockwise

until the cap contacts the housing. If the cap does not thread easily, do not force it.

Echo® Wireless Vibration Sensor Manual

Version 1.2, 2011-12-07

Page 10

5

Cap Material and Chemical Compatibility

Will Damage Polycarbonate

Require Caution

Considered Safe

Alkali bleaches such as sodium hypochlorite

Cyclohexanone

Acetic acid

Acetone

Diesel oil

Ammonium chloride

Acrylonitrile

Formic acid

Antimony trichloride

Ammonia

Gasoline

Borax in H2O

Amyl acetate

Glycerine

Butane

Benzene

Heating oil

Calcium chloride

Bromine

Jet fuel

Calcium hypochlorite

Butyl acetate

Concentrated perchloric acid

Carbon dioxide

Sodium hydroxide

Sulfur dioxide

Carbon monoxide

Chloroform

Turpentine

Citric acid 10%

Dimethylformamide

Copper(II) sulfate

Concentrated hydrochloric acid

Ethyl alcohol, i.e. ethanol 95%

Concentrated hydrofluoric acid

Ethylene glycol

Iodine

Formaldehyde 10%

Methanol

Hydrochloric acid 20%

Methyl ethyl ketone

Hydrofluoric acid 5%

Styrene

Isopropyl alcohol

Tetrachloroethylene

Mercury

Toluene

Methane

Concentrated sulfuric acid

Oxygen

Xylene

Ozone

Cyanoacrylate monomers

Sulfur

Urea

Water

The sensor cap is made from a translucent polycarbonate material. This material was

chosen because it is tough, allows the transmitted RF signal to radiate out of the sensor,

permits visual feedback provided by the imbedded blue status LED, and reduces the

passage of ultraviolet (UV) rays. However, like any “plastic” material, it is compatible

with some chemicals but not others.

Included here is a general chemical compatibility chart for polycarbonate material taken

from information on the Internet. This data is not guaranteed but is offered as a general

guide to chemical compatibility. It is highly recommended that you look up the

compatibility of you specific chemical with polycarbonate material. If polycarbonate is

not compatible with the processes in your plant, contact IMI for potential options.

Echo® Wireless Vibration Sensor Manual

Version 1.2, 2011-12-07

Page 11

6

Magnet Switch and LED Status Indicator

Blue LED Message

Sensor Status

Fast continuous blinking

Magnet switch is currently being activated.

4 second intermittent blink

Sensor is turned on and waiting for the next transmission.

8 second intermittent blink

Sensor is turned off and will not make measurements.

Dim illuminated LED

Sensor is currently measuring vibration levels.

Bright illuminated LED

Sensor is currently transmitting information to receiver.

The Echo® Wireless Vibration Sensor has a magnetic switch located inside the sensor

that is used to activate and deactivate the sensor. Hold a strong magnet next to the sensor

housing at the location indicated on the housing, see figure below, to operate the switch.

The blue LED light should begin blinking quickly within about 4 seconds. When it starts

blinking, remove the magnet from the sensor. If the sensor was previously deactivated it

will become active and immediately take a measurement. If the sensor was previously

active, it will deactivate and no longer take measurements. The blue LED light allows

the user to quickly determine the status of the unit by the time interval between blinks.

An active sensor will blink every 4 seconds while a deactivated sensor will blink every 8

seconds. Note: If the LED does not blink after holding the magnet next to the housing for

5 seconds, remove the magnet and try again.

LED Status Messages

Echo® Wireless Vibration Sensor Manual

Version 1.2, 2011-12-07

Page 12

7

Programming the Echo® Wireless Vibration Sensor

Programming

The Echo® Wireless Vibration Sensor can be programmed with a computer running the

Echo® Monitoring Software through a serial port. While this is a serial port in the sensor,

a micro USB connector is used in order to fit into the small space. A special (optional)

Echo® Programming Cable, Model 070A87, is required.

Note: If your computer is not equipped with a serial port, a USB to RS232 adaptor can be

used. These are readily available from computer electronics vendors.

Connect the Echo® Programming Cable

In general, the Echo® Programming Cable should be connected to the computer’s serial

port prior to connecting it to the sensor. When prompted by the Echo® Monitoring

Software to connect to the Echo® device (instructions below) use the following

procedure. Unscrew and remove the cap to expose the micro USB port inside the sensor,

see photos below. Carefully attach the programming cable to the sensor port (use a USB

to RS232 adaptor if necessary). If the Programming Cable is connected to the computer’s

serial port, the LED will blink 5 times indicating that it is connected and ready to

communicate.

Echo® Wireless Vibration Sensor Manual

Version 1.2, 2011-12-07

Page 13

8

Connect to the Sensor with the Echo® Monitoring Software

Launch the Echo® Monitoring Software. You should see a screen similar to the one

below.

Click on Configuration on the menu bar. You should see a screen similar to the

following, and then click on Echo® EchoPlus® Sensors.

Echo® Wireless Vibration Sensor Manual

Version 1.2, 2011-12-07

Page 14

9

You should see the following selections on the next screen. Click on ‘I want to add |

update | view and Echo® Sensors parameters’, then click on Next > at the bottom of

the screen.

Select the receiver where data from this specific sensor should be sent. This also, by

default, specifies the database where data from this sensor will be stored. The default

setting for a single receiver installation is shown below. After the receiver is selected,

click on Next >.

Echo® Wireless Vibration Sensor Manual

Version 1.2, 2011-12-07

Page 15

10

The software will then prompt for what system components will be changed as shown

below.

Note: If you are setting up your actual database, it is highly recommended that you

configure the Echo® Sensor and update the database together. By doing this, you are

guaranteed that the sensor and database parameters will be set to the same values. Some

important program information and alarms are based on theses settings. See the Echo®

Monitoring Software User’s Manual for setup details.

At this time, we will focus on programming the Echo® Sensor only. Select ‘I will only

configure the Echo® device at this time’ and click Next >.

When the following screen is displayed, make sure the Echo® Programming Cable is

connected to the computer, then; connect the micro USB connector to the sensor. After

the blue LED blinks 5 times, click OK.

Echo® Wireless Vibration Sensor Manual

Version 1.2, 2011-12-07

Page 16

11

The following connection window will appear. Select the appropriate COM port and

click on Link to Echo®.

Note: The Access Level is factory set and is not user selectable.

The green bar should illuminate indicating the connection has been made. The fields to

the right of the window will populate with the current programmed parameters.

Echo® Wireless Vibration Sensor Manual

Version 1.2, 2011-12-07

Page 17

12

Factory Defaults

The factory defaults are defined below unless otherwise specified. See the explanation of

the parameters below.

Sensor ID is a unique factory set number for each sensor and cannot be changed.

Transmission Interval = 8 hours

RVL = 0 (off)

CF Repot Threshold = 0.02

Transmission Power = High

Transmission Band = 1

Explanation of Echo® Wireless Sensor Parameters

Parameters can be changed by using the up and down arrows or by typing the values in

the appropriate box. Click on the Set button by the parameter to actually program the

sensor.

Sensor ID

The Sensor ID is a unique ID programmed into and etched onto each sensor at the

factory. This number cannot be changed.

Transmission Interval

The Transmission Interval is the time between transmissions of measured data.

The factory default is 8 hours. That means the sensor will “wake up” and make a

measurement every 8 hours (3 times per day). At the default 8 hour transmission

interval, the primary lithium-thionyl chloride (Li-SOCl2) batteries are expected to

last in excess of 5 years.

Note: Decreasing the transmission interval (i.e., increasing the number of

measurements per day) will not only reduce battery life but will also use more

receiver bandwidth. Thus, fewer sensors can be used with a receiver. See the

Echo® Receiver User’s Manual for guidelines regarding the number of sensors

that can be used per receiver.

RVL (Residual Vibration Level)

The RVL is an rms velocity level in ips (inches/second). If it is set to 0 (zero), the

feature is off and the sensor will wake up at the programmed interval, make

measurements, and transmit them. If a value is set, the sensor will wale up at the

programmed interval and start a measurement. If the rms velocity is ≥ the RVL,

the measurement and transmission will proceed as normal. If the rms velocity is <

the RVL, the machine is assumed to be off and the measurement is terminated.

This both conserves battery power and minimizes the transmission of “bad data”.

CF Report Threshold

CF (crest factor) is the ratio of true peak acceleration divided by rms acceleration.

For a sine wave, this value is 1.414. Echo® sensors high pass filter both the true

Echo® Wireless Vibration Sensor Manual

Version 1.2, 2011-12-07

Page 18

13

peak and rms acceleration measurements for better HFE (high frequency energy)

response. This type of filtered measurement generally provides an earlier warning

of bearing, gear, and other high frequency faults. It can also result in very low rms

acceleration readings (sometimes in the noise) for healthy machines, particularly

if they operate at slow speeds. The CF Report Threshold value is a minimum rms

acceleration level at which CF will be computed. If the rms acceleration is below

this value, CF is returned as zero.

Transmission Power

The Echo® Wireless Vibration Sensor transmits at 0.75 mW ERP (Effective

Radiated Power). In some cases, the sensor may be so close to the antenna and the

signal strength so strong, that the receiver will see “reflections” of the transmitted

signal. While this does not affect data accuracy, it can use unnecessary receiver

bandwidth to deal with the reflections. If the received signal from a sensor is > 65

dB, the Transmission Power should be changed from High to Low to eliminate

this problem. This will cause the transmitted power to be reduced by about 45 dB.

Transmission Band

The Echo® System can operate on 12 independent user selectable RF bands.

Sensors will only communicate with receivers that are set to the same band that

they are set to. This allows for large installations requiring hundreds or thousands

of sensors and in cases where distances are too far to be picked up by a single

antenna location.

Saving Changes to the Echo® Sensor

Click the Set button next to each field to be updated to program the value in the Echo®

Sensor. To verify the programming when all changes have been made, click the Read

Parameters button. When sensor programming is completed, click the X in the upper

right hand corner of the window.

Echo® Wireless Vibration Sensor Manual

Version 1.2, 2011-12-07

Page 19

14

Updating the Database to Match Sensor Programming

If the sensor has not been previously entered into the database, a message similar to the

following will be displayed. Click OK. For details on setting up the database, see the

Echo® Monitoring Software User’s Manual.

A screen similar to the following will be displayed. Ignore the screen and click Finish.

This will be used when you set up the actual database.

For complete programming options, see the Echo® Monitoring Software User’s Manual.

Echo® Wireless Vibration Sensor Manual

Version 1.2, 2011-12-07

Page 20

15

RV (Raw Vibration) Option

The Model RV670A01 Echo® Wireless Vibration Sensor with RV (Raw Vibration)

Output operates identically to the standard model, plus, it provides a raw vibration output

signal for detailed diagnostic analysis. The unit has a connector on the side of the housing

that can be used with an optional Model 070A86 Echo® RV Output Cable that provides

the analog acceleration signal directly from the embedded accelerometer.

The cable converts the standard constant current sensor power provided by most data

collectors to the low voltage supply required by the Echo® Sensor. To make raw vibration

measurements, remove the shorting cap on the RV output connector. Attach the 4-pin

connector on the cable to the RV output connector. Connect the BNC end to a data

collector and set sensor power to on in the data collector. The nominal sensitivity of the

raw signal is 100 mV/g and there is a ± 20 g range.

Note: Replace the shorting cap after raw vibration data is collected. Wireless operation of

the sensor will not work with it removed.

Echo® Wireless Vibration Sensor Manual

Version 1.2, 2011-12-07

Page 21

16

Mounting

The Echo® Wireless Vibration Sensor should be stud mounted on a clean, flat surface. It

is not recommended to mount the sensor with a magnet due to the size and mass of the

sensor. The correct mounting torque for the sensor is 3 to 5 ft-lb (4 to 7 N-m). It is also a

good idea to put a small amount of silicon grease on the bottom of the sensor before

mounting.

WARNING – Do NOT tighten the sensor by twisting on the housing. Damage to the

sensor WILL occur. Tighten to the correct torque using a wrench on the hex base.

Outline Drawing – See enclosed drawing

Echo® Wireless Vibration Sensor Manual

Version 1.2, 2011-12-07

Page 22

17

Preparing the Surface

If a clean, flat spot is not available on the machine, it is recommended to prepare a flat

machined surface using an optional IMI Model 080A127 1” spot face tool, shown below.

This tool will prepare a flat surface and drill the appropriate pilot hole for a ¼-28 UNF

thread. A ¼-28 tap is NOT included with the spot face tool.

If you are unable to use a spot face tool on the machine, optional Model 080A118

Mounting Pad can be epoxied on to the machine. Optional Model 075A05 Small Epoxy

Kit or Model 075A06 Large Epoxy Kit can be used to attach them to the machine.

Echo® Wireless Vibration Sensor Manual

Version 1.2, 2011-12-07

Page 23

18

Battery Pack

WARNING

Do NOT attempt to recharge batteries

Do NOT heat batteries above 212 °F (100 °C)

Do NOT attempt to replace with standard AA size batteries, they will not work.

Note: The Echo® Sensor uses two 3.6 V, A-size (not AA) primary lithium-thionyl

chloride (Li-SOCl2) high energy density, bobbin cell batteries in series that are NOT

rechargeable. Please contact IMI for replacements.

The Echo® Wireless Vibration Sensor accurately measures battery voltage during each

measurement cycle and transmits the battery status. The battery status is available for

display in the Echo® Monitoring Software. See the Echo® Monitoring Software User’s

Manual for details on monitoring the battery status. The following are recommended

actions based on battery status.

Note: The battery decline is not linear; it will be at a 3 level longer than a 2 level and at a

0 level the shortest amount of time.

3 = Battery is good

2 = Battery good but order replacement

1 = Replace the battery

0 = Battery bad, stop taking measurements with it until replaced

When a battery is required, it is recommended you order a Model 073A20 Echo®

Replacement Battery Kit, shown below. The kit includes a battery pack, 0-ring, silicon

grease, battery securing foam, and instructions.

Echo® Wireless Vibration Sensor Manual

Version 1.2, 2011-12-07

Page 24

19

Battery Replacement Instructions

1. Remove Cap

2. Unplug and remove battery pack

3. Remove O-ring and battery securing foam

4. Place the new O-ring on the housing

5. Place grease completely around the O-ring

6. Place grease on and around the barb on the inside of the cap

Echo® Wireless Vibration Sensor Manual

Version 1.2, 2011-12-07

Page 25

20

7. Place the battery securing foam on the barb in the cap

8. Plug in the new battery cap and place the battery pack in the housing

9. Screw cap onto the housing

a. Make sure that the foam is centered on top of the batteries.

b. Compress foam and hold so the threads of the cap and housing are touching.

c. Turn the cap counter clock wise unit you hear two clicks (This will prevent

cross threading)

d. Thread the cap on to the housing until it bottoms out.

Echo® Wireless Vibration Sensor Manual

Version 1.2, 2011-12-07

Page 26

Model Number

670A01

ECHO® WIRELESS VIBRATION SENSOR

Revision: D

ECN #: 47051

Performance ENGLISH S

I

RMS Velocity Frequency Range(± 3 dB) 4 to 2300 Hz 4 to 2300 Hz

[2]

Velocity HP Filter 2 Hz, 1-pole RC 2 Hz, 1-pole RC

Velocity LP Filter 2400 Hz,3-pole Chebyshev 2400 Hz,3-pole Chebyshev

Velocity Resolution 0.001 ips rms 0.025 mm/s rms

Velocity Range 4 ips rms 101.6 mm/s rms

RMS Acceleration Frequency Range(± 3 dB) 2.2 to 15 kHz 2.2 to 15 kHz

[2]

Acceleration HP Filter 2000 Hz,4-pole Chebyshev 2000 Hz,4-pole Chebyshev

Acceleration LP Filter

15k Hz, 3-pole Chebyshev + 1-

pole RC

15k Hz, 3-pole Chebyshev + 1-

pole RC

Acceleration Resolution 0.007 g pk 0.069 m/s² pk

[3]

Acceleration Range 20 g pk 196.2 m/s² pk

[3]

Transverse Sensitivity ≤ 7 % ≤ 7 %

Velocity Linearity(0-1 ips rms) <1 % <1 %

[4]

Velocity Linearity(0-4 ips rms) <8.5 % <8.5 %

[4]

Acceleration Linearity <1 % <1 %

[4]

Environmental

Overload Limit(shock) 1000 g pk 9810 m/s² pk

Temperature Range -4 to +158 °F -20 to +70 °C

Enclosure Rating IP66 IP66

Transmission Range

250 ft to>1 mile radius,

installation dependent

250 ft to>1 mile radius,

installation dependent

[1]

Electrical

RMS Velocity Analog Integration, FFT Sum Analog Integration, FFT Sum

RMS Acceleration

3.7 Sec time sample @ 61.4

kHz sample rate

3.7 Sec time sample @ 61.4

kHz sample rate

Filtered Crest Factor(max) 16 16

Frequency Band 900 MHz ISM Band 900 MHz ISM Band

Number of RF Bands 12 12

Maximum Power(ERP) 0.75 mW 0.75 mW

RF Data Rate 20 bps 20 bps

ADC/dynamic range 16 bit/>90db 16 bit/>90db

Battery Life(room temperature)

>5 years @ 3-measurements

per day

>5 years @ 3-measurements

per day

Electrical Isolation

>10

8

Ohm >108 Ohm

Physical

Power 7.2V Lithium Battery Pack 7.2V Lithium Battery Pack

Size (Hex x Height) 1.375 in x 4.40 in 34.93 mm x 111.8 mm

Sensing Element Ceramic Ceramic

Weight 1 lb 454 g

Sensing Geometry Shear Shear

Housing Material Stainless Steel Stainless Steel

Housing Diameter 1.66 in 42.0 mm

Mounting 1/4" - 28 1/4" - 28

[5]

Mounting Torque 3 to 5 ft-lb 4 to 7 Nm

Sealing O-Ring O-Ring

Sensor Activation/Deactivation Magnet Switch Magnet Switch

All specifications are at room temperature unless otherwise specified.

In the interest of constant product improvement, we reserve the right to change specifications without notice.

ICP

®

is a registered trademark of PCB Group, Inc.

OPTIONAL VERSIONS

Optional versions have identical specifications and accessories as listed for the standard model

except where noted below. More than one option may be used.

C

S

- Canadian Standards Association Approved Intrinsically Safe [6]

M - Metric Mount

Supplied Accessory : Model M081A61 Mounting Stud 1/4-28 to M6 X 1 (1)

NOTES:

[1]Typ

ical

.

[2] Upper frequency tolerance is ± 10% of the specified value

.

[3] Conversion Factor 1g = 9.81 m/s².

[4] Zero-based, least-squares, straight line method.

[5] 1/4-28 has no equivalent in S.I. units.

[6] CL 1, Div 2, Groups A, B, C, D, T5

SUPPLIED ACCESSORIES:

Model 081A40 Mounting Stud (1)

Entered: LK Engineer: BAM Sales: MC Approved: BAM Spec Number:

Date: 7/18/2017 Date: 7/18/2017 Date: 7/18/2017 Date: 7/18/2017

42657

3425 Walden Avenue, Depew, NY 14043

Phone: 800-959-4464

Fax: 716-684-3823

E-Mail: imi@pcb.com

Page 27

PCB Piezotronics Inc. claims proprietary rights in

the information disclosed hereon. Neither it nor any

reproduction thereof will be disclosed to others

without the written consent of PCB Piezotronics Inc.

6

2

REVISIONS

REV DESCRIPTION DIN

A UPDATED CAP 43669

1

6

9

1

4

B B

4.4 [112]

1.66 [42.0]Ø

1/4-28 UNF-2B x.20 [5.3]

.87 [22.1]Ø

n

1.50 [38.1] ACROSS CORNERS

1.375 [34.9] HEX

A A

1/4-28 UNF - 2B x .20 [5.3]

UNLESS OTHERWISE SPECIFIED TOLERANCES ARE:

DIMENSIONS IN INCHES

DECIMALS XX ±.03

ANGLES

XXX ±.010

`

2 DEGREES

FILLETS AND RADII

.003 - .005

DIMENSIONS IN MILLIMETERS

[ IN BRACKETS ]

DECIMALS X ± 0.8

ANGLES

XX ± 0.25

`

2 DEGREES

FILLETS AND RADII

0.07 - 0.13

2

DRAWN CHECKED ENGINEER

TITLE

01/23/15

BB

ECB

01/23/15

OUTLINE DRAWING

670A01

WIRELESS

BAM

01/23/15

3425 WALDEN AVE. DEPEW, NY 14043

(716) 684-0001 E-MAIL: sales@pcb.com

IDENT. NO.

52681

SCALE: SHEET

41966

1 OF 1FULL

DWG. NO.

CODE

1

Page 28

Certificate of Compliance

Certificate:

!"#"$#%

Master Contract:

$&#'&$

Project:

!"#"$#%

Date Issued:

()*+,-+./!$0/!%$#

121/3%4/5)67/!%$!8%38!! 9-:);/$

Issued to: Industrial Monitoring Instr. (IMI)

A Div. of PCB Piezotronics, Inc.

3425 Walden Ave

Depew, NY 14043

USA

Attention: Gordon Singh

The products listed below are eligible to bear the CSA

Mark shown with adjacent indicators 'C' and 'US' for

Canada and US or with adjacent indicator 'US' for

US only or without either indicator for Canada only.

!"#$%&'()

Issued by:

<-=>/?@AB

PRODUCTS

CLASS 2258 82

8/95C?DEE/?CFG5CH/D2IJ9KDFG/8/(L+/M-N-+OL,P/HL=-QALBP/8

?)+QARA)O/QL/IE/EQ-BO-+OP

CLASS 2258 02

8/95C?DEE/?CFG5CH/D2IJ9KDFG/8/(L+/M-N-+OL,P/HL=-QALBP

Class I, Division 2, Groups A, B, C, D:

KLO)S//TTUU"4%5VV//WA*+-QALB/E)BPL+0/*-QQ)+./LX)+-Q)O/47!/W/E-RQ/HAQ@A,Y/*-QQ)+./X-=>0/G)YX)+-Q,+)/?LO)/G3

-Q/-Y*A)BQ/Q)YX)+-Q,+)/+-B:);//Z/!%[?/QL/\/4%[?7

]@)+)/

TT/+)X+)P)BQP/Q@)/=)+QARA=-QALB/Q.X)7/TT/^/?E/_?E`/6)+PALBa0/DV/_`GDV/-BO/?E`/6)+PALBa

UU/+)X+)P)BQP/Q@)/L+O)+/R)-Q,+)P7//UU/^/bS-B>0/`0K077/////

5/+)X+)P)BQP/R-YAS./=LO)7/5^`0b0?0cccQL/d7

VV/+)X+)P)BQP/OARR)+)BQ/YL,BQAB:0/=-*SAB:0/-BO/-==)PPL+A)P/6-+A-QALBP7/VV^%$0%!/QL/''7

/FLQ)P;

DOC # 58443

REV: NR

ECO: 41674

Page 29

Certificate:

!"#"$#%

Master Contract:

$&#'&$

Project:

!"#"$#%

Date Issued:

()*+,-+./!$0/!%$#

121/3%4/5)67/!%$!8%38!! 9-:);/!

$7//////(L+/?-B-OA-B/JBPQ-SS-QALBP0/Q@)/P)BPL+/Y)Q-SSA=/@L,PAB:/Y,PQ/*)/*LBO)O/QL/:+L,BO/-==L+OAB:/QL/E)=QALB

$&8%4#/LR/Q@)//?D?/9-+Q/$8!%$!7

!7//////(L+/IE/JBPQ-SS-QALBP0/Q@)/P)BPL+/Y)Q-SSA=/@L,PAB:/Y,PQ/*)/*LBO)O/QL/:+L,BO/-==L+OAB:/QL/`+QA=S)/3%$7e%/LR

Q@)/FD?8!%$$7

///////

APPLICABLE REQUIREMENTS

?`Ff?E`8?!!7!/FL7/%8K'$//////////8//////////////g)B)+-S/5)h,A+)Y)BQP/Z/?-B-OA-B/DS)=Q+A=-S/?LO)0/9-+Q/JJ

?!!7!/FL7/$#!8K$'&4/////8//////////////9+L=)PP/?LBQ+LS/Dh,AXY)BQ

?!!7!/FL7/!$e8K$'&4/////8//////////////FLB8JB=)BOA6)/DS)=Q+A=-S/Dh,AXY)BQ/RL+/IP)/AB/?S-PP/J0/1A6APALB/!

M-N-+OL,P/HL=-QALB/////////////////////////

`FEJfJE`/$!7$!7%$8!%%4/8//////////////FLBAB=)BOA6)/DS)=Q+A=-S/Dh,AXY)BQ/RL+/IP)/AB/?S-PP/J/-BO/JJ0/1A6APALB/!/-BO

?S-PP/JJJ0/1A6APALBP/$/-BO/!/M-N-+OL,P/_?S-PPARA)Oa/HL=-QALBP

MARKINGS

8///////////?E`/KLBL:+-Y/]AQ@/?fIE/ABOA=-QL+7

8///////////E,*YAQQL+/JO)BQARA=-QALB

8///////////KLO)S/F,Y*)+

8///////////E)+A-S/F,Y*)+0/1-Q)/?LO)/L+/KLBQ@/-BO/i)-+/LR/K-B,R-=Q,+)

8///////////M-N-+OL,P/HL=-QALB/1)PA:B-QALB;/?S-PP/J0/1A67/!0/g+L,XP/`0/b0/?/-BO/1

8///////////j-+BAB:;/E))/Y-B,-SfWLA+/Y-B,)S

8///////////j-+BAB:/AB/(+)B=@/-BO/DB:SAP@;/DkXSLPALB/@-N-+O8/1L/BLQ/OAP=LBB)=Q/L+/=LBB)=Q/]@AS)/=A+=,AQ/AP/SA6)

,BS)PP/-+)-/AP/>BL]B/QL/*)/BLB8@-N-+OL,P7/b-QQ)+A)P/Y,PQ/BLQ/*)/=@-B:)O/,BS)PP/-+)-/AP/>BL]B/QL/*)/BLB8

@-N-+OL,P7

8///////////E))/K-B,-S/RL+/-OOAQALB-S/Y-+>AB:P/AB/(+)B=@/-BO/DB:SAP@;

////////////8/j-+BAB:;/DkXSLPALB/@-N-+O8/1L/BLQ/LX)B/]@)B/-B/)kXSLPA6)/-QYLPX@)+)/Y-./*)/X+)P)BQ7

////////////8/j-+BAB:;/DkXSLPALB/@-N-+O8/E,*PQAQ,QALB/LR/=LYXLB)BQP/Y-./AYX-A+/P,AQ-*ASAQ./RL+/?S-PP/J0/1A6APALB/!7

Loading...

Loading...