Page 1

Model 683A111001

Indicator/Controller (for use w/ ICP® sensors)

Installation and Operating Manual

For assistance with the operation of this product,

contact PCB Piezotronics, Inc.

Toll-free: 800-959-4464

24-hour SensorLine: 716-684-0001

Fax: 716-684-3823

E-mail: imi@pcb.com

Web: www.imi-sensors.com

Page 2

Service, Repair, and Return

Policies and Instructions

The information contained in this document supersedes all similar information that

may be found elsewhere in this manual.

Service – Due to the sophisticated

nature of the sensors and associated

instrumentation provided by PCB

Piezotronics, user servicing or repair is

not recommended and, if attempted,

may void the factory warranty. Routine

maintenance, such as the cleaning of

electrical connectors, housings, and

mounting surfaces with solutions and

techniques that will not harm the

physical material of construction, is

acceptable. Caution should be observed

to ensure that liquids are not permitted

to migrate into devices that are not

hermetically sealed. Such devices

should only be wiped with a dampened

cloth and never submerged or have

liquids poured upon them.

Repair – In the event that equipment

becomes damaged or ceases to

operate, arrangements should be made

to return the equipment to PCB

Piezotronics for repair. User servicing or

repair is not recommended and, if

attempted, may void the factory

warranty.

Calibration – Routine calibration of

sensors and associated instrumentation

is recommended as this helps build

confidence in measurement accuracy

and acquired data. Equipment

calibration cycles are typically

established by the users own quality

regimen. When in doubt about a

calibration cycle, a good “rule of thumb”

is to recalibrate on an annual basis. It is

also good practice to recalibrate after

exposure to any severe temperature

extreme, shock, load, or other

environmental influence, or prior to any

critical test.

PCB Piezotronics maintains an ISO9001 certified metrology laboratory and

offers calibration services, which are

accredited by A2LA to ISO/IEC 17025,

with full traceability to SI through

N.I.S.T. In addition to the normally

supplied calibration, special testing is

also available, such as: sensitivity at

elevated or cryogenic temperatures,

phase response, extended high or low

frequency response, extended range,

leak testing, hydrostatic pressure

testing, and others. For information on

standard recalibration services or

special testing, contact your local PCB

Piezotronics distributor, sales

representative, or factory customer

service representative.

Returning Equipment – Following

these procedures will ensure that your

returned materials are handled in the

most expedient manner. Before

returning any equipment to PCB

Piezotronics, contact your local

distributor, sales representative, or

factory customer service representative

to obtain a Return Warranty, Service,

Repair, and Return Policies and

Instructions Materials Authorization

(RMA) Number. This RMA number

should be clearly marked on the outside

of all package(s) and on the packing

Page 3

list(s) accompanying the shipment. A

detailed account of the nature of the

problem(s) being experienced with the

equipment should also be included

inside the package(s) containing any

returned materials.

A Purchase Order, included with the

returned materials, will expedite the

turn-around of serviced equipment. It is

recommended to include authorization

on the Purchase Order for PCB to

proceed with any repairs, as long as

they do not exceed 50% of the

replacement cost of the returned

item(s). PCB will provide a price

quotation or replacement

recommendation for any item whose

repair costs would exceed 50% of

replacement cost, or any item that is not

economically feasible to repair. For

routine calibration services, the

Purchase Order should include

authorization to proceed and return at

current pricing, which can be obtained

from a factory customer service

representative.

Contact Information – International

customers should direct all inquiries to

their local distributor or sales office. A

complete list of distributors and offices

can be found at www.pcb.com.

Customers within the United States may

contact their local sales representative

or a factory customer service

representative. A complete list of sales

representatives can be found at

www.pcb.com. Toll-free telephone

numbers for a factory customer service

representative, in the division

responsible for this product, can be

found on the title page at the front of this

manual. Our ship to address and

general contact numbers are:

PCB Piezotronics, Inc.

3425 Walden Ave.

Depew, NY14043 USA

Toll-free: (800) 828-8840

24-hour SensorLineSM: (716) 684-0001

Website: www.pcb.com

E-mail: info@pcb.com

Page 4

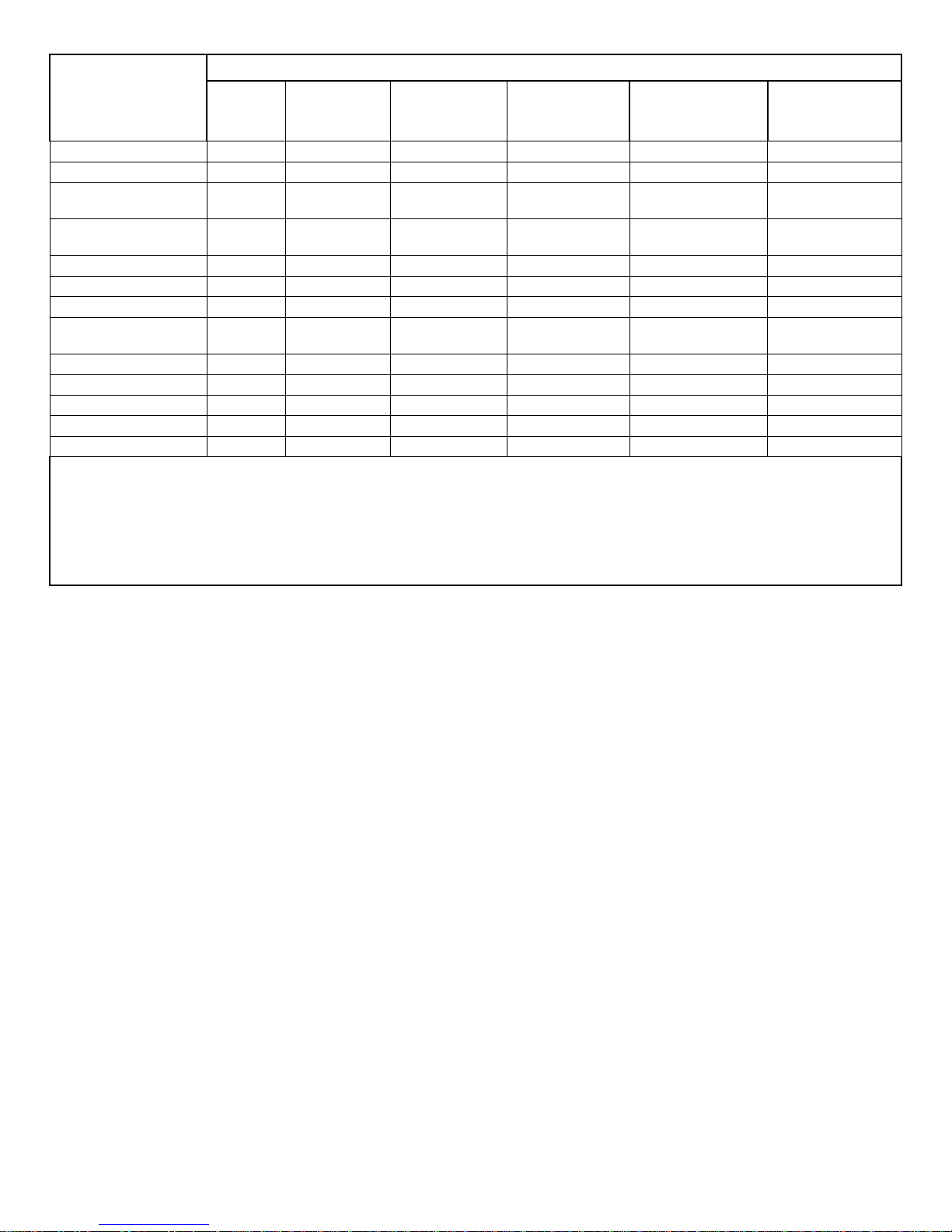

PCB工业监视和测量设备 - 中国RoHS2公布表

PCB Industrial Monitoring and Measuring Equipment - China RoHS 2 Disclosure Table

部件名称

有害物质

铅 (Pb)

汞

(Hg)

镉

(Cd)

六价铬 (Cr(VI))

多溴联苯 (PBB)

多溴二苯醚 (PBDE)

住房

O O O

O O O

PCB板

X O O

O O O

电气连接器

O O O

O O O

压电晶体

X O O

O O O

环氧

O O O

O O O

铁氟龙

O O O

O O O

电子

O O O

O O O

厚膜基板

O O X

O O O

电线

O O O

O O O

电缆

X O O

O O O

塑料

O O O

O O O

焊接

X O O

O O O

铜合金/黄铜

X O O

O O O

本表格依据 SJ/T 11364 的规定编制。

O: 表示该有害物质在该部件所有均质材料中的含量均在 GB/T 26572 规定的限量要求以下。

X: 表示该有害物质至少在该部件的某一均质材料中的含量超出 GB/T 26572 规定的限量要求。

铅是欧洲RoHS指令2011/65/ EU附件三和附件四目前由于允许的豁免。

CHINA RoHS COMPLIANCE

Page 5

Component Name

Hazardous Substances

Lead

(Pb)

Mercury

(Hg)

Cadmium

(Cd)

Chromium VI

Compounds

(Cr(VI))

Polybrominated

Biphenyls

(PBB)

Polybrominated

Diphenyl

Ethers (PBDE)

Housing O O O O O O

PCB Board

X O O O O

O

Electrical

Connectors

O O O O O

O

Piezoelectric

Crystals

X O O O O

O

Epoxy O O O O O O

Teflon O O O O O O

Electronics

O O O O O

O

Thick Film

Substrate

O O X O O

O

Wires O O O O O O

Cables X O O O O O

Plastic O O O O O O

Solder X O O O O O

Copper Alloy/Brass

X O O O O

O

This table is prepared in accordance with the provisions of SJ/T 11364.

O: Indicates that said hazardous substance contained in all of the homogeneous materials for this part is below the limit

requirement of GB/T 26572.

X: Indicates that said hazardous substance contained in at least one of the homogeneous materials for this part is above

the limit requirement of GB/T 26572.

Lead is present due to allowed exemption in Annex III or Annex IV of the European RoHS Directive 2011/65/EU.

DOCUMENT NUMBER: 21354

DOCUMENT REVISION: D

ECN: 46162

Page 6

SENS

ORS AND INSTRUMENTAT

ION FOR MACHINE COND

ITION MONITORING

Model 683A1 ICP® Process Indicator/Controller

Operating Guide with Enclosed Warranty Information

3425 Walden Avenue, Depew, New York 14043-2495

Phone (716) 684-0003

Fax (716) 684-3823

Toll Free Line 1-800-959-4IMI

MANUAL NUMBER: 19163

MANUAL REVISION: C

ECN NUMBER: 18874

Page 7

PAGE 2

SENSORS AND INSTRUME

NTATION FOR MACHINE

CONDITION MONITORING

Table of Contents

Introduction………………………………………………………………………………………. Page 3

General Features, Software Features

Specifications……………………………………………………………………………………. Page 4

Controls and Indicators………………………………………………………………………… Page 5

Glossary of Programming Symbols…………………………………………………………… Page 6

Software Logic Tree…………………………………………………………………………….. Page 7

Programming the 683A1..……………………………………………………………………… Page 8

Wiring and Installation………………………………………………………………………… Page 13

Configuring the 683A1 ……………………………………………………………………….. Page 17

Accessories…………………………………………………………………………………….. Page 18

ESD Sensitivity………………………………………………………………………………… Page 20

Ordering Information………………………………………………………………………….. Page 21

Warranty/Servicing

Warranty, Service & Return Procedure.......................................................................... Page 22

Customer Service.......................................................................................................... Page 23

Page 8

PAGE 3

SENSORS AND INSTRUME

NTATION FOR MACHINE

CONDITION MONITORING

Introduction

The Model 683A1 ICP

®

Process Indicator/Controller is an intelligent 4-digit modular panel meter with software

features for monitoring, measurement, and control applications complete with 0.56” LED in a 1/8 DIN 96x48 case.

The 683A1 operates from a single power supply and will supply 24Vdc/4mA excitation for sensor power. The

indicator/controller comes equipped with two 5 Amp Form A relays with independent setpoints and time delay.

General Features

External transmitters, signal conditioners, or power supplies can be eliminated by direct connection of the

sensor to the indicator/controller.

Optional isolated 16-bit analog output. User or factory scalable to 4 to 20 mA across any desired digital

span from ± one count to the full-scale range of – 1999 to 9999 (12000 counts).

24Vdc/4mA excitation to power sensor.

Standard Internal DIP switch selectable vibration ranges include:

Acceleration (g’s) Velocity (in/sec) Displacement (mils p-p)

5.000 0.500 25.0

10.00 1.000 50.0

20.00 2.000 100.0

Two 5 Amp Form A relays, additionally two 5 Amp Form A or 10 Amp Form C relays are available.

Programmable Time Delay to 9999 seconds.

Internal DIP switch selection for Peak or RMS display.

User specified, factory installed, High and Low pass 2-pole filtering.

Analog output signal connection (RV) for conducting frequency analysis and machinery diagnostics.

Software Features

Three-button front panel programming of:

Scale Factor and Offset

Decimal point setting.

Four-level brightness control of digital display.

Peak and valley view and reset.

Four programmable setpoints.

Adjustable delay-on-make and delay-on-break time for setpoints 1 and 2.

Relay activation can be selected to occur above (HI) or below (LO) each setpoint.

Page 9

PAGE 4

SENSORS AND INSTRUME

NTATION FOR MACHINE

CONDITION MONITORING

Specifications

Input Specs

: ...... 100mV/g

ICP® Sensor Excitation: ...... 24Vdc/4mA, ±1Vdc/±1mA

A/D Converter: ...... 14 bit single slope

Accuracy: ...... ±2.0% of Scale Factor + 2 counts

Frequency Response: 3Hz to 10Khz (Standard)

Acceleration: -3dB at 3Hz ±0.5Hz, -3dB at 10kHz ±0.5kHz

Velocity: -3dB at 3.5Hz ±0.5Hz, -3dB at 10kHz ±0.5kHz

Displacement: -3dB at 3.5Hz ±0.5Hz, 1000Hz max.

Temp. Coeff.: ...... 100 ppm/°C (Typical)

Warm up time: ...... 2 minutes

Conversion Rate: ...... 5 conversions per second (Typical)

Display: ...... 4 digit 0.56" Red LED display, Range –1999 to 9999 counts.

Polarity: ...... Assumed positive. Displays – negative

Decimal Selection: ...... Front panel button selectable, X•X•X•X•

Positive Overrange: ...... Top segments of digital display flash

Negative Overrange: ...... Bottom segment of digital display flash

Relay Output

: ...... Two 5 A Form A (SPST) relays 230VAC/30VDC standard.

Additionally two 5 Amp Form A (SPST) or 10 Amp Form C (SPDT) relays.

Optional Analog Output: ...... Isolated 16 bit user scalable 4-20mA retransmit @ 0 to 500 ohms max

loop resistance.

Power Supply: ...... Auto sensing wide range supply 85-265 VAC / 95-370 VDC @ 2.5W max 3.5W

Operating Temp.: ...... 0 to 60 °C

Storage Temp: ...... –20 °C to 70 °C.

Relative Humidity: ...... <95% (non condensing)

Case Dimensions: ...... 1/8 DIN, Bezel: 96x48 mm (3.78”x1.89”)

Depth behind bezel 117 mm (4.61”)

Plus 11.8 mm (0.47”) for Right-angled connectors, or plus 20 mm (0.79”) for Straight-thru connectors.

Weight: ...... 6.5 oz., 8.5 oz when packed

Page 10

PAGE 5

SENSORS AND INSTRUME

NTATION FOR MACHINE

CONDITION MONITORING

Controls and Indicators

Front Panel Buttons

Program Button

The button is used to move from one program step to the next. When pressed at the same time as the

button, it initiates the calibration mode. When pressed at the same time as the button, it initiates

the setpoint setting mode.

Up Button

When in the operational display, pressing the button alone, allows you to view and reset the Peak and

Valley (Highest and Lowest Readings.)

When in calibration mode or the setpoint setting mode the button is used to increase the value of

the displayed parameter.

Down Button

When in the operational display, pressing the button alone allows you to view, but not change, the

setting of setpoint 1,2,3,& 4.

When in calibration mode or the setpoint setting mode the button is used to decrease the value of

the displayed parameter.

Page 11

PAGE 6

SENSORS AND INSTRUME

NTATION FOR MACHINE

CONDITION MONITORING

Glossary of Programming Symbols

To explain software-programming procedures, logic diagrams are used to visually assist in following the

programming steps. The following symbols are used to represent various functions and associated display

elements of the 683A1:

Symbol Explanation Symbol Explanation

This symbol represents the

OPERATIONAL DISPLAY.

[ScALE]

[9999]

Text or numbers shown between

square brackets in a procedure

indicate the programming code

name of the function or the value

displayed on the meter display.

When a button is shown, press and

release it to go onto the next step in

the direction indicated by the arrow.

When two or more buttons are

shown, each with an arrow, this

indicates there are a number of

programming choices.

When the and buttons are

shown together, the display value

can be increased by pressing and

releasing the button or

decreased by pressing and

releasing the button.

When two buttons are shown side by

side and enclosed by a dotted line,

they must be pressed at the same

time then released to go onto the next

programming step.

When the and buttons are

shown with two displays, either

display can be selected by pressing

and releasing the or

buttons.

If the display is shown with XXXX it

means the value displayed will be the

previously set value. When a number

is shown it indicates the initial factory

default setting or a specific “example

number.”

When there are more than two

display selections they are shown

in brackets below the first display

and are also selectable by pressing

and releasing the or

buttons.

When two displays are shown

together with bursts, this indicates

that the display is toggling (flashing)

between the name of the function and

the value.

A dotted box indicates these

functions are omitted or bypassed

when the related hardware is not

present.

is the PROGRAM button, is the UP button, is the DOWN button.

Page 12

PAGE 7

SENSORS AND INSTRUME

NTATION FOR MACHINE

CONDITION MONITORING

Software Logic Tree

The 683A1 is an intelligent meter with a hierarchical software structure designed for easy programming and

operation, as shown below in the software logic tree. After the meter has been powered up, the four digits light up

for three seconds and then settle to the operational display indicating the input signal.

Page 13

PAGE 8

SENSORS AND INSTRUME

NTATION FOR MACHINE

CONDITION MONITORING

Programming the 683A1

Digital Scaling

The 683A1 meter may be rescaled without applying an external signal by changing the Offset and Scale factor.

Offset is the reading that the meter will display for a 0mV input. The Offset may be set to any value from –1999 to

+9999. The default value of the Offset is 0000.

Scale Factor is the gain of the meter. The displayed reading is directly proportional to the Scale Factor. The

default value of the Scale Factor is 1000 for a 1ips accelerometer, but it may be set to any value between –1999

and +9999.

For an input of 2.000V a calibrated meter will read 1000 with the default Scale Factor of 1000, 2000 with a Scale

Factor of 2000, and 500 with a Scale Factor of 500.

Digital Scaling Procedure

STEP A Enter the Calibration Mode

1) Press the and the buttons at the same time.

Display toggles between [cAL] and [oFF].

2) Press the or button.

Display changes from [oFF] to [on].

3) Press the button. Display toggles between [cAL] and [out].

STEP B Select Between Calibration of Input or Output

Note: If the analog output option is not present, Step B is skipped and the

program goes directly from Step A to Step C.

1) Press the or button to select the display toggling from

[cAL] to [iP].

2) Press the

button. Display toggles between [oFFS] and the

previous offset setting.

STEP C Set the Offset on the Digital Display

1) Using the and buttons, adjust the digital display to the

desired offset. This is the reading the meter will display for a

0mV input.

2) Press the

button. Display toggles between [SCAL] and the

previous scale factor.

STEP D Set the Scale factor on the Digital Display

1) Using the and buttons, adjust the meter display to the

desired Scale Factor. The default value is 1000, for which a

2.000V input will read 1000. If the Scale factor is changed the

display will change proportionally. Therefore if the Scale

Factor is changed to 2000 then for the same 2.000V input the

display will read 2000.

2) Press the button.

The Digital Calibration Procedure Mode is Now Complete.

The menu branches to the DECIMAL POINT AND BRIGHTNESS

SELECTION, (see page 10) and the display flashes [dP] and the previous

decimal point selection.

Page 14

PAGE 9

SENSORS AND INSTRUME

NTATION FOR MACHINE

CONDITION MONITORING

Two Point Analog Output Range Setting and Calibration

STEP A Enter the Calibration Mode

1) Press the and the buttons at the same time.

Display toggles between [cAL] and [oFF].

2) Press the or button. Display changes from [oFF] to [on].

1) Press the button. Display toggles between [cAL] and [out].

Note: If at this point the display skips directly to toggle between [oFFS] and the

previous [oFFS] setting, the software is detecting that the optional analog output

hardware is NOT installed.

STEP B Enter the Analog [oUT] Output Mode

1) Press the

button. Display toggles between [cLo] and internal scale

factor.

STEP C Set or Calibrate the [cLo] Low Analog Output Range

1) Connect a multimeter to pins 16 and 17 on the output module. See

Rear Panel Pinouts on Page 8). Using the and buttons, adjust

the analog output to the desired low value as shown on the

multimeter display. cLo may be adjusted to any value from –

0.3mA to

17mA. (Factory Default is 4mA)

2) Press the button. Display toggles between [cHi] and internal scale

factor.

STEP D Set or Calibrate the [cHi] Analog Output Range

1) Using the and buttons, adjust the analog output to the desired

high value as shown on the multimeter display. cHi may be adjusted

to any value from 17mA to 21mA. (Factory Default is 20mA)

2) Press the button. The display exits the calibration mode and

returns to the operational display.

Note:

Having established the Low and High range of the analog output, the digital

span can now be selected which will set the two digital points between which the

analog output will occur. (See Digital Span selection next page).

Page 15

PAGE 10

SENSORS AND INSTRUME

NTATION FOR MACHINE

CONDITION MONITORING

Decimal Point and Brightness Selection

Digital Span Selection for Analog Range Output

STEP A Enter the Decimal Point and Brightness Mode Through the Sub

Menu [CAL]{oFF]

2) Press the and the buttons at the same time.

Display toggles between [cAL] and [oFF].

3) Press the button. Display shows the previous [dp] selection.

STEP E Set the Decimal Point

1) Using the and buttons, adjust the display to the desired decimal

point setting. (Factory Default is X.XXX)

2) Press the button. Display toggles between [Br] and the previous

[Br] setting.

STEP F Set the Display Brightness

1) Using the and buttons, adjust the display to the desired

brightness setting (4 is the brightest setting).

2) Press the button. Display brightness changes to new setting and

display toggles between [Anhi] and the previous [Anhi] setting.

STEP G Setting the Digital Span Point for Analog High Output

1)

Using the and buttons, adjust the display to the desired digital

value which sets the point at which the selected analog high output

range will occur. (Factory Default is 1000)

2) Press the button. Display toggles between [AnLo] and the

previous [AnLo] setting.

STEP H Setting the Digital Span Point for Analog Low Output

1) Using the and buttons, adjust the display to the desired digital

value which sets the point at which the selected analog low output

range will occur. (Factory Default is 0)

2) Press the button. The display exits the calibration mode and

returns to the operational display.

Note: Any two digital scale points from –1999

to 9999 can be selected. The digital

scale points for analog high and analog low can be reversed for a 20mA to 4mA

output. The span of the digital scale can be as small as two counts however small

spans cause the 16 bit D to A to increment in stair case steps.

Page 16

PAGE 11

SENSORS AND INSTRUME

NTATION FOR MACHINE

CONDITION MONITORING

Setpoint Setting and Relay Configuration Mode

The following programming steps are required to enter the setpoint values and

configure the relay functions in a meter with four relays using four setpoints. Generally

if less than four relays are installed the software auto detects the missing relays and

deletes reference to them from the menu. In some cases setpoints without relays are

operational for display purposes only.

STEP A Enter the Setpoint Mode

1) Press the and buttons at the same time.

Display toggles between [SP1] and the previous [SP1] setting.

STEP B Setpoint1 (SP1)

1) Using the and buttons, adjust the display to the desired SP1 value.

2) Press the button. Display toggles between [doM] and the previous [doM]

setting.

STEP C Set the SP1 Delay-on-Make (doM) Delay Time Setting

1) Using the and buttons, adjust the display to the desired [doM] value

(0 to 9999 seconds). The reading must continuously remain in an alarm

condition until this delay time has elapsed before the relay will make contact

(energize).

2) Press the button. Display toggles between [dob] and the previous [dob]

setting.

STEP D Set the SP1 Delay-on-Break (dob) Delay Time Setting

1) Using the and buttons, adjust the display to the desired [dob] value (0-

9999 seconds). The reading must continuously remain in a non-

alarm condition

until this delay time has elapsed before the relay will break contact (deenergize).

2)

Press the button. Display toggles between [hYST] and the previous [hYST]

setting.

STEP C Set the Hysteresis Setting for Setpoint 1

1) Using the and buttons, adjust the display to the desired hysteresis [hYST]

value.

2)

Press the button. Display toggles between [SP2] and the previous [SP2]

setting.

Note: Steps, F, G, H, and J have functionally the same procedure as steps B, C, D,

and E shown above.

STEP F Set Setpoint 2 (SP2)

STEP G Set the SP2 Delay-on-Make (doM) Delay Time Setting

STEP H Set the SP2 Delay-on-Break (dob) Delay Time Setting

STEP I Set the Hysteresis Setting for Setpoint 2

1) Using the and buttons, adjust the display to the desired hysteresis [hYST]

value.

2) Press the button. Display toggles between [SP3] and the previous [SP3]

setting.

SETPOINT 3

, 4, AND RELAY ACTIVATION MODE CONTINUED NEXT PAGE.

Page 17

PAGE 12

SENSORS AND INSTRUME

NTATION FOR MACHINE

CONDITION MONITORING

STEP J Set Setpoint 3 (SP3)

(No [doM] or [dob])

1)

Using the and buttons, adjust the display to the desired SP3 value.

2) Press the button. Display toggles between [hYST] and the previous [hYST]

setting.

STEP K Set the Hysteresis Setting for Setpoint 3

1) Using the and

buttons, adjust the display to the desired hysteresis [hYST]

value.

2) Press the button. Display toggles between [SP4] and the previous [SP4]

setting.

STEP L Set Setpoint 4 (SP4) (No [doM] or [dob])

1) Using the and buttons, adjust the display to the desired SP4 value.

2) Press the button. Display toggles between [hYST] and 0.

STEP M Set the Hysteresis Setting for Setpoint 4

1) Using the and buttons, adjust the display to the

desired hysteresis [hYST]

value.

2) Press the button. Display toggles between [rLYS] and the previous relay

setting.

STEP N Set Relay Activation mode [rLYS]

(h) High the relay energizes when the setpoint is exceeded. (L) Low the relay

energizes below the setpoint. The setpoint is indicated from left to right SP1, SP2, SP3,

SP4.

1) Using the and buttons, adjust the reading on the display to the desired

relay settings: [LLLL], [LhLh], [hLhL], [hhhh].

If only 2 relays installed [Lh--], [hL--], [hh--], [LL--].

2) Press the button. The meter exits the setpoint mode and returns to the

operational display.

The Setpoint Relay programming mode is now complete.

Page 18

PAGE 13

SENSORS AND INSTRUME

NTATION FOR MACHINE

CONDITION MONITORING

Wiring and Installation

Pinout Diagram

The Rear View Meter diagram shows

the meter with the relay configuration:

dual 10 Amp Form C and dual 5 Amp

Form A relays. An analog output

module is also shown as installed.

The 683A1 uses plug-in type screw

terminal connectors for all input and

output connections. The power supply

connections (pins 14 and 15) have a

unique plug and socket outline to

prevent cross connection. The main

board and input signal conditioner use

right –angled connectors as standard.

The output module uses straight–thru

connectors as standard.

Connectors

WARNING

AC and DC input signals and power supply voltages can be hazardous. DO NOT

connect live wires to screw terminal plugs, and DO NOT insert, remove, or handle screw

terminal plugs with live wires connected.

Page 19

PAGE 14

SENSORS AND INSTRUME

NTATION FOR MACHINE

CONDITION MONITORING

Typical Wiring Diagram (CE Power Supply Option)

To Maintain Conformance I/O Shields must be connected to Pin 3 on the Panel Meter

and all Supplied Accessories must be wired as shown (Power Supply Option 2).

1 2 3 4 5 8 9 10 11

14 15

ICP SENSOR/

SIMULATOR

RV OUTPUT

DMM

+

-

+

-

SHIELD

N/C N/C N/C N/C

3EB1LB

+

-

CORCOM

EMI FILTER

+

-

AC

LINE

AC

NEUTRAL

GND

METALLIC

ENCLOSURE

Page 20

PAGE 15

SENSORS AND INSTRUME

NTATION FOR MACHINE

CONDITION MONITORING

Pin Descriptions

Input Signal - Pins 1 to 6

Pin 1 +ICP® Sensor Excitation/Signal

Pin 2 -ICP® Sensor Excitation

Pin 3 ICP® Sensor Shield (if applicable)

Pin 4 + RV Output (Analog Sensor Signal)

Pin 5

- RV Output (Analog Sensor Signal)

Pin 6 No Connection

Relay Output - Pins 8 to 12

Pin 8 SP1 NO. (Normally Open 5 Amp Form A.)

Pin 9 SP1 NO.

Pin 10 SP2 NO. (Normally Open 5 Amp Form A.)

Pin 11 SP2 NO.

Pin 12 No Connection

AC/DC Power Unit - Pins 14 and 15

Pin 14 AC/DC Neutral. Neutral power supply line.

Pin 15 AC/DC Line. Live power supply line.

OPTIONAL TOP BOARD PINS

Analog Output - Pins 16 and 17

Pins 16 and 17 are the analog output pins on the optional output module.

Pin 16

Positive (+) analog output.

Pin 17 Negative (-) analog output.

Rear Panel Function – Pins 18 to 21

Pin 18 DIM. By connecting the display dim (DIM) pin to the COMMON pin, the display brightness setting is

halved.

Pin 19 COMMON. To activate the LOCK or DIM functions from the rear of the meter, the respective pins have to

be connected to the COMMON pin. This pin is connected to the internal power supply ground.

Pin 20 HOLD. By connecting the HOLD pin to the COMMON pin, the display reading is frozen, however, A/D

conversions continue. When the HOLD pin is disconnected from the COMMON pin, the correct reading is

displayed.

Pin 21 LOCK. By connecting the LOCK pin to the COMMON pin, the meter’s parameters can be viewed but not

changed.

Top Board Secondary Relay Output – Pins 22 to 29

Quad 5A Form A Relays or Dual 10Amp Form C Relays.

Pin 22 SP1 (Quad 5A SPST Relay Option)

Pin 23 SP1 (Quad 5A SPST Relay Option), SP3 COMM (10A SPDT Additional Relay Option)

Pin 24

SP2 (Quad 5A SPST Relay Option), SP3 NC (10A SPDT Additional Relay Option)

Pin 25 SP2 (Quad 5A SPST Relay Option), SP3 NO (10A SPDT Additional Relay Option)

Pin 26 SP3 (Quad 5A SPST Relay Option)

Pin 27 SP3 (Quad 5A SPST Relay Option), SP4 COMM (10A SPDT Additional Relay Option)

Pin 28 SP4 (Quad 5A SPST Relay Option), SP4 NC (10A SPDT Additional Relay Option)

Pin 29 SP4 (Quad 5A SPST Relay Option), SP4 NO (10A SPDT Additional Relay Option)

Page 21

PAGE 16

SENSORS AND INSTRUME

NTATION FOR MACHINE

CONDITION MONITORING

Case Dimensions and Panel Cutout

Page 22

PAGE 17

SENSORS AND INSTRUME

NTATION FOR MACHINE

CONDITION MONITORING

Configuring the 683A1

ICP® Interface PC Board Diagram

The ICP® Interface Board Diagram

shows the location of the internal

DIP switch. This DIP switch is

used to configure the indicator for

various sensor and vibration

ranges. The PC Board is

accessible through the back of the

indicator by removing the Screw

Terminal Plugs and back panel.

The back panel is released by

disengaging the tabs on the TOP

and BOTTOM of the meter with a

screwdriver. Once removed, the

ICP® Interface Board can be slid

out for configuration.

Internal DIP Switch Setting

The Internal DIP Switch of the Model 683A1 must be configured for the Full Scale Output of the ICP® Sensor

connected to it. This is accomplished by removing the back cover and sliding the ICP® Interface PC Board out of

the Panel Meter/Controller. Once removed, the DIP switch should be configured per one of the conditions in the

following table.

Range Setting S1 S2 S3 S4 S5 S6 S7 S8

5g RMS

ON

OFF

OFFONOFF

OFF

OFF

ON

5g Peak

ON

OFF

OFF

OFFONOFF

OFF

ON

10g RMS

ON

OFF

OFFONOFF

OFFONOFF

10g Peak

ON

OFF

OFF

OFFONOFFONOFF

20g RMS

ON

OFF

OFFONOFFONOFF

OFF

20g Peak

ON

OFF

OFF

OFFONON

OFF

OFF

0.5 in/sec RMS

OFFONOFFONOFF

OFF

OFF

ON

0.5 in/sec Peak

OFFONOFF

OFFONOFF

OFF

ON

1.0 in/sec RMS

OFFONOFFONOFF

OFFONOFF

1.0 in/sec Peak

OFFONOFF

OFFONOFFONOFF

2.0 in/sec RMS

OFFONOFFONOFFONOFF

OFF

2.0 in/sec Peak

OFFONOFF

OFFONON

OFF

OFF

25 mils p-p

OFF

OFFONOFF

OFF

OFF

OFF

ON

50 mils p-p

OFF

OFFONOFF

OFF

OFFONOFF

100 mils p-p

OFF

OFFONOFF

OFFONOFF

OFF

Note: Factory Default Setting is 1.0in/sec Peak

5

4

3

2

1

ONOFF

Selector

Switch

S1

S2

S3

S4

S5

S6

S7

S8

Page 23

PAGE 18

SENSORS AND INSTRUME

NTATION FOR MACHINE

CONDITION MONITORING

Accessories

NEMA 4X Lens Cover

The lens cover is designed to be dust and water

proof to NEMA-4X standards. The lens cover

consists of a base and cover with a cam hinge and

key-lock locking device.

An O-ring, or neoprene gasket forms a seal between

the base and the panel. The cam hinge prevents the

cover from closing when opened until pushed closed.

The cover has a tapered recess that, when closed,

forms a capillary seal with a tapered ridge on the

base. Turning the key-lock tightens the cover to the

base, insuring seal integrity. A safety catch keeps the

cover closed even when the key is turned to the

open position and removed. The keyhole can also be

used to attach a safety seal clop, preventing

unauthorized opening.

Page 24

PAGE 19

SENSORS AND INSTRUME

NTATION FOR MACHINE

CONDITION MONITORING

Metal Surround Case

The meter’s plastic case is made from a fire retardant polycarbonate. A metal surround case can be ordered to

enhance the meter’s fire retardant capabilities and also provide shielding against electromagnetic interference

(EMI). The metal case slides over the polycarbonate case and is held firmly in place by spring-type non-return

clips. Once the metal case has been fitted to the polycarbonate case it cannot be removed.

With the metal case in place, the meter’s plastic ratchet-type mounting clips can no longer be used. A pair of

screw-type mounting clips are inserted into holes on the side of the metal case and used to mount the meter in

the panel. A ground tab on the metal case provides a ground connection between the meter’s main board and the

metal case.

**Metal Surround Case must be factory installed.

Page 25

PAGE 20

SENSORS AND INSTRUME

NTATION FOR MACHINE

CONDITION MONITORING

Warning 1 – ESD sensitivity

The power supply/signal conditioner should not be opened by anyone other than qualified service

personnel. This product is intended for use by qualified personnel who recognize shock hazards and are familiar

with the safety precautions required to avoid injury.

Warning 2 – ESD sensitivity

This equipment is designed with user safety in mind; however, the protection provided by the equipment may be

impaired if the equipment is used in a manner not specified by PCB Piezotronics, Inc.

Caution 1 – ESD sensitivity

Cables can kill your equipment. High voltage electrostatic discharge (ESD) can damage electrical devices.

Similar to a capacitor, a cable can hold a charge caused by triboelectric transfer, such as that which occurs in the

following:

Laying on and moving across a rug,

Any movement through air,

The action of rolling out a cable, and/or

Contact with a non-grounded person.

The PCB solution for product safety:

Connect the cables only with the AC power off.

Temporarily “short” the end of the cable before attaching it to any signal input or output.

Caution 2 – ESD sensitivity

ESD considerations should be made prior to performing any internal adjustments on the equipment. Any

piece of electronic equipment is vulnerable to ESD when opened for adjustments. Internal adjustments should

therefore be done ONLY at an ESD-safe work area. Many products have ESD protection, but the level of

protection may be exceeded by extremely high voltage.

Page 26

PAGE 21

SENSORS AND INSTRUME

NTATION FOR MACHINE

CONDITION MONITORING

Ordering Information

IMI Part Number: 683A 1 1 0 2 0 3

Basic Model Number

683A

Sensor Input

1 100mV/g ICP® Sensor

Power Supply

0 85-265Vac/95-370Vdc

1 18-48Vac/10-72Vdc

2 85-265Vac/95-370Vdc CE Certified.

Analog Output*

0 None

1 Isolated 16 bit user scalable 4-20mA retransmit.

Additional Relay Output*

0 None

1 Dual 10 Amp Form C Relays (SPDT)

2 Dual 5 Amp Form A Relays (SPST)

Frequency Response*

0 3Hz to 10kHz (Standard)

1 3Hz to 1kHz

2 10Hz to 10kHz

3 10Hz to 1kHz

Accessories*

0 None

1 96x48mm Clear Lockable Front Cover – NEMA 4X, Splash Proof.

2 Metal Surround Case – Includes screw mounting clips.

3 Clear Lockable Front Cover and Metal Surround Case.

Ordering Example: 683A100001

This is a standard ICP® Indicator/Controller with the following:

Power Supply: 85-265Vac/95-370Vdc

Analog Output: None

Additional Relay Output: None

Frequency Response: Standard (3Hz to 10kHz)

Accessories: 96x48mm Clear Lockable Front Cover – NEMA 4X, Splash Proof.

*Additional Options Available – Please Inquire

Page 27

PAGE 22

SENSORS AND INSTRUME

NTATION FOR MACHINE

CONDITION MONITORING

Warranty

IMI instrumentation is warranted against defective material and workmanship for 1 year unless otherwise

expressly specified. Damage to instruments caused by incorrect power or misapplication, is not covered by

warranty. If there are any questions regarding power, intended application, or general usage, please consult with

your local sales contact or distributor. Batteries and other expendable hardware items are not covered by

warranty.

Service

Because of the sophisticated nature of IMI instrumentation, field repair is typically NOT recommended and may

void any warranty. If factory service is required, return the instrumentation according to the “Return Procedure”

stated below. A repair and/or replacement quotation will be provided prior to servicing at no charge. Before

returning the unit, please consult a factory IMI applications engineer concerning the situation as certain problems

can often be corrected with simple on-site procedures.

Return procedure

To expedite returned instrumentation, contact a factory IMI applications engineer for a RETURN MATERIAL

AUTHORIZATION (RMA) NUMBER. Please have information available such as model and serial number. Also,

to insure efficient service, provide a written description of the symptoms and problems with the equipment to a

local sales representative or distributor, or contact IMI if none are located in your area.

Customers outside the U.S. should consult their local IMI distributor for information on returning equipment. For

exceptions, please contact the International Sales department at IMI to request shipping instructions and an RMA.

For assistance, please call (716) 684-0003, or fax us at (716) 684-3823. You may also receive assistance via email at imi@pcb.com or visit our web site at www.pcb.com.

Page 28

PAGE 23

SENSORS AND INSTRUME

NTATION FOR MACHINE

CONDITION MONITORING

Customer Service

IMI, a division of PCB Piezotronics, guarantees Total Customer Satisfaction. If, at any time, for any reason, you

are not completely satisfied with any IMI product, IMI will repair, replace, or exchange it at no charge. You may

also choose, within the warranty period, to have your purchase price refunded.

IMI offers to all customers, at no charge, 24-hour phone support. This service makes product or application

support available to our customers, day or night, seven days a week. When unforeseen problems or emergency

situations arise, call the IMI Hot Line at (716) 684-0003, and an application specialist will assist you.

3425 Walden Avenue, Depew, NY 14043-2495

Phone: (716) 684-0003 USA Fax: (716) 684-3823 INTL Fax: (716) 684-4703

ICP® is a registered trademark of PCB Group, Incorporated,

which uniquely identifies PCB sensors that incorporate built-in microelectronics.

Page 29

Model Number

683A100000

INDICATOR / ALARM (FOR ICP® SENSORS)

Revision: A

ECN #: 46956

[3]

Performanc

e

ENGLISH S

I

Sensor Input Type(s) ICP® ICP®

Input Signal 100 mV/g 100 mV/(m/s²)

Frequency Response(± 3 dB) 3 to 10k Hz 3 to 10k Hz

Channels 1 1

Accuracy ±2 % FS ±2 % FS

Measurement Range(Acceleration) 5 g 5 g

[1][2]

Measurement Range(Acceleration) 10 g 10 g

[1][2]

Measurement Range(Acceleration) 20 g 20 g

[1][2]

Measurement Range(Velocity) 0.50 in/sec 0.50 in/sec

[1][2]

Measurement Range(Velocity) 1.00 in/sec 1.00 in/sec

[1][2]

Measurement Range(Velocity) 2.00 in/sec 2.00 in/sec

[1][2]

Measurement Range(Displacement) 25.0 mil pk - pk 25.0 mil pk - pk

[1][2]

Measurement Range(Displacement) 50.0 mil pk - pk 50.0 mil pk - pk

[1][2]

Measurement Range(Displacement) 100.0 mil pk - pk 100.0 mil pk - pk

[1][2]

Relay Type(Alert) 5A Form A 230 VAC/30 VDC 5A Form A 230 VAC/30 VDC

Relay Type(Alarm) 5A Form A 230 VAC/30 VDC 5A Form A 230 VAC/30 VDC

Delay 0 to 9999 sec 0 to 9999 sec

Environmenta

l

Temperature Coefficient of Sensitivity 56 ppm/°F 100 ppm/°C

Warm Up <2 minutes <2 minutes

Temperature Range(Operating) 32 to 140 °F 0 to 60 °C

Temperature Range(Storage) -4 to 158 °F -20 to 70 °C

Humidity Range(Non-Condensing) <95 % <95 %

Electrical

Power Required(Auto Sensing) 85-265 VAC/95-370 VDC 85-265 VAC/95-370 VDC

Current Consumption(Typical) 2.5 W 2 .5 W

Current Consumption(Max) 3.5 W 3.5 W

Excitation Voltage(± 1 VDC) 24 VDC 24 VDC

Constant Current Excitation(± 1 mA) 4 mA 4 mA

Physica

l

Size (Depth x Width x Height) 4.61 in x 3.45 in x 1.61 in 117 mm x 87.4 mm x 40.8 mm

Housing Material Polycarbonate Polycarbonate

Weight 8.5 oz 241 gm

Din Rail Mount 1/8 in 3 mm

Electrical Connector Removable Screw Terminals Removable Screw Terminals

BEZEL 3.78 x 1.89 in 96 x 48 mm

Depth Behind BEZEL 4.61 in 117 mm

Depth Behind BEZEL(Rt. Angle Conn.) 5.08 in 129 mm

Depth Behind BEZEL(Straight Conn.) 5.40 in 137 mm

Accessories None None

All specifications are at room temperature unless otherwise specified.

In the interest of constant product improvement, we reserve the right to change specifications without notice.

ICP

®

is a registered trademark of PCB Group, Inc.

OPTIONAL VERSIONS

Optional versions have identical specifications and accessories as listed for the standard model

except where noted below. More than one option may be used.

NOTES:

[1]

Factory set, 0.5 in/sec rms

.

[2] Internal Dip switch selectable

[3] See PCB Declaration of Conformance PS050 for details.

Entered: LK Engineer: BAM Sales: WD

C

Approved: BAM Spec Number:

Date: 8/8/2017 Date: 8/8/2017 Date: 8/8/2017 Date: 8/8/2017

19278

3425 Walden Avenue, Depew, NY 14043

Phone: 800-959-4464

Fax: 716-684-3823

E-Mail: imi@pcb.com

Page 30

Loading...

Loading...