Page 1

Service, Repair, and Return

Policies and Instructions

The information contained in this document supersedes all similar information that

may be found elsewhere in this manual.

Service – Due to the sophisticated

nature of the sensors and associated

instrumentation provided by PCB

Piezotronics, user servicing or repair is

not recommended and, if attempted,

may void the factory warranty. Routine

maintenance, such as the cleaning of

electrical connectors, housings, and

mounting surfaces with solutions and

techniques that will not harm the

physical material of construction, is

acceptable. Caution should be observed

to ensure that liquids are not permitted

to migrate into devices that are not

hermetically sealed. Such devices

should only be wiped with a dampened

cloth and never submerged or have

liquids poured upon them.

Repair – In the event that equipment

becomes damaged or ceases to

operate, arrangements should be made

to return the equipment to PCB

Piezotronics for repair. User servicing or

repair is not recommended and, if

attempted, may void the factory

warranty.

Calibration – Routine calibration of

sensors and associated instrumentation

is recommended as this helps build

confidence in measurement accuracy

and acquired data. Equipment

calibration cycles are typically

established by the users own quality

regimen. When in doubt about a

calibration cycle, a good “rule of thumb”

is to recalibrate on an annual basis. It is

also good practice to recalibrate after

exposure to any severe temperature

extreme, shock, load, or other

environmental influence, or prior to any

critical test.

PCB Piezotronics maintains an ISO9001 certified metrology laboratory and

offers calibration services, which are

accredited by A2LA to ISO/IEC 17025,

with full traceability to SI through

N.I.S.T. In addition to the normally

supplied calibration, special testing is

also available, such as: sensitivity at

elevated or cryogenic temperatures,

phase response, extended high or low

frequency response, extended range,

leak testing, hydrostatic pressure

testing, and others. For information on

standard recalibration services or

special testing, contact your local PCB

Piezotronics distributor, sales

representative, or factory customer

service representative.

Returning Equipment – Following

these procedures will ensure that your

returned materials are handled in the

most expedient manner. Before

returning any equipment to PCB

Piezotronics, contact your local

distributor, sales representative, or

factory customer service representative

to obtain a Return Warranty, Service,

Repair, and Return Policies and

Instructions Materials Authorization

(RMA) Number. This RMA number

should be clearly marked on the outside

of all package(s) and on the packing

Page 2

list(s) accompanying the shipment. A

detailed account of the nature of the

problem(s) being experienced with the

equipment should also be included

inside the package(s) containing any

returned materials.

A Purchase Order, included with the

returned materials, will expedite the

turn-around of serviced equipment. It is

recommended to include authorization

on the Purchase Order for PCB to

proceed with any repairs, as long as

they do not exceed 50% of the

replacement cost of the returned

item(s). PCB will provide a price

quotation or replacement

recommendation for any item whose

repair costs would exceed 50% of

replacement cost, or any item that is not

economically feasible to repair. For

routine calibration services, the

Purchase Order should include

authorization to proceed and return at

current pricing, which can be obtained

from a factory customer service

representative.

Contact Information – International

customers should direct all inquiries to

their local distributor or sales office. A

complete list of distributors and offices

can be found at www.pcb.com.

Customers within the United States may

contact their local sales representative

or a factory customer service

representative. A complete list of sales

representatives can be found at

www.pcb.com. Toll-free telephone

numbers for a factory customer service

representative, in the division

responsible for this product, can be

found on the title page at the front of this

manual. Our ship to address and

general contact numbers are:

PCB Piezotronics, Inc.

3425 Walden Ave.

Depew, NY14043 USA

Toll-free: (800) 828-8840

24-hour SensorLineSM: (716) 684-0001

Website: www.pcb.com

E-mail: info@pcb.com

Page 3

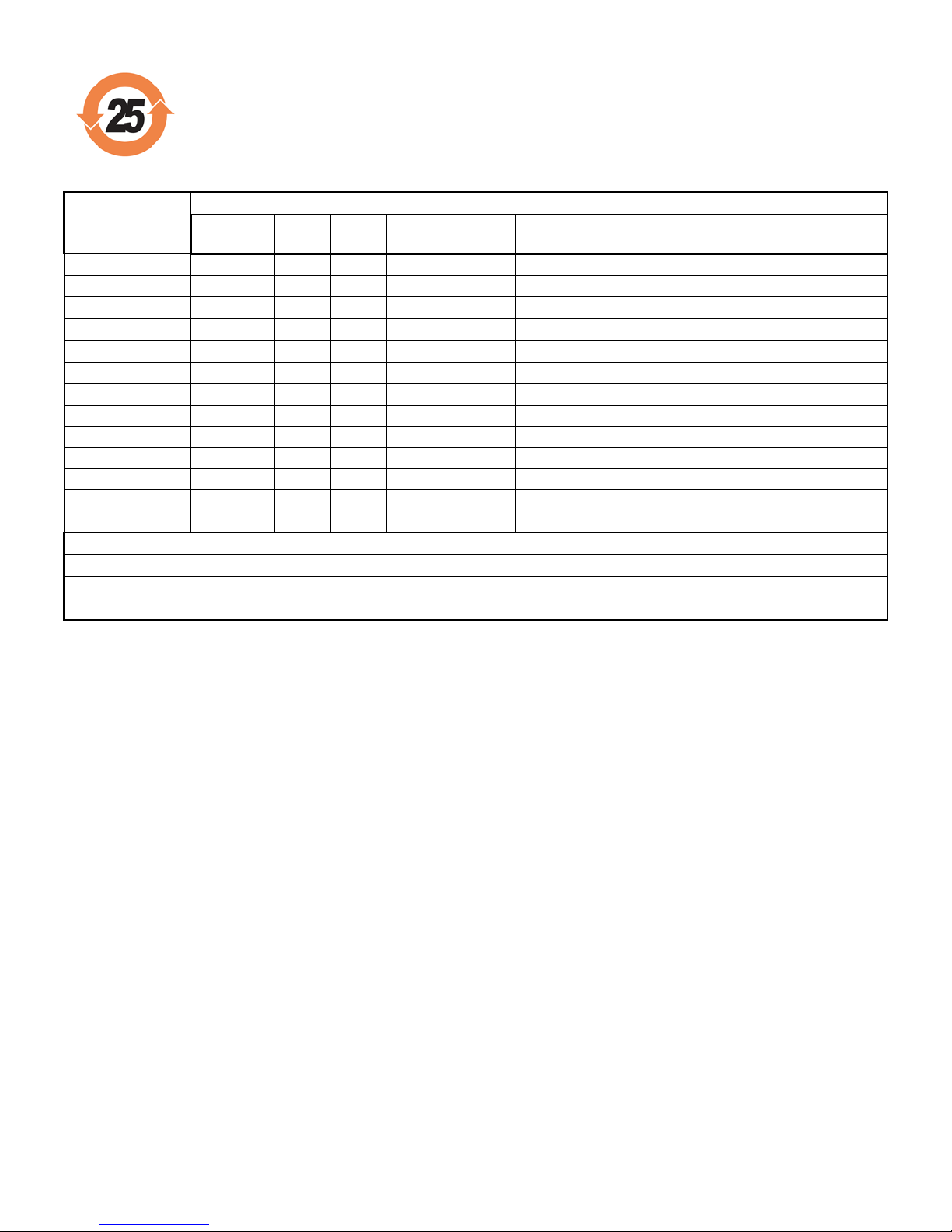

PCB工业监视和测量设备 - 中国RoHS2公布表

PCB Industrial Monitoring and Measuring Equipment - China RoHS 2 Disclosure Table

部件名称

有害物质

铅 (Pb)

汞

(Hg)

镉

(Cd)

六价铬 (Cr(VI))

多溴联苯 (PBB)

多溴二苯醚 (PBDE)

住房

O O O

O O O

PCB板

X O O

O O O

电气连接器

O O O

O O O

压电晶体

X O O

O O O

环氧

O O O

O O O

铁氟龙

O O O

O O O

电子

O O O

O O O

厚膜基板

O O X

O O O

电线

O O O

O O O

电缆

X O O

O O O

塑料

O O O

O O O

焊接

X O O

O O O

铜合金/黄铜

X O O

O O O

本表格依据 SJ/T 11364 的规定编制。

O: 表示该有害物质在该部件所有均质材料中的含量均在 GB/T 26572 规定的限量要求以下。

X: 表示该有害物质至少在该部件的某一均质材料中的含量超出 GB/T 26572 规定的限量要求。

铅是欧洲RoHS指令2011/65/ EU附件三和附件四目前由于允许的豁免。

CHINA RoHS COMPLIANCE

Page 4

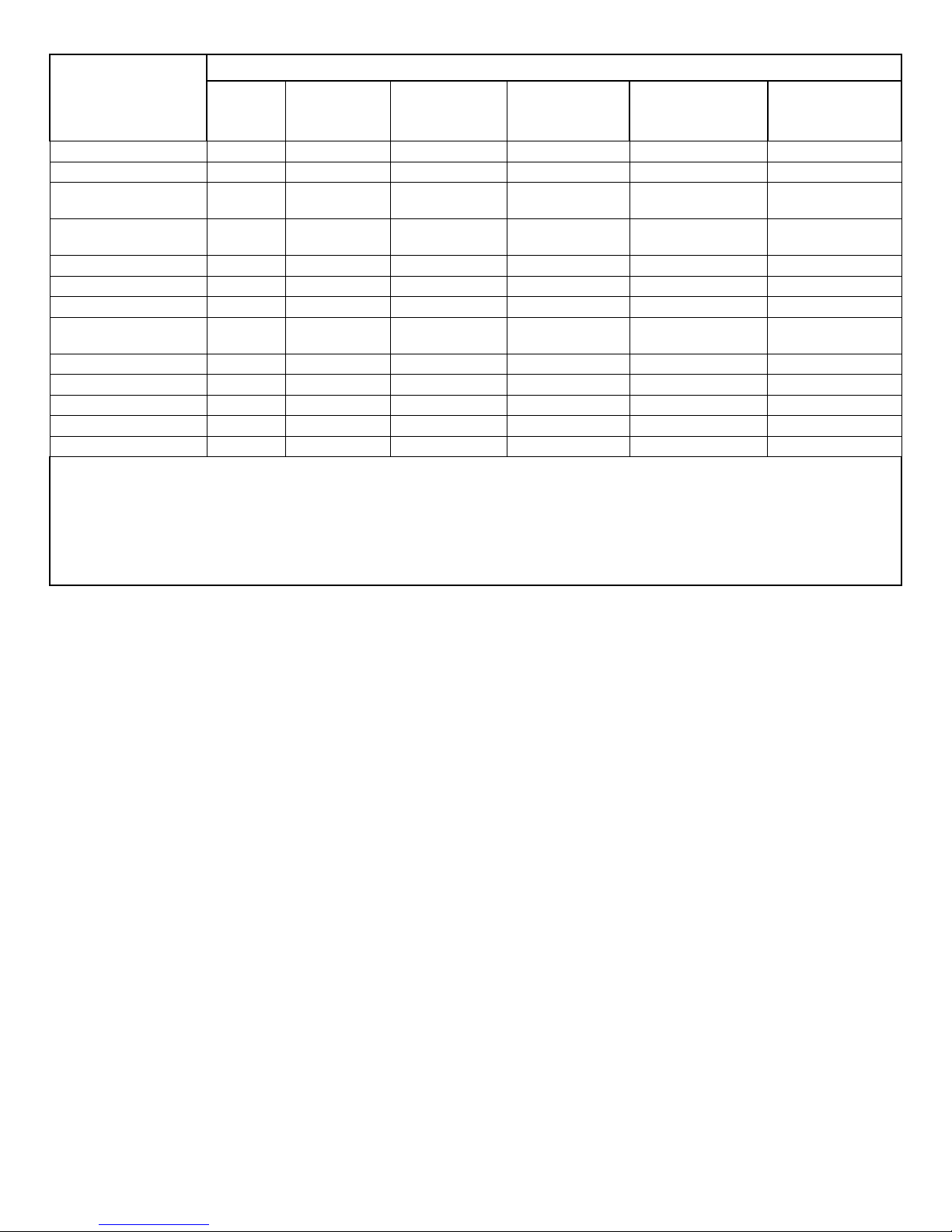

Component Name

Hazardous Substances

Lead

(Pb)

Mercury

(Hg)

Cadmium

(Cd)

Chromium VI

Compounds

(Cr(VI))

Polybrominated

Biphenyls

(PBB)

Polybrominated

Diphenyl

Ethers (PBDE)

Housing O O O O O O

PCB Board

X O O O O

O

Electrical

Connectors

O O O O O

O

Piezoelectric

Crystals

X O O O O

O

Epoxy O O O O O O

Teflon O O O O O O

Electronics

O O O O O

O

Thick Film

Substrate

O O X O O

O

Wires O O O O O O

Cables X O O O O O

Plastic O O O O O O

Solder X O O O O O

Copper Alloy/Brass

X O O O O

O

This table is prepared in accordance with the provisions of SJ/T 11364.

O: Indicates that said hazardous substance contained in all of the homogeneous materials for this part is below the limit

requirement of GB/T 26572.

X: Indicates that said hazardous substance contained in at least one of the homogeneous materials for this part is above

the limit requirement of GB/T 26572.

Lead is present due to allowed exemption in Annex III or Annex IV of the European RoHS Directive 2011/65/EU.

DOCUMENT NUMBER: 21354

DOCUMENT REVISION: D

ECN: 46162

Page 5

SENSORS AND INSTRUMENTATION FOR MACHINE CONDITION MONITORING

Model 682B05 Bearing Fault Detector

Operating Guide with Enclosed Warranty Information

3425 Walden Avenue, Depew, New York 14043-2495

Phone (716) 684-0003

Fax (716) 684-3823

Toll Free Line 1-800-959-4IMI

MANUAL NUMBER: 53377

MANUAL REVISION: B

ECN NUMBER: 46398

Page 6

SENSORS AND INSTRUMENTATION FOR MACHINE CONDITION MONITORING

Table of Contents

Introduction ...................................................................................................................... Page 3

General Features

Installation and Wiring ..................................................................................................... Page 4

Configuring the 682B05 ................................................................................................... Page 8

ESD Sensitivity ............................................................................................................... Page 10

Warranty/Servicing

Warranty, Service & Return Procedure .......................................................................... Page 11

Customer Service ........................................................................................................... Page 12

PAGE 2

Page 7

SENSORS AND INSTRUMENTATION FOR MACHINE CONDITION MONITORING

Acceleration (g’s)

Velocity (in/sec)

5.00

0.50

10.00

1.00

20.00

2.00

Introduction

The Model 682B05 is a 4-20mA Din Rail Signal Conditioner designed to interface with IMI Sensor’s ICP®

accelerometer for bearing fault detection. Specifically, the 682B05 detects high frequency impacts related to

bearing fault/lube starvation and provides a 4-20mA signal proportional to the magnitude of vibration. From the

same sensor, the device also converts overall vibration to a 4-20mA signal, which is used for traditional machine

diagnostics and predictive maintenance such as out of balance and misalignment.

General Features

Early detection of high frequency impact faults related to bearing failure and lube starvation.

External transmitters, signal conditioners, and ICP® power supplies can be eliminated by direct

connection of the sensor to the Din Rail Signal Conditioner.

18Vdc/4mA excitation to power sensor.

Dual 4-20mA Output Signals for Bearing Fault and Overall Vibration.

Selectable High Pass filtering for Bearing Fault Detection.

Overall Output Vibration Ranges include:

Internal DIP switch selection for Peak or RMS on Overall Vibration.

Analog output signal connections (RV) for conducting additional frequency analysis.

Removable Terminal Blocks for easy wiring.

35mm (1.38in.) Din Rail Mount configuration.

Space saving 22.5mm (0.9in.) wide design.

PAGE 3

Page 8

SENSORS AND INSTRUMENTATION FOR MACHINE CONDITION MONITORING

Installation and Wiring

Installation

The Model 682B05 is designed to be mounted on a 35mm Din Rail. Do not install in a harsh area where it can be

exposed to cleaning fluids or machine oils. IMI Sensors recommends mounting the 682B05 in a type NEMA 4

enclosure similar to the Model 682A00 to protect the electronics from contamination.

Dimension Drawing

Inch (mm)

PAGE 4

Page 9

SENSORS AND INSTRUMENTATION FOR MACHINE CONDITION MONITORING

Connector and Pinout Diagram

The 682B05 uses plug-in type screw terminal connectors for all input and output connections.

Strip off 8mm of insulation from the connection wire ends. Using a screwdriver, remove the terminal block from

the enclosure in either the up or down direction, terminate the wire in the correct location. Do not exceed a torque

of 0.5Nm. Re-install the terminal block.

This easy to assemble connection method allows devices to be exchanged easily and the electrical connection to

be visibly isolated.

WARNING

AC and DC input signals and power supply voltages could be hazardous. DO NOT

connect live wires to screw terminal plugs, and DO NOT insert, remove, or handle screw

terminal plugs with live wires connected.

Pin Location Diagram

PAGE 5

Page 10

SENSORS AND INSTRUMENTATION FOR MACHINE CONDITION MONITORING

Pin Descriptions:

DC Power – Pins 1 through 4:

Pin 1 +Power

Pin 2 -Power/Common

Pin 3 Earth Ground

Pin 4 No Connection

ICP® Accelerometer – Pins 5 through 8:

Pin 5 + ICP® Accelerometer

Pin 6 - ICP® Accelerometer

Pin 7 Shield

Pin 8 No Connection

Raw Vibration (RV) – Pins 9 through 12, and BNC Jack:

Pin 9 + RV

Pin 10 - RV

Pin 11 No Connection

Pin 12 No Connection

4 to 20mA Fault Detector Output – Pins 13 & 14:

Pin 13 + 4 to 20mA Fault Output

Pin 14 - 4 to 20mA Fault Output

4 to 20mA Overall Vibration Output – Pins 15 & 16:

Pin 15 + 4 to 20mA Vibration Output

Pin 16 - 4 to 20mA Vibration Output

Notes:

Pins 3 and 7 are tied together but are NOT tied to the grounding tab on the back of the enclosure.

Land the accelerometer cable’s shield on Pin 7.

Tie Pin 3 to either din rail ground or Earth ground with the use of an external wire.

PAGE 6

Page 11

SENSORS AND INSTRUMENTATION FOR MACHINE CONDITION MONITORING

Typical Wiring Diagram

Note: If using the 682A01, mount the 682B05 to the left side of the power supply (as shown) with a recommended

minimum separation distance of 4” where applicable.

PAGE 7

Page 12

SENSORS AND INSTRUMENTATION FOR MACHINE CONDITION MONITORING

T3

T4

T1

T2

T8

T7

T5

T11

T9

T10

T12

T15

T13

T14

T16

OUTPUT1

S3S2

R28

S1

R73

R65

S456

RMS

5K

ACCEL

VEL

PK

S4

S5

PT.NO. 50831-01PCB

S6

1K

R56

R55

T6

LED1

POWER

LED

Configuring the 682B05

Internal PC Board Diagram

The Internal PC Board Diagram shows the location of the internal DIP and Slide switches. The switches are used

to configure the 682B05 for various sensor and vibration ranges.

The PC Board is accessible through the front of the conditioner by removing the Screw Terminal Connectors and

disengaging the tabs on the TOP and BOTTOM of the enclosure with a screwdriver. Once disengaged, the PC

Board can be slid out for configuration.

DIP Switch and Slide Switch Description:

S1: BFD High Pass Filter: 1kHz or 5kHz

S2: Overall Vibration Acceleration or Velocity Mode

S3: Overall Vibration Peak or RMS Mode

S4: Overall: 5g, 0.5ips

S5: Overall: 10g, 1ips

S6: Overall: 20g, 2ips

PAGE 8

Page 13

SENSORS AND INSTRUMENTATION FOR MACHINE CONDITION MONITORING

Range Setting

S2

S3

S4

S5

S6

5g RMS

UP

UP

ON

OFF

OFF

5g Peak

UP

DOWN

ON

OFF

OFF

10g RMS

UP

UP

OFF

ON

OFF

10g Peak

UP

DOWN

OFF

ON

OFF

20g RMS

UP

UP

OFF

OFF

ON

20g Peak

UP

DOWN

OFF

OFF

ON

0.5 in/sec RMS

DOWN

UP

ON

OFF

OFF

0.5 in/sec Peak

DOWN

DOWN

ON

OFF

OFF

1.0 in/sec RMS

DOWN

UP

OFF

ON

OFF

1.0 in/sec Peak

DOWN

DOWN

OFF

ON

OFF

2.0 in/sec RMS

DOWN

UP

OFF

OFF

ON

2.0 in/sec Peak

DOWN

DOWN

OFF

OFF

ON

Speed Range (RPM)

Alert Limit (Peak g-level)

Alarm Limit (Peak g-level)

Less than 5

0.100

0.180

5 - 10

0.150

0.270

10 - 20

0.200

0.360

20 - 60

0.400

0.720

60 - 150

1.000

1.800

150 - 400

2.000

3.600

400 - 700

4.000

7.200

700 - 4000

5.000

9.000

4000 - 10000

7.000

12.600

Warning: Do not make any adjustments to the internal potentiometers. These potentiometers are used for

factory calibration and adjusting them will require return of the 682B05 to the factory for recalibration.

Internal Switch Settings

The internal switches of the Model 682B05 must be configured for the Full Scale Output of the ICP® Sensor

connected to it. This is accomplished by removing the front cover and sliding the PC Board out of the Signal

Conditioner. Once removed, the switches should be configured per one of the conditions in the following table.

Bearing Fault Detector: Set S1 for 1kHz or 5kHz (based on running speed). Range is fixed at 50g’s Peak.

Overall Vibration:

Note: Factory Default Setting is 1.0in/sec Peak

Recommended Alert and Alarm Settings for Fault Detector:

Although each machine will have alert and alarm settings at various levels based on its high frequency spectra,

data has been provided as a baseline to approximate what these limits should be. Note that this data is a

recommendation and levels should be adjusted according to measurements taken from a detailed vibration

analysis and/or machine history. Please contact IMI Sensors for additional information and support regarding Alert

and Alarm settings.

Recommended Fault Detector Alert and Alarm Limits

PAGE 9

Page 14

SENSORS AND INSTRUMENTATION FOR MACHINE CONDITION MONITORING

Warning 1 – ESD sensitivity

personnel. This product is intended for use by qualified personnel who recognize shock hazards and are familiar

with the safety precautions required to avoid injury.

Warning 2 – ESD sensitivity

This equipment is designed with user safety in mind; however, the protection provided by the equipment may be

impaired if the equipment is used in a manner not specified by PCB Piezotronics, Inc.

Caution 1 – ESD sensitivity

Cables can kill your equipment. High voltage electrostatic discharge (ESD) can damage electrical devices.

Similar to a capacitor, a cable can hold a charge caused by triboelectric transfer, such as that which occurs in the

following:

Laying on and moving across a rug,

Any movement through air,

The action of rolling out a cable, and/or

Contact with a non-grounded person.

The PCB solution for product safety:

Connect the cables only with the AC power off.

Temporarily “short” the end of the cable before attaching it to any signal input or output.

Caution 2 – ESD sensitivity

PAGE 10

Page 15

SENSORS AND INSTRUMENTATION FOR MACHINE CONDITION MONITORING

ESD considerations should be made prior to performing any internal adjustments on the equipment. Any

piece of electronic equipment is vulnerable to ESD when opened for adjustments. Internal adjustments should

therefore be done ONLY at an ESD-safe work area. Many products have ESD protection, but the level of

protection may be exceeded by extremely high voltage.

Warranty

IMI instrumentation is warranted against defective material and workmanship for 1 year unless otherwise

expressly specified. Damage to instruments caused by incorrect power or misapplication, is not covered by

warranty. If there are any questions regarding power, intended application, or general usage, please consult with

your local sales contact or distributor. Batteries and other expendable hardware items are not covered by

warranty.

Service

Because of the sophisticated nature of IMI instrumentation, field repair is typically NOT recommended and may

void any warranty. If factory service is required, return the instrumentation according to the “Return Procedure”

stated below. A repair and/or replacement quotation will be provided prior to servicing at no charge. Before

returning the unit, please consult a factory IMI applications engineer concerning the situation as certain problems

can often be corrected with simple on-site procedures.

Return procedure

To expedite returned instrumentation, contact a factory IMI applications engineer for a RETURN MATERIAL

AUTHORIZATION (RMA) NUMBER. Please have information available such as model and serial number. Also,

to insure efficient service, provide a written description of the symptoms and problems with the equipment to a

local sales representative or distributor, or contact IMI if none are located in your area.

Customers outside the U.S. should consult their local IMI distributor for information on returning equipment. For

exceptions, please contact the International Sales department at IMI to request shipping instructions and an RMA.

For assistance, please call (716) 684-0003, or fax us at (716) 684-3823. You may also receive assistance via email at imi@pcb.com or visit our web site at www.pcb.com.

PAGE 11

Page 16

SENSORS AND INSTRUMENTATION FOR MACHINE CONDITION MONITORING

3425 Walden Avenue, Depew, NY 14043-2495

Phone: (716) 684-0003 USA Fax: (716) 684-3823 INTL Fax: (716) 684-4703

ICP® is a registered trademark of PCB Group, Incorporated,

which uniquely identifies PCB sensors that incorporate built-in microelectronics.

Customer Service

IMI, a division of PCB Piezotronics, guarantees Total Customer Satisfaction. If, at any time, for any reason, you

are not completely satisfied with any IMI product, IMI will repair, replace, or exchange it at no charge. You may

also choose, within the warranty period, to have your purchase price refunded.

IMI offers to all customers, at no charge, 24-hour phone support. This service makes product or application

support available to our customers, day or night, seven days a week. When unforeseen problems or emergency

situations arise, call the IMI Hot Line at (716) 684-0003, and an application specialist will assist you.

PAGE 12

Page 17

Loading...

Loading...