Page 1

ICE MAKER

POCKET GUIDE

“I” SERIES CUBE

ICE MAKERS

IMI CORNELIUS

One Cornelius Place

Anoka, MN 55303

1–800–238–3600

Rev 9/18/95

TD 2023/1/95

Page 2

TABLE OF CONTENTS

introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Original Owner, End-user responsibility 1. . . . . . . . . . . .

Serial Plate Locations 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model and Serial Number Defined 2. . . . . . . . . . . . . . . . . . . .

Serial Number Defined After January 1, 1995 3. . . . . . . . . .

Electrical Specification 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Condenser 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ICE CAPACITY INFORMATION 11. . . . . . . . . . . . . . . . . . .

Ice Capacity 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ice Production Check 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTMENT OF ICE BRIDGE THICKNESS 12. . . . . . . .

Ice production capacities and charts 14-29. . . . . . . . . . . .

IAC322/IAC330 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IWC322/IWC330 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IAC522/IAC530 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IWC522/IWC530 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IAC630 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IWC630 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IRC630 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IAC830 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IWC830 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IRC830 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IAC1230 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IWC1230 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IRC1230 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IAC1448 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IWC1448 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IRC1448 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sequence of Operation 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Component Functions 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Board 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED Indicators 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED status indicator chart 32-34. . . . . . . . . . . . . . . . . . . .

Reset Operation 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Voltage Selector Switch 34. . . . . . . . . . . . . . . . . . . . . . . .

Stacking Cable 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Plug 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dump Cycle Options 35. . . . . . . . . . . . . . . . . . . . . . . . . .

Condenser Fan Cycling Control (Intergal Condenser) 36.

Harvest Safety Termination 36. . . . . . . . . . . . . . . . . . . . .

Circuit Board Diagnosis 36. . . . . . . . . . . . . . . . . . . . . . . .

PAGE

i

TD 202

Page 3

TABLE OF CONTENTS (CONT’D)

Sensors 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sensor [Thermistor] Diagnosis 38. . . . . . . . . . . . . . . . . . . . . . .

Evaporator Switches 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switch Notes 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Voltage Checks 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Water Regulating Valve 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

High Pressure Safety Switch 40. . . . . . . . . . . . . . . . . . . . . . . . .

Float Valve with Flow Washer 41. . . . . . . . . . . . . . . . . . . . . . .

Service Stem Valves 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thermostatic Expansion Valves 41. . . . . . . . . . . . . . . . . . . . . .

diagnosis 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starving TXV - Product Symptoms 42. . . . . . . . . . . . . . . . . . .

Flooding TXV - Product Symptoms 42. . . . . . . . . . . . . . . . . . .

Head Pressure Control Valve [Headmaster} Fan Cycle Switch

Contactor Compressor 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compressor & Starting Component Check-Out Procedure 45

Relay 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Capacitors 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compressor 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Moisture Contamination 47. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Diagrams 49-54. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning Procedures 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prep – Cleaning 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Water System & Evaporator 59. . . . . . . . . . . . . .

Sanitizing Procedures 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(Remote Units Only) 43. . . . . . . . . . . . . . . . . . . . . .

Potential – 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Current – 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PAGE

TD 202

ii

Page 4

introduction

This guide is published as an aid to the Service Technician. It is not

intended to replace the service manual. In it you will find useful information not found in the service manual. This information will

help you more quickly identify specific problems, however not all

problems or situations may be listed. We appreciate your comments

or suggestions, or if you have a specific problem not addressed in

this guide or service manual.

Please feel free to contact our service department at:

IMI CORNELIUS

One Cornelius Place

Anoka, MN 55303

1–800–554–3526

The warranty on Cornelius icemakers begins on the date of installation, as reported on the warranty registration card to the original

owner/user. If no warranty card is received by the factory, the date

of shipment from the factory will determine the start of the warranty.

Warranty labor will be paid per the labor rate guide and is subject to

change without notice. Call the Service Department for a copy of the

current Labor Rate Guide and/or applicable Warranty Document

Copy.

ORIGINAL OWNER, END-USER RESPONSIBILITY

1. To verify the equipment installation date by the return

of the warranty registration card to the factory within

five days of the installation.

2. To pay freight or handling charge.

3. To pay for service labor and/or parts required to correct improperly installed equipment. Installation must

comply with the installation instructions.

4. To pay for normal maintenance, adjustments and

cleaning.

5. To pay for service labor and/or parts required to correct unit modification or the use of non-approved remote condensers.

6. To pay for service labor and/or parts required because

of neglect, abuse, misuse, accident, fire, flood, freezing or any act of God.

7. To pay for mileage, truck charges, travel time, premium labor for holidays, weekends or after hours

work, flat rate service call charges, miscellaneous tool

charges, use of diagnostic meters or equipment and all

material not listed on the Warranty Time Rate Guide.

Rev 9/18/95

1 TD 2023/1/95

Page 5

Serial Plate Locations

Exterior: Left side, Lower Front corner.

Interior: Firewall, Front.

Model and Serial Number Defined

IAC 1230

IAC1230

Product

Identifica-

tion

94 A C E 0000

Year

(the first 2

digits

indicates

year of

produc-

tion)

Month of production code will be:

Note: The letter (I) is not used to avoid being confused with the

number(1)

Product Code:

A = Accessory* D = Dispenser (motel/hotel)

B = Bin (storage) E = External condenser (Remote)

C = Cuber F = Flaker

* Any accessory determined to be required to have a serial number.

A=Air

Cooled

Condenser

W=Water

Cooled

R=Remote

Month

Production

A = January G = July

B = February H = August

C = March J = September

D = April K = October

E = May L = November

F = June M = December

Cuber Series

Product

Code

Manufac-

turing

Tracking

Code

30” Wide

3

5

6

8

10

12

14

Cabinet

22 = 22”

Wide

48 = 48”

wide

Unit

Serial

Number

2TD 202 3/1/95

Rev 9/18/95

Page 6

Serial Number Defined

after January 1, 1995

AF 95 01 BC 0000

Eng

change

level

Engineering change level can be either 1 or 2 digits depending

on the revision level.

Month of production code will be:

01 = January 07 = July

02 = February 08 = August

03 = March 09 = September

04 = April 10 = October

05 = May 11 = November

06 = June 12 = December

Note: The Month must always be 2 digits.

Product Code:

BA = Accessory* BD = Dispenser (motel/hotel)

BB = Bin (storage) BE = External condenser (Remote)

BC = Cuber BF = Flaker

* Any accessory determined to be required to have a serial number.

year Month Product

Code

Unit

Serial

Number

Rev 9/18/95

3 TD 2023/1/95

Page 7

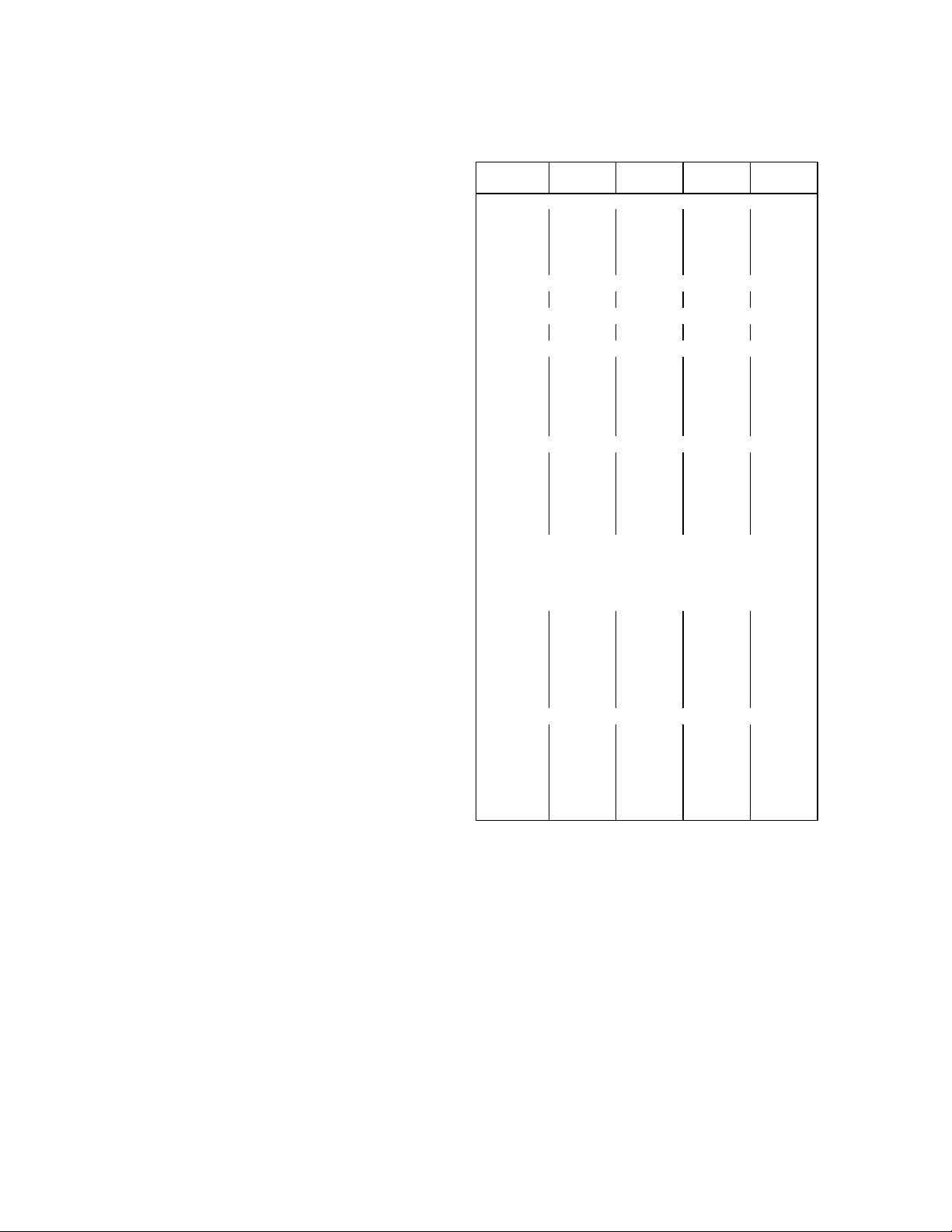

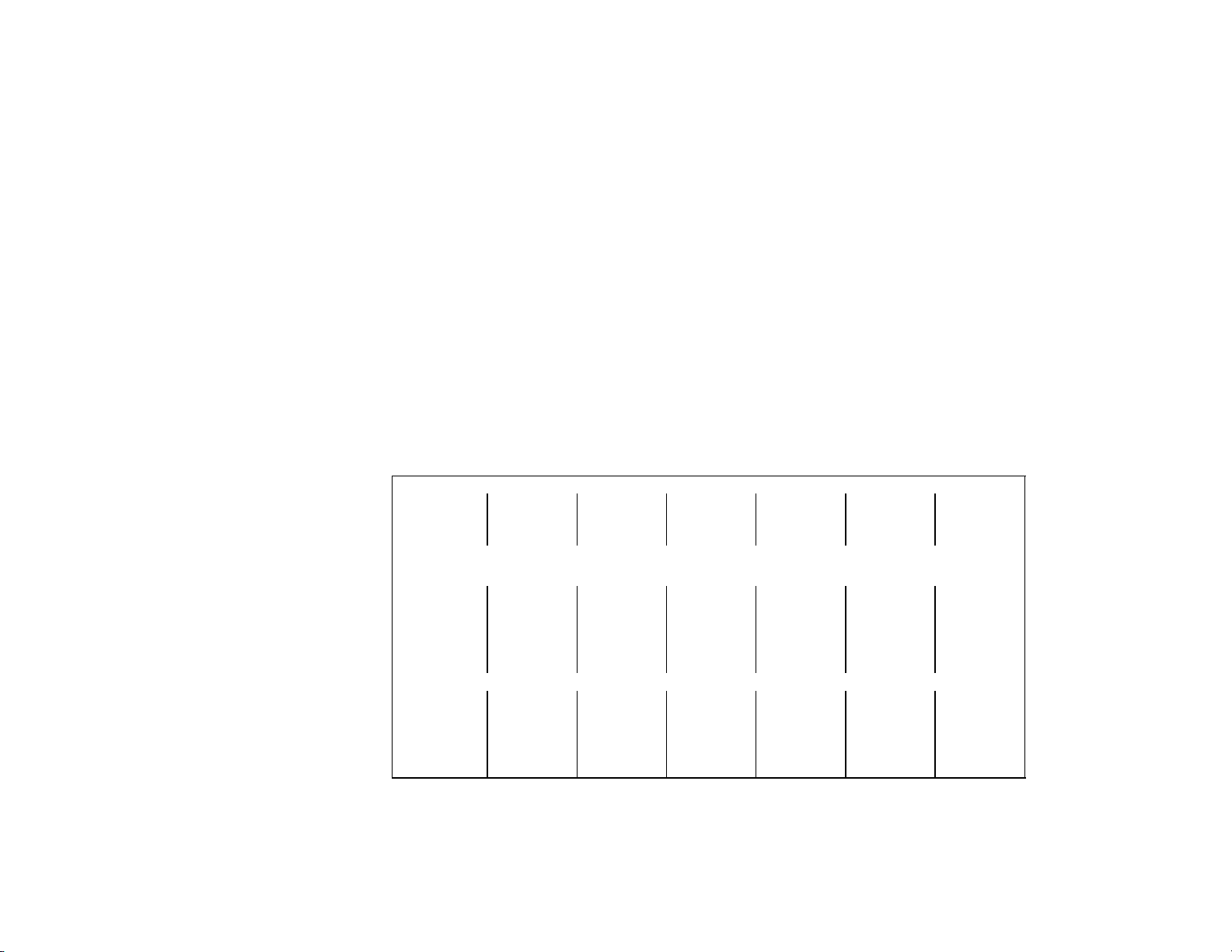

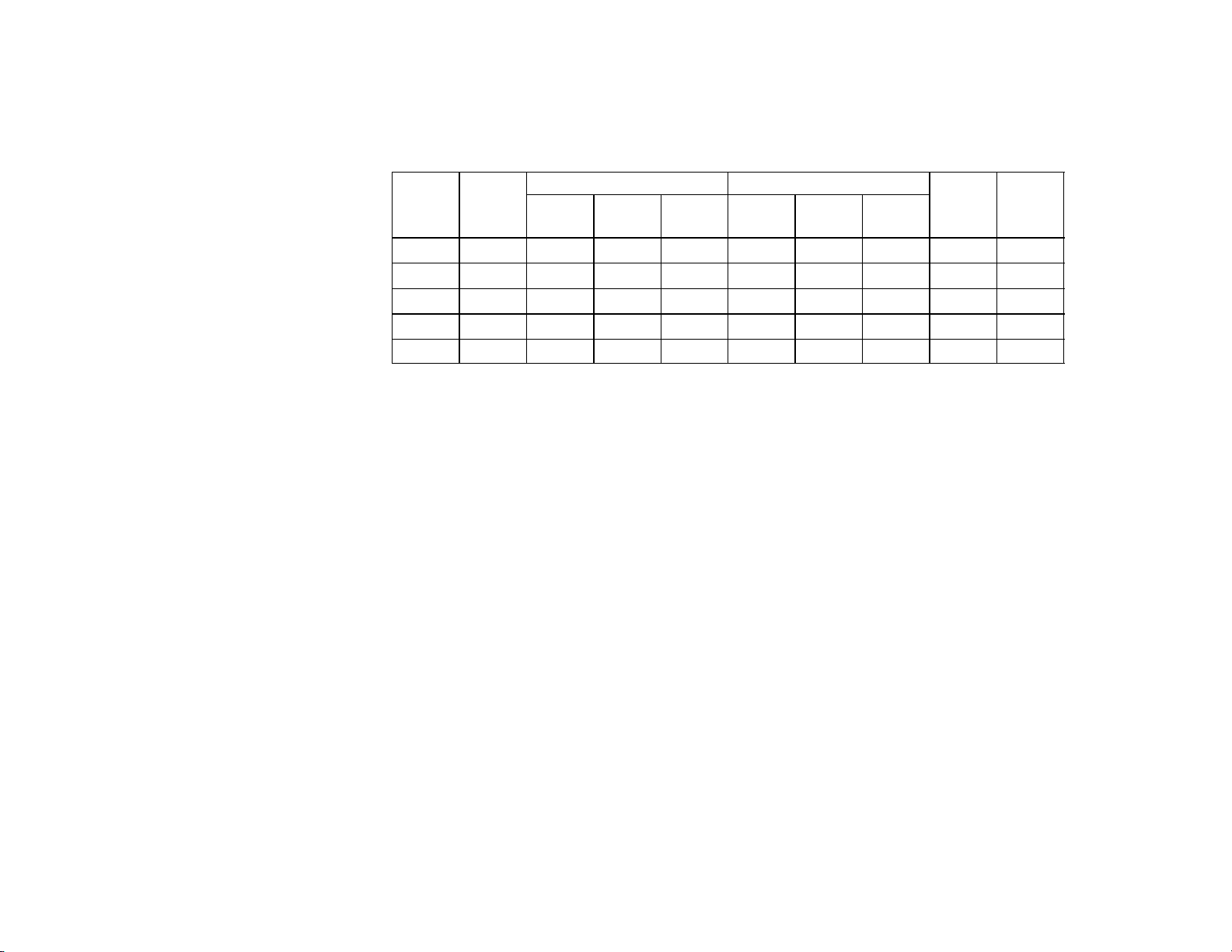

Electrical Specification

MODEL

UNIT

Volts 115 115 115 115

Phase 1 1 1 1

Hertz 60 60 60 60

No. Wires 2+ground 2+ground 2+ground 2+ground

MIN. CIRCUIT

Amps 20 20 20 20

MAX FUSE SIZE (HVAC CIRCUIT BREAKER REQ)

Amps 20 20 20 20

REFRIGERANT

Type

Weight

(oz)

Weight (g) 482 425 737 652

COMPRESSOR

Volts 115 115 115 115

Phase 1 1 1 1

Hertz 60 60 60 60

LRA 51 51 59 59

RLA 11.5 11.5 11.6 11.6

CONDENSER FAN MOTOR (Air-Cooled System

Y OR

onl

AIR CIRCULATION FAN MOTOR (Water-Cooled

and Remote Systems only)

Volts 115 115 115 115

Phase 1 1 1 1

Hertz 60 60 60 60

Amps

Running

Watts 50 6 50 6

WATER PUMP

Volts 115 115 115 115

Phase 1 1 1 1

Hertz 60 60 60 60

Amps

Running

HP 1/40 1/40 1/40 1/40

IAC322/330IWC322/330IAC522/530IWC522/5

R404a

(HP62)

17 15 26 23

1.7 0.38 1.75 0.38

0.88 0.88 0.76 0.88

R404a

(HP62)

R404a

(HP62)

R404a

(HP 62)

30

4TD 202 3/1/95

Rev 9/18/95

Page 8

Rev 9/18/95

5 TD 2023/1/95

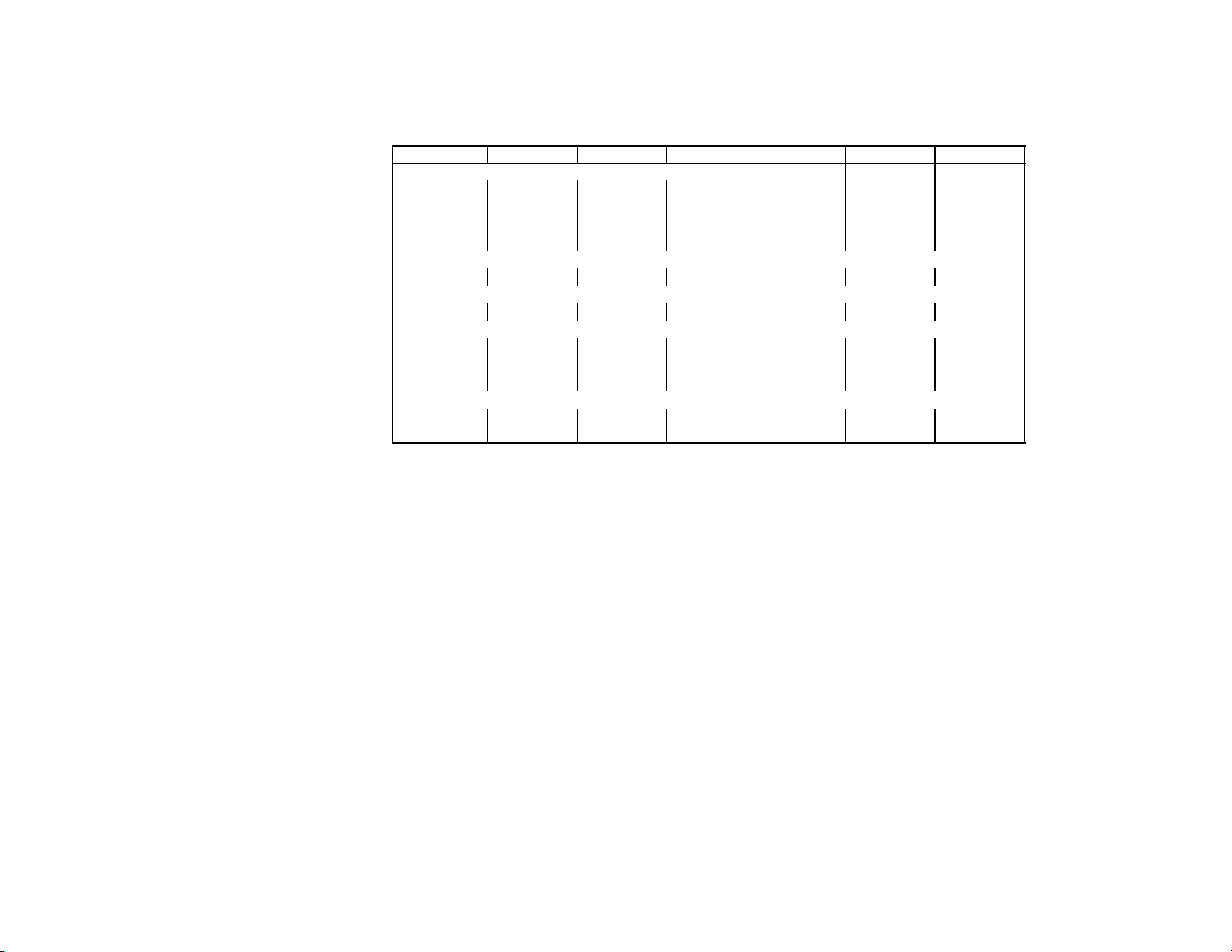

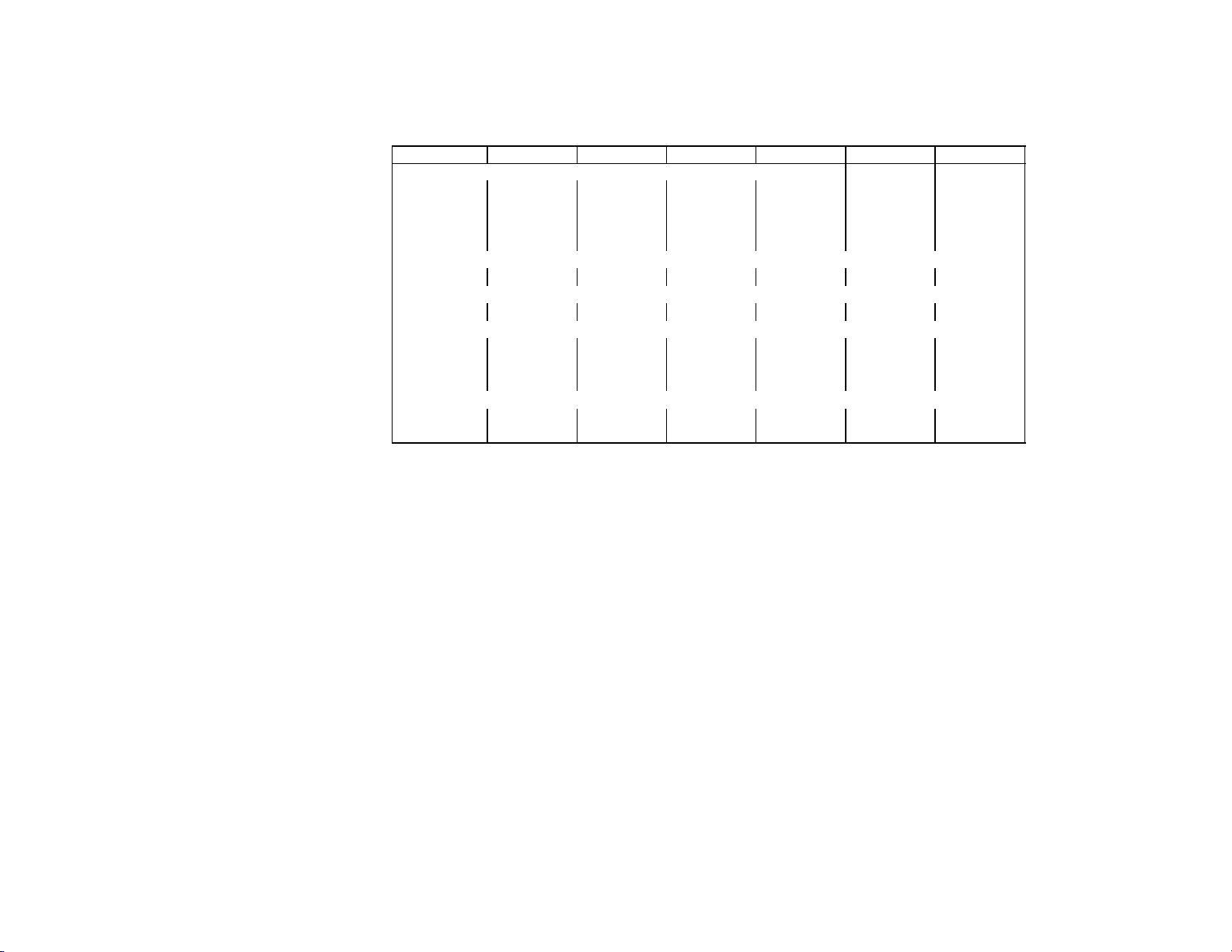

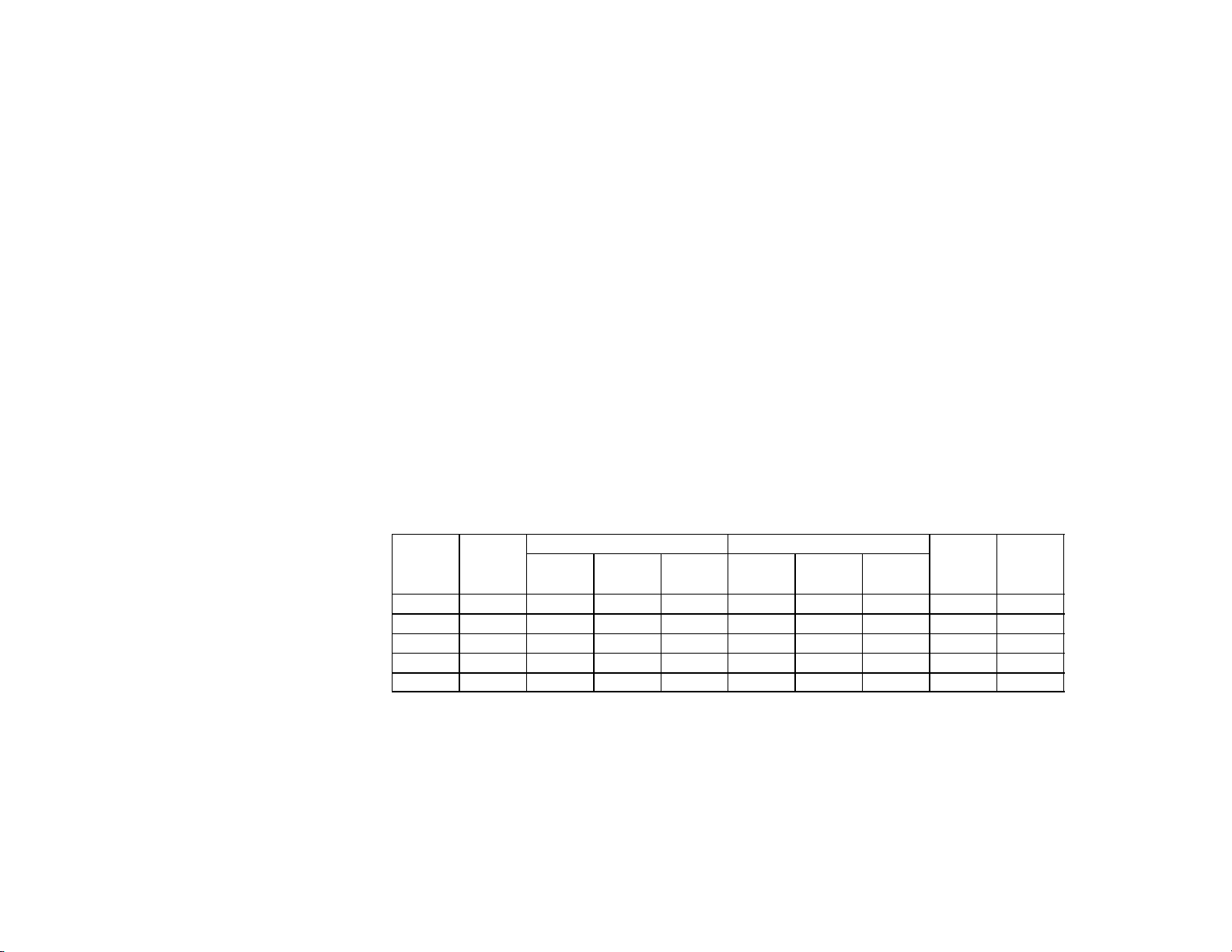

MODEL IAC630 IWC630 IRC630 IAC830 IWC830 IRC830

UNIT ELEC.

Volts 208/230 208/230 208/230 208/230 208/230 208/230

Phase 1 1 1 1 1 1

Hertz 60 60 60 60 60 60

No. Wires 2+ground 2+ground 2+ground 2+ground 2+ground 2+ground

MIN. CIRCUIT

Amps 20 20 20 20 20 20

MAX FUSE SIZE (HVAC CIRCUIT BREAKER REQUIRED)

Amps 20 20 20 20 20 20

REFRIGERANT

Type R404a(HP62) R404a(HP62) R404a(HP62) R404a(HP 62) R404a(HP 62) R404a(HP 62)

Weight (oz) 43 35 170 55 33 170

Weight (g) 1219 992 4820 1559 936 4820

COMPRESSOR

Volts 230 230 230 230 230 230

Phase 1 1 1 1 1 1

Page 9

COMPRESSOR (CONT’D)

Hertz 60 60 60 60 60 60

LRA 69 69 69 61 61 61

RLA 8.8 8.8 8.8 12.5 12.5 12.5

CONDENSER FAN MOTOR (Air-Cooled System only) or

AIR CIRCULATION FAN MOTOR (Water-Cooled and Remote Systems only)

Volts 230 230 230 230 230 230

Phase 1 1 1 1 1 1

Hertz 60 60 60 60 60 60

6TD 202 3/1/95

Amps Running 1.09 0.36 0.36 1.09 0.36 0.36

Watts 75 6 6 75 6 6

WATER PUMP

Volts 208/230 208/230 208/230 208/230 208/230 208/230

Phase 1 1 1 1 1 1

Rev 9/18/95

Hertz 60 60 60 60 60 60

Amps Running 0.5 0.5 0.5 0.5 0.5 0.5

HP 1/30 1/30 1/30 1/30 1/30 1/30

All Product Supply Voltages Should Read 208/230 –5%, +10%

Page 10

Rev 9/18/95

7 TD 2023/1/95

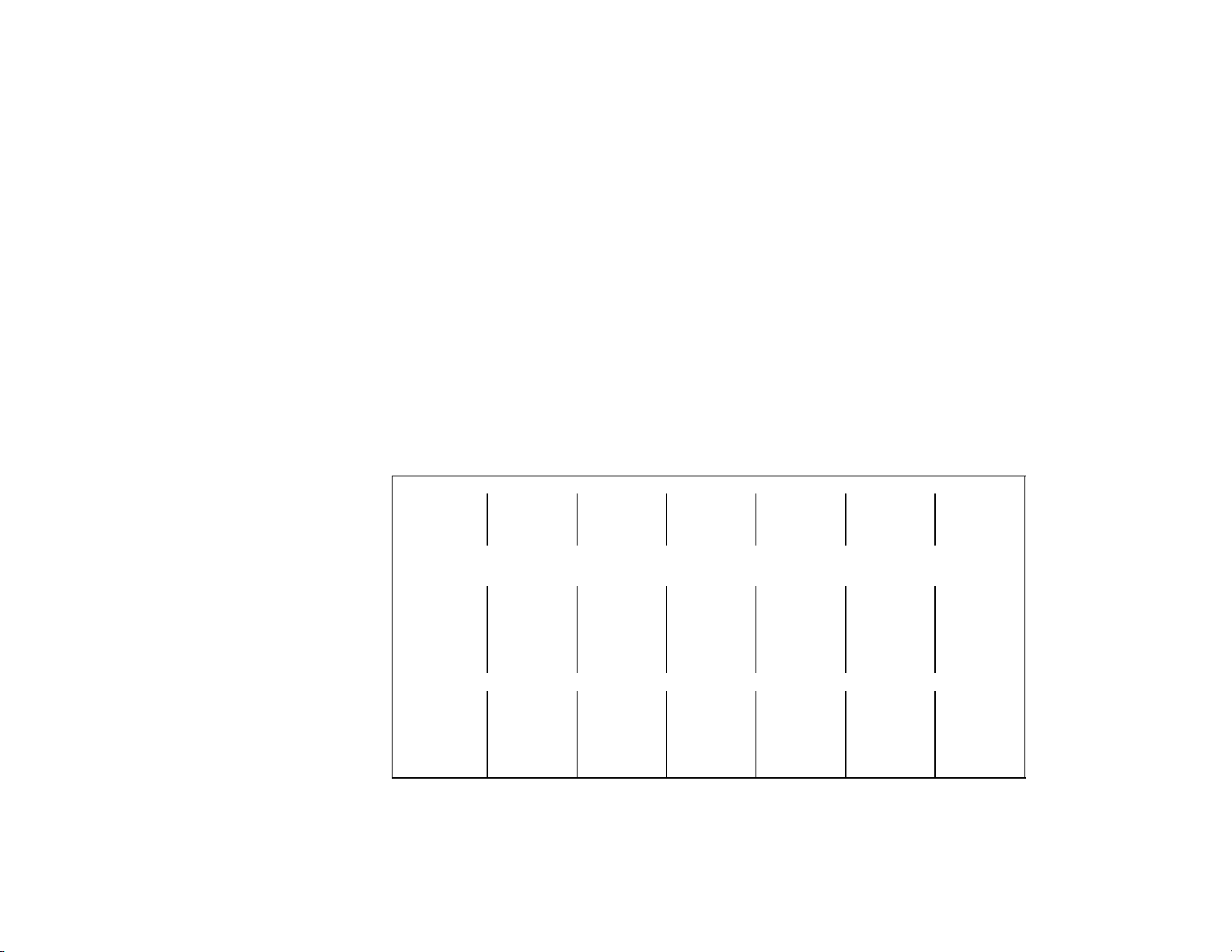

MODEL IAC1230 IWC1230 IRC1230 IAC1448 IWC1448 IRC1448

UNIT ELEC.

Volts 208/230 208/230 208/230 208/230 208/230 208/230

Phase 1 1 1 1 1 1

Hertz 60 60 60 60 60 60

No. Wires 2+ground 2+ground 2+ground 2+ground 2+ground 2+ground

MIN. CIRCUIT

Amps 20 20 20 25 25 25

MAX FUSE SIZE (HVAC CIRCUIT BREAKER REQUIRED)

Amps 20 20 20 25 25 25

REFRIGERANT

Type R404a(HP62) R404a(HP62) R404a(HP62) R404a(HP 62) R404a(HP 62) R404a(HP 62)

Weight (oz) 49 45 210 92 44 250

Weight (g) 1389 1276 5954 2608 1247 7088

COMPRESSOR

Volts 208/230 208/230 208/230 208/230 208/230 208/230

Phase 1 1 1 1 1 1

Page 11

COMPRESSOR (CONT’D)

Hertz 60 60 60 60 60 60

LRA 96 96 96 95.6 95.6 95.6

RLA 13.5 13.5 13.5 23.9 23.9 23.9

CONDENSER FAN MOTOR (Air-Cooled System only) or

AIR CIRCULATION FAN MOTOR (Water-Cooled and Remote Systems only)

Volts 230 230 230 230 230 230

Phase 1 1 1 1 1 1

Hertz 60 60 60 60 60 60

8TD 202 3/1/95

Amps Running 0.89 X 2 0.36 0.36 0.4 0.36 0.36

Watts 50 W X 2 6 W 6 W 1/15 HP 6 W 6 W

WATER PUMP

Volts 208/230 208/230 208/230 208/230 208/230 208/230

Phase 1 1 1 1 1 1

Rev 9/18/95

Hertz 60 60 60 60 60 60

Amps Running 0.5 0.5 0.5 0.5 0.5 0.5

HP 1/30 1/30 1/30 1/30 1/30 1/30

All Product Supply Voltages Should Read 208/230 –5%, +10%

Page 12

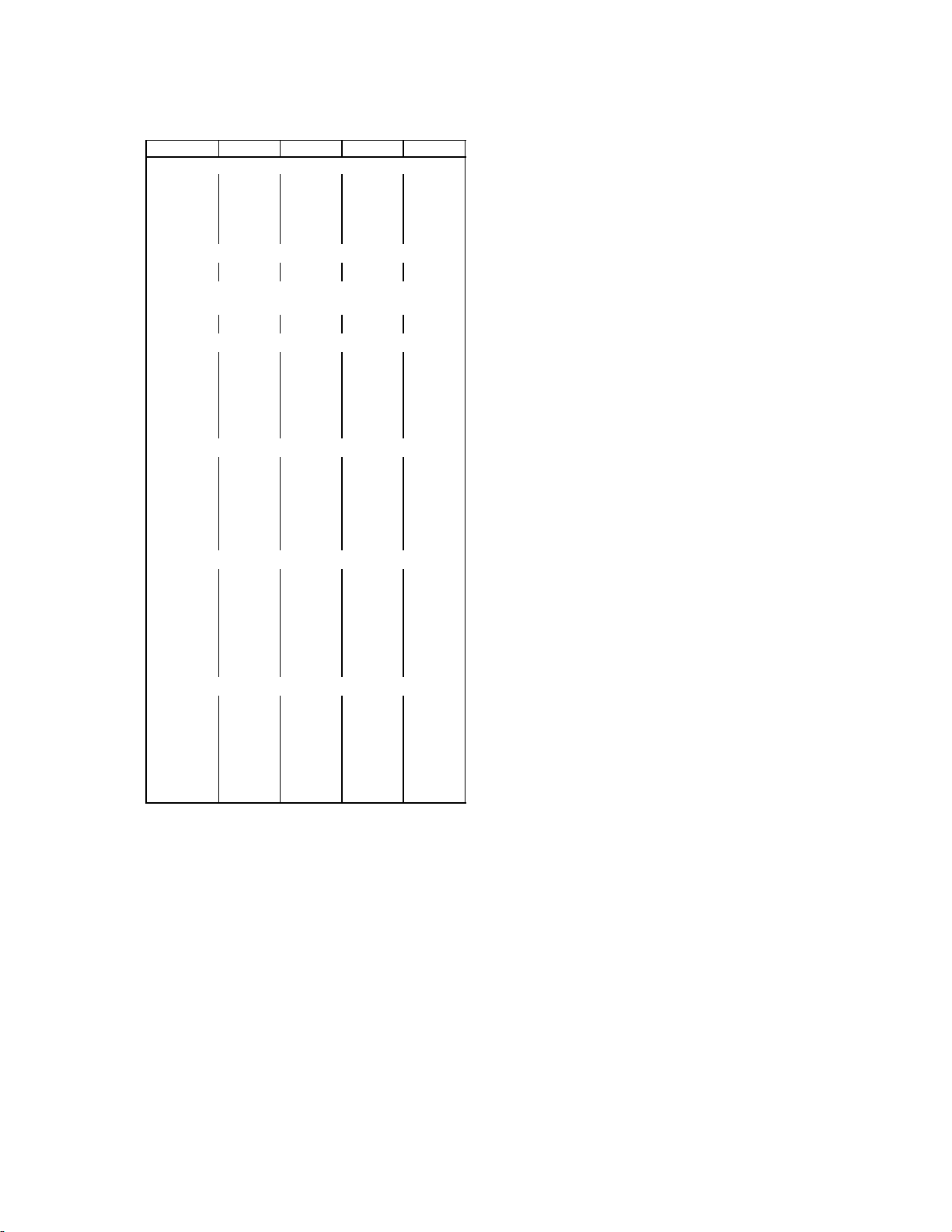

MODEL IRC630 IRC830. IRC1230 IRC1448

UNIT

Volts 230 230 230 230

Phase 1 1 1 1

Hertz 60 60 60 60

No. Wires 2+ground 2+ground 2+ground 2+ground

MIN. CIRCUIT

Amps 20 20 20 25

MAX FUSE SIZE (HVAC CIRCUIT BREAKER REQUIRED)

Amps 20 20 20 25

REFRIGERANT

Type

Weight

(oz)

Weight (g) 4820 4820 5954 7088

COMPRESSOR

Volts 230 230 230 230

Phase 1 1 1 1

Hertz 60 60 60 60

LRA 69 61 96 95.6

RLA 8.8 12.5 13.5 23.9

AIR CIRCULATION FAN MOTOR

Volts 230 230 230 230

Phase 1 1 1 1

Hertz 60 60 60 60

Amps

Running

Watts 6 6 6 6

WATER PUMP

Volts 230 230 230 230

Phase 1 1 1 1

Hertz 60 60 60 60

Amps

Running

HP 1/30 1/30 1/30 1/30

R404a

(HP62)

170 170 210 250

0.36 0.36 0.36 0.36

0.5 0.5 0.5 0.5

R404a

(HP62)

R404a

(HP62)

R404a

(HP 62)

Rev 9/18/95

9 TD 2023/1/95

Page 13

Remote Condenser

MODEL CR800 CR1200 CR1400

Volts 230 230 230

Phase 1 1 1

Hertz 60 60 60

Amps 1.0 1.0 1.0

Output, HP 1/6 1/6 1/6

Max. fuse size, Amps (HVAC

circuit breaker

required)

20 20 20

10TD 202 3/1/95

Rev 9/18/95

Page 14

ICE CAPACITY INFORMATION

Ice Capacity

Ice capacity of any ice maker is affected by many operating conditions, such as water and air temperature and location factors. Please

review the capacity tables in this manual for average 24–hour capacity under various conditions.

NOTE: All printed capacity ratings are 10% except 50 HZ

units these products have 12% increase in cycle time

and capacity decrease of approximately 17%.All

printed capacity ratings are 10% except 50 HZ

units these products have 12% increase in cycle time

and capacity decrease of approximately 17%.

Ice Production Check

If air cooled, take air temperature at the intake of the condenser, 2I

from the condenser fins.. Incoming water temperature at the outlet

of the “float” valve.*

Cycle time (CT) = freeze time plus harvest time, in minutes and seconds. 1440 divided by CT = number of cycles per 24 hours.

Measure weight of ice from one cycle in pounds and fractions of a

pound.

Example: Weight/cycle x cycles/day = total production/24 hrs.

* If water cooled be certain water regulator valve is set to maintain

300/310 PSI head pressure.

Compare to the production tables.

Rev 9/18/95

11 TD 2023/1/95

Page 15

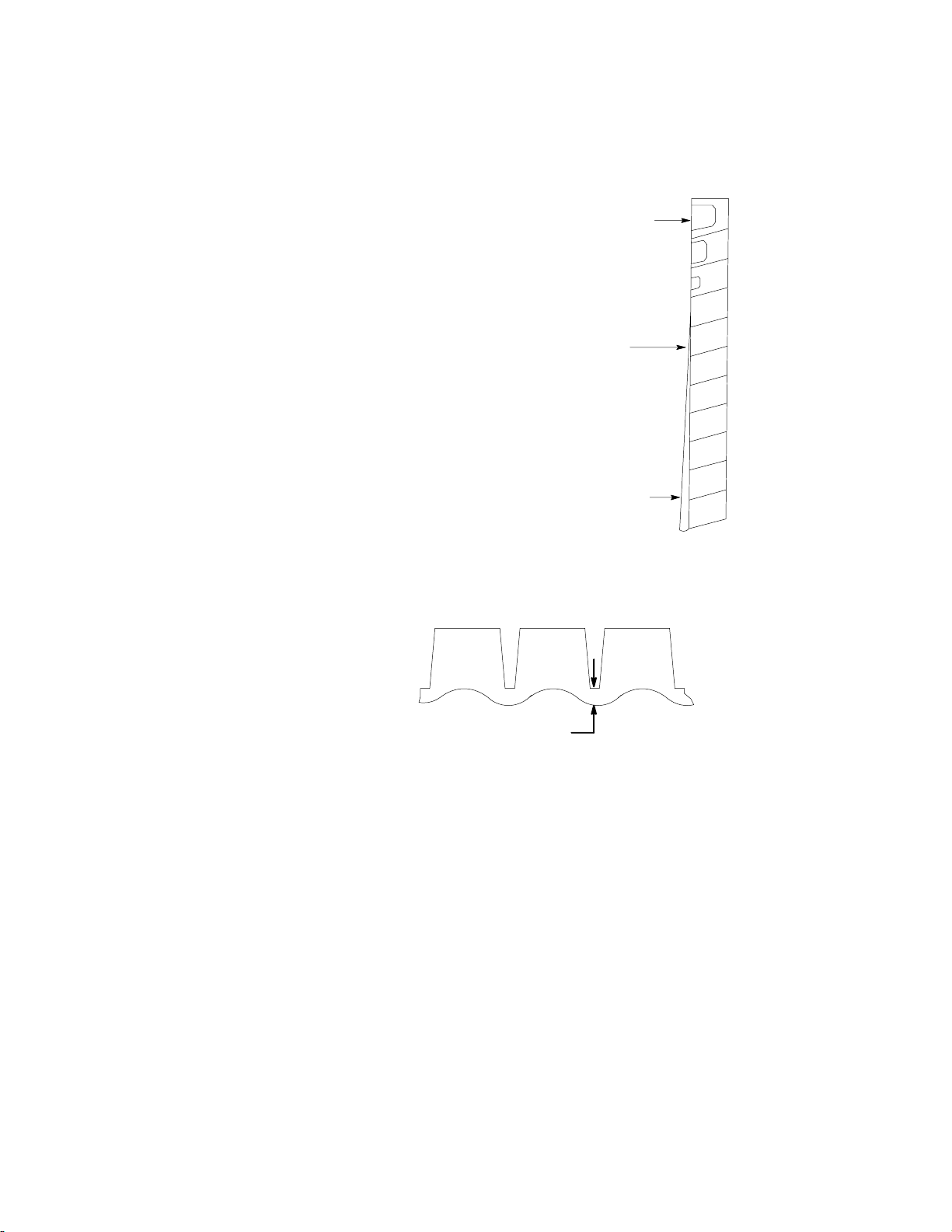

ADJUSTMENT OF ICE BRIDGE

THICKNESS

TOP ROW

3/8” - 5/8” DIM-

PLE

CENTER

1/8” BRIDGE

BOTTOM 2

ROWS

3/16” - 1/4”

BRIDGE

For optimum ice production and maximum cube separation, the ice

connecting the individual cubes should be a minimum of 1/8”

(.32cm) thick at the center area of the ice waffle.

BRIDGE 1/8I (0.32 CM)

It is normal for the ice slab to be slightly thicker at the bottom and

taper off in a slight wedge pattern at the top. The top row of cubes

must have a complete pattern of ice on all four sides and the back

wall. Remember, when you operate the product with the panels off

during testing the additional heat at the top of the evaporator will

cause thinner ice at the top than when the panels are in place.

12TD 202 3/1/95

Rev 9/18/95

Page 16

Should a different thickness of the bridge be desired, it will be required to adjust the ice thickness “POT”, located on the circuit

board, as follows:

1. Thinner Bridge – turn the ice thickness “pot” adjustment screw CW one full turn. Allow two cycles

before determining if additional adjustments are required.

2. Thicker Bridge – turn the ice thickness “pot” adjusting

screw CCW one full turn. Allow two cycles before

determining if additional adjustments are required.

NOTE: Never judge the thickness of the ice from the first

batch of the ice produced – the first cycle is a bal-

ance cycle. Always wait for the second cycle before

making any adjustments.

Rev 9/18/95

13 TD 2023/1/95

Page 17

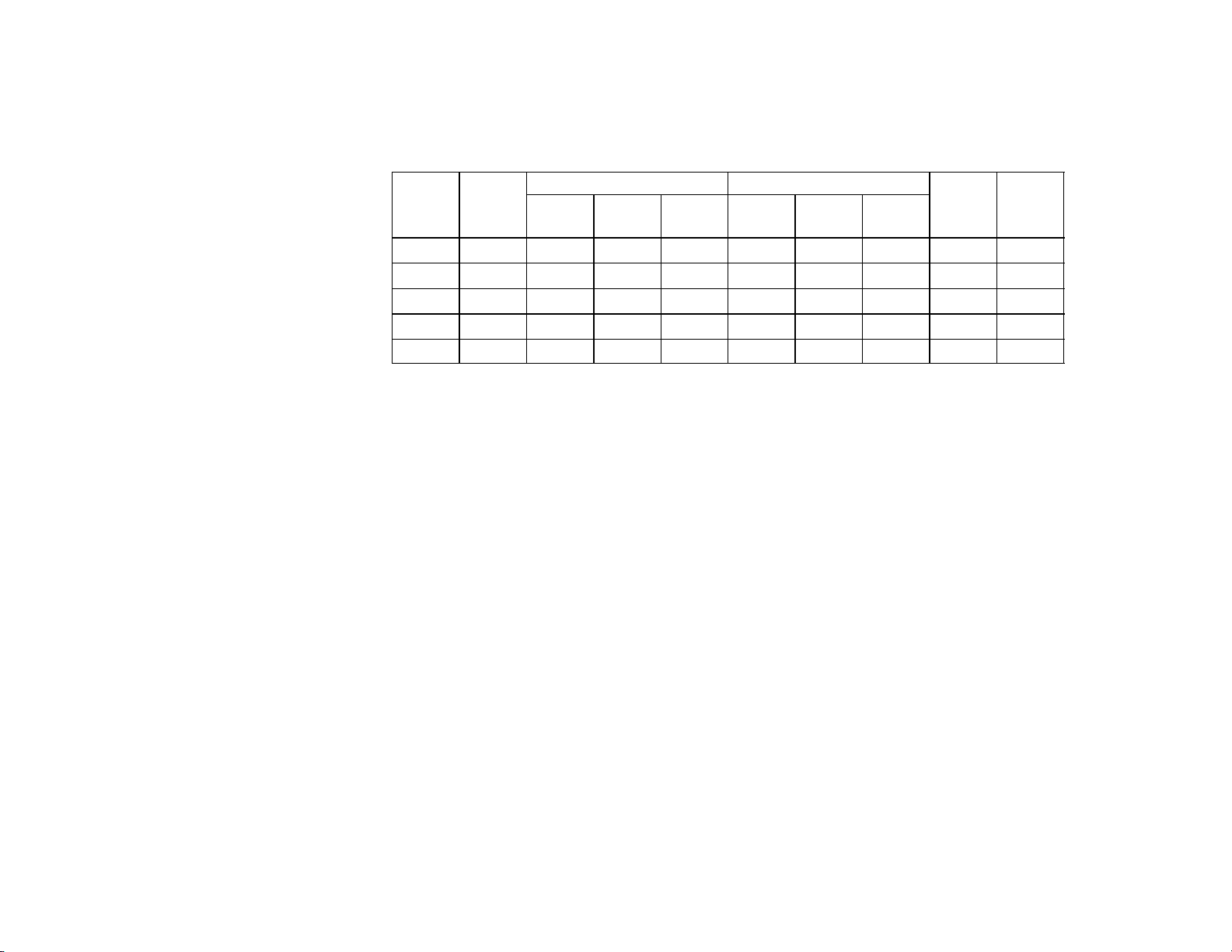

IAC322/IAC330

AMBIENT

TEMP

_F

70 50 200 39 9:5 150 105 1:1 2.4 325

80 70 228 42 12:4 160 110 0:9 2.4 260

14TD 202 3/1/95

90 70 267 44 14:3 183 133 0:7 2.5 240

90 80 270 45 15.1 181 130 0.7 2.4 220

100 70 299 47 19:8 199 142 0:6 2.8 200

Rev 9/18/95

WATER

TEMP

_F

ICE PRODUCTION CAPACITIES AND CHARTS

FREEZE CYCLE HARVEST CYCLE

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

AVERAGE

ICE

WEIGHT

lb/Cycle

AVERAGE

ICE

WEIGHT

lb/day

Page 18

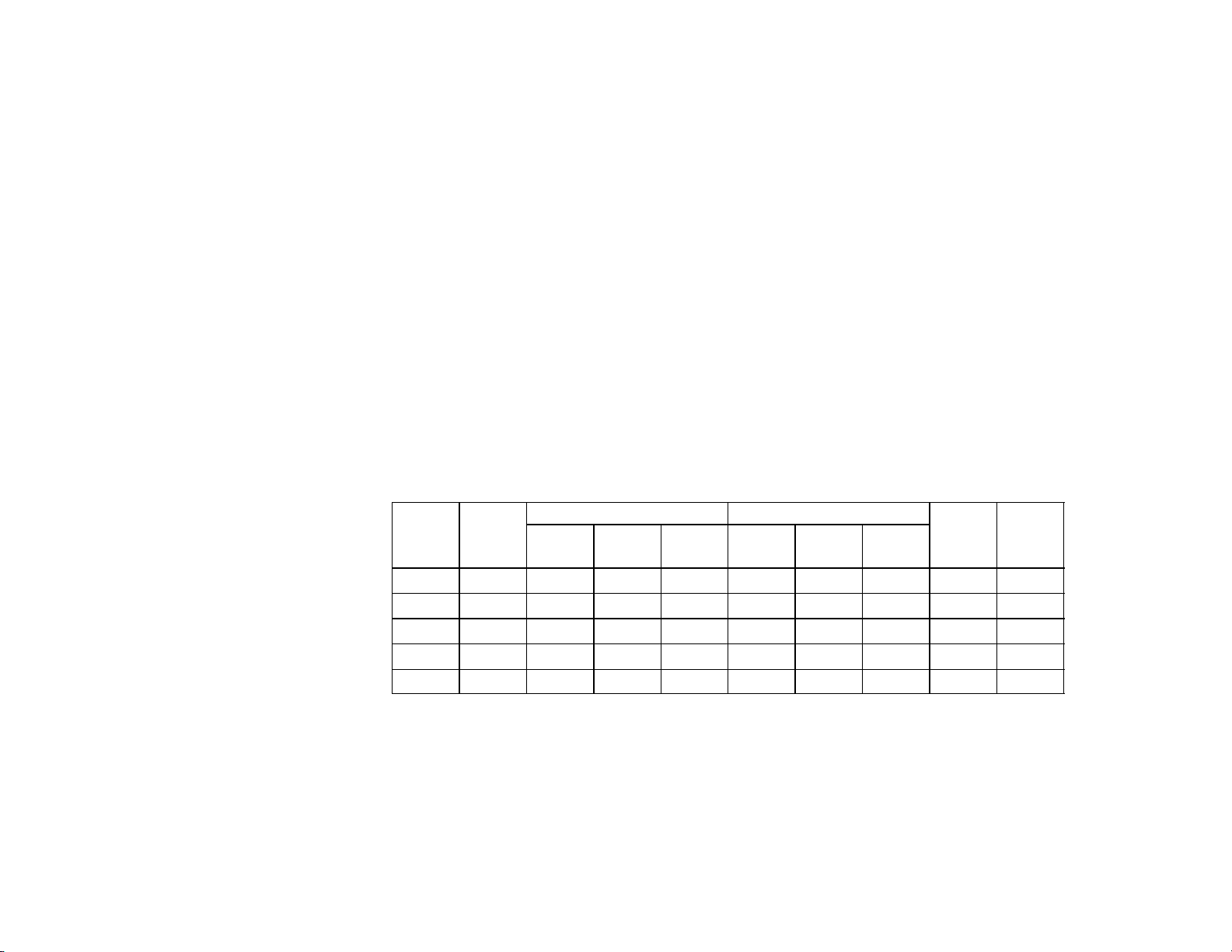

IWC322/IWC330

Rev 9/18/95

15 TD 2023/1/95

AMBIENT

TEMP

_F

WATER

TEMP

_F

HEAD

PRESSURE

Psig

FREEZE CYCLE HARVEST CYCLE

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

AVERAGE

ICE

WEIGHT

lb/Cycle

70 50 300 40 12:1 143 103 0:9 2.8 310

80 70 300 42 15:3 160 116 1:1 2.8 245

90 70 300 43 16:2 160 118 1:2 2.9 240

90 80 303 44 16.4 173 120 1.1 2.8 230

100 70 300 44 16:3 160 117 1:3 2.6 215

AVERAGE

ICE

WEIGHT

lb/day

Page 19

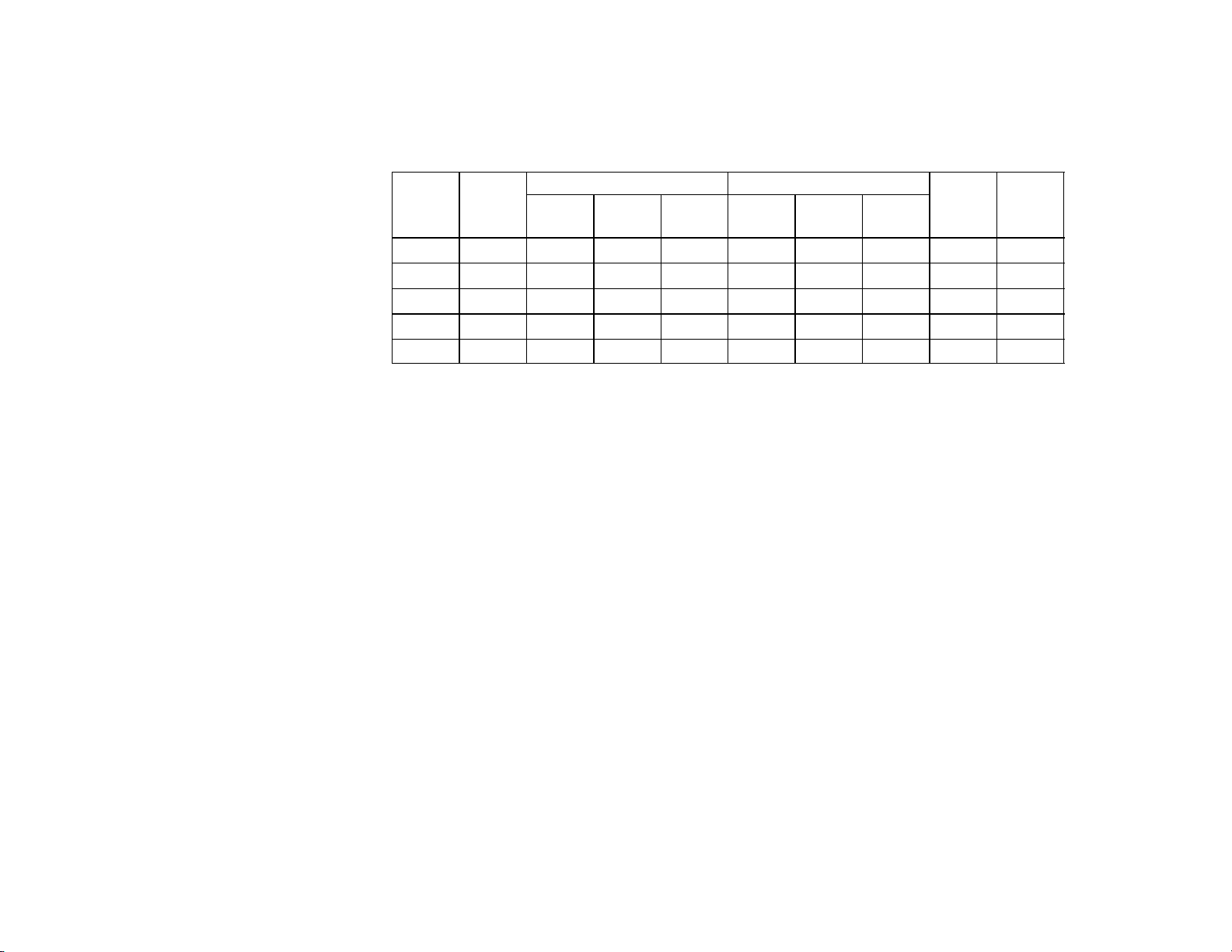

IAC522/IAC530

AMBIENT

TEMP

16TD 202 3/1/95

100 70 320 46 20:9 220 120 0:6 5.2 350

Rev 9/18/95

FREEZE CYCLE HARVEST CYCLE

WATER

_F

TEMP

_F

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

AVERAGE

ICE

WEIGHT

lb/Cycle

AVERAGE

ICE

WEIGHT

lb/day

70 50 220 38 12:5 155 95 1.0 5.1 540

80 70 250 42 14:6 175 111 0:9 4.8 450

90 70 275 41 17:4 195 120 0:7 5.1 405

90 80 290 45 17.9 200 120 0.6 5.0 387

Page 20

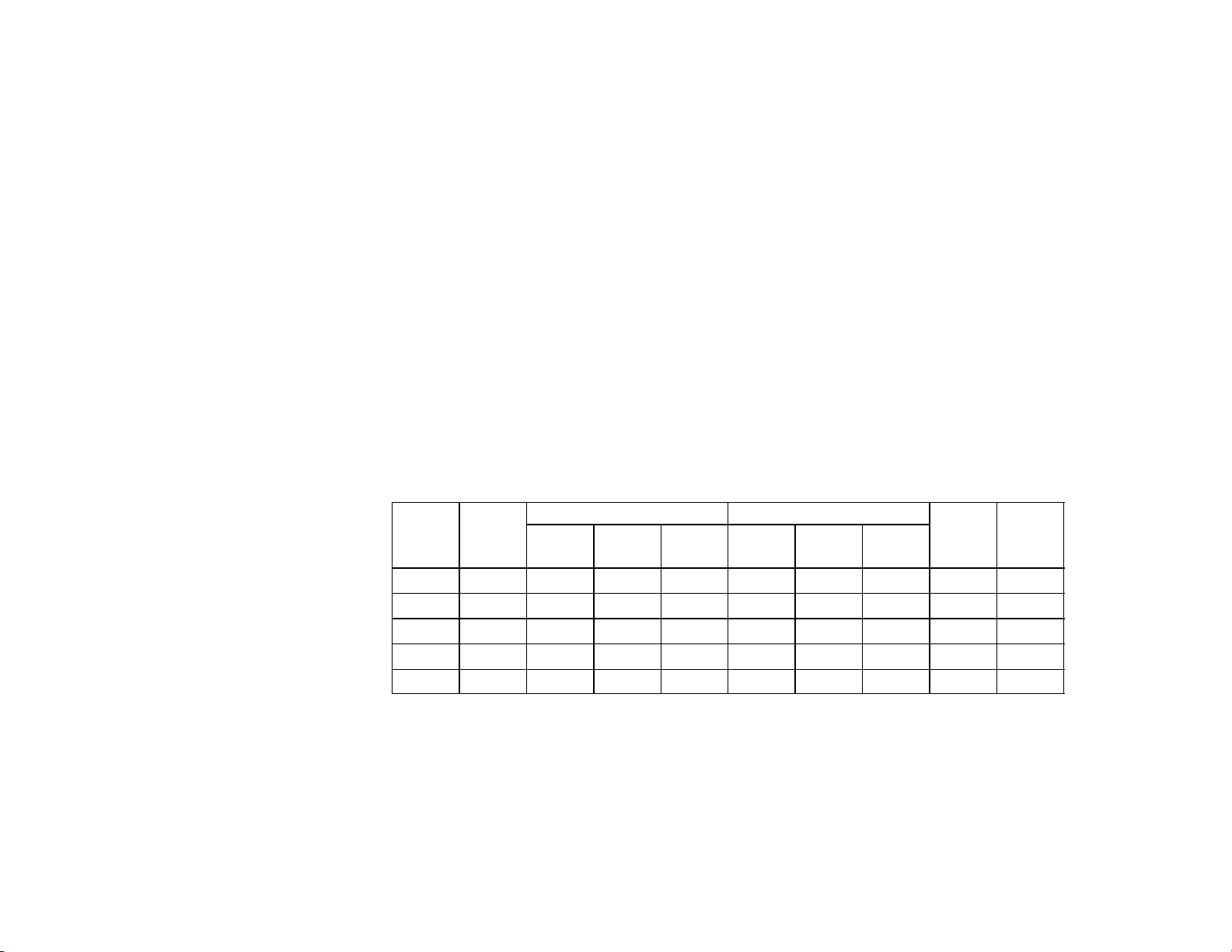

IWC522/IWC530

Rev 9/18/95

17 TD 2023/1/95

AMBIENT

TEMP

_F

WATER

TEMP

_F

HEAD

PRESSURE

Psig

FREEZE CYCLE HARVEST CYCLE

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

AVERAGE

ICE

WEIGHT

lb/Cycle

70 50 323 44 11:3 156 106 1:3 4.3 490

80 70 327 45 13:7 168 115 1.2 4.4 425

90 70 326 45 13:8 173 117 1:1 4.3 420

90 80 328 47 15.2 184 127 1:1 4.3 384

100 70 327 45 13:9 175 119 1:1 4.3 415

AVERAGE

ICE

WEIGHT

lb/day

Page 21

IAC630

AMBIENT

TEMP

18TD 202 3/1/95

100 70 333 43 17:1 200 125 1:1 6.0 475

Rev 9/18/95

FREEZE CYCLE HARVEST CYCLE

WATER

_F

TEMP

_F

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

AVERAGE

ICE

WEIGHT

lb/Cycle

AVERAGE

ICE

WEIGHT

lb/day

70 50 225 34 8:4 148 88 1:5 5.4 755

80 70 261 37 11:3 166 101 1.2 5.6 640

90 70 296 40 12:6 183 113 1:1 5.6 590

90 80 297 40 13:2 184 113 1:0 5.5 560

Page 22

IWC630

Rev 9/18/95

19 TD 2023/1/95

AMBIENT

TEMP

_F

WATER

TEMP

_F

HEAD

PRESSURE

Psig

FREEZE CYCLE HARVEST CYCLE

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

AVERAGE

ICE

WEIGHT

lb/Cycle

70 50 299 35 10:1 143 86 1:6 5.8 715

80 70 299 38 12:4 152 92 1.4 6.0 622

90 70 300 38 12:3 153 93 1:4 5.9 620

90 80 304 39 14:0 166 100 1:2 6.0 570

100 70 300 38 12:2 152 93 1:4 5.8 615

AVERAGE

ICE

WEIGHT

lb/day

Page 23

IRC630

AMBIENT

TEMP

20TD 202 3/1/95

100 70 333 43 17:1 200 125 1:1 6.0 475

Rev 9/18/95

FREEZE CYCLE HARVEST CYCLE

WATER

_F

TEMP

_F

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

AVERAGE

ICE

WEIGHT

lb/Cycle

AVERAGE

ICE

WEIGHT

lb/day

70 50 225 34 8:4 148 88 1:5 5.2 755

80 70 261 37 11:3 166 101 1.2 5.6 640

90 70 296 40 12:6 183 113 1:1 5.6 590

90 80 297 40 13:2 184 113 1:0 5.5 560

Page 24

IAC830

Rev 9/18/95

21 TD 2023/1/95

AMBIENT

TEMP

_F

WATER

TEMP

_F

HEAD

PRESSURE

Psig

FREEZE CYCLE HARVEST CYCLE

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

AVERAGE

ICE

WEIGHT

lb/Cycle

70 50 253 29 7:6 163 83 1:5 5.3 840

80 70 293 33 9:0 187 97 1.0 5.2 745

90 70 335 36 11:5 210 111 0:9 5.8 680

90 80 339 37 12:0 209 111 0:9 5.8 645

100 70 379 40 13:8 232 126 0:8 6.0 595

AVERAGE

ICE

WEIGHT

lb/day

Page 25

IWC830

AMBIENT

TEMP

22TD 202 3/1/95

100 70 295 34 11:1 175 93 1:3 5.9 690

Rev 9/18/95

FREEZE CYCLE HARVEST CYCLE

WATER

_F

TEMP

_F

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

AVERAGE

ICE

WEIGHT

lb/Cycle

AVERAGE

ICE

WEIGHT

lb/day

70 50 298 32 8:6 154 81 1:5 5.6 795

80 70 296 34 10:2 163 86 1.3 5.7 715

90 70 295 34 10:7 164 87 1:3 5.9 710

90 80 298 37 12:1 166 88 1:2 6.0 650

Page 26

IRC830

Rev 9/18/95

23 TD 2023/1/95

AMBIENT

TEMP

_F

WATER

TEMP

_F

HEAD

PRESSURE

Psig

FREEZE CYCLE HARVEST CYCLE

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

AVERAGE

ICE

WEIGHT

lb/Cycle

70 50 253 29 7:6 163 83 1:5 5.3 840

80 70 293 33 9:0 187 97 1.0 5.2 745

90 70 335 36 11:5 210 111 0:9 5.8 680

90 80 339 37 12:0 209 111 0:9 5.8 645

100 70 379 40 13:8 232 126 0:8 6.0 595

AVERAGE

ICE

WEIGHT

lb/day

Page 27

IAC1030

AMBIENT

TEMP

24TD 202 3/1/95

100 70 349 41 18.7 215 100 1.0 10.8 793

Rev 9/18/95

FREEZE CYCLE HARVEST CYCLE

WATER

_F

TEMP

_F

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

AVERAGE

ICE

WEIGHT

lb/Cycle

AVERAGE

ICE

WEIGHT

lb/day

70 50 240 33 13.5 164 75 1.7 11.6 1101

80 70 276 36 14.2 177 83 1.4 10.5 969

90 70 312 38 15.9 196 91 1.1 10.5 890

90 80 313 38 16.8 198 91 1.1 10.5 840

Page 28

IWC1030

Rev 9/18/95

25 TD 2023/1/95

AMBIENT

TEMP

_F

WATER

TEMP

_F

HEAD

PRESSURE

Psig

FREEZE CYCLE HARVEST CYCLE

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

AVERAGE

ICE

WEIGHT

lb/Cycle

70 50 296 34 13.0 155 73 1.8 10.7 1046

80 70 297 36 15.3 161 75 1.7 10.9 925

90 70 297 36 15.7 161 77 1.5 11.0 920

90 80 300 36 17.9 175 81 1.4 11.0 823

100 70 297 41 15.8 164 77 1.5 11.0 915

AVERAGE

ICE

WEIGHT

lb/day

Page 29

IRC1030

AMBIENT

TEMP

26TD 202 3/1/95

100 70 349 41 18.7 215 100 1.0 10.8 793

Rev 9/18/95

FREEZE CYCLE HARVEST CYCLE

WATER

_F

TEMP

_F

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

AVERAGE

ICE

WEIGHT

lb/Cycle

AVERAGE

ICE

WEIGHT

lb/day

70 50 240 33 13.5 164 75 1.7 1.6 1101

80 70 276 36 14.2 177 83 1.4 10.5 969

90 70 312 38 15.9 196 91 1.1 10.5 890

90 80 313 38 16.8 198 91 1.1 10.5 840

Page 30

IAC1230

Rev 9/18/95

27 TD 2023/1/95

AMBIENT

TEMP

_F

WATER

TEMP

_F

HEAD

PRESSURE

Psig

FREEZE CYCLE HARVEST CYCLE

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

AVERAGE

ICE

WEIGHT

lb/Cycle

70 50 231 30 8:8 175 75 1:5 8.9 1249

80 70 266 33 11:4 191 84 1.1 9.5 1090

90 70 296 35 13:6 211 95 1:0 10.1 1000

90 80 295 36 14:5 211 93 0:9 10.1 948

100 70 331 38 16:3 232 105 0:9 10.3 865

AVERAGE

ICE

WEIGHT

lb/day

Page 31

IWC1230

AMBIENT

TEMP

28TD 202 3/1/95

100 70 324 30 14:0 180 76 1:3 10.9 1025

Rev 9/18/95

FREEZE CYCLE HARVEST CYCLE

WATER

_F

TEMP

_F

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

AVERAGE

ICE

WEIGHT

lb/Cycle

AVERAGE

ICE

WEIGHT

lb/day

70 50 336 30 10:1 187 73 1:4 9.8 1221

80 70 324 30 13:2 177 76 1.3 10.7 1065

90 70 330 33 14:0 180 76 1:3 10.9 1030

90 80 323 32 14:8 180 78 1:3 10.9 973

Page 32

IRC1230

Rev 9/18/95

29 TD 2023/1/95

AMBIENT

TEMP

_F

WATER

TEMP

_F

HEAD

PRESSURE

Psig

FREEZE CYCLE HARVEST CYCLE

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

AVERAGE

ICE

WEIGHT

lb/Cycle

70 50 231 30 8:8 175 75 1:5 8.9 1249

80 70 266 33 11:4 191 84 1.1 9.5 1090

90 70 296 35 13:6 211 95 1:0 10.1 1000

90 80 295 36 14:5 211 93 0:9 10.1 948

100 70 331 38 16:3 232 105 0:9 10.3 865

AVERAGE

ICE

WEIGHT

lb/day

Page 33

IAC1448

AMBIENT

TEMP

30TD 202 3/1/95

100 70 352 38 15:8 242 106 0:8 13.1 1140

Rev 9/18/95

FREEZE CYCLE HARVEST CYCLE

WATER

_F

TEMP

_F

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

AVERAGE

ICE

WEIGHT

lb/Cycle

AVERAGE

ICE

WEIGHT

lb/day

70 50 246 31 10:1 185 79 1:3 12.1 1525

80 70 280 34 11:8 201 88 1.3 12.3 1355

90 70 315 35 13:2 220 97 1:1 12.6 1275

90 80 317 37 13:7 222 98 1:1 12.4 1205

Page 34

IWC1448

Rev 9/18/95

31 TD 2023/1/95

AMBIENT

TEMP

_F

WATER

TEMP

_F

HEAD

PRESSURE

Psig

FREEZE CYCLE HARVEST CYCLE

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

AVERAGE

ICE

WEIGHT

lb/Cycle

70 50 316 32 9:9 180 73 1:7 12.1 1505

80 70 318 35 11:9 188 77 1.4 12.7 1370

90 70 318 36 12:2 190 78 1:3 12.8 1360

90 80 317 37 13:0 194 80 1:3 12.6 1270

100 70 316 36 12:7 189 77 1:4 13.1 1335

AVERAGE

ICE

WEIGHT

lb/day

Page 35

IRC1448

AMBIENT

TEMP

32TD 202 3/1/95

100 70 352 38 15:8 242 106 0:8 13.3 1150

Rev 9/18/95

FREEZE CYCLE HARVEST CYCLE

WATER

_F

TEMP

_F

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

HEAD

PRESSURE

Psig

SUCTION

PRESSURE

Psig

CYCLE

TIME

Min:Sec

AVERAGE

ICE

WEIGHT

lb/Cycle

AVERAGE

ICE

WEIGHT

lb/day

70 50 246 31 10:1 185 79 1:3 12.1 1535

80 70 280 34 11:8 201 88 1.3 12.4 1365

90 70 315 35 13:2 220 97 1:1 12.7 1285

90 80 317 37 13:7 222 98 1:1 12.5 1215

Page 36

“I” SERIES

SEQUENCE OF OPERATION

When the on off clean switch is pushed to the on position the compressor will start after a 2 second delay. The fan motor and pump are

delayed. The condenser fan motor on integral air cooled unites will

start when the condenser temperature rises to approximately 100° F.

The water pump will start when the suction line temperature reaches

approximately 25°F. Temperature information is transmitted to the

control board thru thermistor sensors. The unit is now in the freeze

cycle. If after approximately 6 minutes of operation the suction line

temperature is not below 40°F, the unit will shut down and show an

error light on the control board. When the harvesting set point temperature is reached, the circuit board will switch to the harvest cycle.

At the start of the harvest cycle the condenser fan motor will shut off

and the Dump Valve and Hot Gas Valve will open. The Water Pump

will shut down in approximately 15 seconds. Harvest will continue

for approximately 90 seconds. when the Ice is harvested the evaporator curtain opens and closes breaking a magnetic field of the evaporator proximity switch which signals the circuit board to switch

back to the Freeze Cycle.

When the Evaporator Curtain is held open, in the freeze cycle,

breaking the Evaporator Switch Magnetic Field for 5 to 8 seconds,

the circuit board is signaled that a full bin condition has been

reached , and shuts down the unit.

COMPONENT FUNCTIONS

Circuit Board

The circuit board controls the operation of the Ice Maker through information it receives from Thermistor Sensors and Proximity (magnetic) Switches.

Rev 9/18/95

33 TD 2023/1/95

Page 37

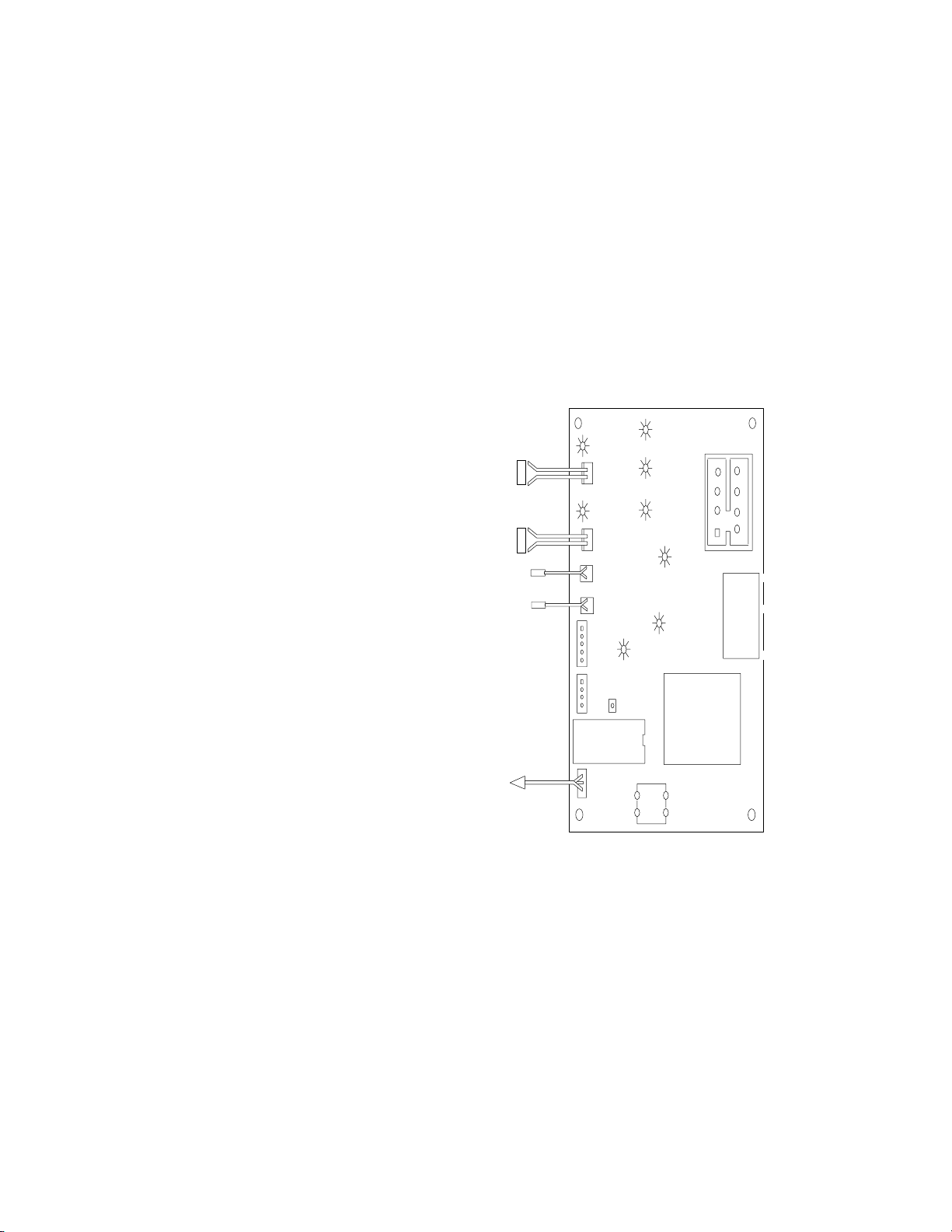

LED Indicators

The LEDs are board circuit indicators. If the LED in the functional

board circuit is complete, check component.

Example: Contactor does not energize and LED is “ON”, board cir-

cuit is OK. Check contactor, coil, leads, & connections.

Yellow;

S Evaporator switch(s) (proximity)

Green;

S D15 Water dump valve

S D14 Compressor contactor

S D12 Water Pump

S D11 Hot Gas Valve

S D6 Condenser Fan (cycles on &

off with fan)

Red D5;

Error in system operation. Product shut down.

Water

DĆ15

RH Evap. Switch

N

S

LH Evap. Switch

N

S

Condenser Sensor

Suction Line Sensor

white

Brown

DĆ13

YL

YL

DĆ10

Condenser

plug

Suction plug

Test

Plug

Options

Plug

RH Evap.

LH Evap.

DĆ14

DĆ12

RD

DĆ5

Error

Adjustable Ice

Thickness Pot.

Dump

Valve

Contactor

GR

DĆ11

Fan

GR

Water

Pump

DĆ6

Hot Gas

Transformer

7

8

5

6

3

4

2

1

230v

Voltage

neutral

Selector

Switch

115v

To Stacked

(if required)

Micro Processor

Stacking

Cable

Plug

Unit

Manual

Harvest

Switch

34TD 202 3/1/95

Rev 9/18/95

Page 38

LED STATUS INDICATOR CHART

D6 Green LED Condenser Fan

D10 Yellow LED Left Water Curtain

D11 Green LED Hot Gas Valve

D12 Green LED Water Pump

D13 Yellow LED Right Water Curtain

D14 Green LED Compressor Contactor

D5 Red LED Error

D15 Green LED Dump Valve

Curtain Open

Yellow LED

D13

D10

D6

D14

D13

D10

D6

D12

D14

D13

D10

Yellow LED

Green LED

Green LED

Yellow LED

Yellow LED

Green LED

Green LED

Green LED

Yellow LED

Yellow LED

Off Right evaporator curtain

open

Off Left evaporator curtain open

Pre-Chill Mode

(on or

Condenser fan cycles on &

off)

off depending upon conĆ

denser temperature

(on) Compressor contactor acĆ

tive - Compressor running

(on) Right evaporator curtain

closed

(on) Left evaporator curtain

closed (only if unit has two

evaporators)

Ice Making Mode

(on or

Condenser fan cycles on

off)

and off depending upon

condenser temperature

(on) Water pump active

(on) Compressor contactor acĆ

tive - compressor running

(on) Right evaporator curtain

closed

(on) Left evaporator curtain

closed (only if unit has two

evaporators)

Table continued on page. 36

Rev 9/18/95

35 TD 2023/1/95

Page 39

D11

D12

D14

D15

D13

D10

D5

D5

D5

Green LED

Green LED

Green LED

Green LED

Yellow LED

Yellow LED

Red LED

Red LED

Red LED

Harvest Mode

(on) Three seconds after water

dump valve becomes acĆ

tive, the hot gas valve beĆ

comes active

(on)

Fifteen seconds after water

15

dump valve becomes acĆ

sec.

tive, the water pump deactiĆ

vates

(on) Compressor contactor acĆ

tive - compressor running

(on)

Water dump valve becomes

15

active at the start of harvest.

sec.

Water dump valve is active

for 15 seconds

(on) Right evaporator curtain

closed. When the ice falls

and the curtain opens the

LED will turn off.

(on) Same as D13 if there is a

second (left) evaporator

Error LED

(on) EVAPORATOR OPEN

THERMISTOR CIRCUIT Ć

thermistor open / broken

wire / poor connection. Ice

maker is SHUT DOWN.

Consult service manual

(Diagnostic Section) for

trouble shooting guide.

(on) EVAPORATOR HIGH TEMP.

ERROR: Six minutes into the

Freeze cycle the suction line

temperature failed to reach

40°F or below. Ice Maker is

SHUT DOWN. Consult serĆ

vice manual (Diagnostic

Section) for trouble shooting

guide.

(on) TWO REPEATED FAILED

HARVEST CYCLES Ć No ice

drop.

Table continued on page .37

36TD 202 3/1/95

Rev 9/18/95

Page 40

Error LED (cont’d)

Red LED

D5

D5

D5

Red LED

Red LED

FlashĆ

CONDENSER OPEN

ing,

THERMISTOR CIRCUIT (Air

1/sec

Cooled only) Ć Thermistor

open / broken wire / poor

connection. Ice Maker is

SHUT DOWN. Consult serĆ

vice manual (Diagnostic

Section) for trouble shooting

guide.

FlashĆ

CONDENSER LOW TEMĆ

ing,

PERATURE CONDITION. Ć

1/sec

Condenser midpoint reachĆ

es 36°F Ć Ice Maker is SHUT

DOWN.

FlashĆ

CONDENSER HIGH TEMĆ

ing,

PERATURE SAFETY SHUT

1/sec

DOWN

Reset Operation

When Cuber is functionally shut down and red “Error LED” is op-

erational, the Cuber power switch must be turned off for 5 seconds

and returned to the on position to reset the circuit board and allow

the Cuber to restart operation.

Voltage Selector Switch

1. Selector bar in center position, switch is open. Product

is inoperative

2. Selector bar in down position, selection is for 115

VAC.

3. Selector bar in up position, selection is for 230 VAC.

Stacking Cable

When stacking the “I” series cuber the connecting cable (connecting

the two (2) circuit boards) will allow: When the bottom product

shuts off on the full bin signal (or any error code) the top product will

finish the cycle it is in and will also shut down. The “I” series should

never be stacked more than two high.

Test Plug

Board manufactures check point.

DO NOT ATTEMPT ANY VOLTAGE CHECKS AT THESE PINS.

Rev 9/18/95

37 TD 2023/1/95

Page 41

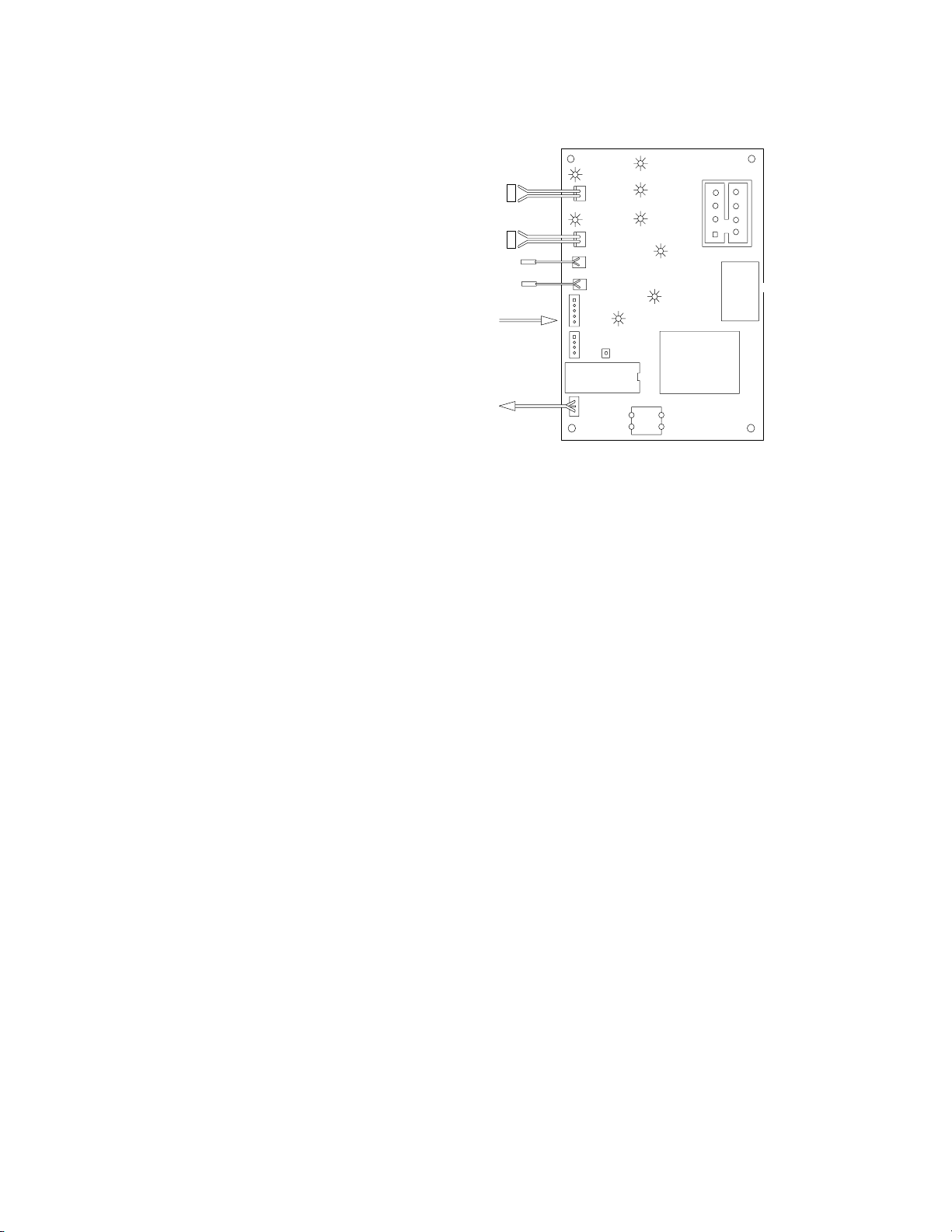

Dump Cycle Options

You have the option of selecting dump cycle intervals of:

S every cycle; (Standard setting from

factory)

S every 3rd cycle;

S every 5th cycle;

S every 7th cycle.

Remember, the higher the mineral content in the water supply the

more often it will be required to dump the water and/or clean the

product if proper water treatment is not used.

Water

DĆ15

RH Evap. Switch

N

S

LH Evap. Switch

N

S

Condenser Sensor

Suction Line Sensor

To Stacked

(if required)

Brown

Unit

white

DĆ13

YL

RH Evap.

YL

DĆ10

LH Evap.

Condenser

plug

Suction plug

Test

Plug

Options

Plug

Micro Processor

Stacking

Cable

Plug

DĆ14

DĆ12

RD

DĆ5

Error

Adjustable Ice

Thickness Pot.

Manual

Harvest

Switch

GR

Dump

Valve

Contactor

Water

Pump

DĆ11

Fan

GR

DĆ6

Hot Gas

Transformer

7

8

5

6

3

4

2

1

230v

Voltage

neutral

Selector

Switch

115v

Sleeve Connector

Dump

Every

Cycle

Options Plug

Dump

Dump

Every

Cycle

Dump

Every

5th

7th

Cycle

Rev 9/18/95

Every

3rd

Cycle

38TD 202 3/1/95

Page 42

Condenser Fan Cycling Control

(Intergal Condenser)

The condenser fan on air-cooled cubers is cycled by the circuit

board. The condenser sensor signals the circuit board when the condenser temperature reaches 100°F (38°C) the fan starts and contin-

ues to run until the temperature is reduced to 88°F (31°C).

NOTE: There is no pressure control used to cycle the fan

motor on Intergal Air Cooled Condenser Units.

Harvest Safety Termination

After 4 minutes in the harvest mode, the safety timer in the circuit

board will terminate the harvest mode and place the Cuber back into

a freeze mode. This safety cycle will protect the evaporator etc.

should the product fail to terminate the harvest mode for any reason.

Circuit Board Diagnosis

Turn the power switch off, center position. Disconnect the proximity switches and thermistors from the circuit board. Remove a sleeve

jumper from the options terminal and place it on terminals 4 and 5

(bottom 2 pins) of the test plug. (See Illustration on page 40) Turn

the power switch to the “on” position and immediately remove the

sleeve jumper from terminals 4 and 5. The LED indicators will cycle

“on” for approximately 2 seconds each in the following sequence.

1. Red D-5 (error)*

*Will only cycle if ice thickness

(pot) is within factory setting

2. Green D-6 (Condenser fan)

3. Green D-11 (hot gas valve)

4. Green D-12 (water pump)

5. Green D-14 (relay-contractor)

6. Green D-15 (dump valve)

Failure of the LED’s to cycle in this sequence will signal a defective

circuit board.

Rev 9/18/95

39 TD 2023/1/95

Page 43

DĆ15

RH Evap. Switch

N

S

LH Evap. Switch

N

S

Condenser Sensor

Suction Line Sensor

To Stacked

(if required)

DĆ13

YL

RH Evap.

YL

DĆ10

LH Evap.

white

Brown

Unit

Condenser

plug

Suction plug

Test

Plug

Options

Plug

Micro Processor

Stacking

Cable

Plug

DĆ14

DĆ12

RD

DĆ5

Error

Adjustable Ice

Thickness Pot.

Manual

Harvest

Switch

GR

Water

Dump

Valve

Contactor

Water

Pump

DĆ11

Fan

GR

DĆ6

Hot Gas

Transformer

7

8

5

6

3

4

2

1

230v

Voltage

neutral

Selector

Switch

115v

Sensors

Condenser sensor (white) and suction line sensor (brown) are

thermistors rated 1k ohm at room temperature.

S Condenser sensor signals the circuit

board for fan cycling and also serves

as the high temperature safety shut

down. The red “Error LED” will flash

on and off every second, during high

temperature safety shut down. Product is functionally shut down. Reset

procedure must be performed to restart product operation.

S Suction line sensor signals the circuit

board the suction line temperature, to

control ice bridge thickness. Also the

sensor serves as suction line high

temperature signal (Cuber has 6 minutes to reduce suction line temperature to 40°F (4.4°C) in the freeze

mode). The red “Error LED” will be

steady on ...should this time frame not

be met, product is functionally inoperative during this safety shut down.

Reset procedure must be performed

to restart product operation.

40TD 202 3/1/95

Rev 9/18/95

Page 44

Sensor [Thermistor] Diagnosis

Sensors

Condenser or suction line – Turn Cuber power switch OFF. Disconnect sensor plug from board. Use digital multimeter set for D.C.

Voltage. Turn power switch ON connect leads of meter across the

two pins of the sensor being checked, meter should read 2.5

VDC0.2 output voltage from the board. If voltage is not correct,

replace the circuit board.

Should the cuber operation indicate there may be a fault

in the sensor [thermistor] or the control board circuit proceed as follows.

1. Using a good multimeter check the control board sensor output voltage.

2. Voltage checks are correct proceed:

a. Disconnect the suction line sensor (brown lead)

from the control board.

b. Install the special test cord* to the control board

and reinstall the sensor to the test cord terminals.

c. Connect the multi-meter (set on VDC - milli-

volts) to the test cord leads.

d. Operate the cuber in the freeze cycle.

3. As the suction line temperature decreases the Millivolt reading will increase.

4. Sensor Shorted - milli-volt reading will cease to increase and will remain steady indicating a shorted sensor.

5. Sensor Open - The voltage reading will indicate the

control board output voltage of 2.5 VDC.

6. Should either “4.” or “5.” happen during this test, the

sensor will require replacement.

* Special test cord, part # 164984009, may be ordered

through the Service Department.

7. Condenser Sensor (white leads) - self-contained air

cooled only - water cooled and remote systems use a

resistor plug on the control board.

Complete the sensor and multi-meter connections as

described in

2- b.,c.,d..

8. Shorted sensor - a steady low milli-volt reading will

be recorded. The reading will not change.

9. Open sensor - the multi-meter will record control

board output voltage of 2.5 VDC.

Rev 9/18/95

41 TD 2023/1/95

Page 45

10. Should sensor (thermistor) pass the voltage test proceed to the control board diagnosis for LED sequence

(see page 39).

NOTE: The sensor controls the condenser fan cycling from

88/100 degree Fahrenheit. Thus any defects in the

condenser circuit will effect the fan cycling rate.

Evaporator Switches

Proximity Switches are half mounted to the water curtain, and the

other half mounted to the evaporator side rail. They provide signals

to the control board to allow the board to change cycles from harves

to freeze as well as shut down of the unit in a full bin condition.

Switch Notes

1. Manually holding the curtain open during freeze

mode, will shut the Cuber down in 5 seconds.

2. During harvest cycle, if curtain is open for 10 seconds,

the water pump will stop. The compressor will operate

for 20 additional seconds before Cuber shut down

takes place. When the water curtain closed, the Cuber

will begin the normal start-up process.

3. In single evaporator machines, the proximity switch

connection must be on the top (RH) connection on the

circuit board.

4. In dual evaporator machines, both RH and LH

switches must open and reset to start the next freeze

mode.

Voltage Checks

Turn Cuber power switch Off. Disconnect proximity switch plug(s)

from the circuit board. Use a digital multimeter set for D.C. Voltage;

turn power switch ON, connect leads of meter across the top two terminal pins on the board, (for the switch being tested), meter should

read 5 VDC ± 0.2 output voltage. If not, replace the circuit board.

42TD 202 3/1/95

Rev 9/18/95

Page 46

Water Regulating Valve

The water regulating valve is used on water–cooled cubers only. The

valve is installed in the condenser outlet water line. It’s function is

to control the proper operating head pressure by regulating the

amount of water flowing through the condenser. The valve is adjustable and factory set to maintain condenser discharge water temperature @ 108/112_F (42-44_C). Setting the water regulating valve to

maintain discharge water temperature eliminates the need to enter

the sealed refrigeration system. When checking the valve, the water

temperature should be taken as close to the condenser discharged as

possible. The water temperature will equate to operating head pressure of approximately 310 PSI (21.1 BAR).

Should adjustment be required, the valve has an adjustment stem on

the top of the valve. After allowing the cuber to operate for 10 minutes in the ice making mode to balance the system, turning the adjusting stem CW will increase the discharge water temperature,

and CCW will decrease the discharge water temperature.

The water regulating valve must close off condenser water flow

completely during the “hot gas” harvest cycle. There should be no

discharge water flowing out of the condenser during the harvest

cycle. Should the valve fail to close during the harvest mode, the

condenser will continue to condense the compressor discharge vapor needed for the harvest cycle and this will result in long harvest

times.

Leaking (by–passing) water regulating valves are normally the result of scale build–up on the valve diaphragm and the valve should

be flushed, not replaced. To flush the valve, open the adjusting stem

wide open CCW (or force the valve spring up with a screwdriver),

open and close the water supply to the condenser resulting in the

flushing action. Should this not correct the problem replace the

valve diaphragm. This can be done without entering the sealed refrigeration system.

Damage to the water regulating valve may also be caused by water

hammer. Water hammer will result from the condenser inlet and outlet water lines being reversed or defective valve stops in the water

supply line. Proper installation of water cooled equipment should always include an anti–water hammer standpipe in the supply inlet

line as close to the cuber as possible.

High Pressure Safety Switch

All water-cooled and remote products contain a high pressure safety

cut-out switch. The function of this switch is to shut down the cuber

should excessive pressure develop in the high side of the refrigeration system. This switch will open the power supply at 450 PSI

(30.61 BAR) high side pressure. Should this control open, it must be

reset manually and the cause for the increase in pressure determined.

Rev 9/18/95

43 TD 2023/1/95

Page 47

Float Valve with Flow Washer

The Float Valve Maintains the proper water level in the water reservoir.

There is a flow washer in the inlet side of the float assembly that will

control inlet water pressure from 20/120 PSI (1.37/8.16 Bars). This

will prevent float flutter. In low water pressure conditions, 20 PSI

(1.37 Bars) or less, the flow washer may have to be removed from

the float assembly for proper volume.

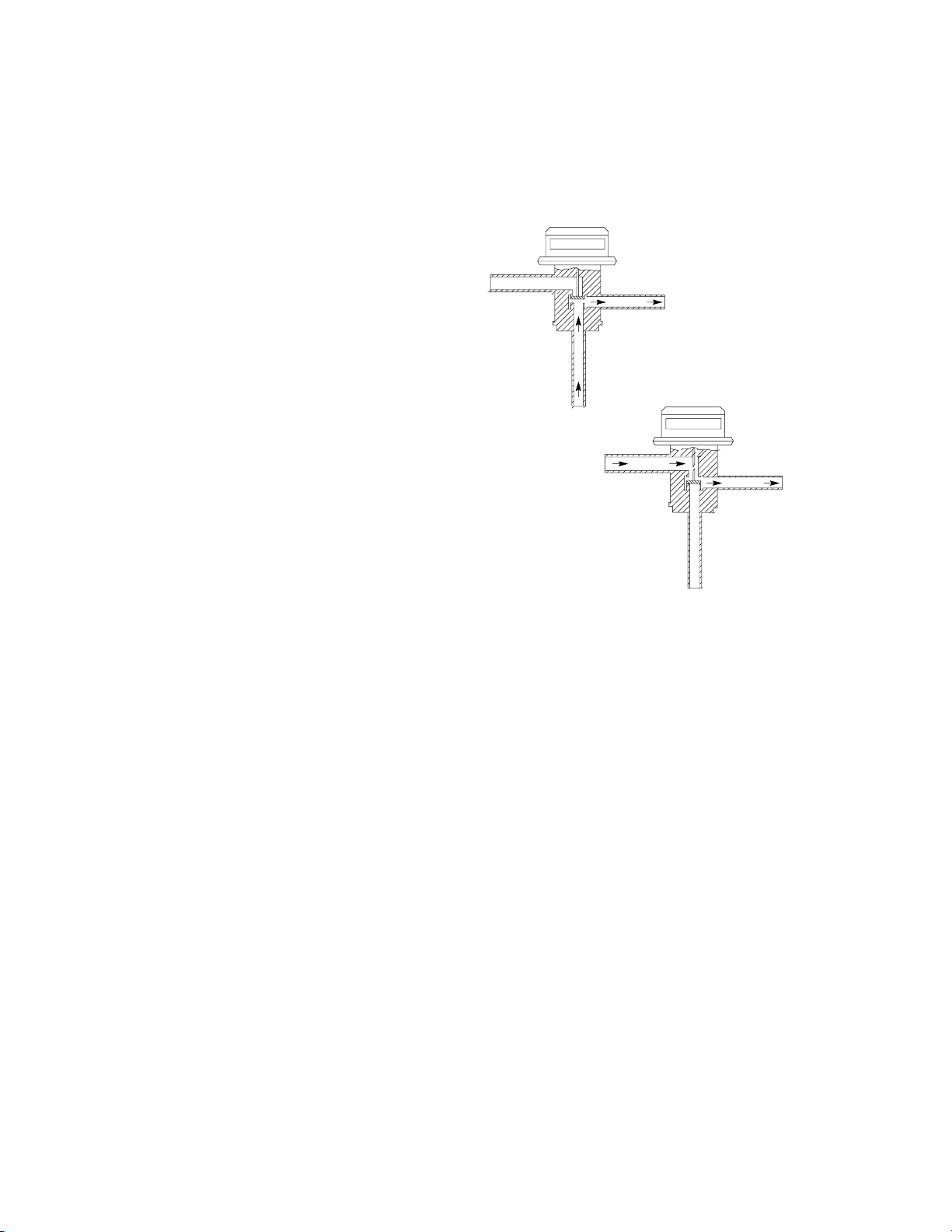

Flow control washer flat side up

Service Stem Valves

When closing the service stem valves to remove your gauge and

manifold set always close the high side stem valve first. Following

this procedure will allow the system to “PULL” the refrigerant vapor

from your manifold set to reduce refrigerant loss. When the pressure

has been reduced, close the low side stem valve.

Thermostatic Expansion Valves

The following suggestions for diagnosis of automatic Thermostatic

Expansion Valve (TXV) are given with the understanding the following have been checked and are correct and/or have been corrected prior to proceeding.

1. The condenser and fan blade are clean and have proper operating conditions.

2. Water supply to the product is correct and flow over

the evaporator is correct.

3. Cuber refrigerant charge is correct.

4. TXV sensing bulb is properly located and secured to

the suction line and correctly insulated.

5. Hot gas valve(s) are not leaking and/or weeping

through.

44TD 202 3/1/95

Rev 9/18/95

Page 48

DIAGNOSIS

Starving TXV - Product Symptoms

1. Suction pressure lower than normal for the operating

conditions.

2. Ice production lower than normal and/or none.

3. Ice pattern on evaporator (if any) thin at top and thick

at bottom.

Flooding TXV - Product Symptoms

1. Ice production lower than normal and/or none.

2. Suction pressure stabilizes at higher than normal pressure for operating conditions. Suction pressure does

not modulate and may start to slowly rise.

3. Ice pattern will be very heavy at the bottom and thin at

the top of the evaporator. Product may not enter harvest cycle because of higher than normal suction line

temperature.

Important: Frost on the suction line may be normal on me-

dium temperature refrigeration equipment. Frost

should be considered a red flag, long run times

will normally produce some type of frost pattern..

Before checking the sealed refrigeration system,

the external conditions that could lead to frost

follow:

1. Dirty condenser

2. Dirty condenser fan blade

3. Improper air clearance around Cuber

4. Loose TXV bulb mount

5. Poor water flow over evaporator

6. Ventilation problems

The expansion valves used on Cornelius “I” series ice equipment

have special super heat settings and bulb charge designed from the

product load and HP 62 refrigerant. Should the need arise to replace

this or any refrigerant components, be certain to use only components recommended by Cornelius for the model of the Cuber being

serviced. Use of nonapproved components will compound system

difficulties and may void product warranty.

Rev 9/18/95

45 TD 2023/1/95

Page 49

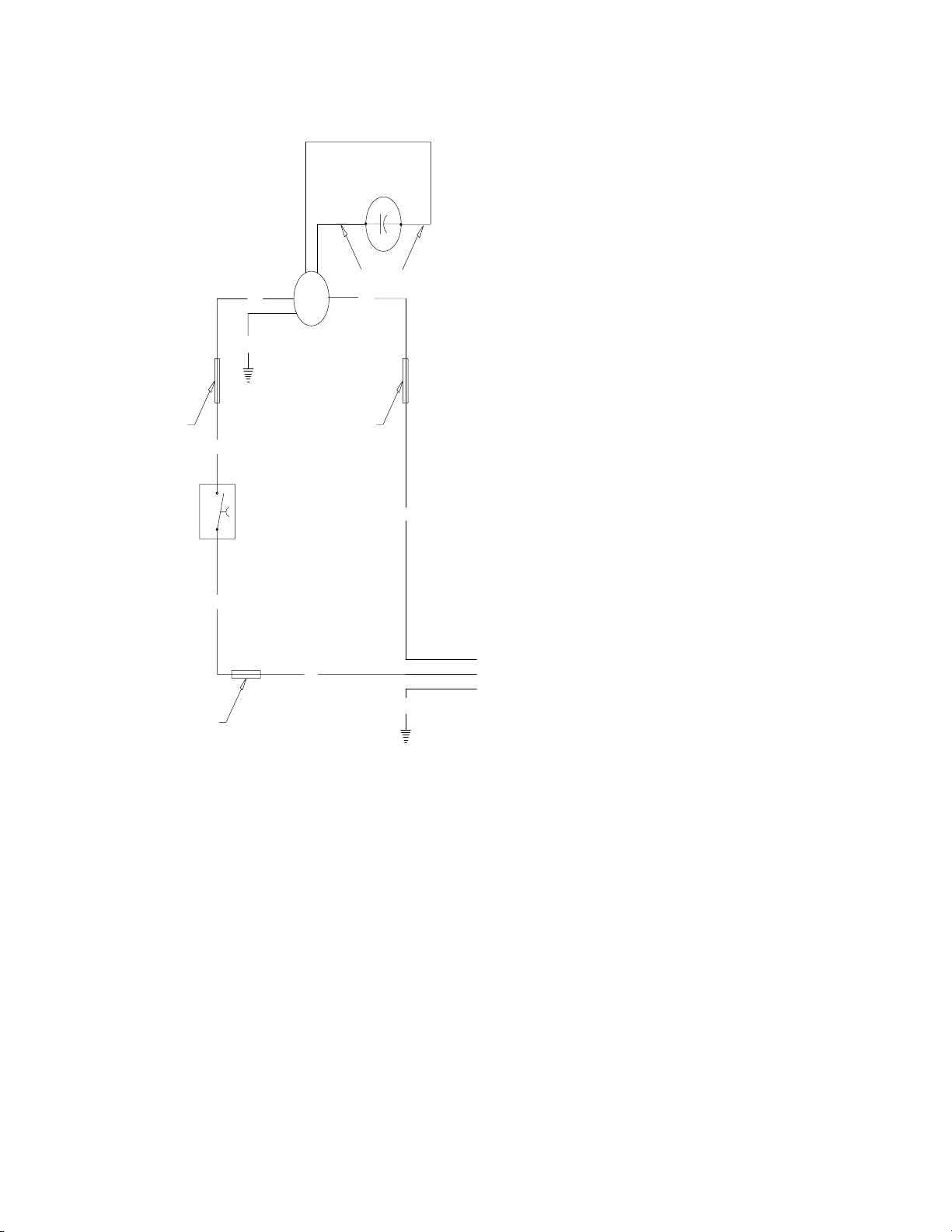

Head Pressure Control Valve

[Headmaster]/Fan Cycle Switch

(Remote Units Only)

condenser

receiver

dis-

charge

receiver

condenser

below 70°F by-pass

discharge

above 70°F

normal

The Cornelius “I” series remote systems use an Alco Head Pressure

Control, normally referred to as a headmaster. This control is

mounted in the remote condenser with a fan cycling control switch.

Using both these controls gives the system positive operation under

a wide range of condensing temperatures.

The fan cycling switch starts the fan at 270 PSI and stop it at 205 PSI

allowing a positive efficient operation at the high temperature operating ranges.

The headmaster controls the operation when the condensing temperature drops below 70°F. The “I” series refrigerant charge is

HP - 62 [R - 404A] and the headmaster dome charge setting is 200

PSI of nitrogen pressure making it stable under the low temperature

operating range down to - 20°F. (Continued on page 46)

The normal flow pattern through the headmaster is from the condenser port to the receiver port. When this flow pattern is unable to

46TD 202 3/1/95

Rev 9/18/95

Page 50

maintain a receiver outlet pressure equal to or above the dome pressure setting of the valve the dome pressure will force the valve portage to change closing the condenser port and opening the bypass

port from the compressor discharge line. This allow the high pressure vapor from the discharge port to “buck” the receiver pressure

back up. With the condenser port closed, the refrigerant is backed up

in the condenser, basically reducing the condenser size, assisting in

maintaining the discharge portage flow and increasing the head

pressure.

Remember, sense of touch to the lines of the headmaster will determine the flow path the headmaster is in, condenser to receive or bypass to receiver.

High side gauge installed at the receiver outlet valve will determine

if the headmaster is functioning to maintain the proper operating

pressure.

In the event the control appears to be “stuck in bypass”, the pressure

drop across the headmaster must be measured. With a gauge

installed at the receiver outlet valve and the high side service valve,

the pressure difference at these two points must be less the 15 PSI.

Three most common causes of an excessive pressure drop are shortage of refrigerant, kinked remote lines, and excessive line length.

Eliminate refrigerant shortage first. Add refrigerant in two pound increments (not to exceed six pounds) to determine if it corrects the

pressure drop. If pressure drop is not corrected, inspect line set for

sharp bends or kinks, correct as required. If adding refrigerant does

not correct continued (bypass) condition and line set is not damaged, replace headmaster.

Contactor Compressor

The contactor serves as the voltage supply switch for the compressor circuit. Voltage to the coil of the contactor is supplied by the circuit board.

Check Out:

The two (2)* line supply screws of the contactor should always have

supply voltage present when voltage is on to the product.

The other two (2)* screws (load) should have line voltage when the

contactor is energized. The contactor coil receives its supply voltage

from the circuit board. Should the contactor fail to energize:

Check for supply voltage from circuit board, lead connections to

contactor coil, and ohms value of coil.

* (3) if the product is 3 phase

Compressor & Starting Component

Check-Out Procedure

When compressors fail to start or run properly, it is normally the external electrical supply or the compressor start components that are

defective. The overload protector, start and/or run capacitor, relay,

circuit board, safety controls, etc.

Rev 9/18/95

47 TD 2023/1/95

Page 51

1. Check voltage at compressor terminals. NO voltage

will require checking the electrical circuit working

back from the compressor to determine where the voltage supply is interrupted and correct as required. The

load voltage, while compressor is trying to start,

should not be less than 90% of rated required voltage.

Line voltage and wire size effect the life expectancy of the electrical

components, compressor, motor winding, solenoid coils, etc.

Poor line quality voltage will cause many erratic electrical problems. Remember every electrical product, ice machine, dispenser,

walk–in, reach–in, air conditioner, etc. required proper power supply to operate. Be certain when voltage checks are performed that

you are measuring load voltage, not line voltage.

2. A defective capacitor or start relay may prevent the

compressor from starting. Should the compressor attempt to start, but is unable to do so, or if the compressor hums or trips off on the over protector, check the

following:

NOTE: For 50 HZ application on dual rated 50/60 HZ mod-

els, load voltage while compressor is starting must

not be less than 90% of 50 HZ rating.

Relay

Potential –

For the potential type, contacts are normally closed. The start contacts open by C.E.M.F. generated by the compressor at approximately 80% of the normal operating speed. As the contacts open, only the

start capacitor is removed from the start circuit. Both the start and

run winding and the run capacitor remain in the circuit. This relay

may or may not be directional in mounting.

Current –

For the current type, contacts are normally open. The start contacts

close by the high current draw from the locked rotor condition with

only the run winding in the circuit. As the contacts close, the start

capacitor and the start winding is energized and the compressor

starts. At approximately 80% of its operating speed the current draw

drops off, the relay contacts open removing the start winding and

start capacitor from the circuit. Remember, current relays are directional in their mounting to allow contacts to lift and close.

Capacitors

A quick check is to replace suspected defective capacitors with

known good capacitors being careful to stay within the range for

substitute values. Should those values be unknown, a basic rule for

capacity is: for start capacitors 10% and run capacitors 5% of

the rating on the defective original capacitor being replaced. Voltage

should always try and be matched, if it cannot be it is acceptable to

48TD 202 3/1/95

Rev 9/18/95

Page 52

increase up to 10% higher than the voltage listed on the capacitor being replaced. NEVER put a capacitor on a product with a voltage

rating lower than the original being replaced. If a capacitor analyzer

is not available, an ohm meter may be used to check a capacitor for

short or open circuits. Set the ohm meter to its highest scale and connect its leads to the capacitor terminals.

1. With a capacitor, without plate defect, the indicator

should first move to zero (0) and then gradually increase to infinity.

2. If there is no movement of the ohm meter indicator, an

open circuit is indicated.

3. If the ohm meter indicator moves to zero (0) and remains there, or on a low resistance reading, a short

circuit is indicated.

4. Please note this check does not determine if the capacitor will deliver the proper rated MFD/UFD required, it

only shows if the capacitor has shorted or open circuits.

5. Capacitors that show any signs of leakage of electrolyte, or damage of the can, should be replaced. DO

NOT TEST!

Compressor

1. Using an ohm meter, check for continuity from compressor terminal C to R and C to S. If the compressor

is hot, wait one (1) hour for compressor to cool and

recheck. An open internal overload protector can

cause a lack of continuity. If continuity cannot be measured through all windings, the compressor must be

replaced.

2. To check the compressor motor for accidental ground,

perform a continuity check between terminals C, R

and S to the compressor shell or a copper line of the

refrigeration system (do not use a painted surface).

Continuity present, the compressor windings are

grounded and the compressor must be replaced.

If the compressor starts, but trips repeatedly on the overload protector, remember that the overload is both temperature and current activated. Be sure to check; (Continued on page 49)

S Low voltage

S Undersized supply lines

S High head pressure

S High suction pressure

S Defective capacitors

S Compressor mechanical problems

S Low Refrigerant Charge

Rev 9/18/95

49 TD 2023/1/95

Page 53

Moisture Contamination

With the major changes in refrigerants in today’s marketplace and

the use of hydroscopic oils the control of moisture and contaminates

have become more critical to safeguard against than ever before in

the history of mechanical refrigeration.

Contaminates are also the most difficult of all problems to determine. A Meg–Ohm meter “Megger” can be a valuable tool to aid in

the analysis of this problem. A Meg–Ohm reading log may be

started any time after 90 days of operation of the product. To perform the test, proceed as listed.

Disconnect all three (3) compressor leads, take a Meg-Ohm meter

reading from each compressor terminal to a good chassis ground.

Compare reading to chart below:

Meter

Reading

Meg-Ohm

100 - ∞

50 to 100 Moisture present Replace drier.

20 to 50 Severe moisture &

.5 to 20 System has severe

(Continued on page 51)

Compressor

Condition

Okay None needed.

possible contaminated

oil with acid present

contamination

Maintenance Required

Replace drier with acid

hold type. Run 24

hours, change to regular drier.

Remove compressor

oil and refrigerant

charge. Evacuate,

install liquid and suction line driers (acid

hold type). Recharge

with new oil and refrigerant. Run 24

hours. Discharge system, discard suction

line drier, replace the

liquid line drier. Evacuate and recharge.

50TD 202 3/1/95

Rev 9/18/95

Page 54

Readings in the range listed below 100 Meg–Ohm would be an indicator that the system being tested may have a contamination problem. Where does the problem come from? As an example, the filter

drier may become saturated and hold large percentages of moisture

and the system function without a problem until such time as the

product operating conditions change. Should the room temperature

increase, or the condenser plug–up etc., the higher operating pressures and temperatures may cause the drier filter to release a portion

of it’s held moisture. It is also imperative to avoid opening the sealed

refrigeration system whenever possible and when it is done to be

certain the true problem is correctly diagnosed and repaired. Remember, service gauge sets should only be installed after all external

checks have been performed.

Caution: Megger checks should NEVER be performed

on any compressor that is under a vacuum.

Rev 9/18/95

51 TD 2023/1/95

Page 55

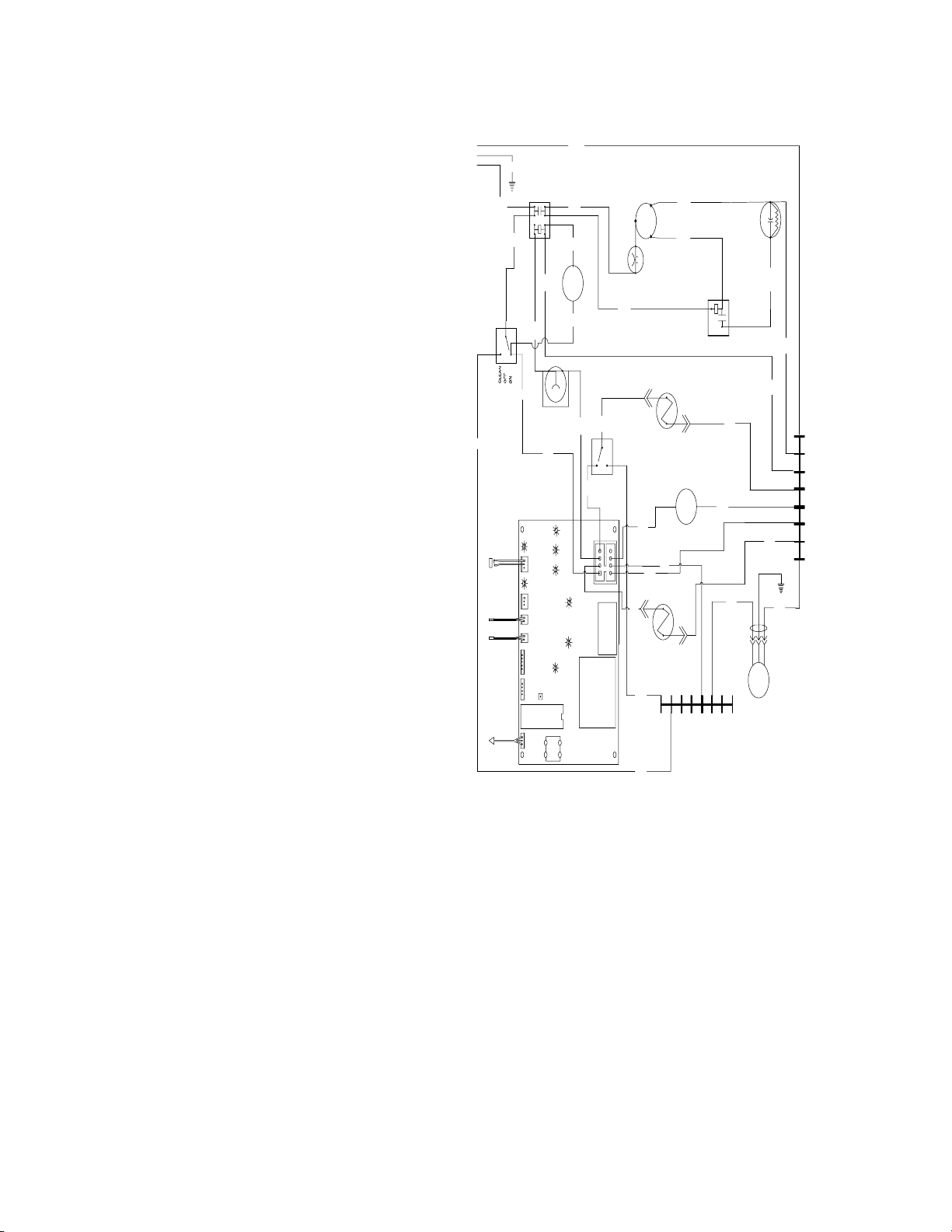

WH

GR

CONTACTOR

UNIT

SWITCH

BL

BK

BK

1

2

3

BR

BL

WH

CO

450 PSIG

BR

BR

BK

M

BK

CONDENSATION

FAN (W/C ONLY)

MANUAL RESET

HIGH PRESSURE

CONTROL(W/C ONLY)

BK

BL

3

1

YL

Water

D-15

Dump

GR

Valve

D-13

D-14

YL

RH Evap.

Switch

N

S

(White Lead)

Condenser

Sensor

See note 1

Suction Line

Sensor

(Brown Lead)

To Stacked

Unit

(if required)

NOTE 1: CONDENSER SENSOR USED ONLY ON A/C UNITS.

Relay

RH Evap.

YL

D-10

LH Evap.

Condenser

Plug

Suction

Plug

Test

Plug

Options

Plug

Micro

Processor

Stacking

Cable

Plug

GR

GR

D-12

Error

Adjustable Ice

Thickness Pot.

7

5

Water

3

Pump

1

D-11

Hot Gas

Valve

GR

GR

RD

D-6

D-5

Condenser

Manual

Harvest

Switch

Fan

Transformer

Voltage

Selector

Switch

230V

115V

1.8K ohm RESISTOR USED ONLY ON W/C UNITS.

COMPRESSOR

BR

WATER DUMP

SWITCH

2

8

6

4

2

C

BK

WH

RD

BL

BL

R

S

EXTERNAL

COMPRESSOR

OVERLOAD

POTENTIAL

START RELAY

BL

HOT GAS

SOLENOID

RD

YL

WATER DUMP

VALVE

CONDENSER

FAN MOTOR

(A/C ONLY)

M

IAC 322 & IWC 322

IAC 330 & IWC 330

243-292 mfd

2

5

1

WH

BK

COMPRESSOR

115 VAC

WH

PUMP

CORD

WATER PUMP

START

CAPACITOR

OR

WH

WH

WH

M

WH

52TD 202 3/1/95

Rev 9/18/95

Page 56

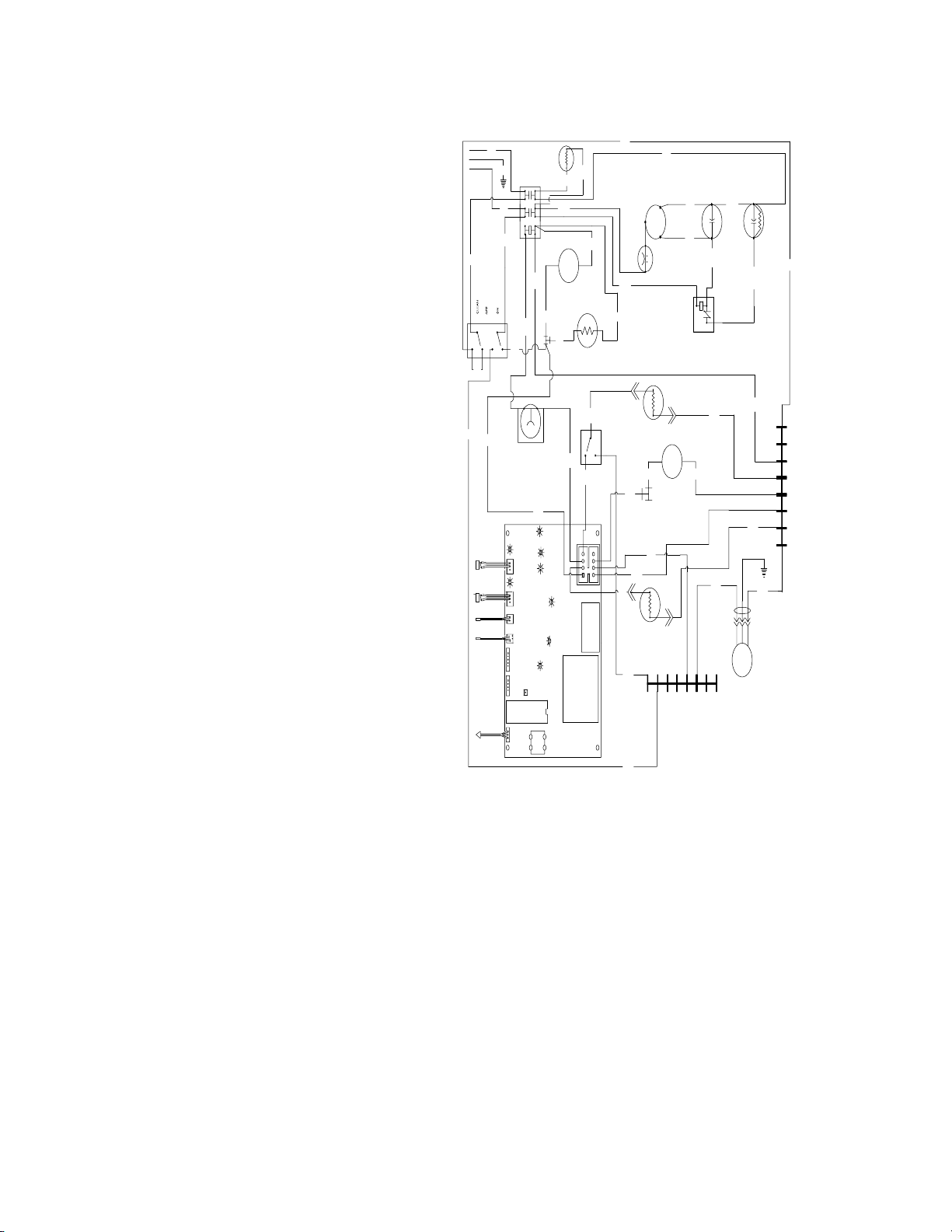

WH

GR

CONTACTOR

BR

BK

M

WH

BK

CONDENSATION

BL

FAN (W/C ONLY)

MANUAL RESET

HIGH PRESSURE

CO

450 PSIG

BR

CONTROL(W/C ONLY)

BK

BL

WATER DUMP

1

SWITCH

3

2

BR

UNIT

SWITCH

BL

BK

BK

1

2

3

YL

Water

D-15

Dump

GR

Valve

D-13

D-14

YL

RH Evap.

Switch

N

S

(White Lead)

Condenser

Sensor

See note 1

Suction Line

Sensor

(Brown Lead)

To Stacked

Unit

(if required)

Relay

GR

RH Evap.

Water

GR

Pump

D-12

YL

D-10

LH Evap.

GR

Condenser

Plug

Suction

Plug

GR

Test

RD

Plug

Error

Options

Plug

Adjustable Ice

Thickness Pot.

Micro

Processor

Stacking

Cable

Plug

NOTE 1: CONDENSER SENSOR USED ONLY ON A/C UNITS.

1.8K ohm RESISTOR USED ONLY ON W/C UNITS.

D-11

D-6

D-5

Hot Gas

Condenser

Manual

Harvest

Switch

Valve

Voltage

Selector

Switch

Fan

Transformer

8

7

6

5

4

3

1

2

230V

115V

COMPRESSOR

R

C

S

COMPRESSOR

BR

BK

WH

RD

BL

BL

440 VAC

EXTERNAL

OVERLOAD

POTENTIAL

START RELAY

WATER DUMP

BL

HOT GAS

SOLENOID

COMPRESSOR

CAPACITOR

RD

30 mfd

YL

VALVE

CONDENSER

FAN MOTOR

(A/C ONLY)

M

IAC 522 & IWC 522

IAC 530 & IWC 530

RUN

5

1

BK

YL

2

WH

WH

PUMP

CORD

COMPRESSOR

START

CAPACITOR

RD

72-86 mfd

330 VAC

OR

WH

WH

M

WATER PUMP

WH

WH

Rev 9/18/95

53 TD 2023/1/95

Page 57

BK

RD

RD

SWITCH

BL

(White Lead)

Condenser

Sensor

See note 1

Suction Line

Sensor

(Brown Lead)

To Stacked

(if required)

RD

CRANKCASE

HEATER

(RC ONLY)

UNIT

RH Evap.

Switch

N

S

LH Evap.

Switch

N

S

Unit

GR

BK

BR

D-13

LIQUID LINE

SOLENOID

(R/C ONLY)

CONTACTOR

RD

BK

BL

450 PSIG

BR

D-15

GR

D-14

YL

GR

RH Evap.

GR

D-10

D-12

YL

LH Evap.

Suction

Plug

Test

Plug

Options

Plug

Adjustable Ice

Thickness Pot.

Micro

Processor

Stacking

Cable

Plug

RD

BR

BK

BK

M

BK

CONDENSATION FAN

(W/C & R/C ONLY)

HIGH PRESSURE CONTROL

(W/C & RC ONLY)

CO

BL

BR

YL

Water

Dump

Valve

Relay

Water

Pump

D-11

Hot Gas

GR

Valve

Condenser

Plug

D-6

Condenser

GR

Fan

RD

D-5

Error

Transformer

Manual

Harvest

Switch

BK

BR

MANUAL RESET

BK

WATER DUMP

1

SWITCH

3

2

7

8

6

5

4

3

2

1

230V

Voltage

Selector

Switch

115V

RD

COMPRESSOR

R

C

S

EXTERNAL

COMPRESSOR

OVERLOAD

BK

RD

RD

HOT GAS

SOLENOID

BL

BL

RD

COMPRESSOR

RD

YL

POTENTIAL

START RELAY

WATER DUMP

VALVE

M

CONDENSOR

FAN MOTOR

(A/C ONLY)

BL

IAC 830, IWC 830 & IRC 830

IAC 630, IWC 630 & IRC 630

RUN

CAPACITOR

YL

2

5

1

RD

See note 2

35 mfd

370 VAC

WH

BK

WH

PUMP

CORD

WATER PUMP

COMPRESSOR

START

CAPACITOR

145-174 mfd

250 VAC

OR

RD

WH

WH

M

RD

NOTE 1: CONDENSER SENSOR USED ONLY ON A/C UNITS.

1.8K ohm RESISTER USED ONLY ON W/C & R/C UNITS.

NOTE 2: CAPACITORS USED ON 630 BRISTOL COMPRESSOR:

RUN CAP, 25mfd 440 VAC

START CAP. 161-193mfd 250 VAC

54TD 202 3/1/95

Rev 9/18/95

Page 58

LIQUID LINE

RD

SOLENOID

(R/C ONLY)

RD

BK

CRANKCASE

HEATER

(RC ONLY)

GR

BK

BK

CONTACTOR

RD

BR

BK

M

RD

BK

BL

BK

CO

450 PSIG

Water

Dump

GR

Valve

D-14

Relay

GR

Water

GR

Pump

D-12

D-11

GR

D-6

GR

RD

D-5

Error

Adjustable Ice

Thickness Pot.

HIGH PRESSURE

BL

BR

Hot Gas

Valve

Condenser

Fan

Transformer

Manual

Harvest

Switch

YL

BK

BR

UNIT

RD

SWITCH

BL

(White Lead)

Suction Line

(Brown Lead)

(if required)

NOTE 1: CONDENSER SENSOR USED ONLY ON A/C UNITS.

D-15

D-13

YL

RH Evap.

Switch

N

RH Evap.

S

D-10

YL

LH Evap.

Switch

N

LH Evap.

S

Condenser Sensor

Condenser

Plug

See note 1

Suction

Plug

Sensor

Test

Plug

Options

Plug

To Stacked

Micro

Processor

Unit

Stacking

Cable

Plug

1.8K ohm RESISTER USED ONLY ON W/C & R/C UNITS.

2: Capacitors used on 103 Compressor

RUN CAP. 37 mfd 370V

START CAP. 145-174 MFD 250v

RD

BK

COMPRESSOR

BR

CONDENSATION

FAN (W/C & R/C)

MANUAL RESET

CONTROL(W/C & R\C)

BK

WATER DUMP

1

SWITCH

3

2

8

7

6

5

43

21

RD

230V

Voltage

Selector

Switch

115V

BL

BL

RD

RD

R

C

S

YL

EXTERNAL

COMPRESSOR

OVERLOAD

POTENTIAL

START RELAY

WATER DUMP

M

BK

M

BL

RD

HOT GAS

SOLENOID

IAC 1230, IWC 1230 & IRC 1230

IAC 1030 IWC 1030 & IRC 1030

COMPRESSOR

CAPACITOR

5

VALVE

CONDENSOR

FAN MOTORS

(A/C ONLY)

RUN

YL

2

1

WH

RD

See note 2

40 mfd

370 VAC

BK

BK

WH

PUMP

CORD

WATER PUMP

COMPRESSOR

START

CAPACITOR

189-227 mfd

330 VAC

OR

RD

WH

WH

M

RD

Rev 9/18/95

55 TD 2023/1/95

Page 59

RD

RD

UNIT

SWITCH

RD

BL

BR

HIGH PRESSURE

RH Evap.

Switch

N

S

LH Evap.

Switch

N

S

(White

Lead)

Condenser Sensor

See note 1

Suction Line

Sensor

(Brown

Lead)

To Stacked

Unit

(if required)

LIQUID LINE

SOLENOID

(R/C ONLY)

GR

CONTACTOR

BK

BK

RD

BK

BL

BR

CO

450 PSIG

MANUAL RESET

CONTROL(W/C & R/C)

BR

D-15

Water

Dump

GR

Valve

D-13

D-14

YL