Page 1

INSTALLATION INSTRUCTIONS

FCB 2 FLAVOR PLUMBING

The following instructions should be used for installation of the CO2, Water, and Syrup plumbing for a

Pinnacle or V-Series 2 Flavor FCB unit at a maximum distance of 50 feet from the unit. Prior knowledge

of the FCB Installation/Service Manual is necessary before attempting the installation.

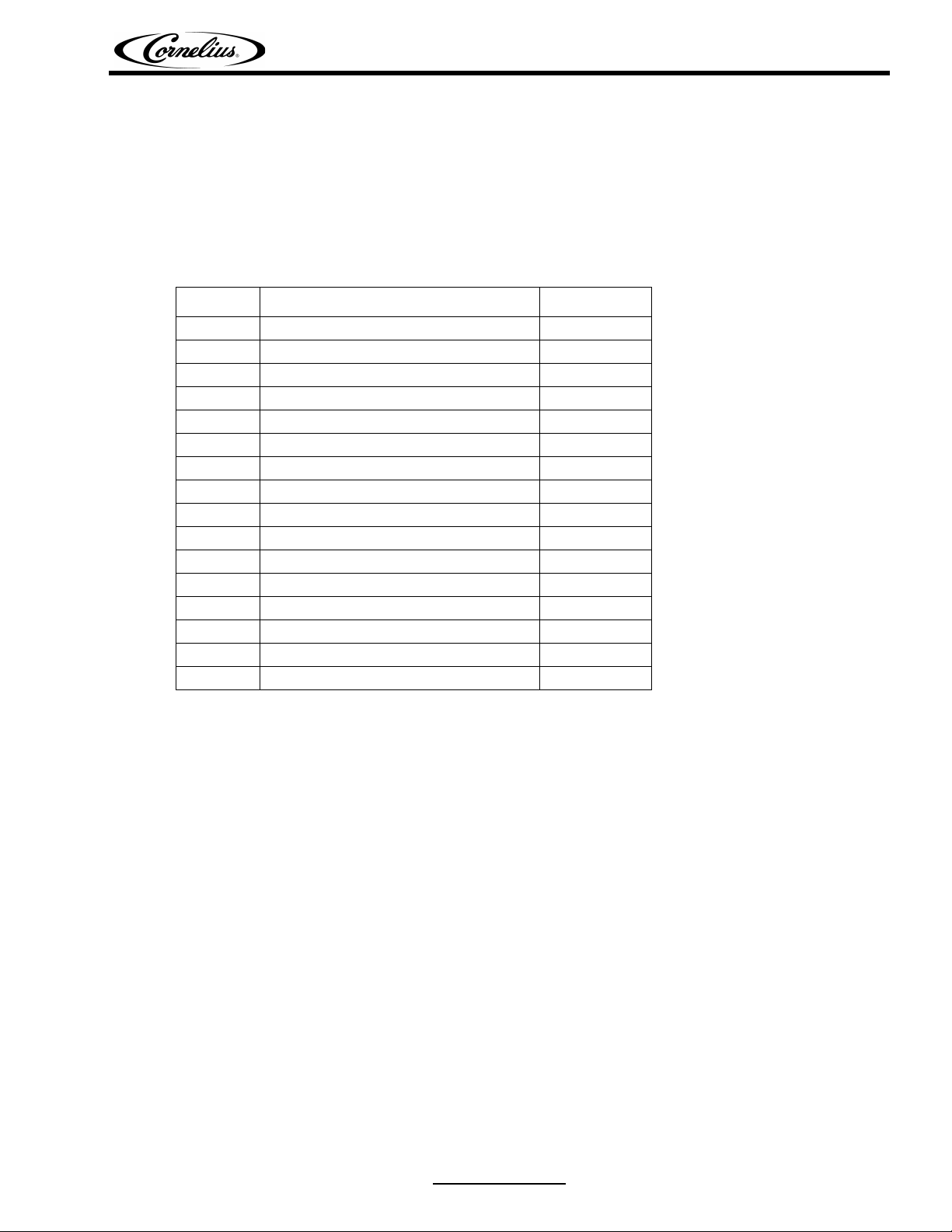

Parts List

Item Description Quantity

1 1/2" - 3/4" Hose Barb to MPT 1

2 1/4" Flow Washer 2

3 1/4" Female Flare Swivel Nut 2

4 1/4" Stem Barb 2

5 1/4" Tee Barb 1

6 1/4" - 1/4" Hose Barb Splice 1

7 1/4" - 3/8" Hose Barb Splice 2

8 3/8" - 1/2" Hose Barb Splice 1

9 17.0 Oetiker .669 O - .571 C 10

10 12.3 Oetiker .490 O - .386 C 15

11 21.0 Oetiker .826 O - .700 C 3

12 11” Cable Tie 10

13 1/4" ID Braided Tubing 100 Ft

14 3/8" ID Braided Tubing 100 Ft

15 1/2" ID Braided Tubing 50 Ft

16 3/8” ID Flexible Tygon Tubing 12 Ft

FCB 2 Flavor Plumbing Installation Instructions

Tools Required

• Adjustable Wrench

• Oetiker Pliers

• Tube Cutters for Beverage Tubing

Additional Items Required

• BIB Disconnects

• BIB Pumps

• BIB Rack

• CO

• Water Filter

Refer to TP01068 for IMI Cornelius part numbers of Additional Items in list above.

Regulators

2

Release Date: October 7, 2003 www.cornelius.com Revision: A

© 2003, IMI Cornelius Inc. - 1 - Publication Number: 629088357INS

Page 2

FCB 2 Flavor Plumbing Installation Instructions

Requirements

Pinnacle

CO

2

Water 25 psi minimum flowing pressure at the unit with 1.67 gallons per minute flow rate

Syrup 60 psi minimum static at the unit and 45 psi minimum flowing pressure with 0.35 ounces

Clearances Refer to Installation/Service Manual

V-Series

CO2 80 psi minimum at the unit

Water 16 psi minimum flowing pressure at the unit with 1.67 gallons per minute flow rate

Syrup 80 psi minimum static at the unit and 65 psi minimum flowing pressure with 0.35 ounces

Clearances Refer to Installation/Service Manual

60 psi minimum at the unit

(100gph) per 2 barrels. If the flowing pressure and flow rate are less than specified, a

water pressure booster is required. See note below.

per second flow rate (0.17gpm)

(100gph) per 2 barrels. If the flowing pressure and flow rate are less than specified, a

water pressure booster is required. See note below

per second flow rate (0.17gpm)

Water Requirement Note: When testing the water supply to the FCB machine the installer must

take into consideration the total potential water demand that may be placed on the store water supply

by all equipment within the store.

Equipment such as fountain dispensers, icemakers, coffee brewers, and juice dispensers typically

draws water from a common source/filter system. The FCB machine must be supplied with water to

the specification above at all times, even when any of the other equipment is drawing water. If the

operation of the other appliances reduces the flow rate of water to this FCB unit below 1.67gpm

(100gph), add the required water booster.

WARNING – Secure the CO

cylinder in an upright position with a safety chain to prevent it from

2

falling over and causing personal injury and property damage.

WARNING – CO

ence tremors, followed by loss of consciousness and death. It is very important to prevent CO

leaks, especially in small, unventilated areas. If a CO

displaces oxygen. Persons exposed to high concentrations of CO2 will experi-

2

leak occurs ventilate the area before fixing

2

2

the leak.

NOTE: Tubing, hoses, and cabling may be routed from beneath or in back of the Pinnacle FCB

unit and ONLY from beneath the V-Series unit. It may be necessary to make a penetration in the

counter or wall to accommodate the desired installation.

NOTE: If the syrup lines will be routed in an area that will see temperatures less than 55°F the

lines must be insulated.

Publication Number: 629088357INS - 2 - © 2003, IMI Cornelius Inc.

Page 3

FCB 2 Flavor Plumbing Installation Instructions

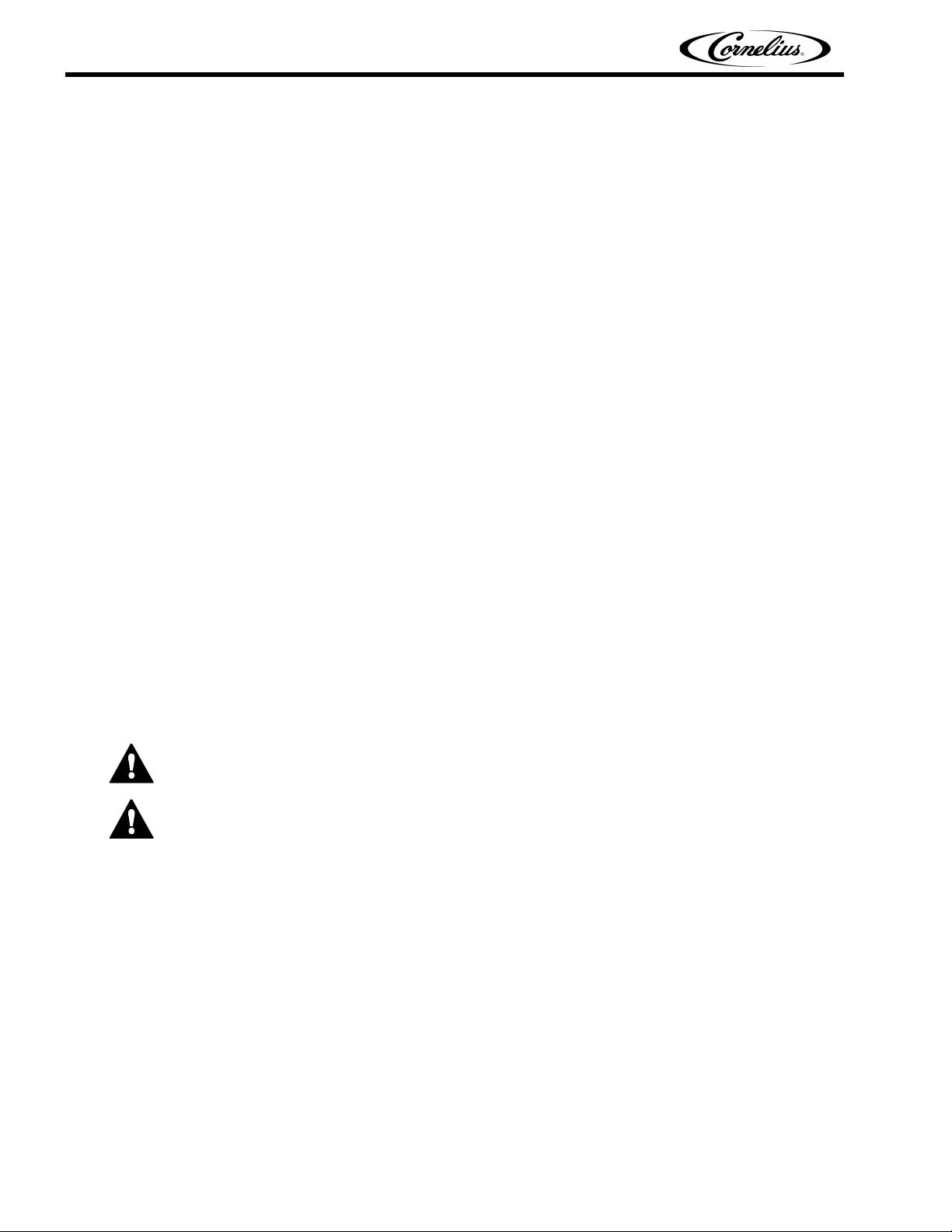

Tubing

½ Inch Beverage Tubing

3/8 Inch Beverage Tubing

¼ Inch Beverage Tubing

3/8 Inch Tygon Tubing

Water Filter

Connections

FCB Unit

Water Inlet

Syrup Line 1

Syrup Line 2

CO2 Inlet

Max 6 Feet

A

D

BB C

A

½ Inch to 3/8 Inch Splicer

B

3/8 Inch to ¼ Inch Splicer

C

¼ Inch to ¼ Inch Splicer

D

½ Inch Hose Barb to ¾ NPT

¼ Inch Female Flare Nut

E

Direct Connection to Syrup

F

Outlet on Syrup Pump

Direct Connection to CO2

G

Inlet on Syrup Pump

Direct Connection to Syrup

H

Inlet on Syrup Pump

I

¼ Inch Tee Barb

Regulator

E E

CO2 Supply

BIB Syrup

BIB Syrup

BIB PumpF

F

BIB Pump

G

H

I

H

G

© 2003, IMI Cornelius Inc. - 3 - Publication Number: 629088357INS

Loading...

Loading...