IMI Cornelius, Inc. COR20RRTM, COR22RRTM, COR40RRTMD, COR48RRTMD, COR74RRTMT Service Manual

Page 1

®

REACH-IN REFRIGERATORS

COR20RRTM, COR22RRTM, COR40RRTMD,

COR48RRTMD, COR74RRTMT

Service Manual

Release Date: June 16, 2004

Publication Number: 630460252SER

Revision Date: NA

Revision: A

Visit the IMI Cornelius web site at www.cornelius.com

for all your Literature needs.

Page 2

SERVICE MANUAL

The products, technical information, and instructions contained in this manual are subject

to change without notice. These instructions are not intended to cover all details or variations of the equipment, nor to provide for every possible contingency in the installation,

operation or maintenance of this equipment. This manual assumes that the person(s)

working on the equipment have been trained and are skilled in working with electrical,

plumbing, pneumatic, and mechanical equipment. It is assumed that appropriate safety

precautions are taken and that all local safety and construction requirements are being

met, in addition to the information contained in this manual.

To inquire about current revisions of this and other documentation or for assistance with

any Cornelius product contact:

www.cornelius.com

800-238-3600

Trademarks and copyrights:

Aurora, Cornelius, Decade, Hydro Boost, Sitco, Spirit, UF-1, Vanguard, Venture, Olympus,

and Vista are registered trademarks of IMI Cornelius Inc.

Optifill trademark is pending.

This document contains proprietary information and it may not be

reproduced in any way without permission from Cornelius.

Printed in U.S.A.

Copyright © 2004, All Rights Reserved, IMI Cornelius, Inc.

Page 3

Reach-In Refrigerator Service Manual

TABLE OF CONTENTS

Features of the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Cleaning and Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

How Your Cabinet Operates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Defrost water flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warning light and thermometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Temperature control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Automatic defrosting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Service Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Light switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Temperature controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Time clocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Blower fan assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Defrost heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Condensing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

COR20RRTM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

COR22RRTM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

COR40RRTMD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

COR48RRTMD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

COR74RRTMT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Possible causes and solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

© 2004, IMI Cornelius Inc. - i - Publication Number: 630460272SER

Page 4

Reach-In Refrigerator Service Manual

Publication Number: 630460272SER - ii - © 2004, IMI Cornelius Inc.

Page 5

FEATURES OF THE UNIT

Heavy duty condensing

unit located on top for

easy-access maintenance.

Reach-In Refrigerator Service Manual

Control panel with

temperature display, door ajar

light, power indicator,

condensate switch

U.L. compliant electrical components

Heavy duty hinges with self-closing mechanism

Strong body with 2 1/2” thick walls injected with

CFC-free polyurethane. Stainless steel front

and exterior sides.

COR48RRTMD

Heavy duty shelves

Recessed handles with cylinder lock

Solid doors save energy by preventing warm air

from reaching your products.

Forced air evaporator for quick temperature pull

down

6” swivel casters

FIGURE 1

© 2004, IMI Cornelius Inc. - 1 - Publication Number: 630460272S ER

Page 6

Reach-In Refrigerator Service Manual

CLEANING AND PREVENTIVE MAINTENANCE

Weekly or sooner, as required:

1. Disconnect the power source before cleaning. Remove all products and place in a proper cooler.

2. Clean the interior and exterior with a mild soap or detergent solution and then rinse with a warm

baking soda solution (one cup of baking soda to one gallon of warm water). Dry the interior

completely before replacing products.

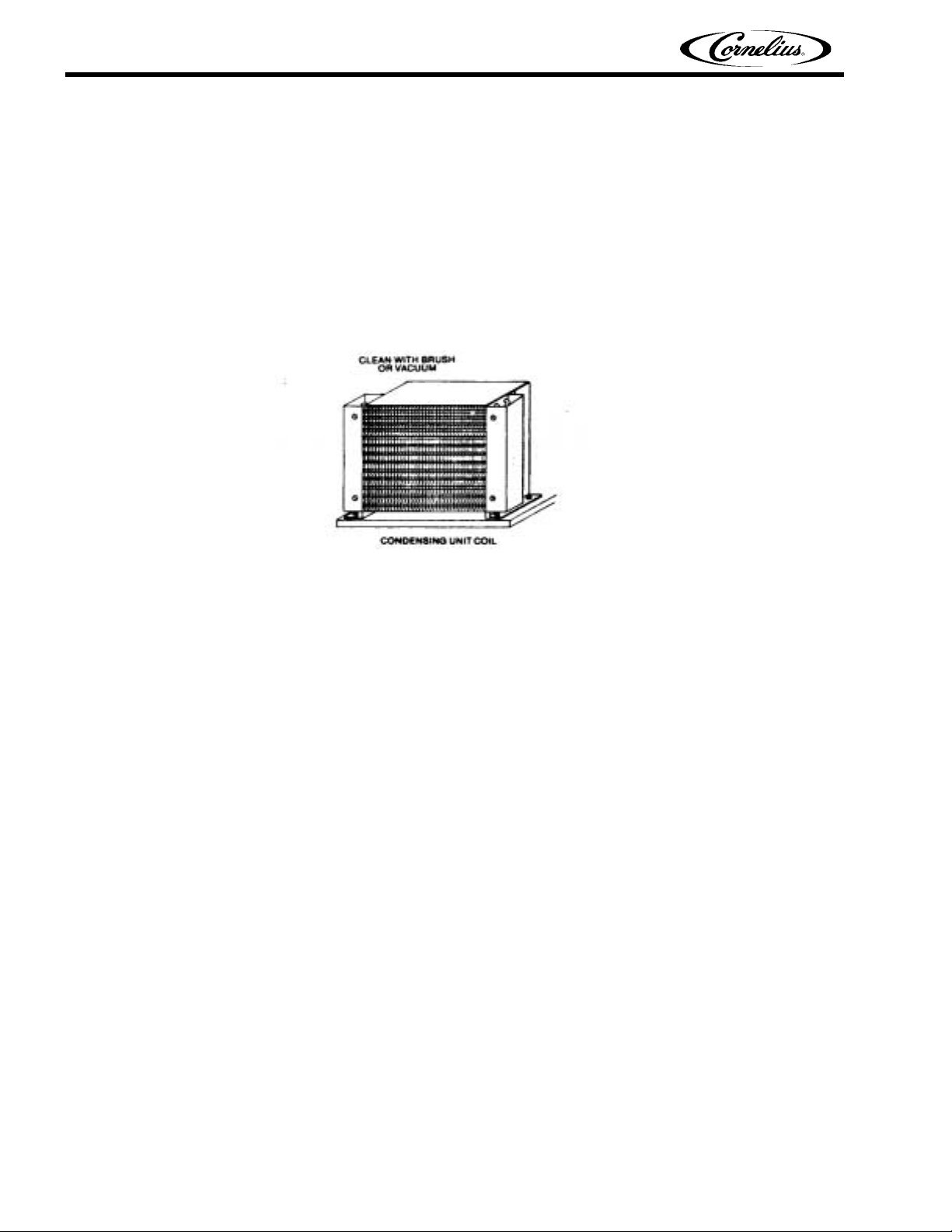

3. Clean the condenser unit periodically by vacuuming the unit compartment, especially the

condenser unit coil (it looks like a small auto radiator). If the condenser coil has accumulated dirt

and grease (possible in heavy traffic areas or a kitchen), use a strong cleaning solution. If you find

any oil in the condensing unit compartment, call a qualified service person immediately.

FIGURE 2

4. Empty out and clean drain pan located next to the condensing unit as required. Check regularly for

excessive water accumulation.

5. Plug in the cabinet and wait until the proper temperature is achieved before reloading the cabinet

with product.

Publication Number: 630460272SER - 2 - © 2004, IMI Cornelius Inc.

Page 7

HOW YOUR CABINET OPERATES

CAUTION - Make sure the power supply is turned off before making any electrical repairs.

Defrost water flow

Your new cabinet is completely self-defrosting. The frost that collects on the concealed coils is

automatically removed at predetermined intervals. The defrost water on top-mounted condensing units

flows into a thermostatically controlled electric vaporizer where it is dissipated into the atmosphere. All

defrost evaporator systems are designed for normal conditions; however, under some conditions, where

practical and convenient, a drain line to a floor drain may be preferable to the vaporizer. On basemounted condensing units, the defrost water flows into the unit compartment and is vaporized by the heat

from the hot gas line.

Reach-In Refrigerator Service Manual

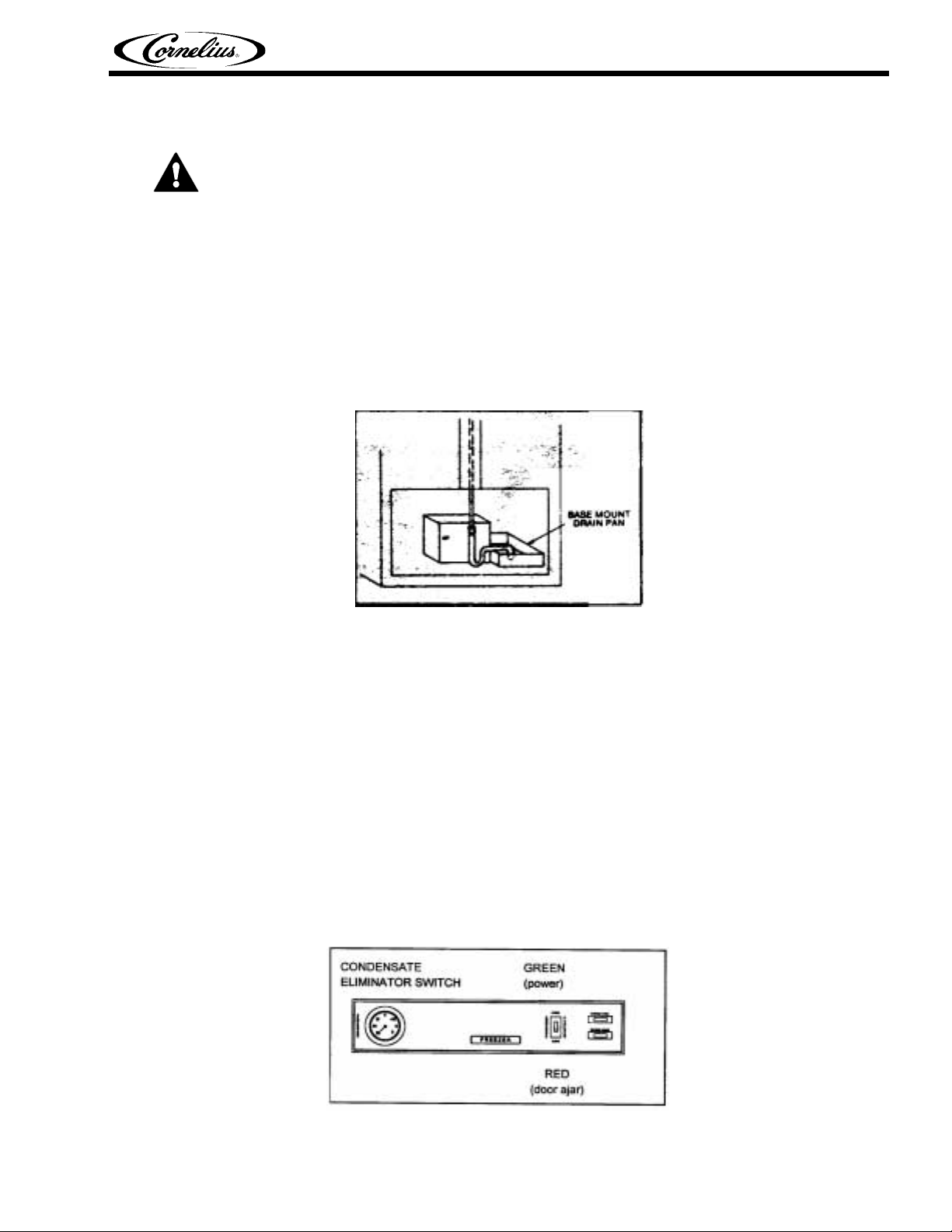

Warning light and thermometer

A fan circulates the cold air from the coil throughout the storage area. This provides uniform

termperatures and more rapid recovery after door openings. The number of door openings and the length

of time the door is left open should be kept to a minimum to reduce the operating cost and maintain the

most efficient operation. The temperature in the cabinet will rise very rapidly whenever the doors are

opened; however, the product temperature is not greatly affected.

Some top-mounted cabinets have a thermometer and two small lights located at the right end of the front

motor cover grill, directly over the door. One light is green and is always lit when there is power to the

cabinet. One light is red and should only be lit when the temperature is above the safe zone. It is

controlled by a bi-metallic disk type switch.

The red light will be on at start up until the temperature comes down to normal. When warm product is

put in or the doors are held open for a time, the red light may come on but it will go out again as soon as

the temperature has recovered. When the doors are closed again, the recovery is very rapid unless a

large quantity of warm product is put in at one time.

FIGURE 3

FIGURE 4

© 2004, IMI Cornelius Inc. - 3 - Publication Number: 630460272S ER

Page 8

Reach-In Refrigerator Service Manual

Temperature control

If the condensing unit does not run after the power cord is plugged in, check that the temperature control

is in the “on” position. This can be done with an ordinary screwdriver. After the system has operated for

several hours, the temperature control may be adjusted to suit your needs. Turn it clockwise to make it

colder and counterclockwise to make it warmer. Do not make more than 1/4 turn at one time; then allow it

to operate for several hours before making any further adjustment. Once it is set there should be no need

to change it.

After the cabinet has been used for a while, if you should notice any great change in termperature, do not

attempt to compensate for it by turning the control. It is much more likely that there is some other problem

and a qualified refrigeration service person should be called.

Automatic defrosting

Normally, when the cabinet storage area temperature is kept at a range of 36oF to 42oF, all refrigerators

will defrost the coil during the off cycle (when the compressor is not running). Under some conditions,

such as heavy product load or a lot of door openings in a high ambient temperature or excessive relative

humidity, it may be advisable to install a time clock which will automatically shut the condensing unit off

for an hour or two each night to be sure the coil is completely cleared of frost. It should be connected so

the blower fan is left on to speed up the defrosting process. A qualified service person should be

consulted before attempting to make these additions.

SERVICE PROCEDURES

FIGURE 5

CAUTION - Make sure the power supply is turned off before making any electrical repairs.

If any electrical problems arise, a wiring diagram is included with each cabinet to aid in tracing the source

of trouble and making the necessary repairs.

Light switches

Each hinged solid door has a switch which will turn on the interior light whenever the door is opened. In

most cases the switch may be examined or exchanged without removing the mounting bracket. Place a

knife blade or similar tool behind the switch flange and pry it out. To replace the switch, disconnect the

Publication Number: 630460272SER - 4 - © 2004, IMI Cornelius Inc.

Page 9

Reach-In Refrigerator Service Manual

leads from the terminals and attach them to the new switch and snap it back in place. Make sure there

are no breaks or bare wires to cause a short before putting the switch back.

FIGURE 6

Lights

The incandescent light bulb can be replaced by any 40 watt appliance bulb.

Temperature controls

CAUTION - Make sure the power supply is turned off before making any electrical repairs.

To replace the temperature control:

1. Remove the two mounting screws.

© 2004, IMI Cornelius Inc. - 5 - Publication Number: 630460272S ER

Page 10

Reach-In Refrigerator Service Manual

2. Pull the feeler bulb from the well which is usually located on the coil or header and pull the lead

wires off the control terminals.

If the temperature control is within the first year warranty and is to be returned for credit, be sure to

coil the tubing neatly and do not kink it or damage the control in any way. No credit can be issued for

any parts that arrive in a damaged condition.

3. Replace the control with an exact factory replacement or one equal to the original specifications. Be

sure the feeler bulb is in the proper well and tight. Do not allow the tubing connecting the feeler bulb

to the body of the control to touch the coil U bends.

Time clocks

In the cabinets which have bottom-mounted condensing units, the time clock will be located along the

side of the unit. It will be readily visible when the motor cover is removed. The timer is set at the factory

for two defrost periods with a fail safe of 40 minutes for both single and multiple door cabinets. (For SAV

models the timer is set at the factory for four (4) defrost periods of 30 minutes.) Tests have shown that the

factory setting is satisfactory for most applications. However, changes can be made after a sufficient trial

period if necessary.

The fail safe is controlled by the small copper pointer on the inner dial. To reset the timer, grasp the

knurled knob and turn it counterclockwise until the pointer is at the correct time. As soon as the power is

turned on, if the temperature control is in the “on” position, the time clock and condensing unit will start.

FIGURE 7

Publication Number: 630460272SER - 6 - © 2004, IMI Cornelius Inc.

Page 11

Reach-In Refrigerator Service Manual

FIGURE 8

When the coil temperature reaches the proper temperature, the fan(s) will automatically start and

continue to run until it comes to the defrost cycle. The fan(s) may turn off if the doors are left open too

long during a loading period and the coil becomes warm. Do not call for service until the freezer is given

enough time to come down to the proper temperature. After the unit is put into operation, the fan(s) will

continue to operate until the storage area reaches a proper temperature (recommended average 38

The red pilot on the front of the top grill should turn off after about an hour of operation or whenever the

sensing element reaches the prescribed temperature. Under some conditions the red warning light may

go on at the end of the defrost cycle. However, after the defrost cycle is ended, the temperature should

recover in a reasonable length of time and the red light will go out. The defrost periods are set at the

factory for 6 a.m. and 6 p.m. and may be changed if needed.

o

F).

When the pin on the outer dial of the time clock is opposite the pointer, the defrost cycle will start. The

condensing unit and the blower fan shut off and the defrost heaters turn on. The heaters are located on

the coil. As soon as the coil has reached approximately 50

limit and fan delay switch will trip the timer solenoid and end the defrost cycle to put the system back into

the refrigeration cycle. The blower fan will remain off until the coil cools down to 20

solenoid should fail to terminate the defrost cycle, the inner fail safe dial will take over and terminate the

defrost cycle when the prescribed time is up. The length of the defrost cycle will vary depending on the

type of product stored in the cabinet, the number of door openings, and the atmospheric conditions. The

defrost cycle will usually take longer in the summer than in the winter. Before you make changes to the

length of the fail safe or the number of defrost periods, a competent service engineer should make a

complete study of all the contributing factors.

o

F and the coil is clear, the combination defrost

o

F. If the limit switch or

© 2004, IMI Cornelius Inc. - 7 - Publication Number: 630460272S ER

Page 12

Reach-In Refrigerator Service Manual

Blower fan assembly

To change the fan blade, remove the speed nut from the threaded shaft. If the fan motor must be

changed:

1. Remove the fan blade and lay it carefully aside. Be careful not to bend or damage the blade or it will

become out of balance.

2. Remove the four machine screws around the perimeter of the hole in the baffle. These hold the

motor mounting bracket in place. The small rubber washers that eliminate vibration should be saved

for reassembly.

3. Drop the motor and bracket through the hold.

4. Remove the three machine screws holding the motor to the mounting bracket and disconnect the

wire leads.

5. Install the new fan motor and reinstall the fan blade.

Defrost heater

To change the defrost heater element:

1. Remove the baffle from under the coil. This is the part that catches the condensate water and

funnels it down the drain. It also directs the flow of air through the coil and down the air ducts. To

remove the baffle, take out the screws and let it down far enough to get to the defrost element.

2. Use a pair of side cutters or diagonal pliers to snip off all of the copper wires holding the heater

element to the coil.

3. Disconnect the element from the cabinet leads.

FIGURE 9

FIGURE 10

Publication Number: 630460272SER - 8 - © 2004, IMI Cornelius Inc.

Page 13

4. Install a new heater element. Be sure to use similar copper wire to install the new element tightly

against the coil. Note that there is a bend in the heater element along the center rear. This must

make good contact with the drain pan or baffle at the drain opening in order to work properly. If it

does not make good contact, the drain line will freeze up and the defrost water will overflow into the

food compartment during the defrost cycle.

Condensing unit

The condensing unit consists of the following parts:

• Compressor

• Condenser fan motor assembly

• Condenser

• Relay

• Starting capacitor (running capacitor on some models)

• Service valves. Most units have high and low side service valves, but in some instances there may be

only a low side service valve.

Some compressors have the mechanism mounted on springs inside the housing (referred to as internal

mounts) and others have the entire compressor body mounted on springs and rubber bushings (referred

to as external mounts) to absorb the vibration. In the latter case bolts run up through the springs and are

secured with a retainer nut. During shipping the nuts on these bolts are tightened to prevent the

compressor from moving and damaging itself or other parts. Before the cabinet is placed in operation,

these nuts must be loosened enough to allow the compressor to float freely on the springs so that

vibration will be absorbed by the springs.

Reach-In Refrigerator Service Manual

Problems with the refrigeration system are usually due to failure of one of the components in the

condensing unit area. The service person should install a set of gages on the service valves to determine

the operating pressures. Compare these pressures to the specifications to determine the cause and

solution.

If there is an electrical problem, the service person should use a volt/amp meter, a watt meter, and a

continuity tester. An ohm meter can be used as a continuity tester.

A common refrigeration failure is a leak of some or all of the refrigerant. Because the leak can be very

small it can be very difficult to find. It usually develops on the high side of the system and only leaks when

the compressor is running. The condenser fan carries the refrigerant away making the leak difficult to

detect. If a leak detector does not find the leak, put a block of wood or a wad of rags against the fan blade

to keep it from turning while the compressor is running. This will cause the pressure to build up and make

the leak easier to find. This will not harm the fan motor or system if the fan blade is only stopped for a few

minutes.

The pick up hose of the torch should be passed back and forth over all tubing joints and over the entire

condenser very carefully. After the leak is found, repair it if possible. If it cannot be repaired, replace the

leaking part.

Whenever a leak has been located and repaired, the entire charge should be removed and a triple

evacuation procedure must be followed to be sure that all contaminants are removed. A good dryer of

proper size should be installed in the liquid line and a new charge of refrigerant put back in allowing extra

to compensate for the dryer.

After the cabinet has run for several hours, it should be rechecked to be sure the gas charge is correct

and the system is balanced.

© 2004, IMI Cornelius Inc. - 9 - Publication Number: 630460272S ER

Page 14

Reach-In Refrigerator Service Manual

WIRING DIAGRAMS

COR20RRTM

TEMP. CONTROL

RED

BLACK

COND. UNIT

FAN MOTOR

BLACK

WHITE

WHITE

RED

WHITE

BLACK

BLACK

PERIMETER HEATER

BLACK

PUSH

BUTTOM

BLACK

JUNCTION

BOX

BLACK

GREEN

WHITE

WHITE

BLACK

RED

BLACK

WHITE

WHITE

WHITE

LIGHT

BULB

BLACK

SPEAR LINE

FIGURE 11

Publication Number: 630460272SER - 10 - © 2004, IMI Cornelius Inc.

Page 15

COR22RRTM

HEATERS - FASCIA

BLACK

WHITE

BLACK

WHITE

MULLION/CANOPY

CONNECTION

BBG

PUSH

BUTTOM

GREY

RED

BLACK

WHITE

LIGHT

BULB

Reach-In Refrigerator Service Manual

GREY

RED

BLACK

WHITE

W

GREEN

BLACK

WHITE

FEED

WHITE

BLACK

GREEN

SWITCH

ELECT. BOX

4 X 4

HEATER

SWITCH

POWER

DOOR

AJAR

GREEN

EVAP.

PAN

COND.

UNIT

WHITE

BLACK

GREEN

RED

WHITE

FAN MOTOR

WHITE

BLACK

FIGURE 12

BLACK

WHITE

BAFFLE

CONNECTION

RED

CONTROL

RED

BLACK

© 2004, IMI Cornelius Inc. - 11 - Publication Number: 630460272S ER

Page 16

Reach-In Refrigerator Service Manual

COR40RRTMD

TEMP. CONTROL

RED

BLACK

COND. UNIT

FAN MOTOR

BLACK

WHITE

WHITE

RED

WHITE

BLACK

BLACK

PERIMETER HEATER

BLACK

PUSH

BUTTOM

BLACK

JUNCTION

BOX

BLACK

GREEN

WHITE

WHITE

BLACK

RED

BLACK

WHITE

BLACK

BLACK

PUSH

BUTTOM

WHITE

WHITE

LIGHT

BULB

BLACK

SPEAR LINE

FIGURE 13

Publication Number: 630460272SER - 12 - © 2004, IMI Cornelius Inc.

Page 17

COR48RRTMD

BLACK

WHITE

BLACK

WHITE

Reach-In Refrigerator Service Manual

MULLION/CANOPY

CONNECTION

GREY GREY

RED

BLACK

WHITE

RED

BLACK

WHITE

HEATER

SWITCH

POWER

DOOR

AJAR

MULLION HEATERS

HEATERS - FASCIA

BLACK

WHITE

BLACK

WHITE

PUSH

BUTTOM

BGGW

LIGHT

BULB

PUSH

BUTTOM

BB

GREEN

BLACK

WHITE

ELECT. BOX

4 X 4

RED

CONTROL

RED

BLACK

EVAP.

PAN

COND.

UNIT

FEED

WHITE

BLACK

GREEN

WHITE

BLACK

GREEN

RED

WHITE

FAN MOTOR

WHITE

BLACK

SWITCH

BLACK

WHITE

BAFFLE

CONNECTION

GREEN

FIGURE 14

© 2004, IMI Cornelius Inc. - 13 - Publication Number: 630460272S ER

Page 18

Reach-In Refrigerator Service Manual

COR74RRTMT

MULLION/CANOPY

CONNECTION

BLACK

WHITE

BLACK

WHITE

GREY GREY

RED

BLACK

WHITE

RED

BLACK

WHITE

HEATER

SWITCH

POWER

DOOR

AJAR

MULLION HEATERS

HEATERS - FASCIA

MULLION HEATERS

BLACK

WHITE

BLACK

WHITE

PUSH

BUTTOM

BGGW

LIGHT

BULB

PUSH

BUTTOM

BB

BW

LIGHT

BULB

FEED

EVAP.

PAN

COND.

UNIT

GB

PUSH

BUTTOM

WHITE

BLACK

GREEN

WHITE

BLACK

GREEN

RED

WHITE

FAN MOTOR

FIGURE 15

WHITE

BLACK

BLACK

WHITE

SWITCH

RED

BLACK

WHITE

BAFFLE

CONNECTION

GREEN

ELECT. BOX

4 X 4

CONTROL

RED

BLACK

GREEN

Publication Number: 630460272SER - 14 - © 2004, IMI Cornelius Inc.

Page 19

TROUBLESHOOTING

Possible causes and solutions

PROBLEM POSSIBLE CAUSE SOLUTION

Reach-In Refrigerator Service Manual

COMPRESSOR WILL NOT

START

No voltage in the electrical

socket.

The electrical conductor or

wires may be cut.

Defective electrical

components such as:

thermostat, relay, thermal

protector, etc.

Thermostat in “off” position. Turn the thermostat’s knob to

Compressor motor has a

winding open or shorted.

Dirty condenser; lack of air

flow.

Low voltage. Use a voltage regulator if the

Compressor is stuck. Change the compressor.

Use a voltmeter to check the

voltage.

Use an ohmmeter to check for

continuity.

Replace defective components.

its maximum position and wait

to see if the compressor starts.

Measure the ohmic resistance

of the main and auxiliary

windings using an ohmmeter.

Compare them with the correct

values.

Clean condenser and allow for

air circulation.

voltage is lower than 103 volts.

THE TEMPERATURE IS TOO

COLD

Temperature control contacts

are open.

Time clock circuits are open. Determine the reason and

Incorrect wiring. Check the wiring diagram and

Thermostat knob is set at a

very cold position.

Thermostat does not

disconnect the condensing unit.

Thermostat capillary bulb is

loose or installed improperly.

Control contacts are stuck

closed.

Defective or incorrect

temperature control.

Repair or replace the contacts.

repair or replace.

correct.

Set the thermostat knob to a

warmer position and check if

the compressor stops

according to the thermostat’s

operating range.

Check the insulation of the

thermostat. If the problem

persists, change the

thermostat.

Correctly fasten the thermostat

capillary bulb.

File contacts. Change the

control. Check amperage load.

Determine correct control and

replace.

© 2004, IMI Cornelius Inc. - 15 - Publication Number: 630460272S ER

Page 20

Reach-In Refrigerator Service Manual

PROBLEM POSSIBLE CAUSE SOLUTION

THE TEMPERATURE IS NOT

COLD ENOUGH

Thermostat knob is set at a

very warm position.

Set the thermostat knob to a

colder position.

Condenser is dirty. Clean the condenser.

The refrigerator has been

placed at an inadequate

location.

The unit must not be near

stoves, walls that are exposed

to the sun, or places that lack

sufficient air flow.

Compressor is inefficient or

there is a high head pressure

If there is air in the system,

purge and recharge.

due to air in the system.

Iced up evaporator coil. Check temperature control,

refrigerant charge, and defrost

mechanism. Remove all ice

manually and start over.

Restriction in system. Locate exact point of restriction

and correct.

The refrigerator has been used

improperly.

The shelves must never be

covered with any type of plastic

or other material that will block

the circulation of cold air within

the refrigerator.

Too many door openings. Advise user to decrease if

Excessive heat load placed in

cabinet.

The refrigerator has been

overcharged with the

refrigerant gas.

The refrigerant gas is leaking. Find the location where the gas

The evaporator and/or

condenser fans aren’t working.

Low voltage. Use a voltage regulator if the

ELECTRICAL SHOCKS Wires or electrical components

are in direct contact with

metallic parts.

possible.

Advise user not to put in

products that are too hot.

Check to see if condensation or

ice crystals have formed on the

suction line. If so, charge with

the correct amount of gas.

is leaking in order to seal it or

replace the defective

component. Change the drier.

Perform a good vacuum and

recharge the unit.

Check the electrical

connections and make sure

that the fan blade isn’t stuck.

Replace the fan motor if it

doesn’t work.

voltage is lower than 103 volts.

Check for appropriate

insulation on the connections of

each electrical component.

Publication Number: 630460272SER - 16 - © 2004, IMI Cornelius Inc.

Page 21

Reach-In Refrigerator Service Manual

PROBLEM POSSIBLE CAUSE SOLUTION

NOISE The refrigerator is not properly

leveled.

The condenser is not fastened

correctly. Copper tubings are in

contact with metal.

The evaporator and/or

condenser fans are loose.

Compressor has an internal

noise.

EXTREME CONDENSATION

INSIDE THE REFRIGERATOR

Thermostat knob is set at a

very cold position.

The outside environment’s

relative humidity is very high

(over 75%).

Check if the noise goes away

after you level the refrigerator.

While the compressor is

working, check to see if metal

parts are in contact with one

another and/or if the screws

that fasten the condenser are

tightened.

Check if the fans are securely

fastened. Also, check if the fan

blades are loose, broken or

crooked. If so, change the

faulty blade.

If the noise persists after all

other measures have been

taken, it may be originating

from the compressor.

Set the thermostat knob to a

warmer position and check if

the compressor stops

according to the thermostat’s

operating range.

This type of occurrence is

caused by local climatic

conditions and not by the

refrigerated unit.

The refrigerator door won’t shut

completely.

The refrigerator has been

placed at an inadequate

location.

NO ILLUMINATION The light switch is in “off”

position.

False contact on the light

switch, the fluorescent tube, or

the ballast.

Light switch, ballast and/or

fluorescent tube are damaged.

Check the door and/or the

magnetic gasket. Adjust the

door hinges if needed; replace

the gasket if broken.

The unit must not be near

sources that produce too much

heat.

Press the light switch to the

“on” position.

Inspect all connections.

Replace the damaged

component.

© 2004, IMI Cornelius Inc. - 17 - Publication Number: 630460272S ER

Page 22

IMI Cornelius Inc.

www.cornelius.com

Loading...

Loading...