Page 1

CAUTION - Only trained and certified electrical, plumbing and refrigeration technicians should

service this unit. ALL WIRING AND PLUMBING MUST CONFORM TO NATIONAL AND LOCAL

CODES.

INTRODUCTION

Bottom Mounted Reach-In Freezer Installation Manual

INSTALLATION MANUAL

Reach-In Freezers

COR23RFBM, COR49RFBM

This manual contains instructions for installation, operation, and general maintenance of your

commercial freezer. It also includes a Troubleshooting chart to diagnose problems along with corrective

actions.

CHECK FOR SHIPPING DAMAGE

Prior to leaving the factory, each cabinet is thoroughly inspected and performance tested up to 12 hours

to assure proper operating temperatures.

Check the crate thoroughly for signs of shipping damage. If external damage exists, internal

damage is also probable and uncrating should be done while the carrier’s representative is present. In

any case, the equipment should be uncrated as soon as possible, preferably within five (5) days.

The manufacturer is not responsible for in-transit damage and the consignee must file any required

damage claims directly with the carrier.

If damage is severe and obvious, write a brief description of the evidence on the carrier’s delivery receipt

and above the carrier representative’s signature.

If hidden damage(s) is found, contact the carrier immediately (save all crating materials) and file the

necessary freight claim with the carrier.

CHECK FOR ACCESSORIES

Upon receiving the equipment, check that the shelves are inside the freezer, including the four clips or

supports for each shelf.

Release Date: May 17, 2004 www.cornelius.com Revision: A

© 2004, IMI Cornelius Inc. - 1 - Publication Number: 630460283INS

Page 2

Bottom Mounted Reach-In Freezer Installation Manual

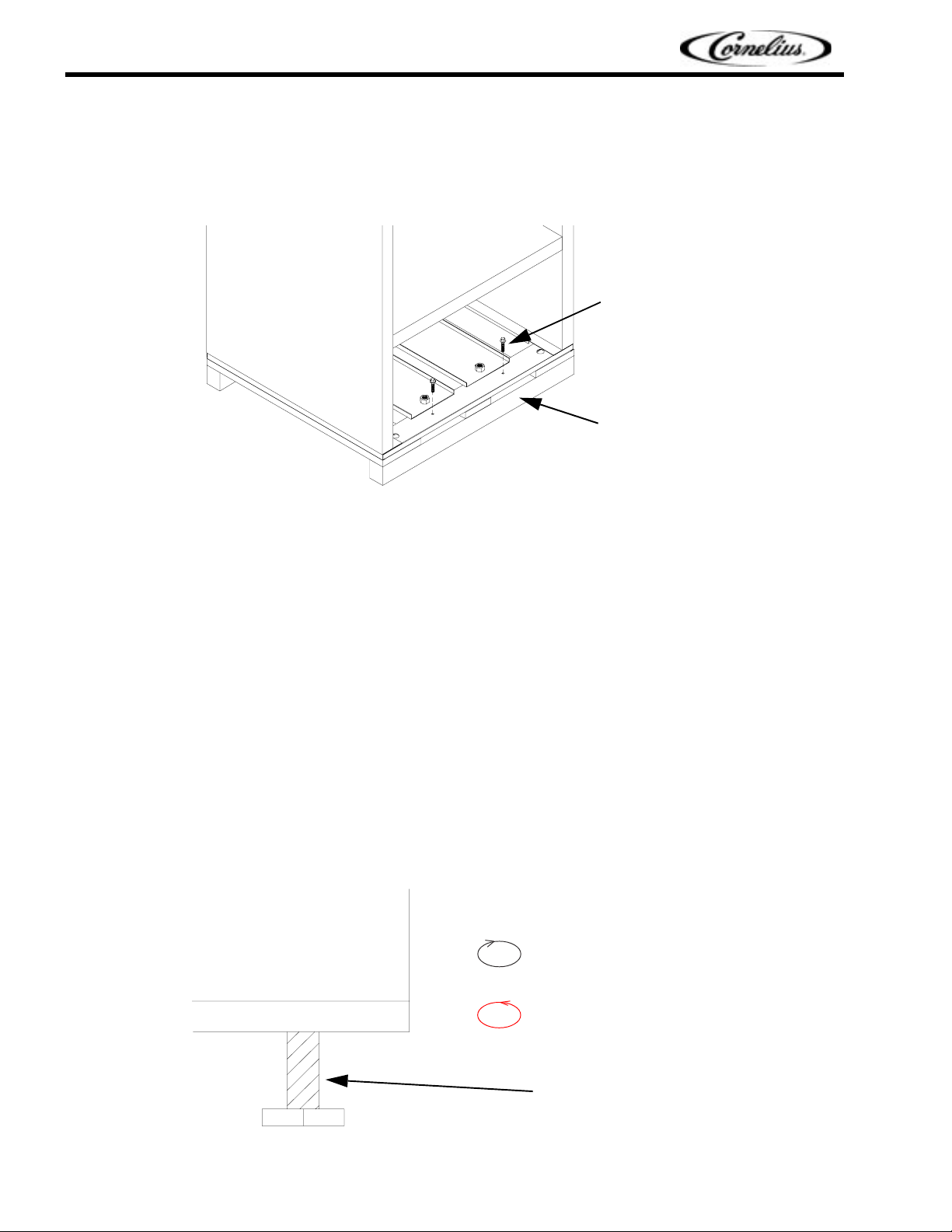

REMOVE THE CRATE AND SKID

Remove the crate carefully to prevent damage to the exterior surfaces of the cabinet. The cabinet is bolted to a

wooden skid with four hex-head bolts. After the skid is removed, always use a dolly to move the cabinet to

prevent damage to the cabinet bottom or the floor.

Bolt

Wooden skid

WHERE TO LOCATE THE CABINET

1. Place the unit on a surface that is solid enough to prevent vibration and strong enough to support

the combined weight of the cabinet and product load. Guideline: Estimate 35 pounds per cubic foot

of storage space.

2. Cabinets should never be placed in front of windows or glass doors in direct sunlight. If a cabinet is

located near a window or glass door, provide an adequate shade to block the sun’s rays.

3. Ambient temperature must be between 59° and 95° F. Low ambient temperatures below 50° are as

harmful as high ambient temperatures. Extreme temperatures will definitely affect the performance

of the cabinet.

4. Leveling legs are optional and are provided on some cabinets. Level the cabinet by using the

adjustable portion of the leveling legs as needed. Failure to properly level the cabinet could hinder

proper drainage and door operation. If the floor is extremely uneven, it may be necessary to shim

the corners with thin sheets of metal. (Shims may also be used when optional casters have been

included.)

FIGURE 1

Turn leg clockwise to lower

Turn leg counterclockwise to

raise

Leveling leg

FIGURE 2

Publication Number: 630460283INS - 2 - © 2004, IMI Cornelius Inc.

Page 3

Bottom Mounted Reach-In Freezer Installation Manual

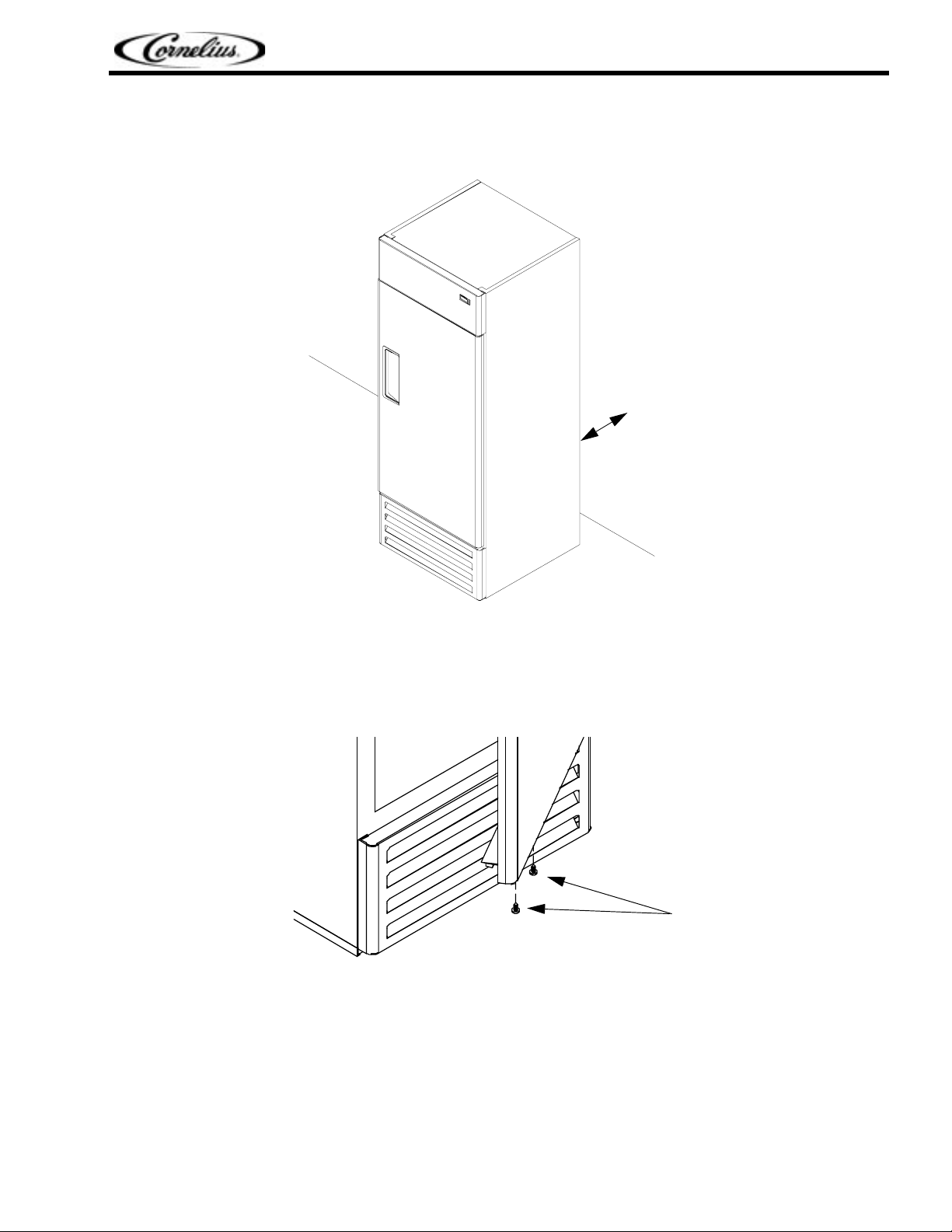

5. Clearance: Leave at least 8” between the back of the cabinet and the wall to provide adequate air

circulation of the unit compartment.

8”

FIGURE 3

REMOVE THE DOOR SUPPORT BRACKET

1. Open the door 30 degrees and loosen the screws.

FIGURE 4

Screws

© 2004, IMI Cornelius Inc. - 3 - Publication Number: 630460283INS

Page 4

Bottom Mounted Reach-In Freezer Installation Manual

2. Use a Phillips screwdriver to remove the door support bracket.

FIGURE 5

INSTALLATION

Measure all doorways and passages before moving the cabinet to its final location. To pass through low

door openings, first remove the shelves shipped inside the cabinet and lay one- and two-section upright

cases on end.

Door support bracket

CAUTION - Lay the cabinet on pads or thick blankets to avoid damage to the cabinet finish. After the

cabinet is set upright, check for oil leaks in the compressor compartment. If you find oil leaks, call a

qualified service person before operating the unit. If no oil leaks are found, wait 1/2 hour before operating

the unit.

If the doorway is too narrow to allow installation of the cabinet, follow these steps to remove the doors

and hinges on the unit:

1. Lift and remove the header sign (if applicable).

2. Use a wrench to loosen the hinge nut.

Publication Number: 630460283INS - 4 - © 2004, IMI Cornelius Inc.

Page 5

Bottom Mounted Reach-In Freezer Installation Manual

3. Relieve the spring tension by turning the spring hinge rod in the direction shown in the following

drawings:

Loosen hinge nut

Left bottom hinge

Spring hinge rod

Loosen hinge nut

Right bottom hinge

FIGURE 6

4. Unscrew the bottom hinge (the bottom hinge remains attached to the spring hinge rod).

5. Unscrew and remove the top hinge.

Top hinge

Spring hinge rod

Units with header sign Units without header sign

FIGURE 7

© 2004, IMI Cornelius Inc. - 5 - Publication Number: 630460283INS

Page 6

Bottom Mounted Reach-In Freezer Installation Manual

CONNECT THE CABINET TO A PROPER ELECTRICAL POWER SUPPLY

Each freezer requires a dedicated circuit to prevent malfunction of the compressor and the electrical

components. All models require a 115 V/60 Hz electrical supply on a 15 amp time-delay relay-type

breaker. Each unit should be connected to its own circuit in accordance with National Electric Codes and

local ordinances.

Check the line voltage to be sure the supply does not fluctuate more than 10%. Low line voltage can

shorten compressor life or contribute to service problems. If an extension cord is used, it must be a threeprong-grounding type (wire size 14 AWG or larger) and more than 15 feet long.

START UP THE CABINET

1. Shelves and shelf clips (4 clips per shelf) are packed inside the cabinet prior to shipment. After

selecting the appropriate spacing inside the cabinet, install the shelf clips by inserting the top of the

clip into the pilaster while pushing inwards and then downwards. Then insert the bottom of the clip

into the pilaster. Repeat until all the clips are in the desired locations. Place the shelves on the clips

and check that the shelves are level and all four corners are supported by the four shelf clips.

Pilaster

Clip

FIGURE 8

2. Plug in the electrical cord. Do not, under any circumstances, cut or remove the round grounding

prong from the power cord. Removal of the grounding prong invalidates the product warranty.

Grounding prong

FIGURE 9

Publication Number: 630460283INS - 6 - © 2004, IMI Cornelius Inc.

Page 7

ELECTRONIC THERMOSTAT

Your commercial freezer is manufactured with an electronic thermostat to control various functions of

your unit, such as the temperature, defrost cycles, fan operation, alarms, etc. The electronic thermostat

has been programmed at the factory and its keyboard was locked to prevent tampering.

Reading the LEDs

Each LED function is described in the following table:

LED Mode Function

Bottom Mounted Reach-In Freezer Installation Manual

FIGURE 10

ON Compressor enabled

To unlock the keyboard

Press and hold the keys for more than three seconds until the “PON” message is displayed.

The Set point parameter is the temperature at which the compressor cuts out.

To see the Set point

Push and immediately release the SET key and the display will show the Set point value.

Flashing

ON Defrost enabled

Flashing

ON Fans enabled

Flashing Fans delay after defrost in progress

ON A temperature alarm happened

• Programming Phase (flashing with )

• Anti-short cycle delay enabled

• Programming Phase (flashing with )

• Drip time in progress

To change the Set point

1. Push and hold the SET key for more than 2 seconds. The value of the Set point will be displayed

and the LED will start blinking.

2. Use the keys within 15 seconds of pressing the SET key to change the Set value.

3. To memorize a new Set point value, push the SET key again or wait 15 seconds. The compressor

Cut In temperature is the Set point value plus the Differential value. The Differential value is

programmed at the factory to protect the compressor from short cycling.

© 2004, IMI Cornelius Inc. - 7 - Publication Number: 630460283INS

Page 8

Bottom Mounted Reach-In Freezer Installation Manual

To lock the keyboard

Press and hold the keys for more than 3 seconds. The “POF” message will be displayed and the

keyboard will be locked. At this point it will only be possible to see the Set point or the Max or Min

temperature stored. If a key is pressed more than 3 seconds, the “POF” message is displayed.

Manual defrost

The electronic thermostat of the freezer controls the intervals between defrost cycle and the defrost

termination temperature. These values are set at the factory. A manual defrost cycle can be initiated if the

evaporator builds up too much ice.

To start a manual defrost, push and hold the DEF key for more than 2 seconds.

Publication Number: 630460283INS - 8 - © 2004, IMI Cornelius Inc.

Page 9

TROUBLESHOOTING

Possible causes and solutions

PROBLEM POSSIBLE CAUSE SOLUTION

Bottom Mounted Reach-In Freezer Installation Manual

COMPRESSOR WILL NOT

START, NO NOISE

WARM STORAGE

TEMPERATURES

COMPRESSOR RUNS

CONTINUOUSLY—PRODUCT

TOO COLD

Power disconnected Check service cord for proper

connection

Blown fuse or breaker Replace fuse or reset breaker

Defective or broken wiring Repair or replace wiring

Defective overload Replace

Defective relay Replace

Temperature control not set

properly

Not enough refrigerant Leak check. Change drier,

Cabinet location too warm Relocate cabinet

Too much refrigerant Change drier, evacuate, and

Low voltage, compressor

cycling on overload

Defective thermostat Replace

Lower set point value

evacuate, and recharge.

recharge

Check voltage supply

COMPRESSOR RUNS

CONTINUOUSLY—PRODUCT

TOO WARM

Temperature control not set

properly

Not enough refrigerant Leak check. Change drier,

Not enough refrigerant Leak check. Change drier,

Inefficient compressor Replace

Increase set point value

evacuate, and recharge.

evacuate, and recharge.

© 2004, IMI Cornelius Inc. - 9 - Publication Number: 630460283INS

Loading...

Loading...