IMI BUSCHJOST 82590G Series, 82640N Series, 84490N Series, 82540G Series Operation Manual

Operation manual –

pre-controlled diaphragm valves

with forced lifting

Document No. 1377006.0000.10011 Revision 8

Keep documentation for future use!

Series

82540

82590

G

G

82640

84490

N

N

G

G-Thread

N

NPT-Thread

Contents

1 About this documentation 1

1.1 Documentation validity 1

1.2 Structure of safety instructions 1

1.3 Hazard classes (ANSI Z535.6) 1

1.4 Styles and symbols 2

1.5 Intended use 2

1.6 Improper use 2

1.7 Obligations of operator 2

1.8 Personnel qualification 2

1.9 Personal protection equipment 2

2 General safety instructions 2

3 Avoid damage to propert y 3

4 Identifying the valve 3

5 Transpor t and storage 3

6 Function 3

6.1 NC-valve (normally closed) 4

6.2 NO-valve (normally open) 4

6.3 Solenoid types AC/DC 4

7 Mounting 4

7.1 Valve dimensions in mm 5

7.2 Mounting accessories 5

7.3 Conditions of installation 5

7.4 Preparation 5

7.5 Mounting valve to pipeline 5

8 Connecting solenoid electrically 6

9 Operating conditions 7

10 Commissioning 7

10.1 Checking the switching function 7

10.2 Flooding the valve 7

11 Operation 7

12 Maintenance 7

12.1 Cleaning and visual inspection 7

12.2 Checking for tightness and strength 7

12.3 Preparing maintenance of internal parts 7

12.4 Checking valve parts 8

12.5 Cleaning valve parts and valve 8

12.6 Replacing spare part s 8

12.7 Tightening torque screws 8

12.8 Lubricating valve parts accordingly 8

12.9 Valve-specific disassembly/reassembly 8

13 Re-commissioning 14

14 Decommissioning 14

15 Replace complete valve 14

16 Trouble shooting 14

17 Return 14

18 Disposal 14

19 Directives and certificates 14

Translation of the original operating manual

Status as of November 2018

1

About this documentation

These mounting instructions guides you to

mount, operate and maintain pre-controlled

diaphragm valves with forced lifting safely.

This operation manual is intended for:

plant operators, installers, maintenance and

service technicians.

1.1

Documentation validity

This operation manual applies to the following

series

•82540, 82590 (G-Thread)

•82640, 84490 (NPT-Thread)

•for special products that are based on the

series mentioned above

in combination with these solenoid:

Series 9151

915 4

9176

9191 x

G

82540

82590

82640

84490

Order No. Connection Connection

xxxx0xx G 1/4 1/4 NP T

xxxx1xx G 3/8 3/8 NPT

xxxx2xx G 1/2 1/2 NPT

xxxx3xx G 3/4 3/4 NPT

xxxx4xx G 1 1 NPT

xxxx5xx G 1 1/4 1 1/4 NPT

xxxx6xx G 1 1/2 1 1/2 NPT

xxxx7xx G 2 2 NPT

Series 8254 0,

• • •

G

• •

N

• • •

N

• •

82590

x

9301

9304

x

9356

9326 x

8264 0,

84490

9401

9404

1.2

Structure of safety instructions

Safety instructions warns against dangerous

situations and must be observed in particular.

Safety instructions are structured as follows:

SIGNAL WORD

Type of hazard

Consequences of non-observance

→ Precautions necessary to avoid the hazard

1.3

Hazard classes (ANSI Z535.6)

! DANGER

Safety information indicates a hazardous situation

with high risk which, if not avoided, will certainly

result in death or (serious) injury.

! WARNING

Safety information indicates a hazardous situation

with moderate risk which, if not avoided, can cause

death or severe injury.

! CAUTION

Safety information indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

NOTICE

Information indicates a hazardous situation which,

if not avoided, could result damage to property.

11/20 18

1377006.0000.10011

1

1.4

Styles and symbols

This documentation uses the following styles

and symbols:

• List

→ Instruction

1.

Preset order of instructions

2.

701 Part number (according to part list)

1 Flexible part number (section)

Replace spare part

q

! + DANGER / WARNING / CAUTION;

NOTICE: embedded safety message

given limits or fixed value

1.5

Intended use

The valve is solely intended to control or stop

a fluid flow within approved operating limits.

The fluid must only flow through the valve in

the determined flow direction.

You may only operate the valve with fluids that

will not cause any chemical reaction with the

valve’ materials or lead to abrasive effects.

Under the following conditions, a valve with

nominal diameter > DN 25 is not approved as

the only shut-off valve at the end of a pressure

line:

•The contents of the pressure system must

not be released into the atmosphere.

•The contents of the pressure system must

not be transferred to a downstream system

with lower nominal pressure rating (PN).

1.6

Improper use

In the following cases it is prohibited to operate the valve:

•The valve is not used for the designated

purpose.

•The permitted temperature and pressure

ranges are exceeded.

•Damages to the valve – e.g. cracks,

deformation – were detected but the valve

remains in operation.

•Malfunctions were detected but the valve

remains in operation.

•The valve has been modified without authori-

zation of the manufacturer.

•The safety instructions of this documentation

are not observed.

For damages caused by improper use, the

liability of the manufacturer is excluded.

Our guarantee expires in the

following cases:

•Undue intervention and altering are done to

the valve.

•This documentation or the operating limits

as shown in the particular datas heet are not

observed.

1.7

Obligations of operator

Product

→ Over the entire life cycle of the valve all

applicable regulations must be observed.

The instructions of this operation manual

must be observed and followed.

→ Initiate a risk assessment of the overall

installation, to detect potential dangers that

may occur in combination of the valve with

other components.

Persons

→ Initiate the instruction of each person who

is working with the valve.

Applicable regulations about occupational safety ad safety engineering must be

known and applied.

Documentation

→ This documentation must be fully read and

understood.

→ The instructions given in this operation

manual must be put into practice.

→ This documentation must be available at

any time.

Markings at the operating site

→ Ensure adequate warning of the risks linked

to the valve. Use in the area of the installed

valve the following warning and prohibition

sings in compliance with EN ISO 7010 und

BGV A8 (VBG125):

Warning sign to indicate risk of

burns at the solenoid

Warning sign to indicate electrical hazards at the solenoid

Prohibition sign to

prevent people from entering

hazardous areas

1.8

Personnel qualification

→ Ensure as operator that persons who work

on or with the valve are sufficient qualified

for this job.

→ Comprehensively train the operating per-

sonnel in terms of safety.

→ Only allow trained specialists to perform

electric connections, commissioning, maintenance and trouble shooting

Demands

Operating personnel must be instructed on

operational sequences and procedures.

Operating personnel must know its responsibilities regarding the work to be performed.

Trained specialists must possess profound

knowledge in mechanical engineering, electrical engineering, hydraulic und pneumatic.

Trained specialists must be authorized to

commission, ground and designate devices,

systems and power circuits according to the

standards of safety technology.

Trained specialists must possess profound

knowledge about design and principle of operation of the valves and the plant.

1.9

Personal protection equipment

→ Wear appropriate protection equipment.

Observe the personal protection equipment as requested in “residual risks” (see

chapter

2 ).

Protective eye glasses

to protect from escaping fluids or

exhausting compressed air

Protective gloves

resistance to cutting to protect

from sharp edges or ridges;

resistance to acids to protect from

hazardous fluids

Protective footwear

to protect from parts or tools falling

down

2

General safety instructions

These safety instructions are only related to

the single valve. In combination with other

plant components there may be other potential

dangers, which must be taken into account by

carrying out a risk analysis for the system.

→ Compare the details on rating plate and

data sheet to the operating data. The limits

for the particular application (e.g. pressure,

temperature) must not be exceeded.

→ Only perform assembly and maintenance

works when the pipe system is in depressurized state.

→ Flood the valve slowly during commissio-

ning. Fast pressurizing will cause the valve

to open briefly.

→ Strength tests with the valve seat open are

permitted maximum up to 1.5 times of the

nominal pressure rating (PN) at room temperature. The valve must not be operated

during these tests.

11/20 18

1377006.0000.10011

2

!DANGER

7 *

8

1

Hazardous electrical voltage

(>25V AC; >60V DC)

There are risks from electrical

voltage during assembly and

maintenance.

→ The electrical connection of the solenoid

must be carried out only by a qualified

electrician.

→ You may only plug or remove the device

socket in de-energized state.

→ Disconnect the power supply off the sole-

noid prior to assembly or disassembly.

! WARNING

Danger from pressurized

pipelines

Pressurized pipelines may burst

resulting in injuries.

→ Depressurize pipe system and block the

fluid flow prior to opening or unmounting

the valve.

! CAUTION

Risk of burns at the solenoid

Solenoid is heating up during

operation. Touching the solenoid

leads to risk of burns.

→ Let the solenoid to cool down before

working on the valve.

Residual risks

Weight of the valve

Phases: transport, storage,

kg

assembly, maintenance, disposal

Risk: falling off, tipping over

Personal protection equipment

(PPE): Protective footwear

Hazardous fluids

Phases: assembly, operation,

maintenance, disposal

Risk: skin contact, eye contact,

breathing vapors

PPE: protective gloves, protective eye

glasses, breathing protection

Potentially explosive atmosphere

Risk: danger of explosion

! WARNING: use solenoid an de-

vice socket with Ex-protection.

Sharp-edges and threads

Phases: transport, assembly,

maintenance, disposal

Risk: risk of cuts

PPE: protective gloves

3

Avoid damage to property

NOTICE

Deposits and dirt lead to malfunctions

If the control bores are clogged or the

core is blocked by soil the valve no longer

closes or opens.

→ Install a strainer (mesh size ≤0.25mm) in

front of the valve inlet P if necessary.

Damages through accumulation of heat

The solenoid will overheat during continuous duty if the heat can not be radiated. This shortens the service life of the

solenoid.

→ You must not cover the solenoid with paint.

→ You must not encase the solenoid in

atight housing or in a thermal insulation.

Residual risks

Pressure against valve outlet

The valve only firmly closes in flow

direction.

Fluid freezing

The valve is not designed to withstand the fluid freezing.

4

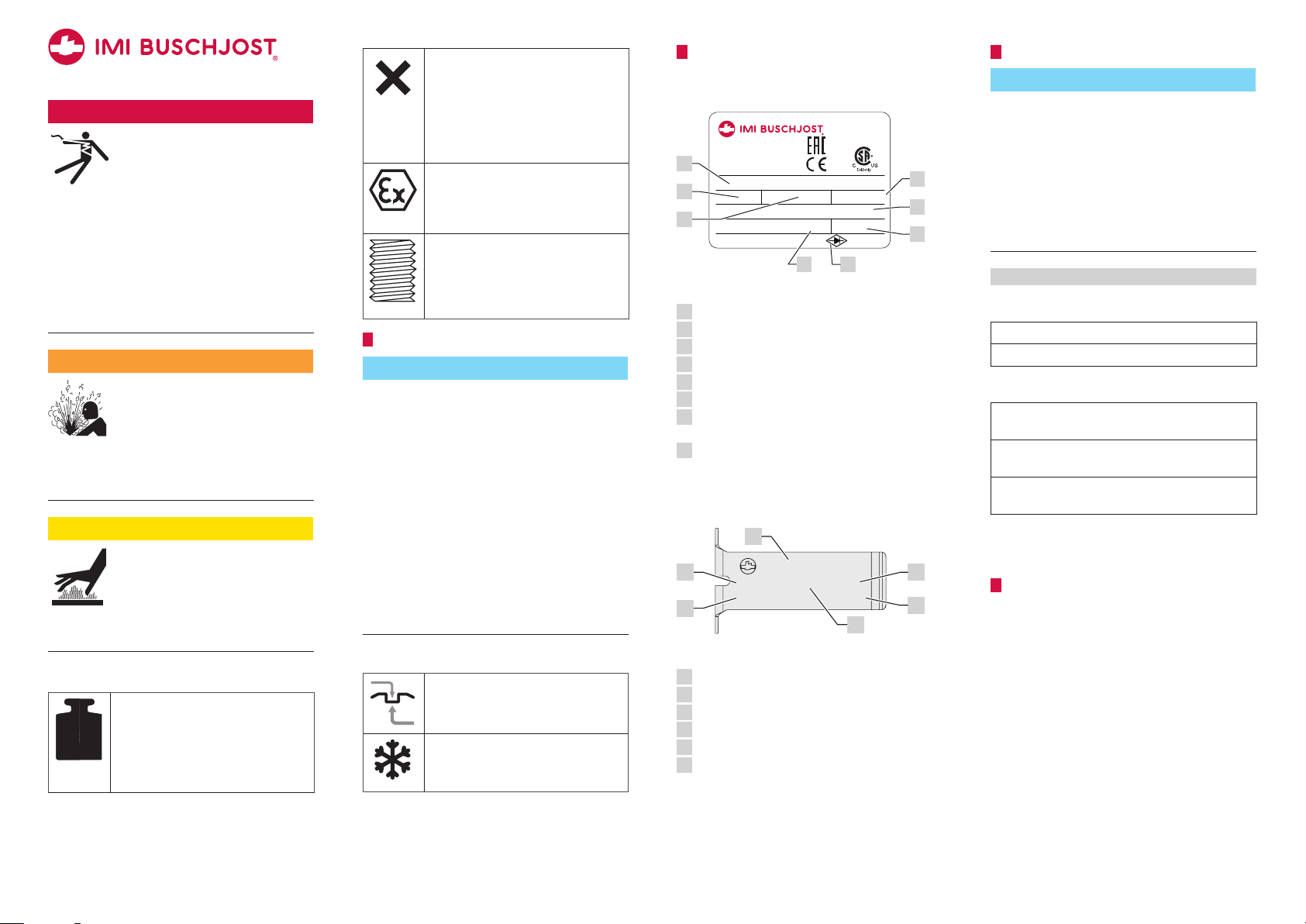

Identifying the valve

The rating plate is situated on the solenoid

body.

Made in Germany

Buschjost GmbH

D-32545 Bad Oeynhausen

1

2

3

Part no./Bestell-Nr.

8254000.9151.02400

VHz

24 00

PA

www.imi-precision.com

100%

18VA /18W

0–10

XXXX

use -plug only

4

5

bar

6

Rating plate (example)

Order number

1

Operating voltage

2

Frequency of voltage

3

Power consumption inrush/holding

4

Operating pressure range

5

Date of manufacture (week /year)

6

* if this marking is shown on the rating plate:

7

use device socket with rectifier

Duty cycle

8

An additional marking is applied to the spring

clip of the c-solenoid 9151, 9154, 9176

and 9191.

22

8254000.9150

0 - 10 bar DC only

G 1/4

xxxx

xxxx

23

6

Marking of the spring clip (example)

Order number (without voltage/frequency)

1

Operating pressure range

2

Size of connection

3

DC only (only with DC coils)

4

Date of manufacture (week /year)

5

Serial number

6

4

5

5

Transport and storage

NOTICE

Damage of the valve

Valve may be damaged if foreign particles

get into the valve.

→ Transport and store the valve dry and only

in the delivery packaging.

→ Take valve out of the packaging immedia-

tely prior to assembly.

→ Let the blanking plugs into valve connec-

tions.

Prolonged storage at −10 °C to +20 °C

Avoid during transport:

Mechanical loads: falling off, tipping over

Damages to the electrical terminal elements

Avoid during storage:

Thermal stress: permanently increased storage

temperatures; distance to heat sources < 1m

Chemical load: at the storing site through solvents, chemicals, acids, fuels and similar

Weather conditions: at construction sites strong,

watertight containers are necessary

Unfavourable storing conditions may reduce

the service life of the sealing materials

6

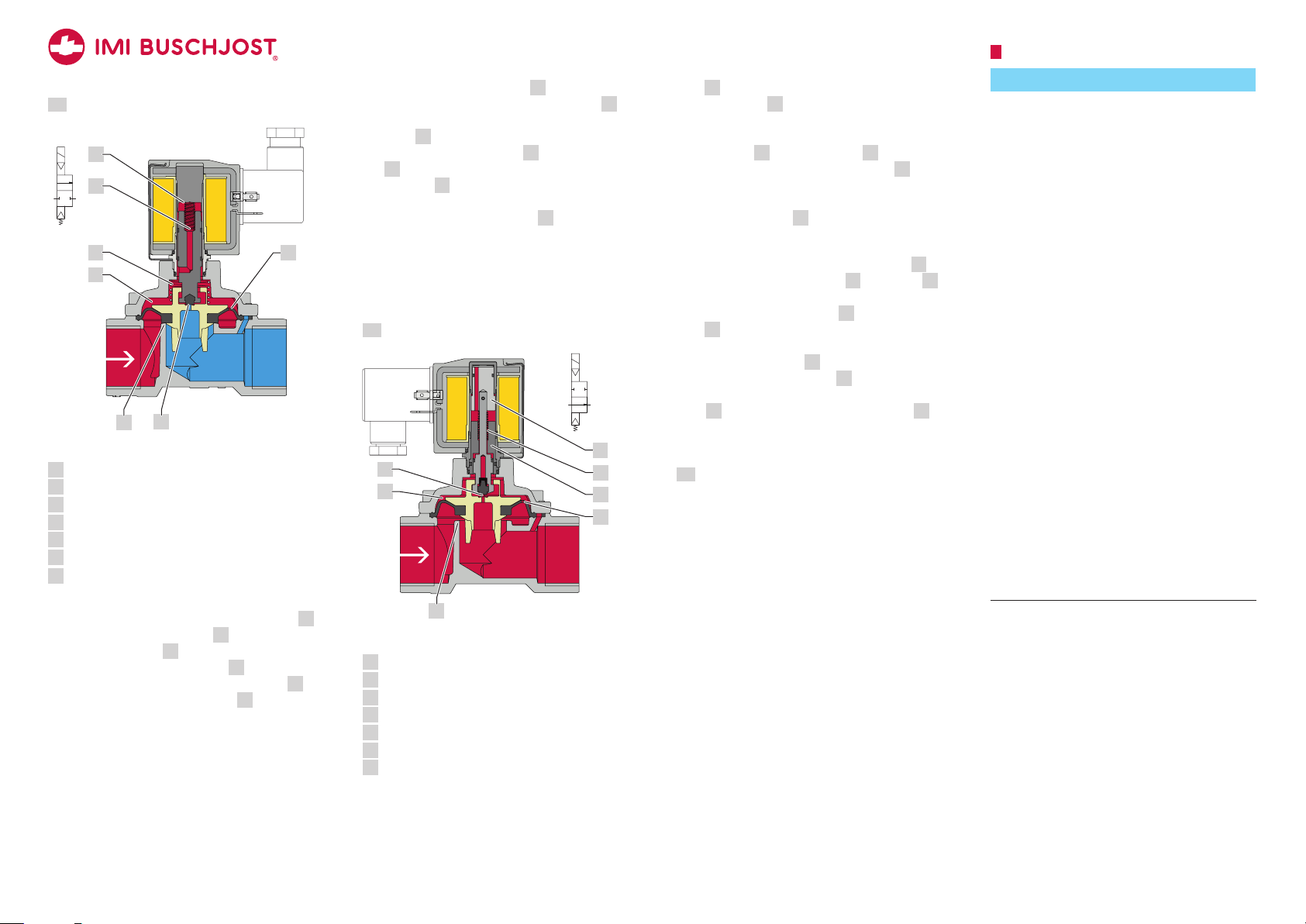

Function

Design

2/2-way seat valve with diaphragm as sealing

device.

Operation

The valve is electromagnetic indirectly-controlled with forced lifting.

11/20 18

1377006.0000.10011

3

P

1

Switching position: open

1

PA

The magnetic force lifts the core towards

6.1

NC-valve (normally closed)

7

6

A

the magnet face of core tube

solenoid is energized. Since the pilot seat

is open the fluid pressure is reducing from

chamber

3 towards valve outlet. More fluid is

flowing off via the pilot seat

ber

3 than the amount flowing in via the

control bore

2 in the diaphragm. The

differential pressure lifts up the diaphragm

and opens the main valve seat

7 when the

5

5 to the cham-

1. Through

the mechanical coupling with the core, the

4

3

2

diaphragm is lifted into open position.

In the absence of differential pressure only

the solenoid force moves the diaphragm in the

open position.

6.2

P

5

Sectional view (NC-valve; closed)

Main valve seat

1

Control bore in the diaphragm (pressure build-up)

2

Chamber

3

Compression spring above the diaphragm

4

Pilot seat (pressure reduction)

5

Compression spring inside the core

6

Magnet face of the core tube

7

Normal position: closed

A

Due to the effect of the compression spring 6

inside the core the pilot seat

compression spring

4 presses the diaphragm

sealingly to the main valve seat

rating fluid flows through the control bore

in the diaphragm to the chamber

5 is closed. A

1 . The ope-

2

3 above the

diaphragm and increases the closing force.

NO-valve (normally open)

P

4

3

Sectional view (NO-valve; open)

Main valve seat

1

Control bore in the diaphragm (pressure build-up)

2

Chamber

3

Pilot seat (pressure reduction)

4

Pole piece

5

Compression spring inside pole piece

6

Core

7

A

7

6

5

2

Normal position: open

When the solenoid is de-energized, the pilot

seat

4 is opened by the effect of the com-

pression spring

6. Through die mechanical

coupling with the core, the diaphragm is lifted

into open position. More fluid is flowing off via

the pilot seat

amount flowing in via the control bore

4 to the chamber 3 than the

2 in

the diaphragm. The resulting differential pressure supports the opening movement.

The main valve seat

Switching position: closed

1 is open.

When the solenoid is energized, the core 7

is attracted by the pole piece

5. The core 7

presses the seal plug sealingly against the

force of compression spring

seat

4. Through the mechanical coupling

6 on the pilot

with the core, presses the diaphragm sealingly

to the main valve seat

fluid flow from the chamber

1. The outflow of the

3 is interrupted.

The operating fluid flows through the control

bore

2 in the diaphragm to the chamber 3

above the diaphragm and increases the closing

force.

6.3

Solenoid types AC/DC

The valve may be equipped without changing

of the mechanical part with an DC voltage

solenoid or AC voltage solenoid. In both cases

the permissible voltage tolerance amounts to

±10%. Special versions may cause deviations.

7

Mounting

NOTICE

Damage of the valve

The valve may be damaged through inappropriate installation.

→ Only trained and authorized specialists

may install the valve..

→ Only use appropriate tools and suitable

sealing materials.

→ Make sure that the valve is mounted in

flow direction.

→ Make sure not to distort the valve body,

particularly in case of a misaligned pipework.

There must be no mechanical loads applied to the solenoid.

→ Do not use solenoid as a lever during

mounting.

Valve only firmly closes in flow direction.

Inflow against the valve’s flow direction

may lead to the destruction of components.

→ Implement adequate measures if back flow

is to expect; for example by adding check

valves to the pipe system.

The valve subassembly may get damaged

by external loads at the operating site.

→ Protect valve from objects falling down.

→ Secure the valve against direct weather

influences and the possible effects.

11/20 18

1377006.0000.10011

4

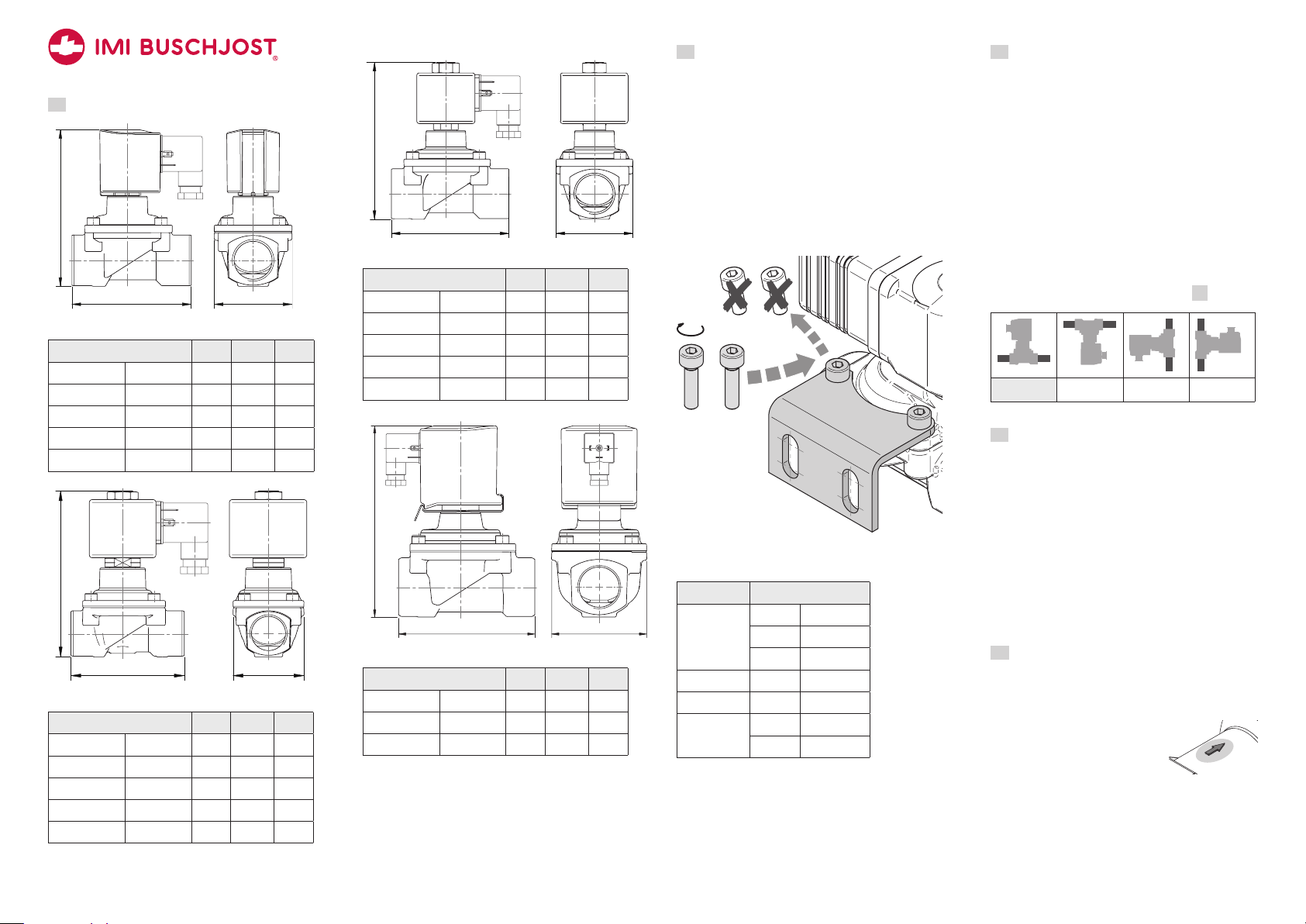

7.1

H

H

H

H

A

Valve dimensions in mm

L

with solenoid 9151, 9154, 9176, 9191

Connection size L H ø A

G 1/4 1/4 NPT 60 107 44

G 3/8 3/8 NPT 60 107 44

G 1/2 1/2 NPT 67 108 44

G 3/4 3/4 NP T 80 115 50

G 1 1 NPT 95 124 62

L

with solenoid 9301, 9304, 9356, 9326 / NC

Connection size L H ø A

G 1/4 1/4 NPT 60 108 44

G 3/8 3/8 NPT 60 108 44

G 1/2 1/2 NPT 67 110 44

G 3/4 3/4 NP T 80 117 50

G 1 1 NPT 95 12 6 62

ø A

ø A

L

with solenoid 9301, 9304, 9356 and 9326 / NO

Connection size L H ø A

G 1/4 1/4 NPT 60 10 9 44

G 3/8 3/8 NPT 60 109 44

G 1/2 1/2 NPT 67 111 44

G 3/4 3/4 NP T 80 118 50

G 1 1 NPT 95 127 62

L

with solenoid 9401 and 9404

Connection size L H ø A

G 1 1/4 1 1/4 NPT 132 186 92

G 1 1/2 1 1/2 NPT 132 186 92

G 2 2 NPT 160 200 109

ø A

ø A

7.2

Mounting accessories

Mounting bracket

With an optional mounting bracket, you can

connect the valve to an load-bearing structure

at the installation site, thus protecting against

vibration, for example.

→ Attach the mounting bracket to a long site

of valve cover before to assembly. Use the

fixing screws delivered with the mounting

bracket to achieve the necessary screw-in

depth.

Nm

Mounting bracket (example)

Available mounting brackets

Order No. Connection size

1258986 G 1/4 1/4 NP T

G 3/8 3/8 NPT

G 1/2 1/2 N PT

125 899 1 G 3/4 3/4 NPT

125 899 6 G 1 1 NPT

125 9005 G 1 1/4 1 1/4 NPT

G 1 1/2 1 1/2 NPT

7.3

Conditions of installation

Compliance with operating limits

Ensure to comply with the operating limits prior to mounting the valve. Observe the valve’s

data sheet.

Planning of the pipe system

The manufacturer recommends to include manual stop valves and drain valves in the plant

so that the pipe system may be depressurized

and drained prior to working on the valve.

Valve’s mounting position

Valve’s mounting position may be any.

preferably: Solenoid vertical on top

✔ ✔ ✔ ✔

7.4

Preparation

→ Check the valve for externally visible

damages.

→ Let the valve in its protective package prior

to mounting.

→ Make sure that there is enough free space

for disassembly the valve in case of maintenance.

→

! WARNING Depressurize the pipe

system.

→ NOTICE Clean the pipe system prior to

mounting the valve.

7.5

Mounting valve to pipeline

→ Mount the valve to the designated pipeline.

Comply with existing connections.

→ Arrange the valve according to the pipe-

line’s flow direction.

An arrow on the valve body

marks the flow direction.

11/20 18

1377006.0000.10011

5

Loading...

Loading...