IMEX ROTATING LASERS

OPERATING MANUAL

77R 88R and 88G

OPERATING MANUAL

ROTATING LASER

77R 88R and 88G

Introduction

Congratulations on your purchase of a quality Imex rotating

laser.

These lasers have been designed for the professional and

incorporate the latest laser technology with a robust and

simple construction for years of trouble-free use.

These instruments are suitable for all interior and exterior

general construction leveling applications and feature quick

set-up, excellent accuracy and ease of use.

The following operating manual has been designed to assist

you in getting the optimum performance from your

instrument. Please read carefully before using the

instrument, and observe all safety conditions.

OPERATING MANUAL

ROTATING LASER

77R 88R and 88G

Contents

1. About the Instrument – Functions 3

2. Basic Operation 5

3. Manual Grade Mode Operation 7

4. Scan Mode Operation – 88R & 88G 9

Page

5. Vertical Operation – 88R & 88G 10

6. Batteries 11

7. Checking Accuracy 12

8. Trouble Shooting 13

9. Warranty, Service and Care 14

10. Technical Specifications 15

11. Available Accessories 16

1. About the Instrument - Functions

a)

Left scan mode direction

f)

Out of level warning light

b)

Right scan mode direction

g)

Rotation speed control

c)

Manual/Automatic level setting

h)

Scan mode

d)

On/Off switch

i)

x-axis(88R and 88G only) grade slope

e)

On/Off light

j)

y-axis grade slope

1.1 Instrument Overview

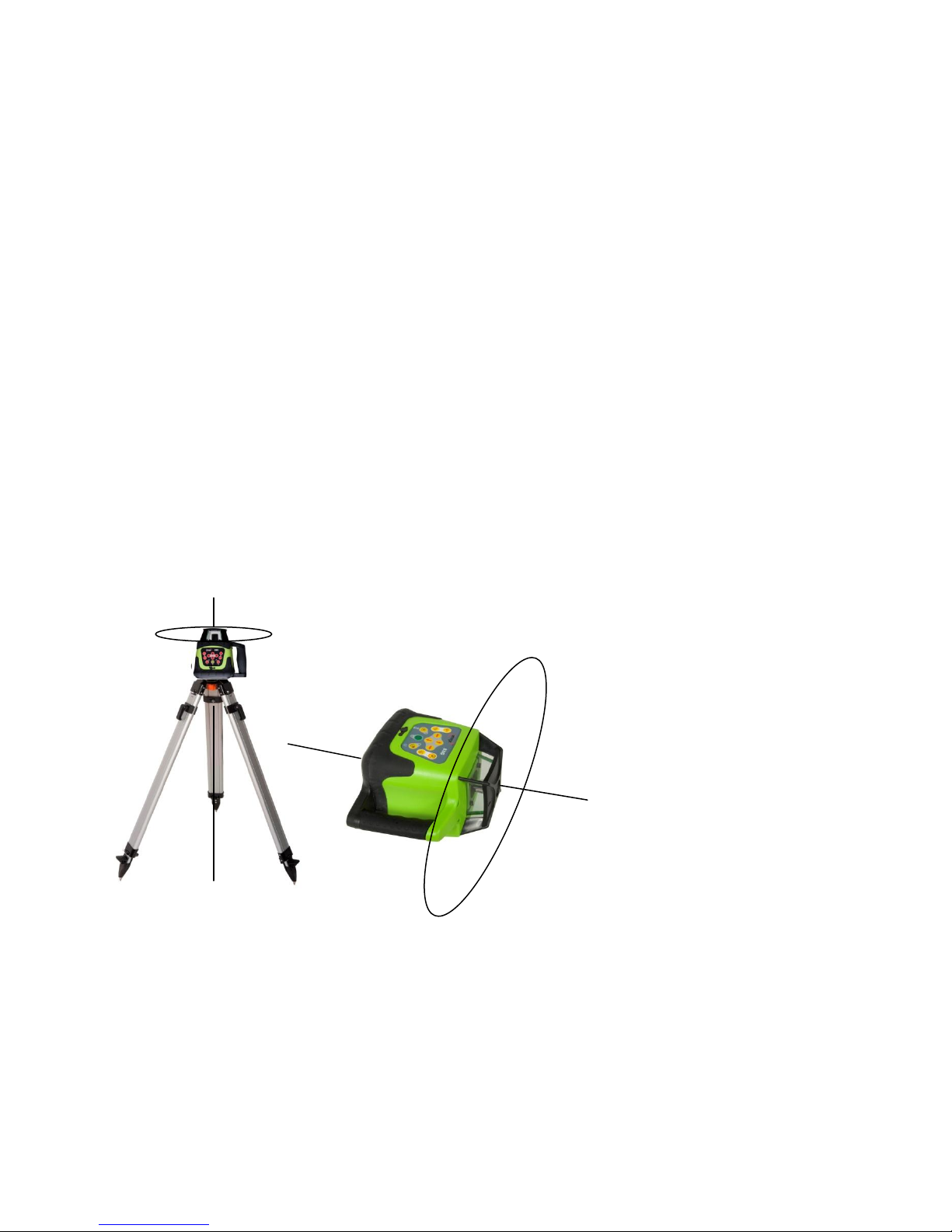

Laser Module Handle Laser Detector

Beam

Windows

Control

Panel

Staff Bracket

Battery recharge outlet Rubber Sheathed base

1.2 Control Panel

i. j.

a. h.

b. g.

c.

d. e. f.

1.3 Function

The instrument is equipped with a semi-conductor diode with

wavelength of 635nm on the red beam models and 532 on

the green beam model. The laser beam is clearly visible, and

the laser module rotates freely to form a laser scanning

surface.

In the upright position, ideally placed on a standard

aluminium tripod the laser beam emits a horizontal line

which can be detected by the instruments receiver.

On the 88 models, if the unit is placed in a horizontal

position, the laser emits a vertical beam.

A plumb spot at 90º to the main beam is emitted from the

base and the top of the instrument.

Horizontal operation Vertical Operation

A remote control is provided which works on an infra-red

system up to 20m-30m from the instrument. The control

panel has the same functions as the control panel on the

instrument itself.

2. Basic Operation

2.1 Standard Set-up Leveling (see dia over page)

Place unit on tripod and roughly set up so that the

instrument is within 5% of level.

Switch the unit on (d).

The unit will then level itself and the diode will emit a beam

and commence spinning. The instrument will commence

spinning at its maximum speed of 600rpm.

If the unit is bumped or moved the laser will stop and the

out of level warning light (f) will flash. After the instrument

has re-leveled itself the laser will recommence spinning.

Warning – If the unit has been bumped or moved and the

unit recommences spinning, the instrument may not

automatically be at the original level. Re-check on a datum

point.

2.2 Rotation Speed

If a slower speed is required, i.e. for better visibility; press

the speed control button (g).

Speed will revert to 0rpm, press button again to get required

speed.

2.3 Receiver Set-up

Using the bracket included, mount this onto a staff or grade

rod.

Turn the receiver on and raise or lower the receiver on staff

until it makes a continuous beeping sound. This is the point

level of with the instrument.

2. Basic Operation cont:

The receiver has two settings; a course and a fine setting.

The band width and the audio volume can be adjusted using

the receiver’s buttons.

Standard Leveling Set-up

When set up the instrument will create a laser beam across

the entire work site to a radius of 250m and the receiver

will give a signal in all points within the instruments range

3. Manual Grade Operation

%

@10m

0.5%

1.0%

1.5%

2.0%

2.5%

3.0%

3.5%

4.0%

50mm

100mm

150mm

200mm

250mm

300mm

350mm

400mm

The instruments have an incorporated grade slope function

to 5º. For the 88R and 88G this is a dual direction in X and Y

axis.

This allows for the following tasks to be performed; Sloped

concrete slabs, drainage slope, ceiling and grid slopes,

fencing slopes.

For additional slope i.e. 10-15ºthe instrument can be set on

a domed tripod and used with the manual button on.

3.1 Manual Mode

For best results use the remote control. Set up the

instrument in the direction of slope required.

Turn on manual mode using button (c).

To adjust slope up or down on the X axis use the (i) buttons.

To adjust slope up or down on the Y axis use the (j)

buttons.

3.2 Setting a Slope

To set a slope as a percentage use the table

included for assistance.

To set a 1% fall;

-Position instrument at the

start of your run.

-Turn on manual mode.

-Measure out 10m from the

unit and get level right.

-When level is right move

receiver 100mm down you staff.

-Now use your slope button (i or j) on your remote to bring beam

down the middle of your receiver.

Manual Grade Operation cont:

Level setting

Slope setting

10m

3.3 Dual Grade Sloping – (88R & 88G only)

Used for areas where a fall is made simultaneously to a

point 90º to the other axis.

Ideally, site instrument to one corner of the worksite. Set Y

axis as shown. At 90º to the Y axis set the X axis in the same

manner. The grade is now set for both runs.

Y axis

Direction of slope

X axis Direction of slope

4. Scan Mode Operation (88R & 88G only)

The scan mode function allows the laser beam to emit

only in a restricted radius.

This function is useful for;

- Internal layout work where work is being carried out in

single runs or sections i.e. wall or ceilings

- On restricted sites internal or external where other laser or

electrical equipment may be in use

- On busy sites where eye safety with other workers may be

an OH & S issue

- On single long external runs i.e. pipe laying where full 360º

is not required

- Especially useful in vertical mode 180º operation

4.1 Operating the Scan

With the unit on, press the scan button (h). Set the width

required 0º, 10º, 45º, 90º or 180º by pressing the button

once for every scan width increment.

To change the direction or position of the scan use the left

spinning and right spinning buttons (a and b). Press either of

these buttons until the desired position is reached.

5. Vertical Function – 88R & 88G only

The vertical function allows for the instrument to be laid

horizontally and a vertical line is emitted.

This function is used for;

- Alignment of formwork or pipeline runs in external

situations

- Alignment of internal wall, floor and ceiling layout

- In conjunction with the plumb spot beam, which is

always 90º to the rotating beam, a set-up reference

point can be determined.

Alignment of internal wall, floor and ceiling layout

5.1 Using the Vertical Mode

Lay the instrument on a floor or board. Make sure the

instrument is approximately level ± 5º and turn on.

Instrument will level as in standard position.

All functions which can be carried out in standard

position can be performed in the vertical position i.e.

scanning, grade slope, vary speed etc.

5.2 External use with Receiver

The vertical beam can be picked up with the use of the

receiver in vertical position or 90º to normal position to

check formwork or pipeline alignment set up instrument

at the end of the run in a horizontal plane.

Determine datum point at end of run with the receiver.

Instrument is now set to give a straight laser beam over the

full length of the run.

Outdoor vertical function

6. Batteries

The instrument is powered by 4 DC4.8-6V Nimh

rechargeable batteries that allow for approximately 20

hours continuous use in standard conditions (20º-25º)

Alternatively you can use the alkaline battery pack supplied.

6.1 Battery Situation

The battery case is located on the base of the instrument. If

changing batteries; undo the cover by unscrewing centre nut,

replace batteries checking polarity.

6.2 Recharging Batteries

A low battery warning light is emitted from the On/Off

light (e) approximately four hours before recharge.

DO NOT OVER CHARGE BATTERIES!

DO NOT CHARGE ALKALINE BATTERIES!

Plug the charger provided into the recharging point on the

instrument, located immediately below the control panel.

The charger plugs into a standard 240V outlet.

6.3 Battery Charging Time

Standard full Charge time is approximately 7 hours.

However the instrument can be charged and used

simultaneously. In some instances a car charger

accessory kit is an advantage.

7. Checking Accuracy

Your Imex instrument has been pre-set and calibrated for

accuracy before dispatch and should perform within the

stated accuracy tolerance in standard conditions. However

if the instrument is knocked, poorly transported or

mistreated in any way the accuracy may be compromised

and unit may need re-calibration.

On commencement of a task it is advisable to carry out a

simple control check.

7.1 Level Checking – Horizontal

Place instrument approximately 30m from a blank wall

and with X1 axis square to the wall project a line onto the

wall and mark line with a fine pencil or similar.

Turn the instrument 180º to X2 and repeat

The value or the difference between the two points should

not exceed 3mm

Repeat the process on the Y axis

x1 Beam

X 2 x 1

X2 Beam 3mm

Rotate 180º max

30m

7.2 Plumb spot Horizontal check

- Place instrument on horizontal axis on tripod or

similar, 10m from a wall

- Mark the spot on the wall

- Turn unit 180º and repeat

The difference between the two points should not

exceed 5mm.

5mm

max

10m

If values exceeded these by 10% contact your local service

centre or 1800 669 110 to organise service and calibration.

8. Trouble Shooting

Problem

Possible Cause/Solution

Out of level

alert – unit won’t

self level

- Check that instrument is within 5ºof

level, before switching on

- Check that manual level switch is not on

- Check that unit hasn’t been bumped

or moved

Low battery light

flashing. No power,

unit won’t operate

- Re-charge batteries

- If batteries are fully charged and still

won’t operate, open battery terminals

and check terminals are clean and

polarity correct

- Batteries may need replacing if over

charged too often

Out of level and

battery light on.

Instrument not

working properly

- Environment and direct sunlight may

be too harsh and instrument can’t

operate without damaging the laser

- Place unit in shaded area and below

50ºC

Receiver not

working or

functioning properly

- Check receiver batteries. Change if

necessary

- Check that receiver is within working

range. 250m radius from unit

- Check that windows of the laser are

not obstructed and are clean and free

of dust

Remote Control not

working

- Check remote control batteries

- Check that remote is in working

range of the unit (20m outdoors 30m

Indoors)

- Check that instrument is turned on

9. Warranty Service and Care

9.1 Warranty

The Imex rotating laser range is covered with a 5 year

warranty as detailed on the warranty form. For registration

please visit: www.imexlasers.com

9.2 Service and Calibration

It is recommended that in general use, laser equipment

should be calibrated by a registered service centre every 12

months. For less frequent use 24 months is permissible.

9.3 Care of Instrument

For optimum results from your instrument care must be

taken to prevent damage. Laser instruments contain

sensitive optical assemblies and need to be treated

carefully.

- Storage – Store in an area away from direct sunlight and

under the storage temperature limit of 70°C

- Transport – Lasers are affected by vibration and shock;

never transport loose on the back of a vehicle.

- Cleaning – When working in a dusty environment always

clean instrument before packing away.

- If working in wet environment, completely dry unit with dry

cloth before packing away. To prevent damage to

instrument. Failure to do this will void warranty.

Model

77R Red Beam

Horizontal/Vertical

NO

Self-Levelling

Range

±50

Water proof

IP64

Accuracy

1.5mm @ 30m

Power

DC 4.8-6v (Ni-MH)

/ 4 ‘C’ cell alkaline

Working Distance

Dia 500m with included

detector

Working time between

charge

20 hours (Ni-MH)

60 hours (Alkaline)

Rotation Speeds

0, 60, 120, 300, 600 rpm

Low Battery Light

Yes, approx 1 hour

warning

Scan Mode

NO

Battery Charger

240V

Grade Slope

±50 (Y axis only)

Working Temperature

-200C - +500C

Plumb Spot

YES -accuracy ± 1mm @

2m

Detector

Double sided

operation fine &

course setting

Light Source

Red laser diode, 635nm

Unit Weight

2.2kgs

Remote Control

YES - Working range

approx 20m

Set Inclusions

Laser unit,

detector and

bracket Remote,

charger, Hard carry

case

Model

88R & 88G

Horizontal/Vertical

YES

Self-Levelling

Range

±50

Water proof

IP64

Accuracy

1.5mm @ 30m

Power

DC 4.8-6v (Ni-MH)

/ 4 ‘C’ cell alkaline

Working Distance

Dia 500m with included

detector

Working time between

charge

20 hours (Ni-MH)

60 hours (Alkaline)

Rotation Speeds

0, 60, 120, 300, 600 rpm

Low Battery Light

Yes, approx 1 hour

warning

Scan Mode

YES 10º,45º,90º,180º

Battery Charger

240V

Grade Slope

±50 (Y and Y axis)

Working Temperature

-200C - +500C

Plumb Spot

YES -accuracy ± 1mm @

2m

Detector

Double sided

operation fine &

course setting

Light Source

88R Red laser diode,

635nm, 88G Green laser

diode 532nm

Unit Weight

2.2kgs

Remote Control

YES - Working range

approx 20m

Set Inclusions

Laser unit,

detector and

bracket Remote,

charger, Hard carry

case

10. Technical Specifications

Copyright © International Measuring Equipment 2015

AU: T: 1800 669 110 E: info@imexlasers.com.au W: www.imexlasers.com.au

UK: T: +44 (0)115 9440399 E: sales@imextools.co.uk W: www.imextools.co.uk

Loading...

Loading...