Electric Contact Grill

Instruction Manual

Model:PG-SA/PG-SF/PG-SC/PG-MA/PG-MB/PG-MC/PG-2SA/PG-2SF/PG-2SC

Please read this instruction manual carefully before operating this equipment

Safety Tips

Read this instruction manual before using and keep them

available at all times!

This instruction manual contains information about the installation, operation and maintenance of

the device and should be consulted as an important source of information and reference guide.

Awareness of the safety instructions and instructions for use in this manual will ensure the safe

and correct use of the device.

In addition to the information given here, you should comply with any local Health and safety

Controls and generally applicable safety regulations. The instruction manual forms part of the

product and should be kept near the device and easily accessible for anyone carrying out the

installation, servicing, maintenance or cleaning.

Please keep these instructions and give them to future owners of the device.

Safety

This device is designed in accordance with the presently applicable technological standards.

However, the device can pose a danger if handled improperly and inappropriately.

All persons using the device must follow the recommendations and instructions in this instruction

manual.

Safety instructions

• The device is not intended for use by individuals (including children) with physical or mental

disabilities, insufficient experience, and/or insufficient knowledge unless such persons are under

the care of a person responsible for their safety or have received instructions regarding

appropriate use of the device.

• Children should be observed to ensure that they are not playing with the device.

• Never leave the device unattended when in use. • Only use the device indoors.

• The device is not adapted for use with an external timer or remote control.

• This device may only be operated in technically proper and safe condition.

• Prevent access of children to the package materials like plastic bags and foamed polystyrene

elements. Suffocation hazard!

• Only a qualified technician and using original spare parts and accessories should carry out

repairs and maintenance of the device. Do not attempt to repair the device yourself.

1

• Do not use any accessory or spare parts that have not been recommended by the manufacturer.

These can be dangerous for the user or lead to damages of the device or personal injury, and

further, the warranty expires.

• To prevent hazards and to ensure optimum efficiency, no modifications or alterations to the

device that are not explicitly approved by the manufacturer may be undertaken.

HOT SURFACE! Burn hazard!

Follow the safety instructions listed in order to avoid the hazard:

• The housing and the grill plates of the appliance become very hot. during operation. Do not

touch them with bare hands. Use always the operating handle in order to open the device. Use

appropriate kitchen utensils for laying and taking of food.

•Also after switching off, the device remains hot for some time. Before cleaning or moving it to

another place wait until the device cools down first.

• Never move this appliance during operation.

WARNING!

Fire or explosion hazard! Follow the safety instructions listed in order to avoid the hazard:

• In order to avoid risk of fire and damage to the device, never place kitchen utensils, towels,

paper and the like on the grill plate during operation.

• Never operate the device near combustible, easily flammable materials (e.g. petrol, spirit,

alcohol etc.). They evaporate through heating and in case of contact with ignition sources

deflagrations can occur which can lead to serious personal injuries and property damages.

• When a fire arises disconnect it from the power supply before you initiate appropriate measures

for fire-fighting. Provide sufficient supply of fresh air.

Caution: Never extinguish the fire with water when the power plug is connected to the socket.

Electric shock hazard!

2

Warning!

Any refitting and wrong installation, adjustment and maintenance can

lead to property loss and causality. Please contact the supplier if user

needs to adjust it and all these should be done by trained special

professionals.

Warning!

For your safety sake, do not put or store any flammable liquid, gas or

other objects around the product.

Warning!

The shell of this equipment must be grounded for safety sake. Thanks for

your cooperation!

3

General information

Electric Contact Grill is designed and developed by the company with combination of the

advantage of both foreign and domestic similar products and achieves advantages such as

fashionable design, reasonable structure and convenient operation and maintenance and

durability. The temperature of the griddle pan can be regulated in a certain scale according to

different cooking requirements. Mainly used for grilling the beef of sandwich and also for other

food, it is the first choice for the food industry enterprises such as western food restaurants, fast

food restaurants, hotels and supermarkets and etc.

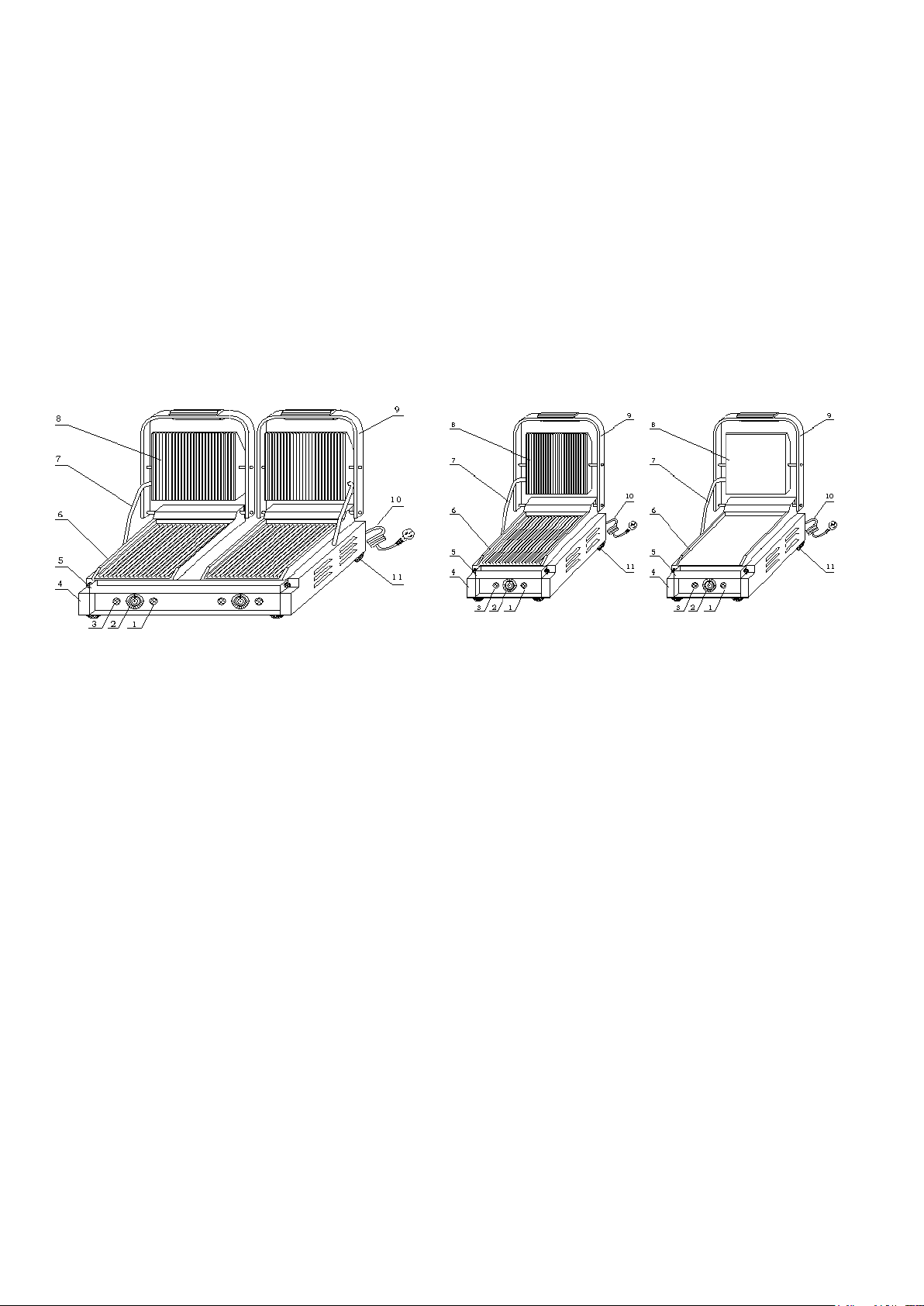

A. Exterior Structure

1—HEATING INDICATOR 2—TEMEPRATURE CONTROLLER

3—POWER INDICAOTR 4—BOTTOM BOX

5—OIL TRAY 6—LOWER MODULE PLATE 7—FEED WIRE TUBE 8—UPPER

MODULE PLATE 9—OPERATION HANDEL 10—POWER CORD

11—RUBBER FEET

B. Features of Function and Structure

1. The upper and lower module plates are enameled and are easy to be cleaned.

2. One-headed and double-headed grilling pans can be chosen freely.

3. Independent temperature controlling system are convenient to handle and can achieve

energy economy as well.

4. Internal temperature protector is reliable and safe.

5. Grilling temperature can be adjusted according to different requirements.

6. It is made by stainless steel and the drawer-style oil tray is also made of stainless steel.

7. It is easy to lift up and down and convenient to handle and maintain.

4

C. Basic Parameter

Name

Contact Grill single

Upper/lower ribbed

Contact Grill single

Upper/lower smooth

Contact Grill single

Upper ribbed/lower

smooth

Contact Grill single

Upper/lower ribbed

Contact Grill single

Upper/lower smooth

Model

PG-SA

PG-SF

PG-SC

PG-MA

PG-MB

Voltage

220~240V

50/60Hz

220~240V

50/60Hz

220~240V

50/60Hz

220~240V

50/60Hz

220~240V

50/60Hz

Power

1.8KW

1.8KW

1.8KW

2.2KW

2.2KW

Temperature

controller

number

1 1 1 1 1

Temperature

range

50~300℃

50~300℃

50~300℃

50~300℃

50~300℃

Upper grill

size

214×214(mm)

214×214(mm)

214×214(mm)

340×220(mm)

340×220(mm)

Lower grill

size

218×230(mm)

218×230(mm)

218×230(mm)

360×285(mm)

360×285(mm)

Dimension

290×395×210(mm)

410×370×220(mm)

410×370×220(mm)

Weight

13kg

13kg

13kg

15.5kg

15.5kg

Name

Contact Grill single

Upper ribbed/lower

smooth

Contact Grill double

Upper/lower ribbed

Contact Grill double

Upper/lower smooth

Contact Grill double

Upper ribbed/lower

smooth

Contact Grill double

Upper smooth/lower

ribbed

Model

PG-MC

PG-2SA

PG-2SF

PG-2SC

PG-2SD

Voltage

220~240V

50/60Hz

220~240V

50/60Hz

220~240V

50/60Hz

220~240V

50/60Hz

220~240V

50/60Hz

Power

2.2KW

3.6KW

3.6KW

3.6KW

3.6KW

Temperature

controller

number

1 2 2 2 2

Temperature

range

50~300℃

50~300℃

50~300℃

50~300℃

50~300℃

Upper grill size

340×220(mm)

214×214(mm)

214×214(mm)

214×214(mm)

214×214(mm)

Lower grill size

360×285(mm)

475×230(mm)

475×230(mm)

475×230(mm)

475×230(mm)

Dimension

410×370×220(mm)

570×395×210(mm)

Weight

15.5kg

27kg

27kg

27kg

27kg

5

Name

Contact Grill double

Upper/lower ribbed

Contact Grill double

Upper/lower smooth

Contact Grill double

Upper ribbed/lower smooth

Contact Grill double

Upper smooth/lower ribbed

Model

PG-2MA

PG-2MB

PG-2MC

PG-2MD

Voltage

220~240V

50/60Hz

220~240V

50/60Hz

220~240V

50/60Hz

220~240V

50/60Hz

Power

4.4KW

4.4KW

4.4KW

4.4KW

Temperature

controller

number

2 2 2

2

Temperature

range

50~300℃

50~300℃

50~300℃

50~300℃

Upper grill size

340×220(mm)

340×220(mm)

340×220(mm)

340×220(mm)

Lower grill size

759×285(mm)

759×285(mm)

759×285(mm)

759×285(mm)

Dimension

810×370×2 20(mm)

Weight

31kg

31kg

31kg

31kg

D. Transportation and Storage

Please handle the griller carefully and cautiously in transportation and do not turn it upside down

to prevent any damage to the shell and interior. The packed griller should be stored in the

storehouse ventilation and non-corrosive gas. Any weatherproof measures should be applied

when temporary storage.

E. Notes

1. The working voltage of the equipment should match that of the power supply.

2. Suitable switch, fuse breaker and three-phase socket should be installed near the

equipment.

3. There is an earth bolt at the back of the equipment. Please connect the earth wire in

compliance with the safety regulations reliably with copper cable of no less than 2mm.

4. Before using user should check whether connection is firm and voltage is regular and

earth connection is safe.

5. Do not put any object onto the upper module plate and shake the lift operation handle

with sudden force.

6. Cut off power supply while cleaning. Do not use wet towel with corrosive cleanser and do

not directly splash water on the equipment.

7. The adjustable temperature of the equipment is between 50~200℃. It is recommended

that the maximum working temperature normally should be 200~250℃.

8. Do not store any flammable objects near the equipment. The environment temperature

lower than 45℃, the humidity is under 85%.

9. The installation and maintenance of the equipment should be made by professional

technicians.

Special Notes

6

WARNING!

● This product is a commercial machine and it must be operated by trained cook.

● Do not dismantle and refit the machine.

Do not lift the upper module plate with sudden force and tilted installation.

The dismantlement and alteration can cause serious accident happens.

● Before cleaning, unplug the machine and cut off power supply.

Do not spray water directly to the product.

Water can conduct electricity and electricity leakage happens.

● Do not pat the product and put heavy object onto the product.

Incorrect operation can cause the equipment be damaged and dangerous.

● High temperature will cause scald.

When the equipment is in use and before or after using it, do not touch the box and

module plate because of high temperature.

● Do not use any power supply which is not coordinated with safety standards.

NOTICE!

● When the thunderstorm is coming, the electricity supply must be cut off soon.

It will avoid the equipment being damaged in cause of lightning stroke.

● Do not destroy the control panel and the surface of the machine with hard or sharp

things.

● When the machine finishes using , user should close main switch.

● The installation and maintenance of circuit must be done by certificated special

professionals.

If the supply cord is damaged, it must be replaced by the manufacturer or its service

agent or a similarly qualified person in order to avoid a calamity.

F. Operation Instruction

1. Before using, check whether the power supply installation is regular to make sure the

supplied voltage is coordinated with the using one.

2. Put the plug in the socket and turn on the power.

3. Turn the temperature controller clockwise to the temperature needed. The yellow

indicator is on that shows heating wire begins to heat and the upper and lower griddle

begins to raise temperature.

4. Temperature can be adjusted according to different food preferably within 180℃~250℃.

About 8 minutes is needed for the temperature to be raised to 250℃ from the power is

on.

5. When the temperature reaches 250℃, lift the upper module plate to a suitable place by

operation handle. Put some edible vegetable oil on the lower module plate and constantly

7

place the food on it. Close the plates and press the handle lightly. Keep an eye on the

food until it is suitably done.

6. When temperature reaches the setting degree, temperature controller can cut off power

supply automatically. At the same time, yellow indicator is off and green indicator is on. It

shows that electricity heating tube stops working for next turn.

7. At the lower front of the lower module is the oil tray. Substantial vegetable oil and the

animal oil from the meat grilled flow to the oil tray from the lower module plate.

8. Lift the upper module plate to take the sandwich and other food already done.

9. When the temperature is a bit lower, the temperature controller can get through power

supply automatically. The heating tubes restart to work to heat the module plates.

10. On completion of the work, temperature controller should be turned to the “off” place.

Unplug the equipment and cut off the power.

11. Notice: There is temperature limiter in the bottom box, the action temperature is 130℃,

and reset temperature is ‹40℃. When temperature is over the protective button works for

protection. When use it again, please use it after press the protective button.

G. Cleaning and Maintenance

1. Cut off the power supply before cleaning in case of accident.

2. Do not use wet towel with non-corrosive cleanser to clean the module plate, the surface

of the equipment and power cord. Direct wash by water is not permitted in case of any

damage of the functions.

3. If do not use it at any time, please turn off temperature controller and main switch.

4. Please store the equipment in a ventilated storehouse without corrosive gas after

cleaning when ceasing its work for a long time.

8

H. Troubleshooting

Troubles

Causes

Solutions

1. Module plates are out of

heating when the power and

heating indicator are both on.

1. Temperature controller is broken.

2. At least one of heating wires is

burned.

3. Temperature protector works.

1. Change temperature controller.

2. Change the burned heating tube.

3. Dismantle the bottom plate and use

hand to reset temperature

protector.

2. When the power is on and

temperature controller is

switched and heating indicator

is on and temperature can be

not controlled.

1. Temperature controller is out of

order.

1. Change temperature controller.

3. Indicator is not on when the

power is on and the heating

process is normal.

1. Indicator is broken.

1.Change

temperature controller.

The indicator is out of order

when the power is on.

1. Abnormal power supply or cut-off

power supply.

2. Fuse is burned.

1. Check power supply and connection

to make power supply be normal.

2. Change fuse.

Aforementioned troubles are just for reference. If any fault occurs, please cease using

and turn to professional technicians for check and repair.

I. Circuit Diagram

PG-SA PG-SF PG-SC PG-MA PG-MB PG-MC

9

PG-2SA PG-2SF PG-2SC PG-2SD PG-2MA PG-2MB PG-2MC PG-2MD

HL1, HL3----POWER INDICAOTR

HL2, HL4----HEATING INDICATOR

SA, SA1, SA2----TEMPERAUTRE CONTROLLER

E----GROUND CONNECTION

SB, SB1, SB2----TEMPERAUTRE CONTROLLER

EH1, EH2, EH3, EH4----HEATING WIRE

THE SHELL OF THIS MACHINE MUST BE EARTH GROUNDED FOR SAFETY SAKE.

THANKS FOR YOUR COOPERATION.

10

J. Daily Check

Before using

Whether the machine is tilted?

Whether the power cord is old, broken or damaged?

Whether the control panel is damaged?

After using

Whether there is strange smell?

Whether the upper and lower module plate cannot be

heated at the same time?

Is there any strange voice or is the machine out of

control while the machine is lifting?

WARNING!

● Must check the machine everyday.

Usually check the product that can avoid serious accident happens.

● Stop using if user feels that there are some problems in the circuit or machine.

Ask the special technicians to check and maintain the machine as soon as

possible.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

Everyday notice the situation of the machine before or after using.

K. Solid Resolution Graph

11

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

51

52

21

49

50

48

Declaration: The structures of PG-SA/PG-SF/PG-SC/PG-MA/PG-MB/PG-MC are different, the

differences are: The upper and lower module plate of PG-SA and PG-MA are ribbed; the upper

and lower module plate of PG-SF and PG-MB are smooth. The upper and lower module plate of

PG-SC and PG-MC are upper ribbed and lower smooth.

12

Declaration: The structures of

1. HEATING INDICATOR

2.TEMPERATURE CONTROLLER

3.CROSS-HEADED SCREW M4×6

4. POWER INDICATOR

5. BOTTOM HULL

6. INTERNAL HEXAGON SCREW M6×10

7. FLAT SPACER

8. INTERMAL HEXAGON SCREW M5×25

9. FLAT SPACER

10. WISTING SPRING

11. REAR ROTARY AXLE

12. FASTONTING STAND

13. INTERNAL HEXAGON SCREW

M6×40

14. BACK UPPER COVERING BOARD

15. SCROSS-HEADED SCREW M4×8

16. SPRING PIN

17. EQUIPOTENTIAL GROUND SCREW

M6×15

18. POWER SUPPLY WIRE JACKET

19. POWER CORD

20. POWER GROUND SCREW M5×15

21. GRILL OF LOWER MODULE

22. UPPER MODULE BOARD

23. CROSS-HEADED SCREW M4×8

24. HEAT-INSULATED COTTON OF

UPPER MODULE

25. PLATEN OF UPPER ELECTRIC

HEATING TUBE

26. GRILL OF UPPER MODULE

27. ELECTRIC HEATING TUBE OF

UPPER MODULE

28. INCOMING LINE TUBE

29. SPRING CHECK RING FOR AXLE

30. SPRING CHECK RING FOR TUBE

31. AXLE OF UPPER MODULE

32. INTERNAL HEXAGON SCREW

M5×16

33. INTERNAL HEXAGON SCREW M6×8

34. HANDLE

35. FRAME OF OPERATION HANDLE

36. OIL TRAY 37. HALF OF CHEESE

HEAD SCREW M6×12

37. HALF OF CHEESE HEAD SCREW

M6×12

38. SMALL BALL

39. HEAT-INSULATED COTTON OF

LOWER MODULE

40. PRESSURE PLATE FOR COTTON

41. CROSS-HEADED SCREW M4×20

42. AMPHENOL CONNECTOR PLATE

43. CROSS-HEADED SCREW M4×8

44. CERMIC CONNECTORS

45. TEMPERATURE LIMITER

46. HEXAGON SCREW M6×20

47. RUBBER FOOT

48. PRESSURE PLATE FOR

ELECTRIC HEATING TUBE OF LOWER

MODULE

49. ELECTRIC HEATING TUBE OF

LOWER MODULE

50. INTERNAL HEXAGON SCREW M6×8

51. BOTTOM BOARD

52. CROSS-HEDED SCREW M4×8

PG-2SA/PG-2SF/PG-2SC/PG-2SD/PG-2MA/PG-2MB/PG-2MC/PG-2MD are different, the

differences are: The upper and lower module plate of PG-2SA and PG-2MA are ribbed; the

upper and lower module plate of PG-2SF and PG-2MB are smooth. The upper and lower module

plate of PG-2SC and PG-2MC are upper ribbed and lower smooth. The upper and lower module

plate of PG-2SD and PG-2MD is upper smooth and lower ribbed.

13

Waste disposal

Discarding old devices

At the end of its service life the discarded device has to be disposed in accordance with the

national regulations. It is advisable to contact a company which is specialized in waste disposal,

or just contact the local disposal service in your community.

WARNING!

To exclude any abuse and the dangers involved make the waste device unfit for use before

disposal. For that purpose disconnect device from mains supply and remove mains connection

cable from the device.

CAUTION!

For the disposal of the device please consider and act according to the national and local rules

and regulations.

WARRANTY

iMettos warrants to the original purchaser of every new product, under normal and proper use

and maintenance service as specified by iMettos and upon proper installation and start-up in

accordance with the instruction packet supplied with each unit. iMettos’ obligation under this

warranty is limited to a period of two (2) year from the date of original installation.

WARRANTY CLAIMS

All claims for parts must be made directly through iMettos. All claims should include:

Personal Details: Products Details:

Your name: Model number:

Your company: Serial number of the product:

Address: Date of purchase:

Email: Proof of purchase :

Phone:

Pertinent information supporting the existence of the alleged defect.(Such as picture etc.)

Please send the above information to services@imettos.co.uk

Our warranty departments will according to the actual situation and reply you within 24hours.

14

iMettos Limited

www.imettos.co.uk

15

Loading...

Loading...