Spiral Mixer

Instruction Manual

Model LM20/LM30/LM40/LM50

Please read this instruction manual carefully before operating this equipment

1

Safety Tips

• Position on a flat, stable surface.

• A service agent/qualified technician should carry out installation and any repairs if required. Do not

remove any components on this product.

• Always stand BEHIND the safety guard when operating the appliance.

• DO NOT place hands near the rotating attachments when in use. This can result in severe injury.

• DO NOT remove food from the appliance until the mixing attachments have come to a complete

stop.

• DO NOT immerse the appliance in water.

• DO NOT attempt to mix items that this machine is not designed for. This can damage the mixing

attachments.

• DO NOT use with a damaged mixing attachment.

• Always switch off and disconnect the power supply to the appliance when not in use.

• NEVER leave the appliance unattended when in use.

• The appliance is heavy. Take care when moving.

• This appliance must only be used in accordance with these instructions and by persons

competent to do so.

• This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliance by a person responsible for their safety.

• Keep all packaging away from children. Dispose of the packaging in accordance to the regulations

of local authorities.

• If the power cord is damaged, it must be replaced by an iMettos agent or a recommended

qualified technician in order to avoid a hazard.

• Never use accessories which are not recommended by the manufacturer. They could pose a

safety risk to the user and might damage the appliance. Only use original parts and accessories.

• Clean the surface of stainless steel periodically with appropriate method to prevent any damage

brought by oxidization or any other chemical interference.

THE SPIRAL MIXER IS A DANGEROUS APPLIANCE AND MUST

ONLY BE USED BY TRAINED PERSONNEL IN ACCORDANCE

WITH THESE INSTRUCTIONS.

!

2

Please take a few moments to carefully read through this manual. Correct maintenance and

operation of this machine will provide the best possible performance from your product.

iMettos LM Series Spiral Mixers

ATTENTION

New user or repairing this product must be performed by the experts or qualified person or those who

have gotten the license of installation, or those who are authorized by the manufacturer.

When installation or maintenance, please obey the following instructions carefully to ensure the safety

use of this appliance.

Please keep this instruction Manual for future reference, or hand it to next user.

Put off the package to make sure none of the parts is missing or damaged. If there is any doubt about

the product, please do not use it, and consult it to the experts.

Keep the packing material out of reach of the children to avoid accident( Especially the plastic bag,

screw etc)

This appliance could be only operated by the person who is familiar with the unit.

When not using the appliance or the operator is absent, please turn off the unit to avoid any accidental

injury or damage.

When it needs to be repaired, please ask for expert, and use the original fitted spare part. It will be

dangerous if not following the above requirements.

This appliance is just for commercial using, not for any other use, otherwise, it may be dangerous.

Do not rinse the equipment with water directly.

Clean the surface of stainless steel periodically with appropriate method to prevent any damage

brought by oxidization or any other chemical interference.

1. DESCRIPTION

LM spiral mixer is a new type of kneader. Both the dough arm and bowl are running, that it can raise the

mixing speed and efficiency greatly. The machine is equipped with protect cover, easy operable and safety.

Overall, the machine is food looking, easily operable and very efficient, suitable for food preparation in

hotels, restaurants, food processing factories and for material preparation in medicine making factories,

chemical working facilities etc

2. FORWARD

We reserves the right to alter the design of their products without prior notice. Whilst every effort is made

to ensure this publication reflects the latest design, the company cannot guarantee full compliance.

Technical specifications

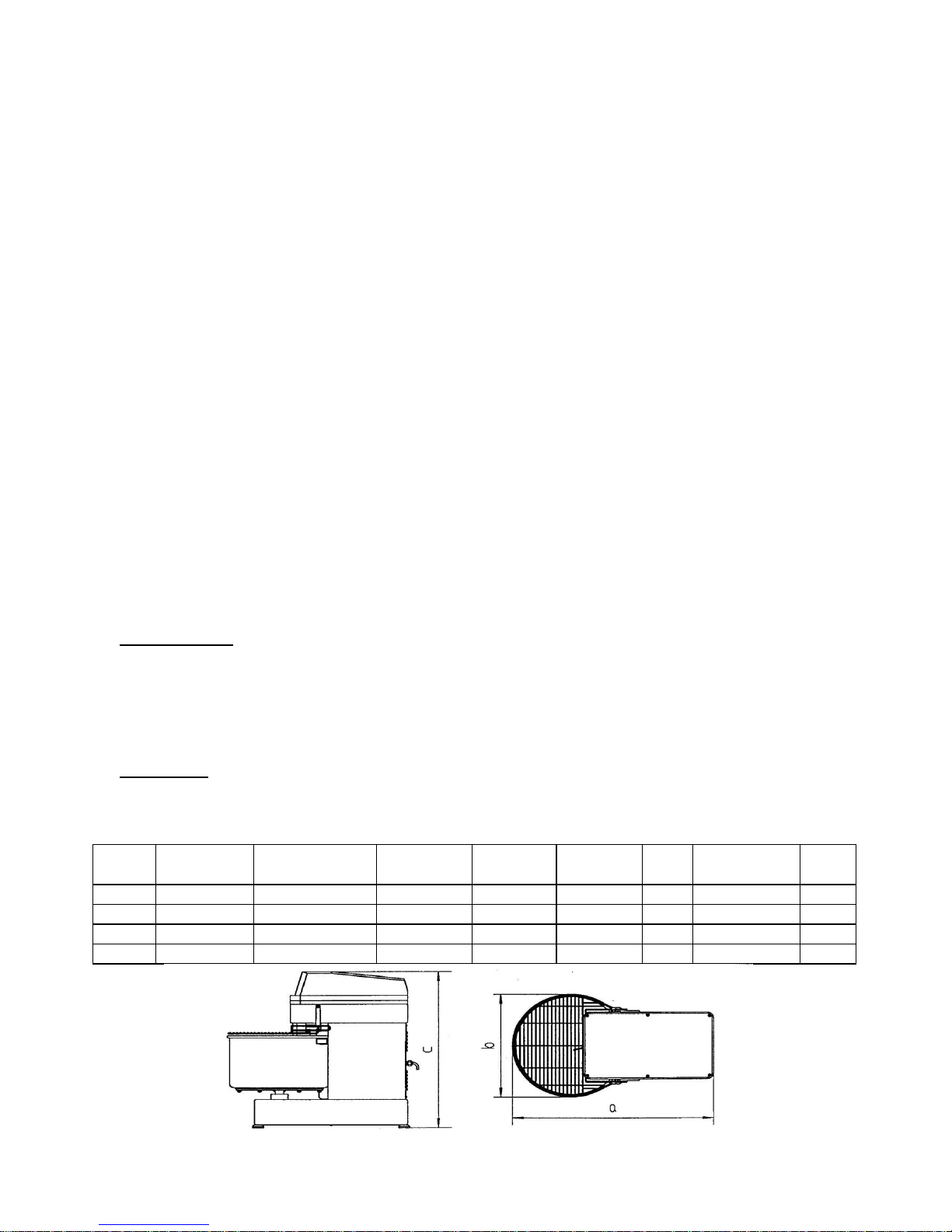

Model

Bowl capacity

(L)

Max flour capacity

(kg)

Mixing speed

(r/min)

Bowl speed

(r/min)

Voltage

(V/Hz)

Power

(kw)

Dimensions

(mm)

Weight

(kg)

LM20

20 8 202

16

220-240/50

0.75

690x380x730

70

LM30

30

12

202

16

220-240/ 50

1.1

730x430x770

90

LM40

40

16

202

16

220-240/50

2.2

870x480x935

127

LM50

50

20

202

16

220-240/50

2.2

920x530x935

130

3

3.GENERAL INFORMATION

The following information and instructions within this manual may not cover all details or variations in the equipment, nor

cover every problem that one may have during installation or use. If additional information is required please contact us.

4. SAFETY INFORMATION

The following procedures and instructions should always be carried out in order to prevent any injuries. If the

machinery is not used as recommended, the operator will be responsible for his/her own safety and for the safety of the

other persons who may be involved.

The information in this manual aims to assist the operator to understand, maintain, and operate the mixer correctly. In

order to prevent accidents, please ensure to read, understand and follow all the precautions and warnings contained in

this manual before installation or operating. To gain a clear under straining of your mixer, it is imperative that one must

study this manual carefully.

Rotating machinery and Electricity are dangerous and may cause injury if sufficient precautions are not taken prior to

operating or servicing the mixer. Ensure that the power supply is not connected to mixer and is isolated before starting

work to clean or service the machine. In certain troubleshooting situations it may be necessary to operate the mixer; in

which case extreme caution must be used. Only suitably qualified personnel must service the mixer.

4.1 SAFETY GUIDELINES

Ensure sufficient precautions are observed during manually handling of the mixer, particularly when moving the mixed into

position on installation. Ensure to adhere to the manual handling regulations.

This appliance is only for commercial and not for domestic use.

The mixer is not intended for use by children.

Whilst the machine is in operation, do not remove any cover

When mixing products that develop dust, extreme care must be taken.

Exposure to dust (including flour) may be harmful to health causing rhinitis (running nose), watering eyes and possibly

occupational asthma.

If dust is a hazard, ensure appropriate PPE (personal protective equipment) is used by operators, i.e., a mask.

All operators must be trained in the safe operation of the mixer and attachments.

This appliance is not to be used by anyone who with a lack of knowledge. Ensure all operators have been

appropriately trained.

This appliance is not intended to be used by those sensory, physical or mental capabilities prevent them from being

able to operate it safely.

Ensure the electrical supply has been isolated and the power cord disconnected before attempting to move or service

the mixer.

Be aware of the start capacitor situated behind the rear motor cover. In normal circumstances this should discharge

when the mixer is switched off. If in doubt discharge the capacitor following adequate safety precautions.

When accessing the electrical components inside the mixer, be cautious of exposed conductors that could be 'live'.

Always have your mixer and attachments regularly serviced; at least twice a year, depending on frequency of use.

Ensure this manual is kept in an easily accessible place for future reference near the mixer.

4.2. SAFETY INSTRUCTIONS

A FULLY TRAINED AND COMPETENT PERSON MUST ONLY USE THE ATTACHMENT AND/OR MIXER.

When manoeuvring or lifting a bowl and contents with a total weight in excess of 500kg a bowl truck must be used.

Avoid tasks concerned with manual handling that involves a risk to health as far as reasonably possible. This

equipment should only be stored in or transported through an environment with an ambient temperature above 5°C

and less than 55°C.

Note: The mixer must only be used for the purpose it was design and inline with the supplied operating instructions.

4

When mixing ingredients care must be taken to avoid the inhalation of dust particles e.g. flour. Reference should be made

to product supplier's data sheets to ensure adequate precautions and protections are taken

The following instructions must be observed when operating the mixer

4.3. NEVER

NEVER Wear loose clothing that may become caught in the mixer whilst it is in operation.

NEVER Attempt to reach into the bowl whilst it is mixing.

NEVER Access rotating parts.

NEVER Use excessive force when operating which could affect the stability of the mixer.

NEVER Operate the mixer if parts are disassembled.

NEVER Override the safety switches fitted to the mixer.

NEVER Open the guard to stop machine.

NEVER Use the mixer in an unsafe condition.

NEVER Operate the mixer or attachment if a fault develops or the mixer is unsafe.

NEVER Attempt to repair the appliance. A qualified technician must service the machine.

NEVER Clean the mixer with scouring powder or a scouring pad.

NEVER Clean aluminium agitators in a dishwasher.

NEVER Inhale mixing ingredient dust particles.

4.4. ALWAYS

Use the mixer as intended and inline with the operating instructions.

Use the mixer in a well-lit area.

Stop the mixer before adding more ingredients.

Use the stop button to stop machine.

Disconnect the mains electricity supply before cleaning the mixer.

Clean the bowl, agitators and after use.

Clean the mixer using mild soap and water.

Clean the mixer daily.

Inspect the power cable and appliance regularly. If a fault is found do not operate.

Disconnect the mains electricity supply before cleaning the mixer.

4.5. LIABILITY

Installations and repairs which are not carried out by Authorised technicians or the use of other then original spare

parts, and any technical alterations to the machine, may affect the warranty set out in the standard conditions of sale

ATTENTION!DO NOT hose or pressure clean this appliance. It is vital to follow the cleaning procedures detailed later in

section 7 of this manual.

5.Operation and Notes:

Place the machine on the horizontal floor, keep it stable, and the environment should keep in the suitable temperature.

Check whether the power supply corresponds to that the machine require, and whether the wire are connected

properly.

Warning: The machine must be earthed properly(user’s power supply must have the earth wire.

Check the protective cover

Open it and the machine can’t started. Fix it and the machine can be started

5

A. Open the protective cover, put suitable flour into the bowl every time(the capacity of the flour can’t exceed the

determined maximum)

B. Fill the bowl with water. Whose weight is 45%-50% of the required flour.

C. Put down the protective cover and start the machine

D. When the dough has been kneaded(probably for 8 minutes),please push stop-button so that the machine can stop

working. Then open the protective cover and take out the dough.

E. During working, putting hand or hard thing into bowl is forbidden. And taking out dough with hand is dangerous.

F. During working, do not clean it, oil or lubricate the machine.

6. MAINTENANCE:

Important: All machine work should be carried out after having unplugged

During service and maintenance, the motor and parts should be dismounted gradually. And it should be clean the machine

and to lubricate the chains and bearing regularly

Advice:

A. After use every time, clean the machine carefully, make sure to keep the machine clear and fill lubricate oil into the

lubricated points

B. Do not start the machine repeatedly, in order to prolong the machine’s service life time, the time of continuous running

Do not be too long.

C. Lubricate the chains and main moving parts about once a mouth.

D. Check the tension of the belts and chains about once six months.

E. Check the electric circuit about once a year.

Trouble shooting:

Trouble

Solution

The machine can not start

1. Electric connection are loose

2. The protection cover is not close

Safety switch is not work

1. Open the cover, and check if press-plate of safety

switch connecting is loose

2. Check the electric circuit of safety switch

The temperature of the machine is too high

1. Working time is too long

2. Check if the supply voltage is lacking

3. Over load, or machine running is wrong g

Low in efficiency

1. It has something wrong with the machine

2. It is too seriously that transmission parts are worn off

3. It has something wrong with the motor

4. The belt and chains loosen—the belt and chains must be

tightened or replaced

6

7. INSTALLATION

A qualified person must install this machine in accordance with current regulations

7.1. UNPACKING AND HANDLING

Wherever possible, the mixer should be transported to the installation position in the packaging provided to avoid any

damage. Do not use a sharp knife to open the box to prevent damaging the machine. On first inspection, check for any

possible shipping damages. If any damage has been found, save the packaging material and contact us.

Caution: The mixer is a heavy object and must be correctly handled and lifted to avoid any and all personal injuries.

With the machine in the vicinity of its final position remove from the transportation pallet. The machine is affixed to the

pallet by four retaining bolts through the pallet into the threaded feet of the base. Care must be taken during this

operation to ensure:

• All required safety measures are taken to ensure correct lifting and handling to avoid risk of injury, which may be

through dropping, falling or tilting.

• No damage is made to the machine which could impair the normal operation.

7.2. LOCATION

The mixer is not suitable for outdoor installation and must not be installed where a water jet could be used for cleaning.

The mixer must only be operated by trained staff and must be installed in an area where the use and maintenance is

restricted to trained personnel.

Ensure that the mixer is at a height with the bowl handles approximately between the knuckle and elbow height. This will

reduce the need to bend at the waist.

Select a suitable flat level surface that can support the weight of the mixer and bowl contents when full. It is

recommended the mixer is secured in position. Ensure the table, stand or work surface is firmly fixed to the floor. The

appliance must be restrained to prevent any movement during use.

Ensure that there is sufficient space around the mixer to allow for the safe operation. Servicing may also become an issue if

there is a greatly reduced clearance, so ensure that the service accesses to the top, side and rear of the mixer are clear

7.3. ELECTRICAL INSTALLATION.

The electrical installation of the mixer must conform to the local or national electricity board regulations.

A competent person must carry out the electrical installation. Ensure that the electrical supply agrees with the machine

specification, prior to connection.

The mixer is 'class l' appliances where the protection against electric shock does not rely solely on basic insulation. An

external electrical isolator and MCB/fuses (both items supplied by others) must be fitted to the incoming electrical supply

to the mixer. In addition a 35mA residual current device is strongly recommended to provide extra protection

“This appliance should be connected to the point of the supply with the impedance value Zsys less than (0.05+j0.03)Ω.

If the supply cord is damaged , it must be replaced by a special cord or assembly available from the manufacture or its

service agent.”

7

LM20 LM30 LM40 LM50 Circuit (Single Phase)

8. MACHINE ILLUSTRATION:

If you want to replace parts, you can give us your requirement referring to the parts list below

LM20 LM30

Code

Name

Qty. M Motor

1

KM

Contactor

1

SB1

Emergency Stop button

1

SB2

Start Button with light

1

SQ

Journey Switch

1

KT

Timer

1

8

No.

Part No.

Name of part

Qty.

No.

Part No.

Name of part

Qty. 1 LM20 30 -13

Protective casing

1

18

LM20 30 -35

Washer

1 2 LM20 30 -11

Bowl

1

19 Switch

1 3 LM20 30 -10

Bowl support

1

20

LM20 30 -09

Top cover

1 4 LM20 30 -25

Chain seat d25

1

21 Belt 1 5

LM20 30 -24

Chain pulley

1

22

LM20 30 -18

Small belt pulley

1 6 GB1243.1-83

Chain

1

23

GB281-64

Bearing 1204

2 7 LM20 30 -01

Frame

1

24

LM20 30 -04

Back cover

1 8 LM20 30 -19-2

Dough arm

1

25

LM20 30 -33A

Upper bearing seat

1 9 LM20 30 -19-1

Shaft

1

26

LM20 30 -05

Locking ring

2

10

LM20 30 -22

Protective plate

2

27

LM20 30 -17

Transmission shaft

1

11

LM20 30 -20A

Center rod

1

28

LM20 30 :YSP711-4 B144

LM30:YSP801-4B14

Motor

1

12

LM20 30 -41

Big chain pulley Z=59

2

29

LM20 30 -33B

Lower bearing seat

1

13

GB1243.1-83

Chain

2

30

LM20 30 -07

Bottom plate

1

14

LM20 30 -41

Chain pulley Z=18

1

31

LM20 30 -12

Guiding wheel

2

15

LM20 30 -32

Belt pulley seat

1

32 Rubber foot

4

16

LM20 30 -38

Big belt pulley

1

33

LM20 30 -31

Small pulley Z=20

1

17

GB278-82

Bearing 80204

2

LM40 LM50

9

9. ONE YEAR PARTS WARRANTY

iMettos warrants to the original purchaser of every new iMettos product, under normal and proper use and maintenance

service as specified by iMettos and upon proper installation and start-up in accordance with the instruction packet

supplied with each iMettos unit. iMettos’ obligation under this warranty is limited to a period of one (1) year from the date

of original installation.

WARRANTY CLAIMS

All claims for parts must be made directly through iMettos. All claims should include:

Personal Details: Products Details:

Your name: Model number:

Your company: Serial number of the product:

Address: Date of purchase:

Email: Proof of purchase :

Phone:

Pertinent information supporting the existence of the alleged defect.(Such as picture etc.)

Please send the above information to services@imettos.co.uk

Our warranty departments will according to the actual situation and reply you within 24hours.

No.

Part No.

Name of part

Qty.

No.

Part No.

Name of part

Qty. 1 LM40 50 -35

Protective casing

1

18

LM40 50 -35

Washer

1

2

LM40 50 -25

Bowl

1

19 Switch

1

3

LM40 50 -28

Bowl support

1

20

LM40 50 -09

Top cover

1 4 LM40 50 -27

Chain seat d25

1

21 Belt 1 5

LM40 50 -16

Chain pulley

1

22

LM40 50 -18

Small belt pulley

1 6 GB1243.1-83

Chain

1

23

GB281-64

Bearing

2 7 LM40 50 -02

Frame

1

24

LM40 50 -04

Back cover

1 8 LM40 50 -24

Dough arm

1

25

LM40 50 -37

Upper bearing seat

1 9 LM40 50 -19

Shaft

1

26

LM40 50 -06

Locking ring

2

10

LM40 50 -22

Protective plate

2

27

LM40 50 -05

Transmission shaft

1

11

LM40 50 -23

Center rod

1

28

LM40/LM50 :YL1001L1

-4-85

Motor

1

12

GB1243.1-83

Big chain pulley Z=59

2

29

LM40 50 -38

Lower bearing seat

1

13

LM40 50 -17

Chain

2

30

LM40 50 -39

Bottom plate

1

14

LM40 50 -13

Chain pulley Z=18

1

31

LM40 50 -21

Guiding wheel

2

15

LM40 50 -10

Belt pulley seat

1

32 Rubber foot

4

16

LM40 50-12

Big belt pulley

1

33

LM40 50 -31

Bottom chain pulley

Z=19

1

17

GB278-82

Bearing 80204

2

34

LM40 50 -29

Tension chain pulley

Z=19

10

What is not conected by this Warranty

iMettos ’ sole obligation under this warranty is limited to replacement of parts, Subject to the additional limitations

below.

This warranty neither assumes nor authorizes any person to assume obligations other than those expressly covered by this

warranty. This warranty is limited to replacement of parts, and the shipment charge is not included.

No consequential damages. iMettos is not responsible for Economic loss; or special, indirect, or consequential damages,

including without limitation, losses or damages arising from food or product spoilage claims whether or not account of

refrigeration failure.

Warranty is not transferable. This warranty is not assignable and applies only in favor the original purchaser/user to whom

delivered. Any such assignment or transfer shall avoid the warranties herein made and shall avoid all warranties, express or

implied, including any warranty of merchantability or fitness for a particular purpose.

Improperusage. iMettos assumes no liability for parts or labor coverage for component failure or other damages resulting

from improper usage or installation or failure to clean and/or maintain product as set forth in the warranty packet

provided with the unit.

Residential applications: iMettos assumes no liability for parts or labor coverage for component failure or other damages

resulting from installation in non-commercial or residential applications.

Alteration, neglect, abuse, issue, accident, damage during transit or installation, fire, flood, acts of god. iMettos is not

responsible for the repair or replacement of any parts that iMettos determines have been subjected after the date of

manufacture to alteration, neglect, abuse, accident, damage during transit or installation, fire, flood, or act of god.

Improper electrical connections. iMettos is not responsible for the repair or replacement of failed or damaged components

resulting from electrical power failure, the use of extension cords, low voltage, or voltage drops to the unit.

No implied warranty of merchantability or fitness for a particular purpose: there are no other warranties, expressed,

implied or statutory, except the one (1) year parts warranty as described above. These warranties are exclusive and in lieu

of all other warranties, including implied warranty and merchantability or fitness for a particular purpose. These are no

warranty which extend beyond the description on the face hereof.

11

iMettos Limited

www.imettos.co.uk

Loading...

Loading...