IMET M550 User Manual

RADIO REMOTE CONTROL

M550

User’s Manual

No part of this manual may be reproduced in any way without written authorization from IMET. This manual is subject to change

with no further notice. Every possible care has been taken in compiling and verifying the contents of this manual; however, IMET

declines any responsibility deriving from using the manual or from any errors or omissions in the information contained herein.

Furthermore, IMET cannot be held responsible for damages or problems deriving from using non-original accessories or spare

parts. The same applies to any person or company involved in the realization of this manual

M550 ALL1-EN.doc 3nd edition- 04 July 2012

IMET S.r.l. via Fornace no. 8, 33077 Sacile (PN) Italy

Tel +39.0434.7878 Fax +39.0434. 737848

.

IMET - M550 ALL1-EN 1/53

CONTENTS

CONTENTS ............................................................................................................................................................ 2

INTRODUCTION .................................................................................................................................................. 4

1. IDENTIFICATION DATA ......................................................................................................................... 5

1.1. DOCUMENTATION........................................................................................................................................... 6

2. CONVENTIONS USED IN THIS MANUAL ............................................................................................ 7

3. CAUTION .................................................................................................................................................... 7

3.1. RISK ANALYSIS ................................................................................................................................................ 7

3.2. APPLICATIONS ................................................................................................................................................ 7

4. PREVENTIVE MAINTENANCE .............................................................................................................. 8

4.1. ROUTINE MAINTENANCE TO BE CARRIED OUT BY OPERATOR .............................................................................. 8

4.2. MAINTENANCE AND INTERNAL CHECKS ............................................................................................................ 8

5. INSTALLING THE RADIO REMOTE CONTROL ................................................................................. 9

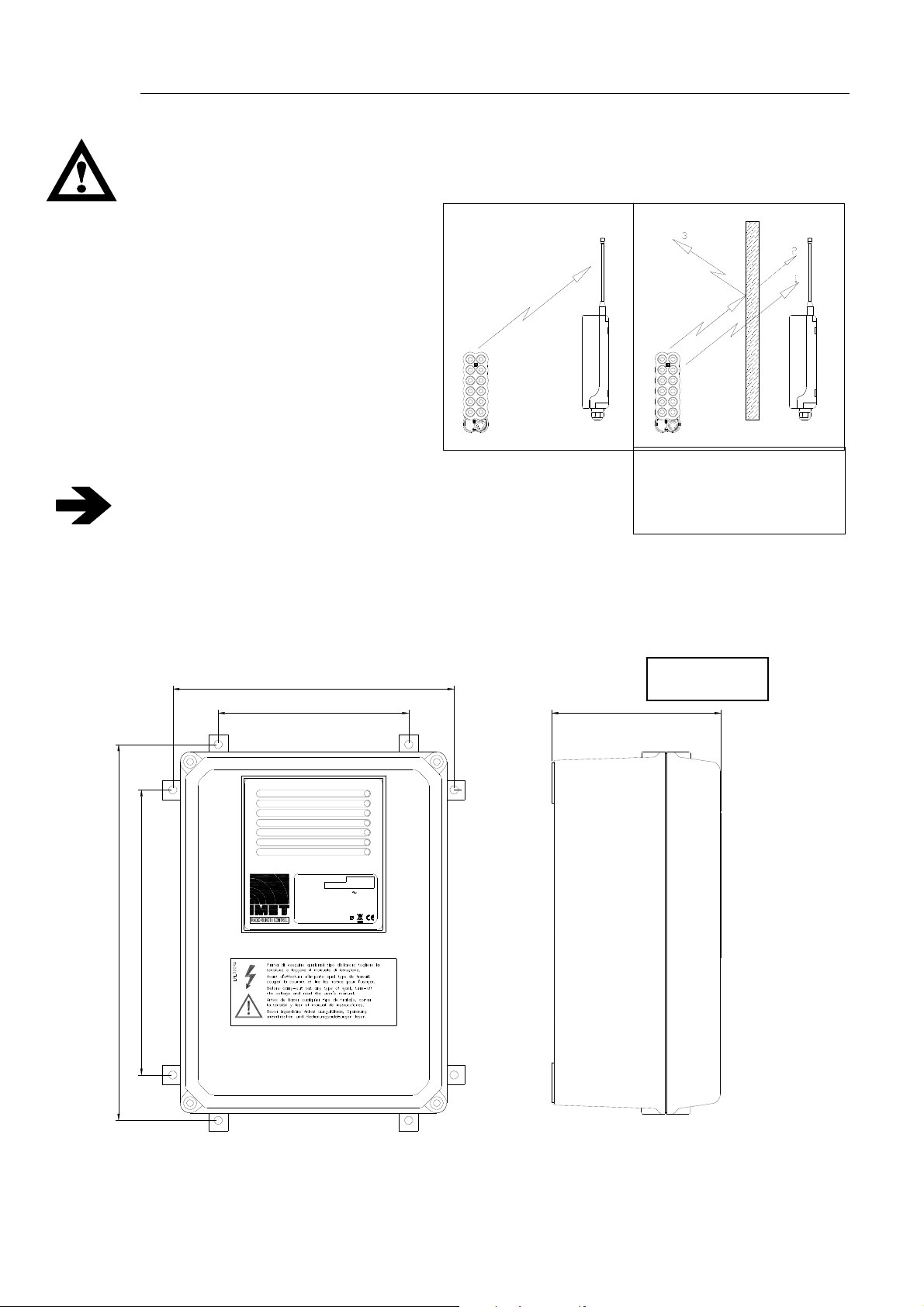

5.1. RECEIVING UNIT DIMENSIONS AND DRILLING DIAGRAM .................................................................................... 9

5.2. CONNECTING THE RECEIVER ......................................................................................................................... 11

5.2.1. INSTALLING THE EXTERNAL ANTENNA ............................................................................................................ 11

5.2.2. STOP (E-STOP) ......................................................................................................................................... 12

5.2.3. SAFETY STOP (S-STOP) .............................................................................................................................. 12

5.3. BASIC FUNCTIONS......................................................................................................................................... 13

5.4. CONNECTION DIAGRAMS OF H RECEIVERS ..................................................................................................... 13

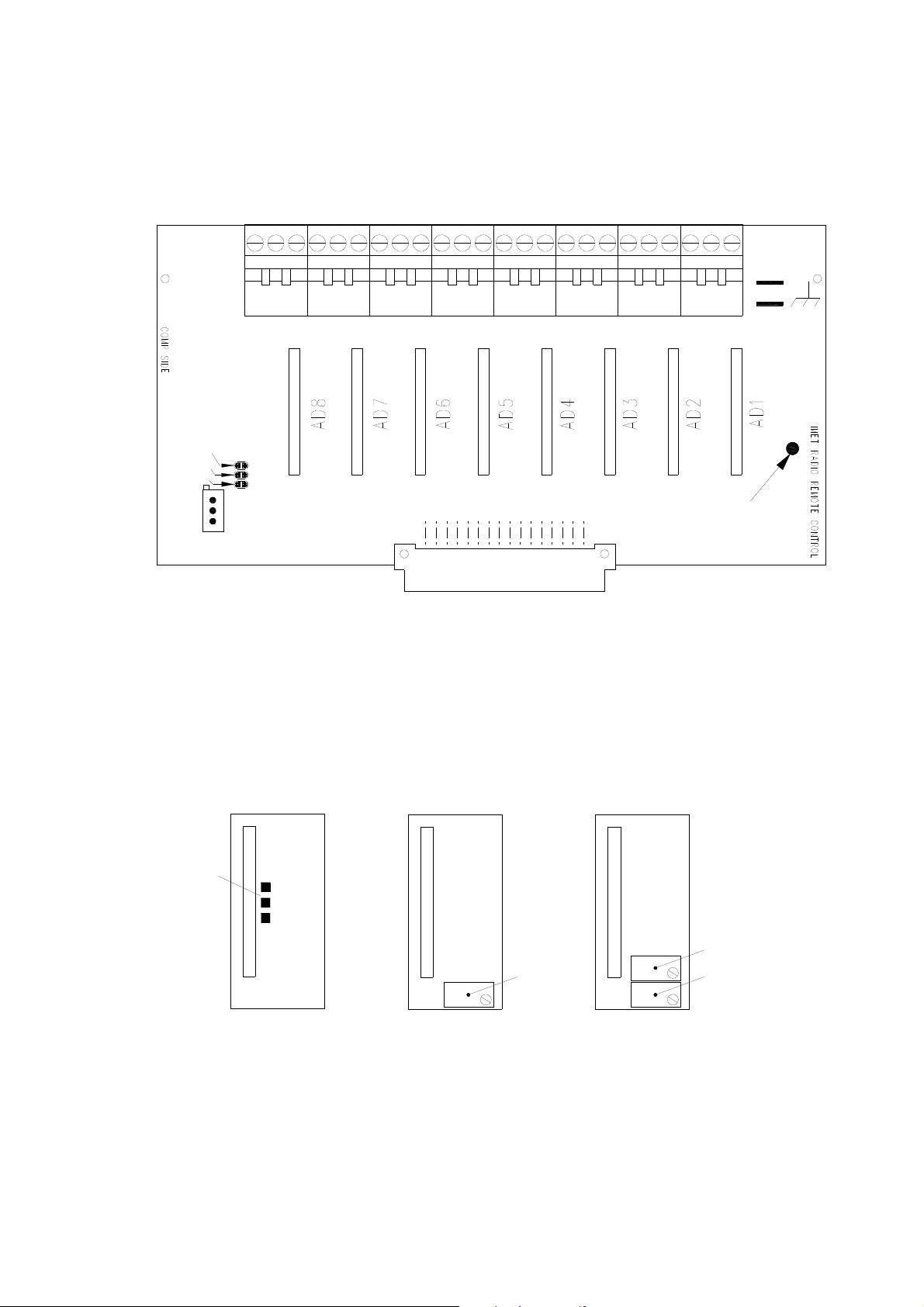

5.4.1. H RECEIVER WITH ANALOG OUTPUT CARD AND DATA FEEDBACK CARD ............................................................ 14

5.4.2. POWER SUPPLY CONNECTIONS OF H-DC AND H-AC RECEIVERS .................................................................... 15

5.4.3. ANALOG COMMAND CARD ............................................................................................................................. 16

5.4.4. LOGIC BOARD ............................................................................................................................................... 17

5.4.5. DATA FEEDBACK CARD ................................................................................................................................. 17

5.4.6. RELAY CONTROL CARDS ................................................................................................................................ 18

5.4.7. POTENTIOMETER CARD ................................................................................................................................. 18

5.5. CONNECTION DIAGRAMS FOR L AND K RECEIVERS ......................................................................................... 19

5.5.1. L-AC VERSION ............................................................................................................................................ 19

5.5.2. L-DC VERSION ............................................................................................................................................. 20

5.5.3. K VERSION ................................................................................................................................................... 21

5.5.4. RELAY CONTROL CARDS FOR L AND K RECEIVERS ........................................................................................... 22

5.5.5. OTHER CONTROL CARDS FOR L-DC AND K-DC RECEIVERS ............................................................................ 23

5.6. SERIAL DATA TRANSMISSION .......................................................................................................................... 24

5.6.1. USER SERIAL (RS232) ................................................................................................................................... 24

5.6.2. SERIAL CONNECTION CABLE .......................................................................................................................... 24

5.7. CONNECTION DIAGRAMS FOR M-AC RECEIVERS ............................................................................................ 25

5.7.1. M-AC RECEIVER .......................................................................................................................................... 25

5.7.2. COMMON CONNECTIONS ON M-AC TRANSCEIVERS ........................................................................................ 26

5.7.3. M-AC TRANSCEIVERS: DATA ACQUISITION CONNECTIONS ............................................................................... 27

6. USING THE RADIO REMOTE CONTROL ........................................................................................... 28

6.1. SAFETY RULES .............................................................................................................................................. 28

6.2. POWERING AND STARTING THE RADIO REMOTE CONTROL ............................................................................... 28

6.3. STOP .......................................................................................................................................................... 28

6.4. TURNING OFF THE REMOTE CONTROL ............................................................................................................ 28

6.5. AUTO POWER-OFF ........................................................................................................................................ 28

6.6. MEANING OF LEDS ...................................................................................................................................... 29

6.7. TRANSMITTING UNIT POWER SUPPLY .............................................................................................................. 30

6.7.1. BATTERY STATE OF CHARGE .......................................................................................................................... 30

6.7.2. CHANGING AND CHARGING THE BATTERY ...................................................................................................... 30

6.8. DIP-SWITCH PROGRAMMABLE OUTPUT CONFIGURATIONS ............................................................................... 31

7. RADIO REMOTE CONTROL OPTIONS ............................................................................................... 32

2/53 IMET - M550 ALL1-EN

7.1. MTRS AND MTRS EASY OPTION ................................................................................................................... 32

7.1.1. TRANSMITTER .............................................................................................................................................. 32

7.1.1.1. DEFINITION OF COMBINATION ................................................................................................................. 32

7.1.1.2. SELECTING THE DESIRED COMBINATION .................................................................................................. 32

7.1.1.3. LOCK PROCEDURE .................................................................................................................................. 32

7.1.1.4. RADIO REMOTE CONTROL START-UP ........................................................................................................ 33

7.1.1.5. UNLOCK PROCEDURE .......................................................................................................................... 33

7.1.1.6. FREQUENCY CHANGE .............................................................................................................................. 33

7.1.2. RECEIVER .................................................................................................................................................... 33

7.1.3. ANOMALIES .................................................................................................................................................. 34

7.2. DSC OPTION ............................................................................................................................................... 34

7.3. IREADY OPTION .......................................................................................................................................... 35

7.3.1. WARNINGS ................................................................................................................................................... 35

7.3.2. TRANSMITTER ............................................................................................................................................... 35

7.3.3. RECEIVER .................................................................................................................................................... 35

7.3.4. OPERATION ................................................................................................................................................. 36

7.3.5. TECHNICAL CHARACTERISTICS ...................................................................................................................... 37

8. CHANGING THE OPERATING FREQUENCY .................................................................................... 38

8.1. BEFORE CHANGING FREQUENCY ................................................................................................................... 38

8.2. CHANGING FREQUENCY ................................................................................................................................ 38

8.3. AVAILABLE FREQUENCIES ............................................................................................................................. 39

9. TROUBLESHOOTING ............................................................................................................................ 40

9.1. MALFUNCTIONS IN THE TRANSMITTER’S STOP CIRCUIT ................................................................................. 41

9.2. PASSIVE EMERGENCY .................................................................................................................................... 41

9.3. TECHNICAL ASSISTANCE ............................................................................................................................... 41

10. TECHNICAL SPECIFICATIONS ........................................................................................................... 42

10.1. WAVE TRANSMITTER .................................................................................................................................... 43

10.2. THOR AND ZEUS TRANSMITTERS ................................................................................................................. 43

10.3. S1, S2 AND G4 TRANSMITTERS ...................................................................................................................... 43

10.4. M8 TRANSMITTER ......................................................................................................................................... 43

10.5. H RECEIVERS ................................................................................................................................................ 44

10.6. L RECEIVER .................................................................................................................................................. 45

10.7. K RECEIVER.................................................................................................................................................. 46

10.8. M-AC RECEIVERS ......................................................................................................................................... 47

10.9. CB5000-AC, CB5000-DC BATTERY CHARGERS FOR WAVE TRANSMITTERS ................................................... 49

10.10. CB3600-AC, CB3600-DC BATTERY CHARGER FOR THOR AND ZEUS TRANSMITTERS ................................... 49

10.11. CB6000-AC, CB6000-DC BATTERY CHARGER FOR S1, S2 AND G4 TRANSMITTERS ........................................ 50

11. RADIO REMOTE CONTROL SPARE PARTS LIST ............................................................................. 51

12. DISPOSAL ................................................................................................................................................ 52

ANNEXES ............................................................................................................................................................ 52

ANNEX A

ANNEX B

ANNEX C

ANNEX D FOR K-DC RECEIVERS .............................................................................................................................. 52

OTHER ANNEXES ...................................................................................................................................................... 52

13. DECLARATION OF CONFORMITY 0470 .......................................................................................... 53

IMET - M550 ALL1-EN 3/53

INTRODUCTION

The M550 family is the result of IMET’s many years’ experience in the production of radio remote

controls. IMET radio remote controls are advanced instruments designed and built using state-of-theart technology.

IMET M550 radio remote controls are available in a large number of versions for any application. They

are easy to install and they become an integral part of any machine that can be operated by remote

control.

IMET radio remote controls come in many

versions: simple units with single transmission

and digital controls (ON/OFF), or more complex

units with digital/analog controls, CAN-bus and

dual transmission (data-feedback option).

The practical, ergonomic control panel lets you

manage all machine functions and perform the

most difficult operations from a safe position.

The units are easily identified by the ID code

printed on the nameplate affixed to every unit.

The meaning of the ID codes is shown in the

tables on pages 5 and 6.

The casings are made of shockproof plastic to

guarantee complete functionality even in the

toughest operation conditions.

M550 portable transmitters are equipped with a

removable, rechargeable sealed battery,

ensuring continuous operation over long work

shifts even in extreme environmental conditions.

The frequency synthesis radio section (PLL) lets

you change the frequency of the transmission

channel directly on the control panel.

Continuous, encoded radio transmission is used:

the receivers are designed to recognize control

signals coming from transmitters having the

same ID code. Signals coming from other

transmitters are ignored. . In the presence of

interference, bad reception or interruption of the

radio signal, the receiver automatically puts itself

in stop status, that involves opening the E-STOP

circuit (clause 9.2.7.3 EN 60204-32).

Every radio remote control is designed and built in conformity with the European Directives and with

the relevant standards and can be used to set up a wireless control station complying with the strictest

safety requirements.

4/53 IMET - M550 ALL1-EN

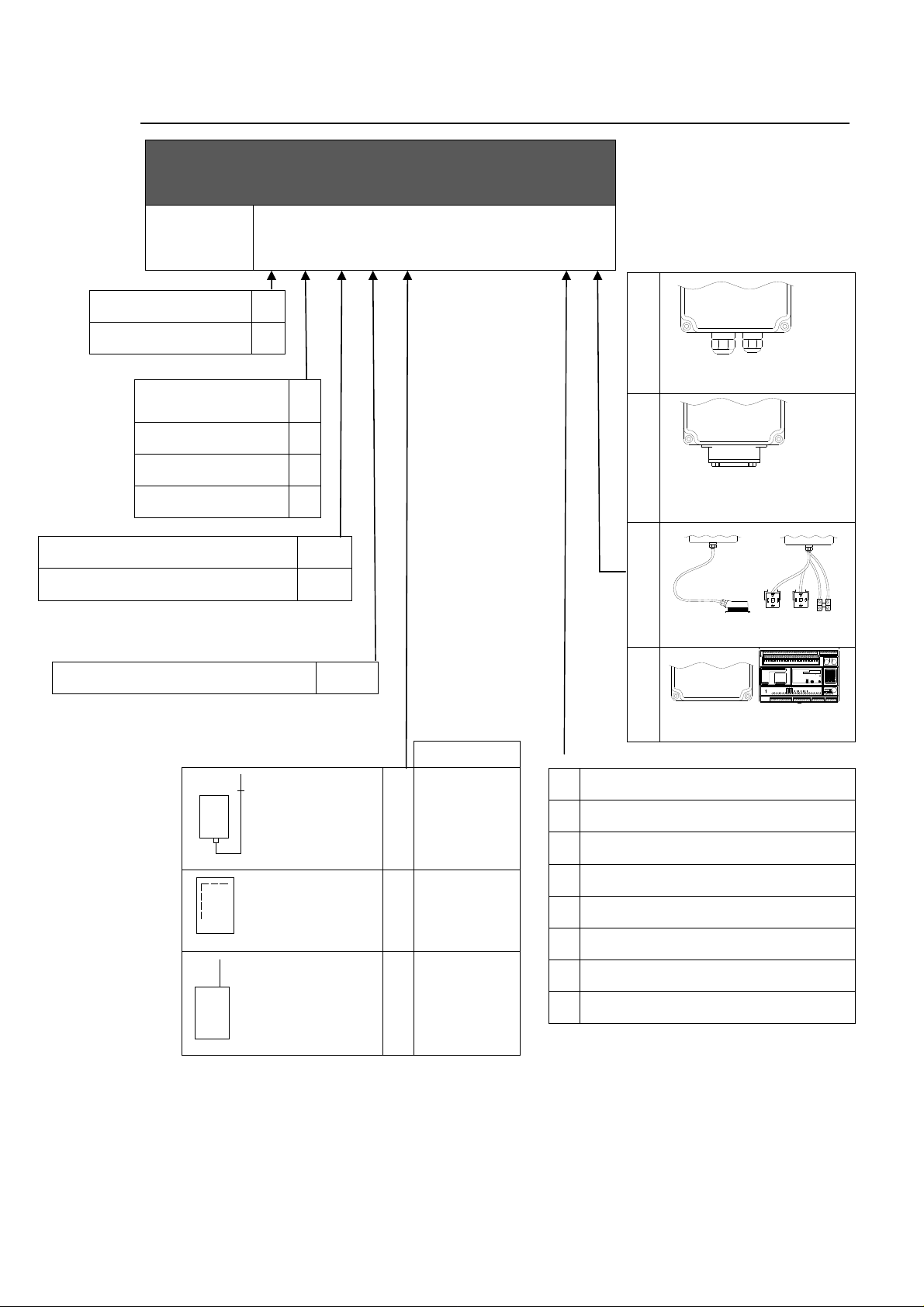

1. Identification data

M550

Single transmission

Dual transmission

Integrated circuit

board

Modular circuit board

DIN rail

BUS receiver

S

D

RECEIVING UNIT ID

L

H

M

K

H

Cable clamp output

I

Recessed multipolar plug

output

Alternating current power supply

Direct current power supply

Project reference number

External antenna

Internal antenna

AC

DC

nnnn

Version

L and K

O

H

M

L and K

I

H

L-AC only

S

L

Cable + plug output

Unwired output

M

24V AC power supply

A

48V AC power supply

B

55V AC power supply

C

110V AC power supply

D

230V AC power supply

E

Power supply selectable from A to E

F

18-28V AC power supply

G

B1B2B3B4B5B6B7B8A1A2A3A4A5A6A7

C1C2C3C4C5

LB534

ANT

T 5A L250VT 5A L250V

LB309

A8

TRX Unit Mod. M550D MAC

LB304

Serial no.

Supply AC 13 - 24V 50/60Hz

13 - 24VSupply DC

Power

1,2A 20VA

Radio Model M550D - UHF ISM Band

DATA ERROR CH. A

EMERGENCY CH. A

POWER SUPPLY

EMERGENCY CH. B

DATA ERROR CH. B

WORKING

RF BUSY

0470

LB305

LB306

T 1.25A L250V

13 - 24V

ACK

RTS

RXD

TXD

ERROR

STROBE

AD OUT 8

AD OUT 7

AD OUT 6

AD OUT 5

GND

OUT VREFD0D1D2D3D4D5D6D7

+VIN

GND

AIN1

AIN2

AIN3

AIN4

+5V

LN

747372717069686766656463626160595857565554535251

7576 7778 79

LB422

12-28V DC/AC power supply

N

Whip antenna

IMET - M550 ALL1-EN 5/53

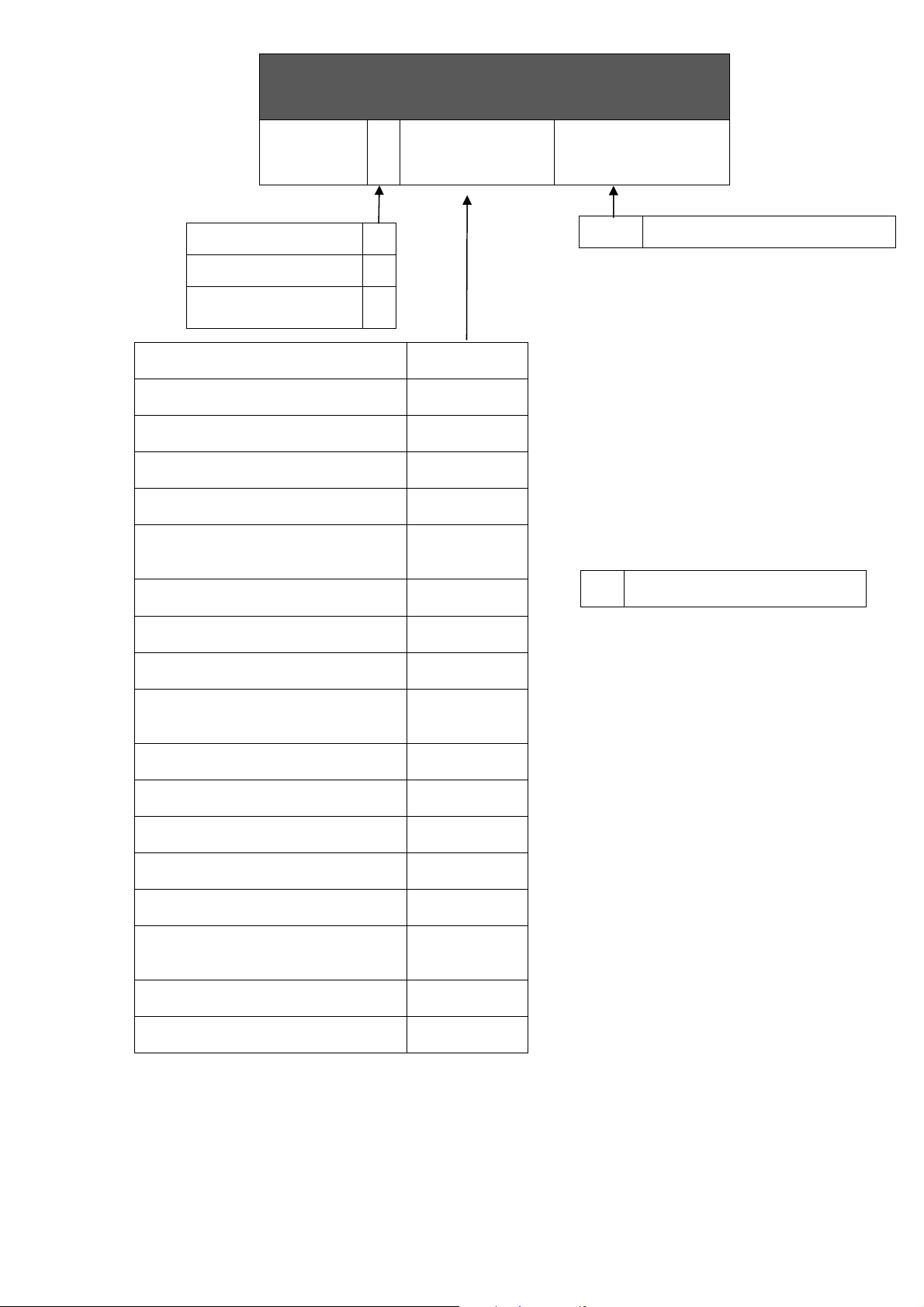

TRANSMITTING UNIT ID

M550

Pushbutton transmitter with 12

buttons + Start/Stop

Pushbutton transmitter with 10

buttons + Start/Stop

Pushbutton transmitter with 8

buttons + Start/Stop

Pushbutton transmitter with 6

buttons + Start/Stop

Pushbutton transmitter with 4

buttons + Start/Stop

Transmitter in THOR casing with

buttons, toggle switches and

potentiometers

Transmitter in THOR casing with

single axis joysticks

Transmitter in THOR casing with

single axis and dual axis joysticks

Transmitter on THOR casing with

dual axis joysticks

Transmitter in ZEUS casing with

buttons, toggle switches and

potentiometers

Transmitter in ZEUS casing with

single axis joysticks

Transmitter in ZEUS casing with

single axis and dual axis joysticks

Transmitter in ZEUS casing with

dual axis joysticks

Transmitter on DIN rail powered

from power panel

Transmitter on S casing with toggle

switches and buttons

Transmitter in S casing with

selectors, buttons and

potentiometers

Transmitter in G casing, compact

version

Transmitter in G casing, standard

version

Single transmission

Dual transmission

Transmission exclusively

by way of cable

S

D

F

WAVE L12

WAVE L10

WAVE S8

WAVE S6

WAVE S4

THOR NJ

THOR M#

THOR X#

THOR B#

ZEUS NJ

ZEUS M#

ZEUS X#

ZEUS B#

M8

S1

S2

G4S

G4L

nnnn

# =

Project reference number

1 to 8 joysticks, depending on

the type of joystick and casing

1.1. Documentation

All IMET radio remote controls are accompanied by the following documents:

• User’s Manual (the annexes are an integral part of the manual)

• Warranty Certificate

If any documents are missing, please contact IMET and provide the unit’s serial number.

6/53 IMET - M550 ALL1-EN

2. CONVENTIONS USED IN THIS MANUAL

Warning: This symbol indicates instructions to be strictly followed for the radio remote control to

work properly.

Danger: This symbol indicates important information on avoiding dangerous situations when using

the radio remote control.

Note: This symbols indicates useful suggestions for the proper use of the radio remote control.

3. CAUTION

READ THE INSTRUCTIONS CAREFULLY BEFORE INSTALLING THE RADIO REMOTE

CONTROL! FAILURE TO APPLY ANY OF THE PROCEDURES DESCRIBED IN THIS MANUAL

MAY LEAD TO INJURIES TO PERSONS OR DAMAGES TO PROPERTY.

NO PART OF THE RADIO REMOTE CONTROL SHOULD BE USED AS A SPARE PART FOR

OTHER RADIO REMOTE CONTROLS.

Follow the local laws on safety and workplace accident prevention. All the regulations on using radio

remote controls for industrial machinery MUST BE OBSERVED AT ALL TIMES.

IMET accepts no responsibility for the unlawful use of the radio remote control.

3.1. Risk analysis

It is necessary to evaluate the risks, in order to establish the safety and health safeguard requisites

concerning the machine with radio remote control use. A risk analysis must be carried out when

deciding whether an application can be radio controlled. It should be carried out by qualified

personnel, who assume all the relevant responsibilities.

IMET accepts no responsibility for failure to carry out a proper risk analysis.

A possible loss of communication between the transmitter and receiver, caused by disturbances or

electromagnetic interferences, has to automatically block the radio command (clause 9.2.7.3 EN

60204-32). This implies a new procedure of starting the machine, so this blockage should be

considered a foreseen condition

3.2. Applications

The most common radio remote control applications regard lifting or carrying apparatus such as tower

cranes, bridge cranes, truck cranes and concrete pumps. Other applications are possible provided the

following conditions are observed.

Do not use the radio remote control in environmental and electrical conditions other than those

specified in Chap. 9. Do not use the radio remote control in environments that are required to be

explosion-proof. The radio remote control should be installed by qualified personnel following the local

regulations.

Keep this manual and the warranty certificate (filled out in every part) in a safe place.

IMET - M550 ALL1-EN 7/53

4. PREVENTIVE MAINTENANCE

Before performing any maintenance operation, turn off the power to both the receiving unit

and the machine and remove the battery from the transmitter.

• Do not expose to heat sources

• Avoid prolonged exposure to direct sunlight

• Do not wash with water under pressure or dip the device in water

• Avoid contact with oil or solvents

• If the device has been opened for any reason, make sure all the seals and gaskets are in place

when closing

To keep you radio remote control in good working order, regularly clean it using a brush and a damp

cloth. Do not use alcohol or solvents: they might damage the components and the casing.

4.1. Routine maintenance to be carried out by operator

Periodically clean the outside of the receiving and transmitting units. Dirt deposits can hinder the

functioning of buttons, toggle switches and manipulators.

Apply special care to the STOP button, keeping it clean and making sure it works with no difficulty.

Remove any traces of oxidation from the battery contacts.

Check the casing and the components for cracks or apparent damages.

All rubber parts, buttons, seals and gaskets should show no sign of tearing.

Damaged components should be immediately replaced to prevent humidity or dirt from penetrating

and jeopardizing the safe operation of the radio remote control.

4.2. Maintenance and internal checks

After every year of use we recommend carrying out a general inspection on the radio remote control

(to be performed by qualified personnel).

Open the housings of the transmitting and receiving units and make sure:

• that the gaskets are in order

• that the cable clamps are efficient

• that the connection terminal screws and the connector couplings are tight

• that the electronic boards are securely fastened

• that the fastening screws of all components are tight

Although IP65 units are hermetically sealed, dust and humidity may accumulate over time when

working in particular conditions. Carefully remove any foreign matter.

When closing the transmitting unit, apply special care to the casing’s sealing, in order to prevent the

infiltration of humidity.

Power on the device, being careful not to touch any live parts in the receiving unit, and perform the

following tests:

• Check the functioning of all the controls.

• Verify that the STOP circuit intervened correctly. By pressing the STOP button, during operation,

relay contacts A and B, of the E-STOP circuit must be opened

• Any broken parts must be replaced with original s pare parts, in order to keep the characteristics of

the radio remote control unchanged. See list of parts that can be replaced in Chapter 11

8/53 IMET - M550 ALL1-EN

5. INSTALLING THE RADIO REMOTE CONTROL

We recommend following the instructions below to set up a properly operating radio remote control

system.

The radio remote control should be installed by qualified personnel only.

Install the receiving unit,or its antenna, in case of versions with an external antenna, in the line

of sight of the transmitting unit, with

no electromagnetic shielding. To

improve the operating range if the

antenna is integrated, do not install

the unit on metal surfaces, if

possible.

F

R

Do not bypass the machine’s safety

systems; follow the manufacturer’s

instructions.

Do not install the receiving unit too high

above the ground (10÷20 metres). At

S

T

P

O

O

P

E

S

T

T

E

R

these heights the unit may receive local

radio signals that can disturb

S

R

E

T

S

E

E

S

T

E

R

RECOMMENDED

transceiving operations.

To prevent water infiltrations, install the receiving unit vertically,

with the cable clamps and any connections at the bottom, as

shown in the figure.

ANTENNA ANTENNA

F

R

S

T

P

O

O

E

P

T

S

T

E

R

S

R

E

T

S

E

E

S

T

E

R

1 Non-attenuating obstacle

2 Partially attenuating

obstacle

3 Shielding obstacle

In case of strong mechanical vibrations, place a rubber shock-absorber between the machine and the

receiver. (dampers).

M-AC receivers and M8 transmitters must be fastened to DIN rails inside a cabinet provided with a

locked door preventing unauthorized access.

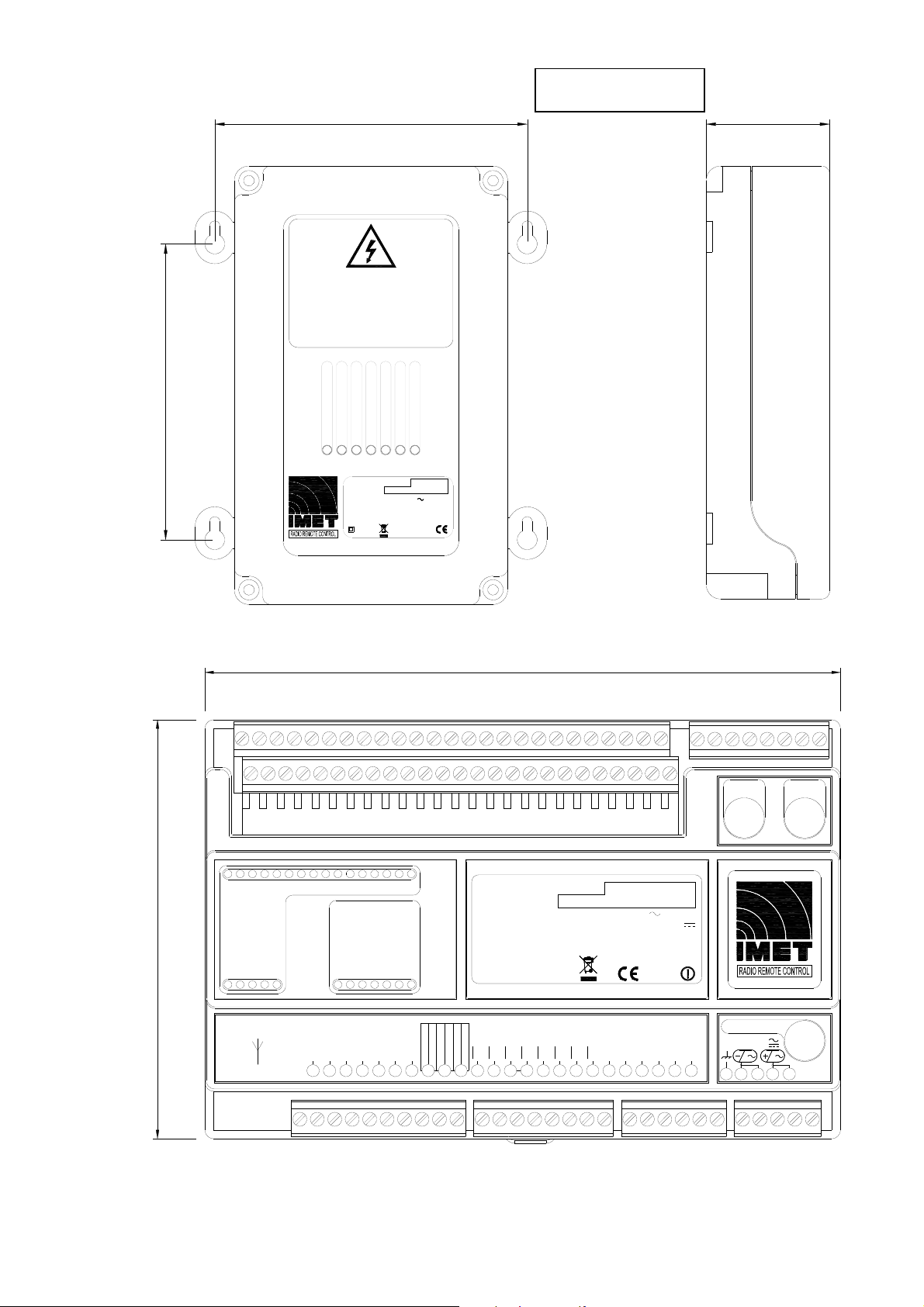

5.1. Receiving unit dimensions and drilling diagram

H version

131

290

220

Data Error ch. B

Passive Emergency ch. B

Data Error ch. A

Passive Emergency ch. A

RF Busy

Power Supply

Working

217

147

RX Unit Mod. M550S HAC

Serial no.

Supply

24/48/55/110/230V 50/60 Hz

Power

Class Protection

Radio Model

M550S - UHF ISM Band

Imax=0.9A 20VA

IP65

LBL550R1

IMET - M550 ALL1-EN 9/53

L and K versions

153

162

Prima di eseguire qualsiasi tipo di lavoro, togliere

la tensione e leggere il ma n uale di istruzione.

Avant d'effectuer n'importe quel type de travail,

couper la courant et lire le notice pour l'usager.

Before carrying-out any type of work, turn-off

the voltage and read the user's manual.

Bevor irgendwelche Arbeit ausgefuehrt wird,

Spannung unterbrechen und

Bedienungsanleitungen lesen.

Data Error ch. A

Data Error ch. B

Passive Emergency ch. B

Passive Emergency ch. A

RF Busy

Power Supply

RX Unit Mod. M550S LAC

Serial no.

Supply

24/48-55/110/230V

Power

Class Protection

Radio Model

Imax=0.9A 20VA

M550S - UHF ISM Band

64

Working

50/60Hz

IP65

The dimensions correspond to 14 mod. DIN.

B1B2B3B4B5B6B7B8A1A2A3A4A5A6A7

A8

120

DATA ERROR CH. A

EMERGENCY CH. A

POWER SUPPLY

EMERGENCY CH. B

DATA ERROR CH. B

AIN1

GND

WORKING

+VIN

TXD

ERROR

C1C2C3C4C5

LB534

ANT

+5V

AIN4

RF BUSY

AIN2

AIN3

182

TRX Unit Mod. M550D MAC

Serial no.

Supply AC 13 - 24V 50/60Hz

Power

Radio Model M550D - UHF ISM Band

LB305

LB306

RTS

RXD

ACK

STROBE

D6

D7

D3

D4

D5

D0

D1

D2

T 5A L250VT 5A L250V

LB309

LB304

13 - 24VSupply DC

1,2A 20VA

0470

T 1.25A L250V

13 - 24V

AD OUT 8

AD OUT 7

AD OUT 6

AD OUT 5

GND

OUT VREF

747372717069686766656463626160595857565554535251

75 767778 79

LN

LB422

10/53 IMET - M550 ALL1-EN

5.2. Connecting the receiver

Do not perform any operation until the equipment is powered off.

The power supply for the radio remote control should be located downstream from the machine’s main

switch.

Connecting to the distribution network directly is prohibited. The network disconnecting

switch foreseen for the distribution network must be equipped w ith a device protecting from

unauthorised closing (padlock

The connection between the receiving unit and the machine should always be REMOVABLE

. If the

connection is made directly on the terminal board inside the machine, a multipolar connector should

be used so that the receiver can be disconnected and the original wired controls restored at any time.

The wire connections between the receiving unit and the machine should respect Standard EN60204.

The wires must have a cross-section of at least 0.75 mm

2

and must be self-extinguishing.

If possible use ferrules for conductor ends, and make sure that the terminals are fastened tightly.

Consult the transmitting unit controls diagram (Annex A) and the receiving unit wiring diagram to

identify the equivalent actuators in the two units.

Be sure to note the supply voltage when connecting the receiving unit.

In versions H-AC and L-AC, the fuse current must be adjusted to the supply voltage.

After installing, test the radio remote control and the machine to make sure they work as

expected. In addition, it is very important to make sure that the STOP circuit works properly.

Pressing the STOP button during normal operation should make the contacts of relays A and B

in the E-STOP circuit open.

Lastly, fill in the sheet showing the connection diagram between the receiving unit and the machine

and write down the date of installation in the box on page 47 of this manual.

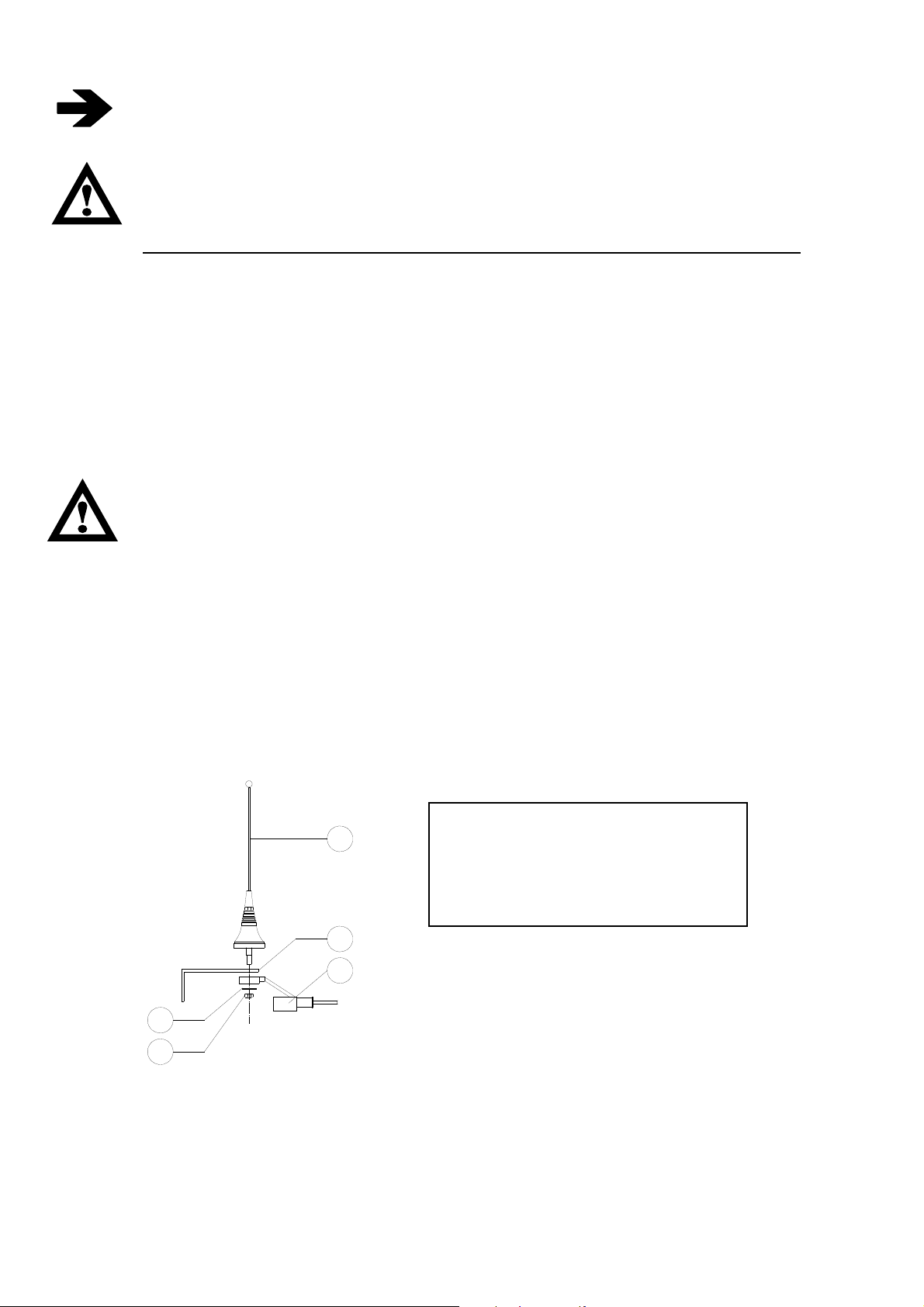

5.2.1. Installing the external antenna

A properly installed antenna is essential for a good operating range. Install the antenna outside at the

highest and most visible point, far from metal structures. Use a tuned antenna only, and connect it to the

receiver using an RG58 coaxial cable (impedance 50Ω). For M550S M8 and M550D M8 type

transmitters only use the antennas supplied by IMET, other types of antenna must be approved in

conformity to the ETSI EN 300 200-2 standard

1

2

SYMBOLS

1 Antenna whip

2 Fastening bracket

3 RG58 cable with protective sheath

4 Washer

5 Locking nut

3

4

5

IMET - M550 ALL1-EN 11/53

5.2.2. STOP (E-STOP)

Connect the contact of the E-STOP circuit so that it commands the coil of the machine’s main line

contactor, and remember that the maximum allowable current is 5A.

Attention: The E-STOP circuit has been designed for category 4 UNI EN 954-1 standard and/or

PLe according to the ISO13849-1 standard. In order to keep this safety category, the relays

must be connected in series (pre-cable standard configuration by IMET) or in parallel ONLY to

manage interruption of the main power supply line (See Example 2).

5.2.3. Safety STOP (S-STOP)

The Safety Stop is an additional safety function. It consists in relay inside the receiver monitored by

the RX logic that can be associated with the commands sent by the transmitter and which in case of

problems automatically stops the receiver, as shown by the status LEDs.

Example 1 (in series to control commands): The Safety Stop introduces a redundancy which activates

the safety function in case the control command relays fail to open.

Example 2 (operating the bypass valve): The Safety Stop can command the drain valve in a hydraulic

machine so that the machine is powered only when a control command is given.

The Safety Stop must not be associated with the bistable selection controls

The risk analysis and safety class are based on Standard UNI EN 954-1 and ISO 13849-1 . The safety

class of each control is shown in Annex B. Take good notice of the maximum currents allowable on

the relay contacts (see Chap. 10).

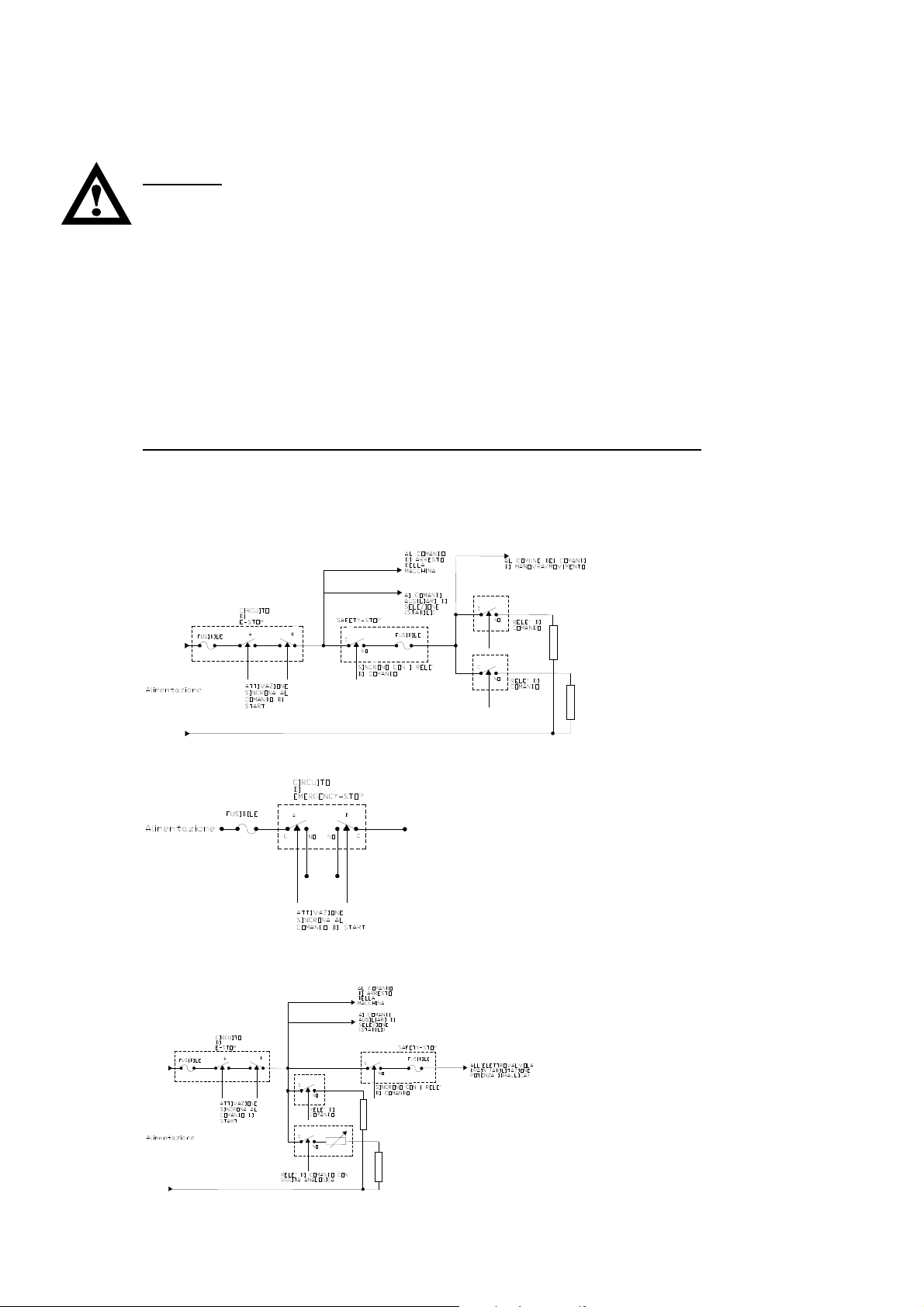

Example of wiring of Safety-Stop relay for AC applications

Alternative for special applications (for L-AC receivers only)

Example of wiring of Safety-Stop relay for DC applications

12/53 IMET - M550 ALL1-EN

5.3. Basic functions

The table below shows the basic functions available on almost all receivers.

Relay Function Typical Uses Remarks

T-STOP The relay is activated for 5 seconds from the moment

the radio remote control is switched off or enters

passive emergency mode.

The T-STOP can be activated at switch-off or with a 2

• Delayed STOP of

combustion engine

• Engine deceleration

second delay.

S-STOP The relay is activated only by an instable command

from a toggle switch, button or joystick

Connected in series

, the function introduces a

redundancy that can be used to increase function

• Enables the drain valve

• Common enabling of control

commands

Relays constantly

monitored by uP.

Opens with a 0.8

second delay

safety

E-STOP The two relays are activated when the radio remote

control is switched on (STOP RELAY cat. 4 UNI

EN954-1 e PL e ISO13849-1) and stay active until a

STOP command intervenes (pressing the STOP

button or passive emergency)

• Powers the main contactor

in the machine’s control box

• Common power supply for

control commands

• Machine power supply

HORN Horn control relay Warns of potentially hazardous

situations

Relays constantly

monitored by uP

it can be associated

to the first START

START START control relay Powers the machine’s control box

and enables machine Start

function

LAMP Blinker control relay Blinker power supply

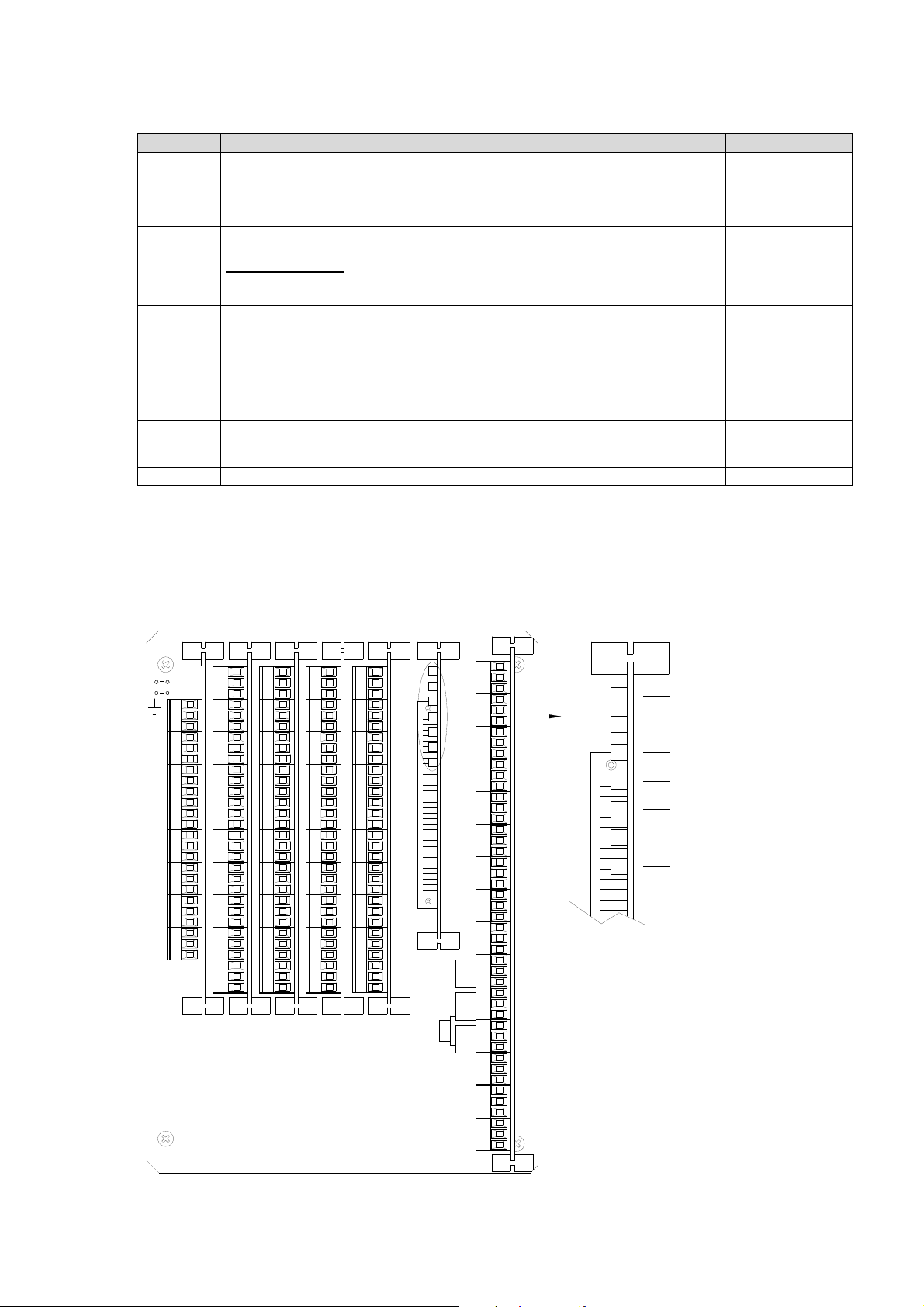

5.4. Connection diagrams of H receivers

Receiving unit version H is provided with 7 slots where the control relay cards, the analogue output

cards and the data feedback card are plugged in. Slot A includes, as well as the group A controls, the

basic functions in the table above.

LOGICA

+

SLOT F

SLOT E

SLOT D

SLOT B

RADIOSLOT C

SLOT A

AD5AD6AD7AD8AD1 AD2 AD3 AD4

C

NC

10

89

7

6

5

4

3

12

10

NO

NC

NO

C

89

NC

NO

C

NC

NO

C

67

NC

NO

C

5

NC

NO

C

43

NC

NO

C

NC

NO

C

21

NC

NO

C

NC

NO NO

NC

NO

NC

NO

NC

NO

NC

NO

NC

NO

NC

NO

NC

NO

NC

NO

NC

NO

NC

C

C

C

C

C

C

C

C

C

C

C

NC

106

NO

C

NC

NO

C

89

NC

NO

C

7

NC

NO

C

NC

NO

C

5

NC

NO

C

41

NC

NO

C

3

NC

NO

C

2

NC

NO

C

NC

NO

C

NC

10

NO

CC

NC

NO

C

89

NC

NO

C

7

NC

NO

C

6

NC

NO

C

5

NC

NO

C

NC

NO

C

3

NC

NO

C

214

NC

NO

C

NC

NO

C

NC

A8

NO

C

NC

A7

NO

C

NC

A6

NO

C

NC

A5

NO

C

NC

A4

NO

C

NC

A3

NO

C

NC

A2A1

NO

C

NC

NO

C

NC

NO

C

NO

NO

S-STOP T-STOP

C

C

C

NO

NO

NO

C

NC

NO

C

NC

START HORN E-STOP E-STOP

NO

C

NC

LAMP

NO

In its basic configuration the receiving unit

is supplied with a relay card (on slot A)

and a logic board.

Depending on project specifications, units

may include cards for control groups B, C,

D, E, an analog output card and, in case

of dual transmission, a data feedback

card

Note: On each project the controls are

based on a unique configuration that may

DATA ERROR CH. B

PASSIVE EMERGENCY CH. B

DATA ERROR CH. A

PASSIVE EMERGENCY CH. A

RF BUSY

POWER SUPPLY

WORKING

be changed only by IMET.

IMET - M550 ALL1-EN 13/53

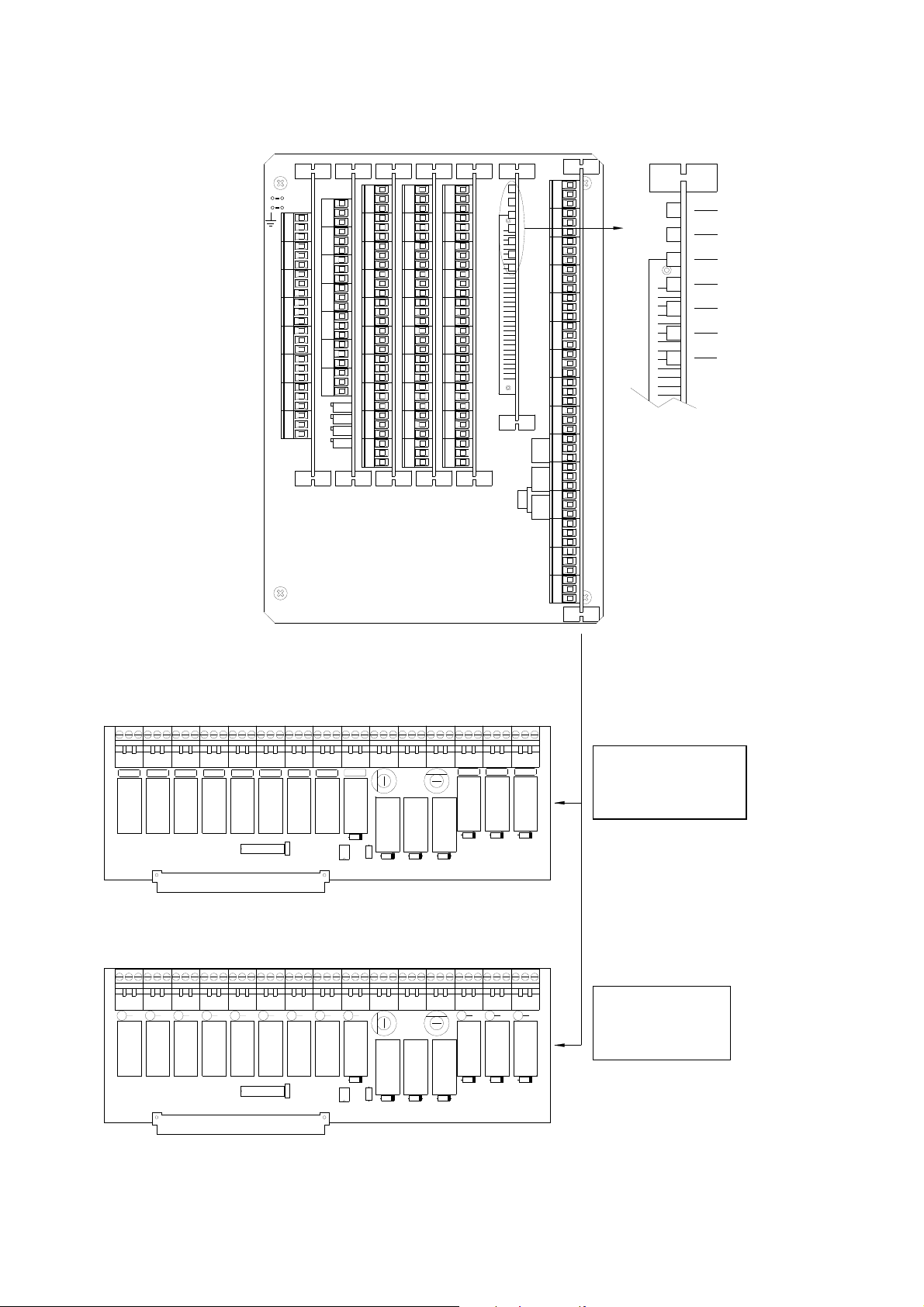

5.4.1. H receiver with analog output card and data feedback card

LOGICA

+

SLOT F

SLOT E

SLOT D

SLOT B

RADIOSLOT C

SLOT A

C

C

NC

10

D0

NO

D1

C

D2

NC

D3

NO

D4

C

D5

89

NC

D6

NO

D7

C

STB

NC

VIN

NO

ACK

C

ERR

67

AD0

AD1

AD2

AD3

GND

+5V

GND

GND

GND

NC

NO

C

5

NC

NO

C

43

NC

NO

C

NC

NO

C

21

NC

NO

C

NC

NO

AD5 AD6 AD7 AD8AD1 AD2 AD3 AD4

C

NC

NC

106789

10

NO

NO

C

C

NC

NC

NO

NO

C

C

89

NC

NC

NO

NO

C

C

7

NC

NC

NO

NO

C

C

6

NC

NC

NO

NO

C

C

5

52341

NC

NC

NO

NO

C

C

NC

NC

NO

NO

C

C

3

NC

NC

NO

NO

C

C

214

NC

NC

NO

NO

C

C

NC

NC

NO

NO

C

NC

A8

NO

C

NC

A7

NO

C

NC

NO

C

NC

A5A4A3 A6

NO

C

NC

NO

C

NC

NO

C

NC

A2A1

NO

C

NC

NO

C

NC

NO

C

NO

NO

S-STOP T-STOP

C

C

C

NO

NO

NO

C

NC

NO

C

NC

START HORN E-STOP E-STOP

NO

C

NC

LAMP

NO

DATA ERROR CH. B

PASSIVE EMERGENCY CH. B

DATA ERROR CH. A

PASSIVE EMERGENCY CH. A

RF BUSY

POWER SUPPLY

WORKING

C

NC

A8 A7 A6 A5 A4 A3 A2 A1

C

NC

C

NO NO

NC

NC

NO

C

NC

NC

NO

A6 A3A4

NC

NC

NO

NO

NO

C

C

NC

NC

NO

NO

NO

A5

NC

NC

NO

NO

C

C

NC

NC

NO

NO

C

C

C

C

C

C

C

NC

NC

NO

NO

T-STOP S-STOP E-STOP E-STOP HORN START LAMP

C

C

NC

NC

NO

NO

A1A2A7A8

NC

NC

NO

NO

C

C

NC

NC

NO

NO

NC

NC

NO

C

C

NC

NC

NO

C

C

C

C

C

C

C

NC

NC

NO

NO

NO

Version for H-AC

receiver

IMET RADIO REMOTE CONTROLM550RST REV00

C

C

NC

NC

NO

NO

NO

LAMPSTARTHORNE-STOPE-STOPS-STOPT-STOP

Version for HDC receiver

IMET RADIO REMOTE CONTROLM550RSA REV02

14/53 IMET - M550 ALL1-EN

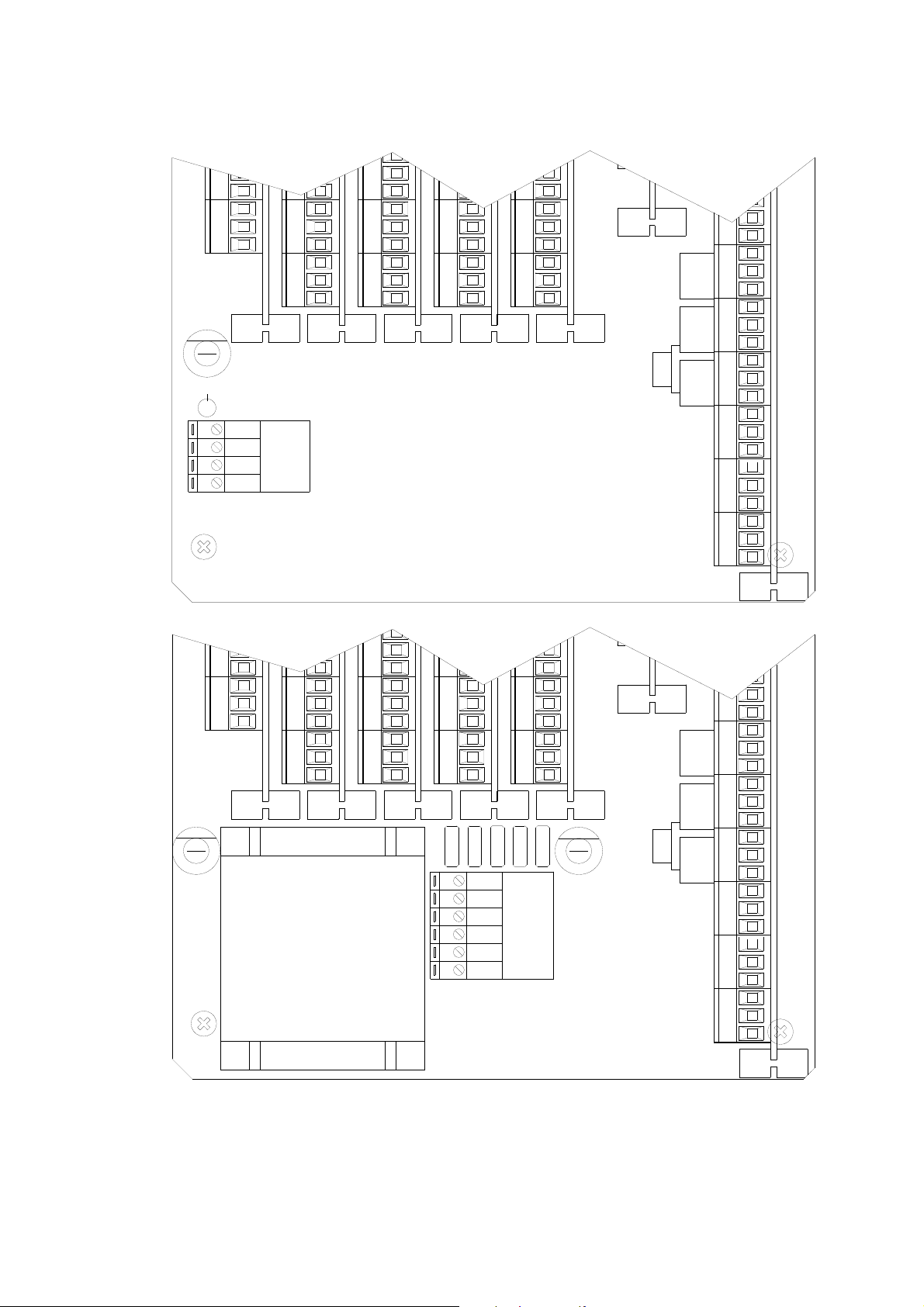

5.4.2. Power supply connections of H-DC and H-AC receivers

NC

NO

F1

1.25AT

+

+

-

-

C

21

NC

NO

C

NC

POWER IN

13 - 24 VDC

C

NC

NO

C

12

NC

NONO

C

NC

NO

C

12

NC

NO

C

NC

NO

C

12

NC

NO

NO

C

NO

NO

S-STOP

C

C

C

E-STOPE-STOPHORNSTART

NO

NO

NO

C

NC

NO

C

NC

NO

C

NC

LAMP

NO

F1

1.25AT

AD1 AD1

NC

NO

C

NC

NO

C

12

NC

NO NO

C

21

NC

NO

C

NC

C

21

NC

NO

C

NC

NO

230V

110V

55V

48V

24V

C

21

NC

NO

C

NC

NO

F2

24-55VAC 1.25AT

110-230VAC 0.63AT

AC

POWER INPUT

N

NO

C

NO

NO

S-STOP

C

C

C

NO

NO

NO

C

NC

NO

C

NC

START HORN E-STOP E-STOP

NO

C

NC

LAMP

NO

IMET - M550 ALL1-EN 15/53

5.4.3. Analog command card

* IN AD8

371 - 1000Hz

131 - 370Hz

50 - 130Hz

* IN AD1, ... ,8 COLLEGATO SOLO PER PWM

T3

T2

JUMPER FREQ. SEL.

T1

FREQ. REG. (PWM)

FOR M550C1

USED ONLY FOR PWM OUTPUT

* IN AD7

OUT AD7

GND

OUT AD8

GND

Control modules

* IN AD6

OUT AD6

GND

* IN AD5

OUT AD5

GND

* IN AD4

OUT AD4

GND

* IN AD3

OUT AD3

GND

* IN AD2

* IN AD1

GND

OUT AD1

OUT AD2

TEST POINT PER

TARATURA FREQUENZA

GND

M550C2: 0-20mA/4-20mA current-operated control

M550C1: PWM current-operated control

M550V: voltage-operated control

M550C2

RANGE SEL.

ANALOG CARD

M550C1 (PWM)

ANALOG CARD

GAIN REG.

M550V SERIES

ANALOG CARD

Vout MAX REG.

Vout MIN REG.

16/53 IMET - M550 ALL1-EN

Loading...

Loading...