IMES S1010 Mk4 Installation & Operating Manual

Prince of Wales Road Tel: + 44 (0) 114 284 1840

Sheffield www.imesint.co.uk

S9 4DZ

United Kingdom

Panel mounting ASCII display

S1010 Mk4

Installation & Operating Manual

Caution: There is a risk of electrical

shock if this instrument is not properly installed

Caution: Risk of danger: Read the whole

manual before you install this meter

Software version F04.01

Dated: 1 May2016

!

Revision:1

1

.

Warranty

We warrant this product against defects in materials or workmanship for a period of three

(3) years from the date of purchase.

In the event of a defect during the warranty period, the unit should be returned, freight (and

all duties and taxes) prepaid by the Buyer to the authorised distributor from where the unit

was purchased.

The Distributor, at its option, will repair or replace the defective unit. The unit

will be returned to the Buyer with freight charges prepaid by the distributor.

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from:

1. Improper or inadequate maintenance by the buyer.

2. Unauthorised modification or misuse.

3. Operation outside the environmental specification of the product.

4. Mishandling or abuse.

The warranty set forth above is exclusive and no other warranty, whether written or oral is

expressed or implied. We specifically disclaim the implied warranties of merchantability

and fitness for a particular purpose.

EXCLUSIVE REMEDIES

The remedies provided herein are the buyer’s sole and exclusive remedies.

In no event shall we be liable for direct, indirect, incidental or consequential damages

(including loss of profits) whether based on contract, tort or any other legal theory.

2

Contents

Warnings 4

Introduction 5

General Description 6

Panel mounting & Installation - Class II 7

Wiring Advice 8

Connections 9

Installation hints for best performance 10-11

Application Notes 12

Language Selection 13

Display Brightness 14

Display Modes 15

Serial Data settings 16-17

Logic Input functions 18

Logic Input connections & Front Buttons 19

Factory defaults 20

Calibration Audit number 20

Scale Factor adjustment 21

Offset Adjustment 22

Menu Timeout adjustment 23

Reverse / Mirror display setting 24

Bootup Routine choices 25

Multi Memory MEM option 26

Error Codes and fault finding 27

Output Options - installing 28

WEEE 29

Equipment Specifications 30

Record of Revisions 31

ASCII Hex codes and displayed characters 32

Signal Levels 33

Special data commands 34

Declaration of Conformity 35

Separate manuals for options

Alarm option settings See Alarm manual *

Analogue output option settings See Analogue manual *

Serial output option settings See Serial manual *

Real Time Clock setting See Serial manual *

* Need a manual urgently?

You can download manuals from our website.

3

Warnings

Please carefully read this manual and all warnings. Install the meter ONLY when you are sure

that you’ve covered all aspects.

Where the product is intended for “UL” installations, removal or

!

!

addition of option boards is not permitted.

Check that the model number and supply voltage suit your application before

you install the meter.

Connect the meter according to current IEE regulations, IEC61010 &

NFPA:70 National Electric Code in USA.

This meter is for Installation class II service only. This means it

has exposed electrical and power terminals. You must install it in a

suitable fire enclosure which will also protect users from electric shock

!

!

!

We designed this meter for Pollution-Degree 2 environments only.

Power supplies to this equipment must have anti-surge (T) fuses rated at 400mA for

230V supply, 400mA for 110V supply or 2A for DC supplies in the range 11-30VDC.

Only Siba fuses in series 189500, cULus listed according to file #E167295 are

accepted for this service under the terms of UL listing. A switch or circuit breaker, clearly

marked as a disconnecting device, must be included close to the installation.

Don’t touch any circuitry after you have connected the meter, because there may be

lethal voltages on the circuit board.

Only adjust on-board switches or connections with the power turned off

Make sure all screw terminals are tight before you switch the meter on.

Only clean the meter’s front with a soft damp cloth. Only lightly dampen with water.

!

Safety First ..............Don't assume anything............. Always double check.

If in doubt, ask someone who is QUALIFIED to assist you in the subject.

4

Do not use any other solvents. The behind-panel case may be cleaned with a dry cloth

only, use no liquid or solvent on it.

Introduction

Please contact us if you need help, if you have a complaint, or if you have suggestions to help

us improve our products or services.

If you contact us about a product you already have, please tell us the full model number and

serial number, so that we can give you accurate and fast help.

This product has a 3 year warranty. We will put right or replace any meter which is faulty

because of bad workmanship or materials. This warranty does not cover damage caused by

misuse or accident.

If you return a unit for repair, please include a detailed description of the problem, and the

name of a contact who we can refer to for any questions. Please mark for the attention of the

QA Department.

IMPORTANT

If this equipment is important to your process, you may want to buy a spare to cover possible

failure or accidental damage in the future.

This is because during factory shutdown periods, you may have to to wait several weeks for

an equivalent replacement, or we may have no stock at the time you urgently need it.

You may also need to pay extra carriage charges if you want a fast, guaranteed courier service.

Warranty repairs or replacements are usually returned with a standard courier service.

We do not offer compensation for losses caused by failure of this instrument.

We thought you’d prefer to know about possible delays and extra charges now, rather than

during a panic. A spare unit could help to avoid these issues.

We always try to improve our products and services, so these may change over time. You

should keep this manual safely, because future manuals, for new designs, may not describe

this product accurately.

We believe these instructions are accurate, and that we have competently designed and

manufactured the product, but please let us know if you find any errors.

5

General Description

This series of meters accepts industrial sensors to allow various physical measurements to

be made, such a weight, temperature, pressure, humidity etc. Different models are available

for different sensor types.

The main function of this series is to give a numeric readout of the variable being monitored.

Most models include an excitation power output, to power the sensor directly.

Various optional output modules are also available to give alarm relay outputs, analogue

output or digital communications, or any combination of these options.

Meters are programmed using front panel pushbuttons. The buttons may be locked with a

rear switch.

Meters have two power supply options : 100-240 VAC or 11-30VDC

These meters are designed to mount into a protective enclosure which will protect users from

contact with power and signal wiring.

These units must be installed fully assembled, and must be installed according to local electrical

installation rules. When properly installed, they provide ingress protection to IP65 / NMA4X

from the front

Safety

Caution: There is a risk of electrical

shock if this instrument is not properly installed

Caution: Risk of danger: Read the whole

!

manual before you install this meter

Obey all safety warnings in this manual, and install the meter according to local wiring and

installation regulations. Failure to follow these guidelines may cause damage to the meter,

connected equipment, or may be harmful to personnel.

Any moving mechanical device controlled by this equipment must have suitable access guards

to prevent injury to personnel if the meter should fail.

6

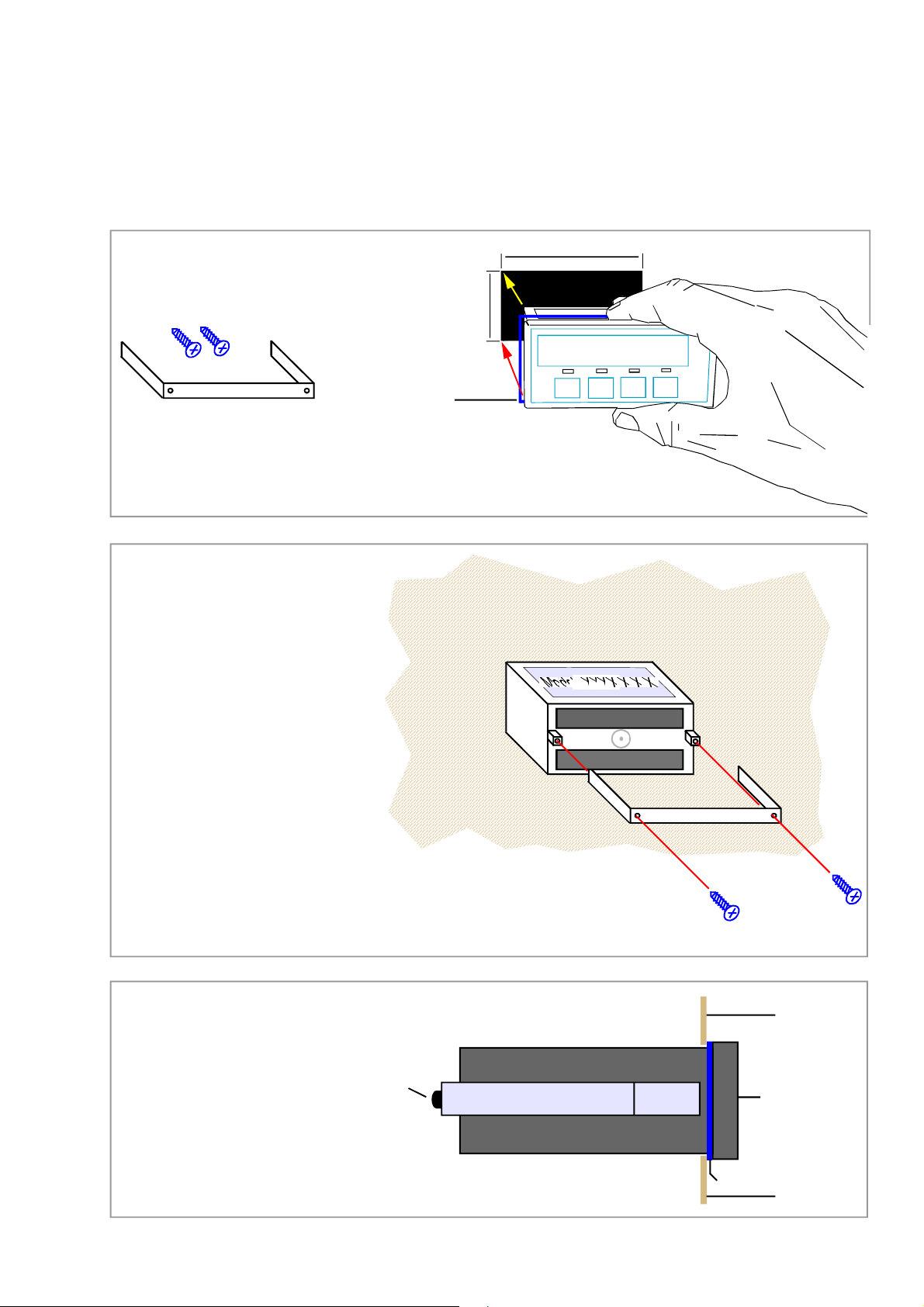

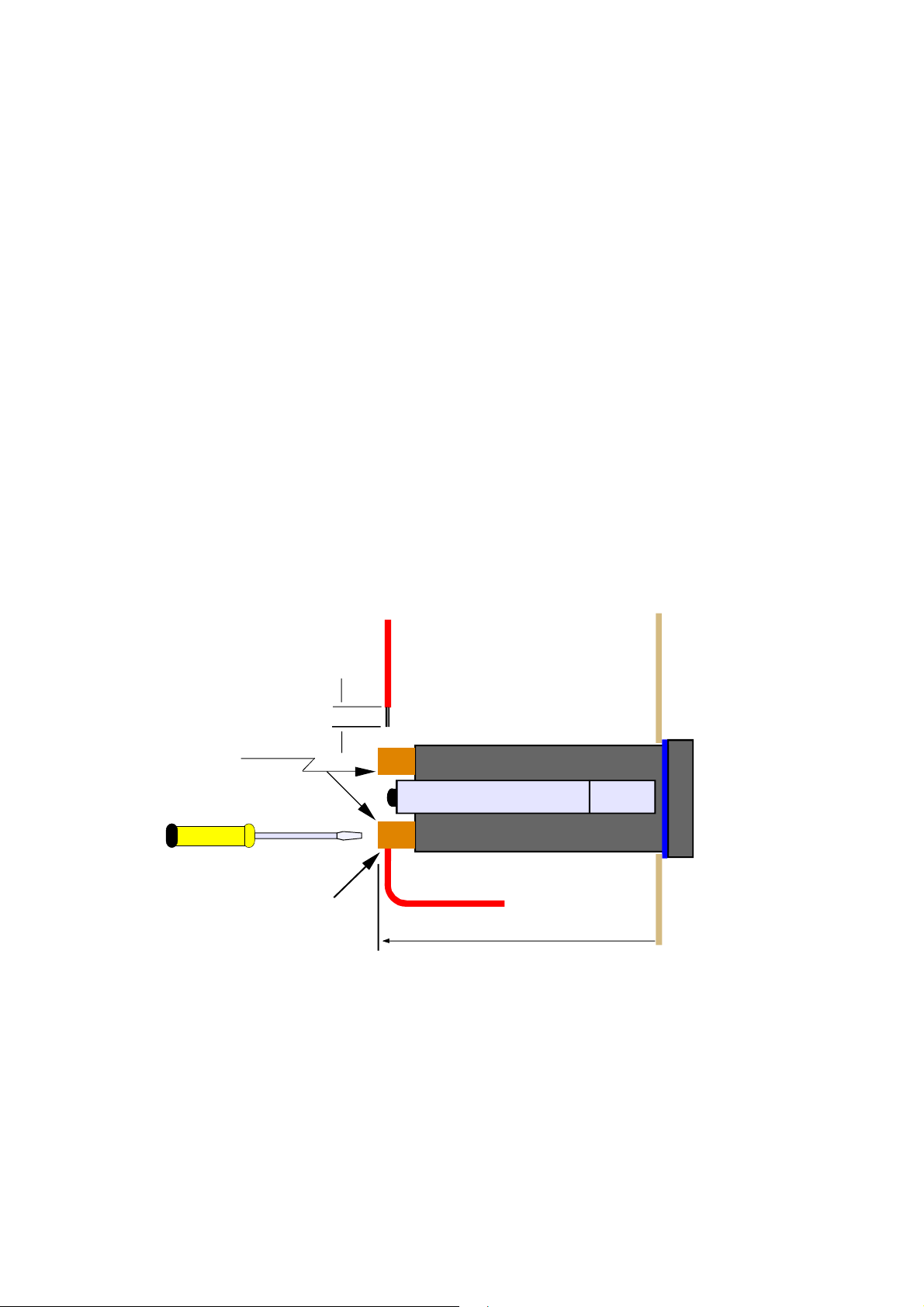

Panel Mounting and Installation - Class II

Install the meters in a suitable protective electrical control enclosure according to local wiring

regulations. See specifications for maximum allowable temperature in enclosure. Allow

adequate air circulation.

Installing into front of panel

Remove the two rear bracket

screws and safely store them

and the U-Bracket for later fitting.

Bracket screws

U-Bracket

45mm +1mm -0mm

Securing into the panel

Re-fit the U-Bracket and tighten the bracket

screws to firmly clamp the meter in place.

Check that the gasket is evenly pinched

between the meter’s front bezel and the

enclosure front

Ventilation

There should be sufficient ventilation in the

enclosure to ensure that the meter’s case is

always kept to less than 60C.

Gasket

92mm +1mm -0mm

Panel cutout

888888

Slide the meter, with gasket

into the panel cutout

Meter Spacing.

Meters should be spaced apart sufficiently

to allow a free flow of ventilation air around

the meters, such that no part of the case will

exceed 60C

Side view of meter installed in panel

Bracket screw (1 of 2)

Left side of meter case

U-Bracket

U-Bracket

Gasket

Bracket screws

Front surface

of enclosure

Front surface

of meter

Front surface

of enclosure

7

Wiring Advice

This meter uses detachable screw terminal connectors. Refer to the wiring diagram on the

following page for the correct positioning of each wire.

The conductors you use must be suitable for the meter’s temperature, current and voltage

rating, which is broadly described as follows:-

Cable Temperature Rating

All cables must be rated for operation up to 90C continuous.

Cable gauge and screw tightness

The connectors on this instrument can accept conductors up to 16 gauge AWG / 1.5mm

c.s.a. The minimum cross sectional area shall be 22 gauge AWG / 0.5mm2 . Tighten screw

terminals to 7.0 lb/in torque / 0.8 Nm torque.

Cable insulation voltage rating

Cables shall have an insulation voltage rating of at least 380V continuous.

2

Wire preparation:

Outside

enclo sure

Strip back

5mm max.

Detachab le

connectors

Terminal screwdiver - 3mm blade

No bare wires exposed

Insid e

enclo sure

Side view of meter

U-Bracket

125mm behind panel

We recommend multi-strand wire, because it withstands vibration better than single strand

cable. Pull the wire firmly after you make the connection to confirm it is tight.

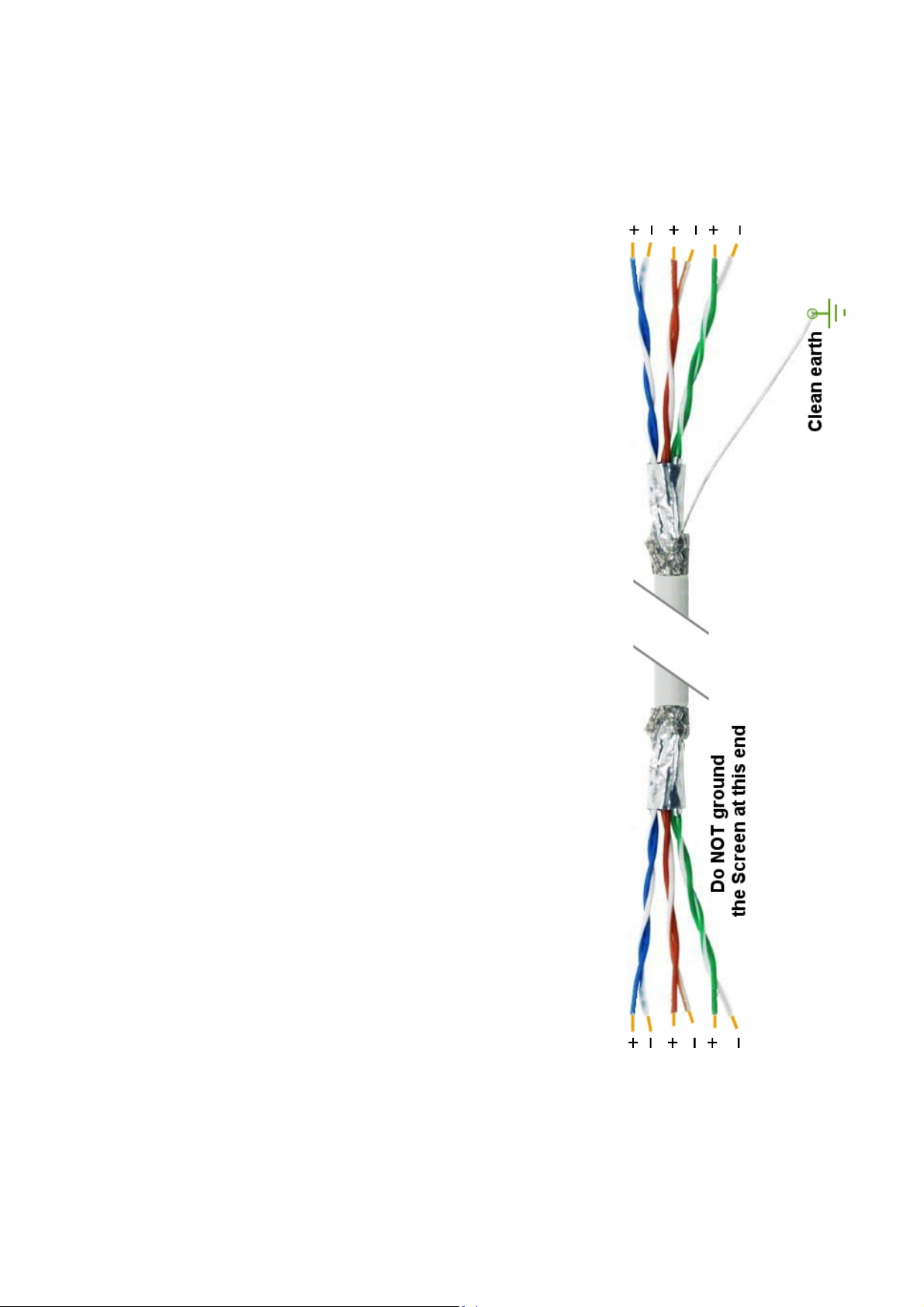

Use screened cable for all signal and control wiring and connect the screen to earth at the

destination end only. Route signal cabling away from power cabling and relay switching

cabling, to avoid electrical noise interference.

8

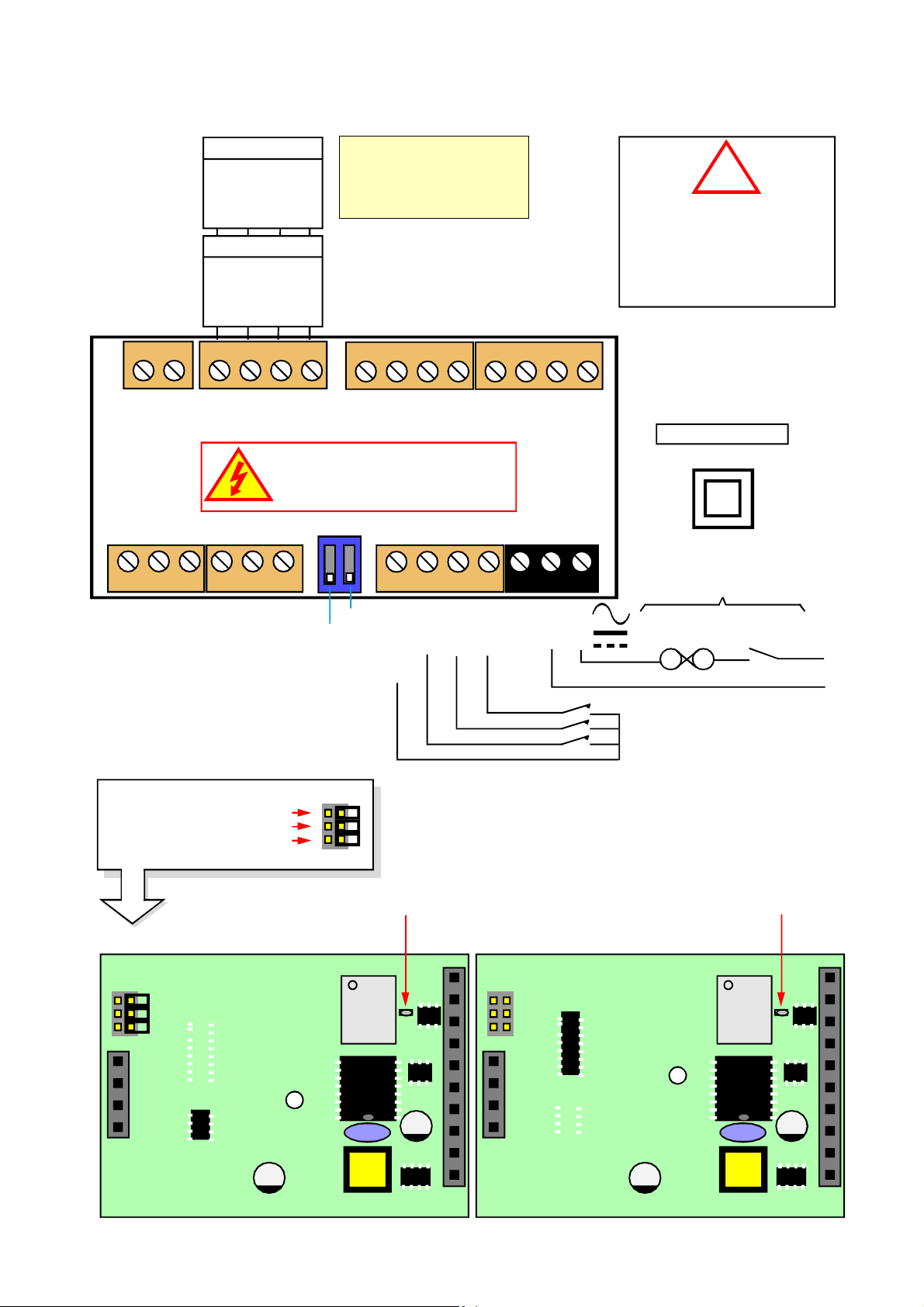

Connections

R S 2 3 2

TxD

RxD

Comm

Enable is used in mode C1

to activate or de-activate the

RS232 or RS485 serial output.

Connect to Comm to continually

transmit data.

Enable

R S 4 8 5

Rated 2A 250VAC Resistive

B

A

Comm

- +

14 15 16 17 18 19 20 21 22 23 24 25 26 27

Analog

o/p option

Serial Data

o/p option

Enable

Warning:

Disconnect all power before

exposing the rear of the meter

Signal I/P & Excitation

1 2 3 4 5 6 7 8 9 10 11 12 13

AL1 AL2 AL3 AL4

0, 2 or 4 Alarm Relay

o/p options

Logic Inputs Power

!

Connectors and options

Connectors may be present

even if output options are not

installed. Refer to rating label

to see installed options.

Class II Installation

Customer-supplied disconnection

and overload protection devices

nil

nil

Demand

Common

Data B- /Txd

Data A+/Rxd

Alarm Lock

Bias +5V on Sig B

Bias 0V on Sig A

120 Ohm termination resistor

C

B

A

Solder Switch closed

RS485 Version (IC4 missing)

9122-0670 P4

C

B

A

IC4

N L

CC.1

CC.2

CC.3

- +

Not used

Common

Calib’n Lock

Remo te

contacts

(5V DC 1mA)

Circuit breaker

Fuse Switch

Power

Solder Switch closed

RS232 Version (IC3 missing)

9122-0670 P4

IC4

IC3

IC3

9

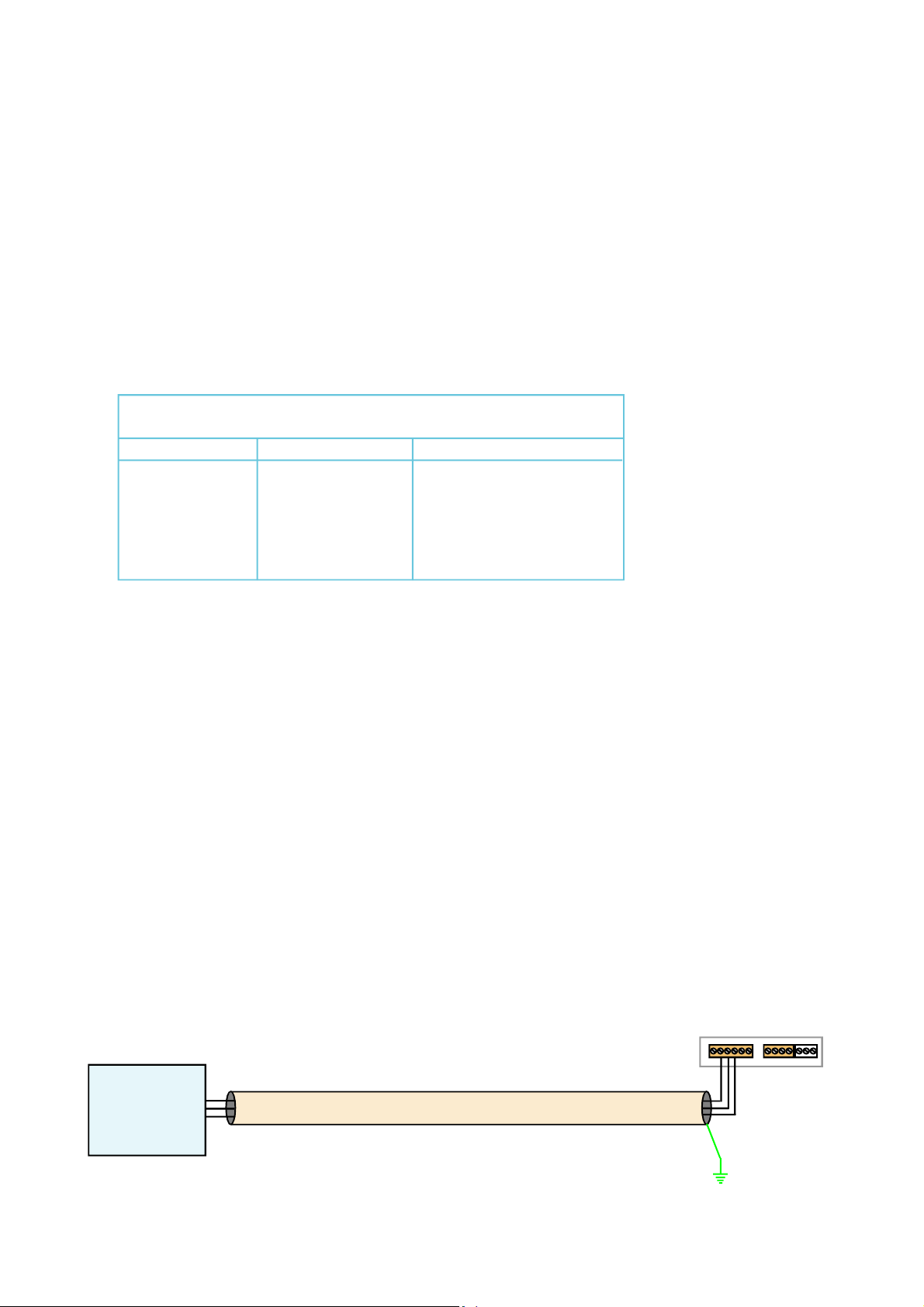

Installation hints for best performance

This section offers several suggestions which will help you get the best performance from

your system.

RS232 and RS485 use comparitively small signals which can easily be corrupted by the

potentially high level of electrical noise which can be created by electrical machinery such as

motors, welding systems, discharge lighting, AC power inverters and solenoids. These steps

will ensure you get the best possible performance from your system.

RS232 has limited capability over long cable distances, due its low driving power (which

causes the signal to reduce in level as cable length increases) and single ended signal (which

is prone to interference by local electrical noise) , as shown below...

Maximum recommended cable distances if using LOW

capacitance screened cable such as CAT5 cable.

Baud Rate RS232 RS485 or RS422

1200 50m 1200m

9600 20m 150m

19200 10m 75m

38400 5m 30m

115200 2m 10m

1. Use good quality screened signal cable, with twisted pairs. Screened twisted pair

CAT5 cable is ideal. The screen should be earthed at the display end only.

2. If you are using multi-pair twisted cable, each pair should be dedicated to a single

display as shown opposite, for maximum noise immunity.This will ensure that any

electrical noise induced in the cable is properly cancelled. Mixing destinations

carelessly amongst the twisted pairs can easily corrupt data.

3. The cable should be routed away from noisy wiring and devices such as power

feeds from inverters, discharge-lighting cables, welder cabling etc, and should

preferrably be routed in a dedicated low voltage signalling/instrumentation conduit

or cable tray.

4. If you want to simulate data, a useful free terminal, with good flexibility is

RealTerm, available from http://sourceforge.net/projects/realterm/

Signal Input

Logic Input

Power Input

RS232 or

RS485

transmitter

Do not

connect

screen at

this end.

Sender connections

10

Length of screened cable

Connect screen

to earth ONLY

at this end.

Clean Earth

Display connections

Display 1

Display 2

Display 3

Displays

Data 1

Data 2

When using multi-core screened cable to connect several displays to several data sources, please be sure to use one twisted

pair for each display and sensor.

Do NOT use a wire from one pair for signal positive and a wire from another pair for signal negative, as this will prevent the

twisted cables form cancelling any induced electrical noise, and can couple noise from one source to another.

Data 3

Data Sources

11

Loading...

Loading...