IMES EPM-XP Operation Manual & Technical Manual

Operation manual EPM-XP

Software Release l.0.5.17 2019-01-29

Page 1 of 50

Operation manual EPM-XP

Software Release l.0.5.17 2019-01-29

Page 2 of 50

Content

1

Introduction ___________________________________________________________ 4

1.1 General __________________________________________________________________ 4

1.2 Other products from IMES __________________________________________________ 4

1.3 IMES-Service _____________________________________________________________ 4

2

Scope of supply ________________________________________________________ 5

3

Important information __________________________________________________ 5

3.1 Use of the operator manual __________________________________________________ 5

4

Description ___________________________________________________________ 5

4.1 Introduction ______________________________________________________________ 5

4.2 Measure functions _________________________________________________________ 6

4.3 Functional description ______________________________________________________ 6

5

Operation _____________________________________________________________ 7

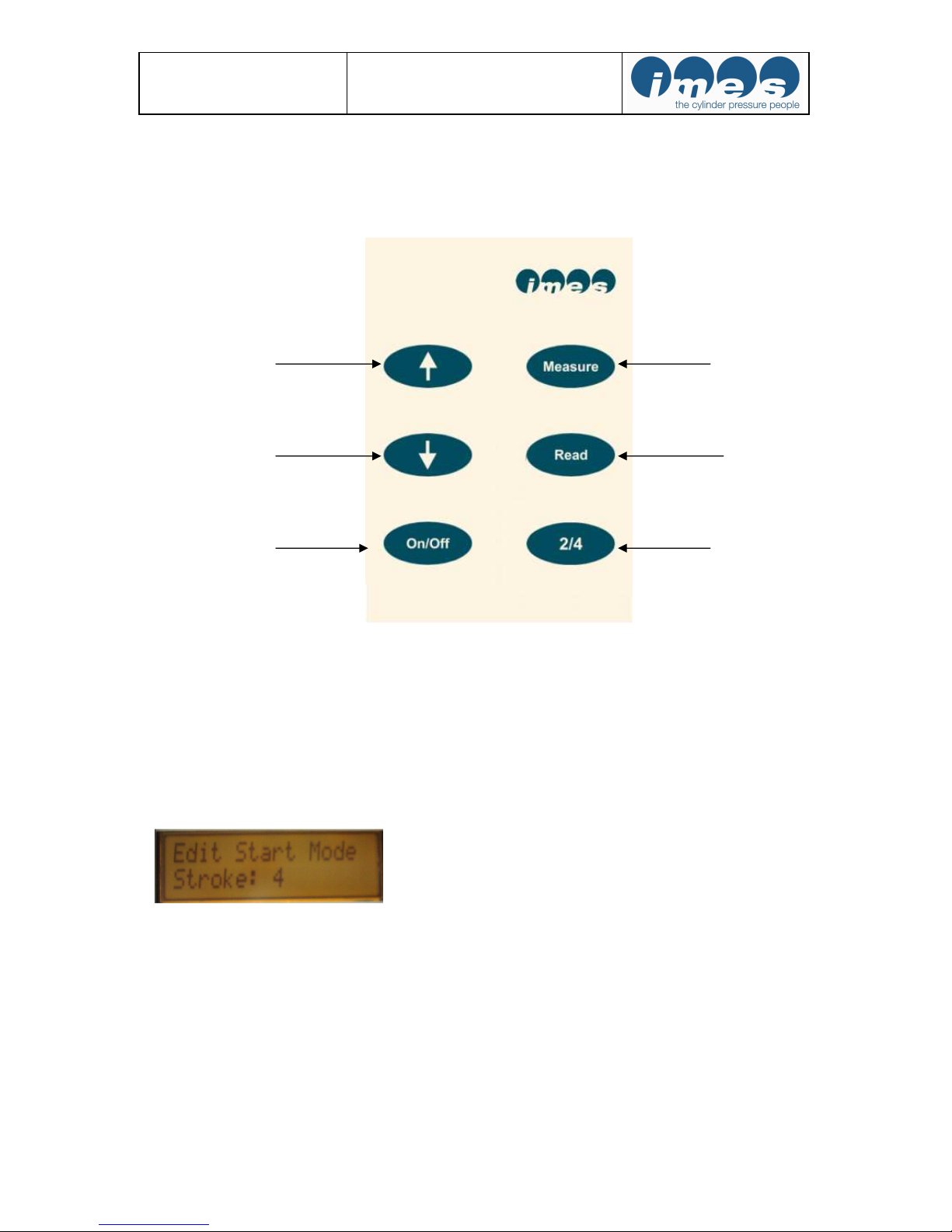

5.1 Operator push buttons _____________________________________________________ 7

5.2 Operating functions ________________________________________________________ 8

5.3 Installation of visualisation- and USB driver software ____________________________ 9

5.1 Installation of reference curves for selected load of MAN B&W MC-C engines ______ 10

5.2 Start visualisation software _________________________________________________ 10

5.3 Selection of COM port on PC _______________________________________________ 11

5.4 Charge battery ___________________________________________________________ 11

5.5 Change battery ___________________________________________________________ 12

5.6 Mounting instructions on 2-stroke engines ____________________________________ 13

5.7 Measurements with EPM-XP _______________________________________________ 13

6

Visualisation software release 1.0.5.17 ____________________________________ 14

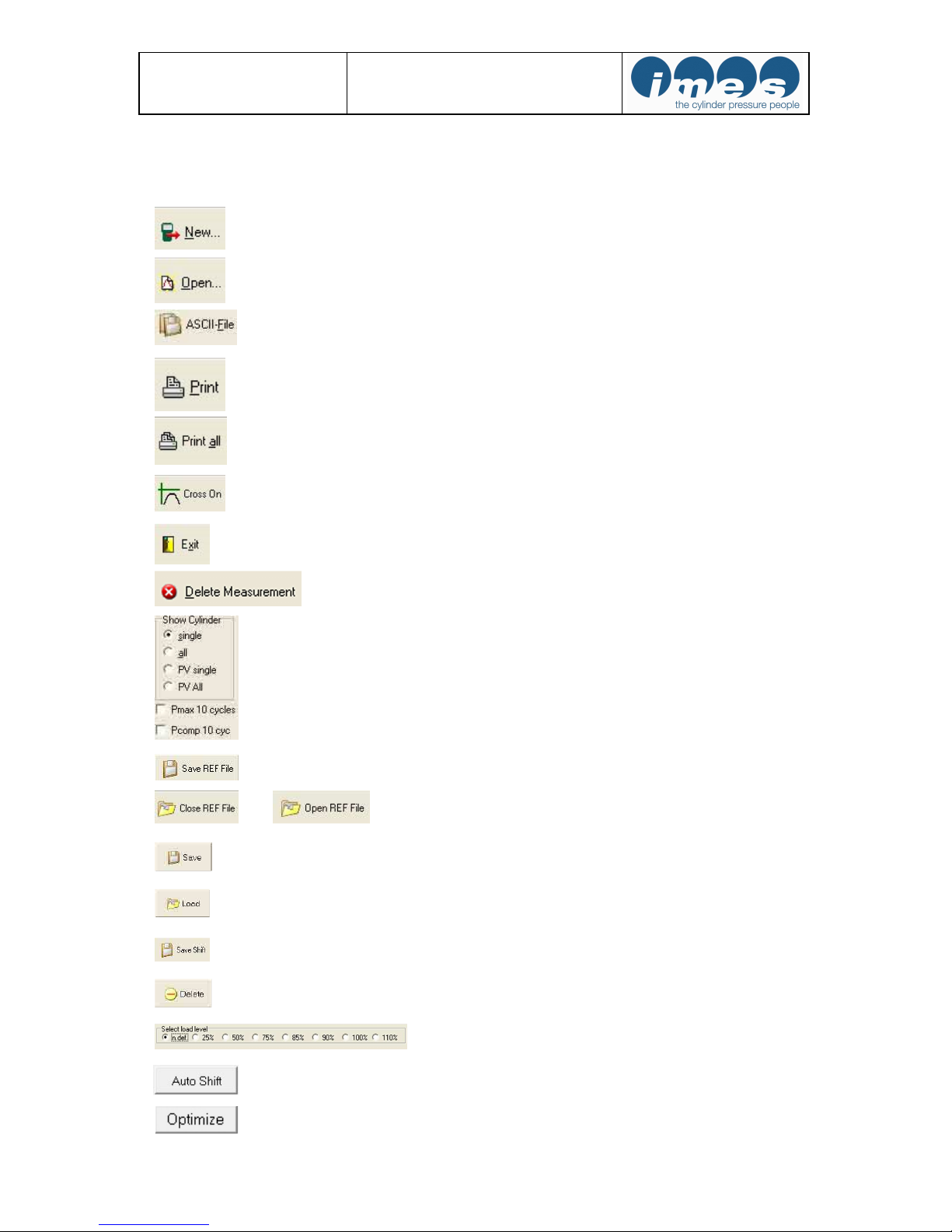

6.1 Main tool bar buttons _____________________________________________________ 14

6.2 Load measured data from EPM-XP to PC ____________________________________ 15

6.3 Load measured data from hard disc to PC ____________________________________ 15

6.4 Monitoring of combustion data _____________________________________________ 16

6.4.1 Screen page “Cylinder pressure curve” _____________________________________________ 16

6.4.1.1

Indication of cylinder pressure (single) versus volume _____________________________ 16

6.4.1.2

Indication of all cylinder pressure (all) versus crank angle __________________________ 17

6.4.1.3

Zoom -function ___________________________________________________________ 17

6.4.1.4

Cross On function _________________________________________________________ 18

6.4.1.5

Save as ASCII ____________________________________________________________ 18

6.4.1.6

Deviations for automatic Pcomp calculation on two-stroke engines ___________________ 19

6.4.1.7

Save shifted curves ________________________________________________________ 21

6.4.1.8

Delete measurement on EPM-XP _____________________________________________ 21

Operation manual EPM-XP

Software Release l.0.5.17 2019-01-29

Page 3 of 50

6.4.1.9

Open *.csv files at Excel ____________________________________________________ 22

6.4.2 Screen page “Engine report” _____________________________________________________ 22

6.4.3 Screen page “Pmax diagram” _____________________________________________________ 23

6.4.4 Screen page “Pmax Balance” _____________________________________________________ 23

6.4.5 Screen page “Pcomp Balance” ____________________________________________________ 24

6.4.6 Screen page “IMEP” ____________________________________________________________ 24

6.4.7 Screen page “IMEP balance” _____________________________________________________ 25

6.4.8 Screen page “Performance” ______________________________________________________ 25

6.4.9 Screen page “Remarks” _________________________________________________________ 26

6.4.10 Screen page “Engine data” _______________________________________________________ 26

6.4.10.1 Calculation of effective Power (= shaft power)___________________________________ 27

6.4.10.2 Indication of effective Power in screen page “Engine report” _______________________ 28

6.4.11 Pipe oscillation filter ____________________________________________________________ 28

6.5 IMEP- and IPOWER calculation ____________________________________________ 29

6.5.1 Application on two-stroke engines _________________________________________________ 29

6.5.1.1

Load measured data from hard disc to PC _______________________________________ 29

6.5.1.2

Enter scavenge air pressure of selected load _____________________________________ 30

6.5.1.3

Indication of IPOWER and IMEP on screen page “Cylinder” _______________________ 30

6.5.1.4

Indication of IPOWER and IMEP on screen page “Engine report” ___________________ 31

6.5.1.5

“Auto shift” function _______________________________________________________ 31

6.5.1.6

Select a curve as reference curve _____________________________________________ 31

6.5.1.7

Save a reference curve ______________________________________________________ 32

6.5.1.8

Open reference curve for to optimize TDC position of other cylinder _________________ 32

6.5.1.9

Open reference curves of selected load for MAN B&W MC-C engines _______________ 32

6.5.1.10 Compare actual measurements with reference curve ______________________________ 32

6.5.1.11 Save shifted curves ________________________________________________________ 33

6.5.1.12 Example for optimum TDC position on MAN B&W MC-C engines __________________ 34

7

Free internet software download _________________________________________ 41

8

Accuracy check _______________________________________________________ 41

8.1 Connection of EPM-XP to pressure calibrator _________________________________ 42

8.1 Generate pressure at pressure calibrator _____________________________________ 43

8.2 Example of displayed EPM-XP values during pressure check ____________________ 44

8.3 Disconnect EPM-XP from pressure calibrator _________________________________ 44

9

Cleaning ____________________________________________________________ 45

9.1 Periodically cleaning ______________________________________________________ 45

9.2 Cleaning in case of hard deposit _____________________________________________ 45

9.3 Cleaning procedure of adaptor ______________________________________________ 46

9.4 Cleaning procedure of cylinder pressure sensor _______________________________ 46

10 Check tightening of sensor on adaptor ____________________________________ 47

11 Basic check for fault finding ____________________________________________ 48

12 Nomenclature ________________________________________________________ 49

13 Technical data ________________________________________________________ 49

14 Warranty ____________________________________________________________ 49

15 IMES Sales and service organization _____________________________________ 49

16 Declaration of conformity _______________________________________________ 50

Operation manual EPM-XP

Software Release l.0.5.17 2019-01-29

Page 4 of 50

1 Introduction

1.1 General

Thanks for choosing this IMES quality product. You

receive a product, which features technical innovation,

high accuracy, reliability and a very long lifetime

1.2 Other products from IMES

IMES offers a variety of products for the application

of cylinder pressure measurement:

- HTT Cylinder pressure sensor

- CPS Cylinder pressure sensor

- IPT Injection pressure sensors

- Compri Compression pressure tester

- CMS Combustion monitoring system

1.3 IMES-Service

For all specific questions which you may have after

studying this manual, we would be pleased to offer our

service to you and to advise you on application specific

problems to achieve optimum results.

Fig. 1: EPM-XP Electronic indicator

Operation manual EPM-XP

Software Release l.0.5.17 2019-01-29

Page 5 of 50

2 Scope of supply

Fig.2: Instrument case with all components

3 Important information

Please study this manual carefully, before using the

equipment. This will ensure that you will receive maximum

benefits from using this engine performance tuning tool with

its versatile functionality and it will guarantee optimum

benefits over its lifetime.

3.1 Use of the operator manual

We strongly recommend you to read the complete manual

before using the equipment. If you have already experience

with IMES systems you may only read the relevant

chapters for the required information.

It was our intention to structure this manual in a clear

layout, to enable you to get easy and instant access to the

information you are looking for. Please keep this manual in

a safe place where it is always available for easy access.

We ask for your understanding, that we will reserve the

right to change information and instructions in this manual

if necessary without giving notice in advance.

4 Description

4.1 Introduction

The electronic indicator EPM-XP is a handy-, battery

powered-, portable device to measure and evaluate cylinder

pressure on diesel engines at speed up to 1500 RPM.

The EPM-XP collect 10 consecutive pressure measurements (cycles) and calculates peak pressure, engine speed.

The measured data are displayed in numerical format on the

LCD screen and can be stored.

- 1 x EPM-XP incl. cylinder

pressure sensor and adaptor

- 1 x Dongle (USB)

- 1 x USB cable

- 1 x USB stick incl.

visualisation software and

documentation

- 1 x tool

- 1 x quick step manual printed

- 1 x calibration certificate

- 1 x instrument case

Operation manual EPM-XP

Software Release l.0.5.17 2019-01-29

Page 6 of 50

Up to 160 measurement data sets can be stored in the

EPM-XP. The stored data can be downloaded via USBinterface to a personal computer for evaluation.

The scope of supply includes software for Windows which

allows additional evaluation and visualization of the

collected data.

4.2 Measure functions

Pmaxmean: average maximum pressure

Pcomp: Compression pressure (only on two stroke

application)

RPM: engine speed

A complete individual pressure curve (or an average over

the selected number of cycles) will be stored in the

EPM-XP memory with each measurement.

4.3 Functional description

The cylinder pressure will be measured with the EPM-XP

unit incl. high temperature pressure sensor at indicator cock

on marine diesel engines.

Memory : 160 data sets

Application 2 – stroke: 40 – 300 RPM

Application 4 – stroke: 200 – 1500 RPM

The battery must be re-charged after approximately one

hour of continuous operation.

Operation manual EPM-XP

Software Release l.0.5.17 2019-01-29

Page 7 of 50

5 Operation

5.1 Operator push buttons

Remarks: After switching “On“ the EPM-XP display automatically shows application on 2-stroke engines.

For automatic 4-stroke engine mode selection after switch „On“ the user must connect the EPM-XP via USB

cable to PC.

Press “Read“ and “Measure“ for automatic 4-stroke engine mode selection.

After display unhand immediately the push buttons to get selected mode.

If user is in 4-stroke mode the EPM-XP can be switched to automatic 2-stroke mode selection after switch „On“

the user must connect the EPM-XP via USB cable to PC.

Press “Read“ and “Measure“ for automatic engine selection to start mode 2-stroke.

Fig. 3: Push buttons

Arrow up “↑“

Arrow down “↓“

On/Off

Start measurement

Read measurement

Selection of

2- or 4-stroke engine

and selection of load on

two-strokes

Operation manual EPM-XP

Software Release l.0.5.17 2019-01-29

Page 8 of 50

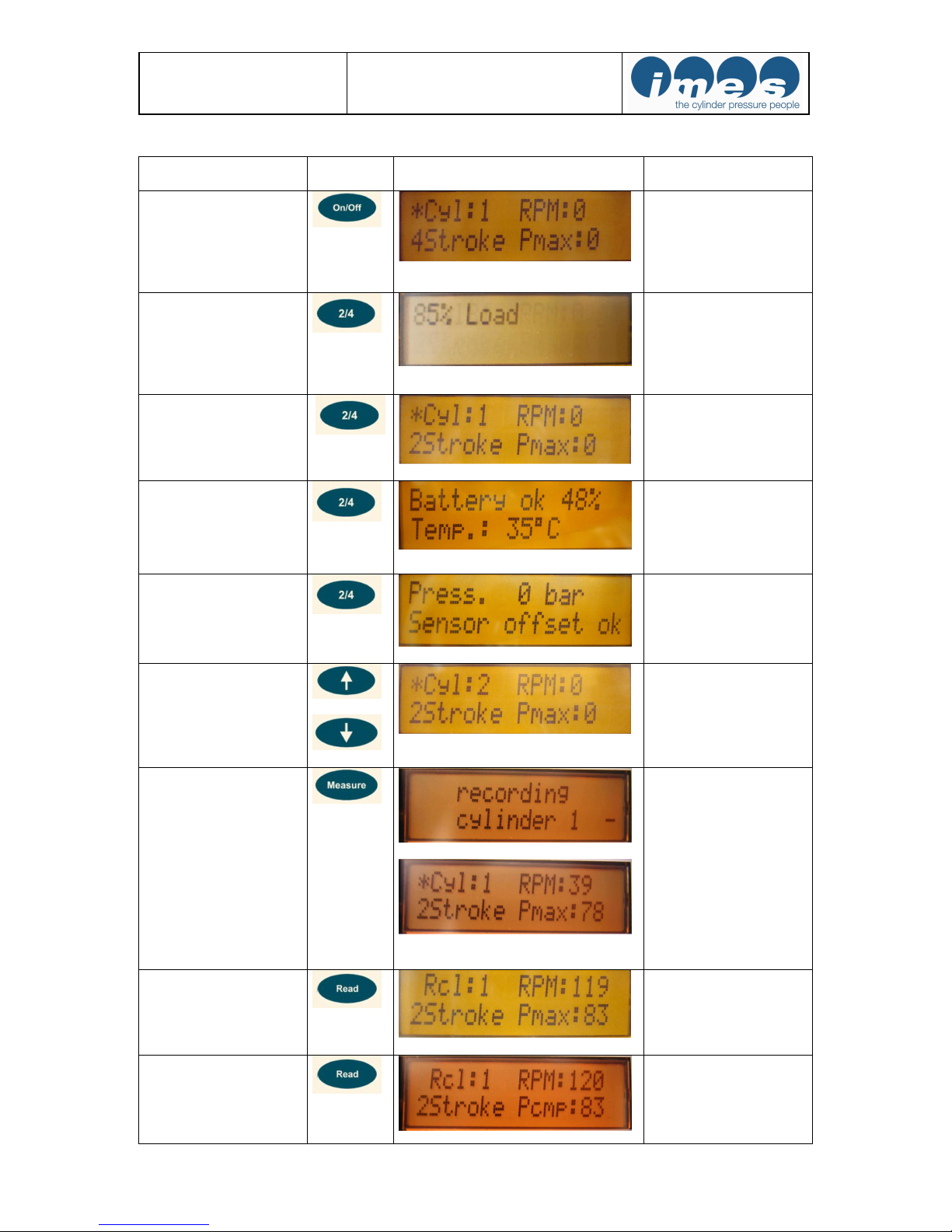

5.2 Operating functions

Function Key board

push button

Display Notes

Switch On/Off

Basic settings will be displayed after switching on:

Cyl:1 = cylinder no.1

2 stroke = 2 stroke engine

4 stroke = 4 stroke engine

Pmax in bar ; RPM: speed

Selection of load on 2stroke engine

Push key “2/4“ for to set-

up load mode for measure-

ment. Steps: Load unde-

fined, 25 %-, 50%-, 75%-

,85%-, 90%-, 100%-,

110% load

Selection of 2 -stroke or 4

–stroke engine

Push key “2/4“ and

change mode of operation

to the desired value (4 or

2 stroke application).

Battery check

Push key “2/4“ two times

to check the battery status.

Also temperature at mea-

suring element will be dis-

played.

Sensor check

Push key “2/4“ three

times to check the sensor

status at 0 bar.

Selection of cylinder

Push arrow key “

↑

↓

“ and

change the displayed value

to the number of the

selected cylinder.

Start measurement

During measurement the

following information

“Recording cylinder” will

be indicated.

Display indication (1-2 s)

of measured cylinder

values. Then EPM-XP

unit switches auto-

matically to the next

cylinder.

Read Pmax

The measured value for

Pmax of the selected

cylinder will be displayed.

Read Pcomp (only on two

stroke engines)

Press 2x

The measured value for

Pcomp of the selected

cylinder will be displayed

Operation manual EPM-XP

Software Release l.0.5.17 2019-01-29

Page 9 of 50

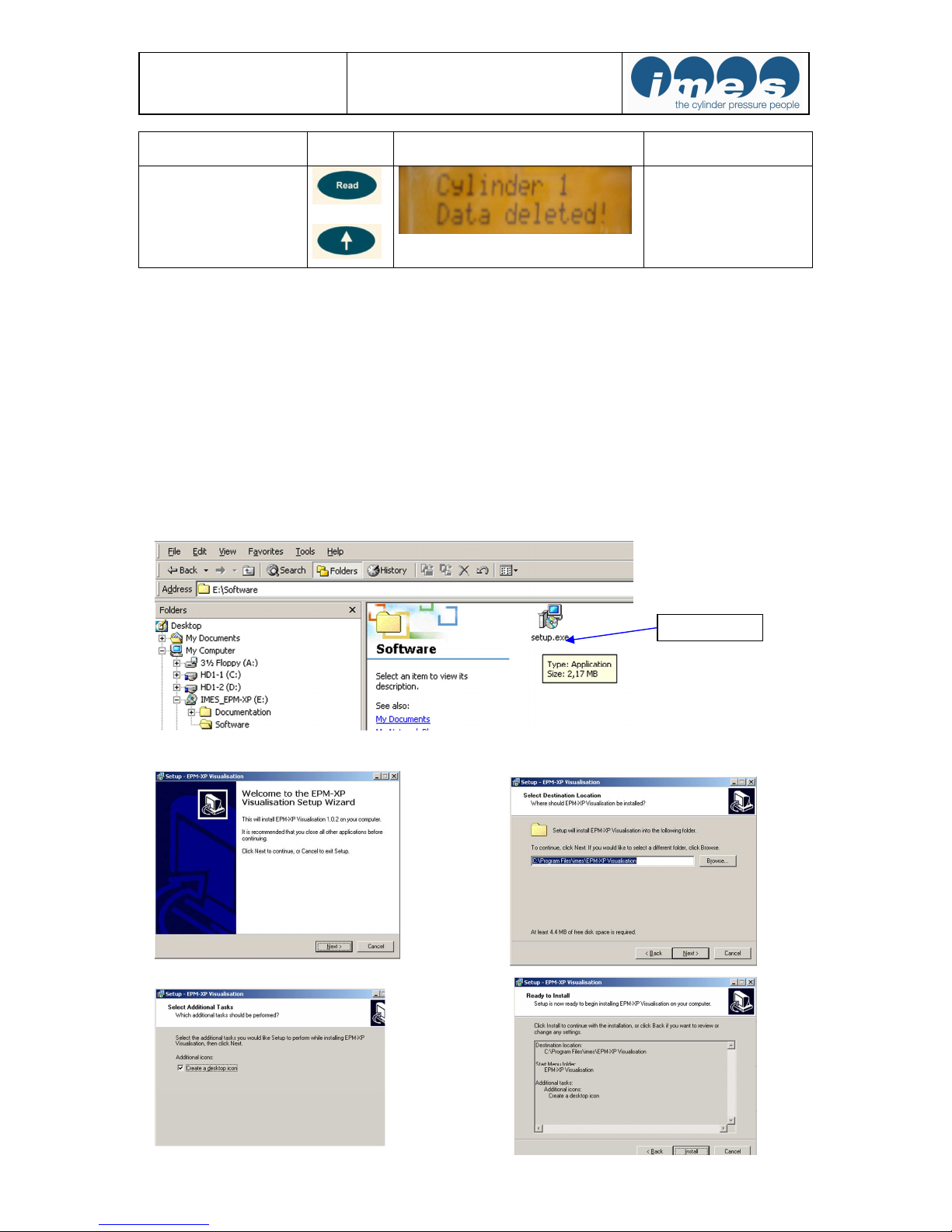

5.3 Installation of visualisation- and USB driver software

The scope of supply includes the IMES visualisation software on USB stick for displaying and analysing the

measured data in numeric and graphic format.

Hardware and software requirements

:

IBM PC Pentium or 100 % compatible, USB port

Windows 7, XP

Main memory minimum 16 MB RAM,

VGA-monitor with minimum resolution of 1024 x 768 pixel.

Install USB stick on your Personal Computer. Open directory software and make a double click at setup.exe for

installation of visualisation- and necessary USB driver software.

The program will install automatically a directory at hard disc and places an icon on the desktop of your

computer.

Function Key board

push button

Display Notes

Delete measurements

+

Push “Read” and “↑“

at the same time for 2s to

delete the currently displayed measurement.

Double click

Operation manual EPM-XP

Software Release l.0.5.17 2019-01-29

Page 10 of 50

USB driver will be installed automatically

Press enter to finalize USB driver installation

5.1 Installation of reference curves for selected load of MAN B&W MC-C

engines

5.2 Start visualisation software

Fig.4: USB Dongle IW 1556

Before starting visualisation software please install EPM-XP ISL Dongle (fig.4) on USB port of PC

EPM-XP Visualisation.lnk

Start visualisation software

by double click on icon

Operation manual EPM-XP

Software Release l.0.5.17 2019-01-29

Page 11 of 50

5.3 Selection of COM port on PC

For selection of COM Port the EPM-XP should be

connected via USB cable to PC

• Switch on EPM-XP

• Connect USB port of PC via USB cable to EPM-XP

• Run “Visualisation software“ with double click on

the desktop icon.

Fig.5: EPM-XP connected via USB cable to PC

For selection of COM Port the EPM-XP should be connected via USB cable to PC and visualisation software

should started with double click on desktop icon.

With mouse click on “Tools” and selection “Interface” the COM port of PC will be selected.

5.4 Charge battery

The EPM-XP has a re-chargeable battery. The battery

charging will start automatically after the EPM-XP unit

has been connected via USB cable from USB port to PC

(fig. 6,7,8,9)

Fig. 6: Indication during charging process Fig. 7: USB-port of EPM-XP

Fig. 8: Indication charging process completed Fig. 9: EPM-XP connected via USB cable to PC

USB por

t

Operation manual EPM-XP

Software Release l.0.5.17 2019-01-29

Page 12 of 50

Note: The battery must be charged at least minimum two hours before its first usage.

Do not change battery during charging process while EPM-XP is connect via USB cable to PC.

When the EPM-XP is connected by USB, the battery charging runs automatically. The indicator can detect the

charging status and continues charging until the battery is fully loaded. Then the charging process stops

automatically. It is not recommended to interrupt the charging process before it is automatically stopped. The

charging process is finished when the display message "EPM-XP charging..." disappeared.

If the battery status is low and the charging process stops after 5-10 minutes, then the user can manually force

the unit to charge the battery for 90 minutes by pressing both arrows + at the EPM-XP unit for

2 seconds (Forced Charging Mode).

Note: It is not recommended to use the Forced Charging Mode when the battery charge condition is more than

40%, due to the risk of overcharging. Please see chapter 5.2 for a description how to check the charge state.

5.5 Change battery

Note: Please only use re-chargeable battery E-block type “ANSMANN 270 mAh NiMH”

For to change re-chargeable battery the battery cover on the back side of EPM-XP must be opened (fig.

10,11,12). Do not change battery during charging process while EPM-XP is connect via USB cable to PC.

Fig.10: Battery cover Fig.11: Re-chargeable E-block battery type: Ansmann

Fig.12: Battery installed on back side of EPM-XP

Note: If battery of standard NiMh 270 mAh type Ansmann can not be charged or is not available than operator

can use for measurements Alkaline battery 9V only for a short time. In this case please disconnect EPM-XP

unit after transferring data to PC !

+ Pol

The battery should only be installed by

correct pole of battery !

-

Pole

Operation manual EPM-XP

Software Release l.0.5.17 2019-01-29

Page 13 of 50

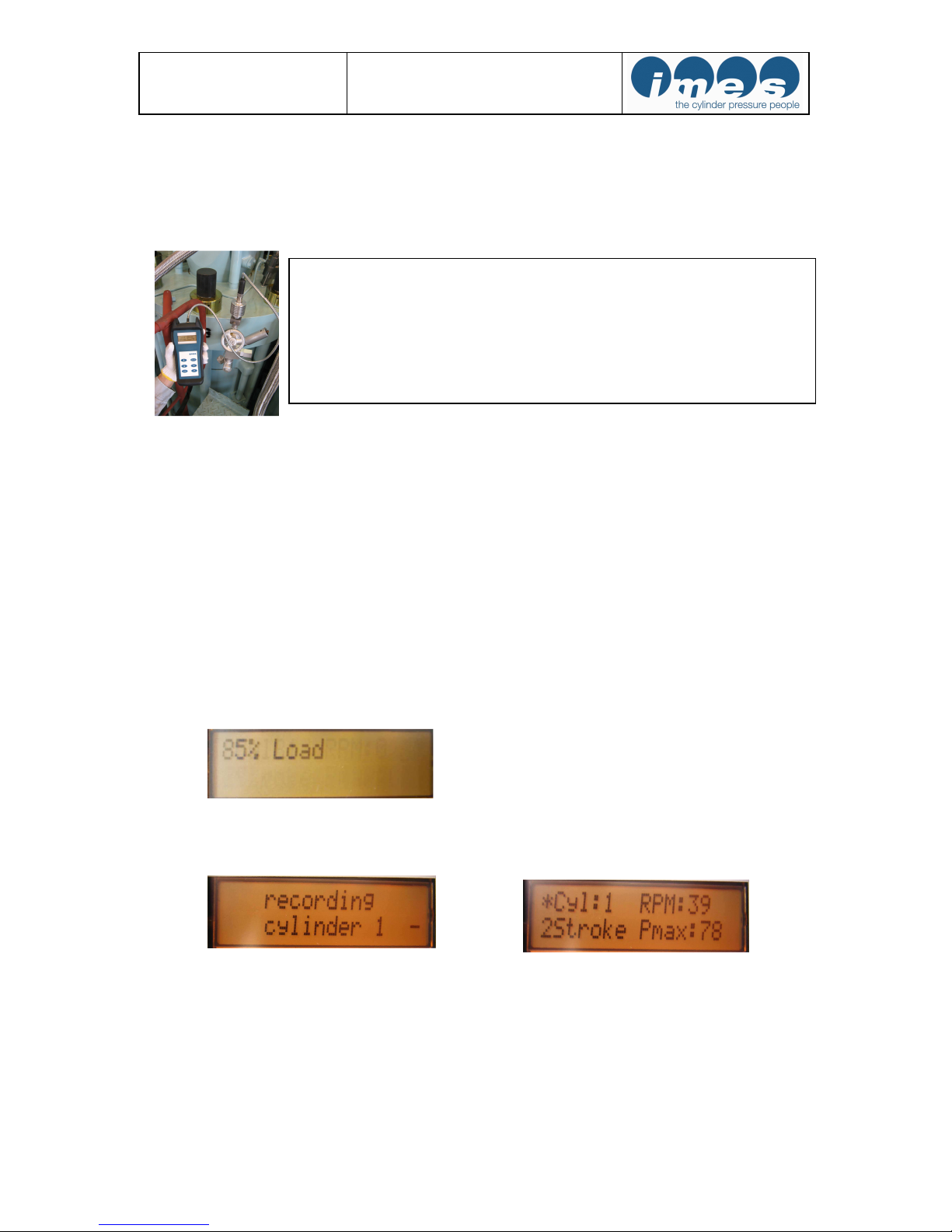

5.6 Mounting instructions on 2-stroke engines

Measuring at the indicator valve

• Before mounting the adapter, please clean the indicator valve by opening (1-2s).

To avoid measurement distortion:

• Check adaptor and sensor periodically for dirtiness and clean it if necessary.

Fig. 13: EPM-XP with HTT sensor mounted on adaptor at the indicator valve

Note: It is not allowed to use a hammer or equivalent tool to open or close the adaptor.

The user must use spanner tool on pins for to close or open adaptor on indicator cock!

5.7 Measurements with EPM-XP

• Charge battery

Charging time: min. 1 hour

• Start measurements on the engine

2-and 4 stroke application

Open and close indicator cock. Install sensor with adaptor on cylinder no.1 and open indicator cock

Press “On” at EPM-XP

Press “2/4” for load selection on 2-stroke engines

Fig.14: Indication of load (Steps: Load undefined, 25 %-, 50%-, 75%-,85%-, 90%-, 100%-, 110% load)

Press “Measure” and wait about 5-10 s

Fig.15: Indication during measurement on cylinder Fig.16: Indication (1-2 s) of measured values

After indication of measured cylinder values (1-2s) the display switches automatically to next cylinder.

Repeat measuring procedure for all remaining cylinders!

For to change engine mode 2- or 4-stroke press “2/4” to select application on a 2- or 4 stroke engine

Remark: The EPM-XP has an overheating protection of measuring cell for temperature > 300 °C

Remark: The EPM-XP turns off automatically after 2 minutes without pressing any push button!

DANGER!

The indicator valve ejects hot gas under high pressure. Danger of sparks and burning.

Hot gases and particles may be ejected.

War gloves and safety glasses!

It must be tighten the sensor and adapter connection part firmly before measuring

operation for safety of worker. Please see also chapter 10.

Operation manual EPM-XP

Software Release l.0.5.17 2019-01-29

Page 14 of 50

6 Visualisation software release 1.0.5.17

6.1 Main tool bar buttons

Load new measurement data from EPM-XP

Open stored measurement data set

Save data as ASCII file (*.csv) from all measurements

Print screen page

Print all sceeen pages

Cross On function

Program exit

Delete measurements at EPM-XP

Selection window of cylinder

p/alpha, p/v diagram

Indication Pmax 10 cycles

Indication of Pcomp 10 cycles (only on two strokes)

Save a reference file

Close and open reference file

Save Engine data

Load Engine data

Save shifted values

Delete Engine data

Load selection

Automatic shift of cylinder curve to reference curve

Funktion for to optimize Pcomp position

Only on two-stroke application available

Operation manual EPM-XP

Software Release l.0.5.17 2019-01-29

Page 15 of 50

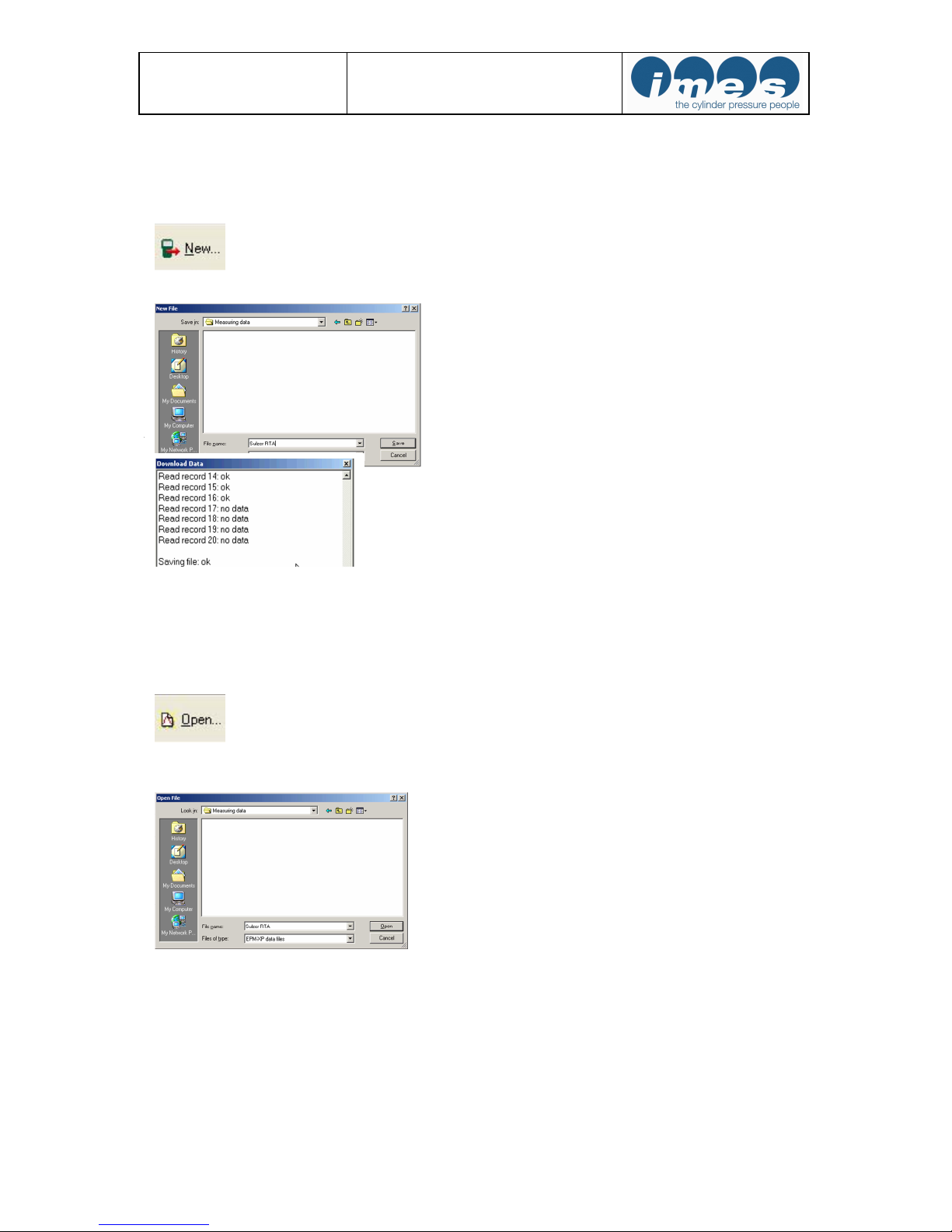

6.2 Load measured data from EPM-XP to PC

Visualization software must be started.

EPM-XP must be connected via USB cable to PC

Press “New” to load measurement data from EPM-XP to PC

The software opens a window to name the file for storing on PC

After entering a file name and storing the data will be transmitted to PC.

After this procedure the measured data will be monitored at visualisation software.

6.3 Load measured data from hard disc to PC

At first the visualization software must be started.

Press “Open” to load measurement data from EPM-XP to PC.

The software opened a window for to open a stored file on PC.

After this procedure the selected data file will be monitored at visualisation software.

Loading...

Loading...