IMER USA MASONRY 350 F 1188792, MASONRY 350F Manual Instruction

U.S.A. inc.

MASONRY 350F Sawing machine

R

MANUAL INSTRUCTION

and

PARTS LIST

Model - 1188792

Machine serial N°

Manual Part. number 3210296 - 05/2002

Write in the serial n° of your machine here

2

MASONRY 350 F

IMER INTERNATIONAL S.p.A.

Thank-you for purchasing a Masonry 350F from an Imer U.S.A. dealer. Your decision is an intelligent one.

There is no other sawing machine in the world which delivers the benefits and features of the Masonry 350F:

- Extremely rigid, mig welded bar steel frame.

- 5.5 H.P. Honda engine.

.

- Compact design for easy trasportation.

- Extremely rigid worktable for a precise cutting.

At IMER U.S.A. we continually search for ways to better serve our customers. Should you have an idea or thought to

share with us regarding this product we would appreciate hearing from you. Our motto is "Tools and Services for the

21st Century" . We look forward to delivering the goods.

Thank you again for your purchase.

Mace T. Coleman, Jr.

President, Imer U.S.A, Inc.

IMER WEST

207 Lawrence Avenue

So. San Francisco, CA 94080

Tel 650 - 872 - 2200

Fax 650 - 873 - 6482

IMER EAST

221 Westhampton Place

Capitol Heights, MD 20743

Tel 301 - 336 - 3700

Fax 301 - 336 - 6681

1

2

3

4

5

6

7

8

9

10

11

12

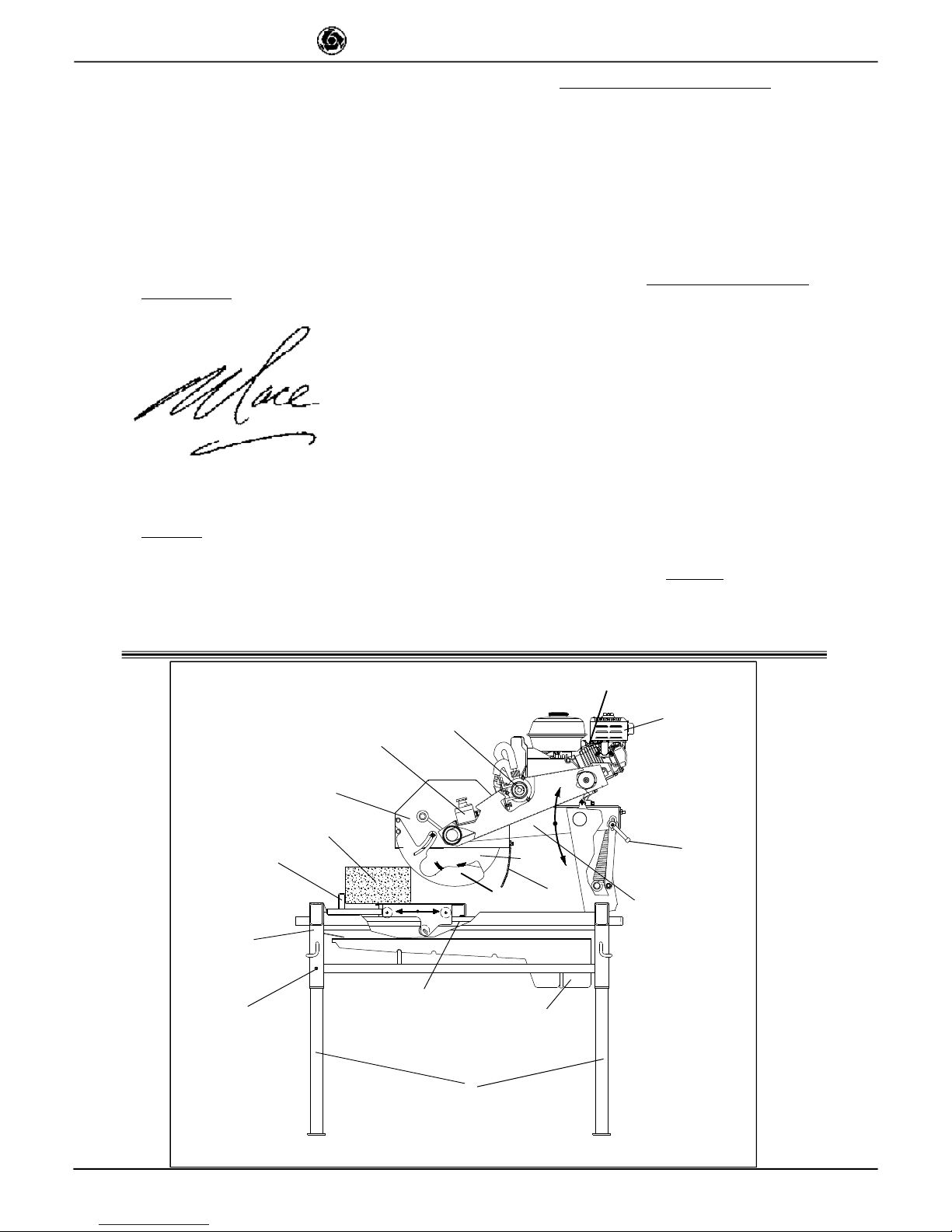

Fig. 1

13

14

15

16

17

1. Telescopic leg

2. Spray guard

3. Engine

4. Blade support

5. Water pump

6. Guide

7. Emergency switch

8. Worktable

9. Water tank

10. Blade cover

11. Support locking handle

12. Work piece

13. Blade

14. Frame

15. Earth screw

16. Blade guard

17. Accelerator lever

3

MASONRY 350 F

IMER INTERNATIONAL S.p.A.

Dear Customer,

Congratulations on your choice of purchase: this IMER saw, the

result of years of experience, is a fully reliable machine and is

equipped with the latest technical innovations.

- WORKING IN SAFETY

Please read this manual before beginning to assemble or

operate this piece of equipment.

- This OPERATION AND MAINTENANCE manual must be kept on site

by the person in charge, e.g. the SITE FOREMAN, and must always

be available for consultation.

- This manual is to be considered an integral part of the machine, and it

must be preserved for future reference (EN292/2) throughout the

machine’s normal working life. If the manual is damaged or lost, a

replacement may be requested from the saw manufacturer.

- The manual contains important information regarding site

preparation, installation, machine use, maintenance procedures

and requests for spare parts. Nevertheless, the installer and the

operator must both have adequate experience and knowledge

of the machine prior to use.

- To guarantee complete safety of the operator, safe operation

and long life of equipment, follow the instructions in this manual

carefully, and observe all safety standards currently in force for

the prevention of accidents at work. Use personal protection

(safety footwear, suitable clothing, gloves, goggles, etc.).

- Safety glasses or a protective visor must be worn at all

times.

- Ear protection must be worn at all times.

- MAKE SURE THAT WARNING SIGNS ARE ALWAYS

LEGIBLE.

- It is strictly forbidden to carry out any form of

modification to the steel structure or working parts of the

machine.

- IMER INTERNATIONAL declines all responsibility for non-compliance

with laws and standards governing the use of this equipment, in

particular; improper use, defective power supply, lack of

maintenance, unauthorised modifications, and partial or total failure

to observe the instructions contained in this manual.

IMER INTERNATIONAL is entitled to modify the characteristics of the

sawing machine and/or the contents of this manual without

necessarily updating previous machines and/or manuals.

1. TECHNICAL DATA

Table 1 shows the saw’s technical data, referring to figure 1.

2. DESIGN STANDARDS

MASONRY 350 F saws are designed and manufactured according

to the following standards: EN 292-1-2; EN 12418.

3. NOISE EMISSION LEVEL

Table 2 indicates the environmental noise levels measured for the panel

saw (lwa) in accordance with EN ISO 3744 and the acoustic pressure

level measured at the operator’s ear with the machine empty (Lpa).

TABLE 2 - [ dB(A)]

SAWING MACHINE TYPE OF MOTOR

L

P

A

L

WA

Masonry 350F ENG HONDA GX 160 K1( Hp 5.5) 95 107

4. CUTTING SPECIFICATIONS

This saw model has been specially designed for cutting stone,

ceramics, marble, granite, concrete and similar materials. Only watercooled diamond blades with continuous or segmented edges (see

paragraph 13) must be used. Under no circumstances must dry

cutting blades be used or materials other than those specified above.

IMER INTERNATIONAL declines all responsibility for damage caused

by improper use of the above machine.

5. CUTTING CAPACITY

- max. cutting capacity with vertical blade = 5 " in. one single pass.

- max. height of workpiece: 9" in. in two passes.

- min. width of workpiece: 2" in.

- max. cutting length: 18" in. (with blade lowered), 21" in (with blade

fully raised).

-Blade at 45°: with support at 45° on the work surface.

6. WARNING

- Do not load the saw with workpieces that exceed the specified

weight (max. 90 lb.)

- Ensure stability of machine: it must be installed on a solid base with

a maximum slope of 5° (fig. 2).

- Ensure the workpiece is stable before, during and after cutting: in

any case, workpieces must not overhang the worktable.

- Respect the environment; use suitable receptacles for collection of

cooling water contaminated with cutting dust.

7. SAFETY PRECAUTIONS

- IMER saws are designed for work on construction sites and under

conditions of natural light, hence the workplace must be adequately lit.

- The machine must never be used in environments subject

to risks of explosion and/or underground sites

- IMER saws may only be used when fitted with all

required safety devices, which must be in perfect

condition.

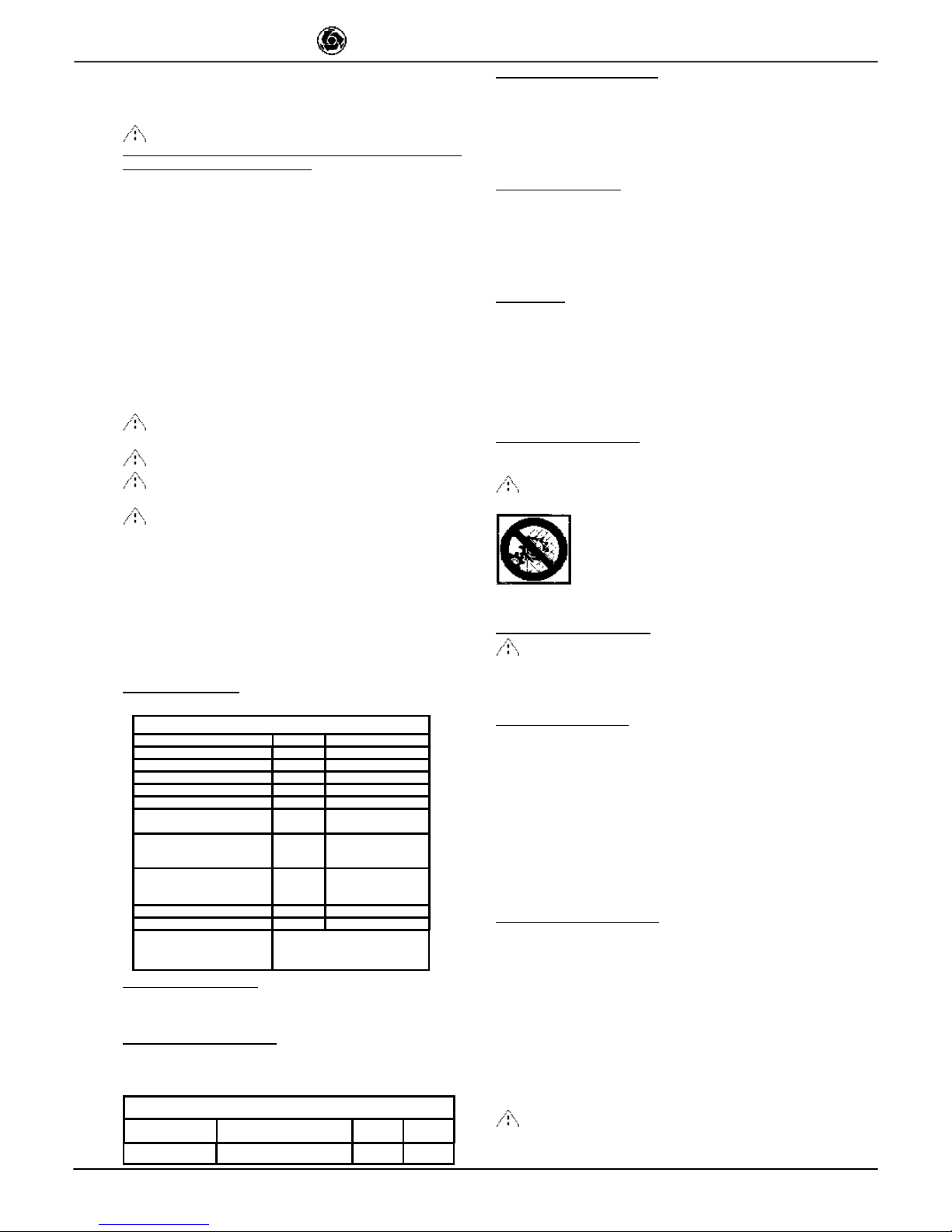

- The symbol shown on the label (fig. 3) indicates the

warning “ENSURE ALL PROTECTION DEVICES ARE

INSTALLED AND IN PERFECT CONDITION BEFORE

SWITCHING ON THE MACHINE”.

8. TRANSPORTATION (fig.4)

- WARNING Lock blade support arm by means of the

relative handle before moving the saw (ref. 11, fig. 1). To

transport the machine use slinging equipment with 4 rope

legs, fixing the hooks to the relative attachments (fig. 4).

9. INSTALLATION (fig. 4)

- Lift the machine out of its package using slinging equipment with 4

rope legs. Fix the hooks to the relative attachments.

- Unlock the legs by sliding out the split pins (ref.1).

- Lock the legs at working height. Refit the pins in the leg supports and

insert the split pins.

- Install the machine on a completely even and stable surface.

- Release the carriage from the lever that secures it to the frame.

– Fill the pump with water, unscrewing the connector (fig.10).

When installing on site it is good practice to connect the machine’s

metal structure to the earthing system by means of the screw

(fig.1 ref.15) using an earthing braid (or cable) with a minimum

cross-section of 16 mm2.

10. STARTING THE MACHINE.

The endothermic motor is equipped with a centrifugal clutch which

engages automatically, transmitting drive to the cutting wheel as the

engine revs up.

The hazard warnings and the instructions for use and maintenance

contained in the manual enclosed with the endothermic engine must

be read and understood before the engine is started.

1-Check the engine (see enclosed engine manual).

2-Check the oil level in the motor; horizontal motor position (see

enclosed motor manual).

3-Fill the fuel tank (enclosed engine manual).

4-Set the accelerator lever to minimum, so as to start the motor

without turning the cutting wheel (clutch not engaged).

5-Warm the engine by letting it run at low speed

- Emergency-stop: press the engine stop button (ref. 7,

fig. 1), (turn to switch on again).

Keep far enough away from the saw when it is running to avoid

inhaling exhaust gases from the endothermic engine.

Fig. 3

TABLE 1 - TECHNICAL DATA

Blade rpm rpm 2.450

Blade diameter in. 14"

Blade mounting hole in. 1"

Engine type Honda GX 160

Power engine Hp 5.5 / 3.600 rpm

Motor rpm rpm 3.400

Cutting table dimension in. 20" x 17"

Overall dimensions

(widthxlengthxheight)

in. 34" x 47" x 58"

Overall dimensions for

transport

(widthxlengthxheight)

in. 33" x 50" x 46"

Weight lb. 250

Weight for transport lb. 300

Blade rotation direction(seen

from blade clamping flange)

CLOCK WISE

Loading...

Loading...