U.S.A. inc.

MASONRY 350F Sawing machine

R

MANUAL INSTRUCTION

and

PARTS LIST

Model - 1188792

Machine serial N°

Manual Part. number 3210296 - 05/2002

Write in the serial n° of your machine here

2

MASONRY 350 F

IMER INTERNATIONAL S.p.A.

Thank-you for purchasing a Masonry 350F from an Imer U.S.A. dealer. Your decision is an intelligent one.

There is no other sawing machine in the world which delivers the benefits and features of the Masonry 350F:

- Extremely rigid, mig welded bar steel frame.

- 5.5 H.P. Honda engine.

.

- Compact design for easy trasportation.

- Extremely rigid worktable for a precise cutting.

At IMER U.S.A. we continually search for ways to better serve our customers. Should you have an idea or thought to

share with us regarding this product we would appreciate hearing from you. Our motto is "Tools and Services for the

21st Century" . We look forward to delivering the goods.

Thank you again for your purchase.

Mace T. Coleman, Jr.

President, Imer U.S.A, Inc.

IMER WEST

207 Lawrence Avenue

So. San Francisco, CA 94080

Tel 650 - 872 - 2200

Fax 650 - 873 - 6482

IMER EAST

221 Westhampton Place

Capitol Heights, MD 20743

Tel 301 - 336 - 3700

Fax 301 - 336 - 6681

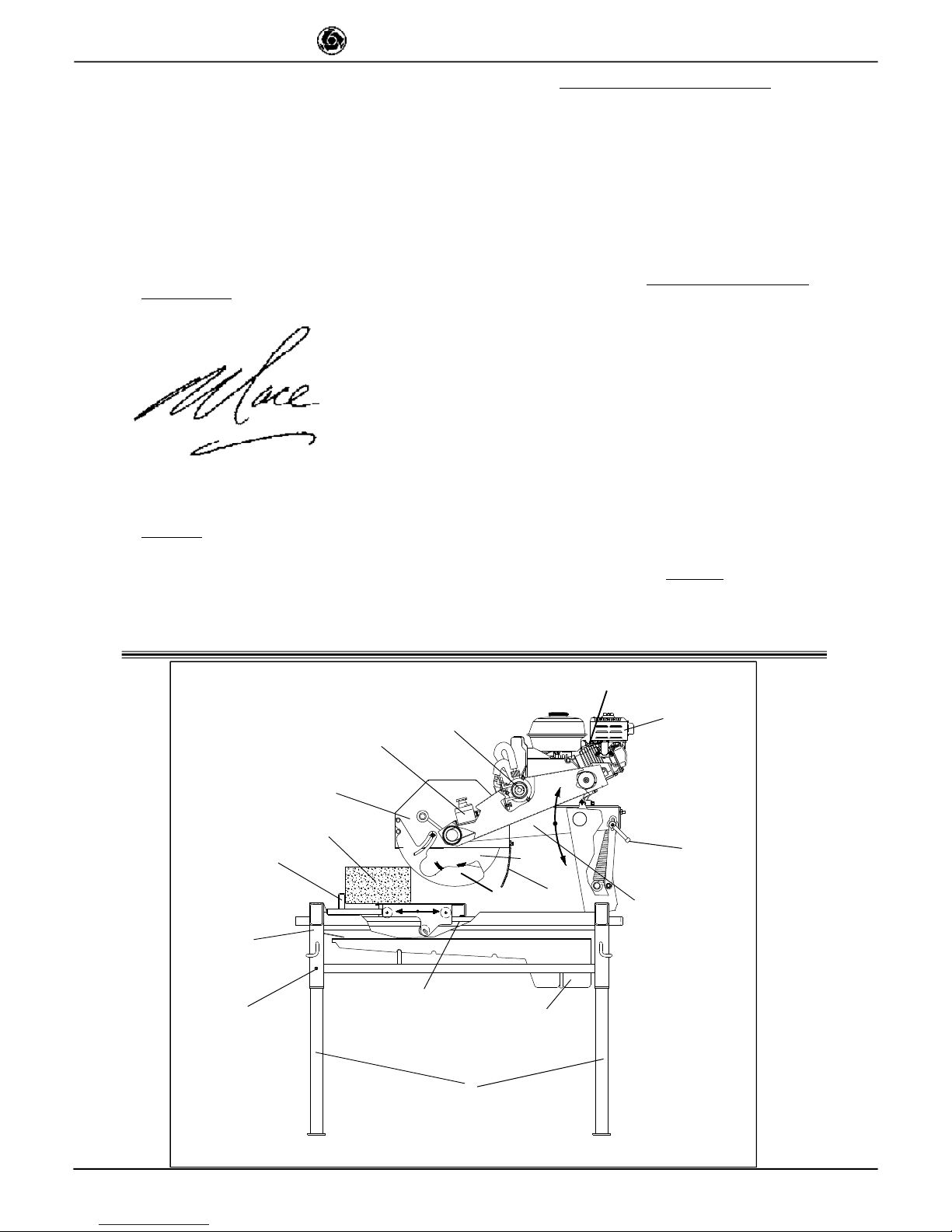

1

2

3

4

5

6

7

8

9

10

11

12

Fig. 1

13

14

15

16

17

1. Telescopic leg

2. Spray guard

3. Engine

4. Blade support

5. Water pump

6. Guide

7. Emergency switch

8. Worktable

9. Water tank

10. Blade cover

11. Support locking handle

12. Work piece

13. Blade

14. Frame

15. Earth screw

16. Blade guard

17. Accelerator lever

3

MASONRY 350 F

IMER INTERNATIONAL S.p.A.

Dear Customer,

Congratulations on your choice of purchase: this IMER saw, the

result of years of experience, is a fully reliable machine and is

equipped with the latest technical innovations.

- WORKING IN SAFETY

Please read this manual before beginning to assemble or

operate this piece of equipment.

- This OPERATION AND MAINTENANCE manual must be kept on site

by the person in charge, e.g. the SITE FOREMAN, and must always

be available for consultation.

- This manual is to be considered an integral part of the machine, and it

must be preserved for future reference (EN292/2) throughout the

machine’s normal working life. If the manual is damaged or lost, a

replacement may be requested from the saw manufacturer.

- The manual contains important information regarding site

preparation, installation, machine use, maintenance procedures

and requests for spare parts. Nevertheless, the installer and the

operator must both have adequate experience and knowledge

of the machine prior to use.

- To guarantee complete safety of the operator, safe operation

and long life of equipment, follow the instructions in this manual

carefully, and observe all safety standards currently in force for

the prevention of accidents at work. Use personal protection

(safety footwear, suitable clothing, gloves, goggles, etc.).

- Safety glasses or a protective visor must be worn at all

times.

- Ear protection must be worn at all times.

- MAKE SURE THAT WARNING SIGNS ARE ALWAYS

LEGIBLE.

- It is strictly forbidden to carry out any form of

modification to the steel structure or working parts of the

machine.

- IMER INTERNATIONAL declines all responsibility for non-compliance

with laws and standards governing the use of this equipment, in

particular; improper use, defective power supply, lack of

maintenance, unauthorised modifications, and partial or total failure

to observe the instructions contained in this manual.

IMER INTERNATIONAL is entitled to modify the characteristics of the

sawing machine and/or the contents of this manual without

necessarily updating previous machines and/or manuals.

1. TECHNICAL DATA

Table 1 shows the saw’s technical data, referring to figure 1.

2. DESIGN STANDARDS

MASONRY 350 F saws are designed and manufactured according

to the following standards: EN 292-1-2; EN 12418.

3. NOISE EMISSION LEVEL

Table 2 indicates the environmental noise levels measured for the panel

saw (lwa) in accordance with EN ISO 3744 and the acoustic pressure

level measured at the operator’s ear with the machine empty (Lpa).

TABLE 2 - [ dB(A)]

SAWING MACHINE TYPE OF MOTOR

L

P

A

L

WA

Masonry 350F ENG HONDA GX 160 K1( Hp 5.5) 95 107

4. CUTTING SPECIFICATIONS

This saw model has been specially designed for cutting stone,

ceramics, marble, granite, concrete and similar materials. Only watercooled diamond blades with continuous or segmented edges (see

paragraph 13) must be used. Under no circumstances must dry

cutting blades be used or materials other than those specified above.

IMER INTERNATIONAL declines all responsibility for damage caused

by improper use of the above machine.

5. CUTTING CAPACITY

- max. cutting capacity with vertical blade = 5 " in. one single pass.

- max. height of workpiece: 9" in. in two passes.

- min. width of workpiece: 2" in.

- max. cutting length: 18" in. (with blade lowered), 21" in (with blade

fully raised).

-Blade at 45°: with support at 45° on the work surface.

6. WARNING

- Do not load the saw with workpieces that exceed the specified

weight (max. 90 lb.)

- Ensure stability of machine: it must be installed on a solid base with

a maximum slope of 5° (fig. 2).

- Ensure the workpiece is stable before, during and after cutting: in

any case, workpieces must not overhang the worktable.

- Respect the environment; use suitable receptacles for collection of

cooling water contaminated with cutting dust.

7. SAFETY PRECAUTIONS

- IMER saws are designed for work on construction sites and under

conditions of natural light, hence the workplace must be adequately lit.

- The machine must never be used in environments subject

to risks of explosion and/or underground sites

- IMER saws may only be used when fitted with all

required safety devices, which must be in perfect

condition.

- The symbol shown on the label (fig. 3) indicates the

warning “ENSURE ALL PROTECTION DEVICES ARE

INSTALLED AND IN PERFECT CONDITION BEFORE

SWITCHING ON THE MACHINE”.

8. TRANSPORTATION (fig.4)

- WARNING Lock blade support arm by means of the

relative handle before moving the saw (ref. 11, fig. 1). To

transport the machine use slinging equipment with 4 rope

legs, fixing the hooks to the relative attachments (fig. 4).

9. INSTALLATION (fig. 4)

- Lift the machine out of its package using slinging equipment with 4

rope legs. Fix the hooks to the relative attachments.

- Unlock the legs by sliding out the split pins (ref.1).

- Lock the legs at working height. Refit the pins in the leg supports and

insert the split pins.

- Install the machine on a completely even and stable surface.

- Release the carriage from the lever that secures it to the frame.

– Fill the pump with water, unscrewing the connector (fig.10).

When installing on site it is good practice to connect the machine’s

metal structure to the earthing system by means of the screw

(fig.1 ref.15) using an earthing braid (or cable) with a minimum

cross-section of 16 mm2.

10. STARTING THE MACHINE.

The endothermic motor is equipped with a centrifugal clutch which

engages automatically, transmitting drive to the cutting wheel as the

engine revs up.

The hazard warnings and the instructions for use and maintenance

contained in the manual enclosed with the endothermic engine must

be read and understood before the engine is started.

1-Check the engine (see enclosed engine manual).

2-Check the oil level in the motor; horizontal motor position (see

enclosed motor manual).

3-Fill the fuel tank (enclosed engine manual).

4-Set the accelerator lever to minimum, so as to start the motor

without turning the cutting wheel (clutch not engaged).

5-Warm the engine by letting it run at low speed

- Emergency-stop: press the engine stop button (ref. 7,

fig. 1), (turn to switch on again).

Keep far enough away from the saw when it is running to avoid

inhaling exhaust gases from the endothermic engine.

Fig. 3

TABLE 1 - TECHNICAL DATA

Blade rpm rpm 2.450

Blade diameter in. 14"

Blade mounting hole in. 1"

Engine type Honda GX 160

Power engine Hp 5.5 / 3.600 rpm

Motor rpm rpm 3.400

Cutting table dimension in. 20" x 17"

Overall dimensions

(widthxlengthxheight)

in. 34" x 47" x 58"

Overall dimensions for

transport

(widthxlengthxheight)

in. 33" x 50" x 46"

Weight lb. 250

Weight for transport lb. 300

Blade rotation direction(seen

from blade clamping flange)

CLOCK WISE

4

MASONRY 350 F

IMER INTERNATIONAL S.p.A.

- Turn off the engine before topping up the tank with

petrol.

Saws with endothermic engines must be used in the open air. If

they have to be used in closed environments, the openings must

be provided to conduct gases from the engine’s exhaust pipe to

the outside using appropriate non-flammable flexible tubes.

These must be checked for leaks and breakages at the beginning

of every shift.

- Do not start the machine with the blade in the

workpiece.

When the saw is not being used, turn the petrol cock to the OFF

position.

10.1 STARTING ROTATION OF THE CUTTING WHEEL.

Gradually move the lever (ref.17; fig.1) so as to bring the motor

revs up to normal working speed and start the wheel turning at

the cutting speed foreseen.

11. STARTING THE MACHINE

Before cutting:

1 – Check that there is enough cooling water in the tank.

2 - adjust the flow of cooling water by turning the cock next to the

blade guard (do not perform cutting without water).

3 - Ensure that blade rotation corresponds to the indications on

the blade guard.

4 – If everything is in order, work can begin.

12. EMERGENCY - STOP

- In an emergency, stop the machine by pressing the

stop control switch (ref. 7, fig. 1).

13. BLADE INSTALLATION (Fig.5)

By means of a hex wrench no.10, unscrew the 3 screws that

lock the moving blade guard (ref.3). Use a hex wrench no. 13 to

remove the screw that locks the flanges on the disc: this screw

has a left-hand thread (rif.1). Remove the mobile flange (rif.2)

and check that the flanges, disc shaft and blade are not damaged.

- Never use worn blades or blades with missing segments.

- Only use blades that are designed for the number of

revolutions indicated on the machine rating plate.

- Check that blade rotation corresponds to that

indicated on the blade guard.

Centre the blade against the fixed flange, position the mobile

flange and tighten the securing screw by means of a hex

wrench no. 13 (turn clockwise). Refit the moving blade guard,

tightening the 3 screws (ref.3).

- Ensure that the blade guard (ref.3) is locked

securely into position.

- WARNING! An incorrectly installed blade, or a

screw insufficiently tightened can provoke damage to

the machine or injury to persons.

- Note that the blade must have

an external diameter of 14"in. , a

central hole diameter of 1" in. and max.

thickness of 1/8" in..

- Check that the blade to be used

is suitable for the material to be cut.

- Do not use blades for wood!

(fig. 6).

14. USE

- Leave a space of at least 5 ft. around the machine to operate

in full safety.

- Do not allow other persons to approach the

machine during cutting.

- Never use the machine in fire-risk areas. Sparks can cause

fire or explosions.

- Make sure that the machine is switched off before positioning

or handling.

- Always ensure that the blade is free of any contact before start-up.

- Ensure correct installation of all protective devices.

- Before starting work, fill the water tank. Top up during operation

whenever necessary: N.B. the pump suction hose must always remain

immersed in water.

- WARNING! For safety purposes the removal of protective

guards from the machine is strictly prohibited.

- WARNING! Always switch off the machine before

carrying out blade adjustment.

Loading and unloading pieces on the machine cutting table.

To avoid the risk of accidental contact with the cutting wheel, the

pieces must be positioned and removed from the carriage with the

cutting wheel stopped. This is done by adjusting the lever (ref.17;fig.1)

so as to reduce the revs to minimum, thus disengaging the clutch.

14.1 VERTICAL BLADE MOVEMENT

To raise or lower the blade, slacken the support locking handle turning

it anti-clockwise (ref. 11, fig. 1). The blade support remains free to

rotate, so it can be secured in the desired position, fully tightening the

handle (ref. 11, fig. 1).

- Ensure that the locking handle is tightened fully before

starting work.

14.2 BLADE POSITIONING FOR 45° CUTS

To make a cut at 45° the 45° support on the carriage is necessary.

Once the workpiece is correctly positioned, cutting can begin, starting

the endothermic engine.

14.3 CUTTING

For safe use of the machine when cutting, push the carriage forwards

as the cut advances, placing your hands to the two sides of the

carriage. Never push directly on the piece to be cut.

- Check that the blade is aligned with the cutting line.

- Place the workpiece on the worktable (ref. 8, fig. 1), resting firmly

against the stop.

- Start the engine.

- Wait until the water reaches the blade.

- Begin cutting.

- Horizontal cutting movement is carried out by pulling the carriage

towards the blade.

- As cutting thickness increases, the blade is subjected to

greater stress. To avoid overloading the engine, the operator

should continually check blade feed speed. The speed will

also depend on the characteristics of the material being cut

(hardness, toughness etc.).

14.3.1 CUTS WITH BLADE LOWERED FROM ABOVE

Bring the blade support to its highest position and lock. Position the

workpiece on the worktable. Start the machine and begin vertical

cutting until the blade reaches its lowest point. Lock the support locking

handle and proceed with horizontal cutting

14.3.2 BLADE CHANGE

To change the blade refer to section 13.

15. MAINTENANCE

- WARNING.. Servicing must always be carried out by

skilled personnel and only after the endothermic engine has

been turned off.

-Always keep the guards in proper working order and

free from damage.Take particular care to ensure that the

blade guards are kept efficient and clean, replacing them if

they are damaged.

- WARNING.. Recommended product for cleaning

mechanical parts: WD-40.

Do not leave the machine outside: it must always be protected from

the weather.

Below is a list of the cleaning operations that must be carried out at the

end of every shift.

15.1 TANK CLEANING

Empty the tank by removing the drain plug. Remove cutting residue

using a jet of water.

Fig. 6

5

MASONRY 350 F

IMER INTERNATIONAL S.p.A.

15.2 TANK REMOVAL (Ref.Fig.7).

- Lift the tank (ref.1) to detach it from its supports (ref.2) and

remove it from the side indicated by the arrow.

15.3 WORK SURFACE CLEANING

Always keep work surfaces clean. Residual dirt can impair

cutting precision.

15.4 GUIDE RAIL CLEANING

It is good practice to remove all traces of dirt from the guides.

15.5 CLEANING AND MAINTENANCE OF COOLING

CIRCUIT

- If water does not reach the blade stop the machine immediately

to avoid blade damage.

- After switching off the machine ensure that the water level is

sufficient.

-Check that there is water in the pump by unscrewing the

connector, and if necessary top up until water flows out (fig.10).

- WARNING. Before starting the panel saw for the

first time, or when starting it after long periods of

inactivity, fill the pump with water as described above.

- At the end of every shift, unscrew the suction hose filter and

clean it. Then, circulate some water through it placing inside a

bucket of clean water.

15.6 TENSIONING THE DRIVE BELT (fig. 8)

- Turn off the endothermic engine.

- Unscrew the 4 screws that lock the movable belt guard (ref. 1).

- Loosen the two screws (ref. 2) that clamp the water pump to

the bracket and move the pulley away so that it does not touch it.

- Loosen the 4 screws (ref. 3) that clamp the endothermic

engine to the blade support.

- Tension the belt using the nut (ref. 4): apply a force of about

F=14 lb. to the centre of the free section of the belt, the arrow

should be about f=1/4" in. (fig. 9).

- Tighten the screws on the endothermic engine, checking the

alignment of the engine pulley and the blade pulley

- Lower the water pump until the pulley touches the drive belt.

Tighten the two screws.

- Refit the guard and lock it using the 4 screws.

- To avoid shortening the life of the belt, the bearings

and the blade shaft, do not overtension the belt. Finally,

check the two pulleys are aligned.

15.7 DRIVE BELT REPLACEMENT

Repeat the operations described in section 15.6, replacing the

belt before tensioning it.

15.8 ENDOTHERMIC ENGINE MAINTENANCE

Read the Honda manual carefully... and follow their instructions.

Changing the oil (with the engine in horizontal position) and

cleaning the air filter frequently ensure a reliable and long lasting

engine.

When you may need Honda Engine Service or Warranty

Assistance take the machine to your local Honda power

equipment dealer, they will honour the Warranty throughout

America.

- It is always a good idea to check the oil level in the

engine cranckcase at the start of each working day.

Clean oil at the correct level markes for an engine that

will last and last.

15.9 REPAIRS

- Do not start the saw during repair work.

Only use genuine IMER spare parts and do not modify

them.

- If the guards are removed to carry out repairs,

they must be refitted properly when the repair work is

finished.

FAULT CAUSE REMEDY

Vertical blade

movement not

smooth

- locking knob too tight - Slacken knob

Horizontal carriage

movement not

smooth

- Guide rails dirty - Clean the guide rails

Lack of cooling water

supply to blade

Refer to section 15.5: "cleaning and

maintenance of cooling circuit" (Chapter 15.5)

Blade does not cut

- Blade is worn

- Drive belt not

tensioned

- Fit new blade

-Tension the belt

Motor starts but

blade does not rotate

Belt is broken Replace drive belt

16. TROUBLESHOOTING

- WARNING.. Stop the saw and turn off the

endothermic engine before carrying out any

maintenance.

6

MASONRY 350 F

IMER INTERNATIONAL S.p.A.

1

1

3

1

1

2

1

2

1

1

3

4

2

5° MAX

Fig. 2

Fig. 4

Fig. 5

Fig. 8

Fig. 7

Fig. 9

Fig. 10

UNSCREW

7

MASONRY 350 F

IMER INTERNATIONAL S.p.A.

TAV.1 - ASSEMBLY OF MOTOR

RIF. COD. GB NOTE

1 3210291 MOTOR HONDA GX 160

2 3210139

BELTS INTERNAL

COVER

3 3210148

BELTS EXTERNAL

COVER

4 3210185 BELT

5 3210159 PULLEY

6 2224190 WASHER 8X32 Z

7 2222076 BOLT M8X25 Z

8 2222176 BOLT M8X50 Z

9 2222004 BOLT M8X35 Z

10 2224140 WASHER 8X18 Z

11 2223923

SELF LOCKING

NUT

M8 Z

12 3203921 BOLT M5X10 Z

13 2222021 BOLT M6X16 Z

TAV. 2

TAV. 3

TAV. 1

TAV.2 - WHEEL KIT

Rif. Cod. GB Note

1 2226700 SPLIT PIN

2 2211150 WHEEL

3 3206261 LEFT TUBE GUIDE

4 3206262 RIGHT TUBE GUIDE

5 2222082 SCREW 5739 M 10X60 Z

6 2223650 DISK 5588 M10 Z

7 3206641 WASHER 6592 28X50X2 Z

8 3206260 WHEEL TUBE

TAV.2 - 45° SUPPORT

Rif. Cod. GB Note

1 2284859 KNOB

8

MASONRY 350 F

IMER INTERNATIONAL S.p.A.

TAV. 4 - MACH IN E STRU C TU RE

RIF. COD . GB NOT E

1 32 084 21 CARRIAGE

2 2222061 BOLT 5739 M 8X20 Z

3 2222515 BOLT 5931 M 8X16 Z

4 32 049 45 BEARING 608-2RS 1

5 2223923 SEL F LOCKING NUT M 8 Z

6 3207397 W HEEL

7 2222090 BOLT 5737 M 8x75 Z

8 3210193 GUIDE BAR

9 3208442

LE FT FE NCE

ADHESIVE LA B E L

10 32 084 41

RIGHT F E NCE

ADHESIVE LA B E L

11 320 5581 RUBBER COAITING

12 22 246 12 WASHE R D.21 X43 Z

13 32 060 86 PIN

14 32 015 17 LEG

15 32 101 78

CUTTING HE A D

GROUP

16 32 060 96 SUP P ORT

17 22 239 20 SELF LOCKING NUT M 10 Z

18 32 010 15 PLUG

19 22 225 87 SCRE W 5933 M 8X 20 Z

20 3210171 SPRAY GUA RD

21 3210169 FRAME

22 3205526

WATER RUN-OFF

TRAY

23 2222425 SCRE W AUTOFOR.TE 4,2X13

24 3204818 DRUM

25 2235428 PLUG

26 3210173 WATE R P UMP

27 3210183 WATER FILTER

28 2224320 WASHE R D.10 X21X 2

29 3210158 SHA F T

30 2209450 NYLON BUSHING

31 2222002 SCREW 5739 M 6x16 Z

32 2222059 SCRE W 5739 M8X25 Z SX .

33 3208414 LEVER

34 3208422 GONIOMETER

35 3207213

GUIDE BAR

SUPPORT

36 3208428 TROLLE Y S L IDE

37 3210236

GUIDE BAR

SUPPORT SX

38 2222580 SCRE W M 4X 20 Z

TAV. 4 - MACHINE STRUCTURE

RIF. CO D. G B NO TE

39 3210153

ROTATION

ADJUSTING ROD

40 3209333 KNO B M 8 Z

41 3210297 TROLLEY CLAM PING

42 2222016 SCREW 5739 M 6x20 Z

43 2223924 NUT M 6 Z

44 3209332 CAM

45 2222018 SCREW 5931 M 8X35 Z

46 2224534 WASHER 6X12.5 Z

47 3210416

HOOSE JOINT 90°

1/4"

48 3210175

EMERGENCY

SW ITCH

49 2288885 HANDG RIP

50 3206513 BEARING 6205 2RS

51 3210179 DISC COVER

52 3232759 OIL SEAL RING 35X52X7

53 3204777 INNER FLANG E

54 3204776 OUTER FLANGE

55 3210156 WATER HOSE

56 3210629 BEARING 6006 2RS

57 3205635 VALVE

58 3210140 BLADE COVER

59 2222006 SCREW M 8X30 Z

60 3210189 SELF LOCKING NUT M 20 Z

61 3210418 HOO SE JO INT 1/4"

62 3204889 LEVER

63 3210160 PULLEY

64 2224910 WASHER DEV. D.10 Z

65 3210142

BLADE GUARD

ROTATION ROD

66 3210152 SPRING

67 2227320 STOP RING E/20

68 3210181 SPRING PIN

69 3210206 SPRAY GUARD

70 3210149 TIE ROD SCREW

71 3210229 PUMP COVER SHEET

72 2226778

HOOSE JOINT F3/8

73 3210542

DISK PROTECTIO N DX

74 3210543

DISK PROTECTIO N SX

75 3210576 NYLO N WASHER 8.4XX17X1.5

76 2224140 WASHER 8X18 Z.

77 2222110 SCREW 8X80 Z

TAV. 4

ONE YEAR WARRANTY

We warrant to the original purchaser that the IMER equipment described herein

(the "equipment") shall be free from defects in material and workmanship under

normal use and service for which it was intended for a period of one (1) year from

the date of purchase by the original purchaser.

Our obbligation under this warranty is expressely limited to replacing or repairing,

free of charge, F.O.B. our designated service facility, such part or parts of the

equipment as our inspection shall disclose to be defective. Parts such as engines,

motors, pumps, valves, electric motors, etc. furnished by us but not manifactured by

us will carry only the warranty of the manifacturer. Transportation charges or duties

shall be borne by the purchaser. This shall be the limit of our liability with respect to

the quality of the equipment.

This warranty shall not apply to any equipment, or parts thereof, which has been

damaged by reason of accident, negligence, unreasonable use, faulty repairs, or

which has not been mantained and operated in accordance with our printed

instructions for our equipment. Further, this warranty is void if the equipment, or any

of its components, is altered or modified in any way.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY OF FITNESS FOR A PARTICULAR PURPOSE.

We make no other warranty, representation or guarantee, nor is anyone authorized

to make one on our behalf. We shall not be liable for any consequential damage of

any kind, including loss or damage resulting, directly or indirectly, from the use or

loss of use of the machine. Without limiting the generality of the foregoing, this

exclusion from liability embraces the purchase's expenses for downtime, damages

for which the purchaser may be liable to other persons, damages to property, and

injury or death of any persons.

This warranty shall not be deemed to cover maintenance parts, including but not

limited to blades, belts, hoses, hydraulic oil or filters, for which we shall have no

responsability or liability whatsoever.

IMER U.S.A., Inc.

207 Lawrence Avenue

South San Fancisco, California 94080

(650) 872-2200

This is a contact addendum to our manuals

Imer USA East

221 Westhampton Pl

Capitol Heights, MD 20743

Phone: 301-336-3700

Fax: 301-336-6687

Order Fax:301-336-5811

Imer USA West

3654 Enterprise Ave

Hayward, CA 94545

www.imerusa.com

800-275-5463

Loading...

Loading...