IMER USA COMBI 350 Operating, Maintenance, Spare Parts Manual

OPERATING, MAINTENANCE, SPARE PARTS MANUAL

09/2003 - R5

- Cod. 3214816 -

IMER U.S.A. Inc.

207, Lawrence Avenue

South San Francisco, California 94080

(650) 872-2200

COMBI 350

SAWING MACHINE

2

IMER U.S.A. Inc.

COMBI 350

Dear Customer,

Congratulations on your choice of purchase: IMER saws are the result of

years of experience and is equipped with all the latest technical innovations.

WORKING IN SAFETY

To work in complete safety, read the following instructions carefully.

- This OPERATION AND MAINTENANCE manual must be kept on site

by the person in charge, e.g. the SITE FOREMAN, and must always be

available for consultation.

- The manual is to be considered integral part of the machine and must

be kept for future reference (EN 292/2) until the machine is disposed of.

If the manual is damaged or lost, a replacement may be requested from

the saw manufacturer.

- The manual contains important information regarding site preparation,

machine use, maintenance procedures, and requests for spare parts.

Nevertheless, the installer and the operator must both have adequate

experience and knowledge of the machine prior to use.

- To guarantee complete safety of the operator, safe operation and long

life of equipment, follow the instructions in this manual carefully, and

observe all safety standards currently in force for the prevention of accidents

at work (use of safety footwear and gloves in accordance with S.I. N°3073

of 30/11/92).

Pay special attention to warnings bearing the following symbol.

Safety glasses or a protective visor must be worn at all

times.

MAKE SURE THAT SIGNS ARE LEGIBLE.

It is strictly forbidden to carry out any form of modification

to the steel structure or working parts of the machine.

- IMER INTERNATIONAL declines all responsibility for non-compliance

with laws and standards governing the use of this equipment, in particular;

improper use, defective power supply, lack of maintenance, unauthorised

modifications, and partial or total failure to observe the instructions contained

in this manual.

2. DESIGN STANDARDS

COMBI 350 saws are designed and manufactured according to the

following standards: I.E.C. 34.4; EN 89/392 (91/368/CEE); CEI EN 60204.

3. NOISE EMISSION LEVEL

Operator exposure to sound emission levels (continuous sound pressure

levels equal to A weighting); the COMBI 350 saw noise emission level

during cutting is 93 dB(A) with continuous rim blade.

4. CUTTING SPECIFICATIONS

This saw model has been specially designed by IMER for cutting stone,

ceramics, marble, granite, concrete and similar materials. Only water-

cooled diamond blades with continuous or segmented edges must be

used. Under no circumstances must dry cutting blades be used or

materials other than those specified above. IMER INTERNATIONAL

declines all responsibility for damage caused by improper use of the

above machine.

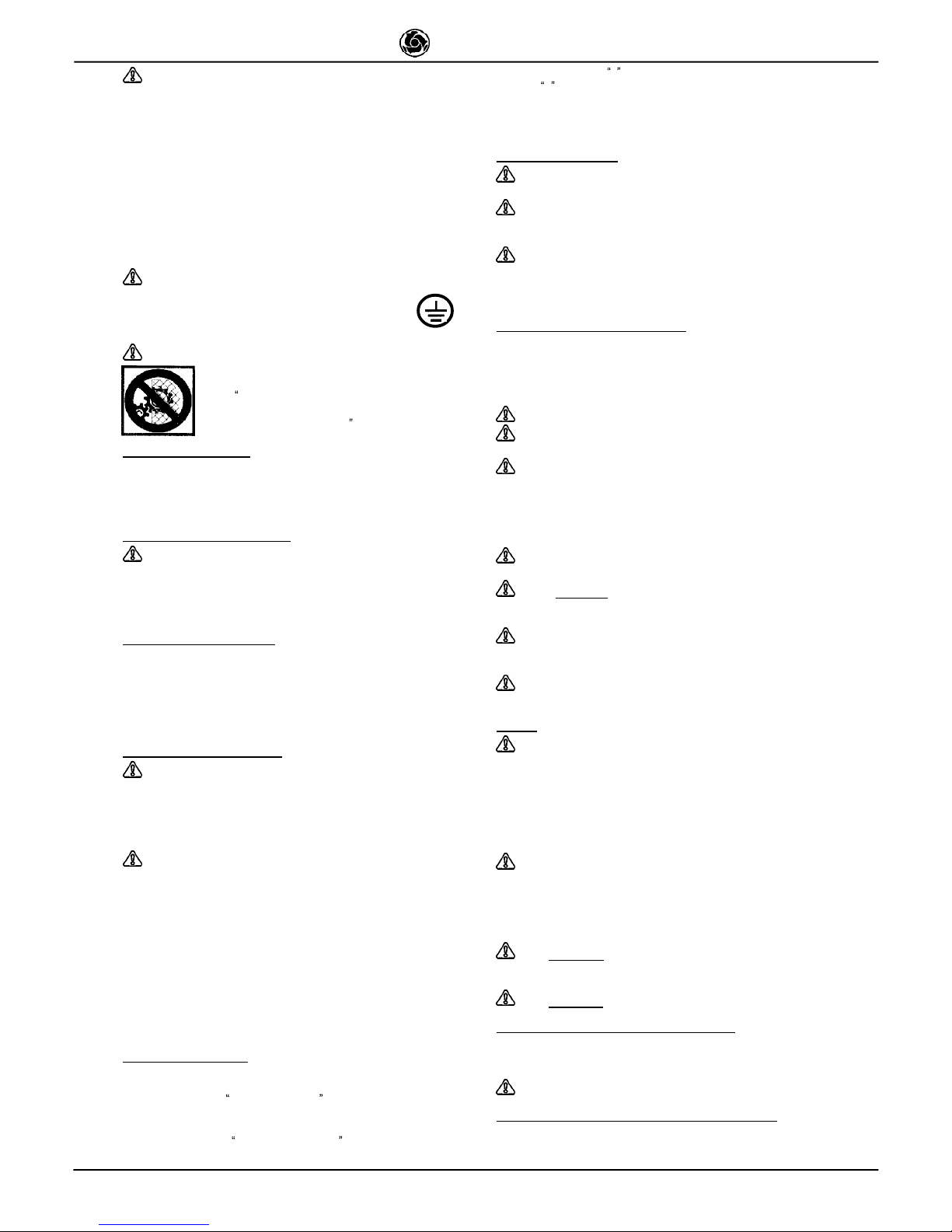

TECHNICAL DATA

COMBI 350

350/600 350/1000

Blade rpm

rpm 2150 2040 / 2150

Blade diameter

inc 14''

Blade mounting hole

inc 1''

Motor rating

Hp 3.0 1.5 / 3.0

Motor rpm

rpm 3450 3260 / 3450

Cutting table

dimensions

inc 20'' x 31'' 20'' x 46''

Overall dimensions

inc 47'' x 34'' x 51'' 63'' x 34'' x 51''

Overall dimensions for

transport

inc 51'' x 28'' x 37'' 67''x 31'' x 37''

Weight

lb 253 287

Weight for transport

lb 298 342

Blade rotation

direction(seen from

blade clamping flange)

ANTI - CLOCKWISE

Current

A 11 13.4 / 11

Voltage

V 230 115 / 230

Frequency

Hz 60

5. CUTTING CAPACITY

- Max. thickness (inc): 5'' (90°); 3'' (45°)

- Workpiece width (inc): max. 20'' ; min 2''

- Length: COMBI 350/600 COMBI 350/1000

thk. x l (inc) 1'' x 24'' 1'' x 40''

3'' x 22'' 3'' x 38''

(*) 90° cut from above

5'' x 21'' 5'' x 37''

5'' x 28'' (*) 5'' x 43'' (*)

(**) 45° 45 x 21'' (**) 70 x 37'' (**)

6. WARNING

- Do not load the saw with workpieces that exceed the specified weight

(max. 90 lb).

- Ensure stability of machine and workpiece before, during or after cutting.

Install supplementary support surfaces at the same height as the

worktable.

- Respect the environment; use suitable receptacles for collection of

cooling water contaminated with cutting dust.

7. SAFETY PRECAUTIONS

IMER saws are designed for work on construction sites and under

conditions of natural light and in workshops under conditions of natural

or artificial lighting of minimum 500 LUX.

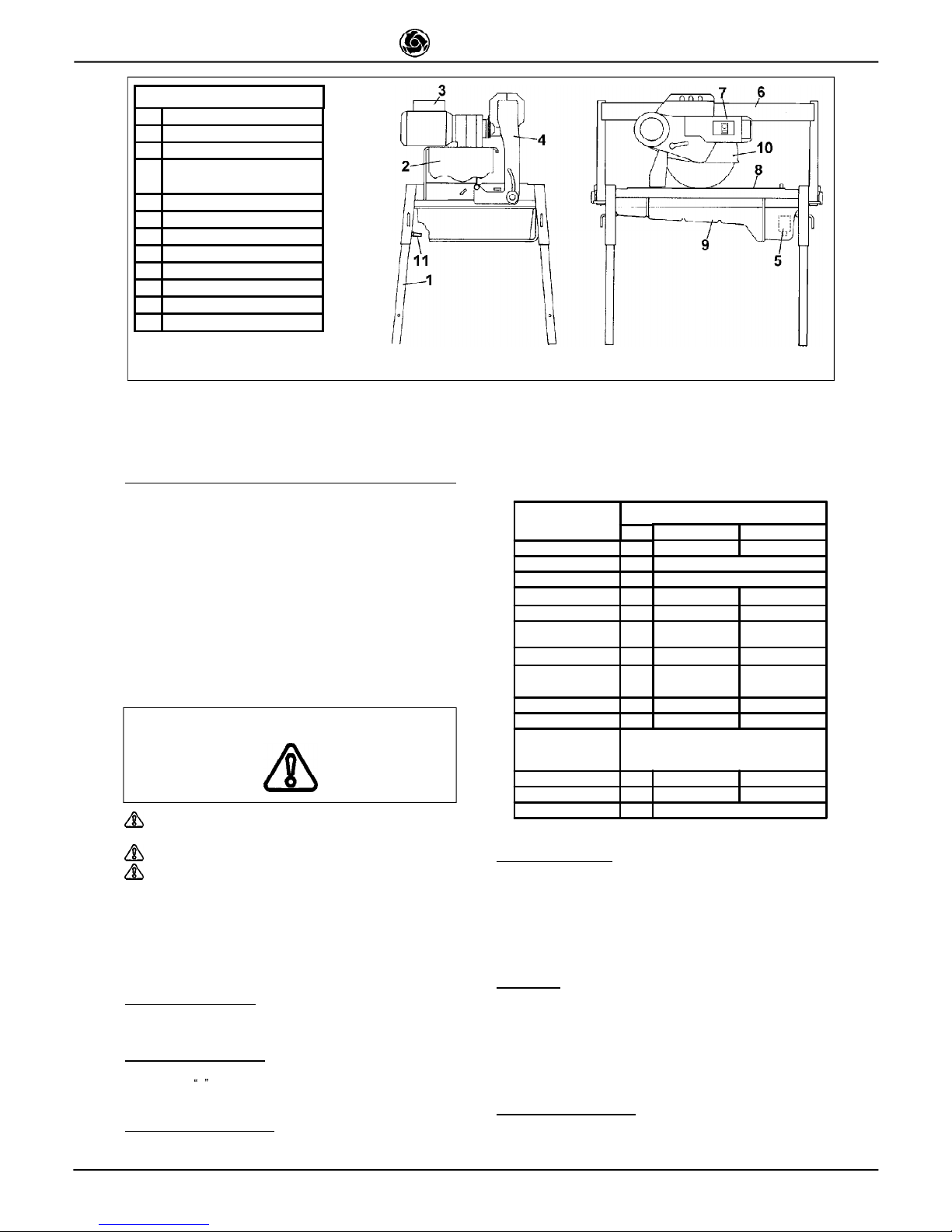

Fig. 1 MACHINE LAY-OUT

1 TELESCOPIC LEG

2 SPRAY GUARD

3 MOTOR

4

BLADE SUPPORT

ARM

5 WATER PUMP

6 GUIDE

7 MAIN SWITCH

8 WORKTABLE

9 WATER TANK

10 BLADE GUARD

11 EARTHING SCREW

12 HEAD BLOCKAGE

Fig. 1 - Machine Lay-out

3

IMER U.S.A. Inc.

COMBI 350

The machine must never be used in environments

subject to risks of explosion and/or underground sites.

- IMER saws may only be used when fitted with all required safety devices

which must be in perfect condition.

- Never use makeshift and/or faulty power cables.

- Make electrical connections on the construction site where they will

not be subject to damage. Never stand the saw on power supply cables.

- Lay power cables where they are not subject to risk of damage or

contact of connectors with water. Only use connectors fitted with waterspray protection (IP55).

- Repairs to electrical installations must only be carried out by qualified

technicians. Always ensure that the machine is disconnected from the

power supply and is completely immobile during repairs and maintenance

operations.

- Connect the machine to a suitable equipotential earthing

plant on the construction site with wire braid of minimum

16 mm² section. The connection point is identified by a

screw welded to the frame (see Fig.1), and on the rating

plate by the

earthing symbol.

- Stop the saw only by means of the main switch.

- The symbol shown on the label (see left) indicates the

warning ENSURE ALL PROTECTION DEVICES ARE

INSTALLED AND IN PERFECT CONDITION BEFORE

SWITCHING ON THE MACHINE

8. ELECTRICAL SAFETY

IMER saws comply with EN 60204-1; and are fitted with:

- protection device against automatic re-start after power failure;

- Short-circuit cutout device;

- Motor overload cutout switch.

9. TRANSPORTATION (Ref. Fig.2)

WARNING! Always remove the plug from the power socket

before moving the saw, and lock head support carriage movement

by means of the relative knob (ref. 3). To transport the machine use

slinging equipment with 4 rope legs, fixing the hooks to the relative

attachments.

10. INSTALLATION (Ref. Fig.2)

Fix the hooks to the relative attachments on the machine and lift the

machine out of its package.

- Unlock the legs by sliding out split pins (ref.2) and pins (ref.1).

- Lock the legs at working height. Refit the pins in the leg supports and

insert the split pins.

- Install the machine on a completely even and stable surface.

11. ELECTRICAL CONNECTION

Ensure that there is an overload cutout device fitted up-

line on the power line. If necessary, install an IMER quick connect

residual current circuit breaker (RCCB) (code no. 1169245 available

in kit form for 230V machines).

Ensure that the mains voltage corresponds to that specified for the

machine: 230V/60Hz - 115V/60Hz.

All power supply installations must comply with CEI 64-

8 standards (harmonised document CENELEC HD384).

The electrical power cable must be suitably sized to avoid voltage drops.

Cable drums (with collector rings) must not be used.

Cable dimensions will vary according to the start-up current and length of

cable. In general cable sizes of 4 mm² are sufficient for lengths up to 160

ft. After installation always carry out voltage testing under load conditions,

both at start-up and during operation. During operation, voltage drops

must never exceed 5%. In the case of longer cables or a power supply

network subject to variations, use cables with a section of at least 6

mm². Cables used on construction sites must be fitted with suitable

external sheathing that is resistant to wear, crushing and extreme weather

conditions.

12. MACHINE START-UP

Before connecting the machine to the power supply:

1 - Ensure that the metal structure is connected to an earthing plant as

indicated in Section 7 Safety Precautions .

2 - Ensure that the tank contains sufficient cooling water.

3 - Ensure that the power circuit corresponds to the requirements as

indicated in Section 11 Electrical connections

4 - Connect the machine to the power supply.

5 - Set the switch to 1 and when the motor is started return to

position 0 after ensuring that cooling water reaches the blade.

6 - Check that the direction of blade rotation corresponds to that

indicated by the arrow on the blade guard.

7 - If all is in order, proceed with cutting.

13. EMERGENCY STOP

- In the event of emergency,stop the machine by pressing

the stop control switch.

- The motor is fitted with an overload cutout device. If the

motor overheats, it will automatically shut down. Allow motor to

cool before re-starting.

- The motor is protected against automatic re-start after

interruptions due to power failure. To resume operation, when power

is re-connected, repeat machine start-up procedure.

14. BLADE INSTALLATION (Ref.Fig.3)

By means of a hex wrench no.10, remove front screws (ref.1) and loosen

the other two screws (ref.2) which secure the blade guard. Turn the guard

clockwise to gain access to the securing screw (ref.4). Use a hex wrench

no. 13 to remove the screw (turn anti-clockwise). Remove the mobile

flange and check that the flanges, disc shaft and blade are not damaged.

- Never use worn blades.

- Only use blades that are designed for the number of

revolutions indicated on the machine rating plate.

- Check that blade rotation corresponds to that indicated

on the blade guard.

Centre the blade against the fixed flange, position the mobile flange and

tighten the securing screw by means of a hex wrench no. 13 (turn

clockwise). Return the guard to its original position and lock by means of

screws (ref.1 and 2).

- Ensure that the blade guard is locked securely into

position.

- WARNING! An incorrectly installed blade, or a screw

insufficiently tightened can provoke damage to the machine or injury

to persons.

- Note that the blade must have an external diameter of

350 mm., a central hole diameter of 25.4 mm and max. thickness of

3 mm.

- Check that the blade to be used is suitable for the

material to be cut.

15. USE

Leave a space of 5 ft around the machine to operate in

full safety.

- Do not allow other persons to approach the machine during cutting.

- Never use the machine in fire-risk areas. Sparks can cause fire or

explosions.

- Make sure that the machine is switched off before positioning or handling.

- Always ensure that the blade is free of any contact before start-up.

- Ensure correct installation of all protective devices.

- Ensure that blade rotation corresponds to the indications

on the blade guard.

Before starting work, fill the water tank. Top up during operation whenever

necessary: N.B. the pump suction hose must always remain

immersed in water.

Insert the plug in the power socket.

WARNING!

For safety purposes the removal of protective

guards from the machine is strictly prohibited !

The machine is protected against overload.

WARNING!

Always switch off the machine before carrying

out blade adjustment.

15.1 VERTICAL BLADE MOVEMENT (Ref. Fig. 4)

To raise or lower the blade, slacken knob (ref.2) by turning it anti-clockwise.

Set blade support (ref.1) to the required position and lock by tightening

the knob fully (ref.2).

Ensure that the locking knob is tightened fully before

starting work.

15.2 BLADE POSITIONING FOR 45° CUTS (Ref.Fig.5)

Slacken knob (ref.1); the blade support arm (ref.2) is unlocked and

so can be set to its limit position, i.e. inclined at 45° with respect to

Loading...

Loading...