IMER 1188174, COMBI 250/1000 VA, COMBI 250/1500 VA, 1188180 Operating, Maintenance, Spare Parts Manual

COMBI 250/1000 VA

SAWING MACHINE

1188174

OPERATING, MAINTENANCE, SPARE PARTS MANUAL

IMER WEST

3654, Enterprise Avenue

Hayward, CA 94545

Ph. 510.670.7970

Fax 510.783.4255

IMER EAST

221 Westhampton Place

Capitol Heights, MD 20743

Ph. 301.336.3700

Fax 301.336.6687

IMER U.S.A. Inc.

Toll Free: 800.275.5463

www.imerusa.com

info@imerusa.com

2016/10 - R11

Cod. 3227118

COMBI 250/1500 VA

SAWING MACHINE

1188180

IMER U.S.A. Inc.

COMBI 250/1000 VA - COMBI 250/1500 VA

2

Dear Customer,

Congratulations on your choice of purchase: IMER saws are the result

of years of experience and are equipped with all the latest technical

innovations.

- WORKING IN SAFETY

To work in complete safety, read the following instructions carefully.

To work in complete safety, read the following instructions carefully before using the machine.

To work in complete safety, read the following instructions carefully before using the machine.

This OPERATION AND MAINTENANCE manual must be kept on site

by the person in charge, e.g. the SITE FOREMAN, and must always be

available for consultation.

The manual is to be considered integral part of the machine and must

be kept for future reference (EN 12100-2) until the machine is disposed

of. If the manual is damaged or lost, a replacement may be requested

from the manufacturer.

The manual contains important information regarding site preparation,

machine use, maintenance procedures, and requests for spare parts.

Nevertheless, the installer and the operator must both have adequate

experience and knowledge of the machine prior to use.

To guarantee complete safety of the operator, safe operation and long

life of equipment, follow the instructions in this manual carefully, and

observe all safety standards currently in force for the prevention of accidents at work (use of safety footwear and suitable clothing, helmets,

gloves, goggles etc.).

- Make sure that all signs are legible.

- It is strictly forbidden to carry out any form of modication to

the steel structure or working parts of the machine.

IMER INTERNATIONAL declines all responsibility for failure to comply with laws and standards governing the use of this equipment, in

particular; improper use, defective power supply, lack of maintenance,

unauthorised modications, and partial or total failure to observe the

instructions contained in this manual.

IMER INTERNATIONAL reserves the right to modify features of the saw

and contents of this manual, without the obligation to update previous

machines and/or manuals.

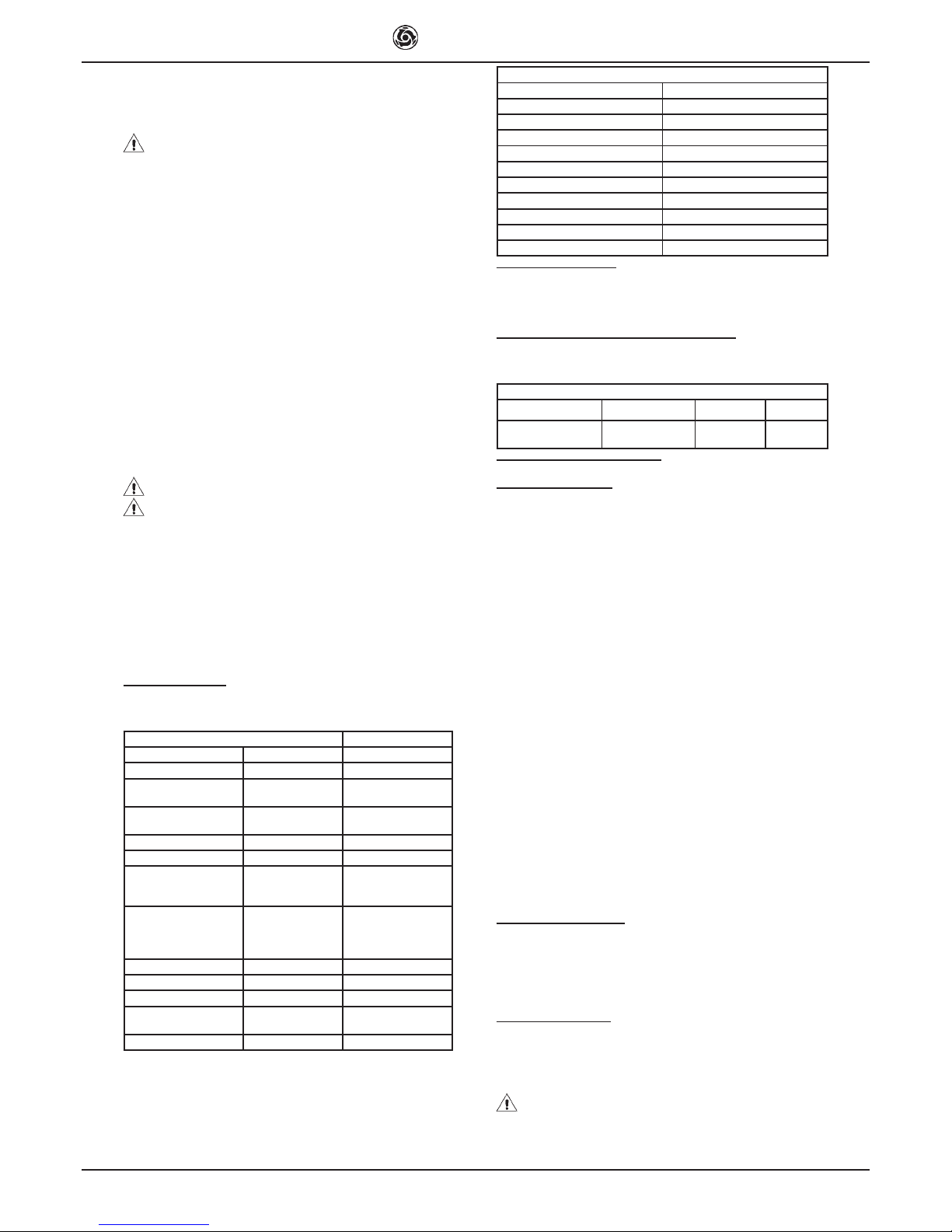

1. TECHNICAL DATA

Technical data are stated in table 1 and electrical specications in table

2.

Table 1 - TECHNICAL DATA

Model Combi 250/1000 VA Combi 250/1500 VA

Max. blade diameter 10 inches 10 inches

Diamond Blade hole

diameter

5/8 inches 5/8 inches

Single phase 115V/60Hz

motor power

1.3 kW 1.3 kW

Max. blade rotation speed 3400 rpm 3400 rpm

Cutting table dimensions 1115x500 mm 1615 x500 mm

Length of 90° cuts

(thickness= 10mm)

Length of cuts from above

950 mm

1000 mm

1450 mm

1500 mm

Maximum cut depth with

single stroke

Maximum cut depth with

two stroke

66 mm

105 mm

66 mm

105 mm

Water pump ow rate 13 l/min 13 L/min

Water tank capacity 40 L 50 L

Machine dimensions 1420x636x619 mm 1920x636x619 mm

Packed machine

dimensions

1454x669x654 mm 1954x669x654 mm

Weight with packaging 65 kg 80 kg

Table 2

Feature Motor (115V/60Hz)

Power (kW) 1.3

Rated voltage (V) 115

Frequency (Hz) 60

Absorbed current 14.4

Number of poles 2

rpm 3400

Service type S6 40%

Insulation category F

Protection category IP55

Capacitor (µF) 110 (Ø 50x120)

2. DESIGN STANDARDS

Combi 250/1000 VA saws have been designed and manufactured according to the following standards: UNI EN 12418:2001; EN 121001/2:2005; EN 60204-1:2006.

3. SOUND PRESSURE LEVEL AND VIBRATIONS

Table 3 shows the sound pressure level measured loadless at the operator’s ear (LpA) and of the vibrations transmitted during operation.

Table 3

Model Type of motor L

pA

A

eq

Combi 250/1000 VA -

250/1500 VA

Electric 86 dB 2.57 m/s

2

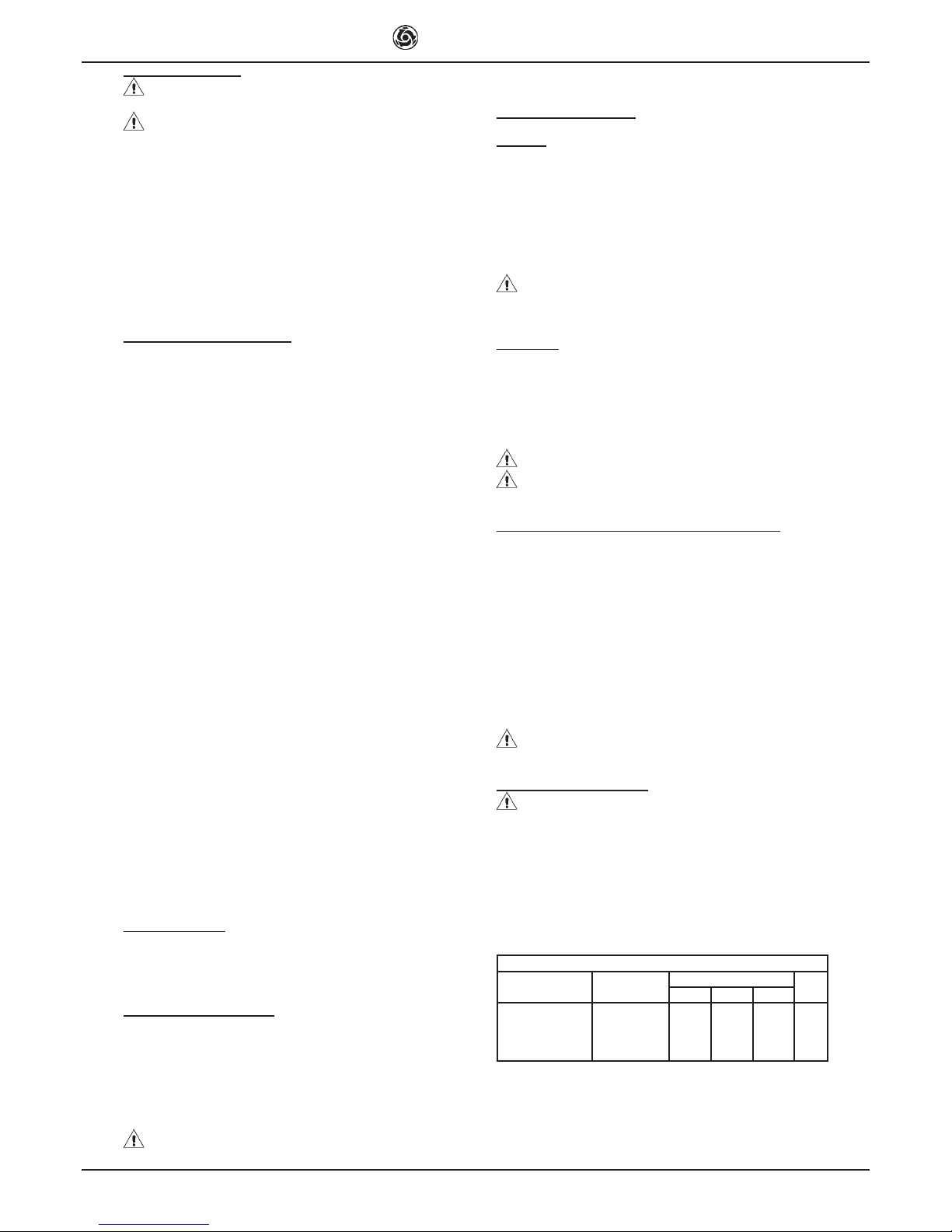

4. GENERAL SAW DESCRIPTION

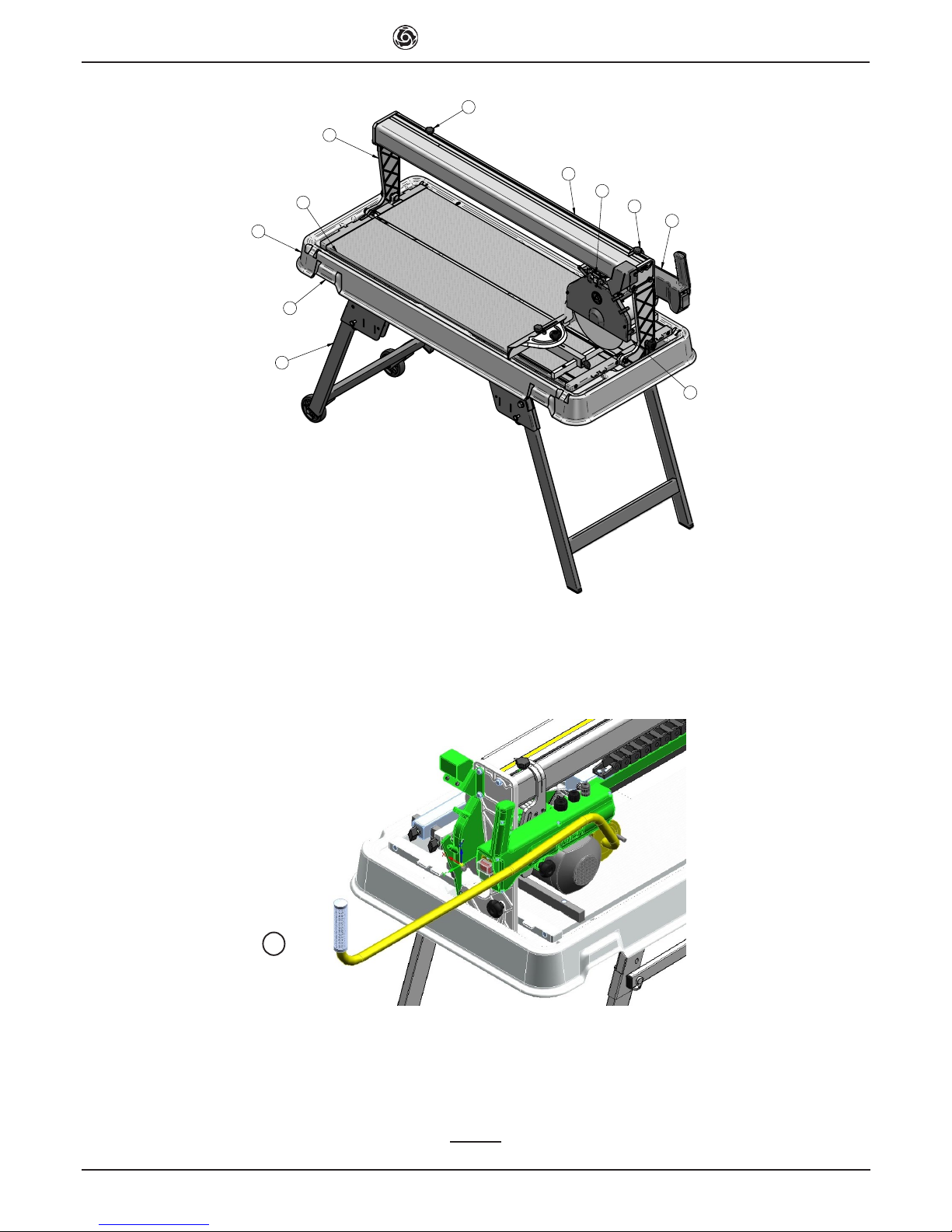

4.1 General description

The Combi 250/1000 VA (250/1500 VA)is a saw comprising the following

main sub-groups:

• cutter head (ref.A, g.1)

• runner guide and arms (ref.B, g.1)

• cutting tables and heads (ref.C, g.1)

• water collection tank (ref.D, g.1)

• frame (ref.E, g.1)

The cutting head is mounted on a reinforced aluminium prole and is

equipped with horizontal and vertical movement facilities. The alumi-

nium prole is hinged onto die-cast arms (ref.F, g.1) and the entire

unit can rotate through 45° (g.2) by means of the relative handwheels

(ref.G, g.2).

The machine is supported by a special metallic frame. There is a

shockproof plastic tank between the machine and the frame. The water

immersion pump is mounted below the cutting surfaces on a special bracket and supplies a water distributor inside the blade guard for cooling

the cutting blade during operation.

The high resistance plastic handle (ref.H, g.2), is equipped with the

main ON-OFF switch on the operator side to facilitate saw activation

and shutdown.The raised position of the red OFF button on the handle is

designed to facilitate shutdown of the machine in the event of an emergency. The motor capacitor is located in a protected position inside the

handle.

The saw is tted with a guard to guarantee optimal safety during operation and to protect the user during cutting cycles.

A valve is mounted above the blade guard to adjust the ow rate of water

delivered to the cutting blade. The version 250/1500 Va the movement

for the cutting head it is possible by the handle (rif Q, g 1)

4.2 Processable materials

This saw has been designed for cutting the following materials: ceramic

tiles, masonry and stone in general with maximum dimensions compatible with the length, cutting depth and dimensions of the surfaces

specied in table 1.

Maximum weight of processable materials: 25 kg.

4.3 Unsuitable material

Materials unsuitable for this machine are all those not specied in paragraph 4.2.

In any event, before using the saw with materials other than as specied

by the manufacturer for this saw model, contact IMER INTERNATIONAL

S.p.A.

- Use of this machine with workpieces outside the specied

dimensions is strictly prohibited and constitutes a hazard for the

operator.

IMER U.S.A. Inc.

COMBI 250/1000 VA - COMBI 250/1500 VA

3

5. OPERATION SAFETY

- Before using the saw, ensure that all protection devices are

tted.

- Never use the saw in environments subject to the risk of

explosions or re.

The saw is not tted with specic lighting and therefore the workplace

must be sufciently lit for this purpose (min. 300 lux).

The power lines must be laid to prevent any possible damage.

Ensure that the electrical connection is protected against the risk of water penetration in connectors. Use exclusively connectors and couplings

equipped with water spray protection.

Never use inadequate or makeshift electrical lines or cables without

earthing; if in doubt consult a specialised technician.

Repairs to the electrical circuit must be performed exclusively by specialised personnel. Disconnect the machine from the power supply before

performing maintenance or repairs.

6. GENERAL SAFETY WARNINGS

Note that this machine has been designed to ensure optimal performance and maximum safety: however the operator must also guarantee this

level of safety by paying special attention to the machine throughout all

work phases.

1. Ensure that an efcient earthing system is installed.

2. Work only with all protection devices tted correctly and in ef-

cient working order.

3. Remove rings, watches, bracelets or ties before using the machine; these elements constitute a serious hazard to the operator.

Also ensure that sleeves are tight around the wrists, hair is tied

back and robust footwear is used.

4. Always use personal protection devices such as safety goggles,

suitably sized gloves, ear muffs or plugs and hair caps when necessary.

5. Never cut workpieces that have dimensions or weight that are

not suited to machine i capacity as specied by the manufacturer

(see point 4.2)

6. Always keep your hands away from the work areas when the

machine is running. Before taking any action to remove a piece

from close to the disc, stop rotation by pressing the stop button.

7. Keep the machine clean: general cleaning (and the work surfaces in particular) represents an important safety factor.

8. Always stop the machine and disconnect from the power supply

before cleaning or removing any protection device (for maintenance or disassembly purposes). If water jets are used for cleaning,

never point jets directly at the power supply unit or electric motor.

9. Use genuine diamond blades as recommended by the manufacturer to ensure optimal performance of the machine.

10. Use exclusively water-cooled continuous rim blades suited to

the material to be cut.

11. Never dry cut material or cut when cooling water levels are low.

12. Never use blades over the rotation speed specied by the manufacturer.

13. Do not use reduction rings to adapt the hole of the disc on the

ange. Only use discs with hole corresponding to the ange supplied with the machine (1" or 7/8").

14. Never use diamond blades that are chipped or deformed.

15. The instructions in this manual are aimed at machine users

(operators, maintenance engineers).

7. SAFETY DEVICES

The Combi 250/1000 VA(250/1500 VA) has been constructed taking into

account current harmonised European safety standards.

According to machine directive 98/37/EEC all safety devices have been

installed with the aim of safeguarding the operator.

7.1 Guards and safety devices

The machine is equipped with xed guards, secured by means of screws

and protections that prevent access to moving or dangerous parts.

All xed guards, covers, shields xed by means of screws have been

envisaged to protect the operator (maintenance engineers, technicians

and others) from possible accidents cause by electrical discharge or

moving mechanical parts.

Therefore use of the machine with guards removed or modied in any

way is strictly prohibited.

- Before performing maintenance or repairs to the machine,

turn it off via the main switch and disconnect from the power sup-

ply to prevent inadvertent start-up and isolate all machine electrical circuits.

8. MACHINE INSTALLATION

8.1 Set up

Remove the machine packing.

The machine can already be used, leaving the legs folded, resting its

frame on a sufciently even surface at least as big as the tank.

Frame assembly:

1. remove the machine and tank from the folded frame.

2. remove the safety pins from the frame and open the legs.

3. put the safety pins back in the holes provided locking the legs in the

open position.

4. reposition the machine and tank on the frame.

- Make sure that the frame is positioned on a at and even surface, capable of bearing the weight of the machine. The maximum

permissible gradient in all directions is 6°.

8.2 Handling

The Combi 250/1000 VA sawing machine weighs 57 Kg(250/1500 VA

80 kg) and can be moved using the side handles on the tank (ref.I,

g.1). For short distances use the wheels tted on the frame. For longer

distances, before moving the machine, close the frame reversing the

sequence of the operations described in point 8.1.

Every time the machine is moved, make sure the head is locked tighte-

ning the knobs (ref.L, g.1).

- Always empty the tank before moving the machine.

- Always disconnect the power plug before moving the machine.

8.3 Additional table assembly (optional kit code 1188176)

The additional table can be installed to the left or right of the machine, or

on both sides at the same time.

First t the cross member (ref.5, g.6) to the bolts on the frame (ref.A,

g.6) and secure it with the nut and washer (ref.6-7, g.6). Secure the

other end of the cross member with the locking pin (ref.8, g.6) on the

front legs.

Fit the strut (ref.1, g.6) to the cross member, making sure that it locates

into the grooves, which hold it perfectly vertical.

Now install the additional table; it is supplied with the side mounts already assembled. Fit the mounts into the provided cavities in the side

panels of the machine, making sure they are fully inserted. Now lower

the additional table until it is properly supported. Level the additional

table with that of the machine itself; to do this, move the strut to the left

or right along the cross member (g.6).

- The use of additional tables without props can cause damage

to them.

9. ELECTRICAL CONNECTION

- Ensure that voltage corresponds to machine dataplate spe-

cications.

The power supply line must be equipped with current overload protection (e.g. thermal cutout) and protection against indirect contact (e.g.

residual current circuit breaker).

Connect the machine to an efcient earthing system.

The size of the power cable wires must be based on operating current

and length of the power line to prevent excessive voltage drops (table

4).

Table 4

Model Type of motor

Cable (mm²)

1.5 2.5 4.0

Combi 250/1000 VA

-250/1500 VA

115 V

14.4 A

0 ÷ 12 13 ÷ 20 21 ÷ 32

Cable

length (m)

Connect the saw plug to the mains and tighten the mechanical retainer

ring with IP67 protection rating.

The saw is now ready for operation.

IMER U.S.A. Inc.

COMBI 250/1000 VA - COMBI 250/1500 VA

4

10. MACHINE USE

10.1 Operation

The correct side for the operator is shown in g.4 ref.X.

Fill the water tank to the maximum level (approx. 40 litres).

Connect the machine to the power mains and start as described in paragraph 10.

Open the valve (ref.N, g.1) and ensure sufcient ow of cooling water

to the diamond blade.

10.2 Cutting

Rest the material to be cut on the cutting table against the stopper. De-

ne the required inclination using the goniometer. To adjust the cutting

head height, loosen the handwheel (ref.O, g.3), position the head at

the required height, then fully tighten the handwheel. Make sure that

handwheels for sloped cutting (ref.G, g.2) are rmly tightened. Start the

sawing machine as described in paragraph 10. To proceed with cutting,

press the piece to be cut on the table with your hand and move the cutter

head gripping the handle and drawing it towards you. If the feed speed

is too fast in relation to the thickness and hardness of the material the

blade might stop turning. In this case, release the disk as quickly as

possible moving the cutter head away from you until the disk recovers

its nominal rotation speed. Resume cutting, adjusting the feed speed

according to the characteristics of the material.

10.3 Angled cuts

Loosen the handwheels (ref.G, g.2), set the cutting head at the required angle, retighten the handwheels, and proceed as described in the

point above.

- Ensure that the tank is kept full during all work phases and in

the event of prolonged work intervals replace water regularly and

remove all processing residue.

10.4 Laser pointer

The machine is tted with a laser pointer that reproduces the cutting line

on the piece being machined. The track of light indicates the trajectory

of the diamond disk during the feed motion. Making the required cutting

prole coincide with the laser prole, it is possible to ensure the highest

accuracy of the operation.

Cuts at right angle with one side of the piece being machined do not re-

quire tracing beforehand: in fact it will sufce to make sure that the side

of reference is in contact with the stopper on the resting surface. Likewi-

se, using the goniometer, cutting at predened inclinations is possible.

The laser light will indicate the actual position of the cut.

The laser pointer is activated when the machine is connected to the

electric mains.

The pointer is aligned with the disk and must not be moved from its

initial position.

- The pointer used emits a low power laser light, but it is in any

case advisable to avoid looking directly at the emitter itself.

11. MAINTENANCE

11.1 Premise

Routine maintenance operations can also be performed by non-speciali-

sed personnel provided that all safety standards specied in the relative

sections of this manual are observed at all times.

11.2 Machine cleaning

The machine should be cleaned exclusively when it is stationary.

- All power switches must be set to “0” and plugs must be

disconnected from the mains.

1. Never use compressed air; this could cause inltration of dust or residue in enclosed parts.

2. Ensure that the cooling water nozzles are not obstructed.

3. Above all the cooling water in the tank must be changed every day.

4. Do not use detergents or lubricants.

11.3 Cleaning the tank

Clean the tank in the event of build-up of sediment on the base, or at least once a day. Failure to clean the tank could impair operation of the immersion pump used for circulation of the diamond blade cooling water.

To clean the tank, disassemble from the machine, lock the head, hold it

by the arms and rinse with a direct water jet (this is to avoid direct contact of the water with electrical parts), the proceed with manual cleaning

using cloths or brushes.

Take care not to damage cables when replacing the machine on the tank

Take care not to damage the pump when placing the machine on the

surface

11.4 Cleaning the cooling water supply circuit

At regular intervals (or when the ow rate of the blade cooling water is

reduced) clean the cooling water supply circuit. To do this, disassemble

the delivery nozzle (ref.P, g.1) located inside the blade guard and clean

in water.

Periodically clean the cooling water delivery line between the pump and

valve and blade guard using water.

11.5 Blade replacement

The diamond blade is made of material that may be damaged when

subject to high temperatures, and therefore must be cooled during the

work phases.

To replace the blade, proceed as follows:

1. Block axial movement of the cutting head by means of the handwhe-

els (ref.L, g.1).

2. Disassemble the front guard (ref.P, g.1).

3. Loosen the locknut by rotating clockwise (left thread), using a 19 mm

wrench.

4. Move the cutting head forward slightly and incline to remove the blade

from its seat.

5. Ensure that there are no foreign objects between the xing ange and

diamond blade. During disassembly, avoid use of tools that could dent

or deform the ange.

6. Insert the new blade proceeding in reverse order of the operation

described at point 4. Take special care to ensure correct direction of

rotation of the diamond blade.

7. Tighten the blade locknut fully down by rotating anticlockwise (left

thread), to a torque of 40 Nm.

- Always disconnect the power plug before changing the disk.

11.6 Repairs

Repairs to the electrical installation must be performed exclusively by

specialised personnel. Use exclusively original IMER spare parts; modi-

cations to parts are strictly prohibited. The special design of the Combi

250/1000 VA ensures that no other maintenance other than as specied

above is required.

Ensure that the contacts of the power plug and plug-switch assembly

are efcient. If oxidation is detected, clean immediately

- In the event of activation of the RCCB, check the machine

and arrange for repairs if necessary exclusively by specialised

personnel.

11.7 Waste disposal

As regards disposal of processing waste observe all current legislation

in the country of use.

IMER U.S.A. Inc.

COMBI 250/1000 VA - COMBI 250/1500 VA

5

12. Residual risks and safety signs

Although the sawing machine has been manufactured fully in compliance with current regulations, residual risks exist that cannot be eliminated

and involve the use of appropriate individual protection devices. Ade-

quate warning signs tted on the machine point out both the risks and

the behaviour to be followed.

NOISE RISK

Ear protection must be worn

RISK OF INJURY TO THE HANDS

Safety gloves must be worn

RISK OF INJURY TO THE EYES

Eye protection must be worn

ABNORMAL USE RISK

Reading the manual before use is compulsory

Cutting with water is compulsory

DANGER OF CUTTING

DANGER OF ELECTROCUTION

DANGER OF LASER BEAM

Please be reminded that checking the use of IPDs is delegated to the

employer.

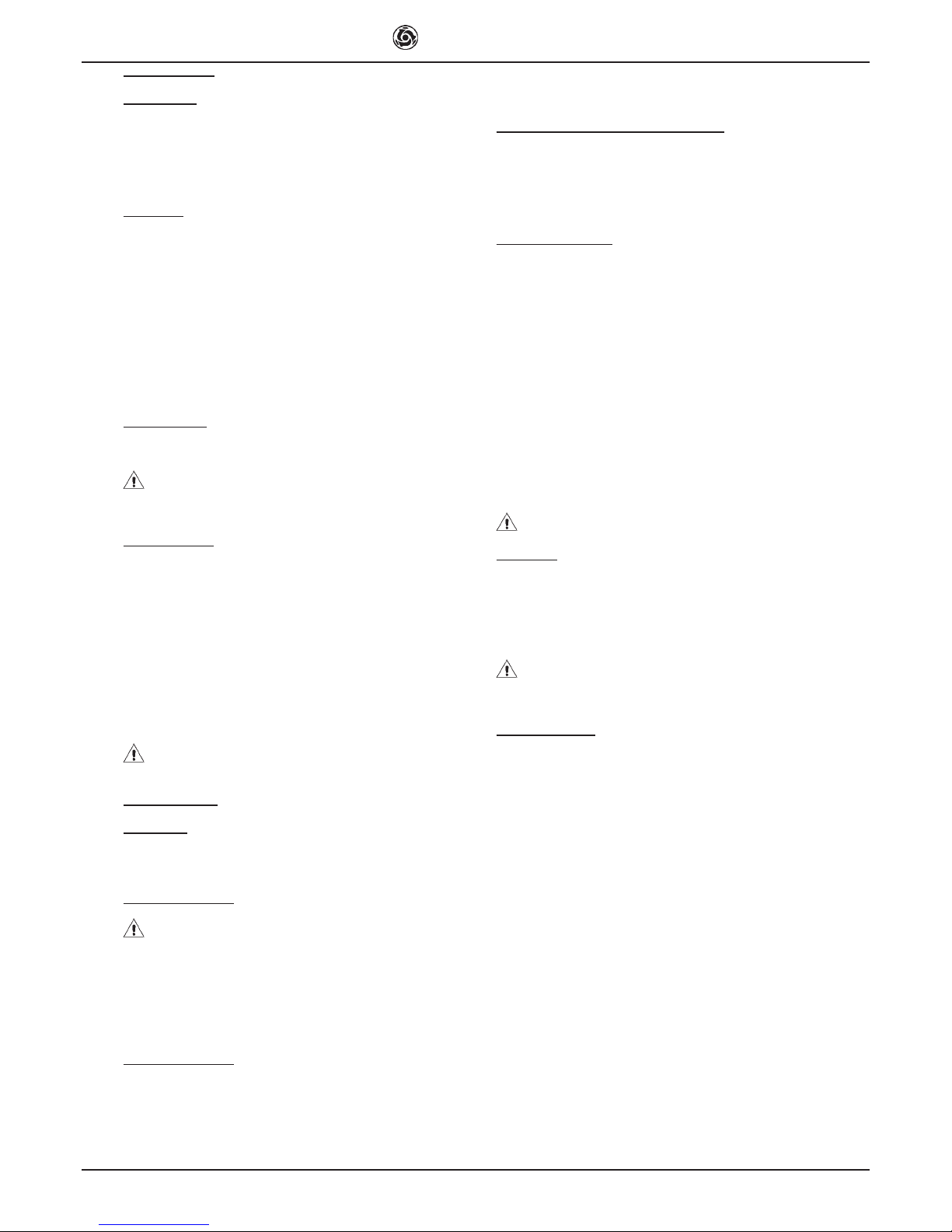

14. Troubleshooting

- CAUTION!!! All maintenance operations must be performed

exclusively with the machine switched off, with the selector set to

“0” and the power plug disconnected from the mains.

Trouble Causes Remedies

The motor does not

start when the start

switch is pressed

Current does not reach

the supply line

Check the line *

The socket and plug

are not connected

properly

Restore correct

connection

The differential switch

is off

Turn the differential

switch on

The power cable from

the plug to the panel

is cut off

Change the cable *

An electric wire inside

the motor terminal strip

is cut off

Restore the connection *

An electric wire inside

the panel is cut off

Change the switch *

The start switch is

faulty

Change the switch *

Cooling water fails

to reach the blade

Low water level in tank Restore the water level

Pump lter clogged Clean the pump lter

Current fails to reach

the pump

Check the pump

electrical supply *

Pump failure Change the pump *

The blade does

not cut

Blade tted in the

opposite direction to

that of rotation

Remove the blade

and reposition it in the

direction shown on the

blade label

Worn blade Change the blade

* Operation to be carried out by an electrician

IMER U.S.A. Inc.

COMBI 250/1000 VA - COMBI 250/1500 VA

6

A

B

C

E

D

F

I

L

L

N

P

FIG. 1

Q

Loading...

Loading...