Imed Gemini PC-4 Service manual (2000)

Jp^

Cut

and

insert

into

label

on spine of

binder

holder

PC-4

WARNINGS,

CAUTIONS

AND

NOTICES

CAUTION: FEDERAL

THE

ORDER

USE

ONLY

GROUNDING.

CONNECTION

OFAPHYSICIAN.

HOSPITAL

GROUNDING

TOARECEPTACLE

DANGER:

WARNING:

(USA)

GRADE

EXPLOSION

FLAMMABLE

TO

WHEN

LAW

RESTRICTS THIS DEVICE TO SALE BYOR ON

POWER

RELIABILITY

HAZARD,

ANESTHETICS.

PREVENT

FLO-STOP

SUPPLY

CAN

ONLY

MARKED

DO

"HOSPITAL

NOT

USEINTHE

UNRESTRICTED

IS

OPEN.

CORD

TO

BE

ACHIEVED

GRADE".

FLOW,

INSURE

PROPER

PRESENCE

CLOSE

BY

OF

CLAMP

/

CAUTION:

$

TO

REDUCE

COVER

PERSONNEL.

OR

RISK

BACK.

OF

ELECTRICAL

REFER

SERVICING

SHOCK,

TO

DO

NOT

QUALIFIED

REMOVE

SERVICE

/

/ A V

TO

MAXIMIZE

THIS

INSTRUMENT

THE

WARNING:

CAUTION:

SERVICE

BE

LIFE OF THE INSTALLED

STORED

BEFORE

AND

REPLACE

CONNECTING

NOTE

OPERATED

IN

CONTROLLED BETWEEN 68°F (20°C) AND 77°F (25°C).

WARNING

IN

THE

EVENT

BIOMEDICAL

THE

INSTRUMENT IS

TECHNICIAN

PRIOR

DROPPED

TO

USE

AT ANY TIME, IT

FOR

PATIENT

FUSEASMARKED.

"REFER

BATTERY,

AN

ENVIRONMENT

CARE.

TO

IT IS

MUST

MANUAL"

RECOMMENDED

THATISTEMPERATURE

BE

CHECKED

THAT

BY A

WARNINGS,

CAUTIONS

AND

NOTICES

SEfflft

WARNING:

CLAMP WHEN FLO-STOP® IS

/1\

TO

PREVENT

CAUTION:

REFER

/ I \

TYPE CF (Equipment

CLASS

1

r\

^

/ A V

TV

V

ALTERNATING

REPLACE

EQUIPOTENTIAL

EQUIPOTENTIAL

SYSTEM IS IN QUESTION,

INTERNAL

FUSE

BATTERY

UNRESTRICTED

OPEN.

TO

MANUAL

useable

CURRENT

ONLY

WITH

GROUND

EARTH

POWER.

CONNECTION

OPERATE

FLOW,

for

SAME

POINT:IFTHE

direct

TYPE

THE

CLOSE

cardiac

AND

OR

ROLLER

applications)

RATING

INTEGRITY

HOSPITAL

INSTRUMENT USING

OF

EARTH

THE

IPX1

ONLY

should

connection

Only

should

connection

DRIP

equipment

be

connected

should

systems

be

connected

should

PROOF

CAUTION

that

has

been

qualifiedtoIEC 601-1

to

the

PC-4's

RS-232-C

Data

Port

ONLYbeperformed by qualified personnel.

CAUTION

that

have

been

qualifiedtoIEC 601-1

to

the

ONLY

PC-4's

be performed by qualified personnel.

ii

Nurse

Call

connector

standards

and

standards

and

the

the

NOTICE

Product design and/or specifications

change

in

without notice.

this

manualiscurrent

The

information contained

asofthe

date

are

of

This publication contains ALARIS Medical

Systems™ proprietary

use oftechnical personnel inrepairing

data

provided

solely

IMED®

Gemini infusion pump/controllers.

subject to

issue.

for

the

Noneofthe

duplicated nor

information contained herein may be

mayitbe

utilized in any manner

other than forthe repairand maintenance of

Gemini infusion pump/controllers

component

the

information contained herein may subject

usertosubstantial

parts thereof. Any unauthorized

liability.

and

the

IMED8

use

of

the

J^v

77?/s

manual

maynot,inwhole orin

electronicormachine-readable

ALARIS Medical

10221 Wateridge Circle

San

Diego, CA 92121

(858) 458-7000

Systems,

USA

Inc.

part,

be copied,photocopied, reproduced,

form

withoutprior

°Copyright

PrintedinUSA

U.S.

4,954,046; 4,859,927; 4,764,166; 5,219,330; D305.060; D305.151; D352.778. AU 580,184; 586,594;

590,179; 601,664; 607,112; 622,088; 596,552; 604,477. CA 1,235.033; 1,258,212; 1,300,977; 1,280,647;

1,296,791; 2,020,926; 1,296,092; 1,238,832. AT 0.225,158. BE 0,225,158. FR 0,225,158 283,614;

315,312; 0,431,726; 0,238,277. GB 0,225,158; 283,614; 315,312; 0,431,726; 0,238,277. NL 0,225,158

283,614. IT 0,225,158; 283,614. SE

3871721T2;

fcW*1 9 0 2 3 8

OtherUSand

IMED®,

2000

Patents

4,617,014; 4,689,043;

P6908208;

Gemini

ALARIS

Foreign

PC-4*

written

Medical

P3774598. TW

79;

«R*1

Patents

and

Flo-Stop*

in

consentofALARIS Medical Systems,

Systems,

4,690,673;

9 6 7

Issued

Inc.

Ail

4,725,205; 4,728,265; 4,836,752; 4,909,710; 4,920,336;

0,225,158

and

are

283,614. CH 0,225,158. DE P3686558.3; P3772.556.9;

UM52721.JPWW*1754470

16

89;tt»*1

Pending.

registered

Rights

translated,

Reserved

7 9 3119#;»ff«1

orconvertedtoany

trademarksofALARIS

Inc.

^;

WW* 1

Medical

81

7 3 0 3 9

Systems™.

6 8

729;

59.

PC-4

PREFACE

This manual contains operation

instructions for

the

IMED®

and

maintenance

GEMINI PC-4®

series

Volumetric Infusion Pumps/Controllers ("PC-4").

The

information provided herein is intended for use

by technical personnel responsible for servicing

these

products.

sections

andispresentedasfollows:

The

material is divided into

Section

seven

1 -

Description; Section 2 - Preparation for Use;

Section 3 - Operation; Section 4 - Principles of

Operation; Section 5 - Maintenance; Section 6 -

Illustrated

and

Parts

Preventative

Breakdown;

Maintenance.

Section

7 - Calibration

of

Additionalcopies of this manual maybeobtained

by contacting your

nearest

ALARIS Medical

Systems CustomerService Department.

This

manual

Maintenance

PC-4

International

9213-00

1340-9217-00

No.

1340-9217-01.

The

featuresofthe

been

incorporated into this manual. Text

graphics

model

are

P/N143649

and

PC-4

that

are

identified

supersedes

Manual,

and

Part

No.

Addendum,

Maintenance

PCM

Technical

220V

modelofthe

related exclusively to

witha©©

PCM

1340-9201-00

Part

No.

1340-

Manual,

Part

Update,

PC-4

have

or

the

220V

symbol.

and

Part

No.

/"^Iik

IV

IPN

PC-4

j^v

SECTION

SECTION

1 -

DESCRIPTION

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

2 -

PREPARATION

2.1

2.2

2.3

INTRODUCTION

OPERATING

OPERATING

USER

PHYSICAL

PRODUCT

OPERATING

ACCESSORIES

INTRODUCTION

PRE-OPERATIONAL

OPERATIONAL

INTERFACE

DESCRIPTION

HISTORY

FOR

2.3.1 Pre-operational

TABLE

CHARACTERISTICS

CONDITIONS

SPECIFICATIONS

USE

MECHANICAL

PERFORMANCE

Check

Battery

OF

CHECK

Charge

CONTENTS

INSPECTION

1-1

1-1

1-1

1-1

1-3

1-3

1-3

1-3

1-3

2-1

2-1

2-1

2-1

2-3

2.3.2 Pre-operational Electrical Inspection 2-3

2.3.2.1 Electrical

2.3.2.2

Electrical

2.3.3 Abbreviated Operational

2.3.3.1

2.3.3.2

Test

Test

Leakage

Ground

Test

Test

Performance

Test

2-3

2-3

2-3

Requirements 2-3

Procedures

2-3

SECTION3-OPERATION

3.1

3.2

3.3

3.3.1 Normal Operation 3-5

3.3.1.1 Pump Controller

3.3.1.2

3.3.1.3 Independent

3.3.1.4 Monitoror Computer Control

3.4

3.5

3.6

SECTION

4-PRINCIPLES

4.1

4.2

4.2.1 Physical Description 4-1

4.2.1.1 Pumping Mechanism 4-1

4.2.1.2 Strain Beam

4.2.2 Functional Operation 4-1

4.2.2.1 Pumping Mechanism 4-1

4.2.2.2 Strain Beam

4.3

4.3.1 Functional Description 4-5

4.3.2 FunctionalOperation 4-6

4.3.2.1 Power On/Power Off

4.3.2.2 5 Volt Regulator Subsystem 4-6

INTRODUCTION

CONTROLS

OPERATING

System

AND

INDICATORS

CONDITIONS

and

Selectable

Modes 3-5

Configuration 3-5

Setup

and

Operating Procedures 3-6

Setup

and

Operating

Procedures

CHANNEL, CENTRAL INFORMATION DISPLAYS AND ALARM

AUDIO

NURSE

INTRODUCTION

MECHANICAL

ELECTRICAL/ELECTRONIC

ALERT

CALL

OF

OPERATION

SYSTEM

FEATURE

OPERATION

(Pressure

(Pressure

Transducer) 4-1

Transducer) 4-5

OPERATION

Subsystem

RESPONSE

3-1

3-1

3-1

3-5

3-47

PROCEDURES 3-51

3-61

3-61

4-1

4-1

4-1

4-5

4-6

V

PC-4

SECTION

4.3.2.3

4.3.2.4 5

4.3.2.5 Battery

4.3.2.6

±8

VoltDCPower

Volt

Protected Subsystem 4-7 1

Charger

System

Reset

Supply

Subsystem

Subsystem

Circuit 4-8

4"7/«%

4-7

4.3.2.7 Battery Depleted Circuit 4-8

4.3.2.8 Pumping Mechanism 4-8

4.3.2.9

4.3.2.10

4.3.2.11 Slide

4.3.2.12

4.3.2.13

4.3.2.14 Display

4.3.2.15

Strain

Beam

Air-ln-Line

Clamp

Door

Sensor

Audio

Subsystem

Subsystem

Nurse

Call

Detector

Detector (SCD) 4-10

System

4-8

4-9

4-10

4-10

4-11

4-12

4.3.2.16 Keyboard Interface 4-12

4.3.2.17

4.3.2.18

5 -

MAINTENANCE

5.1

5.2

Communications Interface

and

Signal Definitions 4-12

Mechanism Alarm Circuit (M.A.C.)

INTRODUCTION

PREVENTIVE

MAINTENANCE

4-12

5-1

5-1

5-1

5.2.1 Cleaning Instructions 5-1

5.2.2

5.3

5.3.1

5.4

5.4.1 Mechanism Alarm Circuit (M.A.C.)

5.5

5.5.1

5.5.2 Front

5.5.2.1 CCA Board Removal

Mechanical Inspection 5-2

MAINTENANCE

Maintenance

TROUBLESHOOTING

MODE

Mode Operation

5-2

5-2

5-6

5-6

DISASSEMBLY

Separating

the

Case

Disassembly (Figure 6-2) 5-22

Case

(Figure 6-1)

and

Disassembly (Figure 6-2) 5-22

5-22

5-22

5.5.2.2 Pumping Mechanism Assembly Removal (Figure 6-2) 5-23

5.5.2.3 Door

Sensor

5.5.2.4 AIL/SCD Assembly Removal

Assembly Removal (Figure 6-2) 5-23

and

Disassembly (Rgure 6-2) 5-23

5.5.2.5 Transducer Assembly Removal (Figure 6-2) 5-23

5.5.2.6 Anchor Bracket Assembly Removal (Figure 6-2) 5-24

5.5.2.7

5.5.2.8

5.5.2.9

5.5.3

Access

Pump

Snap

Rear

5.5.3.1 Audio

Door Assembly Removal and Disassembly (Figures 6-2

Seal

Removal (Figure 6-2)

and

6-3) 5-24

5-24

Bracket Removal (Figure 6-2) 5-24

Case

Disassembly 5-24

Harness

Assembly Removal (Rgure 6-4) 5-24

5.5.3.2 Transformer Harness Assembly Removal (Figure6-4) 5-24

5.5.3.3 AC Power Input Module Assembly Removal (Figure 6-4) 5-25

5.5.3.4

5.5.3.5

Power

Audio

Supply

Control

Board

Removal

Removal

5-25

5-25

5.5.3.6 Pole Clamp Assembly Removal and Disassembly (Rgure 6-5) 5-25

5.5.3.7 Battery Removal 5-25

5.5.3.8

5.6

Equipotential Ground

REASSEMBLY

Stud

Removal

5-25

5-25

SECTION

SECTION

6 -

ILLUSTRATED

6.1

7 -

CALIBRATION

7.1

7.2

————^—————^—————

PARTS

INTRODUCTION

AND

BREAKDOWN

PREVENTATIVE

INTRODUCTION

PREVENTIVE

MAINTENANCE

MAINTENANCE

vi

——^—________^^^^^________^__^^^^^__^^^

6-1

6-1

7-1

7-1

^%

7-1 >

4SK*y

PC-4

JSP\

7.3

7.3.1

7.3.1.1 Calibration Equipment

7.3.1.2

7.3.2 Door

7.4

7.4.1 Electrical Inspection 7-3

7.4.1.1 Electrical

7.4.1.2

7.4.1.3 Dielectric

7.4.1.4 Battery

7.4.2 Qualitative Operational Performance

7.4.3 Quantitative Operational Performance

7.4.3.1 Equipment Requirements 7-4

7.4.3.2

WARRANTY

SALES

TECHNICAL

AND

SERVICE

SERVICE

CALIBRATION

Strain

Beam

Calibration

Calibration

COMPREHENSIVE

Procedures

Sear

Adjustment 7-3

Leakage

Electrical

Ground

Test

Runtime

Test

Procedures

OFFICES

MANUAL

SUPPLEMENTS

PROCEDURES

Requirements

OPERATIONAL

Test

Test

PERFORMANCE

TEST

7-1

7-1

7-1

7-2

7-3

7-3

7-3

(Optional) 7-3

Test

Test

Test

7-3

7-4

7-4

7-4

Vll

PC-4

LIST

OF

FIGURES

Figure

1-1

1-2

2-1 PC-4 Front

2-2

2-3

3-1

4-1

4-2

4-3

4-4

4-5 Slide Clamp Detector

4-6 AIL/SCD Board

4-7

4-8 Display Board

4-9 Display Board (Channel D) P/N 1340-5036

4-10 Display Board P/N

Title

IMED

GEMINI

Audio

Characteristics

Air-in-line

PC-4

Abbreviated

PC-4

Front

PC-4

Pumping Mechanism 4-2

PC-4

Signal Flow

Cross

AIL

Schematic,

Section of Strain Beam Assembly 4-5

Detector

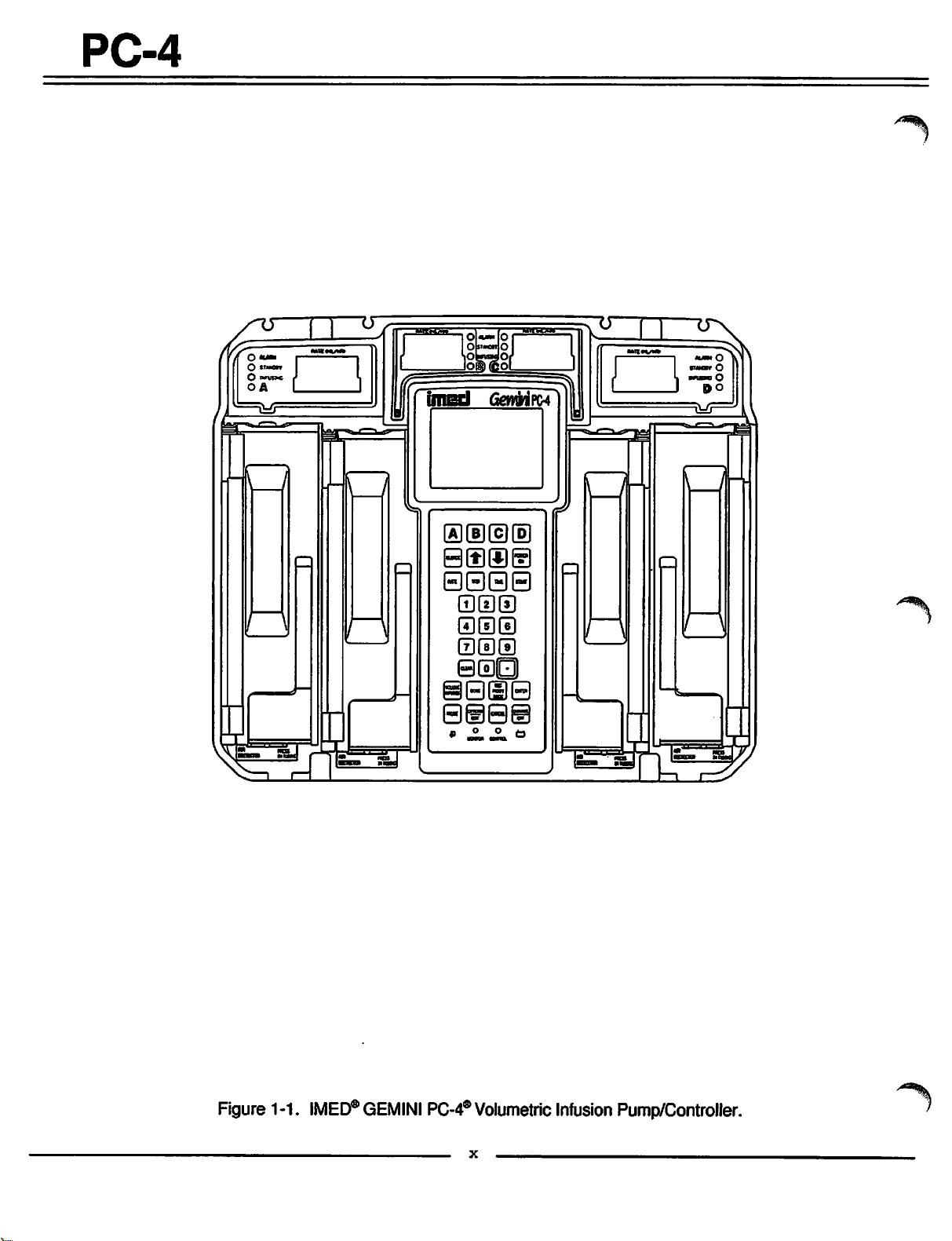

Model PC-4 Volumetric Infusion Pump/Controller x

and

Rear

Panel Operating Features 2-2

Simulator

Test

Data

Sheet

Panel

Cross

SPC,

(Channel

Controls

and

Section

Schematic

PC-4XL

1340-5037

and

Indicators

Interconnect Diagram 4-3

Cross

Section 4-10

(P/N 1340-5012) 4-11

P/N

1340-5039-1

A) P/N 1340-5035

(Sheet

1 of 4)

Page

1-7

2-6

2-7

3-2

4-9

4-14

4-15

4-17

4-19

4-10 Display Board P/N 1340-5037 (Sheet 2 of 4) 4-21

4-10 Display Board P/N

4-10 Display Board P/N

4-11

4-11

4-11

4-11A

4-11A

4-11A

Power

Power

Supply Board P/N 1340-5028 (Sheet 1 of 3) 4-27

Supply Board P/N 1340-5028

PowerSupply

PowerSupply

PowerSupply

PowerSupply

1340-5037

1340-5037

(Sheet

(Sheet

3 of 4)

4 of 4) 4-25

(Sheet2of

Board P/N 1340-5028

(Sheet3of

Board P/N 1340-5038 (Sheet 1

Board P/N 1340-5038

Board P/N 1340-5038

(Sheet2or3)

(Sheet3

3) 4-28

3) 4-31

or3)

or3)

4-23

4-33

4-35^%

4-37 ;

4-12 Motor Control Board P/N 1340-5027 (Sheet 1 of 3) 4-39

4-12 Motor Control Board P/N 1340-5027

(Sheet2of

3) 4-41

4-12 MotorControl Board P/N 1340-5027 (Sheet 3 of 3) 4-43

4-13 Logic Board P/N 1340-5029 (Sheet 1 of 3) 4-45

4-13 Logic Board P/N 1340-5029 (Sheet 2 of 3) 4-47

4-13 Logic Board P/N 1340-5029 (Sheet 3 of 3) 4-49

4-13A Logic Board P/N 1340-5034 (Sheet 1 of 3) 4-51

4-13A Logic Board P/N 1340-5034

(Sheet

2 of 3) 4-53

4-13A Logic Board P/N 1340-5034 (Sheet 3 of 3) 4-55

6-1

6-1

6-2

6-2 Parts Identification- Front

6-3

6-4

6-4 Parts Identification-

6-5

6-6

6-7

6-8

6-9

Parts

Identification - PC-4 Pump Assembly (Sheet 1) 6-3

Parts

Identification - PC-4 Pump Assembly (Sheet 2) 6-4

Parts

Identification - Front

Parts

Identification - Door Assembly 6-10

Parts

Identification -

Parts

Identification -

Parts

Identification -

Parts

Identification - Display Board CCA Channels

Parts

Identification - Display Board CCA Channel A

Parts

Identification - Display Board CCA Channel D 6-30

Rear

Rear

Rear

Power

Case

Assembly (Sheet 1) 6-7

Case

Assembly (Sheet 2) 6-8

Case

Assembly (Sheet 1) 6-13

Case

Assembly (Sheet 2) 6-14

Case

- Pole Clamp Assembly 6-16

Supply Board CCA 6-23

B&C

6-26

6-28

6-10 Parts Identification - Logic Board CCA 6-35

6-10 Parts Identification - Logic Board CCA (Cont'd) 6-36

6-11

7-1 Universal

7-2

7-3 PC-4 Test Data

Parts

Identification-Motor

Test

Air-in-line

Simulator

Station

Sheet

Controller

Setup

CCA

6-41

7-5

7-7^^

7-8 1

,

viii

#^

LIST

OF

PC-4

TABLES

Table

Title

Page

1-1 Product History 1-4

1-2 Operating Requirements 1-5

1-3 Performance Specifications 1-5

1-4

3-1 Description of Controls

3-2 Visual

4-1 RS-232-C Communications

Accessories

Message

*

and

Indicators 3-3

1-8

Displays 3-51

Data

Port

Signal Definitions 4-13

5-1 Troubleshooting Guide 5-7

5-2 PC-4 Error Log

Codes

5-10

5-3 Table of Torque Values 5-26

6-1

6-2

6-3

6-4

6-5

6-6

6-7 Parts List- Display Board CCA

Parts

List-

PC-4

Pump

Assembly 6-2

Parts

List- Front

Parts

List- Door Assembly 6-9

Parts

List-

Parts

List- Pole

Parts

List-

Rear

Power

Case

Assembly 6-5

Case

Assembly 6-11

Clamp

Assembly 6-15

Supply Board CCA 6-17

Channels

B&C

6-24

6-8 Parts List- Display Board CCA Channel A 6-27

6-9 Parts List- Display Board CCA

Channel

D 6-29

6-10 Parts List- Logic Board CCA 6-31

6-11

Parts

List-Motor

Controller

Board

CCA

6-37

JW\

IX

PC-4

m

far^

o

O

O

OA

smkw

n*UM>e

n—it

v/

m

fl

u

r\

a®

BEES

BBBB

EBB

BBB

BBB

BOB

lie

LJ

•

r^

a

•

r^

^z

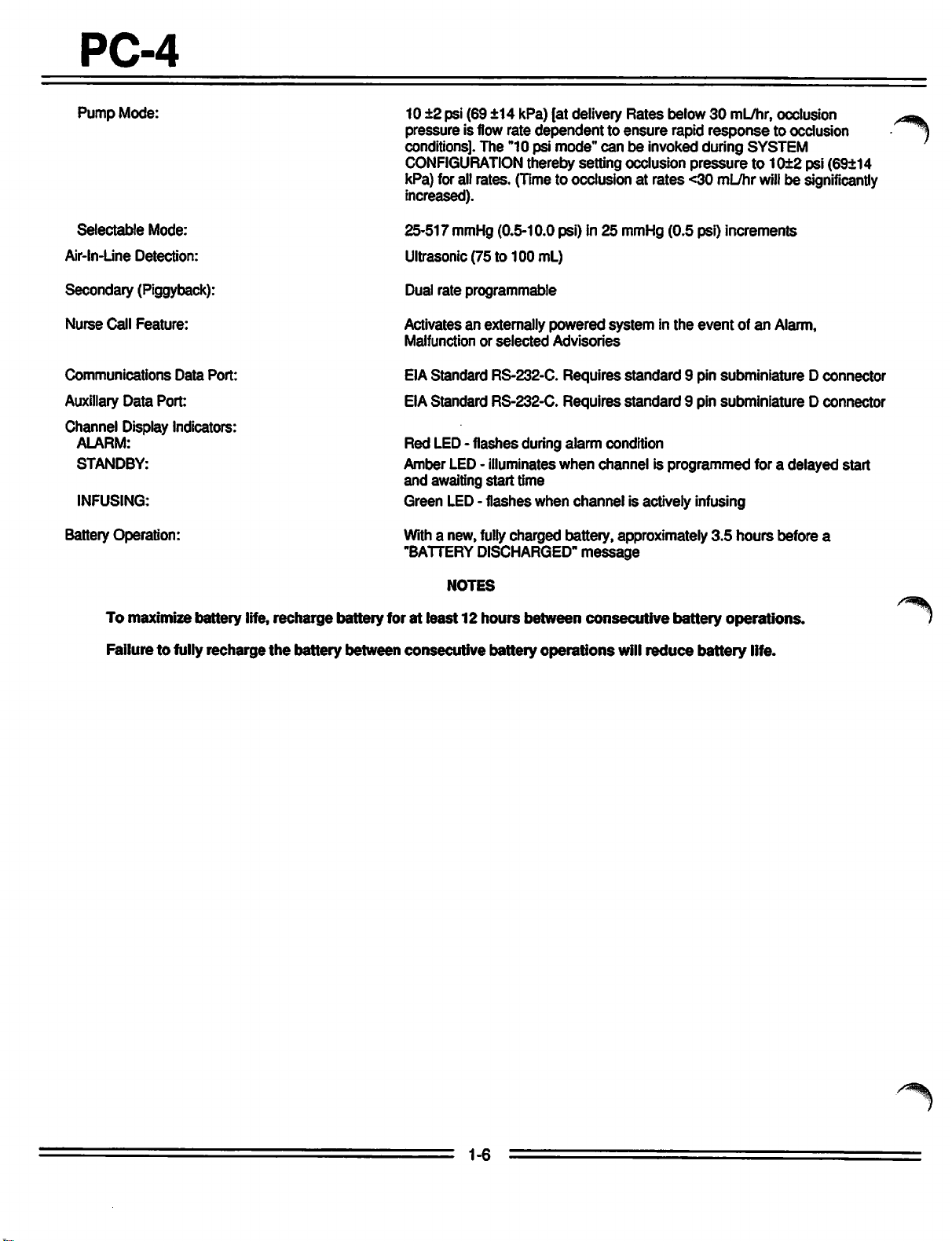

Figure

1-1.

IMED®

GEMINI

PC-4®

Volumetric

Infusion

^%i

Pump/Controller.

PC-4

#*^

SECTION

1.1

INTRODUCTION

This

section

physical description

versionsofthe

includes

IMED®

general

and

GEMINI PC-4® Volumetric Infusion

operating characteristics,

operating specifications for all

Pump/Controller ("PC-4").

1.2

OPERATING

The

GEMINI

infusion pump/controller

intravascular

independent

of

delivery

mode.

peristaltic action.

seriesof12

collapse

pumping

action

cam-actuated

then

segment

produces

a vacuum on

delivering a

accurately

The

four

infusion

continuous

and

channel

techniques

simultaneous

Independent

deliver either a specified volume or

("ALL")

of a solution container.

requires installation

CHARACTERISTICS

Model

PC-4isa

four

usedinthe

drugs

and

fluids.

Each

operationineither

The

pumping

The

peristaltic action is provided by a

mechanism

fingers

release,

in a ripple like action,

of a GEMINI administration

a positive

the

inlet

pressureatthe

sideofthe

flow of infusion solutions reliably,

with a high

configuration

including

primary

and

simultaneous

and

degree

enables

independent

sequential

primary infusions

Useofthe

and

connection ofanEmpty

channel

volumetric

administration of

channel

the

is capable

Pump or Controller

employs linear

that

sequentially

the

set.

outlet

pump, thereby,

of safety.

a variety of

primary,

secondary.

the

entire contents

ALL

soft

setting

Container Detector (ECD) which is availableasan

optional

accessory.

Sequential

secondary

(piggyback)

infusions with independently defined delivery

parameters,

solutions,

Operational control of

control

and

the

instrument. Basic operating instructions

the

right

for both

the

canbeprovided on

and

indicator

Audio

sideofthe

panelonthe

Control

instrument

primary

the

switch

and

secondary

each

channel.

PC-4

is effected through the

front of the instrument

on

the

rearofthe

are

case.

Functional control is

printed on

provided by a 16 bit micro-processor with a stored

program

instrument

subsystem

redundancy

that

includes a

Maintenance

mode

performance,anaudio/visual alarm

to alert

checks

operators

to confirm

to abnormal conditions and

system

accuracy.

to monitor

This

side

can

1 -

DESCRIPTION

1.3

The

Operation) orasa computer controlled device

(Computer Operation). Normal operation includes

Controller

mode. Computer operation includes Monitor

Computer

NORMAL

SYSTEM

The

and

The system configuration

statusofthe

OPERATING

PC-4

canbeoperated

and

Control

OPERATION

OPTIONS

systems

• Adjust

•

Set

•

•

Set

•

To

and

up.

Bold

contrastofthe

the

Time of Day clock

Enable

Anesthesia

up Computer Control

Check

enter

hold

face

System

the

the

type

CONDITIONS

Pump

modes

modes.

option

mode

allows

LCD display

Mode

Configuration

screen

following

selectable

NOTES

Configuration

"OPTIONS/EDIT'

indicates

independently (Normal

plus a Maintenance

the

operatorto:

displays

features:

Setup

mode:

switchatpower

factory

default

• Clock Setup: Military or AM/PM

• Factory Set: Factory default settings

•

Maximum

•

C2

Port:

19200; (Data

xxxx.

•

Aux

•

PCS

Rate:

Max

Baud

300,600,1200,

Frameisset

Port:

No

Port

Mode: P or C or S

usable

rate

2400,4800,

to N81); Serial No.

Channel

1-999

delivery

selection plus mode lock/unlock

• Delayed Start: Enabled or Disabled

• Drug Calc:

•

Multidose:

•

Dose

EnabledorDisabled

Enabled

Display:

FixedorTemp

or

Disabled

• Battery Mode: Disabled Normal High

• Key Audio: Enabled or Disabled

•

Alarm

Audio:

• Switch(over) Audio:

Profile

1,2or3

EnabledorDisabled

the

YES

mL/hr

the

and

current

press

settings.

or NO

9600,

mode

1-1

PC-4

•

Tamper

• Language: English

•

Anesth.

• Comp. Ctrl.:

• Dynamic Press:

•

Press.

•

Vol.

•

S/W

•

MC

•

C2S/N:

•

CRC:

CONTROLLER

In

the

to control

solution.

patient

similar to a gravity infusion.

sensor

bottle

tubing in-line pressure. When in-line

pump input pressure, an occlusion condition exists

and

an alarm is initiated. Actual delivery

directly proportional to container height; increasing

container height raises

reduces

occlusion

from

pressure of <60

FLOWcondition which

pressureisabove

transients

duration or cumulative time required to

volumetric deficiency

in

excess

occlude.

PUMP

In

the

employs a

(69 ±14 kPa) predicated on a nominal container

height of 24 inches (61 cm) and a delivery rate >30

mlJhr. For delivery rates <30

pressure is rate dependent to

of occlusion conditions. Anytransient distal in-line

pressure

occlusion

Mode: Enabled or

Mode:

EnabledorDisabled

Enabled

Enabled

Trend:

Time

Version:

Version:

XXXX/Checksum:

Inf:

XXXX

Enabled

Enabled

SCX.XX.XX.X

X.XX

MODE

CONTROLLER mode,

the

infusion of a specific volume of

The

instrument

side

pressure

measures

and

compares

and

the

hydrostatic

that

and

occlusion

pressure

the

bottle height. Transient

pressure.

toleranceis±12

seconds

stops

the

occlusion threshold.

above

the

occlusion

caused

of30minutes

MODE

PUMP

mode

preset

above

alarm.

occlusion

this limit

will

of operation,

Disabled

or Disabled

or Disabled

or

Disabled

or

Disabled

XXXX

the

PC-4 is programmed

senses

and

responds

container height in a

The

instrument's

pressure

pressure

against distal

pressure

pressure

decreasing

Controller

the

mode

inches

duration

the

threshold

surges

infusion while

in patient

will

produce a LOW

>60

compensate

by periods of Low Flow

cause

pressure

will

the

the

mLThr,

ensure

generate

instrument

instrument

limit

the occlusion

timely detection

a patient

IV

to

manner

pressure

from

the

exceeds

height

(30.5 cm)

the

Pressure

seconds

of 10 ±2 psi

side

is

side

to

for

Software

A

Selectable

occlusion

mmHg (0.5 psi)

Release

(S)

4.10.14.0

pressure

pressuretobe

and

517

and

Subsequent

mode

selected

allows

between

an

25

mmHg (10 psi) in 25

mmHg (0.5 psi) increments. A high occlusion

pressure

will

MAINTENANCE

The

selection

resultinan

maintenance

coupled

increase

MODE

mode

with a slow infusion rate

in

time-to-occlusion.

is intended solely for

use

by biomedical technicians to perform servicing and

maintenance

when

the

maintenance

personnel

test

routines

Maintenance

•

• M/C

•

The

S/C

an

Error Log display with a

COMPUTER

MONITOR

The

Monitor

monitor

performance. Monitor

computer is

Communications

indicatorisilluminated.

COMPUTER

The

Computer Control

once

set

host

computer

actions

and

PCMisconnected

mode

provides biomedical service

accesstothe

and

operating

mode

menu

S/C

board

test

and

board

Press

board

MODE

infusion

test

[off]

to exit

test

and

OPERATION

mode

allows a

status

and

and

modeisenabled

connectedtothe

Data

Port

CONTROL

mode

up, tobecontrolled

installation.

must

never

to

a patient.

closed

loop maintenance

history logs.

includes:

displays

displays

display

sub-menu

100

entry register.

host

computerto

instrument

PC-4 through

and

the

allows an infusion,

and

monitored by a

be

used

includes

when a host

Monitor

The

the

^%

Software

The PC-4, when operating in

Releases

through

3.9.9.4

the

Pump Mode,

locked into a rate-independent (10 psi) occlusion

pressure mode. This mode

increased

time-to-occlusion

will

result in significantly

for

rates

<30

ml_/hr.

can

be

1-2

PC-4

1.4

USER

Instrument control

INTERFACE

and

operation is accomplished

through the 32 keypad controls, the central information

display and

displays. Infusion parameters

the

independent channel information

are

programmed into

the

instrument using the appropriate keypad controls.

Rate

and

Volume-to-be-lnfused (VTBI)

separately for

each

channel.

Rate

secondary infusions (piggyback)

programmable, independent of

parameters, for

Advisory

are

messages

provided to

each

channel. Visual Prompt and

with accompanying audio alerts

assist

operators in setting up

are

the

are

input

and

VTBI

for

also

primary infusion

the

instrument for operation. Infusion completions, alarm

conditions

signaled by both audio

detected

warning. Delayed Start, Multidosing

Calculation

enabled,

menu.

The rear panel of

connection for

Nurse

data

and

software-detected

and

visual alerts; hardware-

malfunctions

infusions,

are

programmed via the Channel Options

each

Call line, a

are

signaledbyan

when

the

PC-4 is configured with an ECD

channel,aconnectortoaccept

standard

RS-232-C

port for interfacing with a

these

host

malfunctions

audio

and

Drug

features

are

communications

computer

are

and

a

an

auxiliaryRS-232-C port for interfacing with ancillary

equipment.

ALARIS

administration

GEMINI

GEMINI

numbersinthe

1.5

The PC-4 instrument

characteristics:

Medical

Systems

sets

are

required for

GEMINI

family of Infusion Pump/Controllers.

Series

PHYSICAL

of instruments

2000

number

DESCRIPTION

has

the

uses

series.

following physical

Series

use

sets

disposable

with

the

The

with part

FRONT

The

aluminum shell which

pumping

pumping

beam), Air-in-line

keypad,

display circuit

and

REAR

The

cast

internally:

oscillator, power supply CCA

harness

supports

storage, battery

retention

the

model.

1.6

The

Pump/Controller

time a

Table

1.7

The

subordinated

Performance

Tables

CASE

front

case

chamber

mechanisms,

the

motor

control

CASE

rear

case

consists

channel

card

assembly

ofaninvestment-cast

houses

access

pressure

and

Slide clamp detectors,

and

assemblies

CCAs.

and

doors, the peristaltic

transducers (strain

central displays, the

(CCAs), logic CCA

consists of an investment-

supports:

aluminum shell which mounts and supports

the

transformer

assembly.

the

pole

access

strap,

power

The

clamp, power entry module, ECD

harness

exterior of

assembly, audio

and

communication

the

with covers, power cord

cord retention bracket

equipotential grounding point on the 220V

PRODUCT

initial

numberofchanges

1-1 for

OPERATING

PC-4

HISTORY

releaseofthe

wasinDecember

product

Operating

history.

SPECIFICATIONS

Specifications

GEMINI PC-4® Infusion

1992. Since that

have

occurred. Refer to

are

into Operating Requirements and

1-2

Specifications

and

1-3 respectively. Tables 1-2 and 1-3

which

are

respectively.

1.8

ACCESSORIES

the

rear

case

and

delineated in

Height: 12 inches (30.5 cm)

Width: 14.75 inches (37.5 cm) with pole clamp

Depth: 7.5 inches (19.1 cm) with pole clamp

*22

Weight:

pounds (10 kg) including power cord

The PC-4 instrument consists of two major

assemblies:

the

front

and

rear

cases.

1-3

The

accessories

are

listedinTable

approved for

1-4.

use

withthe PC-4

PC-4

Model

1340A

1340B

1340C

1340D

The

current PC-4

Options menu,

• Initial

• ECD Support, Drug Amount, Drug Dose Support,

fullyfunctional introduced with Software version 3.2.8.0.

• C2 Monitoring, Anesthesia mode, Pop-up Window, Prompts Split

Replace

3.9.1.0.

• ADDED TX Feature

Pressure

with

•

Rate

5.10.18.4.

• Battery

5.11.17.0.

• Incorporated Corrective Drug Application with Software version 7.05.05.0.

• Software versions 7.05.05.0

in

the

System

then

Configuration may be viewed by pressing Options/Edit key to bring up

pressing#5Keypress, to

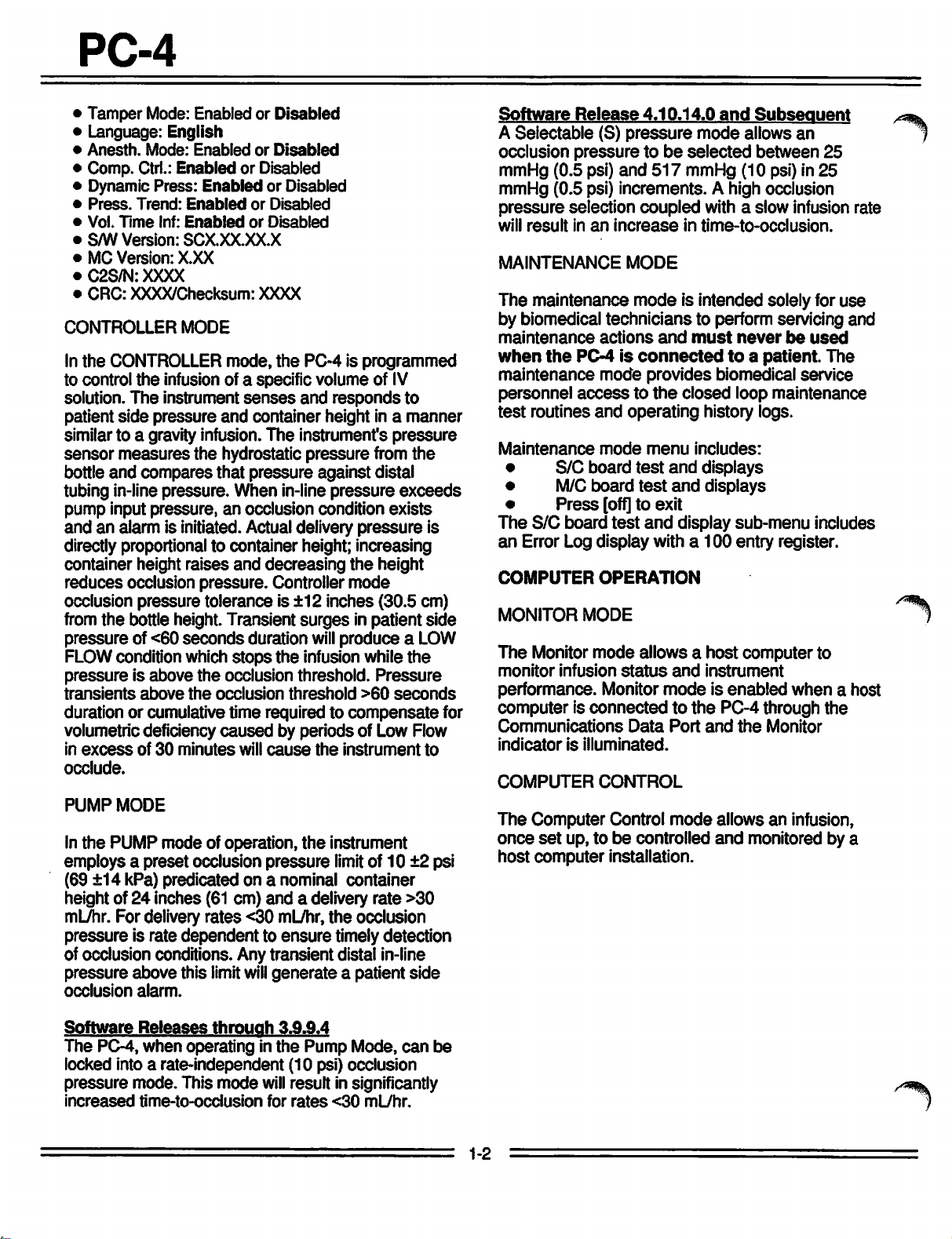

Table

1-1.

Product

History

History

release

of product Software version 1.12.11.1.

paused

Battery, Service Charger error

set

- Volume/time dosing, Selectable output pressure, Dynamic

Readout, pressure Trending (History),7

Software

display

version

test

extension

4.10.14.0.

enabled,

Audio Failure "Pop-up box",

housing implemented 12 Battery

and

earlier,

message

introduced with Software version

segment

system

will

not recognize a year entry beyond 1999

Clock Entry Menu. Introduced Software version 1.85.

access

the

System

Configuration listing.

walkaway feature Nursecall

Screen

display checking

added

with Software version

Pri/Sec

added

with Software version

the

systems

Revision

Revision

Revision

Revision "B"- Software Upgrade for conversion to 12 Volt Battery System Units to

Matrix:

#

1340A

1341AX(220V)

1340B

1340BX(220V)

1341BX

1340C

1340D

"A" -

Initial

PC-4

1.12.11.1,3.2.8.0,

3.9.1.0,3.9.9.1,

3.9.9.4,4.10.14.0,

4.12.9.0,5.1.18.0,

5.2.4.0,5.10.18.4

X

Revision

PCM

5.11.17.0

PCM

7.05.05.0

X X

X

X

PC-4

1.85

X

enhance

X

operation.

PC-4CE

1.86

Revision"C"- Software Upgrade to correct a specific drug calculation concentration for the drug Esmolol (Brevibloc),to

incorrectly displayed.

Revision "D"- Mandatory

1.86.

Note1: 1340/134x = a

Note8:

3.9.9.4,

All

and

PC-4s

then

etc.

have

press

Upgrade

number

to incorporate 12 Volt Battery System

associated

with a particular model,

a Maintenance or Diagnostic Mode. To

Power

On.keypress.

and

access

(sameasRevision B) with Software Revision 1.85, or

software version, i.e., 1340A couldbe5.10.18.4 or

this mode: hold in the Audiocontrol switch on the panel

X

be

CAUTION:

The

"Fractional"

and

"Integer"

Pumping

Mechanisms

1-4

are

not

interchangeable.

^^

Power

Required:

Parameter

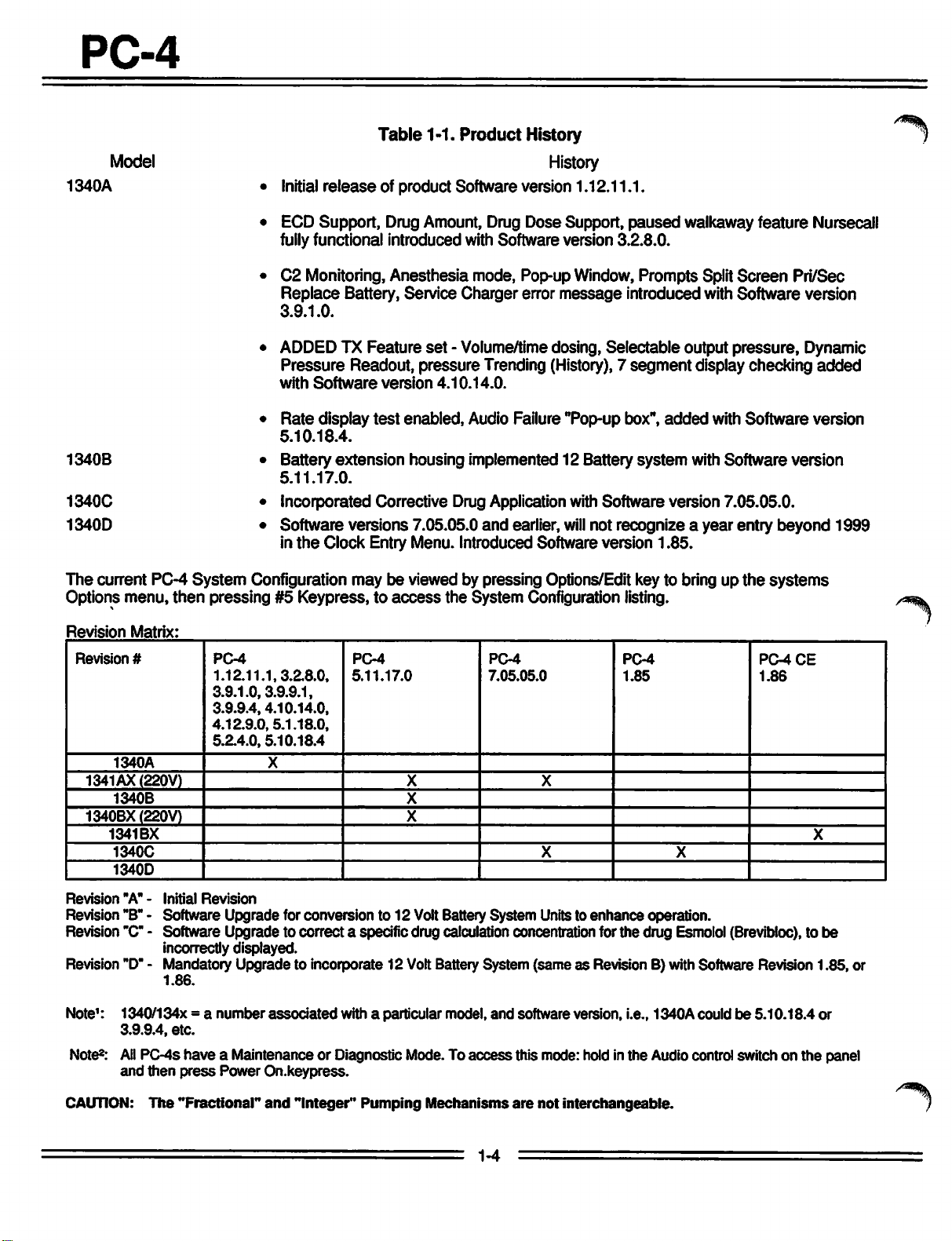

Table

1-2. Operating

Requirements

Specification

110V: 90-132

VAC,

current draw 0.10

amps

Watts, fused at 0.4 A, 50-60 Hz, 3 wire, Single

nominal (.36

<J>

PC-4

amps

max), 10

Rated

Input

Power:

Electrical

Electrical

Level of Protection

Leakage:

Shock

Protection:

against

Electrical Shock:

Level of Protection against fluid ingress:

Battery:

Battery

Nurse Call

Operating

Recharge:

System

Temperature

Power

Limitations:

Range:

Operating Humidity Range:

Storage

Storage

Temperature:

Humidity:

220V: 220-240 VAC, 0.15

Single

<t>

45

VA

amps

nominal,

fusedat200mA,

Less than 100 microamps

Class 2, Internally powered equipment

Type CF equipment

IPX1

Two,sealed lead-acid, 12

8 hours

will

recharge a new battery to the battery operation specification

level(-90% capacity). 24 hours

VDC,

3.4

amp-Hr

will

restore a new battery to a

condition. For maximum battery life, battery should be

each

discharge.

Maximum

recommended Voltage/Current 24 VDC/500 mA

40oF(5°C)to104oF(40°C)

0% to 95% Relative Humidity, non-condensing

-40°F (-40°C) to 158°F (70° C)

0% to 95% Relative Humidity, non-condensing

50/60

fully

fully

recharged after

Hz, 3 wire,

charged

Parameter

Operating Principle:

Mode of Operation:

Operating

Pump

and

Rate:

Range:

Controller

Volume-to-be-lnfused

Keep

Vein

Open

Occlusion

Controller

Pressure:

Mode:

modes:

(KVO)

(VTBI):

Rate:

Table

1-3. Performance

Container height (±12" or 30.5 cm)

Specifications

Specification

Linear

Peristaltic

Continuous

0.1 -

999

mL/hrin0.1

increments

(Controller

0.1 -

1to9999

Fractional

from1to

mode

9999mLin 0.1mLincrementsto999.9

mL

VTBI

1 mLmrfor delivery

ml_/hr

999

maximum

values

rates

incrementsto99.9

mL/hr

recommended

cannot

21 mL/hr, or

be

NOTE

used

set

rateis500

mL

with

rate

delivery

mL/hr

and1ml/hr

and1mL

values

rate

mL/hr)

increments

2100

mL/hr.

if<1.0 mL/hr

from

1-5

PC-4

Pump

Mode:

10 ±2 psi (69 ±14 kPa) [at delivery

pressure is flow rate

dependenttoensure

conditions]. The "10 psi mode"

CONFIGURATION

thereby setting occlusion

Rates

below30mL/hr, occlusion

rapid

response

can

be invoked during SYSTEM

pressure

kPa) for all rates. (Timeto occlusion at rates <30 mL/hr

increased).

to occlusion

to 10±2 psi (69±14

will

be significantly

Selectable

Air-ln-Line

Mode:

Detection:

Secondary (Piggyback):

Nurse

Call

Feature:

Communications

Auxiliary

Data

Port:

Data

Port:

Channel Display Indicators:

ALARM:

STANDBY:

INFUSING:

Battery Operation:

To

maximize

battery life, recharge battery for at least 12

Failure to fully recharge

the

battery

between

25-517 mmHg (0.5-10.0 psi) in 25 mmHg (0.5 psi) increments

Ultrasonic (75 to

100

mL)

Dual rate programmable

Activates an externally

Malfunctionorselected

EIAStandard RS-232-C. Requires

EIAStandard RS-232-C. Requires

Red LED-

flashes

Amber LED- illuminates

and

awaiting

start

Green LED- flashes when

Witha new, fully

"BATTERY

DISCHARGED"

NOTES

hours

consecutive

battery

during

time

charged

between

operations

powered

Advisories

systeminthe

standard

standard

alarm

condition

when

channel is

channel

is actively infusing

battery, approximately

message

consecutive

will

reduce

eventofan

Alarm,

9 pin subminiature D connector

9 pin subminiature D connector

programmed

battery

battery

for a

3.5

hours

operations.

life.

before a

delayed

start

/^Hk

1-6

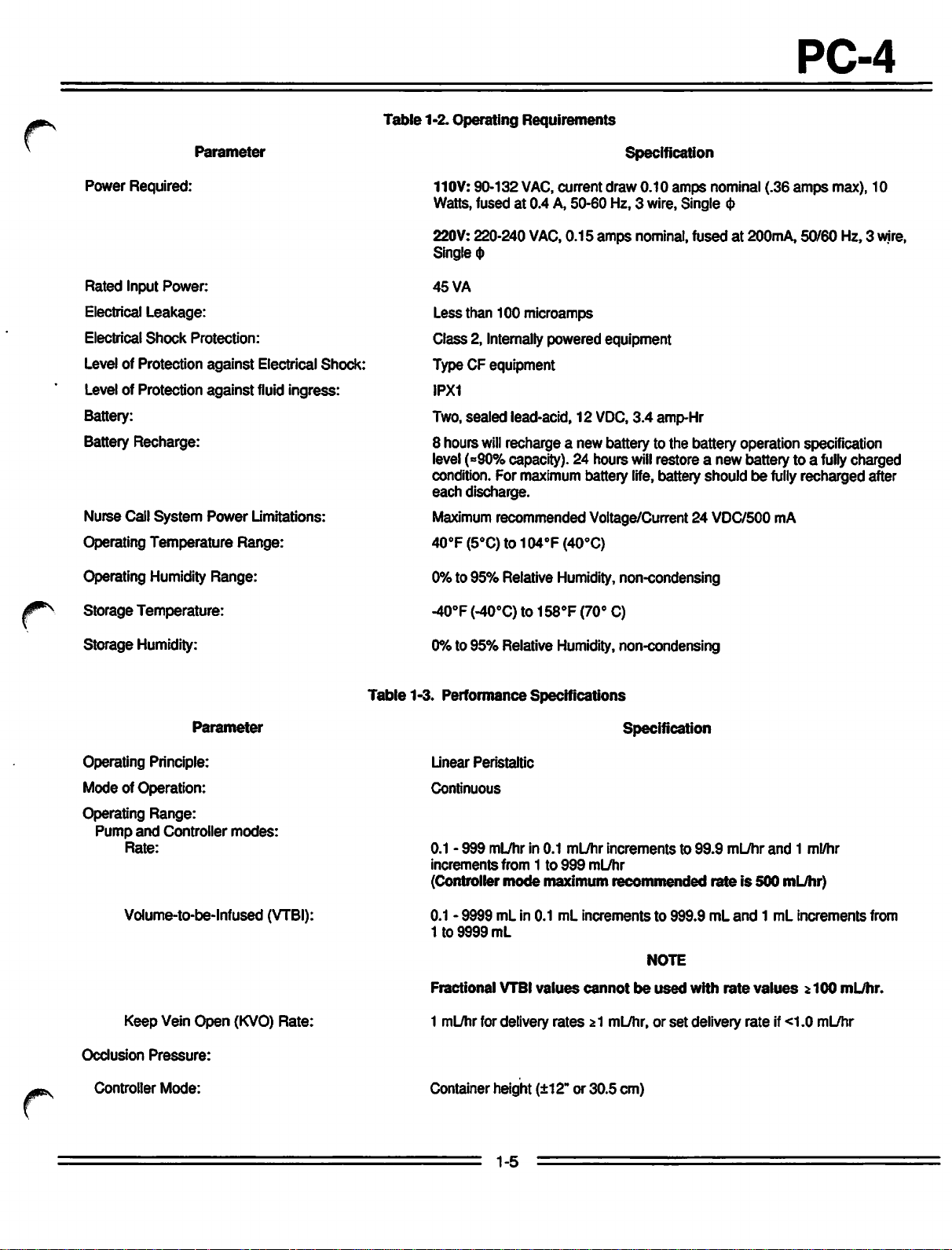

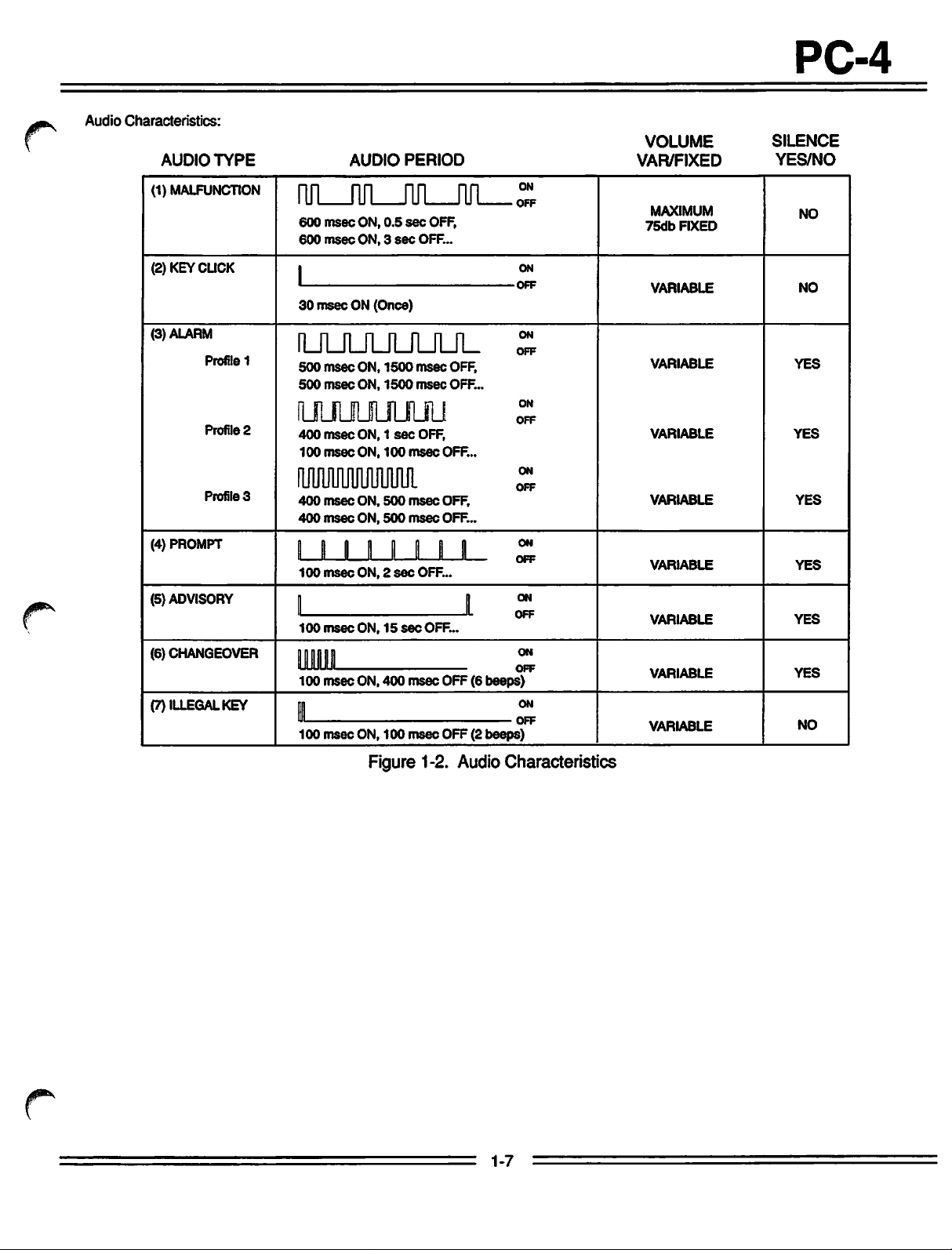

Audio

Characteristics:

AUDIO

(1) MALFUNCTION

TYPE

600

600

msec

msec

AUDIO

ON,

ON,3sec

0.5

PERIOD

sec

OFF,

OFF...

PC-4

VOLUME

VAR/FIXED

ON

—

OFF

MAXIMUM

75db

FIXED

SILENCE

YES/NO

NO

(2) KEY CLICK

(3) ALARM

Profile

1

Profile

2

Profile

3

(4) PROMPT

(5) ADVISORY

(6) CHANGEOVER

(7) ILLEGAL KEY

l

1

30

msec

ON (Once)

UULfULOJL

500

msec

ON,

1500

msec

OFF,

500

msec

ON,

1500

msec

OFF...

uimmjuu

400

msec

100

msec

ON,1sec

ON,

100

OFF,

msec

OFF...

aiMuuuum

400

msec

ON,

500

msec

OFF,

400

msec

ON,

500

msec

OFF...

I I I I » I I I

100

msec

ON,2sec

I I

100

msec

ON,15sec

ggmgg

100

msec

ON,

ll

100

msec

ON,

400

100

OFF...

OFF...

msec

msec

OFF (6 be

OFF (2 be

teps)

—

«ps)

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

VARIABLE

VARIABLE

VARIABLE

VARIABLE

VARIABLE

VARIABLE

VARIABLE

VARIABLE

NO

YES

YES

YES

YES

YES

YES

NO

4^*

Figure 1-2. Audio Characteristics

1-7

PC-4

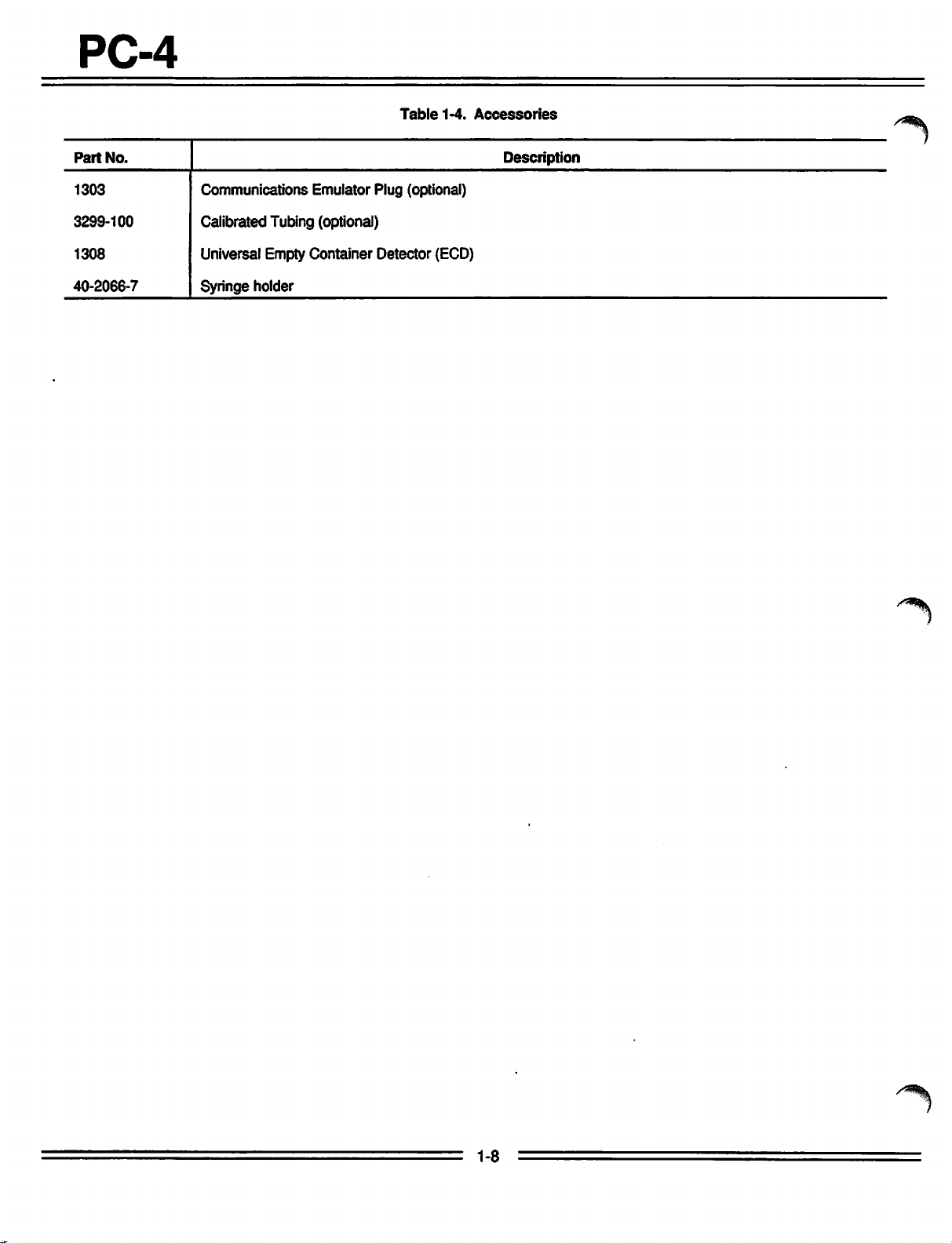

Table

1-4.

Accessories

Part

No.

1303

3299-100

1308

40-2066-7

Communications

Emulator

Plug (optional)

Calibrated Tubing (optional)

Universal Empty Container Detector (ECD)

Syringe holder

Description

1-8

/-^^.

#*N

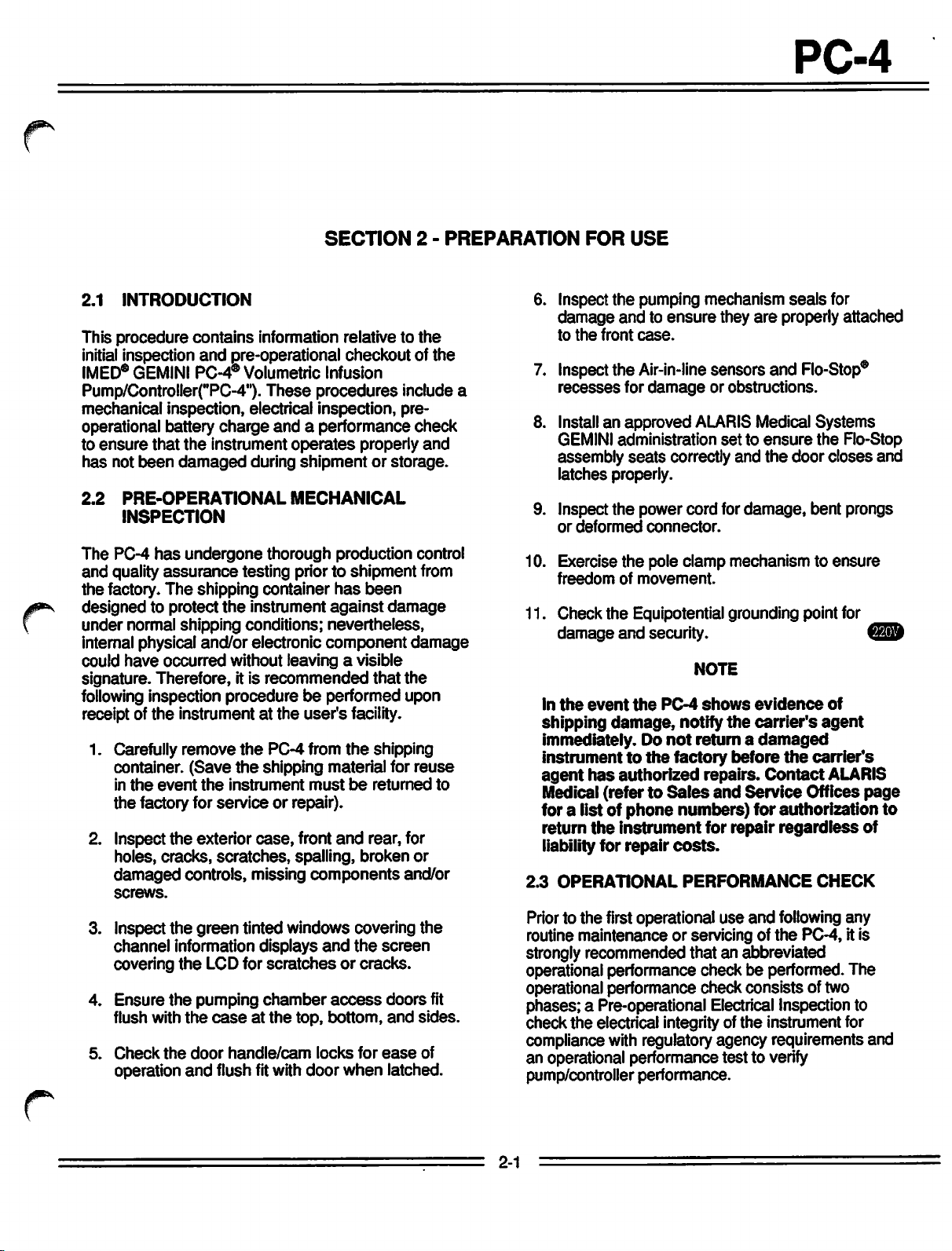

PC-4

SECTION

2.1

INTRODUCTION

This procedure contains information relative to

initial inspection

IMED®

GEMINI PC-4® Volumetric Infusion

Pump/ControllerfPC^").

and

pre-operational

These

checkoutofthe

procedures

mechanical inspection, electrical inspection,

operational battery

to

ensure

has

2.2

The

and

the

that

not

been

PRE-OPERATIONAL

INSPECTION

PC-4

has

quality

factory.

assurance

The

designed to protect

under

normal shipping conditions;

internal physical and/or electronic

could

have

occurred without leaving a visible

signature. Therefore, it is

charge

the

instrument

damaged

undergone

shipping

the

and

a performance

operates

during

MECHANICAL

shipmentorstorage.

properly

thorough production control

testing prior to shipment from

container

instrument

has

been

against

nevertheless,

component

recommended

damage

that

2 -

the

include a

pre

check

and

damage

the

following inspection procedurebeperformed upon

receipt of the instrument at the

1. Carefully

container.

in

the

the

2. Inspect

holes,

damaged

screws.

3. Inspect

remove

(Save

event

the

factory for

the

exterior

cracks,

controls, missing

the

green

the

the

instrument

service

case,

scratches,

tinted windows covering

channel information displays

covering

4. Ensure

flush with

5.

Check

operation

the

the

the

LCDfor

pumping

the

caseatthe

door

and

flush fitwith

handle/cam

user's

PC-4

from

facility.

the

shipping

shipping material for

must

be

returned

or repair).

front

and

rear, for

spalling, broken

components

and

the

screen

scratches

chamber

or cracks.

access

top, bottom,

locks

for

door

when

doors fit

and

ease

latched.

reuse

or

and/or

the

sides.

of

PREPARATION

to

FOR

USE

6. Inspect the pumping mechanism

damage and to

to

the

front

7.

Inspect

the

recesses

8. Install an approved

GEMINIadministration

assembly

ensure

case.

Air-in-line

for

damage

seats

they

sensorsand

or obstructions.

ALARIS

settoensure

correctly

and

seals

for

are

properly attached

Flo-Stop®

Medical Systems

the

Flo-Stop

the

door closes and

latches properly.

9. Inspect the power cord for

or

deformed

10. Exercise

freedom

connector.

the

pole clamp mechanism to

of

movement.

damage,

bent prongs

ensure

11. Checkthe Equipotential grounding point for

damage

In

the

shipping

immediately.Donot

instrumenttothe

agent

Medical (refertoSales

for a listofphone

return

liability for repair

2.3

OPERATIONAL

Priorto the first operational

routine maintenance or servicing of

and

security.

event

the

PC-4

damage,

notify

factory

has

authorized repairs.

numbers) for authorization to

the

instrument

costs.

PERFORMANCE

NOTE

shows

the

return a

before

and

for repair

use

evidence

carrier's

damaged

the

Contact

Service

regardless

and

following any

the

of

agent

carrier's

ALARIS

Offices

CHECK

PC-4, it is

ftjgfi

page

of

strongly recommended that an abbreviated

operational performance check be performed. The

operational performance check consists of two

phases; a Pre-operational Electrical Inspection to

check

the

electrical integrity of

the

instrument for

compliancewithregulatory agency requirements and

an operational performance test to verify

pump/controller performance.

2-1

PC-4

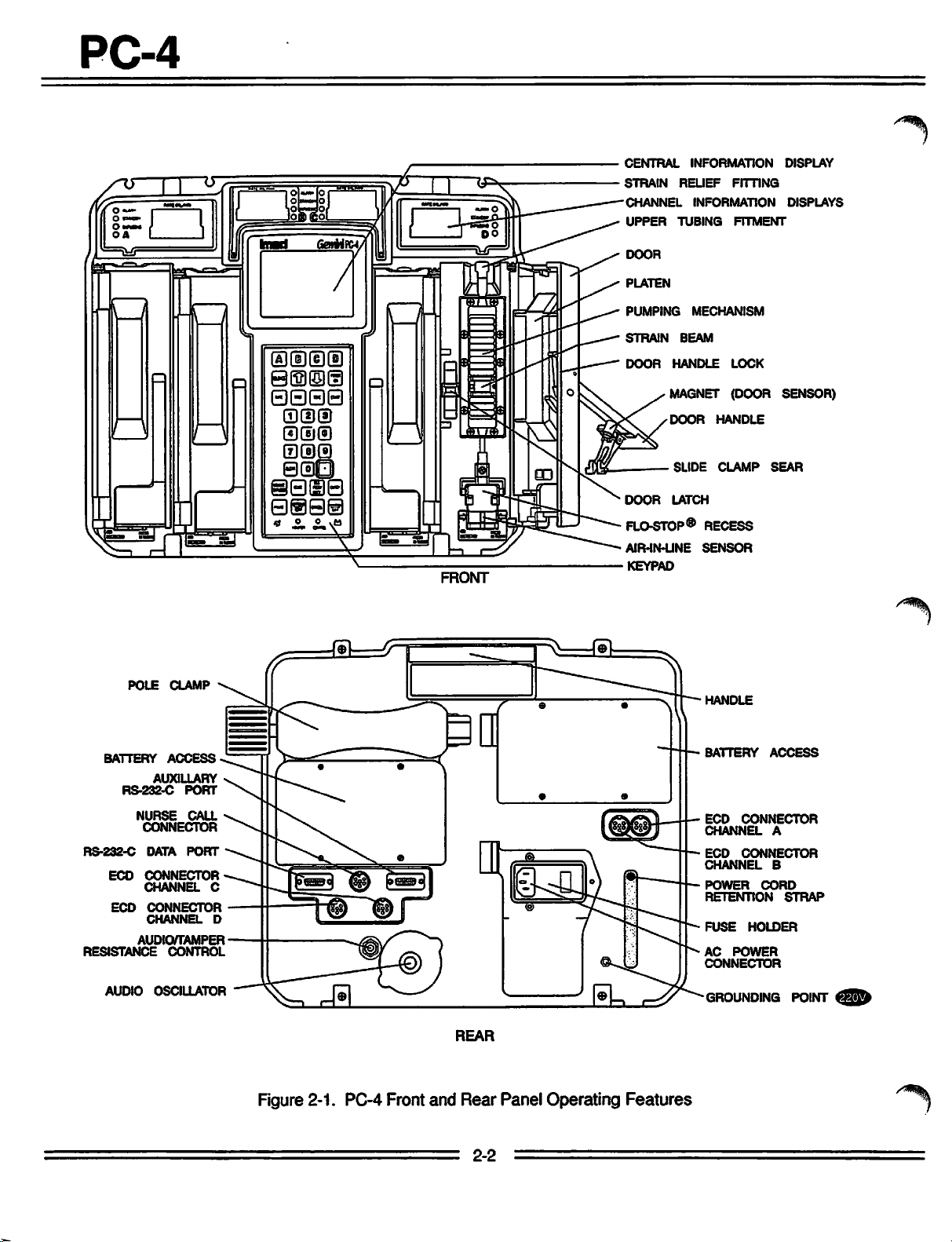

FRONT

CENTRAL

STRAIN

CHANNEL

UPPER

DOOR

PLATEN

PUMPING

STRAIN

DOOR

INFORMATION

RELIEF

INFORMATION

TUBING

MECHANISM

BEAM

HANDLE

FITTING

FITMENT

LOCK

MAGNET (DOOR

DOOR

DOOR

SLIDE

LATCH

HANDLE

CLAMP

FLO-STOP® RECESS

AIR-IN-LINE

KEYPAD

SENSOR

DISPLAY

DISPLAYS

SENSOR)

SEAR

POLE

BATTERY

RS-232-C

RS-232-C

ECD

ECD

RESISTANCE

AUDIO

CLAMP

ACCESS

AUXILIARY

PORT

NURSE

AUDIO/TAMPER

CALL

CONNECTOR

DATA

PORT

CONNECTOR

CHANNEL

CONNECTOR

CHANNEL

CONTROL

OSCILLATOR

HANDLE

BATTERY

ECD

CHANNEL

ECD

CHANNEL

C

D

POWER

RETENTION

FUSE

AC

CONNECTOR

GROUNDING

ACCESS

CONNECTOR

A

CONNECTOR

B

CORD

HOLDER

POWER

STRAP

POINT

<3^h

REAR

Figure2-1. PC-4 Front and Rear Panel Operating Features

2-2

PC-4

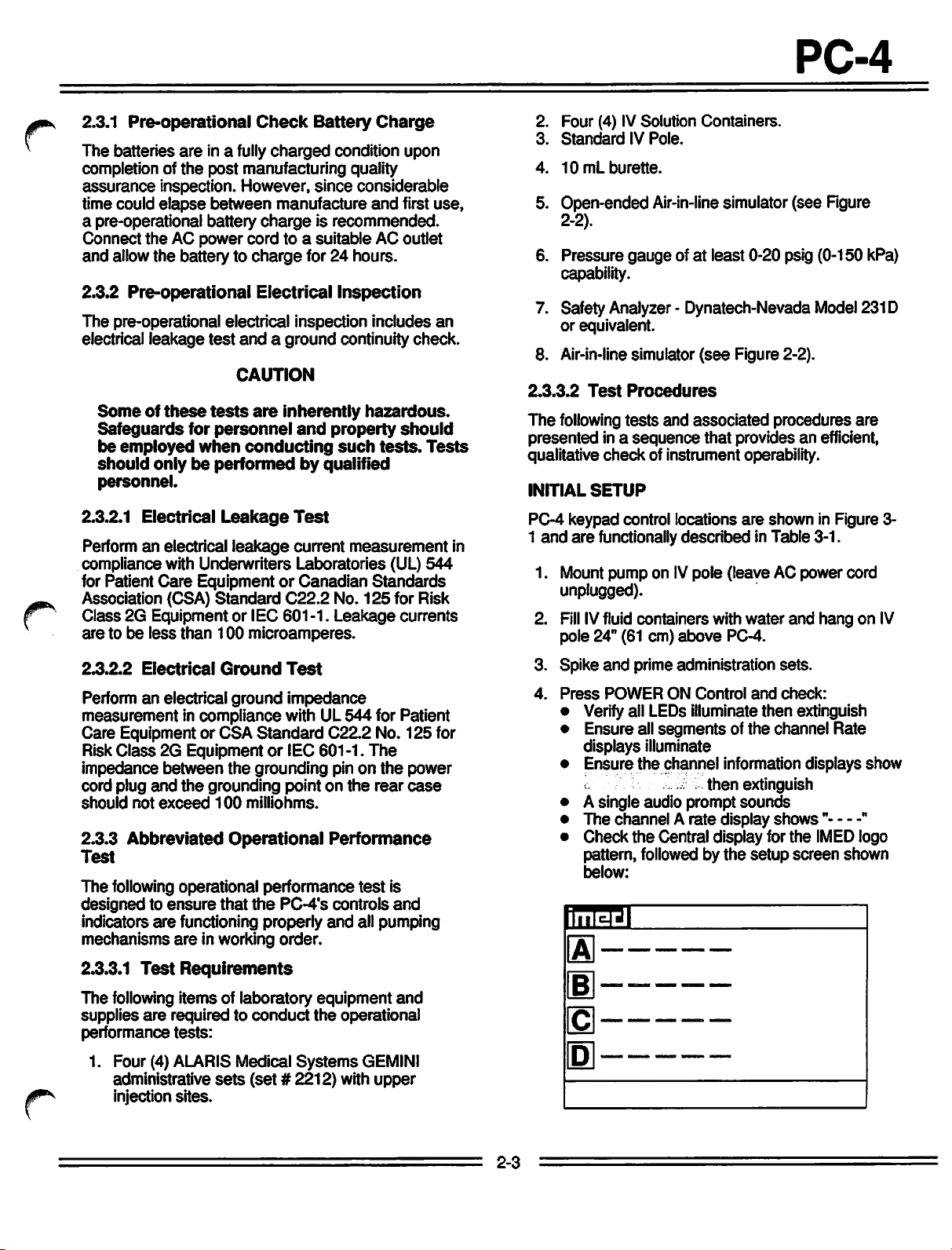

2.3.1

Pre-operational

The

batteries

completion of

assurance

time could

a pre-operational battery

Connect

and

allow

2.3.2

Pre-operational

The

pre-operational electrical inspection includes

electrical

Someofthese

Safeguards

be

employed

should

personnel.

2.3.2.1 Electrical

Perform an electrical

compliance with Underwriters Laboratories (UL)

for Patient

Association (CSA)

Class

2G Equipment or IEC

aretobe

2.3.2.2

Perform an electrical ground

measurementincompliance

Care

Equipment or CSA

Risk

Class

impedance

cord plug

should

2.3.3

Abbreviated

Test

The following operational performance

designed to

indicators

mechanisms

are

in a fully

the

post

inspection. However,

elapse

the

AC power cord to a suitable AC outlet

the

battery to

leakage

onlybeperformed

Care

less

Electrical

2G EquipmentorIEC 601-1.

and

not

exceed

are

test

tests

for

when

EquipmentorCanadian

than

between

the

grounding point on

ensure

functioning properly

are

in working order.

Check

manufacturing quality

between

chargeisrecommended.

charge

Electrical

andaground

CAUTION

are

personnel

conducting

Leakage

leakage

Standard

100

microamperes.

Ground

Standard

the

grounding pin on

100

milliohms.

Operational

that

the

Battery

charged

since

manufacture

for 24 hours.

inherently

and

by

Test

current

C22.2

601-1.

Test

impedance

with UL

PC-4's

Charge

condition upon

considerable

and

first

Inspection

continuity

hazardous.

property

such

qualified

measurement

No.

Leakage

544

C22.2 No.

the

Performance

controls

and

should

tests.

Standards

125

for Risk

currents

for Patient

125

The

the

rear

test

is

and

all pumping

power

case

use,

an

check.

Tests

544

for

in

2. Four (4)IVSolution Containers.

3.

Standard

4.

10

5. Open-ended

2-2).

6. Pressure

capability.

7. Safety Analyzer - Dynatech-Nevada Model 231D

or equivalent.

8. Air-in-linesimulator

2.3.3.2

The

following

presented

qualitative

INITIAL

PC-4 keypad control locations

1

and

are

1. Mount pump on

unplugged).

Fill

2.

pole 24" (61 cm)

3. Spike

4.

Press

• Verifyall LEDs illuminate then extinguish

• Ensure all

•

• A single audio prompt

•

•

IV

Pole.

mL

burette.

Air-in-line

gaugeofat

Test

Procedures

tests

and

in a

sequence

check

of instrument operability.

SETUP

functionallydescribed inTable 3-1.

IV

lIll

IVfluid containers with

lIII

and

prime administration

IIIl

POWER

displays illuminate

Ensure

The

channel A

Check

pattern, followed by

below:

ON

segmentsofthe

the

channel information displays show

the

Central display for

simulator (see Figure

least 0-20 psig (0-150 kPa)

(see

Figure 2-2).

associated

that

pole (leave AC power cord

above

Control

IlII

PC-4.

Illl

.;

then

rate

display

the

procedures

provides an efficient,

are

shown in Figure 3-

water

and

sets.

and

check:

channel Rate

extinguish

sounds

shows"

the

setup

screen

are

hang on

IMED

shown

"

logo

HnltNl

IV

2.3.3.1

The

supplies

performance

1. Four (4) ALARIS Medical

Test

Requirements

following items of laboratory

are

requiredtoconduct

tests:

administrative

injection

sites.

sets

(set#2212)

equipment

the

operational

Systems

with

and

GEMINI

upper

2-3

PC-4

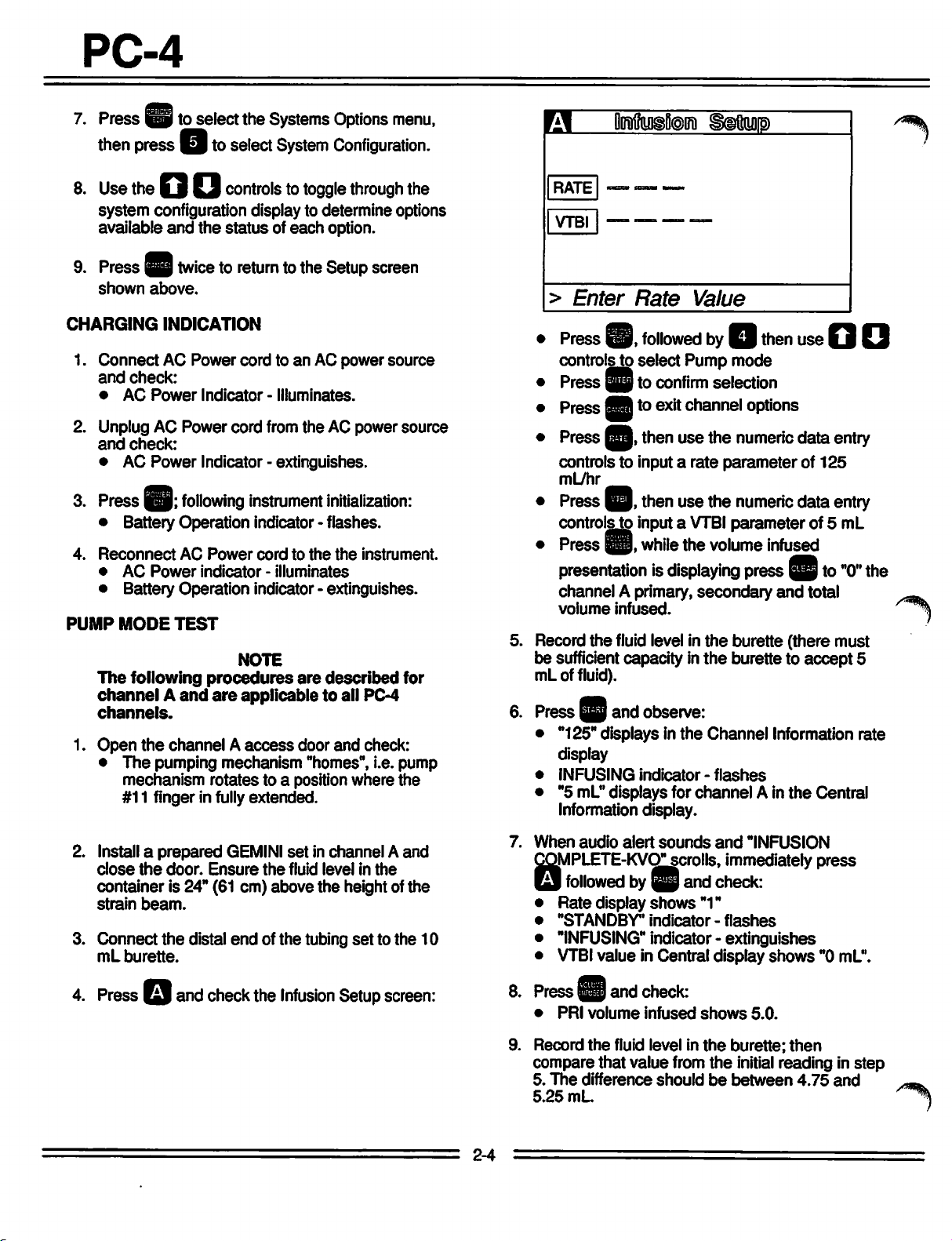

7. Press

8.

Hi

then

press

Use

the

system

available

toselectthe

Q

to

(J

Q

configuration display to determine options

and

the

select

Systems

System

Options

Configuration.

controlstotoggle

statusofeach

option.

through

9. Press 0 twiceto returntothe Setup screen

shown

CHARGING

1.

Connect

and

•

2. Unplug AC

and

• AC

3. Press

• Battery Operation indicator - flashes.

4.

Reconnect

•

• Battery Operation indicator - extinguishes.

PUMP

The

channelAand

channels.

1.

Open

•

above.

INDICATION

AC Power cord to an AC power source

check:

AC

Power

check:

Power

Up;

AC

Power

MODE

following

the

The

mechanism

#11 finger in fully extended.

Indicator-Illuminates.

Power

following

AC

TEST

channelAaccess

pumping

cord from

Indicator - extinguishes.

instrument

Power

indicator-illuminates

procedures

cordtothe the

NOTE

are

applicabletoall PC-4

mechanism

rotates

to a position

the

AC power

initialization:

are

described

door

and

"homes", i.e. pump

instrument.

check:

where

menu,

the

source

for

the

Fil

RATE

VTBI

>

•

Press

controls to

•

Press

• PressBB to

•

Press

controls to input a rate

mL/hr

• Press

controlsto input a

•

Press

Enter

@,

SBt0

^9,

^p,

^p,

Omftuigtoira

Rate

followedbyQ

select

Pump

confirm

exit

channel

then

use

then use the numericdata entry

while

the

presentationisdisplaying

channel A primary,

volume

5. Record

be sufficient capacity in

mLof fluid).

6. Press ^ and observe:

• "125" displays in

display

•

INFUSING

• "5 mL"displays for

Information display.

infused.

the

fluid level in

the

indicator-flashes

Scaup

Value

then

use

Q Q

mode

selection

options

the

numeric

parameterof125

VTBI

parameter

volume

press

secondary

the

burette (there must

the

burette to

Channel Information rate

channel

data

infused

^pto"0"

and

A in

the

entry

of 5 mL

total

accept

Central

the

5

2. Install a prepared

close

the

door.

container is 24" (61 cm) above

strain

beam.

3.

4.

Connect

mL

Press

burette.

Q

the

and

Ensure

distal

check

GEMINI

endofthe

the

the

Infusion

set

in channel A and

fluid

levelinthe

the

height of the

tubing

settothe

Setup

10

screen:

2-4

7.

When

audio

alert

sounds

COMPLETE-KVO"scrolls. immediately

Q

followedbyQ

• Rate display

•

"STANDBY"

• "INFUSING" indicator - extinguishes

VTBI

•

8.

PressHand

•

9.

Record

compare that value from

5.

The

5.25

value in Central display

PRI

volume

the

difference shouldbebetween

mL

shows

indicator-flashes

check:

infused

fluid level in

and

"1"

shows

the

and

"INFUSION

check:

burette;

the

initial

press

shows"0mL".

5.0.

then

reading in step

4.75

and

.-^

^

10.

Repeat

D.

steps

1 through 9 for

channels

B, C

and

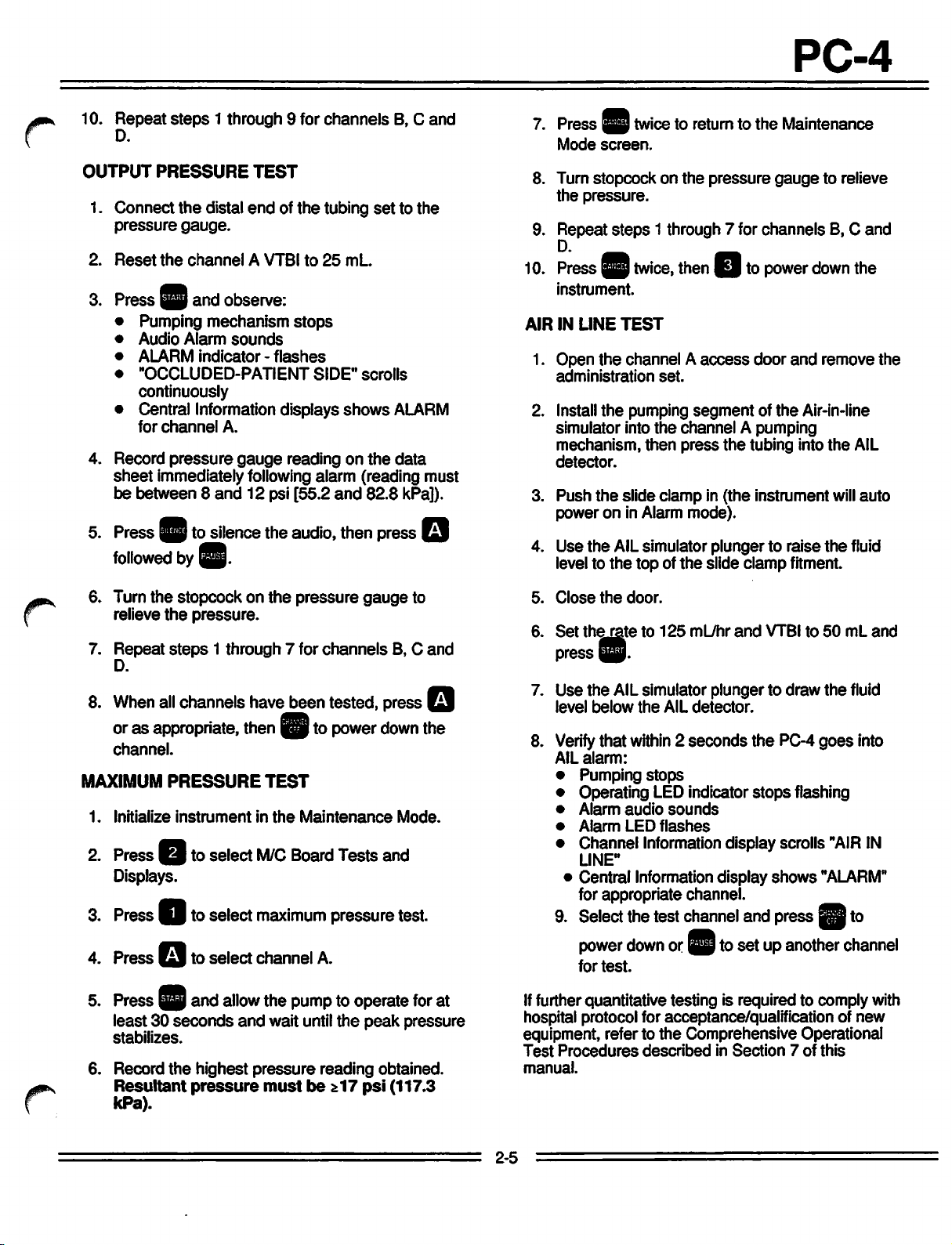

7. Press

Mode

PC-4

^p

twiceto returnto the Maintenance

screen.

f*^

OUTPUT

1. Connect

2.

3. Press

PRESSURE

the

distal

pressure

Reset

• Pumping

•

•

•

gauge.

the

channelAVTBIto25

^p

and observe:

mechanism

Audio

Alarm

ALARM

"OCCLUDED-PATIENT

continuously

indicator-flashes

TEST

end

sounds

• Central Information displays

for

4. Record

sheet

be

between8and

5. Press

channel

pressure

immediately following alarm (reading must

^p

A.

gauge

12 psi [55.2

to silence the audio, then press [•

followedby0.

6. Turn

7.

8.

MAXIMUM

1.

2.

3.

the

stopcock on

relieve

Repeat

D.

When

orasappropriate,

channel.

Initialize

Press

Displays.

Press

the

pressure.

steps1through

all

channels

PRESSURE

instrument

|9

to

select

Q

to

select

then

have

in

M/C

maximum

of the tubing

mL.

stops

SIDE"

shows

reading on

and

the

pressure

7 for

channels

been

tested,

^ptopower

TEST

the

Maintenance

Board

Tests

pressure

set

scrolls

the

82.8

gauge

press

down

and

to the

ALARM

data

kPa]).

to

B, C

and

the

Mode.

test.

8. Turn

9.

10.

AIRINLINE

1.

2. Install

3.

4. Use

5.

6.

7.

8. Verify

stopcockonthe

the

pressure.

Repeat

D.

Press3Qtwice,

instrument.

Open

administration

simulator into

mechanism,

detector.

Push

poweronin Alarm mode).

level to

Close

Set

press

Use

level

AIL

• Pumping

• Operating LED indicator

•

•

•

• Central Information display

9.

steps

1 through 7 for

thenQto

TEST

the

channel A

set.

the

pumping

the

then

the

slide

clampin(the

the

AILsimulator plunger to

the

top of

the

door.

therate

to

125

Q.

the

AILsimulator plunger to

below

the

AIL

that

within 2

alarm:

stops

Alarm

audio

sounds

Alarm

LED

flashes

Channel

LINE"

for appropriate channel.

Select

Information display scrolls "AIR IN

the

test

pressure

gauge

channels

power

access

segmentofthe

channel A pumping

press

the

mL/hr

detector.

seconds

channel

door

and

Air-in-line

the

tubing into

instrument will

raise

slide clamp fitment.

and

VTBIto50

draw

the

PC-4

stops

flashing

shows

and

press

to relieve

B, C

down

the

remove

the

AIL

the

fluid

mL

the

fluid

goes

"ALARM"

^9

to

and

the

auto

and

into

4.

Press

Eltoselect

5. Press

6. Record

^p

least30seconds

stabilizes.

Resultant

kPa).

channel

A.

and allowthe pump to operate forat

and

the

pressure

highest

wait until

pressure

must

reading

be

*17

the

peak

obtained.

psi

(117.3

pressure

powerdownor

for

test.

Iffurther quantitative testing is required to comply with

hospital protocol for acceptance/qualification of

equipment, refer to

Test

Procedures

manual.

2-5

IB

to set up another channel

the

Comprehensive Operational

describedinSection7of

this

new

PC-4

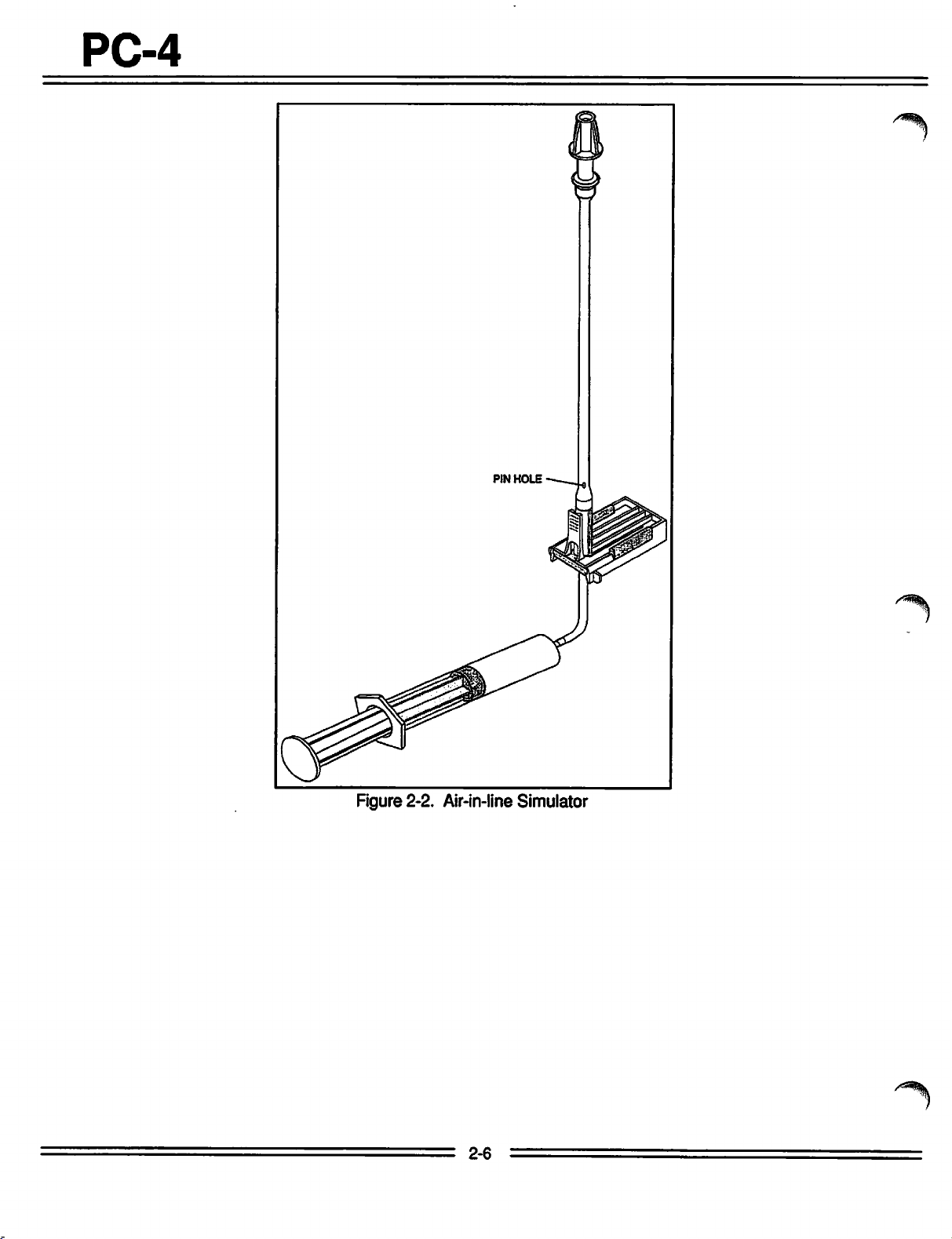

Figure 2-2. Air-in-line Simulator

2-6

PC-4

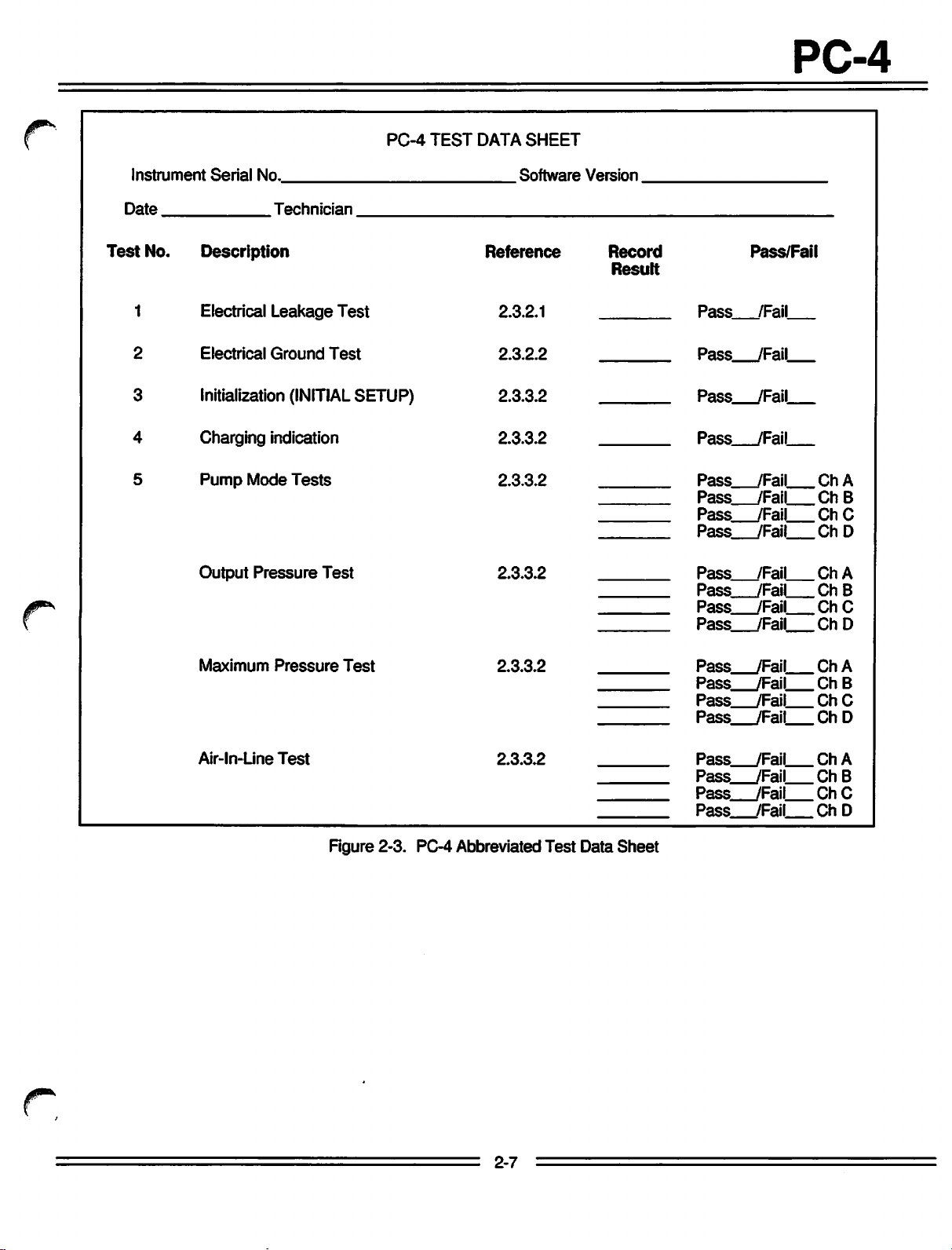

TEST

DATA

PC-4

SHEET

Test

Instruir

Date

No.

1

2

3

4

5

ent

Serial

No.

Technician

Description

Electrical

Electrical

Initialization

Leakage

Ground

(INITIAL

Charging indication

Pump

Mode

Tests

Output

Pressure

Test

Test

Test

SETUP)

Software

Reference

2.3.2.1

2.3.2.2

2.3.3.2

2.3.3.2

2.3.3.2

2.3.3.2

Version

Record

Result

Pass

Pass_

Pass_

Pass_

Pass

Pass

Pass_

Pass

Pass

Pass

Pass

Pass

Pass/Fail

/Fail

.JFail

_JFail

_/Fail

/Fail

/Fail

/Fail

/Fail

/Fail

/Fail

/Fail

/Fail

Ch

Ch

Ch

Ch

Ch

Ch

Ch

Ch

A

B

C

D

A

B

C

D

Maximum

Air-ln-Line

Pressure

Test

Test

2.3.3.2

2.3.3.2

Figure 2-3. PC-4 Abbreviated

Test

Data

Sheet

Pass_

Pass_

Pass_

Pass_

Pass_

Pass

Pass_

Pass_

_JFail

.JFail

_JFail

_/Fail

_JFail

/Fail

_JFail

/Fail

Ch

Ch

Ch

ChD

Ch

Ch

Ch

Ch

A

B

C

A

B

C

D

2-7

PC-4

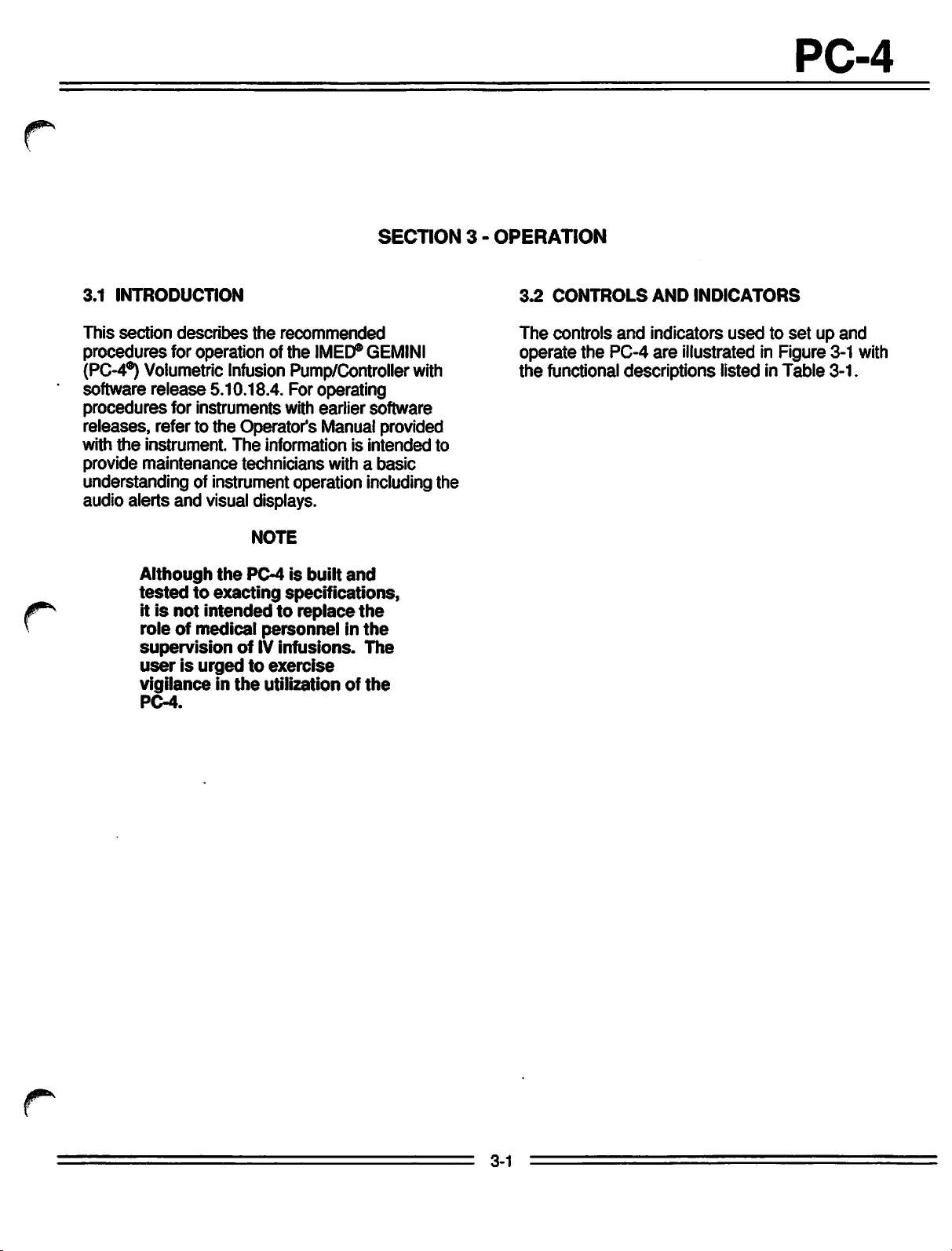

SECTION

3.1

INTRODUCTION

This section describes the recommended

procedures foroperation ofthe

(PC-4®)

software

procedures

releases,

with

provide

Volumetric

release

for instruments with earlier software

Infusion

5.10.18.4. For operating

referto the Operator's Manual provided

the

instrument.

maintenance

The

informationisintended

technicians with a

IMED®

GEMINI

Pump/Controller

basic

with

to

understanding of instrument operation includingthe

audio alerts

and

visual displays.

NOTE

Although

testedtoexacting

itisnot

roleofmedical

supervision

userisurgedtoexercise

vigilanceinthe

PC-4.

the

PC-4isbuilt

specifications,

intendedtoreplace

personnelinthe

ofIVinfusions.

utilizationofthe

and

the

The

3 -

OPERATION

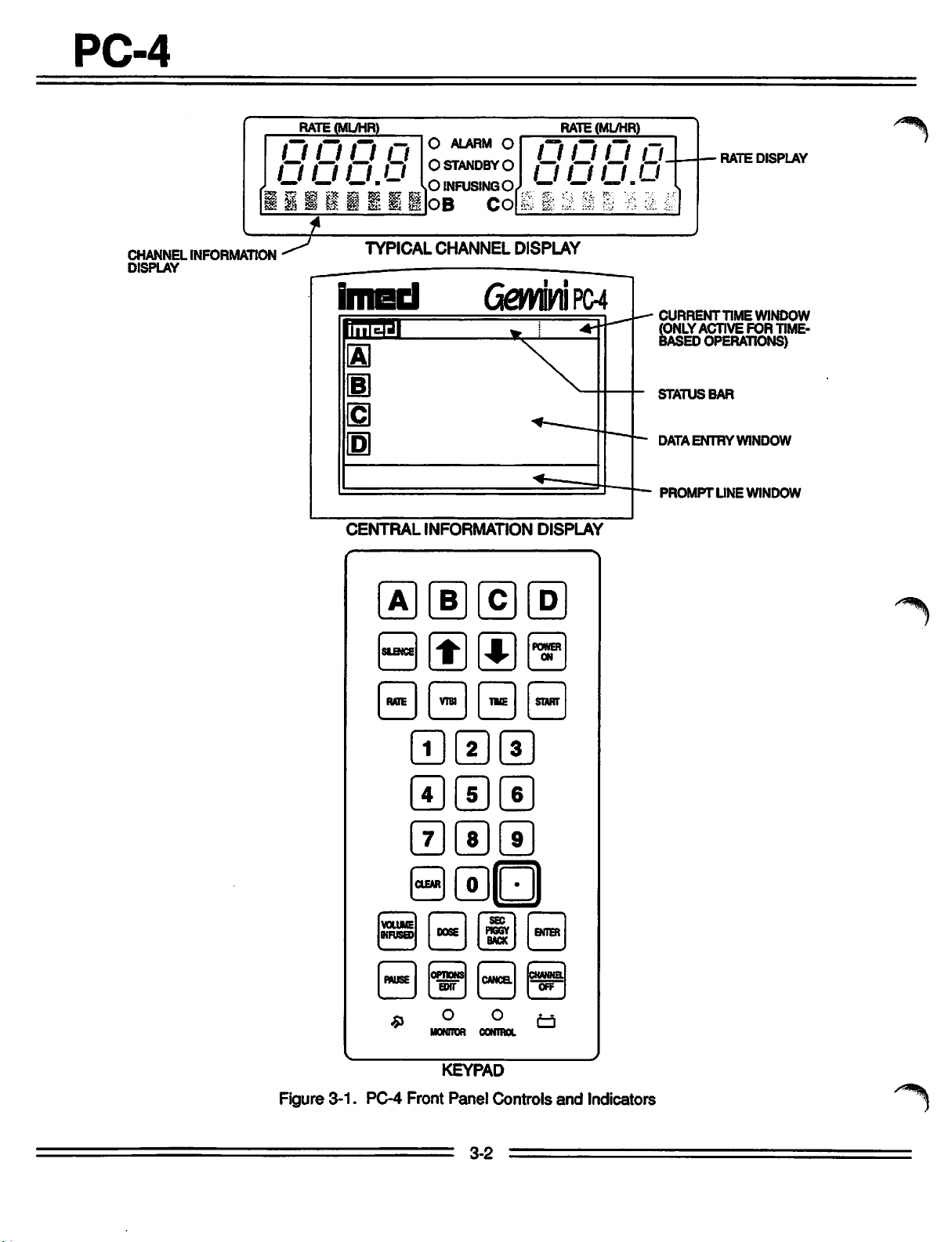

3.2

The

CONTROLS

controls

and

AND

INDICATORS

indicators

usedtoset

operate the PC-4 are illustrated in Figure

the

functional

descriptionslisted inTable3-1.

up and

3-1

with

3-1

PC-4

CHANNEL

DISPLAY

INFORMATION

RATE

(ML/HR)

u

11

u n

u O

u.o

IMililMi]

TYPICAL

imecl

EH3E

B

CENTRAL

O ALARM O

O

STANDBYO

.O

INFUSING

|0B

CHANNEL

Of

CO^

G0WIPC-4

INFORMATION

RATE (ML/HR)

u u u o

uuu.u

DISPLAY

i i

DISPLAY

RATE

DISPLAY

CURRENT

(ONLY ACTIVE FOR TIME-

BASED OPERATIONS)

STATUS

DATA

PROMPT

BAR

ENTRY

TIME

UNE

WINDOW

WINDOW

WINDOW

/^^%\

A B C D

SIENCE

* *

•\ t \ r

VTBJ

TIME

H

BBB

BBB

BBB

BSD

VOLUME

(KFUSED

PAUSE

* ° ° a

DOSE

OPTIONS

HOT

MONnOR CONTROL

SEC

PIGGYj]ENTER

BACK

CANCEL

POWER

ON

START

CHANNEL

OFF

Figure

3-1.

PC-4

Front

KEYPAD

Panel

3-2

Controls

and

Indicators

PC-4

Table

Channel Information (Alarm/Status) Display - Channel

malfunctions.

section of this manual for specific

(RefertoCHANNEL,

3-1.

DESCRIPTION

CENTRAL

response

OF

INFORMATION

procedures.)

CONTROLS

A,B,C,or

Ddisplays various advisories, alarms, and

DISPLAY

RATEdisplay - Channel A, B, C, or D- displays primaryand secondary rate

Channel

infusion

Select

A,B,C, or Dindicators- when illuminated, indicatethat the correspondingchannel is selected for

parameter

entry

and

infusion

setup.

Standby indicator - illuminates whenthe channel is programmed fora

Alarm indicator - illuminates when

Infusing indicator - flashes when the channel is actively infusing.

Central Information Display - displays

parameters during operation ofthe instrument.

confirmation

after the

Keypad

Elto13

M

and displayof prompts, advisories and alarm conditions.The display backlight

last

keypress.

controls-when

*^

and

infusion

pressed

setup.

the

channel is in an alarm or infusion complete condition.

VTBI

(volume-to-be-infused), current time ofday and other operating

During

once,

set

selects

up procedures, providesdisplayfordata entry,

the

corresponding

AND

AND

future

INDICATORS

ALARM

RESPONSE

infusion

start

time.

channel

for

parameters.

will

extinguish 2 minutes

infusion

parameter

PROCEDURES

editing,

entry

r^^

til

**t0

|B|

when

pressed

"PRESS

or

when pressed, allows the rate infusion parameter on the selected channel to be changed using the

appropriate

when pressed, allows

data

when

only that channel

to power off

off

entry controls.

R data entrycontrols - whenpressed,

**

when

when

when

press of the Volume Infused control, clears the total, primaryand secondary volume infuseddisplaysfor

the

operating

pressed,

pressed,

pressed,

selected

duringaninfusion,

START' visual

pressed,

the

PC-4.

data

entry controls.

and

stops

had

the

PC-4. When

the

VTBI

audio prompt begins.)

parameters.

insertsadecimal

allows entry of time-related

clears

channel.

the

currently

the

infusion for

the

infusion for

been

infusing, powers off

pressed

parameter on the selected channel to be changed using the appropriate

pointinnumeric

data

selected

the

selected

the

selected

during a software-detected system malfunction, it powers

allows

sequentialentryof Rate,

channelisstopped.

channel,

the

PC-4. Repeat for all other running channels

deselects

(After ~2 minutes, the

the

selected channel,

VTBI

and other

numerical

data.

inputs for

infusion parametersetting to "0". When

delayed

start

and

multidose infusions.

pressed

following

and

if

a

=

3-3

========^=^==

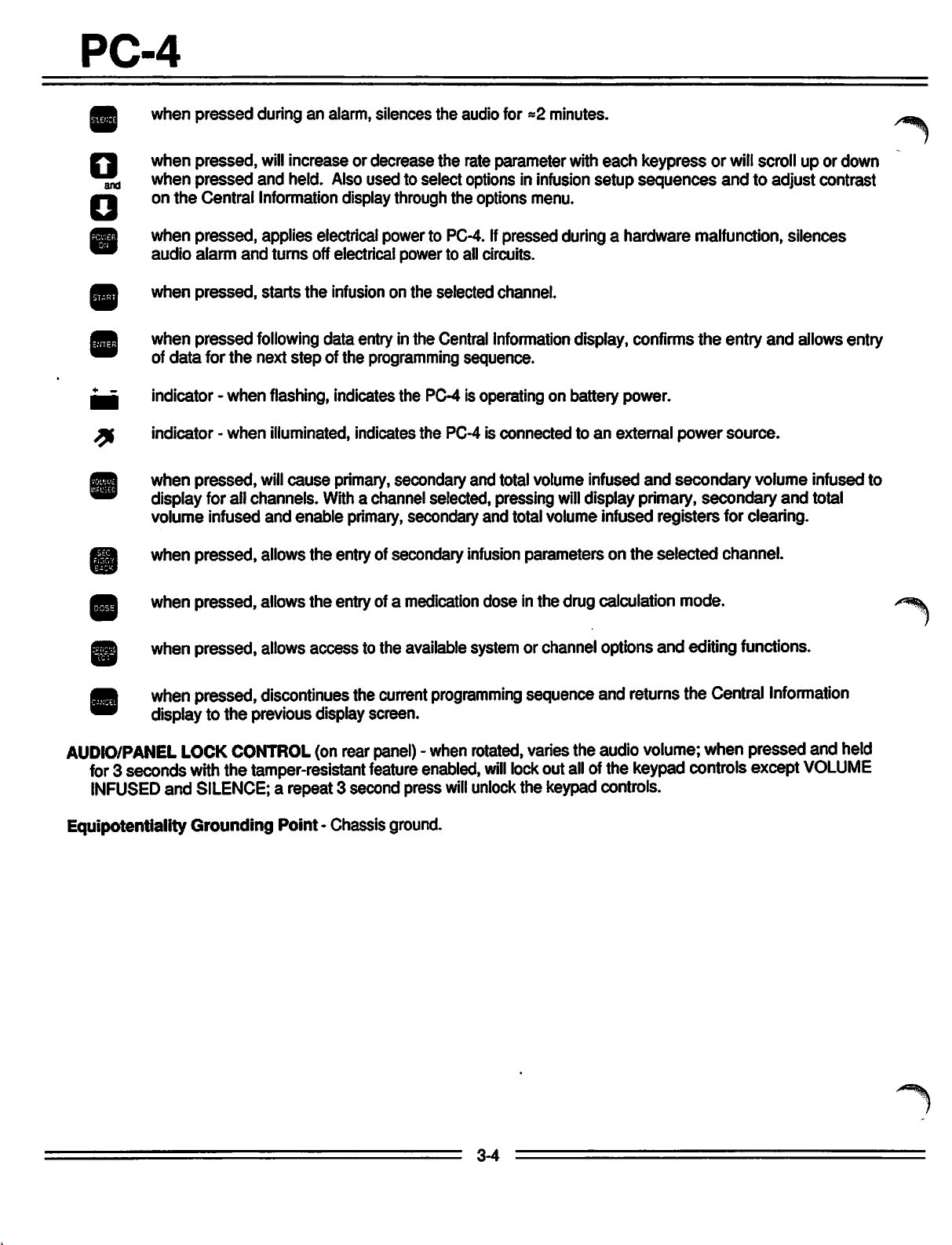

PC-4

when

pressed

during an alarm, silences

the

audio for *2 minutes.

^

•J,

"I

when

pressed,

when

pressed

onthe Central

when

pressed,

audio

alarm

when

pressed,

when

pressed

of

data

for

indicator - when flashing, indicates the PC-4 is operating on battery power.

indicator -

when

pressed,

display for ail channels.

volume infused

when pressed, allowsthe entryofsecondary

when pressed, allows the entry of a medicationdose in the drug calculation mode.

will

increaseordecrease

and

held.

Also

usedtoselect

Information

applies electrical power to PC-4.Ifpressed

and

turns

starts

following data entry in the Central Information display, confirms

the

next

step

when

illuminated, indicates

will

cause

and

display

off electrical power to all circuits.

the

infusion on

of the programming sequence.

primary, secondary

With

a channel selected, pressing

enable primary,secondary and total volume infused registers for clearing.

the

through

the

the

selected channel.

the

PC-4 is

rate

parameter

with

optionsininfusion

options

and

infusion

menu.

during a hardware malfunction, silences

connectedtoan

total volume infused

will

display primary, secondary

parameters on the selected channel.

each

setup

external

keypressorwill

sequences

the

power

and

secondary

scrollupor

andtoadjust

entry

and

allows entry

source.

volume infused to

and

down

contrast

total

//r^%

when pressed,

whenpressed, discontinues the

display to the previous display screen.

AUDIO/PANEL

for

3 seconds

INFUSED

Equipotentiality Grounding Point- Chassis ground.

LOCK

with

and SILENCE; a repeat 3 second press

allows

CONTROL

access tothe available systemor channel optionsand editingfunctions.

(onrear

the tamper-resistant

current

panel)

feature

-when

enabled,

programming

rotated,

will

lock

will

unlock

sequenceand returns the Central

Information

variesthe audio volume; when pressed and held

out

all

ofthe

keypad

the keypad controls.

controls except

VOLUME

3-4

Loading...

Loading...