PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 1

SF104x

Fingerprint Image Sensor Module

User Manual

February 7, 2014

Image Match Design Inc.

http://www.imagematch.com.tw/

B3-2, No. 1, Lising 1st Road, Hisnchu Science

Park, Hsinchu 300, Taiwan (R.O.C.)

Te l:+886-3-666-9388

Fax:+886-3-666-9387

Service:albertke@imagematch.com.tw

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 2

Revision History

Version Date Content Approved Checked Drawn

P01 2014/02/07 Initial draft Albert Ke

P02 2014/3012 I/O spec AL

P03 2014/03/17

Interface and drawing

update

Eros

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 3

Content

1 OVERVIEW .................................................................................................................... 5

1.1 DESCRIPTION ............................................................................................................ 5

1.2 FEATURES ................................................................................................................. 5

1.3 SENSOR BLOCK DIAGRAM .......................................................................................... 6

1.4 APPLICATIONS ........................................................................................................... 6

2 PHYSICAL DIMENSION ................................................................................................ 7

3 DEVICE OPERATION .................................................................................................... 7

3.1 SETTING UP CLOCK DIVIDER ........................................................................................ 7

3.2 CONFIGURING GAIN AND RANGE OF PRE-AMP AND ADC ................................................. 8

3.3 COMMAND AND REGISTERS ......................................................................................... 9

3.4 SPI COMMAND PROTOCOL ........................................................................................ 11

3.5 COMMAND CODE DETAIL ........................................................................................... 13

3.6 REGISTER DETAIL..................................................................................................... 15

4 OPERATION WORKFLOW ......................................................................................... 22

4.1 GENERAL DESCRIPTION ............................................................................................ 22

4.2 RESET .................................................................................................................... 23

4.3 FINGER DETECTION MODE AND INTERRUPT ................................................................. 23

4.4 TIMING CONSIDERATIONS .......................................................................................... 24

4.5 A SAMPLE SESSION .................................................................................................. 25

5 TIMING CHARACTERISTICS ...................................................................................... 28

5.1 SPI INTERFACE TIMING ............................................................................................. 28

6 MAXIMUM RATINGS AND OPERATING CONDITION ............................................... 31

7 ELECTRICAL CHARACTERIST I CS ............................................................................ 32

8 RELIABILITY TEST ..................................................................................................... 32

8.1 ESD IMMUNITY ........................................................................................................ 32

8.2 ENVIRONMENTAL LIMITS ........................................................................................... 33

8.3 MECHANICAL DURABILITY .......................................................................................... 33

9 PACKAGING INFORMATION ..................................................................................... 34

9.1 THE SF104X PACKAGING ......................................................................................... 34

9.2 SIGNAL DEFINITION................................................................................................... 34

9.3 PART DRAWING ........................................................................................................ 35

9.4 PIN CONFIGURATION ................................................................................................ 35

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 4

9.5 REFERENCE SCHEMATIC ........................................................................................... 36

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 5

1 Overview

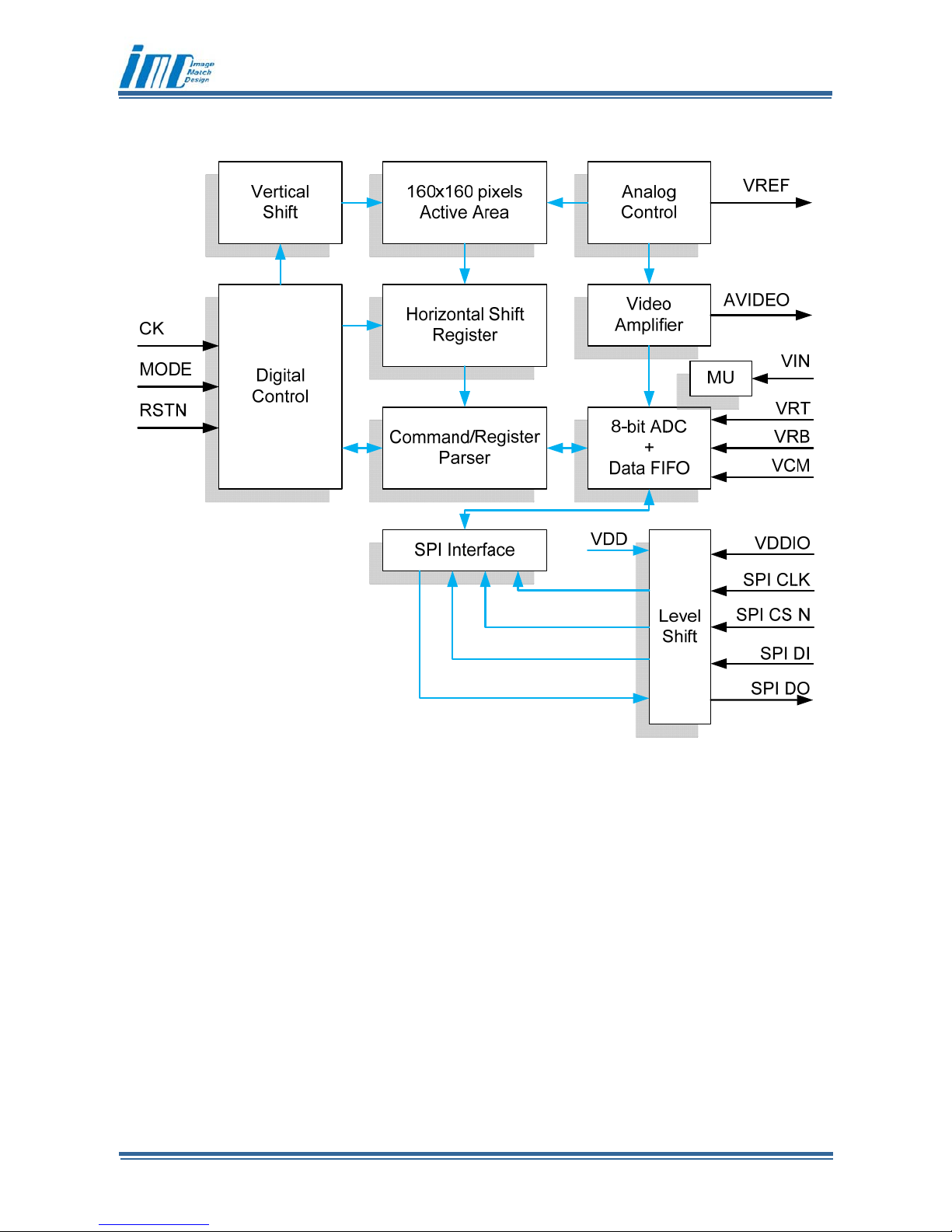

1.1 Description

The SF104x fingerprint image sensor module is based on capacitive-contact

technology with hardened surface and enhanced ESD resistivity. The build-in analog and

digital circuitry minimizes the number of external component, and provides easy-to-use,

standard SPI interface to microprocessors.

The operation of SF104x is controlled through fingerprint image sensing by pixel array,

A/D converting, digital process, following is simple interface protocol. The captured image

quality of SF104x can be adjusted by setting gain, offset and reference voltage parameters.

In addition, the internal operation parameter and interface speed can also be configured to

the need.

1.2 Features

Spatial resolution 508 DPI

2D sensor array of 160x160 pixels

Active sensing area 8 mm x 8 mm

Build-in 8-bit ADC for digitizing image

Build-in programmable voltage reference

High speed SPI interface

0.03 sec read out time

128-byte on-chip data FIFO

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 6

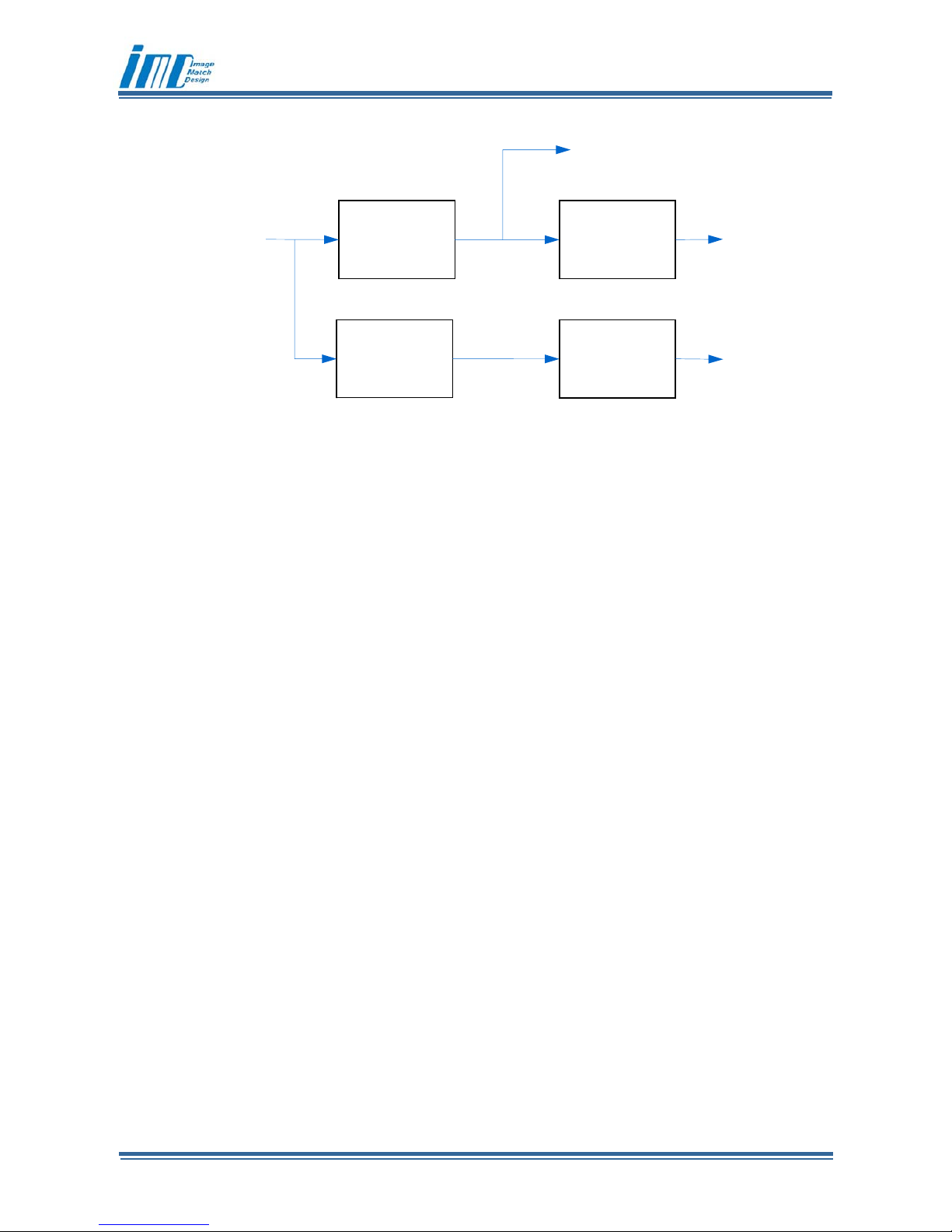

1.3 Sensor Block Diagram

1.4 Applications

The compact, thin packaging of SF104x sensor module allows a wide range of

applications

Security devices

Fingerprint identification systems

Fingerprint recognition systems

PRELIMINARY

SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 7

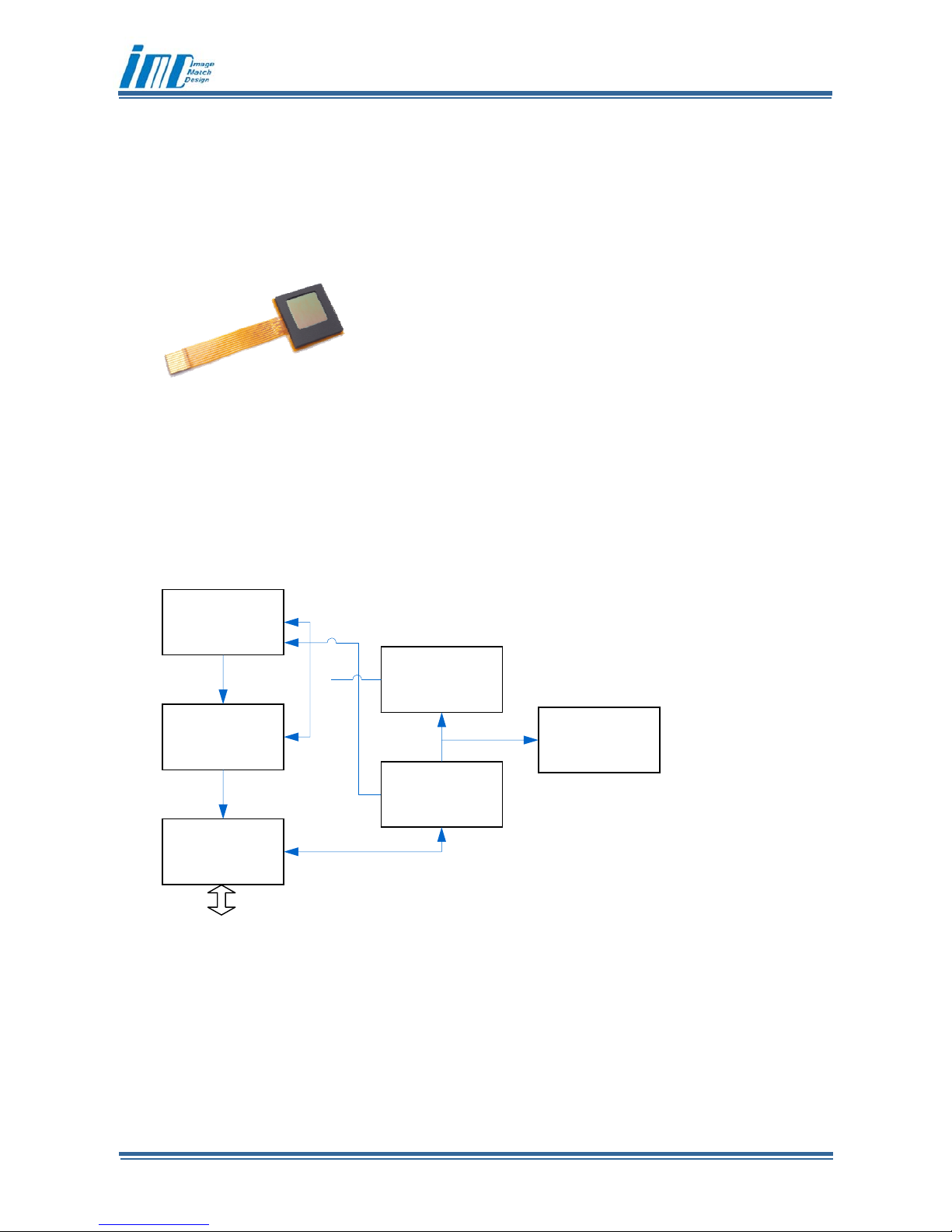

2 Physical Dimension

The sensor’s active pixel array is 160x160 pixels, and the SF104xM module is a

13.4mm*13.9mm highly integrated SPI fingerprint module.

3 Device operation

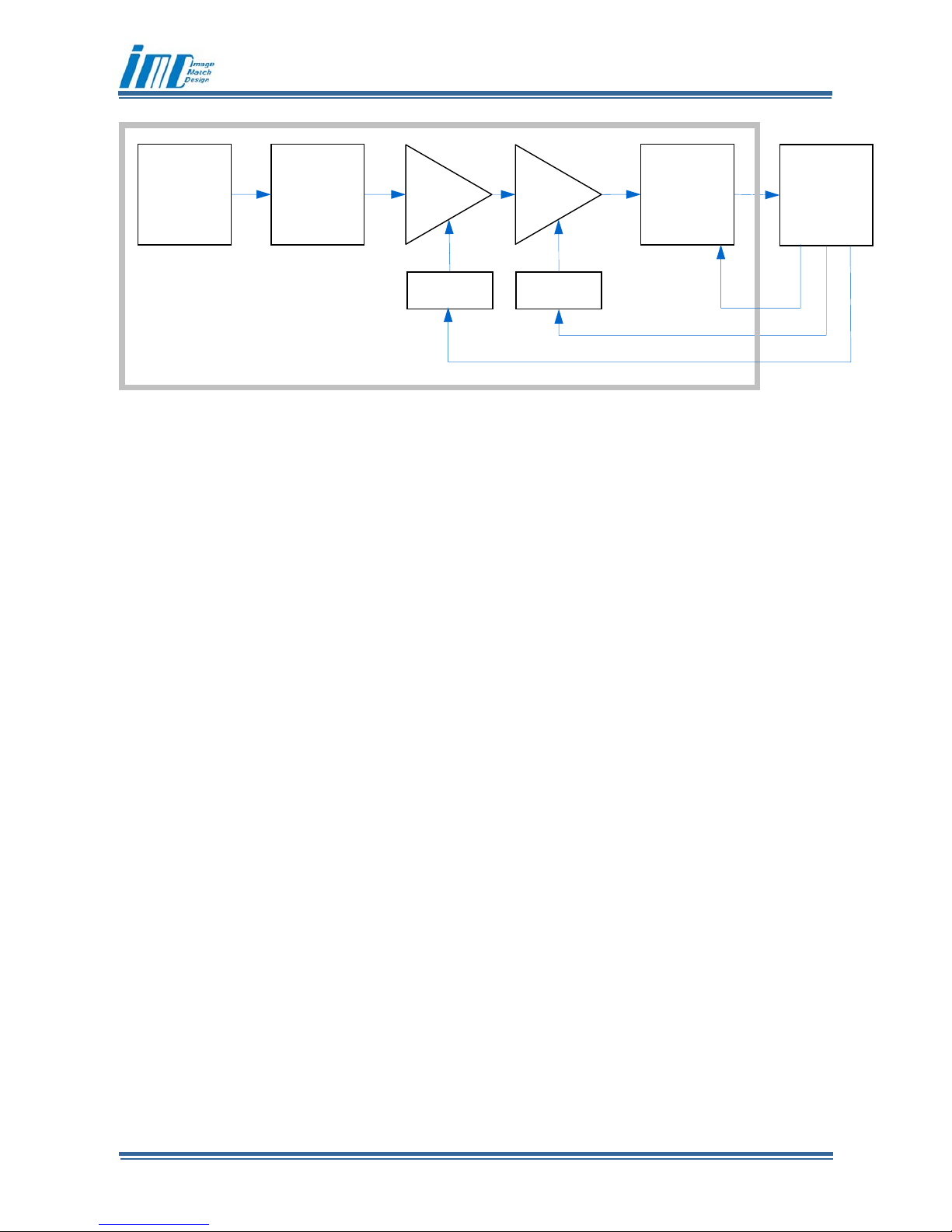

3.1 Setting up clock divider

The fingerprint sensor module has an on-board oscillator of 18Mhz, the sensor’s

internal clock logic is summarized as the following figure:

Sensor

& ADC

128-BYTE

FIFO

SPI

interface

Timing

Generator

Registers

Digital control

Register access

Analog control

D0~D7

D0~D7

ADCCLK

MCU

OTP

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 8

In the above diagram, OPCLK is used for internal timing, and PCLK is for image pixels.

The “detect start” signal starts the short “finger detect” cycle in detect mode.

The PCLK is 1/6 of OPCLK. OPCLK is the system clock pre-scaled by 1~16, controlled

by REG0/REG_CLK bit[3:0]. The detect start clock is controlled by REG9/REG_DDIV

bit[7:0].

For example, given the system clock input of 18Mhz, and REG0/REG_CLK bit[3:0]

value is 2 (divide by 3), then OPCLK is 6Mhz and PCLK is 1Mhz.

3.2 Configuring gain and range of pre-amp and ADC

Divide by

div_opclk

Clock from

external

oscillator

Divide

by 6

Divide by

4096

PCLK

OPCLK

Divide by

(DDIV+1)

detect

start

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 9

Two cascaded programmable gain amplifier are used for conditioning the sensor signal

before converted by ADC. Register REG1/REG_PGA bit [1:0] is for the control of PGA1 gain,

and register REG1/REG_PGA bit [7:4] for the control of PGA2 gain.

The ADC bias current and input voltage range is controlled by BIAS, (VRT-VRB) and

VRB parameters in REG3/REG_ADC. See section 5.0 for the detail of the registers.

3.3 Command and registers

The SF104 operation is controlled by sending commands and setting control registers

through the SPI interface. The SF104 SPI interface follows the SPI protocol with CPHA=0

and CPOL=0 as SPI mode 0.

There are 6 command codes to program the chip:

160x160

Pixel

array

Sample

&hold

ADC

MCU

Gain

Gain

VRT

VCM

VRB

PGA1 PGA2

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 10

command code name function read/write

0x01 rdata read pixel data R

0x02 start start scan W

0x03 status read status R

0xC0 srst software reset W

0x20+N rread read register R

0x40+N rwrite write register W

For the rread and rwrite command, the number N is the register address. The effective

N is in the range of 0x00 to 0x11.

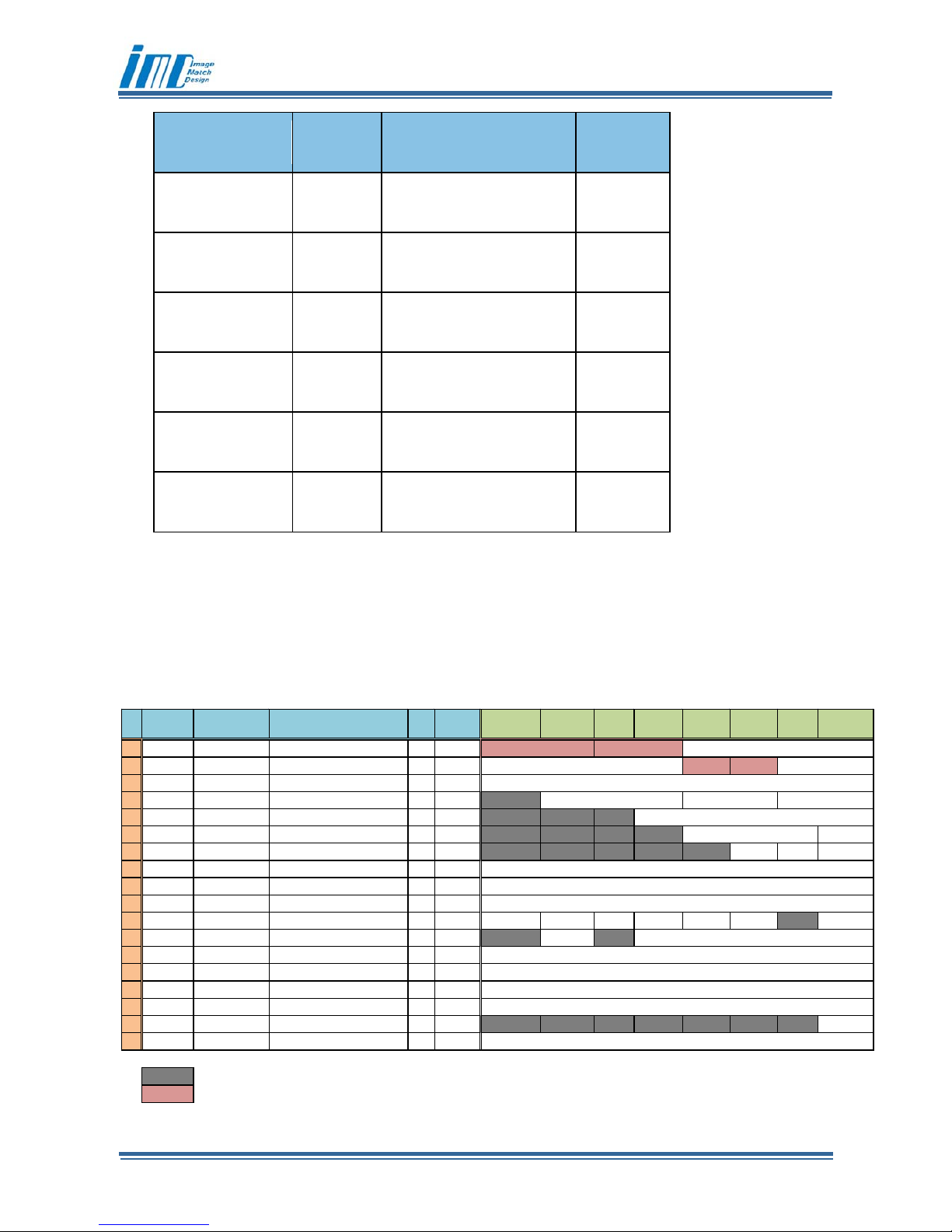

The register content is summarized in the following table:

N Address Name Function RW

Default

Value

76543210

0 0x00 reg_clk clock control RW 0

1 0x 01 reg_pag pag control RW 0 en_test1 en_t est0

2 0x 02 reg_dcoc dc offs et RW 0

3 0x 03 reg_adc adc setting RW 0

4 0x 04 reg_otp_addr OTP address RW 0

5 0x 05 reg_otp_wdat OTP wirte dat a RW 0 otp_wd

6 0x 06 reg_otp_m ode OTP cont rol RW 0 otp_prg otp_rst otp_c eb

7 0x 07 reg_otp_rdat OTP read data RW

8 0x 08 reg_deth finger detection threshold RW 0xFF

9 0x 09 reg_ddiv cloc k divider for detect ion RW 0

10 0x0A reg_enab function enable bits RW 0 en_window en_inscan en_det en_sqwv lowcap en_osc en_analog

11 0x0B reg_mode mode cont rol bits RW 0 en_intr

12 0x0C reg_llx windowing function sett ing RW 0

13 0x0D reg_lly windowing function sett ing RW 0

14 0x0E reg_urx windowing funct ion setting RW 0x9F

15 0x0F reg_ury windowing funct ion sett ing RW 0x9F

16 0x10 reg_c hmd c hange mode W (N/A) ch_mode

17 0x11 reg_inscanline in s can detec tion line number RW 0x40

Reserve

Internal test

otp_rdat

test1 tes t0 div_opclk

pga2_gain pga1_gain

dc_offset

adc_bias adc_vrt adc_vrb

otp_yp

otp_ain

ury

in_sc an_line

deth

ddiv

en_bits

llx

lly

urx

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 11

3.4 SPI command protocol

Command and data are exchanged throught the SPI MISO and MOSI wires. Each byte

of data sent through the MOSI port brings back a received byte through the MISO port.

Commands can be cascaded one by another. The term “SPI command sequence” in

the following context is defined as a sequence of command code and data bytes exchange

within one active SPISEL strobe.

An SF104 command code may or may not have associated data. The “start” and “srst”

commands don’t have associated data, and take effect immediately after the command code

is sent.

For read/write data commands, the second byte will be the beginning of data byte or

bytes, as illustrated below:

read command

write command

Writing and reading a series of register content may look different. For writing to

consecutive registers, an internal address counter is incremented automatically after each

byte written. This design eliminates the need to repeat sending the 0x40+N command for

each byte. So the sequence of read/write commands may look like the following.

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 12

read sequence (the last command byte is a dummy command)

write sequence

read image sequence

In fact, except for the write register command (which writes a sequence of register

content), commands can be mixed in a single sequence like following:

mixed mode of read image and status sequence

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 13

3.5 Command code detail

Code 01 / RDATA command (read only)

This command pumps image data from FIFO and sends it to host

Code 02 / START command (write only)

This command starts fingerprint image scan

Code 03 / status read command (read only)

This command sends the 8-bit internal status flags to host.

The status flags are defined as below

Bit Function

0 Data FIFO is “half full”

1 Data FIFO is empty

2 Data FIFO is “almost full”

3 Data FIFO is full

4 Image scan active

5 Detect interrupt flag

6 Detect result is OK

7 (not used)

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 14

Code 0xC0 / SRST command (write only)

This command generates a software reset to the system. Its effect is the same as

hardware reset except that the register content is left unchanged.

Code 0x2N / register read command

This command starts reading register at address N

At least to bytes needs to be written, the first byte is the command code, and the second

(dummy) byte is for the register content.

Subsequent register read command can be cascaded in one command sequence.

Code 0x4N / register write command

This command starts writing registers starting at address N

The first byte is the command code, followed by subsequent bytes that are written to

registers starting at the specified starting address N.

Code 0x3E, 0x3F / Chip ID read command

These two command read back the chip id of high and low byte

0x3E : Chip ID High Byte – Value 0x01 for SF104.

0x3F : Chip ID Low Byte – Value 0x04 for SF104.

All command code as the first byte in a command sequence returns the state byte

(which can be explicitly read by the 03 command).

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 15

3.6 Register detail

REGISTER

NAME

ADD

R

R/W Bit(s) DEFAULT DESCRIPTION

REG_CLK 0 R/W

0000_0000 Clock control

[7:6]

Test mode 1

00 : AREGC[2]

01 : TESTPIN = VREF

10 : TESTPIN = VINPTST

11 : AREGC[0]

[5:4]

Test mode 0

00 : AREGC[3]

01 : TESTPIN = VAMP

10 : TESTPIN = CDS

11 : invert ADC data, TESTPIN = VGND

[3:0]

DIV_OPCLK

The 4-bit DIV_OPCLK value (0~15) is the divider defining the ratio between

system clock (OSC) and opclk:

opclk_freq = sysclk_freq / (DIV_OPCLK + 1)

REG_PGA 1 R/W

0100_0000 PGA Gain Control

[7:4] PGA2_GAIN

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 16

For the gain control of PGA2

PGA2 gain =PGA_gain*[(Vinp_pga-Vinn_pga)+Voff]/[2*(VRT-VRB)]*255

[3]

EN_TEST1

0 : Disable Test mode 1

1 : Enable Test mode 1

[2]

EN_TEST0

0 : Disable Test mode 0

1 : Enable Test mode 0

[1:0]

PGA1_GAIN

00 : 4.6

01 : 7.6

10 : 12.8

11 : 22.7

REG_DCOC 2 R/W

0000_0000 DC_OFFSET - DC offset control of PGA2

[7]

Sign bit

0 : negative

1 : positive

[6:0]

Offset compensated voltage

The DC offset voltage is set as the following formula:

Voff=0.4545*(2*B7-1)*[<B6:B0>/128*(VRT-VRB)+Vos1]

Vos1 ~ N(μ1,σ1) normal distribution, μ1=0 & σ1~=3.5mV~5mV

REG_ADC 3 R/W

0010_0101 Adc setting

[7] Not used

[6:4] ADC_BIAS

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 17

ADC bias current settings

000 : 8uA

001 : 12uA

010 : 16uA (default)

011 : 20uA

1xx : 24uA

[3:2]

ADC_VRT

(VRT-VRB) settings:

00 : 0.90V

01 : 1.05V (default)

10 : 1.20V

11 : 1.35V

[1:0]

ADC_VRB

VRB settings:

00 : 0.800V

01 : 0.844V (default)

10 : 0.933V

11 : 0.978V

REG_OTP_A

DDR

4 RW

0000_0000 OTP address

[7:5] Not used

[4:0]

OTP_YP

Byte address

REG_OTP_

WDAT

5 RW

0000_0000 OTP write data

[7:4] Not used

[3:1] OTP_AIN

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 18

Bit address for writing

[0]

OTP_WD

Write data

REG_OTP_

MODE

6 RW

0000_0000 OTP control

[7:3] Not used

[2]

OTP_PRG

OTP “PRG” control bit (Program enable)

[1]

OTP_RST

OTP “RST” control bit (Reset)

[0]

OTP_CEB

OTP “CEB” control bit (Enable, active low)

REG_OTP_R

DAT

7 R

OTP read data

[7:0]

OTP_RDAT

OTP read data

REG_DETH 8 RW

1111_1111 D et ec ti on th re shol d

[7:0]

DETH

Finger detection threshold value

See the “finger detection” section below

REG_DDIV 9 RW

0000_0000 Clock divider for detection interval

[7:0]

DDIV

A clock divider for finger detection interval

See the “finger detection” section below

REG_ENAB A RW 0000_0000 Enable bits

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 19

[7]

EN_WINDOW

Enable windowing mode

The windowing size is assigned by reg_llx, reg_lly, reg_urx and reg_ury

(0x0C~0x0F)

0 : Disable

1 : Enabl

[6]

EN_INSCAN_DET

Enable the in scan line detection mode

The finger detection scan line can be changed according to value of

reg_inscanline (0x11) if enable

0 : Disable

1 : Enable

[5]

EN_DET

Enable the detect mode

0 : Disable

1 : Enable

[4] Reserve

[3]

LOWCAP

Enable the low capacitance mode for the sensor array

0 : High capacitor (96ff), compensation capacitor (1.05 pF)

1 : Low capacitor (48ff), compensation capacitor (2.57 pF)

[2]

EN_OSC

Enable internal clock oscillator

0 : Disable

1 : Enable

[1] Not used

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 20

[0]

EN_ANALOG

Enable analog circuit

0 : Disable

1 : Enable

REG_MODE B RW

0000_0000 Mode control bits

[7] Not used

[6]

EN_INTR

Enable detect interrupt

0 : Disable

1 : Enable

[5] Not used

[4:0]

ENBITS

Must be set to value 21 (0x15H) to enable the chip

REG_LLX C RW

0000_0000 Windowing function position setting

[7:0] LLX

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 21

Windowing is a flexible function which user can read the image data within

160x160 pixel size according to your need.

The windowing size is assigned by 4 registers, REG_LLX, REG_LLY,

REG_URX and REG_URY.

Refer to following picture to how to set the windowing position and size.

REG_LLY D RW

0000_0000 Windowing function position setting

[7:0]

LLY

Refer to REG_LLX for details.

REG_URX E RW

1001_1111 Windowing function position setting

[7:0]

URX

Refer to REG_LLX for details.

REG_URY F RW

1001_1111 Windowing function position setting

[7:0]

URY

Refer to REG_LLX for details.

REG_CHMD 10 W

Change mode

[7:1] Not used

[0] CH_MODE

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 22

Change mode for switching mode.

See the “finger detection” section below.

REG_INSCA

NLINE

11 RW

0100_0000 Set in scan detection finger detection line number

[7:0]

INSCANLINE_NUMBER

In scan line number value which limitation is 0~0x9F or Y axis range when

enable windowing function.

4 Operation workflow

4.1 General description

The SF104 hardware design implements a protection scheme that fingerprint image

will only be delivered when “finger touch” is detected. If not, reading image will return invalid

data. After the finger first touch the sensor, it can detect the finger on sensor and continue

to read out fingerprint image to speed up the frame rate of image readout until finger remove

from sensor and it will output white image data after in scan line number. The process is

summarized in the diagram below:

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 23

4.2 Reset

There are 3 sources of Reset that can force the chip entering reset state (in which all

internal logic are disabled)

the hardware reset pin

the SPI software reset command

the reset caused by the content of REG_MODE (REG11) register, as described earlier.

However the internal SPI state machine can only be reset by the hardware reset pin.

Since the hardware reset pin is multiplexed with the interrupt signal, the hardware reset

pin becomes unavailable when the (finger detect) interrupt is enabled.

4.3 Finger detection mode and interrupt

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 24

The finger detection mode is enabled by setting the EN_DET bit (bit 5 of REG10) to 1.

Finger detect interrupt is enabled by setting the EN_INTR bit (bit 6 of REG11) to 1. Enabling

interrupt also changes the hardware Reset pin to INTR output pin.

In finger detection mode, the hardware logic will periodically scan the row which assign

by REG_INSCANLINE of the pixel array. In instead of sending pixel data to FIFO, the pixel

data bytes are summed up and compared with a threshold value (determined by the

REG_DETH/REG8) at the end of line. If the sum is greater than the content of REG8, then

the interrupt flag will be raised.

Once the “Detect result is OK” status bit or “finger detected” interrupt flag is raised, the

internal image channel will be opened to allow full image data to be transferred to MCU.

The timing period of detection scan is given by:

sysclk_freq / (4096 * (REG9+1))

If at the end of detect scan, the summed pixel is less than the threshold value, the

interrupt flag will be set to (or return to) 0, and also the image data channel will be closed.

Whenever the detection mode control bit is turned on or off, it is required to write (any

value) to the REG_CHMD (REG16) register to inform the internal logic to change the scan

geometry.

There are two status bits in the status register associated with detection mode:

Status.bit5 is the detection interrupt flag, which is set at the end of each detection scan,

and cleared whenever a new scan (either image scan or detection scan) is started.

Status.bit6 is the detection OK flag, which is only set or cleared at the end of a detection

scan. This bit is used to enable or disable the image channel.

Both bit5 and bit6 are cleared by reset.

4.4 Timing considerations

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 25

Several timing parameter should be kept in mind for good estimation of timing:

Upon power up, reset, or whenever detection mode is turned off, the delay time from

sending the start command to the first data byte available is about 180 pclk cycles.

For the subsequent scans, the delay time is reduced to 19 pclk cycles.

Image sample is taken at the speed of pclk, i.e., one pixel per pclk cycle.

There is a small delay of 11 pclk cycles between lines.

4.5 A sample session

The following sample procedure demonstrates a typical session.

function spiwrite(char *data, int cnt)

{

GPIO.SSEL = 0;

for (i=0; i< cnt; i++)

SPIWRITE(data[i]);

GPIO.SSEL = 1;

}

main ()

{

GPIO.RSTN=1;

GPIO.SSEL=1;

// make sure hardware reset is enabled

spiwrite({0x4A,0x00,0x00}, 3);

// hardware reset

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 26

GPIO.SRST=0;

GPIO.SRST=1;

// initialize registers

// detect threshold (REG8=128)

// detect divider (REG9=128)

// enable analog (REG10[0]=1)

# enable clock (REG10[2]=1)

# enable detect (REG10[5]=1)

# enable interrupt pin (REG11[6]=1)

spiwrite({0x40,0x32,0xE5,0x50,0x25,0x00,0x00,0x00,0x00,0x00,0x20,0x85,0x15,0x00,0x00,0x9F,0x9F},

17);

spiwrite({0x50,0x00},2); // inform chang of geometry

// software reset

spiwrite({0xc0},1);

// wait for interrupt

while (~GPIO.INTR)

nop;

// stop detect mode

spiwrite({0x4a,0x85},2);

spiwrite({0x4f,0x00},2); // inform change of geometry

again:

// start image scan

spiwrite({0x02},1);

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 27

// delay 180 pclk cycle or wait for FIFO status is half-full

GPIO.SSEL = 0;

SPISEND(0x03);

repeat {

byte=SPIREAD({0x03});

} until (byte.bit0 == 1);

GPIO.SSEL = 1;

// read image

GPIO.SSEL = 0;

SPISEND(0x01);

for (i=0; i<(160*160); i++)

image[i] = SPIREAD(0x01);

GPIO.SSEL = 1;

if (checkimage() != TRUE) {

adjust_setting();

goto again;

}

// waiting for the finger to be removed

// start detect mode

spiwrite({0x4a,0xa5},2);

spiwrite({0x4f,0x00},2); // inform change of geometry

GPIO.SSEL = 0;

SPISEND(0x03);

repeat {

byte=SPIREAD({0x03});

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 28

} until (byte.bit6 == 0); // wait until DETOK bit goes away

GPIO.SSEL = 1;

} // end of main

5 Timing characteristics

5.1 SPI interface timing

General SPI Timing

Instruction without return data

Instruction with return data

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 29

Terminating read by applying new command

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 30

SPI timing parameters

SYMBOL PARAMETER NOTE MIN. TYP. MAX. UNITS

f

CK

Clock frequency 1 18 MHz

t

RST

Reset time 1 50 ns

t

RD

Rise time for digital inputs 2 2 ns

t

FD

Fall time for digital inputs 2 2 ns

f

SPI_SCK

Frequency for SPI clock. 1 0

fCK

MHz

t

SCKL

Part of SPI_CK clock period,

during which SPI_CK is low.

1 23 ns

t

SCKH

Part of SPI_CK clock period,

during which SPI_CK is high.

1 23 ns

t

CSCKF

Time from falling edge on

SPI_CK to edge on SPI_CS_N

1 8 ns

t

CSCKR

Time from edge on SPI_CS_N to

rising edge on SPI_CK

1 8 ns

t

DSU

Setup time for data before rising

edge of SPI_CK

2 6 ns

t

DH

Hold time for data after rising

edge of SPI_CK

2 6 ns

t

SCKD

Delay from falling clock to data

available.

2 1 3 ns

t

SSU

Delay from SPI_CS_N low to

SPI_DI mode change.

2 1 3 ns

Note 1: Estimated value

Note 2: Simulated value

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 31

6 Maximum ratings and operating condition

6.1 Maximum rating

Symbol Parameter Conditions Value Unit

VDD Supply voltage -0.3 to 3.3 V

V

VDDIO

Supply voltage of I/O -0.3 to 3.3 V

VI1 Input pin voltage 1 (SPICLK,

SPIDI, SPICSn)

(Note1) -0.3 to V

VDDIO

+0.3 V

VI2 Input pin voltage 2 (RSTn) (Note2) -0.3 to V

VDDIO

+0.3 V

VO1 Output pin voltage 1( INTn,

SPIDO)

0.3V to V

VDDIO

+0.3V V

TA Operating temperature -20 70

℃

ST Storage temperature

-65

150

℃

PT10 Soldering temperature (10

seconds)

250

℃

PT

120

Soldering temperature (2

minutes)

183

℃

Note 1: Each Input and Output pin has internal ESD protection diode between pin and

VDDIO.

Note 2: V

I2

has internal pull high current of 100 µA.

6.2 Operating condition

Symbol Parameter Conditions Min. Typ Max Unit

VDD Supply voltage 2.6 3.0 3.6 V

VDDIO Supply voltage of I/O 1.65 1.8 3.6

IDD Total supply current (CLK =

4Mhz)

VDD=3.3 V 12 mA

IDDIO Total I/O supply current (CLK = VDDIO=3.3 1 mA

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 32

4Mhz) V

CLK System Clock 4 MHz

ESDKV ESD protection 15 kV

7 Electrical characteristics

Symbol Parameter Conditions MIN TYP MAX Unit

Digital inputs

VIH High level input voltage

0.8*VDD

V

VIL Low level input voltage

0.2*VDD

V

IIH High level input current 1 uA

IIL Low level input current 1 uA

CI Input capacitance

5

pF

Digital outputs

VoH High level output voltage

IOH = 1mA 0.8*VDD

V

VOL Low level output voltage

IOL = 1mA 0.2

0.5 V

8 Reliability Test

8.1 ESD immunity

The packaged sensor fulfills the following requirements with regard to ESD immunity:

PARAMETER REFERENCE CONDITIONS VA LU E UNITS

ESD IEC61000-4-2 Air discharge > ±15 KV

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 33

Table 9-1 Requirements for ESD immunity

The ESD immunity is achieved by the combination of a surface coating with ability to

withstand > ±6 kV, a drive frame and a primary drive electrode that leads charge away from

the sensor. The length of the internal wiring connecting the drive frame should be minimized

to increase the capacity to divert the fast ESD-pulses.

8.2 Environmental limits

The sensor chip fulfills the following requirements regarding to environmental

durability:

P ARAMETER REFERENCE CONDITIONS Normal Low Limit UNITS

Cold operational IEC60068-2-1 Ab 16h -20 0

℃

Hot operational IEC60068-2-2 Bb 16h +85 +55

℃

Cold storage IEC60068-2-1 AB 100h -40 -40

℃

Hot storage 100h +85

℃

Temperature cycling IEC60068-2-14 Na 30 min/30 min 200 cycles -40/+85 -40/+85

℃

Humid heat IEC60068-2-67 Cy 85ºC /85% RH 1000 1000 Hours

Table 9-2 Requirements for environmental performance

8.3 Mechanical durability

The sensor chip fulfills the following requirements with regard to mechanical durability:

P ARAMETER REFERENCE CONDITIONS REQUIREMENT

Abrasion Specified test method 1,000,000 cycles / 800g load Normal performance

Vibration IEC60068-2-64 Random Normal performance

PRELIMINARY

SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 34

Table 9-3 Requirements for mechanical durability

9 Packaging information

9.1 The SF104 packaging

Size:13.4mm*13.9mm*1.1mm (with FPC)

9.2 Signal definition

Pin# Description

1 INTn

2 SPIDO (SPIMISO)

3 VDD

4 RSTn

5 SPICLK

6 GND

7 SPIDI (SPIMOSI)

8 SPICSn

9 ESD

10 VDDIO

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 35

9.3 Part drawing

9.4 Pin description

Pin Name Type Pin Description

INTn Output

An interrupt to the processor can be

generated by finger detection.

SPIDO

(SPIMISO)

Output Master In Slave Out

VDD Input

System power. Voltage supply for core

operation.

RSTn Input

A LOW on this pin resets the SF104x to take

on its default states

SPICLK Input

The SPI clock rate provided by the master

must not exceed 18MHz. depending on

PRELIMINARY SF104-P01

SF3013M Fingerprint Image Sensor Module User Manual Page - 36

Pin Name Type Pin Description

different application, SPICLK should be

adjusted for best image quality.

GND Power Ground

SPIDI

(SPIMOSI)

Input Master Out Slave In

SPICSn Input Chip select for SPI

ESD ESD Connect ESD pin to Ground for

VDDIO Input

System power. This voltage is supplied for IO

interface operation. Normally it can be tied to

the VDD if the IO operation voltage is 3.3V. If

lower IO voltage is needed, providing the right

IO voltage to this pin.

9.5 Reference schematic

VDD

GND

1M

chasis(ESDdrain)

MCU

SPIDI

SPIDO

SPICLK

SPICSN

RSTN

VDD

GND

ESD

SF104xM

TVS

10u

Loading...

Loading...