IMCO SCX SERIES INFORMATION, OPERATION & MAINTAINANCE

1. SCX & SCX4 Drives will not fit on a standard gimbal helmet, IMCO HELMET:

#05-8025 Black or #05-8027 Silver or #05-8028 ITS Black is required.

2. Maximum engine idle speed is 800 RPM. Shift drive with a positive move, do not let

clutch sit between neutral and in gear position.

3. Do Not

install propeller until the drive shift linkage has been properly installed and

tested with the engine running!

4. When using SCX or SCX4 drives it is necessary to have full hydraulic steering for

your safety.

5. When tuning engine remove propeller and shift drive into forward gear!

6. Do not run your boat with a worn or loose gimble ring or helmet, worn clevis pins, or clevis bushings.

7. Every hull is different and requires a different setup: Many different things contribute to performance:

water pickup location, cavitation plates, gear ratio, drive height, prop, weight distribution, water conditions,

weather conditions.

8. If you are installing the drive on a new application, consult the manufacture or a dealer with experience

with the hull to determine the proper drive height.

9. SCX Drive is 19 7/8” from crankshaft center line to prop shaft center line (2” shorter than standard Bravo).

SCX4 Drive is 17 7/8” from crankshaft center line to propshaft center line (4” shorter than standard Bravo).

10. The bolt pattern is different from the SCX to the SCX4, lowers cannot be interchanged.

11. Max propeller diameter on the SCX is 16 3/4”, SCX4 is 17” (always check that there

is at least 1/2” clearance between the propeller blades and the drive case.

12. Large diameter propellers installed on a #6 prop shaft will require a torque tab on single engine boats.

13. SCX and SCX4 drives require a drive oil reservoir with a minimum capacity of 1 1/2 quarts.

14. When installing drive to gimbal or lower to upper always use anti-seize on all threads

15. When installing lower to upper, inspect all “O” rings, replace as necessary, pressure check to insure

proper seal.

16. If you do your own maintenance and repairs on your IMCO drive, you will need a service manual and the

proper tools. Service manuals and tools are available at www.imcomarine.com/cal_store.

17. Always wear proper safety equipment when operating your boat, testing or running at high speeds.

18. Inspect for: oil level in drive and reservoir, leaks, loose fasteners, worn parts.

Warning!

Warning!

Warning!

Danger!

Warning!

Warning!

Before Runnng!

Recommended oil: Torco RTF GL-6 (Torco Part #A220015CE (unit) Part # S220015C (case) IMCO Part #

09-2600 (unit) Part # 09-2605 (5 Gal.) Part # 09-2610 (case) (100% Synthetic Raceing Transmission Fluid)

Replaces SAE 75W90.

To drain oil: remove drain screws from bearing carrier (right below the prop shaft) and on port side of upper.

To replace oil: pump oil in from lower drain screw until it comes out of upper drain screw hole. Replace drain

screws and add oil to drive oil reservoir.

When changing oil, run the used oil through a strainer to check for metal particles, if ther are metal

particles in the oil it is time for inspection of the gears and bearings. If oil appears milky or off colored check

for leaks.

SCX, SCX4 capacity: 5 qts + reservoir - SCX Upper with SC Lower 4 1/2 qts + reservoir.

19. Drive must be turning before shifting.

20. Do not run engine when drive is trimmed extremely high, or in trailer tow mode.

21. Do not use solvents or chemical cleaners to clean painted surfaces on the drive.

22. When installing or changing propeller use extreme caution, propeller blades can

be very sharp.

23. SCX upper vertical shaft is 17 tooth spline, SC, Merc lowers are 15 tooth spline. A 17-15 tooth

coupler is available 01-2150 (cannot be used with a spacer).

24. Use extreme caution if modifying lower, case can be weakened or handling can

be adversely affected.

25. Break in: Do not use full throttle until drive is fully warmed up, do not hold drive at wide open throttle for

more than 2 minutes for the first 3 hours of use.

26. Inspect anode (located on front of cavitation plate) for corrosion or debris; if necessary clean or replace.

27. Do not shift drive while running on hose with

propeller installed.

28. Rotation: shift linkage pushed in - right hand rotation, shift

linkage pulled out - left hand rotation.

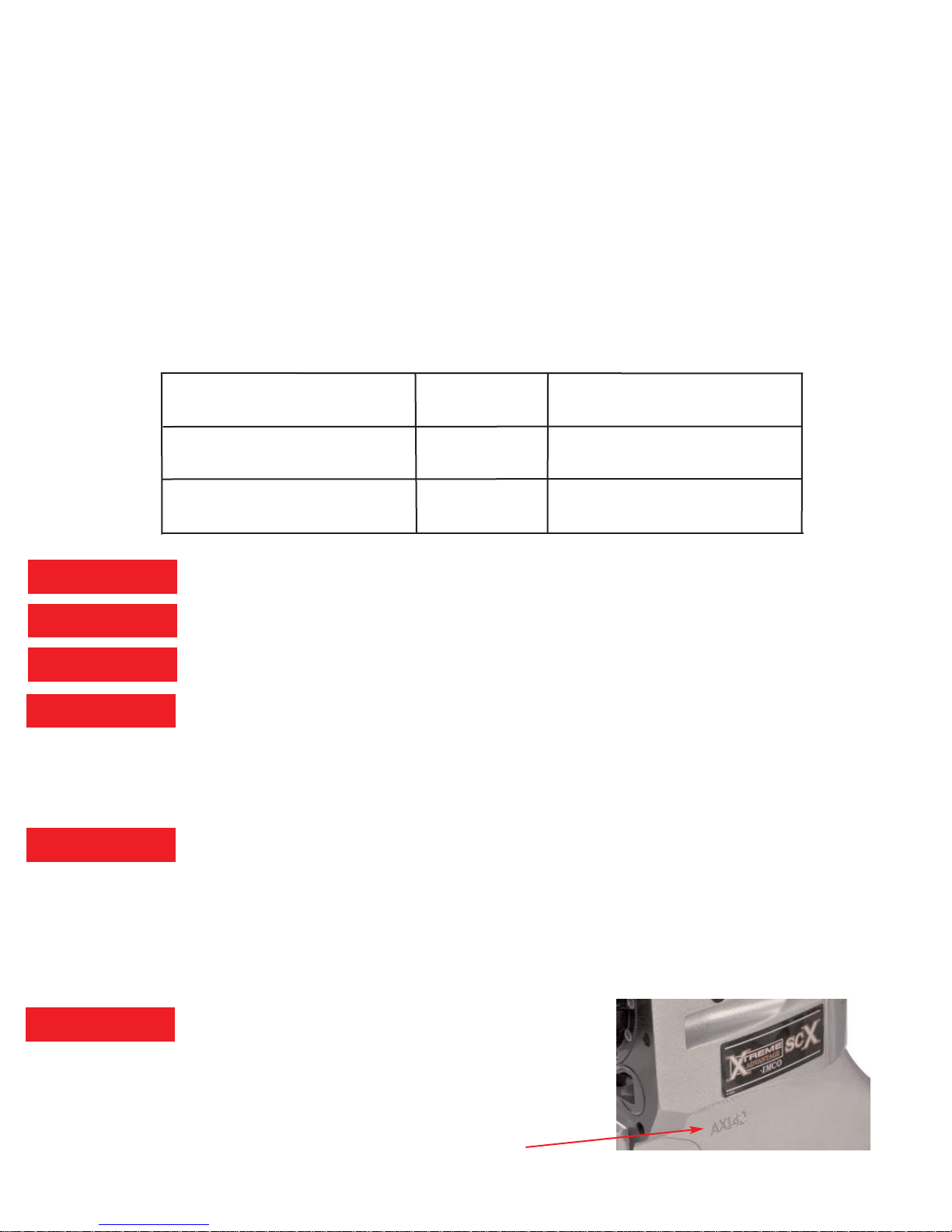

29. Serial # location: Port side below SCX, SCX4 sticker

3/10/14

SCX Upper & SCX Lower

New Break in

20 hours

After Break In

80 hours

SCX4 Upper & SCX4 Lower

New Break in

20 hours

New Break in

20 hours

SCX Upper & SC Lower

After Break In

80 hours

Check Drain Plug Magnet

Every 20 Hours

Warning!

Warning!

Caution!

Danger!

Caution!

Caution!

X

X

XTREME

ADVANTAGE

sc

sc

X-

X-

sc

sc

Parts and Service Manual

IMCO

510 East Arrow Highway

San Dimas, CA 91773

(800) 899-8058 (909) 592-6162 Fax (909) 592-6052

www.imcomarine.com email info@imcomarine.com

TABLE OF CONTENTS

Upper Gear Case - Disassembly 1

Upper Case Hardware & Seals (Drawing) 2

Upper Case Hardware & Seals (Parts List) 3

Upper Case Gear & Components (Drawing) 4

Upper Case Gear & Components (Parts List) 5

Upper Gear Case Assembly 6

Upper Gear Case Assembly Cont. 7

SCX Setup Diagrams 8

SCX Setup Work Sheet 9

Backlash Assembly (Diagram) 10

Lower Gear Case-Disassembly 11

Lower Gear Case (Drawing) 12

Lower Gear Case (Parts List) 13

Lower Gear Case-Assembly 14

Lower Pinion Height Measurments 15

Dissassembly-Assembly Tools 16

02/15/10 Rev 1

Serial Number

Date of Purchase

Purchased From

Check Oil Before Running

First break in oil change 5-8 hours.

Oil is filled to upper drain screw [Fig 1-33]

Pump oil from bottom drain screw [Fig 6-32]

Recommended oil change intervals 20-30 hours.

Heavy use or high HP change more often.

UPPER GEAR CASE-DISASSEMBLY

NOTE; The following instructions assume that the drive has been removed from the

transom assembly and is shifted to the “neutral” position. The lower unit has also been

removed, along with the yoke coupler end, center socket, and cross and bearings. Steps

followed by asterisk (**) are required only if inspection indicates component replacement.

Brackets following the part name represent the drawing figure # and item #.

1. Remove upper cap screws [1-7,8], remove upper cap [1-3].

2. Remove steering cap screws [1-28], remove steering cap [1-2 ]

3. Remove detent kit from steering cap [1-31].

4. Remove cotter key [2-23].

5. Remove shift link [2-24], shift cable retainer [2-21], shift arm [2-22]. (Shift link

removes out front of gear case).**

6. Remove shift shaf t screws [2-27].

7. Remove shift shaft plug [1-9], shift shaft [2-26], yoke & cam [2-28].

8. Remove pinion hub screws [1-(22,23)].

9. Remove pinion hub assembly [2-(31-45)].

10. Disassemble pinion hub assembly.

11. Remove yoke nut [2-36], and washer [2-37].

12. Remove yoke [2-32].

13. Remove retainer nut [2-31].

14. Remove Yoke gear end shims [2-42], pinion shoulder washer [2-43], and pinion

seal carrier [2-45].

15. Remove bearings [2-(38,41)], bearing cups [2-(39,40)], and pinion gear [2-12].

Note; be sure to maintain correct assembly position of the upper & lower thrust

bearings & races.

16. Remove upper thrust race [2-6], and upper thrust bearing [2-7].

17. Remove gear assembly [2-(7-17)].

18. Disassemble gear assembly, press down on upper clutch gear to release the

clutch shaft retainer keepers and remove all components from the clutch shaft.

19. Remove lower thrust race [2-6], lower thrust bearing [2-7].

20. Remove oil tank cover [1-43], in spect magnet [1-40].

Page 1

Page 2

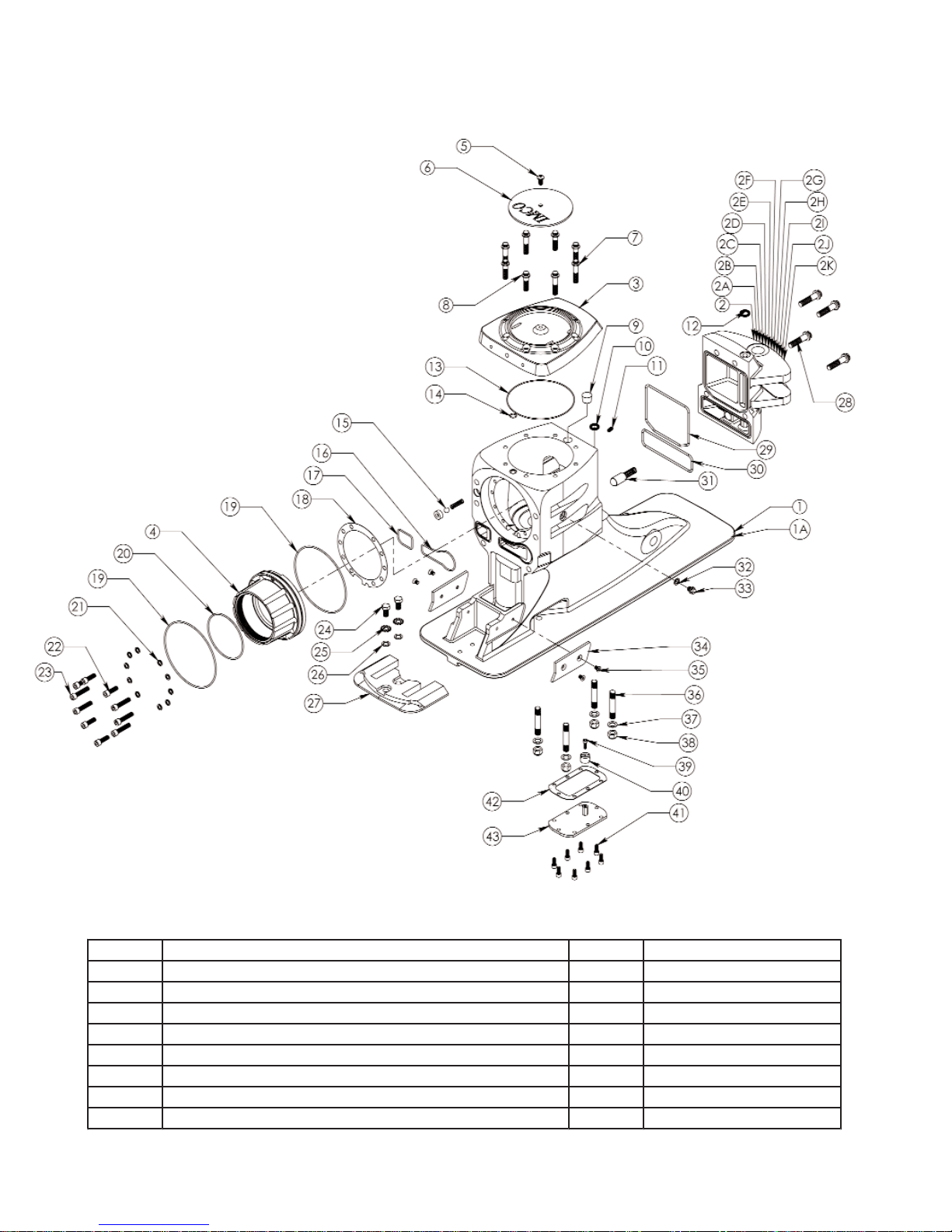

Upper Case Hardware & Seals

Fig-1

Item Des c ription Qty Part Number

1 Upper Case Black 1 01-1550

1A Upper Case Silver 1 01-1557

2 Steer in g Cap CA Black 1 01-1551

2A Steer in g Cap NV Black 1 01-1552

2B Steer in g Cap Generic Black 1 01-1553

2C Steer in g Cap ITS Black 1 01-1554

2D Steer in g Cap Tie Bar Starboard Black 1 01-1555

2E Steering Cap Tie Bar Port Black 1 01-1556

Page 3

Upper Case Hardware & Seals

Fig-1

Item Des c ription Qty Part Number

2F Steer in g Cap CA Silver 1 01-1558

2G Steering Cap NV Silver 1 01-1559

2H Steer in g Cap Generic Silver 1 01-1560

2I Steer in g Cap ITS Silver 1 01-1561

2J Steering Cap Tie Bar Starboard Silver 1 01-1562

2K Steer in g Cap Tie Bar Port Silver 1 01-1563

3 Upper Cap 1 01-2555

4 Pinion Hub 1 01-2560

5 Screw (5/16-18 x 1/2" But t on He ad) 1 08-040705041

6 Top Cap Lid 1 01-2071

7 Screw (3/8-16 x 1 3/4" S/S 12 Point) 4 08-070806111

8 Screw (3/8-16 x 1 1/2" S/S 12 Point 4 08-070806101

9 Shift Shaft Plug 1 11-1024

10 Quad Ring (Cooling Water, Bottom) 1 11-4024

11 Screw (5/16-18 x 1/2" Allen Set)(Tower Retainer) 1 08-050705041

12 Quad Ring (Cooling Water, Top) 1 11-4025

13 "O" Ring (Top Cap) 1 11-2049

14 "O" Ring (Top Cap Oil Pressu re) 1 11-2013

15 Spring Kit (Seal,Ball & Spring) Kit 01-2045

16 "O" Ring (Water Passage- Upper to Gimbal) 1 11-2148

17 "O" Ring (Shift Linkage) 1 11-2129

18 Pinion Hub Shims Kit 01-2548

19 "O" Ring (Pinion Hub) 2 11-2161

20 "O" Ring (Pinion Retain er Nut) 1 11-2154

21 Pinion Hub (5/16" Copper Sealing Washe r s) 10 08-120700004

22 Screw (5/16-18 x 1" Socket Cap) 4 08-060705082

23 Screw (5/16-18 x 1 1/2" Socket Cap) 6 08-060705102

24 Screw (3/8-16 x 3/4" HH) 2 08-010806061

25 Washer ( 3/8" Star) 2 08-110800001

26 Washer ( 3/8" AN) 2 08-100800001

27 Anode 1 01-2067

28 Screw (7/16-14 x 1 3/4" S/S 12 Po in t ) 4 08-070907111

29 "O" Ring (Steerin g Cap, Oil) 1 11-2250

30 "O" Ring (Steering Cap, Shift Cavity) 1 11-2242

31 Detent Kit (Spring & Ball Cylinde r) Kit 01-2044

32 Drain Screw Sealing Washer 1 11-1017

33 Drain Screw 1 01-2504

34 Guide Pads (Port & Starbo ard) 2 01-2471

35 Screw (1/4-20 x 1/2" Flat Head Undercut) 4 08-020604041

36 Stud (7/16 x 2 1/2") 4 08-130904141

37 Washer ( 7/16" AN S/S) 4 08-100900001

38 Nut (7/16-20 Nylock S/S) 4 08-080904001

39 Screw (10-24 x 5/8" Socket Cap) 1 08-060403052

40 M ag n et 1 01-9587

41 Screw (1/4-20x 5/8" Socket Cap) 8 08-060604051

42 Oil Tank Gasket 1 11-1030

43 Oil Ta nk Cover 1 01-2574

Page 4

Upper Case Gear & Components

Fig-2

Item Des c ription Qty Part Number

1 Upper Case Black 1 01-1550

1A Upper Case Silver 1 01-1557

2 Roller Bearing (Clutch Shaft Cap) 1 10-3042

3 Upper Cap 1 01-2555

4 Pinion Hub 1 01-2560

5 Tower Race 2 10-6041

6 Thrust Race 2 10-5045-X

7 Thrust Bearing (Gear ) 2 10-4044

8 Keep ers (Clutch Shaft) 2 01-2047

9 Clutch Shaft Ret ain er (Thrust Collar) 1 01-2189

10 Spirol Retainer Ring 2 01-2055

11 Roller Bearin g (Internal Gear) 2 10-3046

12 SCX Pinion Ge ar 1 01-4538

13 SCX Clutch Gear 2 01-4539

14 Thrust Bearing (Clutch Spring) 2 10-4020

15 Clutch Spring 2 01-2056

16 SCX Clutch 1 01-2562

17 SCX Clutch Shaft 1 01-3556

18 Pinion Hub Shims Kit 01-2548-X

19 Roller Bearin g (Clutch Shaft Tower) 1 10-3043

20 SCX Tower 1 01-2561

21 SCX Shift Cable Retainer 1 01-2573

22 SCX Shift Arm 1 01-1578

23 Cotte r Key 1 08-150200141

24 SCX Shift Link 1 01-1577

25 Shift Shaft Bushing 1 10-7018

26 SCX Shift Shaft 1 01-3559

27 Screw (1/4-28 x 3/4" Socket Cap) 2 08-060602062

28 Yoke & Cam 1 01-8095

29 Seal, Shift Shaft 2 11-3030

30 Shift Shaft Bushing 1 10-7019

31 Retainer Nut 1 01-2239

32 Yoke Gear End 1 01-2085

33 Cross & Bearing 2 01-2086

34 Center Socket 1 01-2087

35 Yoke Coupler End 1 01-2088

36 Nut (Yoke Gear End) ( 5/8-18 Thin Nylock Steel) 1 08-091105002

37 Washer ( Yoke Gear End) 1 08-121100002

38 Bearin g Cone (Pinion Be aring) 1 10-1021

39 Bearin g Cup (Pinion Be aring) 1 10-2022

40 Bearin g Cup (Pinion Be aring) 1 10-2024

41 Bearin g Cone (Pinion Be aring) 1 10-1023

42 Yoke Gear End Shims Kit 01-2020- X

43 Pinion Shoulder Washer 1 01-2241

44 Yoke Gear End Seal 1 11-3029

45 Pinion Seal Carrier 1 01-2240

Page 5

Upper Case Gear & Components

Fig-2

UPPER GEAR CASE-ASSEMBLY

NOTE; Optimum performance of the upper gear case requires “setting up” the pinion &

clutch gears with IMCO procedure as follows.

1. Take all measurements using the “SCX Setup Dia grams” (Fig 3) and the “SCX

Work Sheet” (Fig 4).

2. After all measurements are taken and proper race thickness has been

determined, place lower race [2-6] and thrust bearing [2-7] in case.

3. Place lower clutch gear [2-13] with attached tool (backlash tower 01-5579) into

case.

4. Adjust rolling preload (8-10 in/lbs) on pinion gear by changing Yo ke Gear End

Shims [2-42]. Tighten nut [2-36] to 75 ft/lbs.

5. After proper rolling preload is determined, assemble pinion pack with pinion

retainer nut “O” ring [1-20] between pinion seal carrier [2-45] and retainer nut

[2-31].

6. Torque retainer nut to 200 ft/lbs. ((Tool: Pinion Retainer Nut Driver 01-5590)

(torque wrench centered on retainer nut or if using longer tool be sure to

compensate on torque value). Use new lock nut [2-36] and torque to 75 ft/lbs.

7. Install pinion pack using 4 screws [1-23] for testing.

8. Install dial indicator (indicator bracket 01-5588) and pinion gear locking tool

(pinion gear lock 01-5587) Fig-5.

9. Check backlash, adjust backlash with pinion hub shims [2-18] (average backlash

should be .006-.008.

10. Once backlash is determined check upper clutch gear by placing gear in lower

position with lower thrust race and backlas

h tower. This will insure backlash is

.006 -.008 is correct on upper gear.

11. Assemble drive shaft gear assembly [2-(8-17)].

12. Place the lower clutch gear [2-13] onto the clutch shaft [2-17], allowing it to rest

on the thrust collar.

13. Place the lower clutch spring thrust bearing [2-14] (silver side “up), lower clutch

spring [2-15], clutch cone [2-16], upper clutch spring [2-15], upper clutch spring

thrust bearing [2-14], (Note; use a thin layer of grease between the bearing and

the gear to keep bearing in place during assembly), (silver side “down”), upper

clutch gear [2-13], clutch shaft retainer [2-9] onto the upper clutch shaft [2-17].

14. Compress the upper clutch gear and install the upper drive shaft retainer

keepers [2-8].

15. Install complete clutch s

haft assembly into gear case.

16. Align the clutch gear timing marks (“+” over “-“, or “-“ over “+”) with the center of

the rear face of the gear case.

17. Install pinion pack with “O” ring [1-19] and shims [2-18] (shims must be properly

aligned).

18. Torque pinion pack screws [1-(22-23)] (important:

make sure copper sealing

washers [1-21] are in place, short screws in 2 top holes & 2 bottom holes [1-22]

longer screws in 3 port & 3 starboard holes [1-23] to 20 ft/lbs. Use “Loctite 242”

on all screws. Note: make sure that the clutch gear timing marks align to case

timing marks, roll pinion to check.

Page 6

UPPER GEAR CASE-ASSEMBLY

19. Place the shift yoke & cam assembly [2-28] into the clutch cone groove with the

nuts facing down.

20. Insert the shift link [2-24] with shift cable retainer [2-21] through front of gear case.

21. From the rear of gear case, place the small hole of the shift arm [2-22] onto the

“pin” of the shift link and secure with cotter pin [2-23]. (Be sure that the shift arm

is positioned to except the detent kit [1-31]

22. Install shift shaft [2-26] through the yoke & cam (note; use caution while installing

to avoid cutting seals) and shift arm [2-22].

23. Torque the 2 shift shaft screws [2-27] to 100 in/lbs. Use “Loctite 262” on screws.

24. Install quad ring [1-10] steering cap [1-2] including detent kit [1-31], insure “O”

rings [1-29 & 1-30] are in place.

25. Torque steering cap screws to 35 ft/lbs. Use “Perfect Seal” on threads.

26. Install quad ring [1-12] in steering cap, shift shaft plug [1-9], top cap “O” r ing [1-13]

top cap oil pressure “O” ring [1-14]

27. Install top cap.

28. Torque top cap screws [1-8] (important: short screws in 2 front & 2 rear holes [1-7]

longer screws in 2 port and 2 starboard holes) to 25 ft/lbs. Use “Perfect Seal” on

threads.

29. Install oil tank cover [1-43], oil tank gasket [1-42] with “Permatex Form-Gasket 2’

(note; use a very thin layer on gasket), oil tank cover screws [1-41] with “Loctite

242”, torque to 10 ft/lbs.

Page 7

Page 8

UPPER CAP

Parallels 2.250

Measurement A - Norm 1.862

C a p D e ck to Thr u s t Seat Tota l B = N or m 0.3 8 8

DECK TO PINION CENTERLINE

Deck to To ol Measurem ent C No r m 2.252

Less Pa r a l lel - 1.000

Total Norm 1.252

Pl u s 1/2 t oo l + 2. 012

Deck to Pinion CL Total D = Norm 3.264

UPPER THRUST SEAT

Deck to Pinion CL D Norm 3.264

B - Norm 0.388

Pinion CL to Upper Thrust Seat To tal E = Norm 2.876

Bearin g Thi ck n ess - 0.157

Mounti ng Di sta nce - 2.659

Race Thick n ess F = N orm 0.060

LOWER THRUST SEAT

Me asurement G Norm 7.138

Parallel - 1.000

Deck to Lower Thrust Seat Total = No rm 6.138

Deck to Pi nio n C L D - No r m 3.262

Pinion CL to Low er Thrust Seat Total H = Norm 2.876

Bearin g Thi ck n ess - 0.157

Mounti ng Di sta nce - 2.659

Race Thick n ess J = No r m 0.060

GE AR ME AS URMENTS

Gear One Measu rement K1 No r m 2.091

Less Pa r a l lel - 1.000

Gear D epth One Tot al L Norm 1.091

Gear Two Mea su r ement K2 No r m 2.091

Less Parall el 1.000

Gear Depth Two Tot a l M = No r m 1.091

GE AR AS SEMBLY

Gear Depth One L No r m 1.091

Gear Depth Two M + No r m 1.091

Race Thick n ess F + No r m 0.060

Race Thick n ess J + No r m 0.060

2 x Bearin g Thi ckness + 0.314

Reta iner Spa ci n g Measurem ent N + No r m 3.162

Gear Assem b l y To tal O = 5.778

CAP CRUSH

Pinio n C L t o Upper Thrust Seat E + No rm 2.876

Pinio n C L t o Lo wer Thrust Seat H + Norm 2.876

Upper Thrust Seat to Lower Thrust Seat Total P = Norm 5.752

Gear Assem b l y To tal O = N orm 5.778

Ca p C r u sh = No r m . 020-.030

SCX WORK SHEET Serial #

Page 9

Backlash Assembly

Fig-5

Page 10

LOWER GEAR CASE – DISASSEMBLY

Note; The following instructions assume that the lower unit has already been separated from

the upper gearhead. Steps followed by asterisks (**) are required only if inspection indicates

component replacement. Brackets following the part name represent the drawing figure #

and item #.

1. Bend the tabs of the bearing carrier tab washer [6-31] away from the bearing

carrier retainer nut [6-30].

2. Remove the bearing carrier retainer nut [6-30].

3. Remove the bearing carrier [6-34].

4. Remove the prop shaft [6-27]. (The prop shaft bushing [6-26], used only with the

01-8244 & 01-8248 gear sets, may come out with the prop shaft).

5. Remove the bearing carrier “O” ring [6-38], shims [6-39], & thrust washer [6-40].

6. Remove the vertical shaft flange nut [6-29].

7. Remove “O” ring [6-13], & alignment spacer [6-14], shims [6-15], & tab washer

[6-16].

8. Remove the vertical shaft [6-2] (with bearings) & pinion gear [6-25].

9. Remove the prop gear [6-25], (with bearing). (The prop shaft bushing [6-26] may

be removed from the gear at this time, if it was not removed in step #4).

10. Remove the lower vertical shaft bearing cup [6-20], & shims [6-21].

11. Remove the vertical shaft roller bearing [6-28]. **

12. Re move the upper [6-18], & lower [6-19] bearing cones from the vertical shaft. **

13. Re move the roller bearing race [6-3] from the vertical shaft. **

14. Remove the bearing cup [6-36] from the bearing carrier. **

15. Re move the prop shaft seals [6-35] from the bearing carrier. **

16. Remove the prop gear bearing cone [6-24] from the prop gear. **

17. Re move the prop gear bearing cup [6-23], & shims [6-22]. **

18. Remove the bearing cone [6-37] from the prop shaft. **

19. Remove the “O” ring [6-6]. “O” ring [6-7], & “O” ring [6-8]. **

Page 11

Lower Gear Case

Fig-6

Page 12

Description Qty Part Numb er

1 Lower Case (-0) Stand ar d L en g th 1 01-1120

1A Lower Case (-1") Sh or ter 1 01-1121

1B Lower Case (-2") Sh or ter 1 01-1122

2 Ver tical S h aft-Stan d ar d L en g th (17 Tooth) 1 01-3265

2A Vertical S h aft-1" S h o rter (17 Tooth) 1 01-3266

2B Vertical S h aft-2" S h o rter (17 Tooth) 1 01-3267

3 Bear i n g Race 1 10-6005

4 Nut (7/16-20 Nyl ock S/ S T h i n ) 2 08-090904001

5 W asher ((7/ 16" AN S / S Th i n ) 2 08-160900001

6 "O" Rin g (Oi l P assage) 1 11-4011

7 "O" Rin g (Water P assage) 1 11-2143

8 "O" Rin g (Cooli n g Water P assage) 1 11-2014

9 Pi p e P lug - 1/ 8 NP T S/ S 1 09-2007

10 Stud (7/16 x 2" S / S) 2 08-130904121

11 Retai ner Ring (Vertica l Shaft Coupler) 1 08-121500001

12 Ve rtica l Shaft Coupler (17 Tooth) 1 01-2140

13 "O " Ri n g (Al ign ment S p acer) 1 11-2228

14 Al ign ment S p acer 1 01-2015

15 Shi m (V ertical S h aft Upper ) Kit 01-2012

16 T ab Washer (V er ti cal Shaft) 1 01-2043

17 Bearing Cup (V er ti cal Sh aft Upp er) 1 10-2012

18 Bearing Con e (V er ti cal Sh aft Upp er) 1 10-1011

19 Bearing Con e (V er ti cal Sh aft Lo we r) 1 10-1010

20 Bearing Cup (V er ti cal Sh aft Lo we r) 1 10-2009

21 Shi m (V ertical S h aft Lo wer ) 1 01-2013

22 Shi m (P ro p Gear ) Kit 01-2014

23 Bearing Cup (P r op Gear ) 1 10-2007

24 Bearing Con e (P r op Gear ) 1 10-1008

25 Prop & P ini o n Gear 1:50 Set 01-8240

25A Pro p & P i n ion G ear 1:34 Set 01-8244

25B Pro p & P i n ion G ear 1:25 Set 01-8248

26 Bu shing - P ro p S h aft, -X 1 01-2178

27 Prop S h aft, 1" 1 01-3009

27A Pro p S h aft, 1 1/ 4" 1 01-3010

27B Pro p S h aft, 1 7/ 16" 1 01-3570

28 Bearing (Rol ler) 1 10-3006

29 Nu t (Pinion Gear ) 1 01-2251

30 Co ver Nut 1 01-2065

31 T ab Washer (Beari n g Carrier) 1 01-2042

32 Drain S cr ew 1 01-2504

33 Drain S cr ew Seal i n g Washe r 1 11-1017

34 Bearing Carrier (1" P r op Shaft) 1 01-2130

34A Bear i n g Carrier (1 1/ 4" Pro p Shaft) 1 01-2131

34B Bear i n g Carrier (1 7/ 16" Pro p Shaft) 1 01-2575

35 Seal (P ro p S h aft 1") 1 11-3035

35A Seal (P r o p Shaft 1" Line Cu t) 1 11-3032

35B Seal (P r o p Shaft 1 1/ 4") 2 11-3033

35C Seal (P r o p Shaft 1 7/ 16") 2 11-3034

36 Bearing Cup (I " Prop Shaft) 1 10-2014

36A Bear i n g Cup (1 1/ 4" P ro p S h aft) 1 10-2016

36B Bear i n g Cup (1 7/ 16" P ro p S h aft) 1 10-2018

37 Bearing Con e (1" P r op Shaft) 1 10-1013

37A Bear i n g Con e (1 1/ 4" P ro p S h aft) 1 10-1015

37B Bear i n g Con e (1 7/ 16" P ro p S h aft) 1 10-1017

38 "O " Ri n g (Bearing Carrier) 1 11-2344

39 Shi m (Beari n g Carrier) Ki t 01-2011

40 T h ru st Washer (. 109 T h i ck) 1 01-2042

Lower Gear Case Fig-6

Page 13

LOWER GEAR CASE - ASSEMBLY

Note; Optimum performance of lower gears requires pinion height setup, use “ Lower Pinion

Gear Height Measurement” (Fig. 7) sheet to set pinion gear.

1. Install the vertical shaft roller bearing [6-28] into the gear case.

2. Install the vertical shaft lower bearing cup [6-20], & shims [6-21].

3. Install the lower [6-19], upper [6-18] bearing cones, and roller bearing race [6-3]

onto the vertical shaft [6-2].

4. Install the vertical shaft into the gear case.

5. Install the upper bearing cup [6-17]. Tab washer [6-16], shims [6-15], & alignment

spacer [6-14] onto the vertical shaft.

6. Install the vertical shaft clamp plate onto the gear case. (Mercury Part # 43559T)

7. Check the rolling torque of the vertical shaft (optimum 3 to 5 lb/in).

8. Adjust the thickness of the upper shim to obtain the correct rolling torque.

9. Temporarily install the pinion gear [6-25], & flange nut [6-29].

10. Check the pinion gear height (optimum .025) (see “Lower Pinion Height

Measurement” (Fig. 7)

11. If pinion gear height requires correction remove all associated components and

adjust the lower bearing shims. Any adjustment here requires that the upper

bearing shims be compensated by the same amount.

12. Remove the vertical shaft & pinion.

13. Install the prop gear bearing shims [6-22], & bearing cup [6-23] into the gear case.

14. Install the prop gear bearing cone [6-24] onto the prop gear [6-25].

15. Install the prop gear with bearing into the gear case. (The prop shaft bushing

[6-26], used only with the 01-8244 and 01-8248 gear sets, must be installed into

the prop gear at this time).

16. Re-install the vertical shaft components described above, and install the vertical

shaft clamp plate.

17. Install the bearing carrier bearing cone [6-37] onto the prop shaft.

18. Install the prop shaft with bearing into the gear case.

19. Install the prop shaft seals [6-35], & bearing carrier bearing cup [6-36] into the

bearing carrier [6-34].

20. Temporarily install the bearing carrier into the gear housing.

21. Install the bearing carrier tab washer [6-31], & retainer nut [6-30], and torque the

retainer nut to 150 lb/ft.

22. Rotate the vertical shaft at least 3 turns and check the prop gear backlash

(optimum .012 to .015).

23. Adjust the thickness of the prop gear bearing cup shims [6-22] to obtain the correct

backlash readings.

24. During final assembly be sure to clean & loctite the vertical shaft flange nut [6-29].

Torque the nut to 100 lb/ft.

25. Temporarily install the bearing carrier thrust washer [6-40], & shims [6-39] prior to

prop shaft & bearing carrier installation.

26. Torque the bearing carrier retainer nut to 150 lb/ft.

27. Check overall rolling torque at the vertical shaft (optim um 11 to 17 lb/in).

Page 14

LOWER GEAR CASE – ASSEMBLY CONT.

28. Adjust the thickness of the bearing carrier shims [6-39] to obtain the correct rolling

torque readings.

29. Upon final assembly be sure to install the bearing carrier “O” ring [6-38] prior to

installation of the bearing carrier.

30. After applying final torque of the bearing carrier retainer nut [6-30], bend one tab

of the tab washer [6-31] to engage with one of the slots in the retainer nut.

Lower Pinion Height Measurement

Fig-7

Page 15

Disassembly-Assembly Tools

SCX Upper

IMCO Mercury

1. Tower & Cap Race Puller Kit 01-5443

2. Tower Internal Bearing Puller Kit 01-5445

3. Tower Removal Tool Kit 01-5448

4. Pinion Retainer Nut Driver 01-5590

5. Pinion Center Measuring Slug 01-5583

6. Pinion Bearing Cup Installer (Front) 01-5580

7. Pinion Bearing Cup Installer (Back) 01-5581

8. Bearing & Race Installer (Cap) 01-5581

9. Bearing & Race Installer (Tower) 01-5582

10. Backlash Tool Kit 01-8017

A. Backlash Tower 01-5579

B. Indicator Bracket 01-5588

C. Pinion Gear Lock 01-5587

D. Backlash Wand 01-5449

E. Dial Indicator 01-5591

SC Lower

1. Cover Nut Wrench (1” Prop Shaft) 91-61069T

2. Cover Nut Wrench (1 ¼” Prop Shaft) 91-840393

3. Lower Pinion Height Gauge 91-42840

4. Prop Gear Cup Installer 91-31106

5. Vertical Shaft Roller Bearing Driver

A. Pilot 91-813653

B. Driver rod 91-37323

C. Bearing Remover 91-638T

6. Vertical Shaft Roller Bearing Installer

A. Pilot 91-813653

B. Threaded Rod 91-31229

C. Bearing Installer 91-89867

7. Clamp Plate 91-43559T

8. Dial Indicator 91-58222A1

9. Vertical Shaft Bearing Cup Puller 01-5409

10. Prop Gear Cup Puller 01-5410

11. Bearing Carrier Cup & Seal Installer (1 ¼”) 01-5411

Loading...

Loading...