IMC SP Series, SP25, SP12 Installation, Operating And Maintenance Manual

SP-RANGE

SP25 PEELER

SP12 & SP25 – SERIES 4

INSTALLATION, OPERATING AND MAINTENANCE MANUAL

PLEASE LEAVE WITH OPERATOR

A34/013 R17 ECN 8818 February 2019

1 | P a g e

SP-RANGE

EC DECLARATION OF CONFORMITY

(Guarantee of Production Quality)

We, Imperial Machine Company Limited of:

Unit 1, Abbey Road, Wrexham Industrial Estate, Wrexham, LL13 9RF

Declare under our sole responsibility that the machine

SP12 & SP25 – SERIES 4

As described in the attached technical documentation is in conformity with the Machine Safety

Directive 98/37/EC and is manufactured under quality system BS EN ISO 9001. It is also in

conformity with the protection requirements of the Electro Magnetic Compatibility Directive

2004/108/EEC and is manufactured in accordance with harmonised standards EN 61000-6-1

Immunity and EN 61000-6-3 Emissions (plus product specific standards).

It also satisfies the essential requirements of the Low Voltage Directive 2006/95/EC and is

manufactured in accordance with harmonised standard EN 60204-1 Safety of Machinery

(Electrical Equipment).

Approved by E Plumb, Engineering Manager

Signed at Wrexham, Date February 2019

2 | P a g e

SP-RANGE

CONTENTS

GUARANTEE .................................................................................................................... 4

DELIVERY ......................................................................................................................... 4

SAMPLE RATING LABEL.................................................................................................... 4

INTRODUCTION ............................................................................................................... 5

YOUR PEELER ................................................................................................................... 5

CONTROLS ....................................................................................................................... 6

INSTALLATION .......................................................................................................... 6 & 7

WATER SUPPLY ................................................................................................................ 7

WASTE OUTLET CONNECTION ......................................................................................... 7

WASTE EJECTOR .............................................................................................................. 8

ELECTRICITY SUPPLY CONNECTION ........................................................................ 9 & 10

COMMISSIONING .......................................................................................................... 10

OPERATION ................................................................................................................... 10

SAFETY ........................................................................................................................... 11

CLEANING ...................................................................................................................... 11

DO’S AND DON’TS ......................................................................................................... 12

MATERIAL CONTENT...................................................................................................... 12

MAINTENANCE .............................................................................................................. 13

WIRING DIAGRAM 1PH UNITS ....................................................................................... 14

WIRING DIAGRAM 3PH UNITS ....................................................................................... 15

PARTS ILLUSTRATION .................................................................................................... 16

SPARES PART LIST ..................................................................................................17 & 18

1PH CONTROL BOX SPARE PARTS LIST .......................................................................... 19

3PH CONTROL BOX SPARE PARTS LIST .......................................................................... 20

ORDERING SPARE PARTS ............................................................................................... 21

3 | P a g e

SP-RANGE

GUARANTEE

This equipment is guaranteed by IMC for 2 Years from the date of purchase from IMC or from one of

its stockists, dealers or distributors.

The guarantee is limited to the replacement of faulty parts or products and excludes any consequential

loss or expense incurred by purchasers. Defects which arise from faulty installation, inadequate

maintenance, incorrect use, connection to the wrong electricity supply or fair wear and tear are not

covered by the guarantee.

PLEASE OBSERVE THESE INSTRUCTIONS CAREFULLY

This guarantee applies in this form to installations within the UK only.

DELIVERY

The machine is packaged in a carton. Please check the contents against the list below.

Peeler Unit, with lid, control box and mounting bracket 1

Peeling plate 1

Water supply pipe and 2 hose clips 1

1m long 3” flexible waste hose and hose clip 1

Instruction Booklet 1

If any accessories have been ordered they will be supplied in separate packages.

Please notify the carrier and the supplier within three days of receipt if anything is missing or damaged.

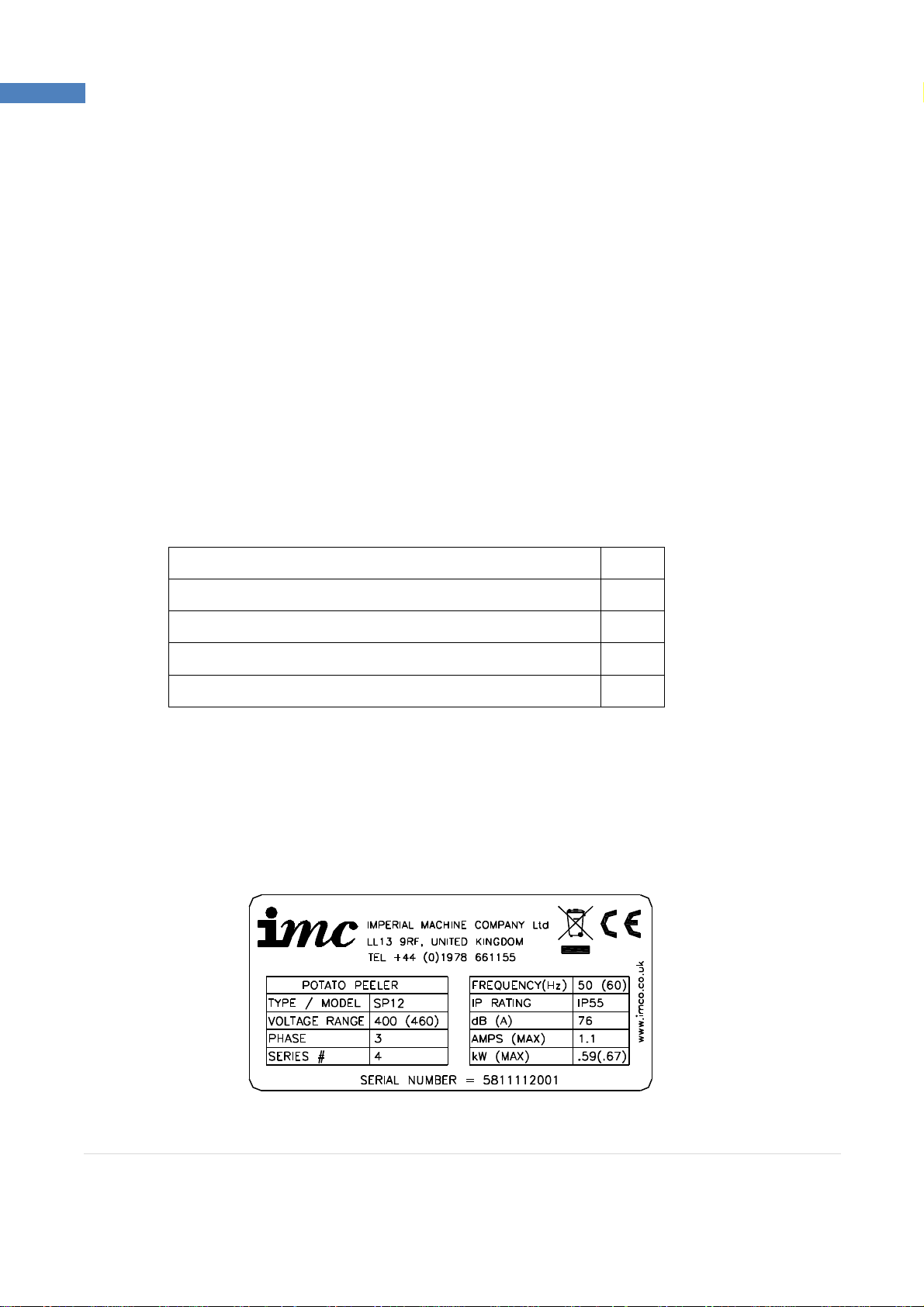

Check that the correct machine has been supplied and that the voltage, marked on the rating plate on

the motor, is suitable for the supply and control voltage available. The rating plate is located at the back

of the cylinder near the supply cable inlet.

SAMPLE RATING LABEL

4 | P a g e

SP-RANGE

INTRODUCTION

This machine is intended for peeling potatoes. Its use may be extended to other root vegetables. It is

not recommended to use this machine for peeling onions.

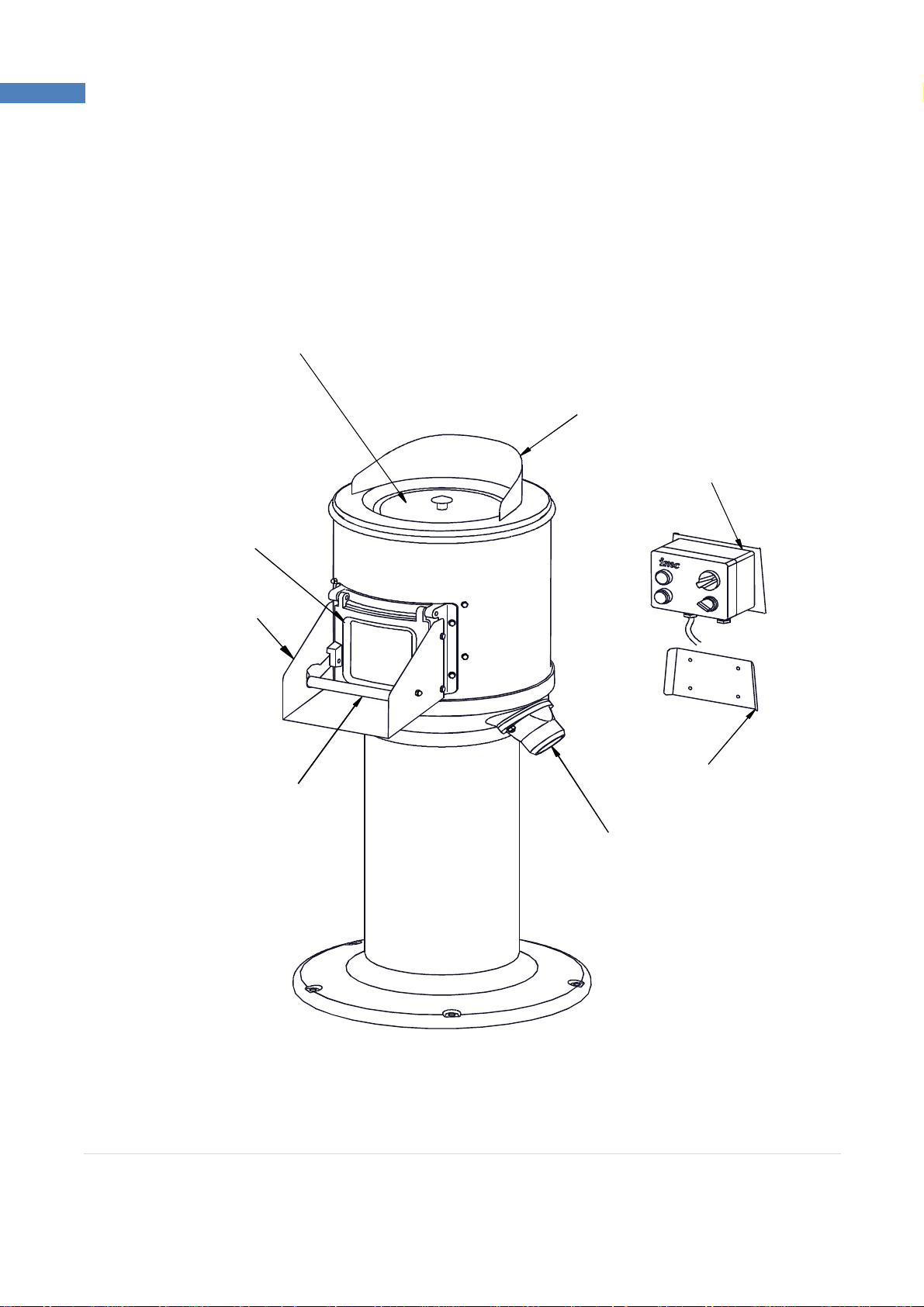

YOUR PEELER

SPLASH COVER

LID

CONTROL BOX

DOOR

CHUTE

MOUNTING BRACKET

DOOR HANDLE

WASTE OUTLET

5 | P a g e

SP-RANGE

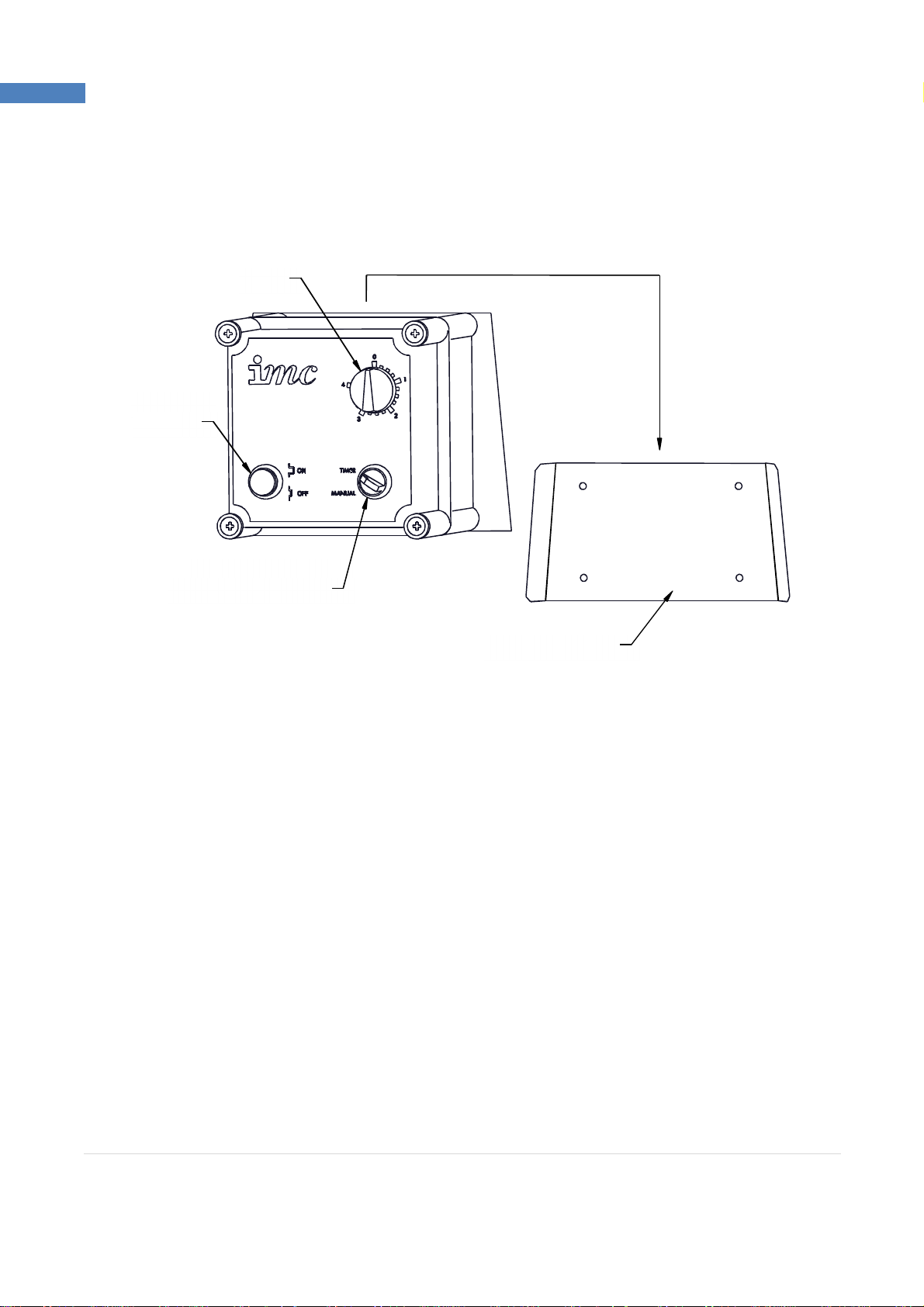

CONTROLS

The peeler has a separate box for mounting on a wall bracket near the machine.

TIMER

ON/OFF

BUTTON

TIMER / MANUAL

SELECTOR SWITCH

WALL BRACKET

Note: Control boxes for three phase machines have separate on and off buttons

INSTALLATION

For the Installer:

· These instructions contain important information designed to help the user obtain the

maximum benefit from the investment in an IMC SP Peeler.

· Please read them carefully before starting work, and consult with the supplier in the event of

any queries.

· Be sure to leave this instruction manual with the user after the installation of the machine is

complete.

Procedure:

The SP Range is supplied with a pedestal and is designed to be bolted to the floor. The control box is

designed to be mounted on a wall bracket so that it is easily accessible once the machine is installed.

Place the machine in its desired location and mark through the pedestal base the location of the five

floor fixing holes. Remove the machine and prepare the floor for rawl bolts or other suitable floor

fixings. Replace the unit into working position and fit the rawl bolts or other fixings. Tighten up the

fixings.

6 | P a g e

SP-RANGE

Place the control box bracket in the desired location and mark through the four screw holes. Remove

the bracket and prepare the wall for rawl plugs or other suitable wall fixings. Secure the bracket in

place with four screws. Slide the control box onto its wall bracket.

WATER SUPPLY

Connect the water supply pipe to the water inlet located on the top of the lid, and secure using the

supplied hose clips. Fit the other end of the supply pipe to a cold water supply that incorporates a tap

or shut off valve that can be used to regulate the water flow to approximately 3 – 4 litres per minute.

The water inlet is fitted with a baffle to improve the distribution of water into the cylinder. This may

cause minor splashing on the surface of the lid; if this becomes severe, reduce water flow as required.

The maximum water pressure for the supply is 10 bar. Ensure that the hose supplied with the machine

is used and that an old hose is not reused.

PLEASE NOTE: These machines are fitted with an air-break to prevent back syphonage into the mains

supply. Some local authorities may nevertheless require connection is made to a storage cistern rather

than direct to the mains supply.

This applies to UK installations only. Overseas customers should install the machine in accordance with

local regulations.

If in doubt, check with your local authority.

WASTE OUTLET CONNECTION

The peeler has two possible waste outlet locations. If it is required to change the waste outlet location,

remove both the existing waste outlet and the blanking plate on the opposite side. Refit both the waste

outlet and the blanking plate in their new positions.

A flexible hose, supplied with the machine, can be fitted over the waste outlet to direct the waste into

a gully or intercepting tank. If required, secure with the hose clip supplied. Longer lengths of flexible

hose are available from IMC on request.

The waste outlet also incorporates a 2” BSP female thread for connection to standard 54mm (2”) waste

pipe. DO NOT reduce the diameter of the waste pipe to below 54mm. The length of the pipe should

be kept to a minimum and the pipe must have a fall of at least 1:15. Changes of direction should be

made by swept bends rather than elbows and cleaning eyes should be fitted where possible in

accordance with standard plumbing practice.

A trap is not necessary if the discharge is into a gully or an intercepting tank, although a trap must be

provided in the outlet pipe from the intercepting tank. If a trap is required, it should be made with 45°

bends and not with a ‘U’ or ‘P’ bend or with a bottle trap.

7 | P a g e

Loading...

Loading...