Imac NGS 1000 Installation, Operation & Maintenance Instructions Manual

IMAC Systems, Inc.

90 Main Street, PO Box 1605

Tullytown, PA 19007

1-800-955-4GAS

Phone: (215) 946-2200

Fax: (215) 943-2984

sales@imacsystems.com

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS FOR

NGS 1000 NATURAL GAS SCRUBBERS

10 AND 25 SCFM UNITS

10001000

Natural Gas Scrubber

NEW

PRODUCT

NGS-4

10 SCFM

Outlet

Outlet

Inlet

NGS-12

25 SCFM

APPLICATION

Designed specifically for industrial applications with natural gas

supply lines such as:

· Cata-Dyne™ Series MKII, WX, and BX heaters

· Enclosure systems

· Instrument gas pre-heaters

STANDARD PRODUCT FEATURES

· CRN Certified (#0H6573.213) to 250 psi and 200°F

· Two sizes available

SIZE 4, 10 SCFM, ؼ” NPT

SIZE 12, 25 SCFM , Ø ¾” NPT

MOUNTING OPTIONS

With appropriate brackets, the NGS 1000 natural gas scrubber can

be installed in an existing piping system or it can be bolted to a

wall/panel using the factory supplied stainless steel wall mounting

kit.

FEATURES

CRN CERTIFIED #0H6573.213

Max. Pressure = 250 psi

Max. Temperature = 200°F

Min. Temperature = -40°F

Flow Rates: 10 SCFM to 25 SCFM

SAE/ORB o-ring design.

Inlet

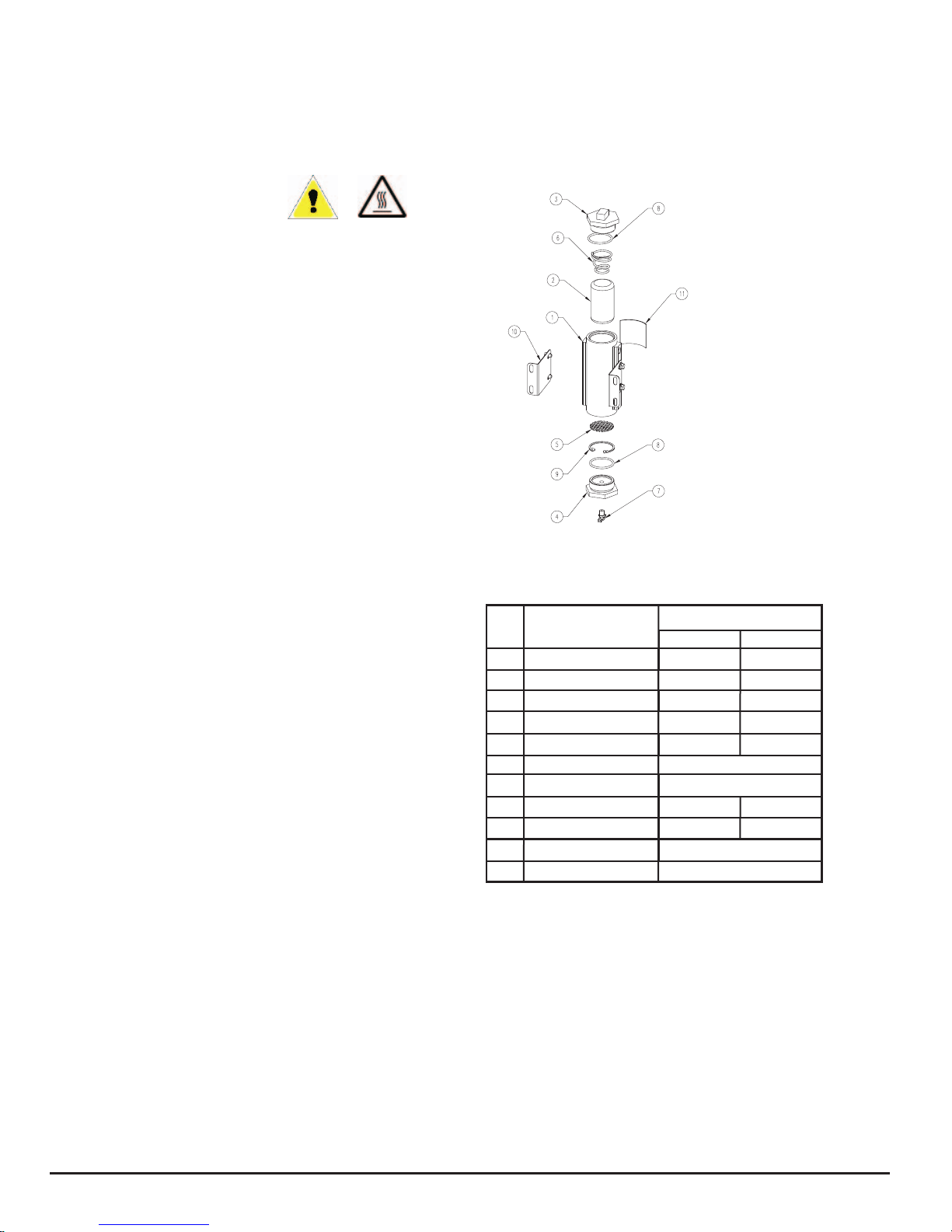

Figure 1. NGS 1000

Natural Gas Scrubber

Two sizes available NGS-4 and NGS-12

Table 1. Natural Gas Scrubber, Cartridge, and Mounting Kit Coded Numbering System.

BENEFITS

Extend the life of your Cata-Dyne™ infrared heater if sour gas or

moisture is present.

Low-pressure drop at rated flow.

Gas Scrubber Cartridge Mounting Kit

NGSNGS NGC- - -4 4 K

Natural Gas

Scrubber

4 = 10 SCFM

12 = 25 SCFM

Natural Gas

Cartridge

4 = 10 SCFM

12 = 25 SCFM

Natural Gas

Scrubber

A Leader in Advanced Heating Solutions

K = Mounting

Kit

INSTALLATION & MAINTENANCE INSTRUCTIONS

ITEM DESCRIPTION

NGS-4* NGS-12*

1 SCRUBBER HOUSING B16135-01 B16138-01

2 CARTRIDGE NGC-4 NGC-12

3 THREADED COVER B16142-01 B16143-01

4 THREADED BASE B16142-02 B16143-02

5 BAFFLE A16146-01 A16146-02

6 CONICAL SPRING

7 DRAIN COCK

8 ORING A10069-42 A10069-43

9 SNAP RING A16154-01 A16154-02

10 MOUNTING BRACKET

11 LABEL

PART NUMBER

B16158-01

NGS-K

A16150-01

A16149-01

WARNINGS

NGS 1000

Natural Gas Scrubbers

1. Read and follow all instructions contained in this manual before

installing, operating, and maintaining this equipment. Failure to

do so could void the warranty, damage the equipment, or cause

severe injury or death.

2. Relieve all pressure before dismantling unit.

NGC - Cartridges

1. Do not use cartridge if the package has been damaged or seal is

broken.

2. Store cartridges at room temperature in a dry/dark place.

3. Avoid contact with eyes or exposed skin.

4. Contents may be harmful if swallowed or inhaled as dust.

5. Spilled or discarded product should be disposed of in accordance

with all applicable government regulations.

6. Contents may become hot if exposed to water.

HOW TO ORDER

Natural Gas Scrubber cartridge and mounting kit coded numbering system

is presented in Table 1, while the parts list is in Table 2.

INSTRUCTIONS

INSTALLATION PROCEDURE

A. Read and follow all instructions contained in this manual before

installing, operating, and maintaining this equipment. Failure to do so

could void the warranty, damage the equipment, or cause severe injury

or death.

Figure 2. NGS 1000 Gas Scrubber and NGC Cartridge

Table 2. Parts List

B. Review Figure 2 for NGS 1000 scrubber component nomenclature.

Refer to Figure 3 for mounting dimensions and NGS scrubber general

arrangement. Install scrubber units only in vertical position shown.

C. Install the NGS 1000 scrubber using appropriate mounting hardware.

Optional (factory supplied) universal mounting brackets are available.

D. Relieve and block all pressure before installing, maintaining, or

dismantling the NGS 1000 scrubber.

E. Remove the NGS 1000 scrubber cover (Item 3). Carefully inspect the

spring (item 6), the o-ring (item 8), and the cover/housing threads.

Remove any dirt, contaminants, or residue from the cover/housing

threads prior to final assembly.

F. Read the label on the NGC Natural Gas Cartridge (Item 1) then remove

the cartridge from the factory-sealed bag. Ensure the contents of the

NGC cartridge are never exposed to water.

G. Insert the NGC cartridge (Item 1) into the scrubber housing (Item 2).

To help with this process you may choose to insert a sheet of rolled

paper or transparency into the scrubber housing (Item 2) prior to

inserting the NGC cartridge. Remember to remove the paper or

transparency once the NGC cartridge has been installed.

H. Re-install the NGS cover (Item 3) using a wrench (see Table 3(b) for

hex size) and ensure the cover has completely bottomed out and there

is zero gap between the cover and the housing. CAUTION: DO NOT

OVERTIGHTEN the cover or thread damage may occur. Contact

the factory if threads are damaged, corroded, stripped, or galled.

I. Ensure all fittings are installed and sealed in accordance with the

manufacturer's specifications.

J. Verify that the drain cock (Item 7) is in the fully closed position

(clockwise hand tight) before pressurizing the system.

A Leader in Advanced Heating Solutions

* ADD SUFFIX-G FOR Ø1/8” NPT GAUGE PORT OPTION

MAINTENANCE PROCEDURE

I. Refer to Table 4 to determine the suggested change-out

frequency for your Cata-Dyne™ heater application.

II. Relieve and block all pressure before installing, maintaining,

or dismantling the NGS 1000 scrubber.

III. Release and contain any residual water/ contaminates from the

drain bowl by opening the drain cock (Item 7) counterclockwise.

IV. Repeat step E of the Installation Instructions.

V. Remove and properly dispose of used or contaminated cartridges

in accordance with all applicable government regulations.

VI. Repeat steps F through J of the Installation Instructions.

Loading...

Loading...