ILX Lightwave LDX-3200 Service Manual

User’s Guide

Precision Current Source

LDX-3200 Series

ILX Lightwave Corporation P. O. Box 6310 Bozeman, MT, U.S.A. 59771 : · · · 1-800-459-9459 · ·

www.ilxlightwave.com

U.S. & Canada International Inquiries: 406-586-1244 Fax 406-586-9405

E-mail: support@ilxlightwave.com

7002820200_7/01

S

!

AFETY AND

! ! ! ! ! ! ! ! ! ! ! ! ! ! ! ! ! !

The Safety and Warranty Information section provides details about cautionary symbols used in the

manual, safety markings used on the instrument, and information about the Warranty including

Customer Service contact information.

W

ARRANTY INFORMATION

Safety Information and the Manual

Throughout this manual, you will see the words Caution and Warning indicating potentially

dangerous or hazardous situations which, if not avoided, could result in death, serious or minor

injury, or damage to the product. Specifically:

CAUTION

Caution indicates a potentially hazardous situation which can result in minor or

moderate injury or damage to the product or equipment.

WARNING

Warning indicates a potentially dangerous situation which can result in serious injury or

death.

WARNING

Visible and/or invisible laser radiation. Avoid direct exposure to the beam.

General Safety Considerations

If any of the following conditions exist, or are even suspected, do not use the instrument until safe

operation can be verified by trained service personnel:

• Visible damage

• Severe transport stress

• Prolonged storage under adverse conditions

• Failure to perform intended measurements or functions

If necessary, return the instrument to ILX Lightwave, or authorized local ILX Lightwave distributor,

for service or repair to ensure that safety features are maintained (see the contact information on

page vi).

All instruments returned to ILX Lightwave are required to have a Return Authorization Number

assigned by an official representative of ILX Lightwave Corporation. See Returning an Instrument on

page v for more information.

Safety and Warranty Information

S

AFETY

This section describes the safety symbols and classifications.

Technical specifications including electrical ratings and weight are included within the manual. See

the Table of Contents to locate the specifications and other product information. The following

classifications are standard across all ILX Lightwave products:

• Indoor use only

• Ordinary Protection: This product is NOT protected against the harmful ingress of moisture.

• Class I Equipment (grounded type)

• Mains supply voltage fluctuations are not to exceed ±10% of the nominal supply voltage.

• Pollution Degree II

• Installation (overvoltage) Category II for transient overvoltages

• Maximum Relative Humidity: <80% RH, non−condensing

• Operating temperature range of 0 °C to 40 °C

• Storage and transportation temperature of ˘40 °C to 70 °C

• Maximum altitude: 3000 m (9843 ft)

• This equipment is suitable for continuous operation.

S

YMBOLS

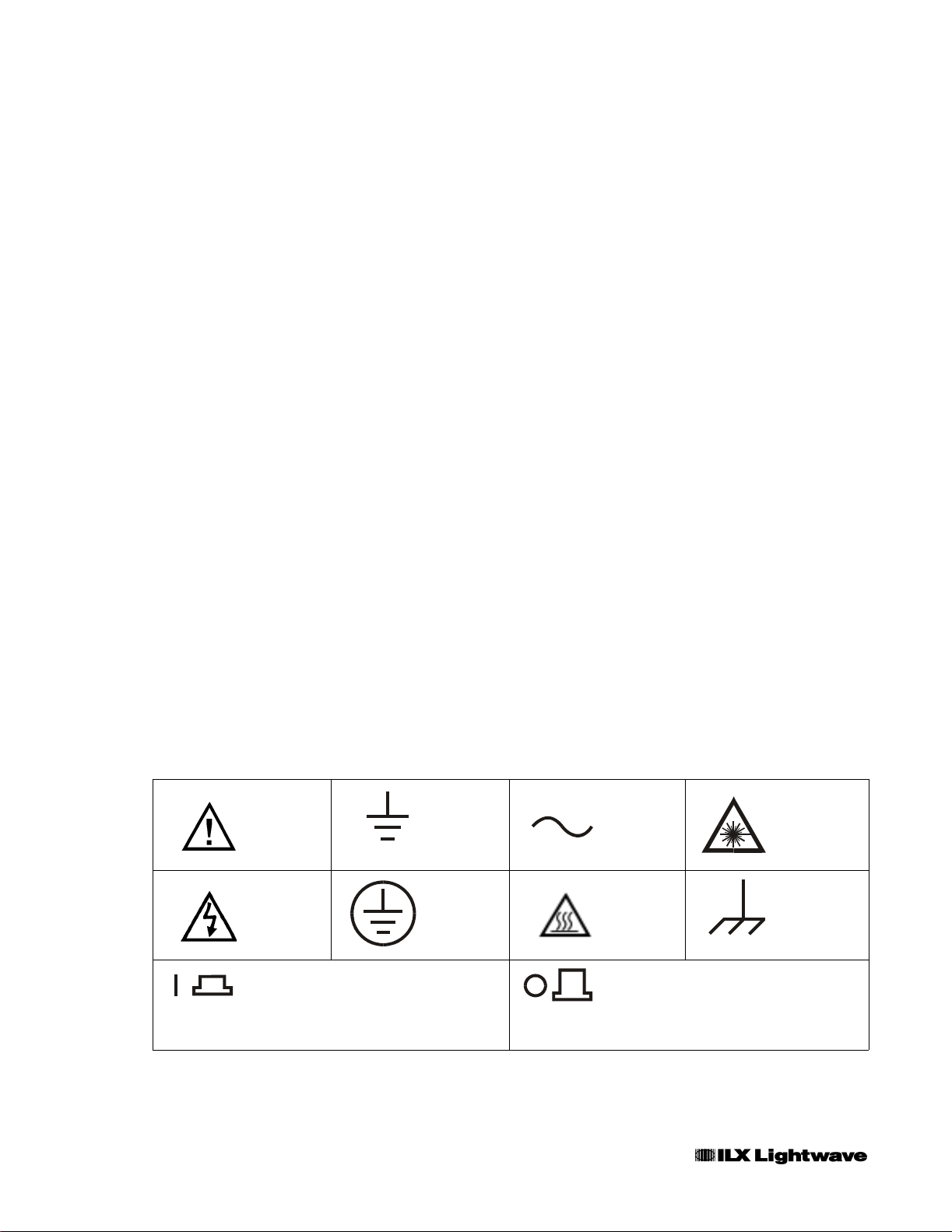

Safety Marking Symbols

This section provides a description of the safety marking symbols that appear on the instrument.

These symbols provide information about potentially dangerous situations which can result in death,

injury, or damage to the instrument and other components.

Caution,

refer to

manual

Caution, risk

of electric

shock

or

(I)

On: In position of a bistable push control. The

slash (I) only denotes that mains are on.

Earth

ground

Terminal

Protective

Conductor

Terminal

or

(O)

Alternating

current

Caution, hot

surface

Off: Out position of a bistable push control.

The circle (O) only denotes that mains are off.

Visible and/or

invisible laser

radiation

Frame or

chassis

Terminal

Safety and Warranty Information

W

ARRANTY

ILX LIGHTWAVE CORPORATION warrants this instrument to be free from defects in material and

workmanship for a period of one year from date of shipment. During the warranty period, ILX will

repair or replace the unit, at our option, without charge.

Limitations

This warranty does not apply to fuses, lamps, defects caused by abuse, modifications, or to use of

the product for which it was not intended.

This warranty is in lieu of all other warranties, expressed or implied, including any implied warranty

of merchantability or fitness for any particular purpose. ILX Lightwave Corporation shall not be liable

for any incidental, special, or consequential damages.

If a problem occurs, please contact ILX Lightwave Corporation with the instrument’s serial number,

and thoroughly describe the nature of the problem.

Returning an In strument

If an instrument is to be shipped to ILX Lightwave for repair or service, be sure to:

1 Obtain a Return Authorization number (RA) from ILX Customer Service.

2 Attach a tag to the instrument identifying the owner and indicating the required service or

repair. Include the instrument serial number from the rear panel of the instrument.

3 Attach the anti−static protective caps that were shipped with the instrument and place the

instrument in a protective anti−static bag.

4 Place the instrument in the original packing container with at least 3 inches (7. 5 cm) of

compressible packaging material. Shipping damage is not covered by this warranty.

5 Secure the packing box with fiber reinforced strapping tape or metal bands.

6 Send the instrument, transportation pre−paid, to ILX Lightwave. Clearly write the return

authorization number on the outside of the box and on the shipping paperwork. ILX

Lightwave recommends you insure the shipment.

If the original shipping container is not available, place your instrument in a container with at least 3

inches (7.5 cm) of compressible packaging material on all sides.

Repairs are made and the instrument returned transportation pre−paid. Repairs are warranted for the

remainder of the original warranty or for 90 days, whichever is greater.

Claims for Shipping Damage

When you receive the instrument, inspect it immediately for any damage or shortages on the

packing list. If the instrument is damaged, file a claim with the carrier. The factory will supply you

with a quotation for estimated costs of repair. You must negotiate and settle with the carrier for the

amount of damage.

Safety and Warranty Information

Comments, Suggestions, and Problems

To ensure that you get the most out of your ILX Lightwave product, we ask that you direct any

product operation or service related questions or comments to ILX Lightwave Customer Support.

You may contact us in whatever way is most convenient:

Phone . . . . . . . . . . . . . . . . . . . . . . . . . . . (800) 459−9459 or (406) 586−1244

Fax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (406) 586−9405

Email. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . support@ilxlightwave.com

Or mail to:

ILX Lightwave Corporation

P. O. Box 6310

Bozeman, Montana, U.S.A 59771

www.ilxlightwave.com

When you contact us, please have the following information:

Model Number:

Serial Number:

End−user Name:

Company:

Phone:

Fax:

Description or sketch of what

is connected to the ILX

Lightwave instrument:

Description of the problem:

If ILX Lightwave determines that a return to the factory is necessary, you are issued a Return

Authorization (RA) number. Please mark this number on the outside of the shipping box.

You or your shipping service are responsible for any shipping damage when returning the

instrument to ILX Lightwave; ILX recommends you insure the shipment. If the original shipping

container is not available, place your instrument in a container with at least 3 inches (7.5cm) of

compressible packaging material on all sides.

We look forward to serving you even better in the future!

Safety and Warranty Information

Table of Contents

Chapter 1 Introduction to the LDX-3200 Series

Introduction ...............................................................................................................................................................1

Safety Symbols and Terms..............................................................................................................................................2

Product Overview............................................................................................................................................................2

Initial Inspection..............................................................................................................................................................2

Installing your LDX-3200 Precision Current Source.......................................................................................................3

Maintenance ...............................................................................................................................................................4

How to Obtain Repair Services .......................................................................................................................................6

LDX-3200 Series Specifications......................................................................................................................................6

Available Options and Accessories .................................................................................................................................8

Chapter 2 How to Operate Your LDX-3200

Introduction ...............................................................................................................................................................1

Applying Power to Your LDX-3200..............................................................................................................................1

Connecting to the Laser...................................................................................................................................................2

Front Panel Operation.....................................................................................................................................................5

Operating a Laser in Constant Current, “I” Mode.........................................................................................................5

Operating a Laser in Constant Power Mode, P...............................................................................................................7

Error Indicators ...............................................................................................................................................................8

Chapter 3 Operating in Remote Control

Introduction ...............................................................................................................................................................1

LDC-3700B Series Current Source Command Set...........................................................................................................2

Status Reporting..............................................................................................................................................................7

Chapter 4 Command Reference

Introduction ...............................................................................................................................................................1

LDX-3200 Series Device-Dependent Commands...........................................................................................................4

LDX-3200 Series Device-Dependent Command Reference............................................................................................5

Chapter 5 Functions and Features

Introduction ...............................................................................................................................................................1

Saving and Recalling from the Front Panel.......................................................................................................................1

Using the Laser Compliance Voltage Adjustment ...........................................................................................................2

Using the LDX-3200 Trigger Function............................................................................................................................2

Modulating the Laser Current Source..............................................................................................................................3

Chapter 6 Calibration and Troubleshooting Guide

Introduction ...............................................................................................................................................................1

Local Calibration of the LDX-3200 Series Current Source..............................................................................................2

Remote Calibration of the LDX-3200 Series Current Source..........................................................................................6

Troubleshooting Guide..................................................................................................................................................10

CHAPTER 1 1

INTRODUCTION TO THE LDX-3200 SERIES 1

Introduction 1

Product Overview 2

Initial Inspection 2

Installing Your LDX-3200 Precision Current Source 3

Grounding requirements 3

AC Line Power Requirements 3

GPIB Connector 3

The GPIB Address 3

Tilt-Foot Adjustment 4

Operating the LDX-3200 Precision Current Source 4

Maintenance 5

How to Obtain Repair Services 6

General Shipping Instructions 6

LDX-3200 Series Specifications 7

Laser Current Source Specifications 7

Available Options and Accessories 8

INTRODUCTION TO THE LDX-3200 SERIES CHPT 1

CHAPTER 1

INTRODUCTION TO THE LDX-3200 SERIES

INTRODUCTION

This chapter is an introduction to the LDX-3200 Series Precision Current Sources containing unpacking information,

instructions on how to install and apply power, and safety considerations and instructions. It also contains some

maintenance information, specifications, and listings of the LDX-3200 options and accessories.

WARNING

If any of the following symptoms exist, or are even suspected, remove the LDX-3200 from service.

Do not use the LDX-3200 until trained service personnel can verify safe operation.

1. Visible damage

2. Severe transport stress

3. Prolonged storage under adverse conditions

4. Failure to perform intended measurements or functions

If necessary, return the LDX-3200 to ILX Lightwave for service and repair to ensure that safety

features are maintained.

In order to get the most out of your ILX Lightwave product, we ask that you direct any product operation or service

related questions or comments to Customer Support at 1-800-459-9459 (USA and Canada), 406-586-1244

(International) or by fax at 406-586-9405. Or E-mail us at SUPPORT@ILXLIGHTWAVE.COM.

When calling, please have the following information on hand (if applicable):

1) Product Model: ________________________________________________

2) Unit Serial Number: ________________________________________________

3) End user name and telephone/fax

Name: ________________________________________________

Company: ________________________________________________

Phone: ________________________________________________

Fax: ________________________________________________

4) Description/sketch of what is connected to the ILX Lightwave instrument.

5) Description of the problem.

INTRODUCTION TO THE LDX-3200 SERIES CHPT 1

PAGE 1

SAFETY SYMBOLS AND TERMS

The following safety terms are used in this manual:

• The WARNING heading explains dangers that could result in personal injury or death.

• The CAUTION heading explains hazards that could damage your instrument.

• The NOTES heading gives information to the user that may be beneficial in the use of the instrument and to the

devices being tested.

The following symbols are used in this manual and on the instrument:

Earth Ground and/or Protective conductor terminal

Caution: Refer to accompanying documents

Caution: Risk of Electrical Shock

Instrument Power Off

Instrument Power On

PRODUCT OVERVIEW

The LDX-3200 Series instruments are precision current sources. They provide a high stability output with a fully

redundant current limit and multiple laser protection features. The LDX-3200 Series' fast, sophisticated GPIB option

lets you automate your experiment.

INITIAL INSPECTION

When you receive your LDX-3200 instrument, verify that the following items were shipped with the instrument:

LDX-3200 Series Precision Current Source

LDX-3200 Series Instruction Manual

Power Cord

Shipping Kit

INTRODUCTION TO THE LDX-3200 SERIES CHPT 1

PAGE 2

INSTALLING YOUR LDX-3200 PRECISION CURRENT SOURCE

Grounding requirements

The LDX-3200 Series Precision Current Source comes with a three conductor AC power cable. The power cable must

either be plugged into an approved three-contact electrical outlet or used with a three-contact or two-contact adapter

with the grounding wire connected to an electrical ground (safety ground). The LDX-3200’s power jack and supplied

power cable meet IEC safety standards.

AC Line Power Requirements

You can operate the LDX-3200 Series instrument from a single phase power source delivering nominal line voltages

of 100, 120, 220, or 240 VAC (all values RMS), at 50/60 Hz. The line power voltage can vary + 10% but cannot exceed

250 VAC. Maximum power consumption is 60 VA (Volt-Amps). The instrument’s operational voltage is factory

configurable and need not be changed before operating the instrument. However, check to be sure that the voltage

printed on the back panel of the instrument matches the power-line voltage in your area.

WARNING

Before connecting the LDX-3200 Series Precision Current Source to a power source, verify that the AC power

source matches the setting of the LDX-3200’s voltage printed on the rear panel of the instrument.

To avoid electrical shock hazard, connect the instrument to properly earth-grounded, 3-prong receptacles only.

Failure to observe this precaution can result in severe injury or death.

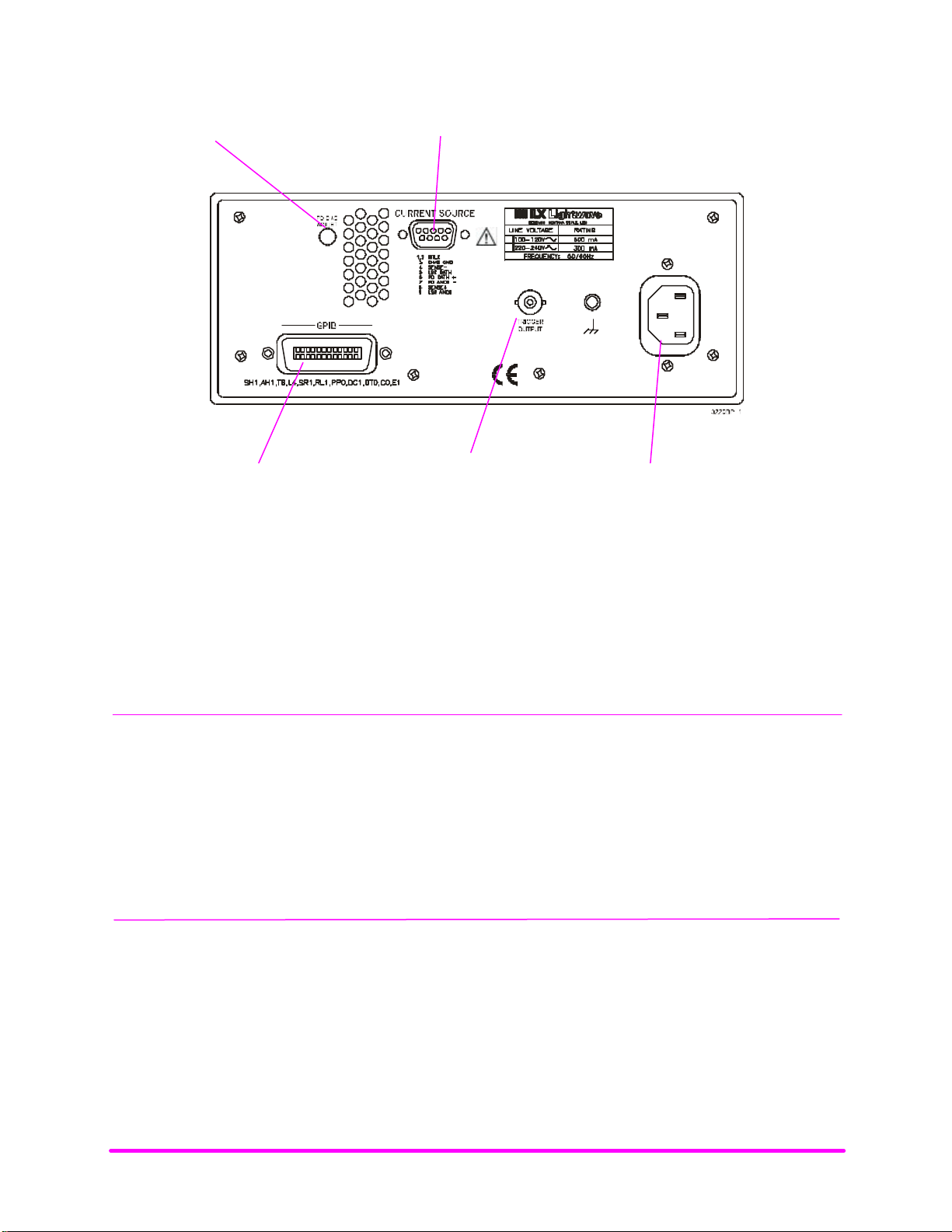

GPIB Connector

The IEEE 488.2 GPIB interface connector is located on the rear panel, directly above the power input module and fuse.

See Figure 1.2, LDX-3200 Series Rear View. Attach the GPIB cable to the 24-pin connector located on the rear panel.

The connector is tapered to ensure proper orientation. Using your fingers, tighten the two screws on the cable

connector.

A total of 15 devices can be connected together on the same GPIB interface bus. The cables have single male/female

connectors on each end so that several cables can be stacked. This allows more than one cable to be attached to any

one device. However, the maximum length of the GPIB cables must not exceed 20 meters (65 feet) total, or 2 meters

(6.5 feet) per device.

The GPIB Address

The talk and listen addresses on the LDX-3200 Series Precision Current Source are identical. This GPIB address is

read locally by pressing the (GPIB) LOCAL switch with the address displayed on the LCD display. The instrument

comes from the factory configured with the GPIB address set to 1. You can change the LDX-3200’s GPIB address

locally (via front panel). A procedure for changing the address can be found in the section “Changing the GPIB

Address” in Chapter 3.

INTRODUCTION TO THE LDX-3200 SERIES CHPT 1

PAGE 3

Tilt-Foot Adjustment

The LDX-3200 Series Precision Current Source comes standard with folding front legs and two rear feet for use as a

bench top instrument. Extending the front feet so that the instrument front panel sits up makes it easier to view the

LED displays. To use them, place the unit on a stable base and rotate the front legs downward until they lock into

position.

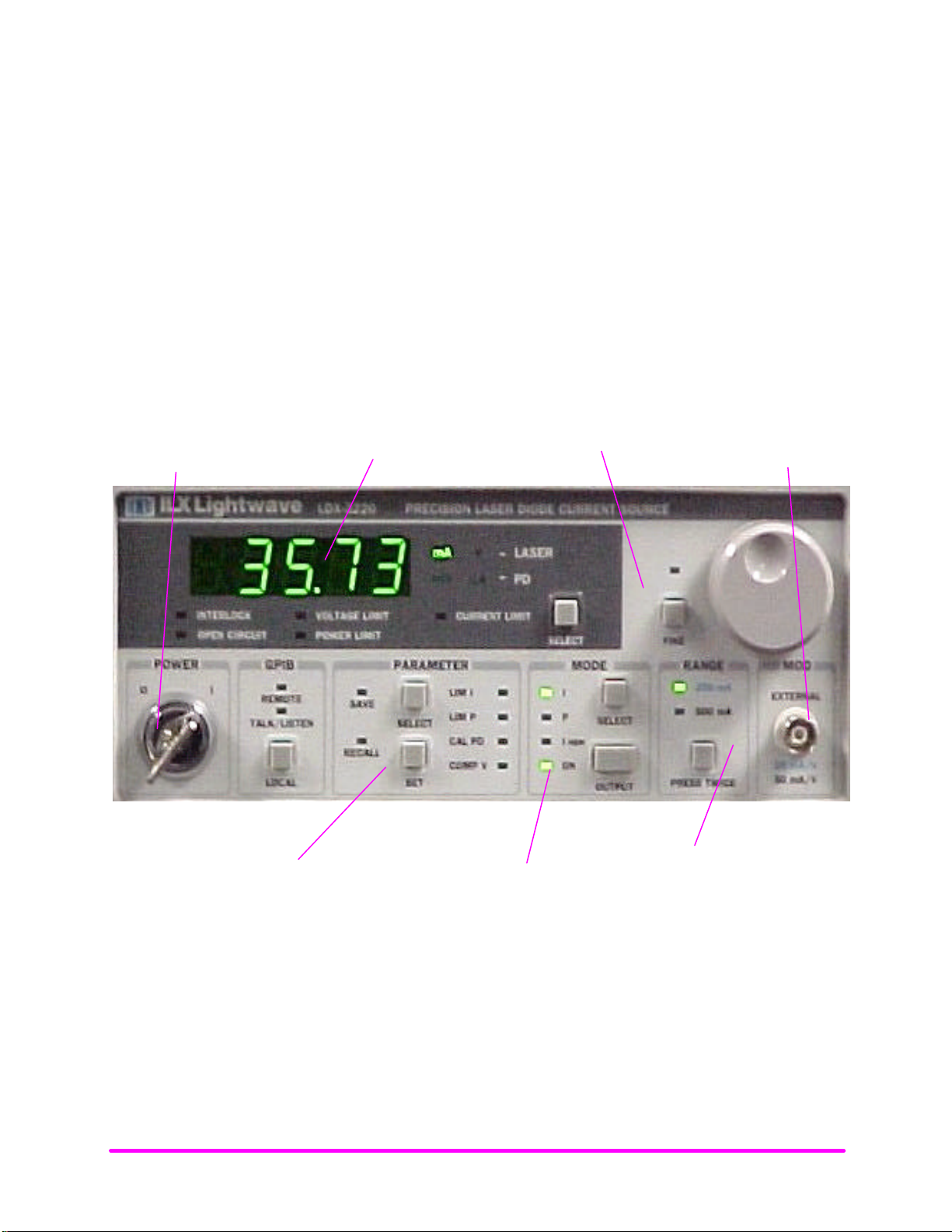

Operating the LDX-3200 Precision Current Source

Now that the LDX-3200 Precision Current Source is installed and ready for use, you can begin to learn about its

operation. The following figures are photographic copies showing the functional keypad groupings, back panel

connectors, and so on. Use these figures to familiarize yourself with the LDX-3200. After that, use Chapter 2 for

fundamentals of operating your instrument.

Power

Switch

Parameter

Selection

Display

Laser Mode

Selection

Adjust Section

Current

Range Selection

Modulation Input

Connector

FIGURE 1.1 LDX 3200 Series Front View

INTRODUCTION TO THE LDX-3200 SERIES CHPT 1

PAGE 4

PD Bias Adjust

LD Connector

GPIB Connector

Trigger Output

Connector

FIGURE 1.2 LDX-3200 Series Rear View

Power Cord

Connector

MAINTENANCE

This section covers information on how to obtain repair services.

WARNING

Potentially lethal voltages exist within the LDX-3200 Series Precision Current Source. To avoid electric shock, do

not perform any of the maintenance on the instrument unless you are qualified to do so. Qualified service personnel

are required to wear protective eyeglasses and anti-static wristbands while working on the LDX-3200 Series

Precision Current Source circuit boards. High voltages are present on and around the instrument’s printed circuit

boards.

INTRODUCTION TO THE LDX-3200 SERIES CHPT 1

PAGE 5

HOW TO OBTAIN REPAIR SERVICES

You may have to return your instrument to the ILX Lightwave facility at some time for repair or service whether it is

under warranty or not. There is a charge for repairs after the warranty period has expired. Contact an ILX Lightwave

service representative for shipping instructions prior to returning the instrument. Have the model number, instrument

serial number and a description of the problem or request at the time of the call. All ILX Lightwave instruments are

identified by a serial number located on the rear panel. The first four or five digits are the model number, the last four

digits are unique to the instrument and identify your instrument specifically. A return authorization number will be

given to you at the time of your request for repair or service. Please use this number in all communications

concerning your instrument.

General Shipping Instructions

If you need to ship your LDX-3200 Precision Current Source back to the factory for repair, be sure that the LDX-3200

is packaged in an enclosure with cushioning material to prevent damage to the instrument during shipment (use the

original shipping containers and accessories if possible). Re-install the ESD protective caps on the rear and front

panels over the connectors (9 pin D, BNC, and GPIB). Shipping damage is not covered under warranty.

Attach a tag to the instrument identifying the owner and indicating the service or repair needed. Include the model

number and serial number. We suggest that you insure the shipment.

In North America, contact ILX Lightwave for return authorization and shipping instructions. Outside of North

America, contact your ILX distributor for the shipping information.

INTRODUCTION TO THE LDX-3200 SERIES CHPT 1

PAGE 6

LDX-3200 SERIES SPECIFICATIONS

±

±

±

±

±

±

±

±

±

±

±

±

±

±

±

±

±

±

±

±

±

±

±

±

±2 µA±2 µA±2 µA±2 µ

Laser Current Source Specifications

Model Number LDX-3210 LDX-3220

DRIVE CURRENT OUTPUT

Output Current Range: 0 to 50 mA 0 to 100 mA 0 to 200 mA 0 to 500 mA

Set-Point Resolution: 1 µA 2 µA 4 µA 10 µA

Set-Point Accuracy (% of FS):

Compliance Voltage: 0 - 10 V, 0 - 10 V, 0 - 10 V, 0 - 10 V,

Temperature Coefficient: <50 ppm/°C <50 ppm/°C <50 ppm/°C <50 ppm/°C

Short-Term Stability (1 hr.):

Long-Term Stability (24 hr.):

Noise and Ripple (µA rms)

High Bandwidth Mode: <1.5 µA <1.5 µA <4 µA <4 µA

Low Bandwidth Mode: <1.5 µA <1.5 µA <2 µA <2 µA

Transients

Operational:

1kV EFT/Surge:

COMPLIANCE VOLTAGE ADJUST

Range: 0 - 10 V 0 - 10 V 0 - 10 V 0 - 10 V

Resolution: 50 mV 50 mV 50 mV 50 mV

Accuracy:

DRIVE CURRENT LIMIT SETTINGS

Range: 1 to 50.5 mA 1 to 101 mA 1 to 202 mA 1 to 505 mA

Resolution: 0.25 mA 0.5 mA 1 mA 2.5 mA

Accuracy:

PHOTODIODE FEEDBACK

Type: Differential Differential Differential Differential

PD Reverse Bias : 0 - 5V, adjustable 0 - 5V, adjustable 0 - 5V, adjustable 0 - 5V, adjustable

PD Current Range : 5 to 5000 µA 5 to 5000 µA 5 to 5000 µA 5 to 5000 µA

Output Stability:

Accuracy, set point (% of FS):

EXTERNAL ANALOG MODULATION

Input: 0-10V, 10k Ω 0-10V, 10kΩ 0-10V, 10kΩ 0-10V, 10kΩ

Transfer Function: 5 mA/V 10 mA/V 20 mA/V 50 mA/V

Bandwidth (3 dB)

High Bandwidth:

Low Bandwidth:

TRIGGER OUTPUT

Type: TTL TTL TTL TTL

Pulse Width: 13 µS 13 µS 13 µS 13 µS

Delay: 12 mS 12 mS 12 mS 12 mS

MEASUREMENT (DISPLAY)

Output Current Range: 0 to 50.000 mA 0 to 100.00 mA 0 to 200.00 mA 0 to 500.00 mA

Output Current Resolution: 0.001 mA 0.002 mA 0.01 mA 0.01 mA

Output Current Accuracy:

Photodiode Current Range: 0 to 5,000 µA 0 to 5,000 µA 0 to 5,000 µA 0 to 5,000 µA

Photodiode Current Resolution: 1 µA 1 µA 1 µA 1 µA

Photodiode Current Accuracy:

PD Responsivity Range:

PD Responsivity Resolution: 0.01 µA/mW 0.01 µA/mW 0.01 µA/mW 0.01 µA/mW

Optical Power Range: 0.00 to 101.00 mW 0.00 to 101.00 mW 0.00 to 505.00 mW 0.00 to 505.00 mW

Optical Power Resolution: 0.01 mW 0.01 mW 0.01 mW 0.01 mW

Forward Voltage Range: 0.000 to 10.000 V 0.000 to 10.000 V 0.000 to 10.000 V 0.000 to 10.000 V

Forward Voltage Resolution: 1 mV 1 mV 1 mV 1 mV

Forward Voltage Accuracy:

5

7

1

0.05%

0.05%

0.05%

0.05%

adjustable adjustable adjustable adjustable

2

3

4

6

8

9

10

11

<10 ppm <10 ppm <10 ppm <10 ppm

<20 ppm <20 ppm <20 ppm <20 ppm

<1 mA <1 mA <1 mA <1 mA

<5 mA/< 8 mA <5 mA/< 8 mA <8 mA/< 12 mA <8 mA/< 12 mA

2.5%

0.5 mA

0.02%

0.05%

DC to 1 MHz DC to 1 MHz DC to 1 MHz DC to 1 MHz

DC to 15 kHz DC to 15 kHz DC to 15 kHz DC to 15 kHz

0.05% FS

0.00 to 1000.00 µA/mW 0.00 to 1000.00 µA/mW 0.00 to 1000.00 µA/mW 0.00 to 1000.00 µA/mW

2.5%

1 mA

0.02%

0.05%

0.05% FS

2.5%

2 mA

0.02%

0.05%

0.05% FS

2.5%

5 mA

0.02%

0.05%

0.05% FS

A

±2 mV ±2 mV ±2 mV ±2 mV

1 All values relate to a one-hour warm-up period.

2 Over any 1-hour period, half-scale output.

3 Over any 24-hour period, half-scale output.

4 Measured optically, evaluating noise intensity of a laser diode into a photodectector with 150 kHz bandwidth. Request ILX Application Note #3.

5 Maximum output current transient resulting from normal operational situations (e.g., power on-off, current on-off), as well as accidental situations (e.g., power line plug

6 Maximum output current transient resulting from a 1000 V power-line transient spike. Tested to ILX Lightwave Technical Standard #LDX-00196. Request ILX Application Note

7 Maximum monitor photodiode current drift over any 30 minute period. Assumes zero drift in responsivity of photodiode.

8 300 mA set point, 60 mA modulation current.

9 Small signal specification is for typ. 10% modulation depth. Large signal spec. assumes 50% modulation depth at mid-scale output.

10 Responsivity value is user-defined and is used to calculate the optical power.

11 Four wire voltage measurement at the load. Voltage measurement accuracy while driving calibration load. Accuracy is dependent upon load and cable used.

removal).

#3.

INTRODUCTION TO THE LDX-3200 SERIES CHPT 1

PAGE 7

GENERAL

Size (H x W x D) 4" x 8.5" x 13.4", 102 mm x 216 mm x 340 mm

Weight

LDX-3210 approx 12 lbs (5.5 kg)

LDX-3220 approx 12 lbs (5.5 kg)

Power (50-60 Hz) 100 V, ±10%

Temperature 0 to +40 °C operating; -40 to +70 °C storage

Humidity < 90 % relative humidity, non-condensing.

Laser Safety Features: Key switch, interlock and output delay (meets CDRH US21 1040.10)

Display type: 5-digit, green LED

120 V, ±10%

220 V, ±10%

230-240 V, ±10%

AVAILABLE OPTIONS AND ACCESSORIES

Options and accessories available for the LDX-3200 Series Precision Current Sources include the following:

DESCRIPTION MODEL NUMBER

Rack mount flange kit Tba

Temperature Controlled Laser Diode Mount LDM-4407

Temperature Controlled Laser Diode Mount

(available with collimating assembly)

DIL Laser Diode Mount LDM-4982

Butterfly Laser Diode Mount LDM-4894

High Power Laser Diode Mount LDM-4442

Current Source Interconnect Cable (unterminated) CC-306S

Current Source Interconnect Cable (terminated) CC-305S

LDM-4412

Other Laser Diode Mounts are available. Please contact ILX Lightwave for information on additional options for your

applications.

INTRODUCTION TO THE LDX-3200 SERIES CHPT 1

PAGE 8

CHAPTER 2 1

HOW TO OPERATE YOUR LDX-3200 1

INTRODUCTION 1

APPLYING POWER TO YOUR LDX-3200 1

The Power-On Sequence 1

The Power-On State 1

CONNECTING TO THE LASER 2

Interlock Connections 4

Photodiode Connections 4

Setting the PD bias 4

Grounding considerations 4

FRONT PANEL OPERATION 5

The Display 5

OPERATING A LASER IN CONSTANT CURRENT, “I” MODE 5

Setting Up the Precision Current Source 5

Conditions Which Will Automatically Shut Off the LASER OUTPUT 6

OPERATING A LASER IN CONSTANT POWER MODE, P 7

Entering Photodiode Responsivity values 7

ERROR INDICATORS 8

HOW TO OPERATE YOUR LDX-3200 CHPT 2

Chapter 2

HOW TO OPERATE YOUR LDX-3200

INTRODUCTION

This chapter introduces you to the operation of the LDX-3200 Series Precision Current Source. It offers instructions

for connecting your laser to the current source, and describes powering up the instrument. This chapter also

contains step by step procedures that teach you how to operate your current source in Constant Current Mode and

Constant Power Mode. We recommend that you review the contents of this chapter at a minimum before operating

the LDX-3200 Series Precision Current Source.

APPLYING POWER TO YOUR LDX-3200

To turn on the LDX-3200, rotate the key in the “POWER” section of the front panel from

“O” to “I”. This action will initiate the power on sequence. If the LDX-3200 does not appear

to turn on, verify that it is connected to line power. If line power is not the problem, remove

the power cord and check the line power fuse.

The Power-On Sequence

During the power-up sequence, the following takes place. For about three seconds all indicators light up, and all of

the 7-segment displays indicate "8". Then all lamps are turned off for three seconds. Next, the firmware version will be

displayed. Then, a self-test is performed to ensure that the instrument’s hardware and processor are communicating.

After this test, the instrument is ready to operate, and is configured to the state it was in when the power was last

shut off.

The Power-On State

You can choose to "clear" the last saved state by recalling the default values. These values are stored in BINS to

which you can save or recall instrument configurations (described in more detail in Chapter 5). "BIN 0" contains all of

the default configurations listed in Table 2.1.

NOTE

If the instrument cannot successfully complete the power on test, an error message of E-512 or E-513 will be

displayed on the Display. See Chapter 3 for a list of error codes and actions to take when your instrument

indicates these errors.

HOW TO OPERATE YOUR LDX-3200 CHPT 2

PAGE 1

LDX-3200 Series DEFAULT CONFIGURATION

GPIB mode in LOCAL via front panel, or in REMOTE via GPIB

PARAMETERS not selected

CAL PD = 0 µA/mW

LIM I (high range) = 125 mA (LDX-3220), 25 mA (LDX-3210)

LIM I (low range) = 50 mA (LDX-3220), 12.5 mA (LDX-3210)

LIM V = 10 volts

LIM P = 1000 mW (LDX-3220), 200 mW (LDX-3210)

LASER output off

LASER DISPLAY enabled, in I mode

Constant I, low bandwidth mode selected

LASER display showing actual current (0.00 with output off)

LASER STEP value = 1 (see LAS:STEP command, chapter 4)

LASER Tolerance values = 1.00 mA, 1.0 seconds

LASER I Set Point = 0 mA

LASER IPD Set Point = 0 µA

LASER PPD Set Point = 0 mW

RECALL BIN number = 0

MODULATION Enabled

Table 2.1 LDX-3200 Series Default Settings

CONNECTING TO THE LASER

When connecting your laser or any other sensitive devices to the LDX-3200 Series Precision Current Source, we

recommend that the instrument be powered up and the LASER output be off (MODE) ON LED unlit. In this

condition, a low impedance shunt is active across the output terminals. When disconnecting devices, it is only

necessary to turn the current source output off.

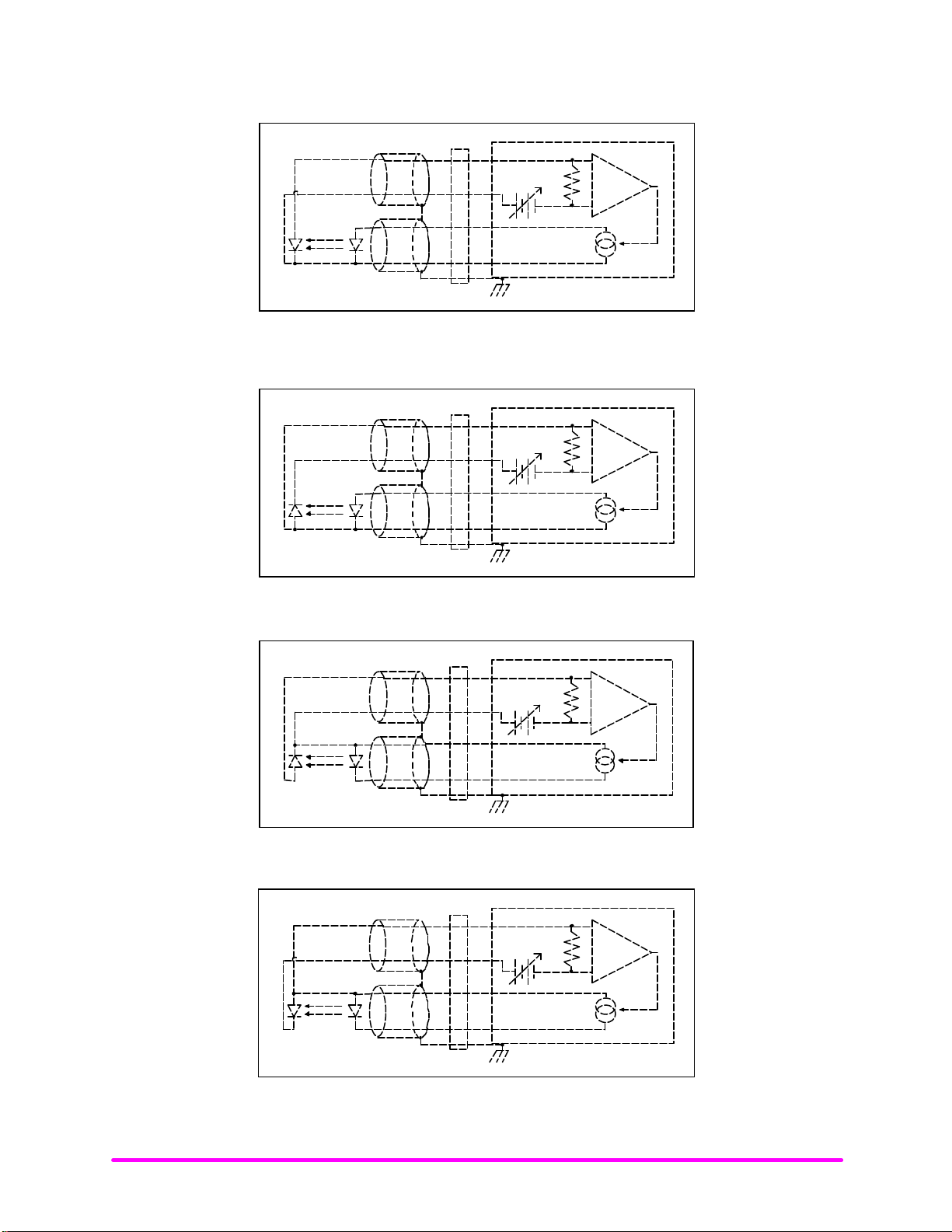

It is also recommended that the connections to the LDX-3200 Series Precision Current Source output be made using

twisted wire pairs with an earth-grounded shield (see Figures 2.1 A - D). The output terminals of the instrument are

left floating relative to earth ground to suppress AC power-on/power-off transients that may occur through an earthground path. If the output circuit is earth-grounded at some point (such as through the laser package and mount), the

user must be careful to avoid multiple earth grounds in the circuit. Multiple earth grounds may provide circuit paths

that induce spurious currents in the photodiode feedback circuit and output leads.

IMPORTANT

Experience indicates that should an open circuit occur during laser operation (while the LASER is ON),

the laser may be damaged by a momentary circuit break-and-remake before the final circuit break. The

cable connections to the laser must be secure enough that they will not open-circuit, should they be

jostled or bumped.

Figures 2.1A - D show the possible configurations of connecting laser diodes and photodiodes with the LDX-3200

Series Precision Current Source.

HOW TO OPERATE YOUR LDX-3200 CHPT 2

PAGE 2

+

-

LDX-3200 Series Precision Current Source

OUTPUT

+

-

LDX-3200 Series Precision Current Source

+

-

LDX-3200 Series Precision Current Source

+

-

LDX-3200 Series Precision Current Source

7

Bias

+

6

9

5

P. D. L. D.

3

Earth Ground

Figure 2.1A Common Laser Cathode - Photodiode Cathode

OUTPUT

7

Bias

+

6

9

5

P. D. L. D.

3

Earth Ground

Figure 2.1B Common Laser Cathode - Photodiode Anode

OUTPUT

7

Bias

+

6

9

5

P. D. L. D.

3

Earth Ground

Figure 2.1C Common Laser Anode - Photodiode Cathode

OUTPUT

7

Bias

+

6

9

5

P. D. L. D.

3

Earth Ground

Figure 2.1D Common Laser Anode - Photodiode Anode

HOW TO OPERATE YOUR LDX-3200 CHPT 2

PAGE 3

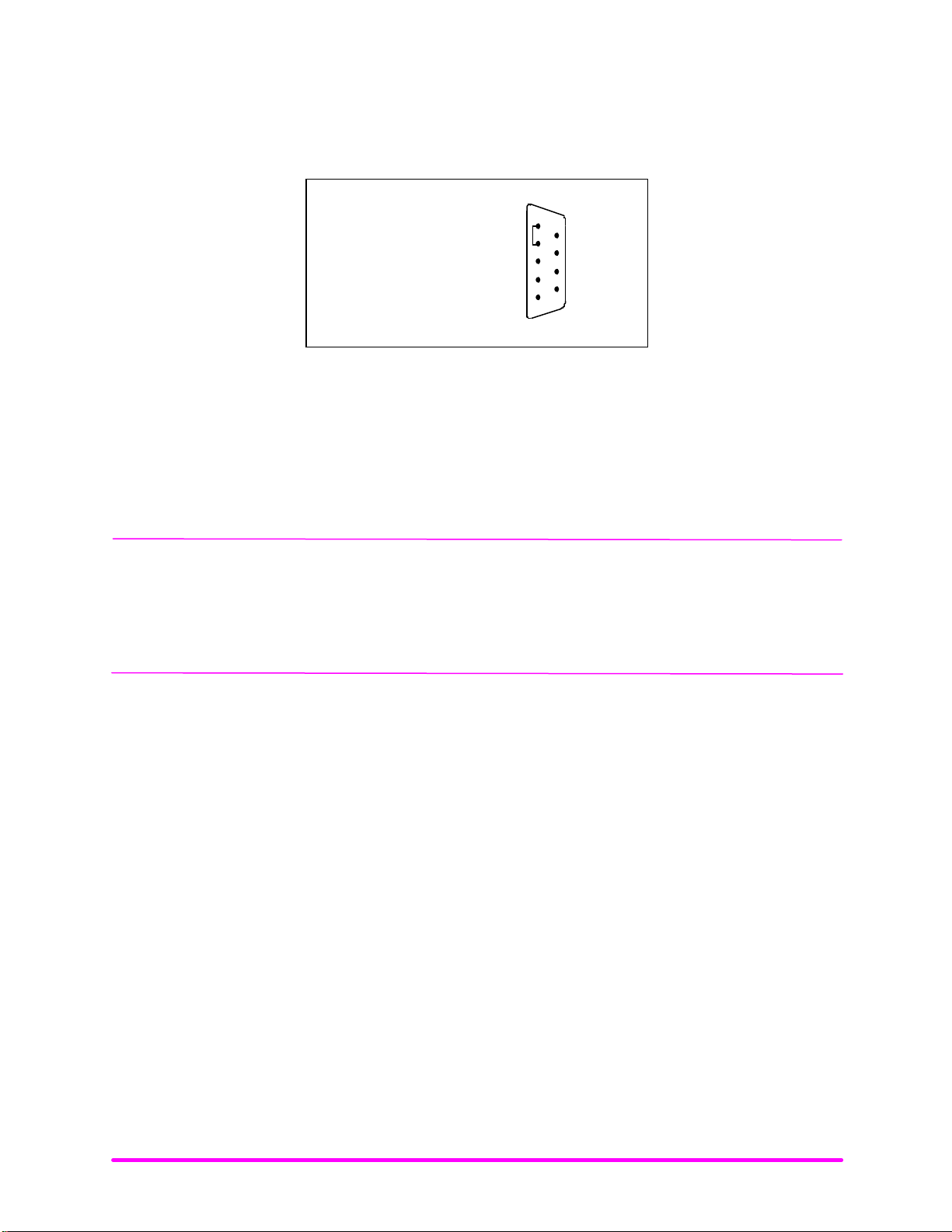

The 9-pin connector marked CURRENT SOURCE on the back panel is used to connect your laser diode to the

6

LDX-3200. There are connections provided for laser cathode and anode, photodiode cathode and anode, chassis

ground and interlock. The pinout diagram for this connector is shown in Figure 2.2.

1, 2 Interlock

3 Chassis Ground

4 Cathode Voltage Sense

5 Laser Cathode

6 PD Cathode (+)

7 PD Anode (-)

8 Anode Voltage Sense

9 Laser Anode

1

2

7

3

8

4

9

5

Figure 2.2 Back Panel LD Connector

Interlock Connections

In order for the laser output to be enabled a short circuit must exist between the Interlock pins (pins 1 and 2) of the

connector. The short can be a direct short across the pins or a switch to prevent laser operation until the switch is

closed. If a short does not exist between these two pins, the INTERLOCK LED will illuminate on the front panel and

the laser output will be disabled.

CAUTION

The interlock terminals on the LASER connector, pins 1 and 2, must be kept isolated from all other connections

including earth ground.

Photodiode Connections

Many laser diode modules contain an internal photodiode that monitors the back-facet emission of the laser. Usually,

this photodiode is internally connected to either the laser anode or cathode.

The photodiode and laser connections to the LDX-3200 Series Precision Current Source are electrically isolated from

ground and each other. So, if a 4-pin connection is made (no common connections) no additional jumpers are

required. Figures 2.1A - 2.1D show the recommended connections and shielding for 3-pin lasers (where the common

connection is internal to the device). A 4-pin laser should be connected with the same shielding as shown in Figure

2.1, but the common connection (between the photodiode and the laser) is optional.

Setting the PD bias

The LDX-3200 Series Precision Current Source provides an adjustable reverse bias of 0 - 5 VDC for the photodiode.

To set the photodiode bias to 5 volts reverse bias, turn the back panel PHOTODIODE BIAS ADJUST fully clockwise.

To set the photodiode bias to 0 volts reverse bias, turn the back panel PHOTODIODE BIAS ADJUST fully counterclockwise

Grounding considerations

The LASER outputs of the LDX-3200 Series Precision Current Source are isolated from chassis ground allowing

either output terminal to be grounded at the user's option. Figure 2.1 shows the proper earth-ground shielding for

laser diode/photodiode connections.

HOW TO OPERATE YOUR LDX-3200 CHPT 2

PAGE 4

FRONT PANEL OPERATION

This section describes fundamentals of operation for your LDX-3200 Series Precision Current Source in two

operating modes, Constant Current (I), and Constant Power (P).

The Display

The digital display is used to show control parameters such as laser

drive current (mA), laser current limit (mA), laser forward voltage (V),

voltage limit (V), monitor photodiode current (µA), and laser optical

power (mW) in both set point and measurement modes. It will also

display error codes that relate to LASER operation. Error indicators

underneath the display indicate control errors and are explained in the section titled “ERROR INDICATORS”. All

laser control parameters are displayed on this digital display with the appropriate annunciator illuminated.

OPERATING A LASER IN CONSTANT CURRENT, “I” MODE

Suppose you have an LDX-3220 and you want to run the instrument in Constant Current, low bandwidth mode, with

a set point of 150 mA and a current limit of 175 mA. This particular mode uses a low-pass filter on the laser drive

current output to significantly reduce noise. In this mode a modulation input of up to 15 kHz may be used, via the

front panel MOD EXTERNAL connector. Follow the instructions below in the sequence presented.

Setting Up the Precision Current Source

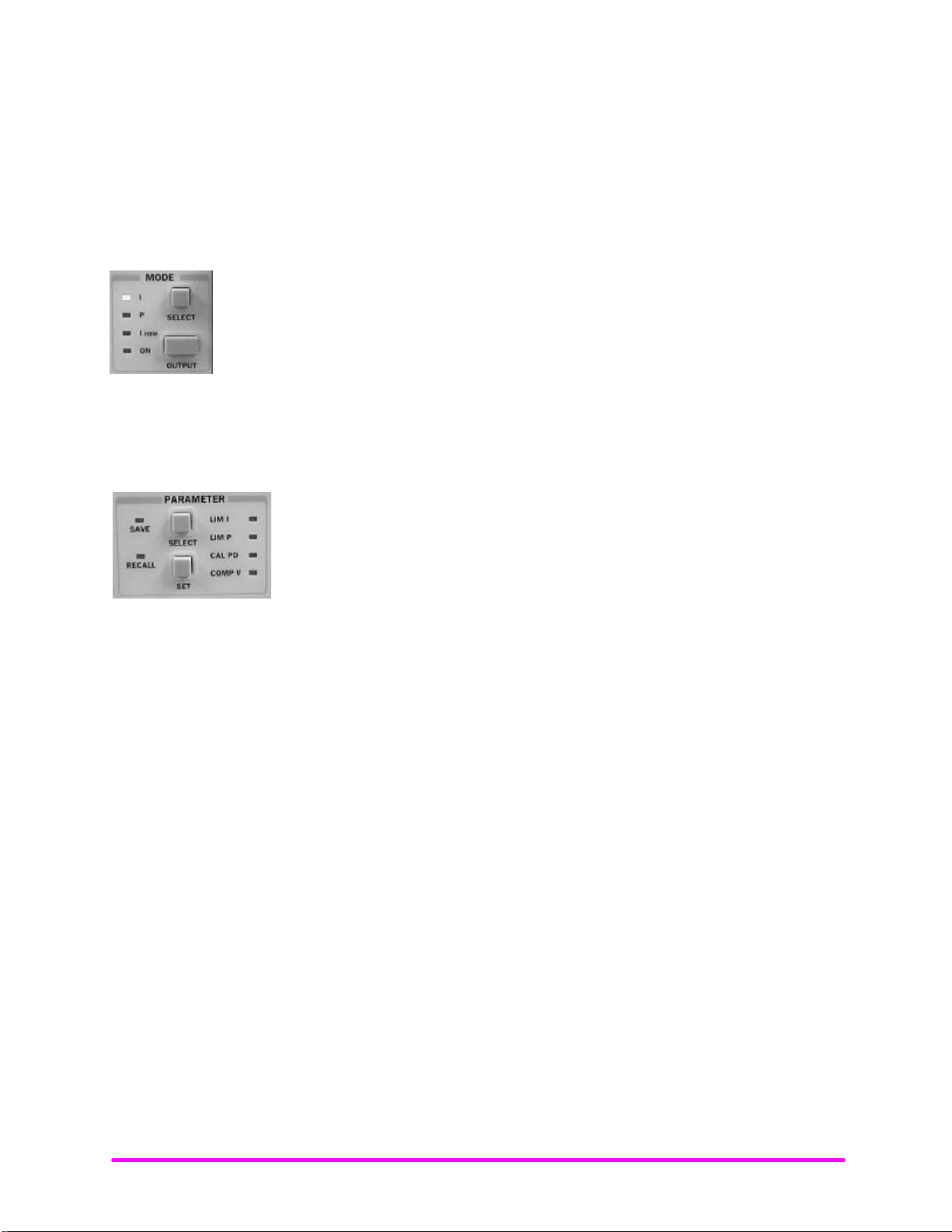

Set the LDX-3200 in Constant Current, low bandwidth mode by selecting I in the MODE

section of the front panel. Do this by toggling the SELECT push button until the I indicator

is illuminated. Repeatedly pressing the (MODE) SELECT switch cycles through the current

(I), light power (P), or high-bandwidth current (I

Next, in the RANGE section set the current source range by selecting the 200 mA range

indicated by the accompanying LED. You will need to press the SELECT push button twice to

change the range. It must be pressed twice quickly (within less than 1 second) to switch

between ranges, and the LASER output must be off (LASER MODE ON indicator unlit) in order

to change ranges.

Configure the display so that it reads laser current in mA. Press and release the SELECT switch in the DISPLAY

section of the front panel until the mA annunciator is lit. The (DISPLAY) SELECT switch is also used to select the

I

(photodiode current, µA), PPD (laser power, mW), or V (forward voltage, V) measurement or set point display

PD

modes. When the set point mode is active, the corresponding annunciator will flash to indicate set point rather than

measurement display.

) control modes.

HBW

To just view the set point, press and hold down the display SELECT switch for two or more seconds. When the

SELECT switch is released the previous measurement mode will be restored.

HOW TO OPERATE YOUR LDX-3200 CHPT 2

PAGE 5

At this point the LDX-3200 Series current source is in Constant Current Mode, (I), in the 200 mA range, and the

display is reading in mA. Next, we need to adjust the set point of the laser current source.

To adjust the set point of the current source to 150 mA, turn the adjust knob to vary the set point. When the adjust

knob is turned, the LDX-3200 automatically changes to set point mode indicated by the flashing annunciator. Adjust

the set point to 150 mA. After an adjustment has been made, and the adjust knob is released, the set point mode will

time out in three seconds. The display will revert to the original measurement display mode (I, IPD, V, or PPD).

We’re not quite ready to turn on the laser. One of the laser protection features our precision current sources offer is a

fully independent hardware current limit. The current limit protects your laser by never allowing the laser drive

current to exceed the limit independent of the set point and the output control mode (Constant Current or Constant

Power).

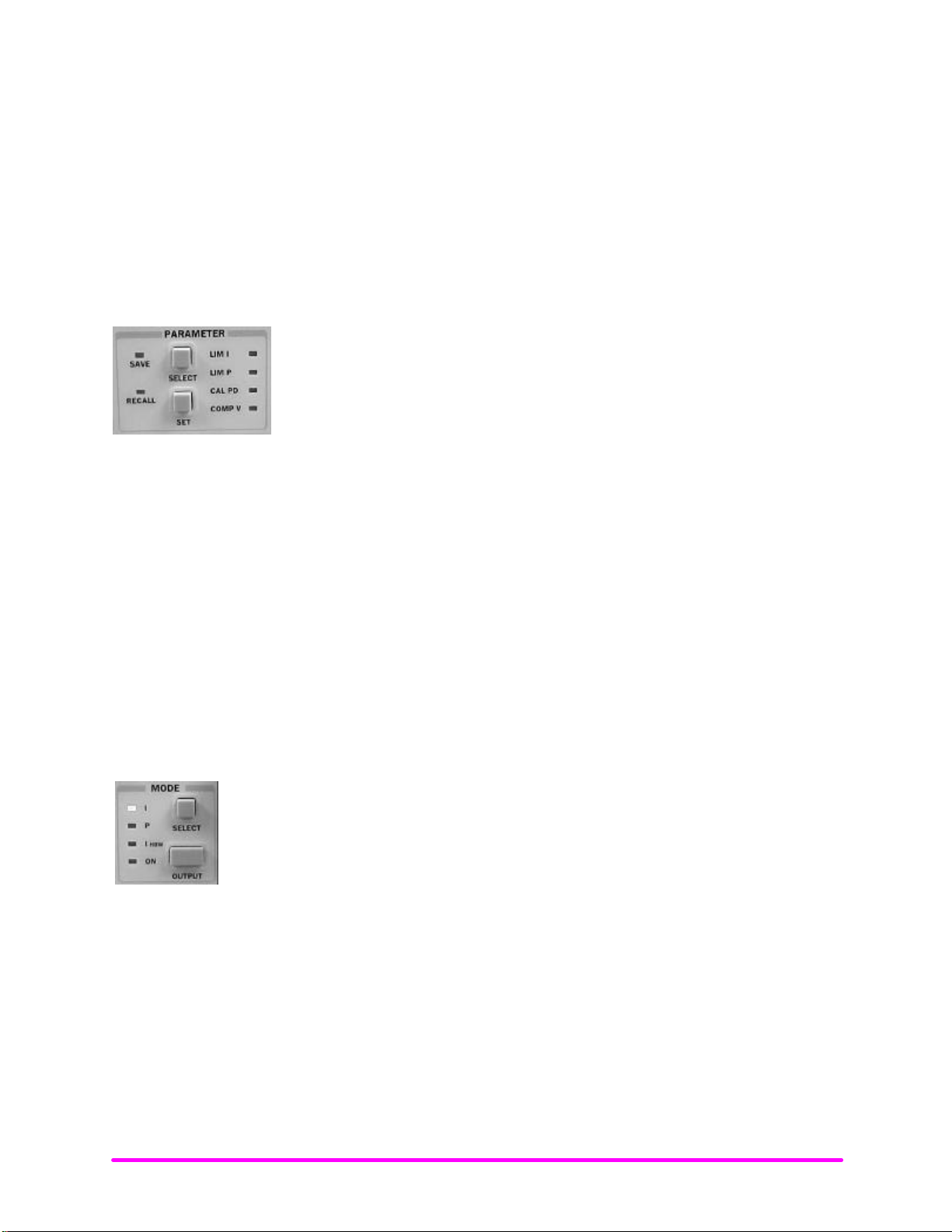

To set the current source limit, use the SELECT push button in the PARAMETER

section of the front panel to select LIM I . Press and hold the (PARAMETER) SET

push button and rotate the adjust knob to vary the limit set point value. Set the limit

to 175 mA. Once the (PARAMETER) SET push button is released, the new

parameter value is stored in non-volatile memory.

When the LASER current limit is reached, the CURRENT LIMIT error indicator flashes. The current limit setting is

independent of the voltage drop of the device connected to the LASER output, and therefore, no dummy load is

required for precise adjustment of the current limit. Furthermore, since the current limit circuitry is fully independent

of the main current control, the current limit can be adjusted safely, even while the LASER output is active.

An additional feature of the LDX-3200 Series instruments is an adjustable voltage limit. This allows an extra level of

laser protection in the event of an intermittent open circuit. For maximum protection via the fastest open-circuit

detection, the voltage limit should be set to a value slightly greater than the intended operating voltage.

To set the LASER voltage limit, use the SELECT push button in the PARAMETER section of the front panel to

select COMP V and then press and hold the (PARAMETER) SET push button. While holding the (PARAMETER)

SET push button, adjust the voltage limit using the adjust knob.

Now you are ready to enable the current source output for your laser diode.

In the MODE section of the front panel, press the push button labeled OUTPUT. The

accompanying LED labeled ON will illuminate, indicating that the laser current source’s

output is enabled. The instrument will drive the current source to the value set by the

corresponding MODE set point. When the LASER output is off, an internal short is placed

across the LASER output. The OUTPUT switch has a toggling action. Pressing the switch

again will disable the current source output and the ON LED will not be illuminated. The

default condition for the current source output is off when the instrument is first powered up.

With the laser output enabled, the LASER display should be indicating measured laser current. If the output won’t

function, check the following conditions:

Conditions Which Will Automatically Shut Off the LASER OUTPUT

The following conditions will automatically cause the instrument to disable the current source output:

1. LASER High Power Limit

2. LASER Interlock/Key Lock turned off

3. LASER Open Circuit or Voltage Limit

HOW TO OPERATE YOUR LDX-3200 CHPT 2

PAGE 6

OPERATING A LASER IN CONSTANT POWER MODE, P

Suppose you want to operate a 3 mW laser at constant 1 mW level. The LDX-3200 Series instrument allows you to

operate the laser current source driver in a Constant Power mode. In this mode, the LDX-3200 Series instrument

drives current to the laser to reach a set point power value (in mW). The control loop feedback parameter is

photodiode current that the LDX-3200 converts to optical power via a user-defined photodiode responsivity number.

If laser power changes due to internal or environmental conditions, the LDX-3200 will increase/decrease the current

to the laser to maintain the power set point. The following paragraphs detail the instrument configuration in Constant

Power Mode.

To set the LDX-3200 in Constant Power mode, select P in the MODE section of the front panel

by toggling the SELECT push button. Repeatedly pressing the (MODE) SELECT switch

cycles through the current (I), light power (P), or high bandwidth current (I

HBW

) control

modes. The LED indicator shows the selected mode.

Entering Photodiode Responsivity values

The photodiode responsivity, CAL PD, is used to convert between photodiode

current and optical power of the laser diode. To enter the CAL PD parameter, select

CAL PD with the (PARAMETER) SELECT push button by toggling down past LIM

P. The indicator becomes lit when CAL PD is selected and the display indicates the

responsivity parameter in µA/mW (not enunciated). Rotate the adjust knob while

holding the (PARAMETER) SET push button to enter a new value for responsivity.

When the correct value is displayed, store the number by releasing the

(PARAMETER) SET pushbutton.

A method to calculate the responsivity is suggested below.

1. Measure (with a calibrated detector) the output power of the device.

2. Measure the corresponding photodiode current.

3. Calculate the responsivity by dividing the photodiode current by the optical power noting the units

required are µA/mW.

The LDX-3200 Series Precision Current Source can be put into a special mode with the CAL PD parameter set to zero.

When the CAL PD value is zero, the LASER output will be controlled to the IPD set point value. Therefore, the

instrument is in Constant IPD mode. The display will indicate "-.-" for the power measurement.

Next, configure the display so that it reads in mW by pressing and releasing the (DISPLAY) SELECT switch until the

mW annunciator is lit.

Adjust the Constant Power set point of the LDX-3200 to 1.00 mW. To do this, turn the adjust knob to vary the set

point. When the adjust knob is turned, the LDX-3200 automatically changes to set point mode as indicated by the

flashing annunciator. Adjust the set point to 1.00 mW. After an adjustment has been made, and the adjust knob is

released, the set point mode will time out in three seconds. The display will then return to the measurement display

mode (I, IPD, V, or PPD).

Before the laser output is enabled, the power limit for the laser under test should be set. In Constant Power mode, this

is accomplished by setting a Power limit, LIM P value. The LDX-3200 uses the responsivity value entered to calculate

a power limit as a function of monitor current (Ipd). This is a software limit only.

HOW TO OPERATE YOUR LDX-3200 CHPT 2

PAGE 7

To set the Constant Power limit, use the SELECT push button in the PARAMETER section to select LIM P. When

the LIM P is indicated by the accompanying LED, the display will indicate the limit set point in mW. Press and hold

the (PARAMETER) SET push button and rotate the adjust knob to set the limit to 1.50 mW. When the desired value

is reached, release the (PARAMETER) SET push button to store the new limit value.

The LIM P is the absolute limit of optical power, as detected by the unit via the monitor PD feedback loop. In order

for this limit to be meaningful, the monitor photodiode responsivity (CAL PD) must be adjusted correctly. This limit

is a software limit only. The LASER output is normally turned off if this limit is reached (See LASer:ENABle:OUTOFF

command in Chapter 4 for instructions on disabling this function). The maximum LIM P value is 100.0 mW (LDX-

3210), and 500.0 mW (LDX-3220).

Also, in constant power mode the LASER current limit and voltage limit values are in effect. Refer to the discussion

on page 8 that describes how to set these limits.

Now the instrument is configured to operate in Constant Power Mode. In the MODE section,

enable the output of the laser current source by depressing the OUTPUT push button once.

The accompanying led labeled ON will illuminate indicating that the laser output is on and

current is being driven to the laser. The LDX-3200 current source will drive the laser to the

Constant Power set point and maintain closed loop control with the PD current measurement.

ERROR INDICATORS

The LDX-3200 Series Precision Current Sources indicate general operational error conditions. Each error condition

results in an action as shown in the following table.

ERROR INDICATORS

Error Condition Action

Interlock Output off, INTERLOCK light flashes at 1 Hz

Open circuit Output off, OPEN CIRCUIT light flashes at 1 Hz.

If this condition was caused by an excessively high

compliance voltage, the VOLTAGE LIMIT light will also

be turned on.

Current limit CURRENT LIMIT light flashes at 1 Hz

Voltage limit VOLTAGE LIMIT light flashes at 1 Hz. This indicator warns that the

output is within 0.25 volts of LIM V setting. If the voltage limit (LIM

V) is reached, the LASER output will shut off.

Optical Output Power Limit Output off, POWER LIMIT light flashes at 1 Hz

Table 2.2 LDX-3200 Error Indicators

HOW TO OPERATE YOUR LDX-3200 CHPT 2

PAGE 8

CHAPTER 3 1

OPERATING IN REMOTE CONTROL 1

INTRODUCTION 1

Reading the GPIB Address 1

Changing the GPIB Address 1

Changing Operation from Local to Remote 1

LDX-3200 SERIES CURRENT SOURCE COMMAND SET 2

Command Syntax 2

Command Paths 4

IEEE488.2 Common Commands 5

LDX-3200 Current Source Often Used Commands 6

STATUS REPORTING 7

Event and Condition Registers 7

Operation Complete Definition 7

Output Off Register 9

Command Timing and Completion 10

Error Messages 11

OPERATING IN REMOTE CONTROL CHPT 3

Loading...

Loading...