User’s Guide

LDT-5900 Series Temperature Controllers

High Power

Temperature Controller

LDT-5980

and

Precision

Temperature Controller

LDT-5948

ILX Lightwave Corporation P. O. Box 6310 Bozeman, MT, U.S.A. 59771 : · · · 1-800-459-9459 · ·

www.ilxlightwave.com

U.S. & Canada International Inquiries: 406-556-2481 Fax 406-586-9405

E-mail: support@ilxlightwave.com

70036602_R00_09_05

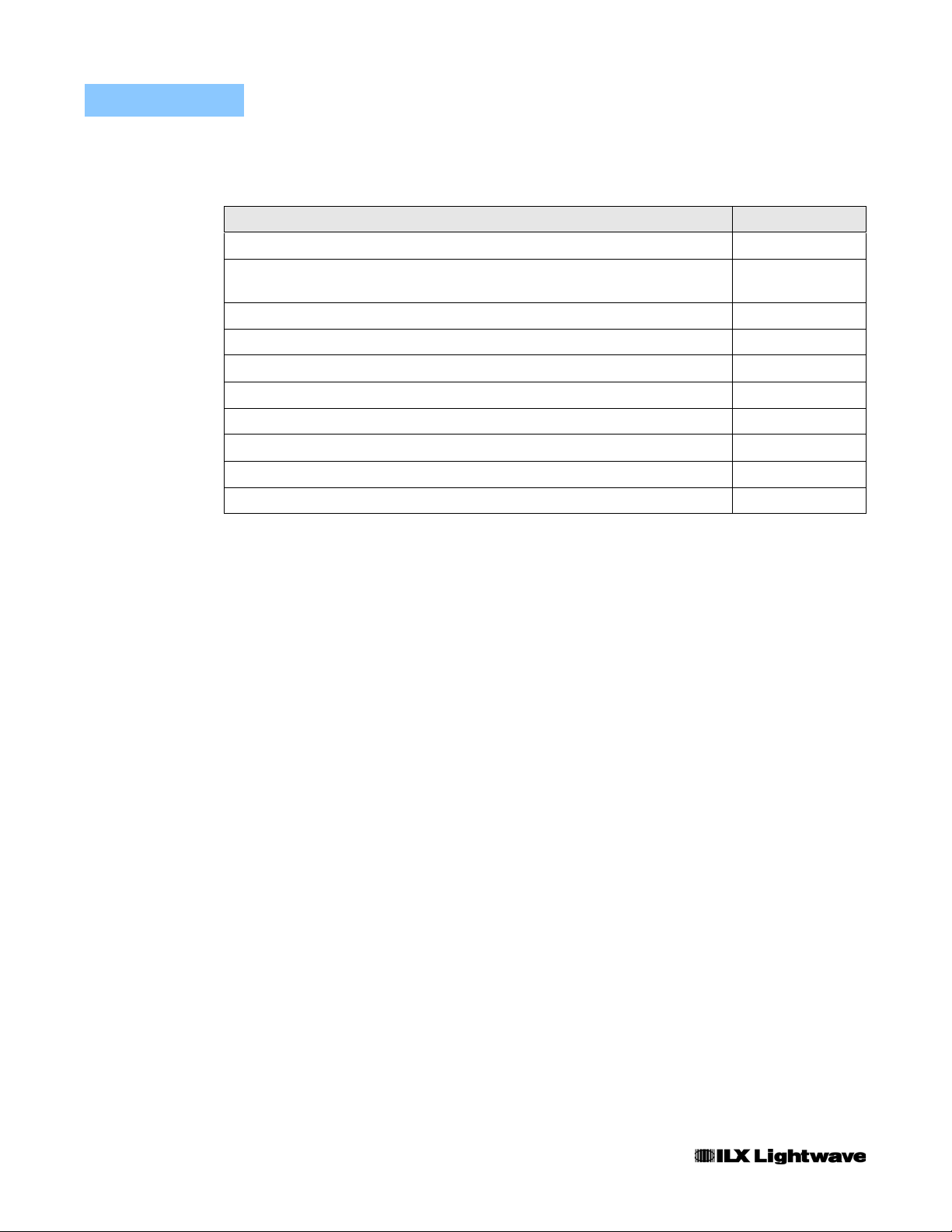

TABLE OF CONTENTS

TABLE OF CONTENTS

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

List of Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

List of Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Safety and Warranty Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Safety Information and the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

General Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Safety Marking Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Returning an Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Claims for Shipping Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xii

Comments, Suggestions, and Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Chapter 1 Introduction and Specifications

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installing the LDT-5900 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Grounding Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

AC Line Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Tilt-Foot Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

09_05 LDT-5980/5948 i

TABLE OF CONTENTS

Available Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 2 Operations

Front Panel Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Rear Panel Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Rear Panel Controls and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

AC Power Entry Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Trigger Input Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Trigger Output Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

GPIB Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

General Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Warm Up and Environmental Considerations . . . . . . . . . . . . . . . . . . . . . . . . 12

Rear Panel Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

TEC Grounding Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Front Panel Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Display Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Adjust Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Measurement and Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

System Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Parameter Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

PID / AUTO-TUNE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Auto-Tune Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Modifying the PID Coefficients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

LIMITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

SAVE / RECALL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Mode Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

R

SNSR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

ITE or V

R

Basic TEC Operation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

General Guidelines for Sensor Selection and Safety Limits . . . . . . . . . . . . . 34

Sensor Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Setting Safety Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

TE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

AC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

ii LDT-5980/5948

Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Chapter 3 Remote Operations

Remote Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

GPIB Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Reading the GPIB Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Changing the GPIB Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

RS-232 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Reading the Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Changing the Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Remote Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Changing Operation from Local to Remote . . . . . . . . . . . . . . . . . . . . . . . . . 43

GPIB Versus RS-232 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Command Syntax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Letters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

White Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Terminators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Command Separators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Syntax Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

TABLE OF CONTENTS

IEEE 488.2 Common Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Command Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Sequential/Overlapped Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Query Response Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Status Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Status Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Event Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Output Off Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Chapter 4 Command Reference

GPIB Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Command Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

09_05 LDT-5980/5948 iii

TABLE OF CONTENTS

Chapter 5 Calibration and Troubleshooting

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Recommended Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

iv LDT-5980/5948

LIST OF FIGURES

LIST OF FIGURES

Figure 2.1 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Figure 2.2 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Figure 2.3 Trigger Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Figure 2.4 Rear Panel TEC Connector . . . . . . . . . . . . . . . . . . . . . . .12

Figure 2.5 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Figure 2.6 Auto Tuning Process . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Figure 2.7 Example Thermistor Resistance vs. Temperature . . . . .35

Figure 3.1 LDT-5900 Command Path Structure . . . . . . . . . . . . . . . .47

12_02 LDT-5980/5948 v

LIST OF FIGURES

vi LDT-5980/5948

LIST OF TABLES

LIST OF TABLES

Table 2.1 PID Constant Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Table 3.1 Substitute Parameter Names . . . . . . . . . . . . . . . . . . . . . .46

Table 3.2 Invalid Syntax Command Strings. . . . . . . . . . . . . . . . . . . .48

Table 3.3 LDT-5900 Status Registers: Status Register 0 . . . . . . . . .51

Table 3.4 LDT-5900 Status Registers: Status Register 1 . . . . . . . . .52

Table 3.5 LDT-5900 Event Register Contents: Event Register 0. . . . 54

Table 3.6 LDT-5900 Event Register Contents: Event Register 1. . . . 55

Table 3.7 LDT-5900 Output Off Register Contents: Output Off Enable Register

0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Table 3.8 LDT-5900 Output Off Register Contents: Output Off Enable Register

1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Table 3.9 Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

12_02 LDT-5980/5948 vii

LIST OF TABLES

Table 4.1 GPIB Command Summary Reference List . . . . . . . . . . . .62

Table 5.1 Problem and Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

Table 5.2 LDT-5980/5948 Error Codes . . . . . . . . . . . . . . . . . . . . . .129

viii LDT-5980/5948

CHAPTER 1

INTRODUCTION AND SPECIFICATIONS

This manual contains operation and maintenance information for the LDT-5900

Series Temperature Controllers. If you want to get started right away, read

Chapter 2, which covers Operations, first.

Our goal is to make the best laser diode instrumentation available anywhere. To

achieve this, we need your ideas and comments on ways we can improve our

products. We invite you to contact us at any time with your suggestions.

If any of the following symptoms exist, or are even suspected, remove the LDT-5900

Series Temperature Controller from service. Do not use until trained service personnel

can verify safe operation.

Visible damage

Severe transport stress

Prolonged storage under adverse conditions

Failure to perform intended measurements or functio ns

If necessary, return the LDT-5900 Series Temperature Controller to ILX Lightwave for

service and repair to ensure that safety features are maintained. Follow the “Returning an

Instrument” process described on page xi.

Potentially lethal voltages exist within the LDT-5900 Series Temperature Controllers. To

avoid electric shock, do not perform any maintenance on the instrument unless you are

qualified to do so. Qualified service personnel are required to wear protective eye wear

and anti-static wristbands while working on the LDT-5900 Series circuit boards. High

voltages and high currents are present on and around the printed circuit boards.

LDT-5980/5948 1

CHAPTER 1

INTRODUCTION AND SPECIFICATIONS

Product Overview

Product Overview

The LDT-5900 Series Temperature Controllers consists of two family members,

the LDT-5948 60W Precision Temperature Controller and the LDT-5980 120W

High Power Temperature Controller. These instruments are bi-directional current

sources with precision measurement circuits to monitor and control the

temperature of the device under test. They have the following operating

characteristics:

• PWM (pulse width modulated) output power of 60 W for the LDT-5948;(5A @ 12V DC) and

120 W for the LDT-5980 (10A @ 12V DC)

• 0.001 oC set point resolution

modes

o

C stability

• 0.005

• Constant temperature, constant current, constant resistance and constant voltage control

• Compatible with thermistors, IC and RTD temperature sensors

• Four-wire sensor measurements

• Four-wire TEC voltage measurement

• AC resistance measurement

• Heating and cooling temperature and current limits

• Software controlled PID feedback loop control

• PID Autotune mode

• IEEE GPIB and RS-232 remote interfaces

• Programmable triggers

• Closed case calibration

2 LDT-5980/5948

INTRODUCTION AND SPECIFICATIONS

Installing the LDT-5900

Installing the LDT-5900

This section provides information about the necessary requirements to install a

LDT-5900 Series Temperature Controller and how to begin operating the

instrument.

Initial Inspection

Verify that the following items were shipped with the instrument:

• LDT-5900 User’s Guide

• Power Cord

When unpacking the instrument, make sure to save the packaging an d protective

Electrostatic Discharge (ESD) cap on the rear of the instrument, in case you have

to return the instrument to ILX Lightwave. Shipping damage is not covered under

the standard instrument warranty.

Grounding Requirements

CHAPTER 1

The LDT-5900 Series Temperature Controller comes with a three-conductor AC

power cable. The power cable must be plugged into an approved three-contact

electrical outlet or used with a three-contact to two-contact adaptor with the

grounding wire connected to an electrical ground (safety ground). ILX Lightwave

recommends connecting the instrument only to properly earth-grounded

receptacles. The power cord connector and power cable meet IEC safety

standards.

AC Line Power Requirements

This instrument operates from a single-phase power source delivering line

voltages of 100-240 VAC (all values RMS), from 50-60 Hz.

Tilt-Foot Adjustment

The LDT-5900 Series comes standard with folding front legs and two rear feet for

use as a benchtop instrument. Extend the front legs to tilt the front panel upward,

making it easier to read the display.

Rack Mounting

The LDT-5900 Series Temperature Controllers conform to international standards

for a 2U height 1/2 width rack mounting. Rack mount accessory kits contain

detailed mounting instructions.

09_05 LDT-5980/5948 3

CHAPTER 1

INTRODUCTION AND SPECIFICATIONS

Available Options and Accessories

Available Options and Accessories

Description Model Number

Single Rack Mount Kit (enables installation into a standard 19 inch rack) RM-139

Dual Rack Mount Kit (enables installation of two LDT-5900 instruments into a

standard 19 inch rack)

Temperature Controlled Laser Diode Mount 498X

High Power Laser Diode Mount 4442

5900 TE Controller / Unterminated 10A Interconnect Cable (6 feet) CC591H*

5900 TE Controller / Laser Diode Mount 5A Interconnect Cable (6 feet) CC595H*

Calibrated 10 Kohm Thermistor 510

Uncalibrated 10 Kohm Thermistor 520

Uncalibrated AD590LH IC Temperature Sensor 530

Uncalibrated LM335 IC Temperature Sensor 540

* To prevent fire hazard, ILX recommends using only the CC59XH Series cables with the 5900

Series Temperature Controllers. Unless properly configured, use of other cables may lead to fire

hazard and may limit the controller’s maximum output current. See Chapter 2 for more details.

RM-140

Other laser diode mounts, sensors and accessories are available. Please contact

ILX Lightwave for information on additional options for your applications.

4 LDT-5980/5948

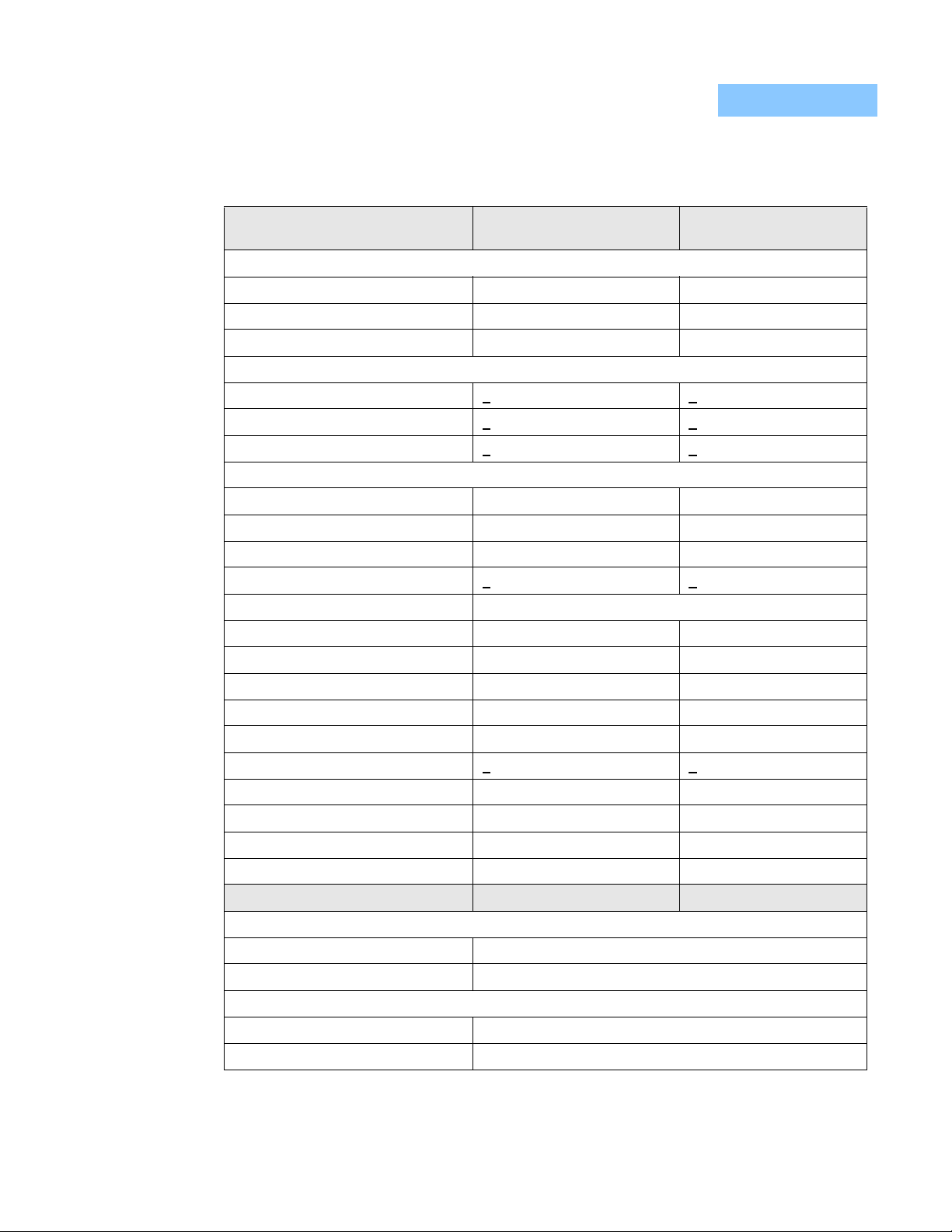

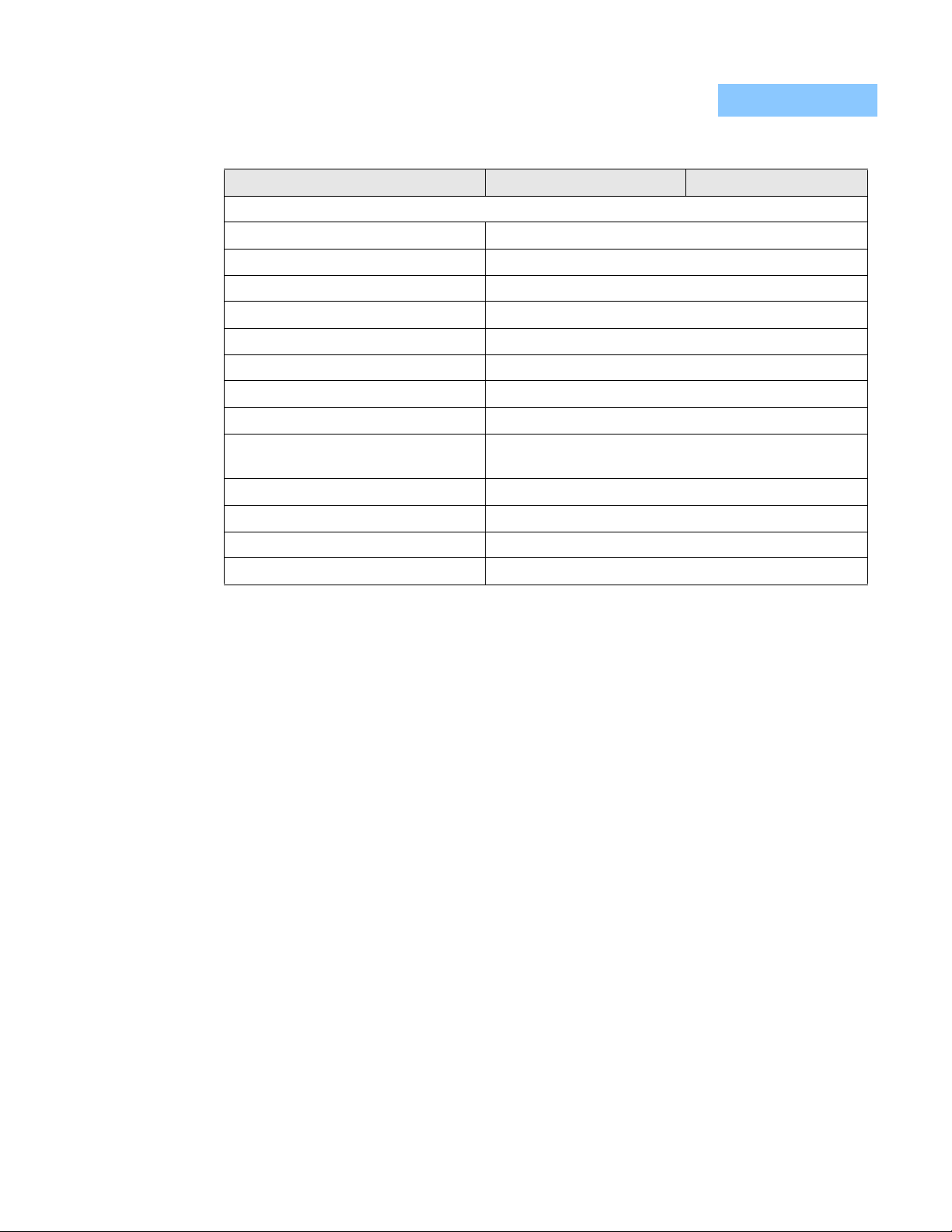

Specifications

INTRODUCTION AND SPECIFICATIONS

Specifications

CHAPTER 1

TEMPERATURE CONTROL

OUTPUT

1

Temperature Control Range

Thermistor Sensor

IC Sensor

RTD

Set Point Accuracy

3

T Mode

Mode

I

TE

4

Mode

V

TE

2

LDT-5948 LDT-5980

o

-50.000

-50.000

-50.000

C to +250.000 oC -50.000 oC to +250.000 oC

o

C to +150.000 oC -50.000 oC to +150.000oC

o

C to +199.999 oC -50.000 oC to +199.999 oC

+0.005 oC+0.01 oC

+0.03 A +0.03 A

+0.05 V (typical) +0.05 V (typical)

Set Point Resolution

T Mode

Mode

I

TE

Mode

V

TE

Temperature Stability (24 hours)

5

o

C 0.001 oC

0.001

0.001 A 0.001 A

0.001 V 0.001 V

+0.005 oC+0.005 oC

Output Type Bidirectional current source

Compliance Voltage 12V DC 12V DC

Output Current Range -5.000 to 5.000 A -10.000 to 10.000 A

Maximum Output Power 60W 120W

Current Noise and Ripple

6

15 mA rms (typical) 15 mA rms (typical)

Current Limit Range -5 to 5 Amps -10 to 10 Amps

Current Limit Set Accuracy +0.050 Amps +0.050 Amps

Control Algorithm

Proportional Term

Integral Term

Derivative Term

7

Software PID Loop Software PID Loop

0 to 9999.99 0 to 9999.99

0 to 999.999 0 to 999.999

0 to 999.999 0 to 999.999

TEMPERATURE SENSOR LDT-5948 LDT-5980

Types

Thermistor

RTD Sensor

NTC (2-wire)

Platinum 100 Ω / 1000 Ω

IC Sensor

IC-V (LM-335)

IC-I (AD-590)

Voltage output, 5 mV/

Current output, 1µA/

o

C to 14mV/oC

o

K

09_05 LDT-5980/5948 5

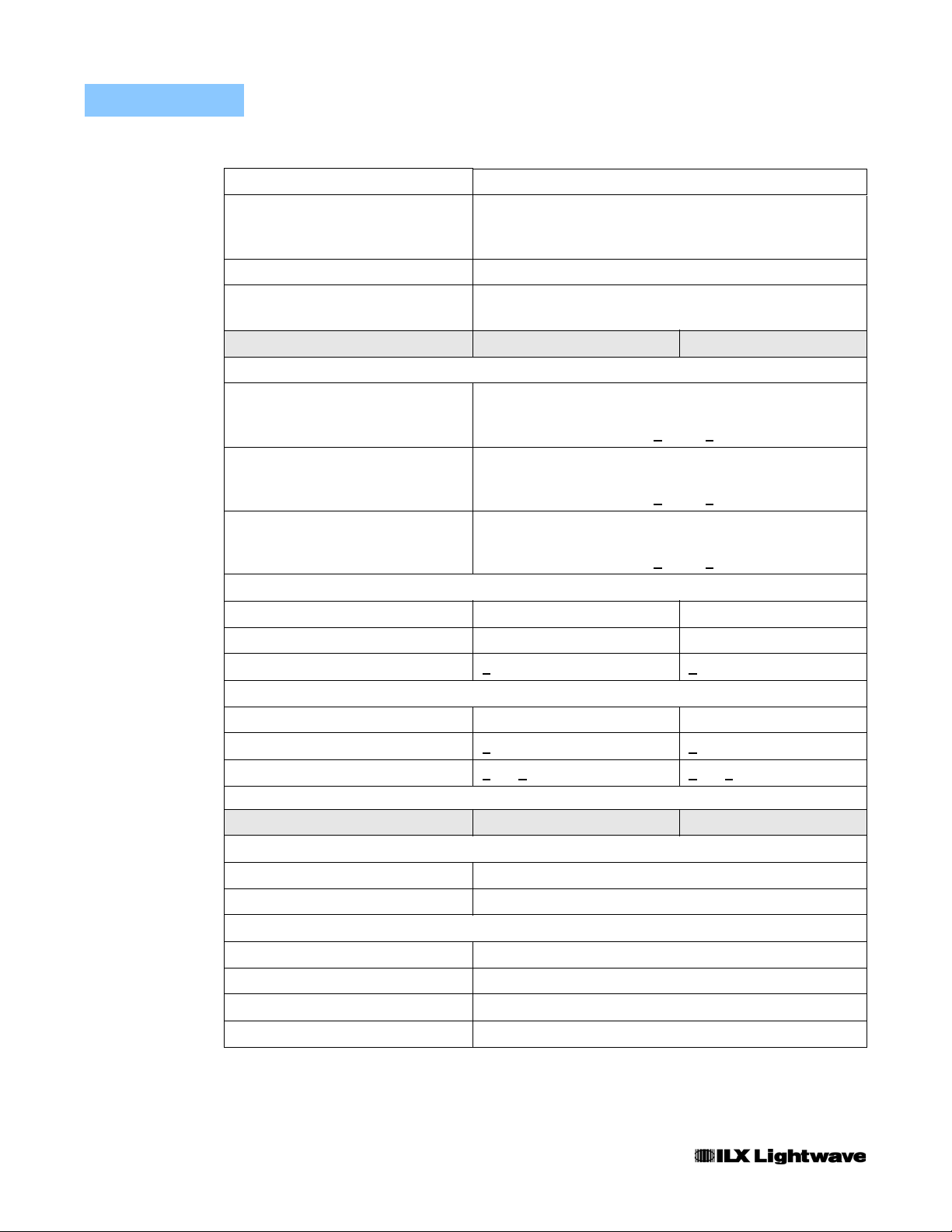

CHAPTER 1

INTRODUCTION AND SPECIFICATIONS

Specifications

Thermistor Sensing Current

Useable Thermistor / RTD Range 10 µA; 10 kΩ to 600 kΩ

Sensor Bias IC-V = 9V, LM335 = 1mA, RTD = 1.0 mA

User Calibration Thermistor: Steinhart-Hart, 3 constants

TEC MEASUREMENT (DISPLAY) LDT-5948 LDT-5980

Thermistor Resistance

10 µA Setting

100 µA Setting

1 mA Setting

Voltage Measurement

Range

Resolution

Accuracy

8

10 µA / 100 µA / 1 mA

100 µA; 1 kΩ to 60 kΩ

1mA; 10 Ω to 6 kΩ

IC Sensors offset/slope, RTD = R

Range: 10 kΩ to 600 kΩ

Resolution: 0.001 kΩ

Accuracy: +0.05% + 5.0 Ω

Range: 1 kΩ to 60 kΩ

Resolution: 0.001 kΩ

Accuracy: +0.05% + 0.5 Ω

Range: 10 Ω to 6 kΩ

Resolution: 0.001 kΩ

Accuracy: +

-12.000 to 12.000 V -12.000 to 12.000 V

1 mV 1 mV

10 mV + 10 mV

+

, A, B, C

0

0.08% + 0.6 Ω

AC Resistance Measurement

Waveform

Amplitude

Accuracy

SYNCHRONIZA TION LDT-5948 LDT-5980

Trigger In

Type

Resolution

Trigger Out

Type

Jitter

Delay

Resolution

9

Pseudo AC Pseudo AC

10 mA +10 mA

+

+ 1% + 0.01 Ω + 1% + 0.01 Ω

TTL; rising edge triggered

100 µs

TTL; active high

5 ns

Programmable 1ms to 60 seconds

1 ms

6 LDT-5980/5948

INTRODUCTION AND SPECIFICATIONS

Specifications

CHAPTER 1

GENERAL LDT-5948 LDT-5980

Output Connectors

TEC I/O

GPIB

RS-232

Trigger In

Trigger Out

Female 25 pin, D-sub

IEEE-488

Female 9 pin D-sub

BNC

BNC

Power Requirements 90 - 260V at 50/60 Hz

Size 3.5” x 7.3” x 12”

Weight 10.0 pounds (4.5 kg)

o

Ambient Temperature Range Operating: 10 to 40

Storage: -40 to 70

C

o

C

Humidity < 85%, relative, non-condensing

Warm-up Five (5) minutes to rated accuracy

EMC EN 61326-1:2000 (CE Requirements)

Safety EN 61010-1:2001; 73/23/EEC, 93/68/EEC

1. All values relate to a five minute warm up period.

2. Software limits of range. Actual range possible depends on the physical load, thermistor type and TEC module used.

3. Accuracy figures are set point referenced and represent the un cert ainty that the 5948/5 980 adds to the measure ment. This figure

does not include the sensor uncertainties which can add up to 2

and 100 µA current setting for -5

the instrument.

4. Into a 0.1 to 2.5 Ω load.

5. Temperature stability measurements made at 25

the avg P-P value over the measurement period.

6. Measured over the full DC current range into a 1Ω load.

7. P=Proportional, I=Integral, D=Derivative. Software programmable terms through the front panel or GPIB.

8. Thermistor sensing current range software selectable through the front panel or GPIB.

9. Resistance range 0.3Ω to 10Ω with 4-wire voltage sense for rated accuracy.

10. Higher resolution can be obtained through GPIB; less than 0.1 Ω with 10 µA thermistor current and <0.01 Ω with 100 µA

thermistor current.

o

C to 50 oC. Both resolution and accuracy are dependent upon the user-def ined configur ation of

o

C with a 10 kohm thermistor on the 100 µA setting. The number is derived from

o

C. Accuracy figures are quoted for a typical 10 kΩ thermistor

09_05 LDT-5980/5948 7

CHAPTER 1

INTRODUCTION AND SPECIFICATIONS

Specifications

8 LDT-5980/5948

CHAPTER 2

OPERATIONS

This chapter describes the operation of the LDT-5900 Series Temperature

Controller. It is divided into five sections covering front panel overview, rear panel

overview, general operations, front panel operations and basic TEC operations.

Front Panel Overview

The LDT-5900 Series Temperature Controller’s front panel contains a Vacuum

Fluorescent Display (VFD) display, power switch, LED indicators, buttons and

adjust knob. Each of the labeled areas on the front panel is described in the Front

Panel Operations section.

Vacuum Fluorescent Display

Power Switch

LED Indicators

Figure 2.1 Front Panel

Adjust Knob

Buttons

LDT-5980/5948 9

CHAPTER 2

OPERATIONS

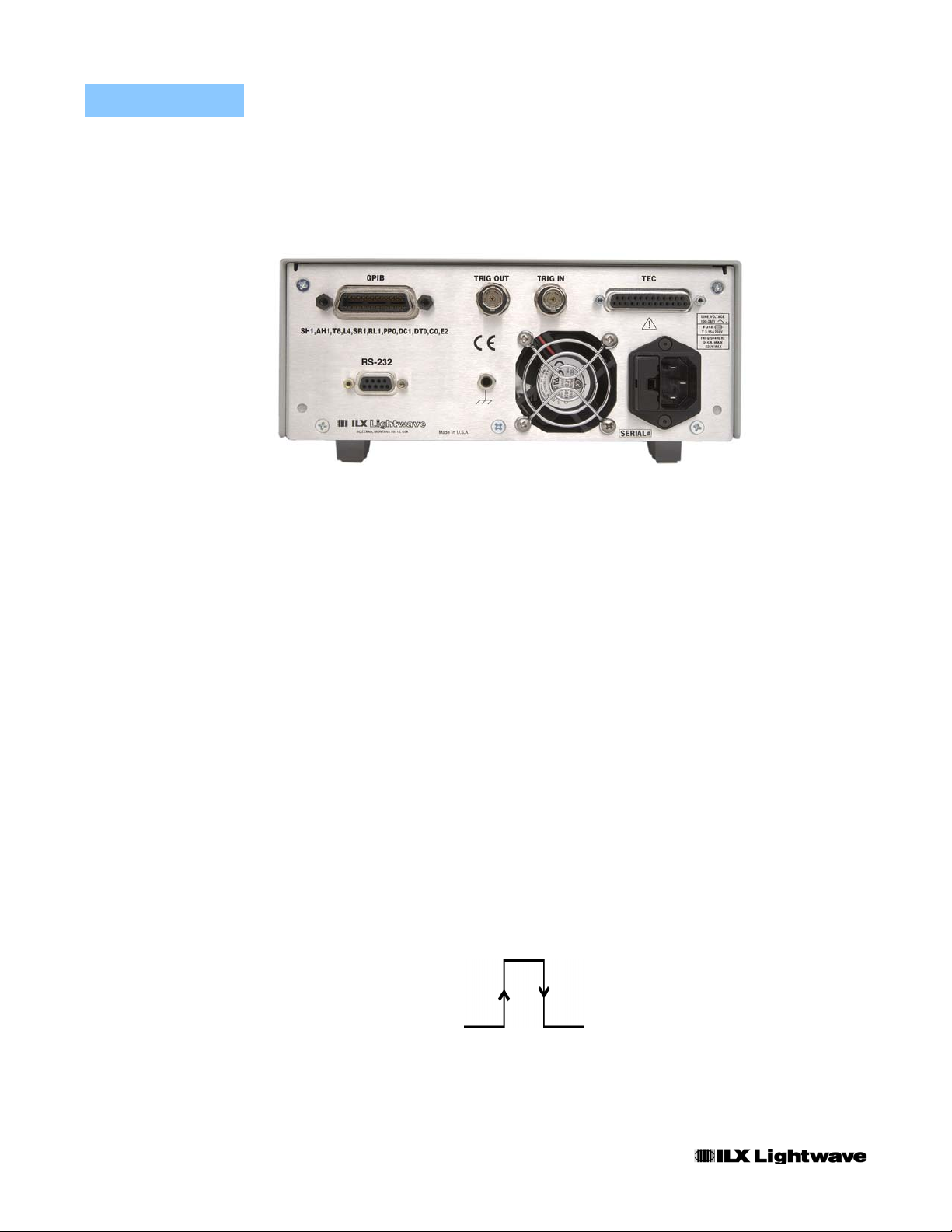

Rear Panel Overview

Rear Panel Overview

Rear Panel Controls and Connections

AC Power Entry Module

Figure 2.2 Rear Panel

The AC Power Entry Module is located on the lower right side of the rear panel. The

LDT-5900 must be connected to a properly rated AC source in order to operate.

T rigger Input Connector

The TRIGGER IN connector is located to the right of center on the rear p anel. The

leading edge input of this signal is used to initiate a programmable temperature

setpoint step. The TRIGGER IN is a BNC input connector and can be driven with

a TTL signal. For more information on trigger functionality, see “Front Panel

Operations” in Chapter 2.

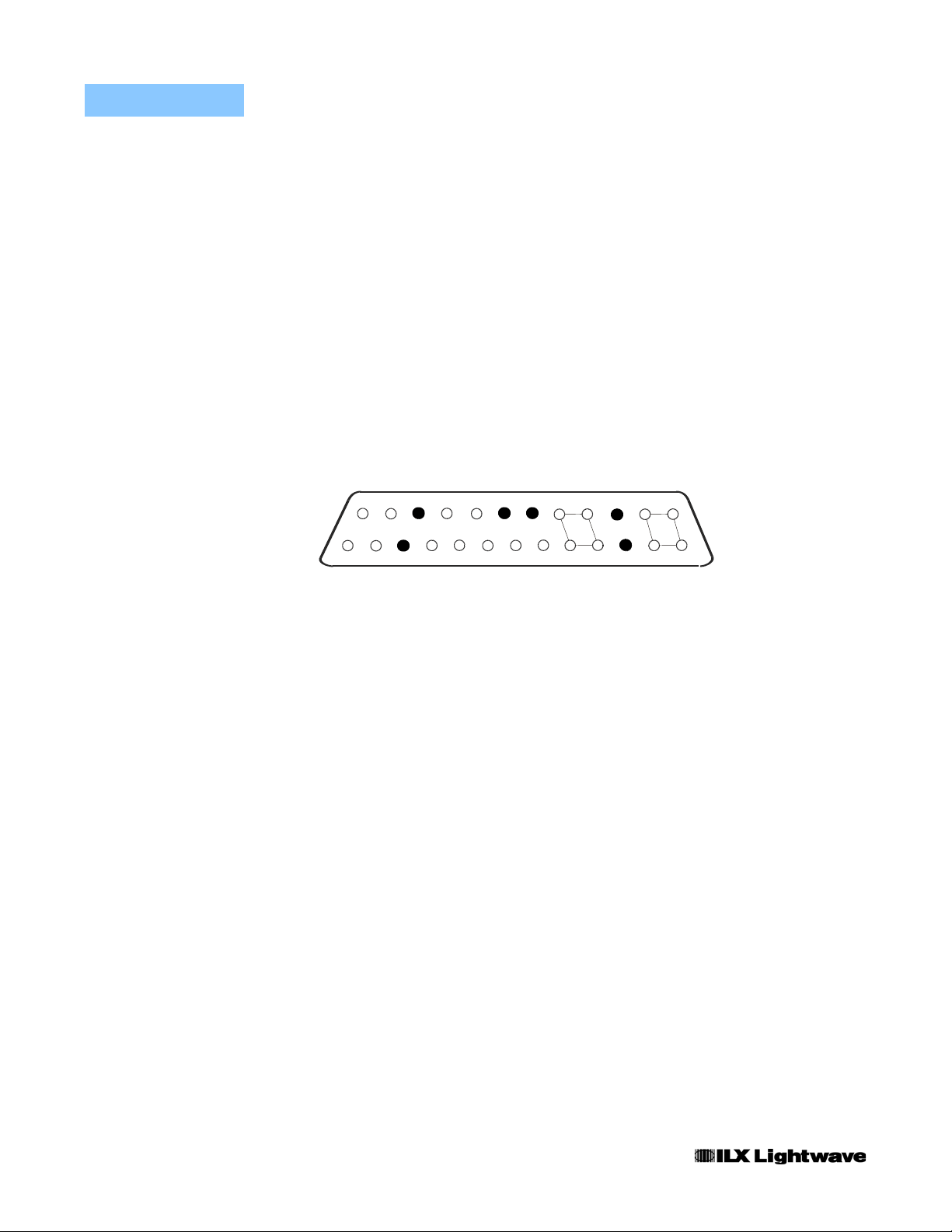

T rigger Output Connector

The TRIGGER OUT connector is located next to the Trigger In connector. This

output indicates if the measurement for the currently selected control mode (e.g.

Temperature) is within the specified setpoint tolerance. This is a TTL signal

generated by the instrument with programmable delay. The signal is low when the

measurement is out of the tolerance window and high when within the tolerance

window. For more details on trigger functionality, see “Front Panel Operations” in

this chapter

High when measurement

within tolerance window

Low when measurement

out of tolerance window

10 LDT-5980/5948

Figure 2.3 Trig g er O u t

OPERATIONS

Rear Panel Overview

CHAPTER 2

GPIB Connector

The GPIB interface connector is located in the upper left corner of the rear panel.

Refer to Figure 2.2. The 24-pin GPIB interface connector is tapered to ensure

proper orientation. Finger tighten the two screws on the cable connector.

A total of 15 devices can be connected together on the same GPIB interface bus.

The cables have single male/female connectors on each end so that several

cables can be stacked. This permits more than one cable to be attached to any

one device. The maximum total length of the GPIB cables must not exceed 20

meters (65 feet) or 2 meters (6.5 feet) time the total number of devices on the bus.

The maximum individual cable length must not exceed 4 meters (13 feet).

For more information regarding GPIB communications, see Chapter 3.

RS-232 Connector

The RS-232 connector is located under the GPIB interface connector. This is a

standard female DB-9 connector for RS-232 communications. This connection

can be cabled to a computer’s serial communication port. ILX recommends a

maximum cable length of 3 meters (9.8 feet).

For more information regarding RS-232 communications, see Chapter 3.

09_05 LDT-5980/5948 11

CHAPTER 2

OPERATIONS

General Operation

General Operation

The following sections present some guidelines for operation, as well as some

common operating procedures. Remote operations are discussed in Chapter 3

and the command reference is discussed in Chapter 4.

Warm Up and Environmental Considerations

Operate the LDT-5900 Series Temperature Controller at an ambient temperature

o

range of 10

o

+70

C. To achieve the rated stability, let the LDT-5900 warm up for at least five

C to 40 oC. Storage temperatures should be in the range of -40 oC to

minutes.

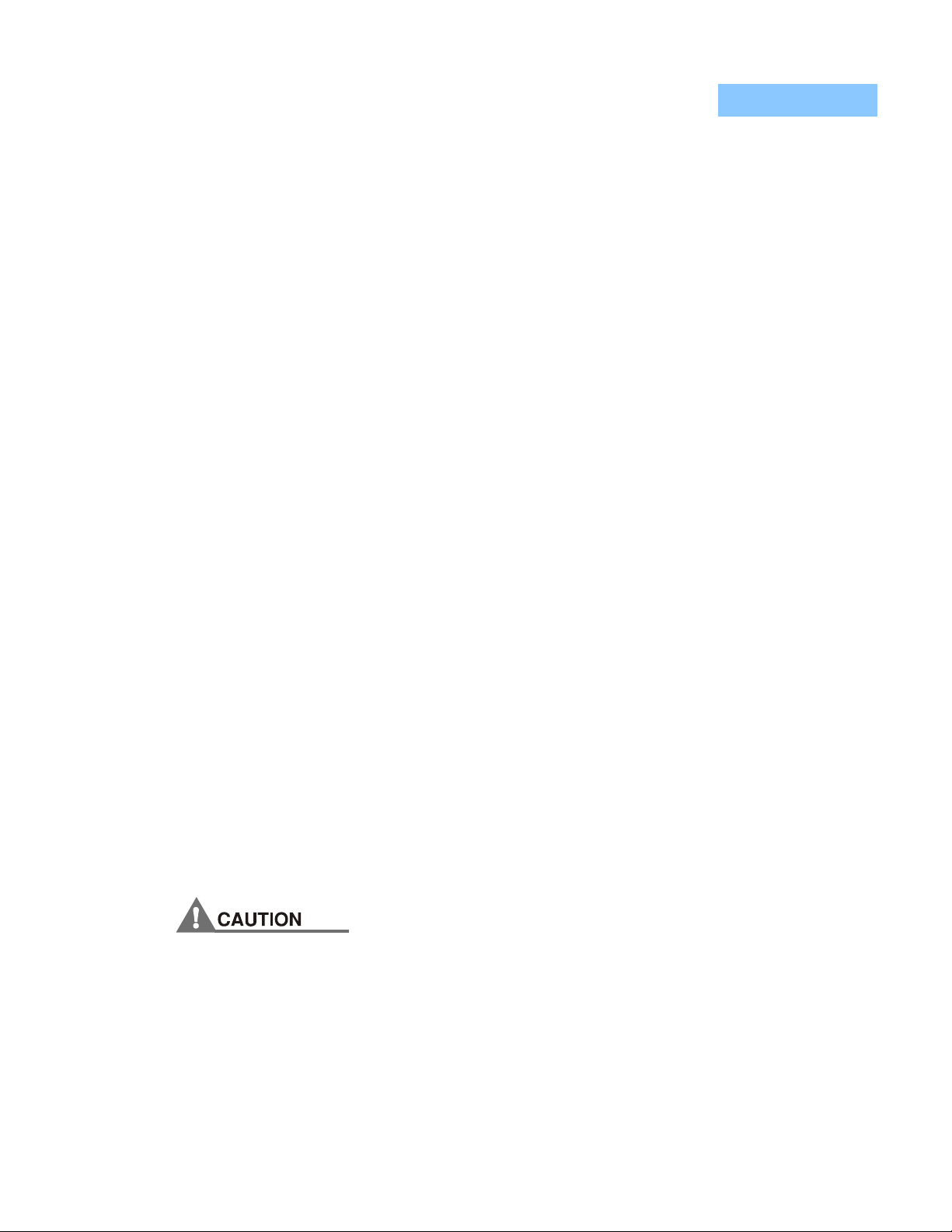

Rear Panel Connections

14

1

1 RT+_SENSE 6 CHASSIS 11 N/C 16 N/C 21 TEC+

2 RT-_SENSE 7 TEC+_SNS 12 TEC - 17 CABLE ID1 22 TEC+

3 N/C 8 TEC-_SNS 13 TEC - 18 CABLE ID2 23 N/C

4 ID1 9 TEC+ 14 RT- 19 N/C 24 TEC5 ID2 10 TEC+ 15 RT+ 20 N/C 25 TEC-

Figure 2.4 Rear Panel TEC Connector

25

13

12 LDT-5980/5948

OPERATIONS

General Operation

CHAPTER 2

When the LDT-5900 is controlling a thermoelectric (TE) module in cooling

mode, current flows from TEC+ (pins 9, 10, 21 and 22 connected internally) to

TEC- pins (12, 13, 24 and 25 connected internally). This is referred to as

positive current. Sensor current (10 µA, 100 µA or 1 mA) flows through the

sensor connected at RT+ (pin 15) and RT - (pin 14). A volt age develop s across

the temperature sensor connected to these pins and can be accurately

measured at the sensor through the 4-wire voltage sense pins (1 and 2), RT+

Sense and RT-Sense. Similarly, the TE voltage can be accurately measured

through the 4-wire TE voltage sense pins 7 and 8. The sensor input (pins 14

and 15), as well as the RT sense and TEC sense (pins 1,2,7, and 8) should be

floating with respect to ground. Pin 6 is connected to the chassis, which is

connected to earth ground via the AC power cord earth conductor.

ILX recommends using either the CC-591H, 5900 TE Controller / unterminated

10A interconnect cable or the CC5955 TE Controller / Laser Diode Mount 5A

interconnect cable to connect the module to the load. The CC-59X Series cables

are specifically designed to be compatible with the 5900 Series Temperature

Controllers. See the ILX Lightwave product catalogue or contact ILX Customer

Service (see page xii for contact information) for information about the cable.

Note: If you choose to assemble your own interconnect cables, 18AWG wire is

recommended to minimize voltage drop at high current. Note that the DB-25 connector pins

are rated for I

is to be delivered to a load as well as all 4 TEC- pins (12, 13, 24, 25) for the return.

Also, the cable ID pins must be configured as follows or the output current from the

LDT-5900 will be limited to 1A.

MAX Output Current Cable ID1

10A Shorted Shorted

5A Shorted Open

= 2.5A, and thus all four TEC+ pins (9, 10, 21, 22) must be used if 10A

nominal

Cable ID2

Pin 17 to 4

Pin 18 to 5

TEC Grounding Considerations

The cable ID ground (pins 4 and 5) are isolated from chassis ground (pin 6). The

chassis is provided for shielding purposes only.

Do NOT connect the TEC Module pins (9, 10, 12, 13, 21, 22, 24 and 25) to any grounded

pins (4, 5 and 6) or damage could occur to the mo dule.

09_05 LDT-5980/5948 13

CHAPTER 2

OPERATIONS

Front Pan el Operation

Front Panel Operation

Figure 2.5 shows the front panel of the LDT-5900 Series Temperature Controller.

The key operating parameters for the LDT-5900 Series Temperature Controller

can be set, adjusted, and displayed through various menus accessible by using

the front panel push buttons (keys) and knobs.

Vacuum Fluorescent Display

Power Switch

System Section

LDT-59XX TEMPERATURE CONTROLLER

Display Section

Parameter Section

Figure 2.5 Front Panel

Adjust Section

Adjust Knob

Mode Section

Display Section

Three important areas of the front panel display section are the display screen,

the DISPLAY / MENU buttons and the error indicators. The display is a vacuum

fluorescent display that is continually updated at approximately a 2 Hz rate. The

DISPLAY / MENU arrow keys allow the user to select which measurement to

display and to select the parameters to adjust in the various menus.

Display Screen

14 LDT-5980/5948

025.508 000

Error Indicators

o

C

OPERATIONS

Fro nt Pa ne l Oper ation

CHAPTER 2

The error indicators (LEDs) in the display section are described as follows:

• TEMP LIMIT - The Temperature Limit LED will be RED when either the Low Temperature or

the High Temperature Limit is met or exceeded and the output will be shut off.

• VOLTAGE LIMIT - The Voltage Limit LED will be RED when either high or low TEC voltage

limit is reached.

• CURRENT LIMIT - The Current Limit LED will be GREEN when either the high or low current

limit is reached and the temperature error signal is decreasing, (e.g. when driving the load to

a given setpoint). The Current Limit LED will be RED when either the high or low current limit

is reached and the temperature error signal is increasing, (e.g. system is in a thermal runaway condition.)

• SENSOR ERROR - The Sensor Error LED will be RED if the temperature sensor (either a

thermistor, IC or RTD) is open, shorted or outside of the nominal measurement range.

• TEC ERROR - The TEC Error LED will be RED if the TEC is either shorted, open or not

connected.

For more information on which errors will cause the output to turn off, see “Out put

Off Registers” in Chapter 3.

Adjust Section

The Adjust section of the front panel contains the Adjust Knob and the ENTER /

LOCK Key. (See Figure 2.5) The adjust knob (digital encoder) allows the user to

change the value of a selected menu parameter. The parameter selected is

indicated by brackets [123.456]. The ENTER / LOCK key is used in menus to

enter and store a parameter that has been modified by the knob. When not in a

menu, this key is used to lock (disable) or unlock the adjust knob.

• LOCK - The Lock LED will be GREEN when the adjust knob has been locked and is

disabled.

09_05 LDT-5980/5948 15

CHAPTER 2

Measurement and Setpoint

OPERATIONS

Front Pan el Operation

By default, the LDT-5900 Series Temperature Controller displays the temperature

measurement from the selected sensor in

keys, the user can change the displayed temperature conversion units (

o

C. Using the DISPLAY / MENU arrow

o

C, oF, K)

or the measurement parameter altogether (sensor measurement, TE current, TE

voltage, TE power). After exiting any menu, the instrument will always return to

the measurement display.

LDT-59XX TEMPERATURE CONTROLLER

025.508 oC

Whilte the measurement display is active, the user can access and change the

setpoint for the selected control mode. (See the Mode Section later in this chapter

for details on control modes and setpoints.) Turning the adjust knob will cause the

screen to switch from displaying the measurement to displaying the setpoint. This

is indicated by brackets around the setpoint value. The setpoint value can then be

adjusted with the knob and stored by pressing the ENTER / LOCK key. After 10

seconds of inactivity, the screen will switch back to display the measurement, or

the user can press either DISPLAY / MENU arrow key to immediately switch back

to the measurement display.

16 LDT-5980/5948

OPERATIONS

Fro nt Pa ne l Oper ation

CHAPTER 2

System Section

The System section of the front panel contains the MAIN / LOCAL button and the

REMOTE indicator. Sending a command over the GPIB or RS-232 interfaces

automatically puts the instrument in Remote Mode and illuminates the Remote

LED. The MAIN / LOCAL button returns the instrument to local (front panel)

control. (See the Remote Communication section of Chapter 3 for more details).

System Menu

Pressing the Main / Local Key cycles through the system menu as described in

further detail below. System menu entry will automatically timeout after 10

seconds of no activity and the instrument will return to is default measurement

display mode.

Communication

The first page of the system menu allows the user to select the appropriate

remote communications and appears as follows:

COMMUNICATION 00000001/7

GPIB Addr : [01]

For GPIB communications, the GPIB address can be set between 0 and 30 by

using the adjust knob to select the desired value, and then pressing the ENTER /

LOCK key to save it. By pressing the down arrow key, the RS-232 baud rate is

09_05 LDT-5980/5948 17

CHAPTER 2

OPERATIONS

Front Pan el Operation

selected and can be set between a minimum of 1200 and a maximum of 230400.

For more information on remote communications, see Chapter 3.

GPIB Addr : 01

RS232 Baud: [9600 ]

Display

The second page of the system menu allows the user to set the brightness of the

display between 25% and 100% by using the adjust knob and then pressing the

ENTER / LOCK key.

DISPLAY 00000000000002/7

Brightness: [62%]

Error Log

The third page of the system menu allows the user to view the error log and

appears as follows when no errors are present. Pressing the ENTER / LOCK key

clears the error log. The DISPLA Y / MENU up and down arrow keys scroll t hru the

error log, which lists the most recent error at the top. Table 3.7 in Chapter 3 lists

the error codes for the LDT-5900 Series Temperature Controllers.

ERROR LOG 00000000003/7

No Errors

18 LDT-5980/5948

OPERATIONS

Fro nt Pa ne l Oper ation

Buttons

CHAPTER 2

The fourth page of the system menu allows the user to set the beep for the

buttons either on or off by using the adjust knob and then pressing the ENTER /

LOCK key.

BUTTONS 0000000000004/7

Beep: [Off]

Trigger In

The fifth page of the system menu allows the user to set up all parameters for the

trigger in functionality. From this menu, the trigger in can be enabled or disabled.

TRIGGER IN00000000005/7

Enable: [False]

Pressing the down arrow key scrolls through the various parameters within this

menu, allowing the user to then set the start, stop and step temperatures.

Start: 000.000 oC

Stop :[060.000] oC

When enabled, the Trigger In feature allows the user to modify the temperature

control setpoint by sending a TTL pulse into the TRIG IN BNC connector on the

back of the instrument. (See the Rear Panel Overview section earlier in this

chapter for connector location.) The first time a Trigger In pulse is received, the

temperature setpoint will be set to the Start temperature specified in this menu.

Subsequent pulses will increment (or decrement) the setpoint by the Step value.

09_05 LDT-5980/5948 19

CHAPTER 2

OPERATIONS

Front Pan el Operation

When the setpoint reaches the specified Stop temperature, the next pulse will

reset the setpoint back to the Start temperature. The setpoint cannot exceed the

Stop temperature, and any attempt to step beyond the Stop temperature will

instead reset the setpoint back to the Start temperature.

Trigger Out

The sixth page of the system menu allows the user to set up the trigger out delay

time..

TRIGGER OUT0000000006/7

Delay:[001.000] sec

The Trigger Out feature allows the user to determine if the instrument is

controlling a TEC within a specific tolerance window. This window is defined by

the setpoint +/- a user specified tolerance. (See the Limits portion of the

Parameter Section later in this chapter for details on how to set this tolerance

value.) If the measurement for the selected control mode (e.g. Temperature) is

within this tolerance window, the Trigger Out TTL level will be high, if out of

tolerance, the level will be low. The Trigger Out signal is output from the TRIG

OUT BNC connector . (See the Rear Panel Overview section earlier in this chapter

for connector location.

The delay time determines how long the measurement must remain within the

tolerance window before Trigger Out is asserted high. If the measurement goes

out of tolerance during this delay period, the delay time interval is restarted when

the measurement goes back into tolerance.

20 LDT-5980/5948

OPERATIONS

Fro nt Pa ne l Oper ation

A/D Setup

CHAPTER 2

The last page of the system menu allows the user to set up the A/D filter to reject

either 50 Hz or 60 Hz AC line noise. The default frequency for this filter is 60 Hz.

A/D SETUP00000000007/7

Line Freq: [60 Hz]

Parameter Section

The Parameter section contains the SELECT key and the parameter indicators.

Pressing the SELECT key cycles through each of the available menus. An

illuminated green LED next to each of the listed menus indicates which is currently

active. The parameter menus are PID / AUTO-TUNE, Sensor, Limits and Save /

Recall, all of which are described as follows.

Parameter menu entry will automatically timeout after 10 seconds of no activity

and the instrument will return to its default measurement display mode.

09_05 LDT-5980/5948 21

Loading...

Loading...