ILX Lightwave DPM-79810, FOS-79710, FOS-79800E, FOM-7900B User Manual

User’s Guide

Multi-Channel Fiber Optic Test System

FOM-7900B

also includes:

FOS-79800E Fiber Optic Source Module

FOS-79710 1 x 4 Fiber Optic Switch Module

DPM-79810 Dual Power Meter Module

ILX Lightwave Corporation P. O. Box 6310 Bozeman, MT, U.S.A. 59771 : · · · 1-800-459-9459 · ·

www.ilxlightwave.com

U.S. & Canada International Inquiries: 406-586-1244 Fax 406-586-9405

E-mail: support@ilxlightwave.com

70032603_1/02

ILX Lightwave

70032603 Revision 00

FEEDBACK

To ensure that you get the most out of your ILX Lightwave product, we ask that you direct any

product operation or service related questions or comments to ILX Lightwave Customer Support.

You may contact us in whatever way is most convenient:

Telephone 800-459-9459

FAX (406) 586-9405

E-mail support@ilxlightwave.com

CS webpage http://ilx.custhelp.com/cgi-bin/ilx.cfg/php/enduser/home.php

Mail 31950 East Frontage Road

Bozeman, Montana, USA 59715

When you contact us, please have the following information:

Model Number _________________________

Serial Number _________________________

End-user name and telephone/fax: _________________________

Name: _________________________

Company: _________________________

Phone: _________________________

Fax: _________________________

Description or sketch of what is connected to the ILX Lightwave instrument.

Description of the problem

If ILX Lightwave determines that a return to the factory will be necessary, you will be issued a

Return Authorization (RA) number. Please mark this number on the outside of the shipping box.

NOTE: The shipping box and packing material have been designed specifically for each

product and should be saved for possible transportation at a later date.

i

ILX Lightwave

70032603 Revision 00

ii

ILX Lightwave

70032603 Revision 00

WARRANTY ILX LIGHTWAVE CORPORATION warrants this instrument to be free

from defects in material and workmanship for a period of one year from

date of shipment. During the warranty period we will repair or replace the

unit, at our option, without charge.

Limitation This warranty does not apply to shipping damage, fuses, lamps, defects

caused by abuse, modifications, or to use of the product for which it was

not intended.

This warranty is in lieu of all other warranties, expressed or implied,

including any implied warranty of merchantability or fitness for any

particular purpose. ILX Lightwave Corporation shall not be liable for any

incidental, special, or consequential damages.

If a problem occurs, please notify ILX Lightwave Corporation and

thoroughly describe the nature of the problem and give the serial number.

Returning an

Instrument

If an instrument is to be shipped to ILX Lightwave for repair or service, be

sure to:

1) Obtain a Return Authorization (RA) number from the factory.

2) Attach a tag to the instrument identifying the owner and indicating the

required service or repair. Include the instrument serial number (the

model number followed by a sequenced four-digit number on the rear

or side panel).

3) Contact ILX Lightwave for packing and shipping instructions. The

original shipping container must be used.

NOTE: The shipping box and packing material have been designed specifically for each

product and should be saved for possible transportation at a later date.

4) Send the instrument, transportation pre-paid to ILX Lightwave, referencing the return authorization number. We suggest that you insure

the shipment.

Repairs will be made and the instrument returned transportation pre-paid.

Repairs are warranted for the remainder of the original warranty or for 90

days, whichever is greater.

Claims for Shipping

Damage

When you receive the instrument, inspect it immediately for any damage

or shortages on the packing list. If the instrument is damaged, file a claim

with the carrier. ILX Lightwave can supply you with a quotation for

estimated costs of repair. You must negotiate and settle with the carrier

for the amount of damage.

iii

ILX Lightwave

70032603 Revision 00

iv

Copyright This document and the software described in it are copyrighted by ILX

Lightwave, with all rights reserved. The document may not be copied, in

whole or in part without the written consent of ILX Lightwave.

No Warranty This document has been prepared for use by ILX Lightwave customers as

a guide to the proper use and operation of its products, and no warranty

or representation, either expressed or implied, is made with respect to the

documentation or to the software described in this document with regard

to their quality, performance, merchantability, or fitness for any particular

purpose.

CALIBRATION AND REPAIR

ILX Lightwave offers complete calibration and repair service across our

entire line of products. ILX Factory Authorized Service Centers are

located at several locations around the globe in order to facilitate your

service requirements. Quick service turn-times, an easy fixed-price repair

and calibration service schedule along with knowledgeable and

professional staff all combine to ease instrument maintenance and repair.

ILX Lightwave

70032603 Revision 00

ILX Lightwave provides in-house and on-site calibration services for ILX

instruments. Most ILX instruments require yearly calibration to insure

performance to published specifications. ILX factory calibrations employ

NIST traceable measurement instrumentation. Our Calibration Engineers

and Technicians use automated test equipment to accurately and

efficiently capture and record calibration data of the ILX equipment. A

detailed report showing any pre-calibration, out-of-tolerance conditions

are available upon request. An original certificate of calibration

authenticity is provided on all instrument calibrations. On-site calibrations

can be performed whenever your production schedule allows, night or

day, seven days a week. Please call an ILX Customer Service or Sales

Engineer at (800) 459-9459 to discuss how we can help you keep your

ILX Lightwave instrumentation at peak performance.

v

ILX Lightwave

70032603 Revision 00

PRODUCT SAFETY INFORMATION

Definition of symbols

Important operating and maintenance (servicing) instructions.

Risk of electrical shock.

Static-sensitive device, use proper grounding provisions.

Power ON symbol

Standby Symbol

Cautions and Warnings

CAUTION:

NO USER SERVICEABLE PARTS INSIDE, REFER SERVICING TO

QUALIFIED SERVICE PERSONNEL

WARNING: The operating line voltage of the 7900B is set at the factory. The voltage setting

is marked on the back panel. Changing the line voltage requires disassembly of

the mainframe. In addition to voiding the warranty, removing the back panel may

expose the user to the risk of electrical shock.

WARNING: Equipment may produce high leakage currents when the safety ground is faulty.

Ensure that the power supply cord is connected to a properly grounded mains

receptacle.

WARNING

TO PREVENT FIRE OR SHOCK HAZARD,

DO NOT EXPOSE THIS EQUIPMENT TO MOISTURE

vi

LASER SAFETY FOR THE FOS-79800E

There are laser and electrical safety issues that must be considered

during the operation of the FOS-79800E laser source modules. The FOS79800E laser source modules must be used as intended in this manual.

Any other use not specified in this manual may result in a hazard.

The high brightness, sometimes invisible light output of laser diodes and

other laser sources pose a definite eye hazard. Direct viewing of the laser

output can produce retinal or corneal damage. Absorption of the laser

light by the eye causes localized heating and denaturing of tissue

proteins. The ANSI publication Z-136.1, “The Safe Use of Lasers”, lists

Maximum Permissible Exposure (MPE) levels for direct, or intrabeam

viewing of laser beams. From the MPE levels, a “hazard zone” may be

computed for a particular laser and exposure time. For more information

concerning lasers and laser diode safety, contact the Center for Devices

and Radiological Health or ILX Lightwave.

Laser Warning Label

IEC Triangle

ILX Lightwave

70032603 Revision 00

Visible and/or invisible laser radiation. Avoid direct

eye exposure to the beam.

vii

ILX Lightwave

70032603 Revision 00

(page left blank intentionally)

viii

CONTENTS

Calibration and Repair ..............................................................................v

PRODUCT SAFETY INFORMATION ...................................................... vi

LASER SAFETY FOR THE FOS-79800E............................................... vii

Laser Warning Label......................................................................... vii

CHAPTER 1 INTRODUCTION

Company and Technology Overview ................................................... 1-1

Product Overview ................................................................................. 1-1

ILX Lightwave

70032603 Revision 00

Available Options ................................................................................. 1-1

Summary of Instruction Manual ........................................................... 1-2

CHAPTER 2 SYSTEM OVERVIEW

FOM-7900B System Characteristics .................................................... 2-1

FOM-7900B System Specifications ..................................................... 2-2

Internal Modulation ........................................................................ 2-2

Modulation In ................................................................................. 2-2

Modulation Out .............................................................................. 2-2

External Trigger Input/Output ........................................................ 2-3

Computer Interface ........................................................................ 2-3

GPIB/IEEE-488.2 .................................................................... 2-3

RS-232 .................................................................................... 2-3

Rear Panel ........................................................................................... 2-4

Power Entry Module and Fuse ...................................................... 2-4

Fuse Rating ................................................................................... 2-4

GPIB Connector ............................................................................. 2-5

RS-232 Connectors ....................................................................... 2-5

Trigger Input/Output Connectors ................................................... 2-5

Modulation Input Connector (External Modulation) ....................... 2-5

Modulation Output Connectors ...................................................... 2-6

Module Installation ............................................................................... 2-7

Power-Up ............................................................................................. 2-8

Warm-up and Environmental Considerations ................................ 2-8

ix

ILX Lightwave

70032603 Revision 00

CHAPTER 3 FOM-7900B MAINFRAME OPERATION

Front Panel Controls ............................................................................ 3-1

Display ........................................................................................... 3-1

Local/Remote Control .................................................................... 3-2

Channel Selection .......................................................................... 3-2

Parameter Selection ...................................................................... 3-2

Parameter Adjustment ................................................................... 3-3

Parameter Entry ............................................................................. 3-3

Sweeping Parameter Values ......................................................... 3-3

Mainframe Parameter Menu ................................................................ 3-4

Modulation Setup ........................................................................... 3-4

Modulation Frequency............................................................. 3-5

Modulation Source .................................................................. 3-5

Return to Main Menu............................................................... 3-5

Modulation ON/OFF ....................................................................... 3-6

Coherence Control ON/OFF .......................................................... 3-6

Sources ON/OFF ........................................................................... 3-6

Setup Mode ................................................................................... 3-7

Set GPIB Address ................................................................... 3-7

Set Bank Address ................................................................... 3-7

Return to Main Menu............................................................... 3-7

Error Display .................................................................................. 3-8

CHAPTER 4 FOS-79800E MODULE

FOS-79800E Specifications ................................................................. 4-2

SS-810 Source Shutter OPTION ......................................................... 4-4

FOS-79800E Source Module Parameter menu ................................... 4-5

Module Identification ...................................................................... 4-5

Output ON/OFF ............................................................................. 4-6

Source Shutter OPEN/SHUT ......................................................... 4-6

Set Power Level ............................................................................. 4-6

x

ILX Lightwave

70032603 Revision 00

Set Wavelength ............................................................................. 4-7

User Calibration ............................................................................. 4-7

Calibrate Power Level ............................................................. 4-7

Calibrate Wavelength.............................................................. 4-8

Reset User Calibration ............................................................ 4-8

Return to Main Menu............................................................... 4-8

Error Display .................................................................................. 4-9

External Trigger .................................................................................... 4-9

Error Indicator ...................................................................................... 4-9

On Indicator .......................................................................................... 4-9

Modulation ............................................................................................ 4-9

Coherence Control ............................................................................. 4-10

CHAPTER 5 DPM-79810 MODULE

Warm-up and Environmental Considerations ................................ 5-1

Measuring Higher Power ............................................................... 5-1

Understanding the Calibration Certificate ...................................... 5-2

Photodetector Responsivity .................................................... 5-2

DPM-79810 Specifications ................................................................... 5-4

DPM-79810 DUAL POWER METER MODULE ................................... 5-5

Connecting to the Power Meter Input Port ........................................... 5-6

Measurements Using a Connector ................................................ 5-6

Protecting the Cavity ...................................................................... 5-6

DPM-79810 Dual Power Meter Module Parameter Menu .................... 5-7

Module Identification ...................................................................... 5-9

Request Zero Operation ................................................................ 5-9

Mode of Operation ....................................................................... 5-10

Display Power .............................................................................. 5-10

Operating Parameters Setup ............................................................. 5-11

Recall Stored Setup Parameters ................................................. 5-11

Source Wavelength ..................................................................... 5-12

xi

ILX Lightwave

70032603 Revision 00

Filtering Value (Averaging Rate) .................................................. 5-12

Measurement Units ...................................................................... 5-12

Reference Power Reading ........................................................... 5-13

Range Setting .............................................................................. 5-13

User Calibration ........................................................................... 5-14

Save Setup Parameters ............................................................... 5-14

Request End Setup ...................................................................... 5-14

Warnings ............................................................................................ 5-15

OPERATING IN REMOTE CONTROL .............................................. 5-15

Remote Configuration .................................................................. 5-15

Terminology ................................................................................. 5-15

COMMAND REFERENCE ................................................................. 5-16

CHAPTER 6 FOS-79710 MODULE

FOS-79710 Parameters ....................................................................... 6-3

Module Identification ...................................................................... 6-4

Select Switch Port .......................................................................... 6-4

Select External Trigger .................................................................. 6-4

Enable External Trigger .......................................................... 6-5

Initialize Trigger Switch Sequence .......................................... 6-5

Customize Trigger Switch Sequence ...................................... 6-5

Return to Main Menu............................................................... 6-6

Select Timed Mode ........................................................................ 6-6

Enable Interval Timer .............................................................. 6-6

Set Interval Time ..................................................................... 6-7

Initialize Timer Switch Sequence ............................................ 6-7

Customize Timer Switch Sequence ........................................ 6-7

Return to Main Menu............................................................... 6-8

Error Display .................................................................................. 6-8

External Trigger Specifications ............................................................ 6-9

xii

CHAPTER 7 RS–232 INTERFACE

RS-232 Communications Protocol ....................................................... 7-1

Linking Multiple FOM-7900B Systems ................................................. 7-1

Communication with multiple FOM-7900B systems ............................. 7-3

CHAPTER 8 GPIB REMOTE OPERATION AND

COMMON COMMANDS

ILX Lightwave

70032603 Revision 00

7900 and GPIB Controller Synchronization ......................................... 8-2

Preparation for GPIB Control ............................................................... 8-2

LOCAL Control .............................................................................. 8-2

REMOTE Control ........................................................................... 8-2

GPIB Address ................................................................................ 8-3

ANSI/IEEE-488.2 Definitions ................................................................ 8-3

Syntax Diagrams ........................................................................... 8-3

<white space> ................................................................................ 8-4

<nrf value> ..................................................................................... 8-4

<suffix unit> ................................................................................... 8-4

<PROGRAM MESSAGE TERMINATOR> .................................... 8-5

<PROGRAM MESSAGE UNIT SEPARATOR> ............................. 8-5

<PROGRAM HEADER SEPARATOR> ......................................... 8-6

<compound command program header> ...................................... 8-6

<PROGRAM DATA> (Parameters) ............................................... 8-7

<ARBITRARY BLOCK PROGRAM DATA> ................................... 8-8

<PROGRAM DATA SEPARATORS> ............................................ 8-8

Power-on Conditions ..................................................................... 8-9

Default Parameters ........................................................................ 8-9

xiii

ILX Lightwave

70032603 Revision 00

Getting Started with GPIB .................................................................. 8-10

Overview of the FOM-7900B Syntax ........................................... 8-10

Using Commands with Parameters ............................................. 8-11

Substitute Parameter Names ................................................ 8-11

Queries.................................................................................. 8-12

Terminators ........................................................................... 8-12

Common Commands and Queries ..................................................... 8-13

Error Messages .................................................................................. 8-24

Status Reporting ................................................................................ 8-24

Device Dependent Event and Condition Registers ...................... 8-24

Operation Complete Definition ..................................................... 8-25

Command Timing and Completion .............................................. 8-25

Input Buffer and Output Data ............................................................. 8-26

Remote Interface Messages .............................................................. 8-26

Interface Function Subsets .......................................................... 8-27

Remote Messages ....................................................................... 8-27

Remote Interface Messages Not Supported by FOM-7900B ...... 8-27

CHAPTER 9 COMMAND REFERENCE

Terminology ......................................................................................... 9-1

Commands and Queries ...................................................................... 9-2

Substitute Parameter Names ......................................................... 9-2

Compound Command Structure .................................................... 9-2

Common Commands ..................................................................... 9-2

Device Specific Commands ................................................................. 9-5

FOM-7900B Mainframe and Module Command Reference ................. 9-9

xiv

CHAPTER 10 PROGRAMMING EXAMPLES

CHAPTER 11 MAINTENANCE

Fuse Replacement ............................................................................. 11-2

Line Voltage Selection ....................................................................... 11-2

Module replacement ........................................................................... 11-3

FOS-79800E and FOS-79710 Module Maintenance ......................... 11-4

Cleaning Fiber Optic Connectors ................................................. 11-4

User Calibration of the FOS-79800E Module ..................................... 11-5

ILX Lightwave

70032603 Revision 00

Wavelength Calibration ................................................................ 11-5

Power Calibration ........................................................................ 11-5

CHAPTER 12 ERROR MESSAGES

FOM-7900B FIBER OPTIC SYSTEM ERRORS ................................ 12-2

CHAPTER 13 TROUBLESHOOTING

System Troubleshooting Guide .......................................................... 13-1

GPIB Troubleshooting Guide ............................................................. 13-2

xv

ILX Lightwave

70032603 Revision 00

(page left blank intentionally)

xvi

LIST OF FIGURES

FIGURE 2-1 FOM-7900B Fiber Optic System Rear Panel .............. 2-4

FIGURE 5-1 Sample Detector Response ........................................ 5-2

FIGURE 7-1 FOM-7900B Stacked System...................................... 7-3

FIGURE 8-1 White Space Syntactic Diagram.................................. 8-4

FIGURE 8-2 Suffix Syntactic Diagram ............................................. 8-4

FIGURE 8-3 <PROGRAM MESSAGE TERMINATOR>.................. 8-5

FIGURE 8-4 <PROGRAM MESSAGE UNIT SEPARATOR> .......... 8-5

FIGURE 8-5 <compound command program header>.................... 8-6

FIGURE 8-6 <compound query program header>........................... 8-7

FIGURE 8-7 <ARBITRARY BLOCK PROGRAM DATA> ................ 8-8

FIGURE 8-8 <PROGRAM DATA SEPARATOR>............................ 8-8

FIGURE 8-9 Standard Event Status/Status Enable Register......... 8-15

FIGURE 8-10 Service Request Enable Register ............................. 8-22

FIGURE 8-11 FOM-7900B Status Reporting Schematic Diagram... 8-25

FIGURE 9-1 Command Format ....................................................... 9-3

ILX Lightwave

70032603 Revision 00

xvii

ILX Lightwave

70032603 Revision 00

(page left blank intentionally)

xviii

LIST OF TABLES

ILX Lightwave

70032603 Revision 00

Table 1-1 Module Options .............................................................. 1-1

Table 3-1 Mainframe Parameter Menu ........................................... 3-4

Table 4-1 DFB Source Modules ..................................................... 4-2

Table 4-2 79800E Performance Specifications .............................. 4-3

Table 4-3 Module General Specifications ....................................... 4-4

Table 4-4 SS-810 Source Shutter Specifications ........................... 4-4

Table 4-5 FOS-79800E Parameter Menu ....................................... 4-5

Table 4-6 FOS-79800E Module Commands ................................ 4-10

Table 5-1 DPM-79810 MODULE SPECIFICATIONS ..................... 5-4

Table 5-2 DPM-79810 Module Initial Factory Settings ................... 5-5

Table 5-3 DPM-79810 Parameter Menu......................................... 5-7

Table 5-4 DPM-79810 Module Commands .................................. 5-16

Table 6-1 FOS-79710 Performance Specification .......................... 6-2

Table 6-2 FOS-79710 1 x 4 Switch Parameter Menu ..................... 6-3

Table 6-3 External Trigger Specifications ....................................... 6-9

Table 6-4 FOS-79710 1 x 4 Switch Module Commands .............. 6-10

Table 7-1 RS–232 Parameter Values............................................. 7-1

Table 7-2 RS–232 Connector wiring............................................... 7-2

Table 8-1 GPIB Capability .............................................................. 8-1

Table 8-2 FOM-7900B Default Settings.......................................... 8-9

Table 8-3 Valid Syntax for Commands ......................................... 8-10

Table 8-4 Invalid Syntax for Commands....................................... 8-11

Table 8-5 Substitute Parameter Names ....................................... 8-11

Table 8-6 GPIB Common Commands .......................................... 8-13

Table 8-7 FOM-7900B Allowed GPIB Interface Messages .......... 8-27

Table 8-8 GPIB Interface Messages Not Supported .................... 8-27

Table 9-1 FOM-7900B Mainframe Specific Commands ................. 9-4

Table 9-2 FOS-79800E Module Commands .................................. 9-5

Table 9-3 FOS-79710 1 x 4 Switch Module Commands ................ 9-6

Table 9-4 DPM-79810 Module Commands .................................... 9-7

Table 9-5 FOM-7900B Channel Numbers .................................... 9-13

Table 9-6 Error Codes for the FOS-79710 1 X 4 Switch Module.. 9-23

Table 9-7 Error Codes for the FOS-79800E Source Module........ 9-23

Table 9-8 Mainframe Specific Errors ............................................ 9-23

Table 10-1 GPIB Driver .................................................................. 10-1

Table 10-2 Display Calibration........................................................ 10-2

Table 12-1 Error Code Classification .............................................. 12-1

Table 12-2 Parser Errors ................................................................ 12-2

Table 12-3 Execution Control Errors .............................................. 12-3

Table 12-4 GPIB Errors .................................................................. 12-4

Table 12-5 Mainframe Specific Errors ............................................ 12-4

Table 12-6 Module Specific errors .................................................. 12-5

Table 12-7 FOS-79710 Switch Error Messages ............................. 12-5

Table 13-1 System Troubleshooting............................................... 13-1

Table 13-2 GPIB Troubleshooting .................................................. 13-2

xix

ILX Lightwave

70032603 Revision 00

LIST OF TABLES (CONTINUED)

Table 13-3 FOS-79710 Switch Module Errors ................................ 13-4

Table 13-4 FOS-79800E Source Module Errors............................. 13-5

Table 13-5 DPM-79810 Dual Power Meter Module Errors ............. 13-6

xx

CHAPTER 1 INTRODUCTION

COMPANY AND TECHNOLOGY OVERVIEW

ILX Lightwave is a market and technology leader in the manufacture of

photonic test and measurement instrumentation. ILX Lightwave’s global

customer base is comprised of leading manufacturers of fiber optic

telecommunications systems and components.

ILX Lightwave serves customers from five strategically located

manufacturing, sales and service centers in the United States, Canada,

Japan and Europe. In keeping with its commitment to product leadership

and business growth, ILX Lightwave continuously introduces new

products that are designed to offer customers long-term benefits such as

manufacturing yield enhancement, greater productivity or reduced cost of

ownership.

ILX Lightwave

70032603 Revision 00

PRODUCT OVERVIEW

The FOM-7900B Fiber Optic System supports up to eight modules of

stabilized DFB or Fabry Perot laser sources, fiber optic switches or dual

power meters. All are controlled from a single user interface.

The mainframe and modules can be controlled by a GPIB/IEEE-488.2 or

RS-232 interface. Up to twenty-five FOM-7900B Systems can be linked to

control up to 200 channels from one GPIB address.

AVAILABLE OPTIONS

The following options are available with the FOM-7900B Fiber Optic

System.

Table 1-1 Module Options

DESCRIPTION MODEL NUMBER

1 x 4 Fiber Optic Switch Module FOS-79710

Precision Fiber Optic Source Module FOS-79800E

Dual Power Meter DPM-79810

CHAPTER 1 INTRODUCTION 1-1

ILX Lightwave

70032603 Revision 00

SUMMARY OF INSTRUCTION MANUAL

Thank you for purchasing an ILX Lightwave FOM-7900B Fiber Optic

System. This manual describes the maintenance and operation of the

FOM-7900B Fiber Optic System and modules. We recommend that you

read this manual before operating the FOM-7900B Fiber Optic System.

CHAPTER 2 System Overview

Before using the FOM-7900B Fiber Optic System the user should

become familiar with the physical components of the unit. This chapter

describes the exterior and interior components and provides

specifications for the FOM-7900B Fiber Optic System.

CHAPTER 3 FOM-7900B Mainframe Operation

This chapter is a guide for front panel operation of the mainframe.

CHAPTER 4 FOS-79800E Module

This chapter is a guide for front panel operation of the source module.

CHAPTER 5 DPM-79810 MODULE

This chapter is a guide for front panel operation of the dual power meter

module.

CHAPTER 6 FOS-79710 Module

This chapter is a guide for front panel operation of the 1 x 4 switch

module.

CHAPTER 7 RS–232 Interface

This chapter is an overview of the RS–232 interface.

CHAPTER 8 GPIB Remote Operation and Common Commands

This chapter is a guide to the syntax and usage of the various IEEE/488.2

common commands. It also includes hardware diagrams and other

information relating to remote operation.

1-2 CHAPTER 1 INTRODUCTION: Summary of Instruction Manual

CHAPTER 9 Command Reference

This chapter is a guide to the syntax and usage of the various

device-dependent commands for the FOM-7900B System.

CHAPTER 10 Programming Examples

This chapter provides FOM-7900B programming examples using GPIB

commands.

CHAPTER 11 Maintenance

This chapter describes how to maintain the FOM-7900B System.

ILX Lightwave

70032603 Revision 00

CHAPTER 12 Error Messages

This chapter provides information on error messages and warnings.

CHAPTER 13 Troubleshooting

This chapter is intended to be used as a guide when the FOM-7900B

mainframe or modules do not perform as expected.

CHAPTER 1 INTRODUCTION: Summary of Instruction Manual 1-3

ILX Lightwave

70032603 Revision 00

(page left blank intentionally)

1-4 CHAPTER 1 INTRODUCTION: Summary of Instruction Manual

CHAPTER 2 SYSTEM OVERVIEW

FOM-7900B SYSTEM CHARACTERISTICS

Power Input1: 100-120VAC (50Hz/60Hz, 1.5 A)

Rack Mounting: 19” (48.3cm)

Weight: 28lbs (12.7Kg)

Height: 5.5” (14.0cm)

Depth: 17.5” (44.5cm)

Width: 17.75” (45.1cm)

ILX Lightwave

70032603 Revision 00

220-240VAC (50Hz/60Hz, 0.8 A)

Maximum Relative Humidity: <90% relative humidity, non-condensing

Operating temperature range2: 0°C to +40°C

Storage temperature range: -40°C to +70°C

Maximum altitude: 3,000 meters

Chassis Ground 4mm Banana jack

Suitable for continuous operation

Ordinary Protection (Not protected against harmful ingress of moisture)

Class 1 Equipment (Grounded Type) Indoor use only

NOTE: The mains supply voltage is factory set and cannot be changed by the user.

If a change is required, contact ILX Lightwave Customer Service.

1. Permitted fluctuations in rated line voltage of +6% and -10%

2. Operating temperature range may vary for individual modules

CHAPTER 2 System Overview 2-1

ILX Lightwave

70032603 Revision 00

FOM-7900B SYSTEM SPECIFICATIONS

Internal Modulation

Waveform Square Wave

Frequency 1-500kHz

Duty Cycle 50% ± 1%

Modulation Depth 100%

Rise/Fall time < 250ns

Channel to Channel

Synchronization

3

<100ns

Modulation In

Level TTL

Frequency 1-500kHz

Duty Cycle

Polarity 0 volts = Laser turned OFF

Optical Delay

Channel to Channel

Synchronization

Jitter

Connector BNC female on back panel

Modulation Out

Level TTL

Polarity of OUT 0 volts = Laser turned OFF

Polarity of OUT 0 volts = Laser turned ON

Optical Delay

Gate Delay

Jitter

1

2

3

4

50% ±1%

+5 volts = Laser turned ON

<1µs

<100ns

<50ns

+5 volts = Laser turned ON

+5 volts = Laser turned OFF

2

5

4

<1µs

< 60ns/mainframe

< 50ns

1. Input modulation duty cycles other than 50% ±1% will result in output power inaccuracies.

2. Optical Delay is defined as the time between the rising edge of the electrical input

modulation signal and the rising edge of the modulated optical output.

3. Channel to Channel Synchronization is defined as the maximum variation in optical delay

between modules in the same mainframe.

4. Jitter is defined as the variation in optical delay for any given module.

5. Gate Delay is defined as the time between the input modulation signal and the output

modulation signal.

2-2 CHAPTER 2 System Overview: FOM-7900B System Specifications

Fanout Capable of driving 3 additional FOM-7900B

Connector BNC female on rear panel

External Trigger Input/Output

Level TTL, Active Low

Pulse Width 100ns minimum

Connector BNC female on rear panel

Computer Interface

GPIB/IEEE-488.2

Hardware meets ANSI/IEEE Std. 488.1 - 1987

Software meets ANSI/IEEE Std. 488.2 - 1992

SH1, AH1, T6, L4, SR1, RL1, PP0, DC1, DT1, C0, E1, E2

ILX Lightwave

70032603 Revision 00

mainframes in parallel

RS-232

Baud Rate 9600

Stop Bits 1

Parity None

Data Bits 8

Flow Control None

RS-232 A Connector 9 pin male “D” connector

RS-232 B Connector 9 pin female “D” connector

CHAPTER 2 System Overview: FOM-7900B System Specifications 2-3

ILX Lightwave

70032603 Revision 00

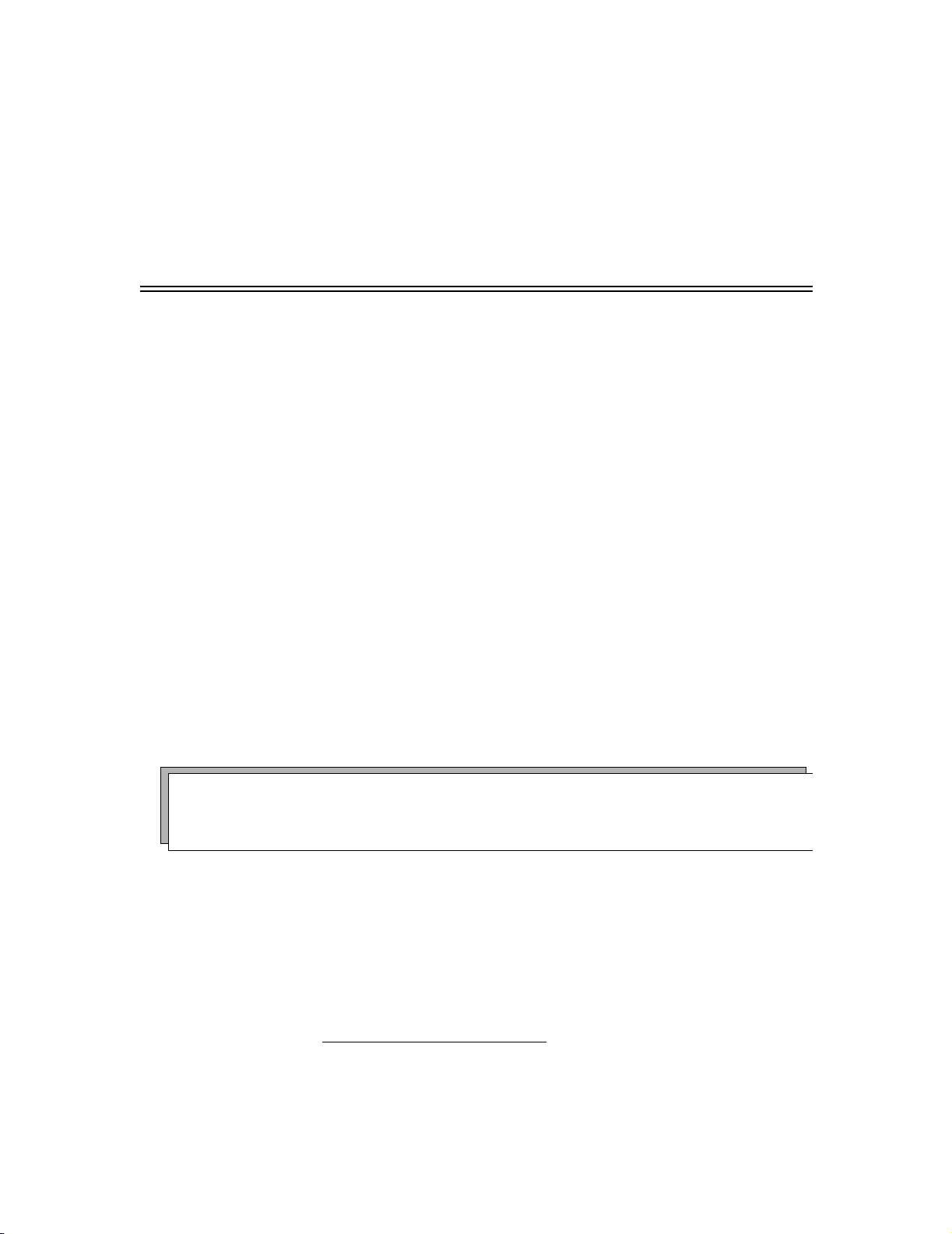

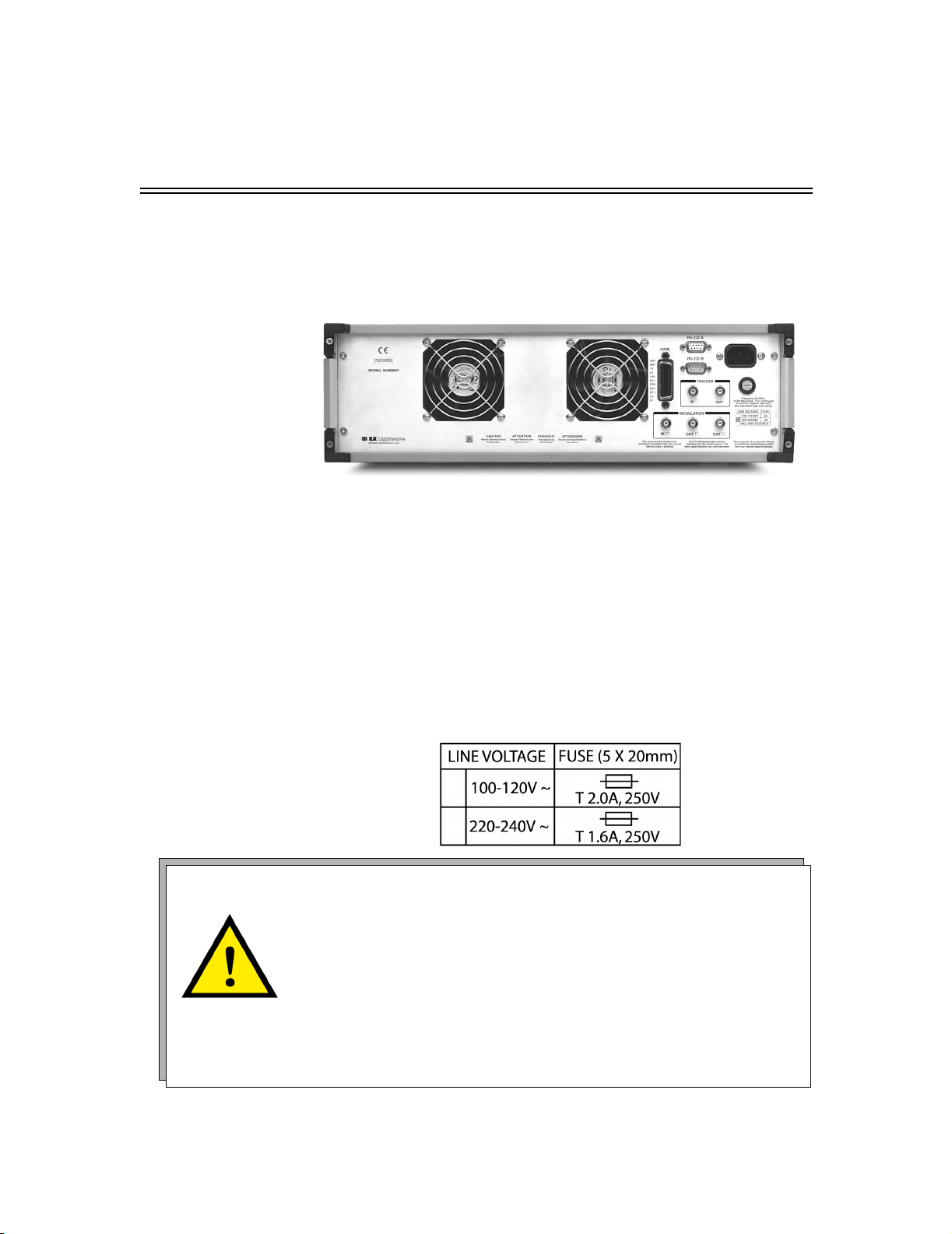

REAR PANEL

The following paragraphs describe the rear panel of the FOM-7900B

Fiber Optic System. The FOM-7900B Mainframe Rear Panel is shown in

FIGURE 2-1.

FIGURE 2-1 FOM-7900B Fiber Optic System Rear Panel

Power Entry Module and Fuse

The AC Power Entry Module and fuse are located on the right side of the

FOM-7900B rear panel. The unit must be connected to a properly rated

AC power source in order to operate. The AC line voltage is preset at the

factory and is not adjustable in the field. Permitted fluctuations from rated

line voltages are +6% and -10%.

Fuse Rating Replace fuse only with the specified type and rating as listed on the back

panel of your FOM-7900B. Instructions for replacing a fuse are found in

CHAPTER 11 Maintenance.

NOTE: FOR CONTINUED PROTECTION, REPLACE FUSE ONLY WITH

SPECIFIED TYPE AND RATING.

ZUM FORTBESTEHENDEN SCHUTZ, ERSETZEN SIE DIE SICHERUNG

NUR MIT DEM SPEZIFIZIERTEM TYP AND NENNWERT.

POUR ASSURER LA PROTECTION FUTURE, LE FUSIBLE DE

REMPLACEMENT DOIT ETRE AUX MEMES SPECIFICATIONS.

PER UNA CORRETA PROTEZIONE, SOSTITUIRE IL FUSIBILE SOLO

CON UNO DI IDENTICO TIPO E POTENZA.

2-4 CHAPTER 2 System Overview: Rear Panel

Loading...

Loading...