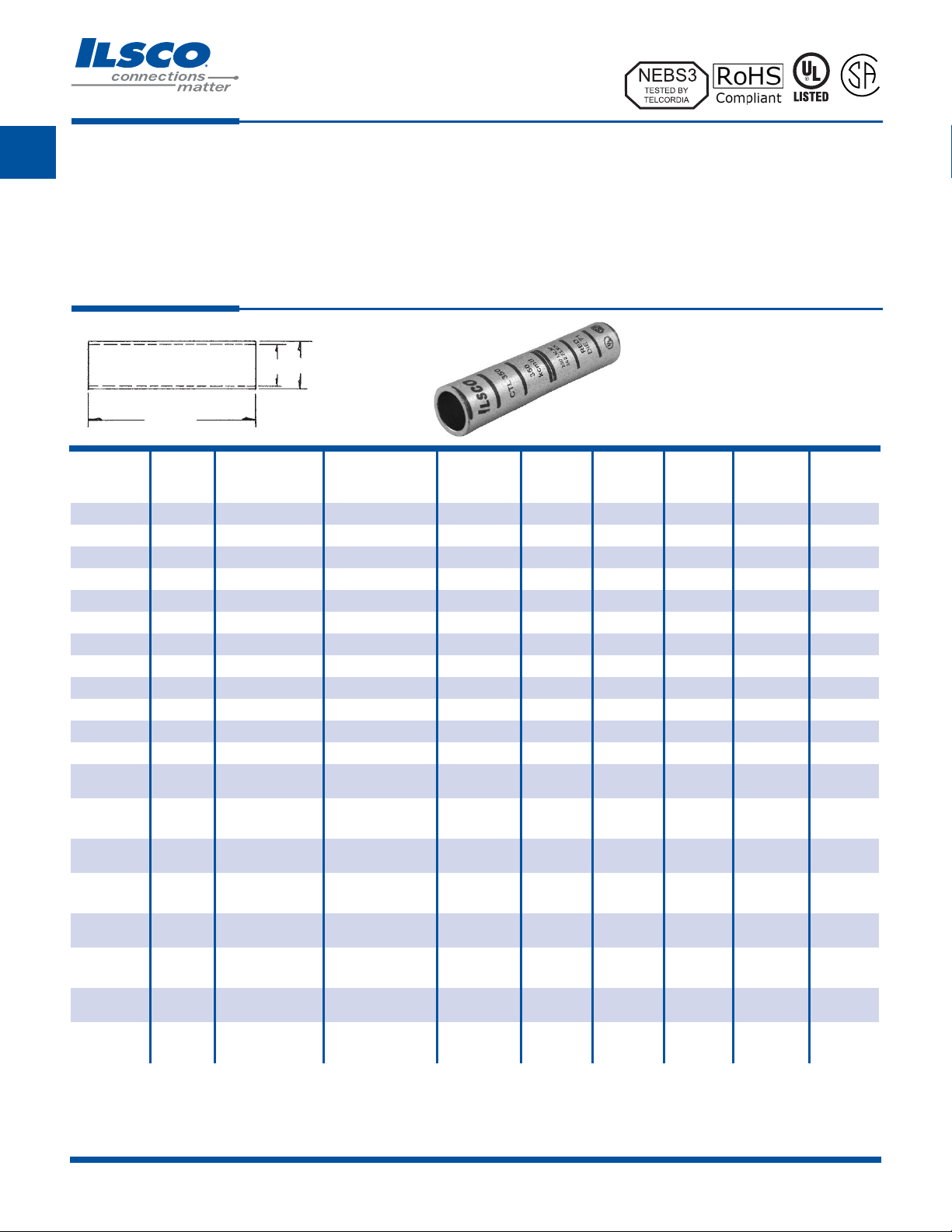

Copper Compression Sleeves

Long Barrel

Conductor Range: 1000kcmil-#6

453G

L

1

R

0

-

2

6

9

A

TYPE

CTL

Length

Catalog Wire Alt Expanded* Barrel Color Die Catalog

Number Size Wire Size Wire Range Length Code Index Number O.D. I.D.

CTL-8 8 AWG #8 Flex, #8 Sol - 1.75 Red I-21 ILD-21 0.272 0.179

CTL-6 6 AWG #6 Flex, #6 Sol - 2.375 Blue I-24 ILD-24 0.320 0.225

CTL-4 4 AWG #4 Sol 4-6 AWG 2.375 Gray I-29 ILD-29 0.343 0.250

CTL-3 3 AWG #4 Flex 3-6 AWG 2.375 White I-29 ILD-29 0.375 0.275

CTL-2 2 AWG #2 Sol 2-6 AWG 2.625 Brown I-33 ILD-33 0.421 0.312

CTL-1 1 AWG #2 Flex 1-6 AWG 2.875 Green I-37 ILD-37 0.468 0.359

CTL-1/0 1/0 AWG #1 Flex 1/0-6 AWG 2.875 Pink I-42 ILD-42 0.515 0.390

CTL-2/0 2/0 AWG 1/0 Flex 2/0-4 AWG 3.125 Black I-45 ILD-45 0.562 0.437

CTL-3/0 3/0 AWG 2/0 Flex 3/0-2 AWG 3.125 Orange I-50 ILD-50 0.609 0.484

CTL-4/0 4/0 AWG 3/0 Flex 4/0-1 AWG 3.375 Purple I-54 ILD-54 0.687 0.546

CTL-250 250kcmil 4/0 Flex 250kcmil-1/0 AWG 3.375 Yellow I-62 ILD-62 0.750 0.593

CTL-300 300kcmil 250 G,H Flex 300kcmil-2/0 AWG 4.125 White I-66 ILD-66 0.812 0.660

CTL-350 350kcmil

CTL-400 400kcmil

CTL-500 500kcmil

CTL-600 600kcmil

CTL-650 650kcmil

CTL-700 700kcmil

CTL-750 750kcmil

CTL-1000 1000kcmil

Features

Manufactured from high strength seamless copper tubing

•

Electro-Tin plated

•

Chamfered entry

•

Color coded

•

Suitable for use in circuits rated 35KV or less, proper high

•

voltage spacing and insulation techniques must be used

UL Listed and CSA Certified with ILSCO and major

•

competitor’s compression tools

UL467 Listed 500 kcmil - 8 AWG , #8 - #2 SOL

•

Rated to 90˚ C

•

O.D.

I.D.

250 I,K,M Flex

262.2 DLO

300 G,H,I,K,M Flex

313.1 DLO

350 G,H,I,K,M Flex

373.7 DLO

400 G,H,I,K,M Flex

444.4 DLO

500 G,H,I,K,M Flex

535.3 DLO

500 G,H,I,K,M Flex

535.3 DLO

600 G,H,I,M Flex

646.4 DLO

750 G,H,I Flex

777.7 DLO

350kcmil-3/0 AWG 4.125 Red I-71 ILD-71 0.890 0.703

400kcmil-4/0 AWG 4.375 Blue I-76 ILD-76 0.937 0.750

500kcmil-250kcmil 4.625 Brown I-87 ILD-87 1.062 0.828

600kcmil-250kcmil 4.625 Green I-94 ILD-94 1.187 0.920

650kcmil-350kcmil 4.625 Pink I-99 ILD-99 1.222 0.962

700kcmil-350kcmil 5.875 Pink I-99 ILD-99 1.250 0.991

750kcmil-500kcmil 5.875 Black I-106 ILD-106 1.313 1.031

1000kcmil-750kcmil 6.125 White I-125 ILD-125 1.500 1.172

Benefits

Offers maximum conductivity and excellent crimping characteristics

•

Provides low contact resistance

•

For easy conductor insertion

•

Identifies the proper compression die

•

Application versatility

•

Reduces inventory requirements

•

For grounding and bonding applications

•

Die Die

All wire sizes, unless noted otherwise, are American Wire Gauge (AWG)

* When installed with specified dieless tools

See pages 98 to 103 for complete tooling information.

UL File E6207

4730 Madison Road, Cincinnati OH 45227-1426 | PH: 513.533.6200 | FAX: 513.871.4084 | www.ilsco.com

47

In Canada: 1050 Lakeshore Road East, Mississauga, Ontario, Canada L5E 1E4 | PH: 905.274.2341 | FAX: 905.274.8763

Loading...

Loading...