NextSeq 500

System Guide

Document # 15046563 v04

May 2018

For Researc h Use Only. Not for use in diagnostic procedure s.

ILLUMINA P ROP RIETARY

NextSeq 500 System Guide

This docume nt a nd its c on tents are proprietary to Illumina, Inc. a nd its a ffiliates ("Illumina ") , and are inte nded sole ly for

the contrac tual use of its custome r in conne ction with the use of the produc t(s) desc ribed herein a nd for no othe r

purpose. This docume nt and its conten ts shall n ot be used or distribu te d f or a ny othe r pu rpose and/or oth erwise

communicate d, disc losed, or reproduce d in any way wha tsoever without the prior written consent of Illum ina. Illumin a

doe s n ot con ve y any lic ense un de r its pa tent, trademark, copyright, or c ommon -law rights nor similar righ ts of a ny th ird

parties by this docume nt.

The instruction s in this documen t must be strictly and explicitly followe d by qualified and properly traine d pe rsonnel in

orde r to ensure the proper and safe use of the product( s) described here in . All of th e conte nts of this docume nt must be

fully rea d a nd unde rstood prior to using suc h product(s) .

FAILURE TO C OM PL ETELY READ A ND EXPLIC ITLY FOLLOW A LL OF THE INSTRUCTION S CON TAINED HEREIN MAY

RESUL T IN DAMAGE TO THE PRODUC T( S), INJURY TO PERS ON S, INC LUDING TO USERS OR OTHERS, AND DAMAGE

TO OTHER PROP ERTY , AND WIL L VOID ANY WA RRA NTY APPLICA BLE TO THE PRODUCT(S) .

ILLUMINA DOES N OT ASSUME A NY LIABILITY ARISING O UT O F THE IMPROPER USE OF TH E PRODUC T( S)

DESC RIBED HEREIN (IN CLUDIN G PARTS THEREO F OR SOFTWA RE) .

© 2018 Illumin a, Inc. All rights re se rve d.

All tra de ma rks a re the property of Illumina, Inc. or their respective own ers. F or specific trademark information , see

www .illumina.com/ company/lega l.h tml.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

ii

NextSeq 500 System Guide

Revision History

Document Date Descri pti on of Change

Material # 2000 6818

Documen t # 15046563

v04

Material # 2000 6818

Documen t # 15046563

v03

Material # 2000 6818

Documen t # 15046563

v02

Material # 2000 1879

Documen t # 15046563

v01

May 2018

March

2018

March

2016

Octobe r

2015

Added support for N extSeq v2.5 rea ge nts.

Updated storage/ sh ipping inf ormation for NextSe q v2.5 Rea ge nt Kits

shippin g flow ce lls at a mbien t temperatu res. N extSeq v2.5 flow c ells

continue to re quire previous storage condition s.

Added informa tion about N e xtSeq v2.5 Re agent Kits requiring softw are

update s to ve rsion 2.2.

Added note regarding mid output kit loading conc entra tion.

Added note regarding sa ving flow c ells.

Added note recomme nding th at high output flow c ells are use d for

system chec ks.

Removed the default user name and pa ssword required to log on to th e

ope rating system. Illumina recommen ds using site-spe cific credentials.

Added informa tion about the Illu mina Proac tive monitoring service in th e

Se le ct Ba se Spac e Configuration section.

Updated RTA v2 software refe renc es to RTA2.

Added sec tion titled Indexing C onside ra tions.

Removed steps to inspec t the flow cell.

Spe cified loading volume and concen tration in the step to Loa d

Libraries onto the Reagent Cartridge .

Spe cified that an equ ivalen t to the recomme nded supplier of N aOC l is a

labora tory-gra de equiv alent.

Added recomm enda tion for a nn ual preven tive mainte na nce se rvic e .

Reorga nize d informa tion in the Ove rview an d Getting Sta rte d c hapters.

Added instruction s f or customizin g system settings.

Removed Live Help instructions from troubleshooting c hapter. This

fe ature wa s re moved from the control software .

15046563 I May 2015 Correc te d desc ription of rese rve d reservoirs on the reagen t c a rtridge.

15046563 H May 2015 Correc te d the volume of Tween 20 in the wash solu tion u se d f or

manu al wash es.

Restruc tured information about system c on figuration options.

Moved inf ormation about Rea l-T ime Ana lysis software to Appendix A.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

iii

NextSeq 500 System Guide

Document Date Descri pti on of Change

15046563 G Fe bruary

2015

Updated software descriptions to N extSe q Con trol Sof twa re v1.4.

• Added man ua l wash options: Quick Wash and Manual Post-Run

Wa sh.

• Added desc ription of run customiza tion fea tures to pu rge

consu ma bles at e nd of run an d to skip pre -ru n chec k c onfirmation .

• Added option to c anc el a nd resta rt a pre -run che ck.

• Added option to e na ble run monitorin g in stan dalon e mode .

• Removed desc ription of off sets file s and pha sin g file s, whic h are no

lon ge r writte n to the run folder.

• Updated sc atter plot imag e to sh ow more ev enly distributed base calls

when using version 1.4 of the syste m software.

• Added desc ription of Run Copy S ervic e.

• Added option to use a custom Index 2 prime r, possible with the

Ne xtS eq 50 0 K it v2. F or more inf ormation, se e

Primers Guide (doc ument # 15 057456)

Updated reagen t prep instruction s f or using the Ne xtS eq 500 Kit v2:

Removed manual steps for loading sodium h ypo chlorite an d dualindexing prime rs to the reagent cartridge. The se rea ge nts a re pref illed in

the v2 rea ge nt ca rtridg e. For more inf ormation, se e the

500/550 Kit v2 Refere nce Gu ide (doc ument # 15058065)

Added Seque ncing Con sumable s se c tion tha t lists kit ve rsions,

compa tible NC S versions, and the na me and part n umber of the

associated kit refere nc e guide .

Updated user-supplie d consum ables to specify uses of N aOC l f or

manu al wash options in troduced in NC S v1.4.

Correc te d the require me nts for c lu ste rs pa ssing filter to no more tha n 1

base call below c hastity in the first 25 cycles.

Added volu me of 120 ml of laboratory-grade water to the Syste m Chec k

instruc tions.

Ne xtS eq C ustom

.

Ne xtS eq

.

15046563 F Se pte mber

2014

15046563 E August

2014

Document # 15046563 v04

Correc te d f eatu re descriptions for N extSe q Con trol Sof twa re v1.3.

Updated URL for Sa fety Data Sheets (SDS ) to

support.illu mina .c om/sds.html.

Updated NextSe q produc t m arkings from ™ to ®.

Updated software descriptions to N extSe q Con trol Sof twa re v1.3:

• Updated de scriptions of the Syste m Customization a nd Software

Updates commands on the Man age Instru me nt sc ree n.

• Updated de scription of the Pre-Run C hec k scre en, which grou ps the

ch ecke d items into 4 e xpa ndable ca tegories.

• Updated the Live Help instru ction s to a cce ss Live Help using th e URL.

The icon on the Hom e scre en is not ava ilable in N C S v1.3.

• Added the on-instrumen t re hybridiza tion proce dure to rehybridize the

Read 1 prim er. Th e option to rehybridize a f low c ell is compatible with

NC S v1.3, or later, a nd requ ires a ne w reagent cartridge and buffe r

ca rtridge.

Added

Ne xtS eq C ustom Primers Gu ide (doc ument # 15057456 )

of additiona l re sources.

For Researc h Use Only. Not for use in diagnostic procedure s.

to list

iv

NextSeq 500 System Guide

Document Date Descri pti on of Change

15046563 D June 2014 Added instruction s to load BP 13 in position #18 of the rea ge nt cartridge

when performing du al-inde xe d runs.

Correc te d c yc le at whic h cluste r de nsity metrics a ppe ar, whic h is c yc le

25.

Correc te d re agent cartridge positions for c ustom prime rs a s position #7

(Rea d 1), #8 (Read 2), a nd #9 ( Index 1).

Added a n ote about potential damage from reloca ting the instrumen t

af ter in sta lla tion. Alwa ys con ta ct your Illumina repre senta tive bef ore

relocating the instrument.

Updated URL for Sa fety Data Sheets (SDS ) to

support.illu mina .c om/sds.ilmn.

15046563 C April 2014 Update d software descriptions to N extSeq Con trol Sof twa re v1.2 a nd

RTA v2.1:

• Added recipe na me NextSe q Mid for use with the NextSe q 500 Mid

Output Kit.

• Removed instru ction s to a dd NaOCl to the buffer wash cartridge for a

manu al wash .

• Correc te d N aOC l volu me to 3 ml for position 28 o f the rea ge nt

ca rtridge, which is re quired for th e au tomatic post-run wash.

• Noted that long run names appea r in a sc rolling field on th e Run

Se tup sc reen .

• Noted that RTA v2 does not a pply phasing a nd pre phasing correc tions

to index re ads.

• Added desc ription of log file s to list of f ile s used for troubleshooting.

• Added instru ction s f or emptying a fu ll spen t re a ge nts containe r du ring

a run.

• Added desc ription of recipe folde rs, including location of custom

rec ipes.

• Added desc ription of therma l c hec ks for fan s a nd therm al probes.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

v

NextSeq 500 System Guide

Document Date Descri pti on of Change

15046563 B F ebrua ry

2014

15046563 A January

2014

Updated software descriptions to N extSe q Con trol Sof twa re v1.1:

• Added sea rch f eatu re on Run Setup scre en to filte r list of a va ilable

runs.

• Added that ava ila ble recipes include NextSeq High or NextSeq Mid,

depen din g on f low c ell type.

• Noted that software updates in clude license agree me nt, re le ase

notes, a nd list of software to be updated.

• Added desc ription of the RAID error m essage.

• Noted that an Exit button closes NSSan d re sta rts NCS auto ma tic ally

at end of a syste m chec k.

Added reagent storage dura tion of u p to 1 wee k a t 4°C.

Updated reagen t c a rtridge label for reservoir #10 to Loa d Libra ry Here.

Updated user-supplie d consum ables list to spec ify 3%–6% sodium

hypochlorite and list a supplier catalog num ber.

Updated in structions for pre pa rin g a 0.06% dilution of Na OC l for

instrumen t washe s, whic h inc lu des a reduc tion in volume to 2 ml and a

3%–6% starting conc entra tion.

Added illustrations to show good and ba d c lip position on the flow c ell.

Updated the Rea l-Time Ana lysis cha pte r to include an overvie w of RTA

v2, the output folde r struc ture , and the base calling process.

Updated troublesh ooting c ha pte r to include RTA v2 e rrors and in clude

Run Pa ra me ters.xml in the list of trouble shooting files.

Initial re le ase.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

vi

Table of Contents

Chapter 1 Overview 1

Introduction 1

Additional Resources 1

Instrument Components 2

Sequencing Consumab les Overview 4

Chapter 2 Getting Started 8

Starting the Instrument 8

Customize System Settings 8

Customize Run Settings 9

User-Supplied Consumables and Equipment 10

Chapter 3 Sequencing 12

Introduction 12

Sequencing Workflow 13

Prepare the Reagent Cartridge 13

Prepare the Flow Cell 14

Prepare Libraries for Sequencing 15

Set Up a Sequencing Run 15

Monitor Run Progress 21

Automatic Post-Run Wash 23

Chapter 4 Maintenance 24

Introduction 24

Perform a Manual Wash 24

Software Updates 26

Shut Down the Instrument 27

Appendix A Troubleshooting 29

Introduction 29

Troubleshooting Files 29

Resolve Automatic Check Errors 30

Spent Reagents Container is Full 31

Rehybridization Workflow 31

Custom Recipes and Recipe Folders 33

System Check 33

RAID Error Message 35

Configure System Settings 35

Appendix B Real-Time Analysis 38

Real-Time Analysis Overview 38

Real-Time Analysis Workflow 39

Sequencing Outp ut Files 42

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

vii

NextSeq 500 System Guide

Flow Cell Tiles 42

Output Folder Structure 45

Index 47

Technical Assistance 50

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

viii

Chapter 1 Overview

Introduction 1

Additional Resources 1

Instrument Components 2

Sequencing Consumab les Overview 4

Introduction

The Illumina®NextSeq™500 system combines the power of high-throughput sequencing with the simplicity

of a desktop sequencing instrument.

Features

u High-throughp ut sequencing—The NextSeq 500 enables sequencing of exomes, whole genomes, and

transcriptomes and supports TruSeq®and Nextera®libraries.

u Flow cell types—Flow cells are available in configurations for high output and mid output. Each flow cell

type is kitted with a compatible prefilled reagent cartridge.

u Real-Time Analysis (RTA)—Integrated analysis software performs on-instrument data analysis, which

includ es image analysis and base calling. The NextSeq uses an implementation of RTA called RTA v2,

which includes important architecture and feature differences. For more information, see

Analysis

u BaseSpace

on p age 38.

®

integration—The sequencing workflow is integrated with BaseSpace, the Illumina genomics

computing environment for data analysis, storage, and collaboration. For instruments configured for

BaseSpace, library information and run parameters are specified on the BaseSpace Prep tab. Runs that

were set up in BaseSpace appear on the instrument interface during run setup. As the run progresses,

output files are streamed in real time to BaseSpace or BaseSpace Onsite.

Real-Time

Additional Resources

The following d ocumentation is available for download from the Illumina website.

Resource Descri pti on

Ne xtS eq Syste m Site Prep Guide

(document # 15045113)

Ne xtS eq Syste m Safe ty and

Complianc e Guide (document #

15046564)

RFID Rea de r - Mode l # TR-001-44

User Gu ide (doc um ent # 15041950)

Den aturing and Diluting Libraries for

the NextSe q Syste m (docu me nt #

15048776)

Ne xtS eq C ustom Primers Gu ide

(document # 15057456)

BaseS pa ce help

(h elp.basespac e.illumina.com)

Visit the NextSeq 500 support page on the Illumina website for access to documentation, software

downloads, online training, and frequently asked questions.

Provide s spec ifications for laboratory spac e, e le ctrical requ ire me nts, a nd

en vironmenta l c onsidera tions.

Provide s informa tion a bout opera tiona l safety c onside rations, complian ce

statements, an d instrume nt la be ling.

Provide s informa tion a bout the RFID reader in th e instrumen t, complia nce

ce rtific ations, and sa fe ty considera tions.

Provide s instructions for denaturin g and diluting prepa red libraries for a

seque ncing run, and pre pa ring a n optiona l PhiX control. This step applies to

most library types.

Provide s informa tion a bout using c ustom seque nc in g primers in pla ce of

Illumina seque nc in g primers.

Provide s informa tion a bout using Base Space®an d a va ilable analysis option s.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

1

NextSeq 500 System Guide

Instrument Components

The NextSeq 500 system includes a touch screen monitor, a status bar, and 3 compartments.

Figure 1 Instr ument Components

A Imaging compartment—Holds the flow cell during a sequencing run.

B Touch screen monitor—Enables on-instrument configuration and setup using the control software interface.

C Status bar—Indicates instrument status as processing (blue), requires attention (orange), ready to sequence

(green), or when a wash is due within the next 24 hours (yellow).

D Buffer compartment—Holds the buffer cartridge and the spent reagents container.

E Reagent compartment—Holds the reagent cartridge.

Imaging Compartment

The imaging compartment houses the stage, which includes three alignment pins for positioning the flow cell.

After loading the flow cell, the imaging compartment d oor closes automatically and moves components into

position.

Reagent and Buffer Compartments

Setting up a sequencing run on the NextSeq 500 requires access to the reagent compartment and buffer

compartment to load run consumables and empty the spent reagents container.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

2

NextSeq 500 System Guide

Figure 2 Reagent and Buffer Compart ments

A Reagent compartment door—Encloses the reagent compartment with a latch under the lower-right corner

of the door. The reagent compartment holds the reagent cartridge. Reagents are pumped through the

sippers and fluidics system, and then to the flow cell.

B Reagent cartridge—The reagent cartridge is a prefilled single-use consumable.

C Buffer cartridge—The buffer cartridge is a prefilled single-use consumable.

D Spent reagents container—Spent reagents are collected for disposal after each run.

E Buffer compartment door—Encloses the buffer compartment with a latch under the lower-left corner of the

door.

NextSeq Software

The instrument software includes integrated applications that perform sequencing runs.

u NextSeq Control Software (NCS)—The control software guides you through the steps to set up a

sequencing run.

u Real-Time Analysis (RTA) software—RTA performs image analysis and base calling during the run. The

NextSeq 500 uses RTA v2, which includes imp ortant architecture and feature differences from earlier

versions. For more information, see

Real-Time Analysis

on p age 38.

Status Icons

A status icon in the top-right corner of the control software interface screen signals any change in conditions

during run setup or during the run.

Status

Icon

Status N ame Descri pti on

Sta tus OK System is norma l.

Proce ssing System is proce ssing.

Wa rning A warning has occurred.

Wa rnings do not stop a run o r require action before proceeding.

Error An error ha s occ urre d.

Errors re quire ac tio n before procee ding with the run .

When a change in condition occurs, the icon blinks to alert you. Select the icon to view a description of the

condition. Select Ack nowledge to accept the message and Close to close the dialog box.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

3

NextSeq 500 System Guide

Power Button

The power button on the front of the NextSeq turns on power to the instrument and instrument comp uter.

The power button performs the following actions depending on the state of instrument power.

Power State Act ion

Instrume nt power is

off

Instrume nt power is

on

Instrume nt power is

on

Brie fly pre ss the button to tu rn on the power.

Brie fly pre ss the button to tu rn off the power. A dialog box a ppe a rs on the scree n to c onfirm a normal

instrumen t shutdown.

Pre ss and hold the powe r bu tton f or 10 sec on ds to cau se a hard shutdown of th e instrument a nd

instrumen t c om puter.

Use this method to turn off the in strument only if the instrume nt is unre sponsive.

NOTE

Turning off the instrument during a sequencing run ends the run immediately. Ending a run is final. Run

consumables cannot be reused and sequencing data from the run is not saved.

Sequencing Consumables Overview

Contents and Storage

The sequencing consumables required to run the NextSeq are provided separately in a single-use kit. Each

kit includes one flow cell, a reagent cartridge, a buffer cartridge, and library dilution buffer. When you receive

NextSeq 500 Kit:

u Do not open the white foil packages until instructed to do so.

u Promptly store components at the indicated temperatures to ensure proper performance.

u Store cartridges so that the pack age labels face up.

Cons umabl e Quanti ty Storage Temp erature Descri pti on

Reagen t C artridge 1 -25°C to -15°C Conta in s c lu ste ring a nd se quen cing rea ge nts

Buf fe r C artridge 1 15°C to 30°C Conta in s buffe r and wash solution

HT1 1 -25°C to -15°C Hybridiza tion Buffe r

Flow Cell 1 2°C to 8°C * Single-use flow ce ll

*Shi pped at room t emperature for NextSeq v2. 5 Re agents k it s

Reagents are sensitive to light. Store the reagent cartridge and buffer cartridge in a dark location away from

light.

The flow cell, reagent cartridge, and buffer cartridge use radio-frequency identification (RFID) for accurate

consumable tracking and compatibility.

All other kits include dual-index sequencing primers and NaOCIin the prefilled cartridge. No additional steps

are req uired.

Kit Compatibility Labeling

Kit components are labeled with color-coded indicators to show compatibility between flow cells and reagent

cartridges. Always use a compatible reagent cartridge and flow cell. The buffer cartridge is universal.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

4

NextSeq 500 System Guide

Each flow cell and reagent cartridge is lab eled High or Mid. Always check the label when you prepare

consumables for a run.

Kit Type Mark ing on Label

High Output Kit C om pon ents

Mid Output Kit C om pon ents

Flow CellOverview

Figure 3 Flow Cell Cartridg e

A Lane pair A—Lanes 1 and 3

B Lane pair B—Lanes 2 and 4

C Flow cell cartridge frame

The flow cell is a glass-based substrate on which clusters are generated and the sequencing reaction is

performed. The flow cell is encased in a flow cell cartridge.

The flow cell contains 4 lanes that are imaged in pairs.

u Lanes 1 and 3 (lane pair A) are imaged at the same time.

u Lanes 2 and 4 (lane pair B) are imaged when imaging of lane pair A is complete.

Although the flow cell has 4 lanes, only a single library or set of pooled libraries is sequenced on the flow cell.

Libraries are loaded onto the reagent cartridge from a single reservoir and transferred automatically to the

flow cell to all 4 lanes.

Each lane is imaged in small imaging areas called tiles. For more information, see

Flow Cell Tiles

on p age 42.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

5

NextSeq 500 System Guide

Reagent Cartridge Overview

The reagent cartridge is a single-use consumable with RFIDtracking and foil-sealed reservoirs that are

prefilled with clustering and sequencing reagents.

Figure 4 Reagent Cartridge

The reagent cartridge includes a d esignated reservoir for load ing prepared libraries. After the run begins,

libraries are transferred automatically from the reservoir to the flow cell.

Several reservoirs are reserved for the automatic p ost-run wash. Wash solution is pumped from the buffer

cartridge to the reserved reservoirs, through the system, and then to the spent reagents container.

WARNING

This set of reagents contains potentially hazardous chemicals. Personal injury can occur through inhalation,

ingestion, skin contact, and eye contact. Wear protective equipment, including eye protection, gloves, and

laboratory coat appropriate for risk of exposure. Handle used reagents as chemical waste and discard in

accordance with applicable regional, national, and local laws and regulations. For additional environmental,

health, and safety information, see the SDS at support.illumina.com/sds.html.

Reserved Reservoirs

Figure 5 Numbered Reservoirs

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

6

NextSeq 500 System Guide

Posit ion Descri pti on

7, 8, a nd 9 Reserved for optional c ustom prime rs

10 Load libraries

For information about custom primers, see

NextSeq Custom Primers Guide (document # 15057456)

.

Removable Reservoir in Position #6

The prefilled reagent cartridge includes a denaturation reagent in position 6 that contains formamide. To

facilitate safe disposal of any unused reagent after the sequencing run, the reservoir in position 6 is

removable. For more information, see

Remove Used Reservoir from Position #6

on p age 19.

Buffer Cartridge Overview

The buffer cartridge is a single-use consumable containing three reservoirs that are prefilled with buffers and

wash solution. The contents of the buffer cartridge are sufficient for sequencing one flow cell.

Figure 6 Buffer Cartridge

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

7

Chapter 2 Getting Started

Starting the Instrument 8

Customize System Settings 8

Customize Run Settings 9

User-Supplied Consumables and Equipment 10

Starting the Instrument

Turn on the power toggle switch to the I (on) position.

Figure 7 Po wer Swit ch Located on Back o f Inst rument

1 Press the power button above the reagent compartment. The p ower button turns on the instrument

power and starts the integrated instrument computer and software.

Figure 8 Po wer Button Located on Front of I nst rument

2 Wait until the operating system has finished loading.

The NextSeq Control Software (NCS) launches and initializes the system automatically. After the

initialization step is complete, the Home screen op ens.

3 If your system has been configured to require login credentials, wait for the system to load, and then log

on to the operating system. If necessary, consult your facility administrator for the user name and

password.

Customize System Settings

The control software includes customizable system settings for start-up options, input preferences, audio

settings, and instrument name.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

8

NextSeq 500 System Guide

Select Start-Up Option

1 From the Manage Instrument screen, select System Customization.

2 Select from the following start-up options:

u Select Kiosk Mode to use the control software interface in full screen.

u Select Windows Mode to allow access to Windows on the instrument computer. Interaction with the

software interface, such as button location, is likely to be altered in this mode.

3 Select Save to save settings and advance the screen.

Set Input Option and Audio Indicator

1 From the Manage Instrument screen, select System Customization.

2 Select the Use on-screen keyboard checkbox to activate the on-screen k eyboard for input to the

instrument.

3 Select the Play audio checkbox to turn on audio indicators for the following events.

u Upon instrument initialization

u When a run is started

u When certain errors occur

u When user interaction is required

u When a run has finished

4 Select Save to save settings and advance the screen.

Customize Instrument Identification

1 From the Manage Instrument screen, select System Customization.

2 To assign a preferred image for your instrument, select Browse and navigate to the image.

3 In the Nick Name field, enter a preferred name for the instrument.

4 Select Save to save settings and advance the screen.

The image and name appear at the upper-left corner of each screen.

Customize Run Settings

The control software includes customizable settings for run setup preferences and purging of unused

reagents.

Set Run Setup Options

1 From the Manage Instrument screen, select System Customization.

2 Select Save to advance to Run Customization.

3 Select the Use Advanced Load Consumables checkbox to enable the option to load all run consumables

from a single screen.

4 Select the Skip Pre-Run Check Confirmation checkbox to start sequencing automatically after a

successful automatic check.

5 Select Save to save settings and exit the screen.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

9

NextSeq 500 System Guide

Set Automatic Purge Option

1 From the Manage Instrument screen, select System Customization.

2 Select Save to advance to Run Customization.

3 Select the Purge Consumables at End of Run checkb ox to purge unused reagents from the reagent

cartridge to the spent reagents container automatically after each run.

NOTE

Purging consumables automatically adds additional time to the workflow.

4 Select Save to save settings and exit the screen.

User-Supplied Consumables and Equipment

The following consumables and equipment are used on the NextSeq 500.

User-Supplied Consumables for Sequencing Runs

Cons umabl e Sup pli er Purpos e

1 N NaOH

(sodiu m hydroxide )

200 mM Tris-H C l, pH7 Gene ral lab supplier Library den atura tion

Alcohol wipes, 70% Isopropyl

or

Etha nol, 70%

La b tissue, low-lint VWR, ca ta log#21905 -026

Gene ral lab supplier Library den atura tion, dilu ted to 0.2N

VWR, ca ta log#95041 -714

(or equivalent)

Gene ral lab supplier

(or equivalent)

Flow cell c le a ning and genera l purpose

Flow cell c le a ning

User-Supplied Consumables for Instrument Maintenance

Cons umabl e Sup pli er Purpos e

Na OC l, 5%

(sodiu m hypochlorite)

Twe e n 20 Sigma -A ldrich , c a talog # P7949 Wa shing th e instrume nt using man ua l

Wa te r, laboratory-grade Ge nera l lab supplier Wa shing the instrument (ma nu al wash)

Sigma -A ldrich , c a talog # 239305

(or la boratory-grade equivale nt)

Wa shing th e instrume nt using th e

manu al post-run wash ; diluted to 0.12%

wash options; dilu ted to 0.05%

Guidelines for Laboratory-Grade Water

Always use laboratory-grade water or deionized water to perform instrument proced ures. Never use tap

water. Use only the following grades of water or equivalents:

u Deionized water

u Illumina PW1

u 18Megohms (MΩ) water

u Milli-Q water

u Super-Q water

u Molecular biology grade water

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

10

NextSeq 500 System Guide

User-Supplied Equipment

Item Source

Fre ezer, -25°C to -15°C , frost-fre e Gene ral lab supplier

Ice bucke t Gene ral lab supplier

Refrigera tor, 2°C to 8°C Gene ral lab supplier

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

11

Chapter 3 Sequencing

Introduction 12

Sequencing Workflow 13

Prepare the Reagent Cartridge 13

Prepare the Flow Cell 14

Prepare Libraries for Sequencing 15

Set Up a Sequencing Run 15

Monitor Run Progress 21

Automatic Post-Run Wash 23

Introduction

To perform a seq uencing run on the NextSeq 500, prep are a reagent cartridge and flow cell, and then follow

the software prompts to set up and start the run. Cluster generation and sequencing are performed oninstrument. After the run, an instrument wash begins automatically using components already loaded on the

instrument.

Cluster Generation

During cluster generation, single DNA molecules are bound to the surface of the flow cell, and then amplified

to form clusters.

Sequencing

Clusters are imaged using 2-channel sequencing chemistry and filter combinations specific to each of the

fluorescently labeled chain terminators. After imaging of a tile on the flow cell is complete, the next tile is

imaged. The process is repeated for each cycle of sequencing. Following image analysis, the software

performs base calling, filtering, and quality scoring.

Monitor run progress and statistics from the control software interface, from the Run tab on BaseSpace, or

from a networked comp uter using the Sequencing Analysis Viewer (SAV) software. See

Viewer

on p age 22.

Sequencing Analysis

Analysis

As the run progresses, the control software automatically transfers base call (BCL) files to BaseSpace or the

specified output location for secondary analysis.

Several analysis method s are available depending on your application. For more information, see the

BaseSpace help (help.basespace.illumina.com)

.

Sequencing Run Duration

Sequencing run duration depends on the number of cycles performed. The maximum run length is a p airedend run of 150 cycles each read (2 x 150), plus up to 8 cycles each for 2 index read s.

For expected durations and other system specifications, visit the NextSeq 500 specifications page on the

Illumina website.

Number of Cycles in a Read

In a sequencing run, the number of cycles performed in a read is 1 more cycle than the number of cycles

analyzed. For example, a paired-end 150-cycle run performs reads of 151-cycles (2 × 151) for a total of 302

cycles. At the end of the run, 2 x 150 cycles are analyzed. The extra cycle is required for phasing and

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

12

NextSeq 500 System Guide

prephasing calculations.

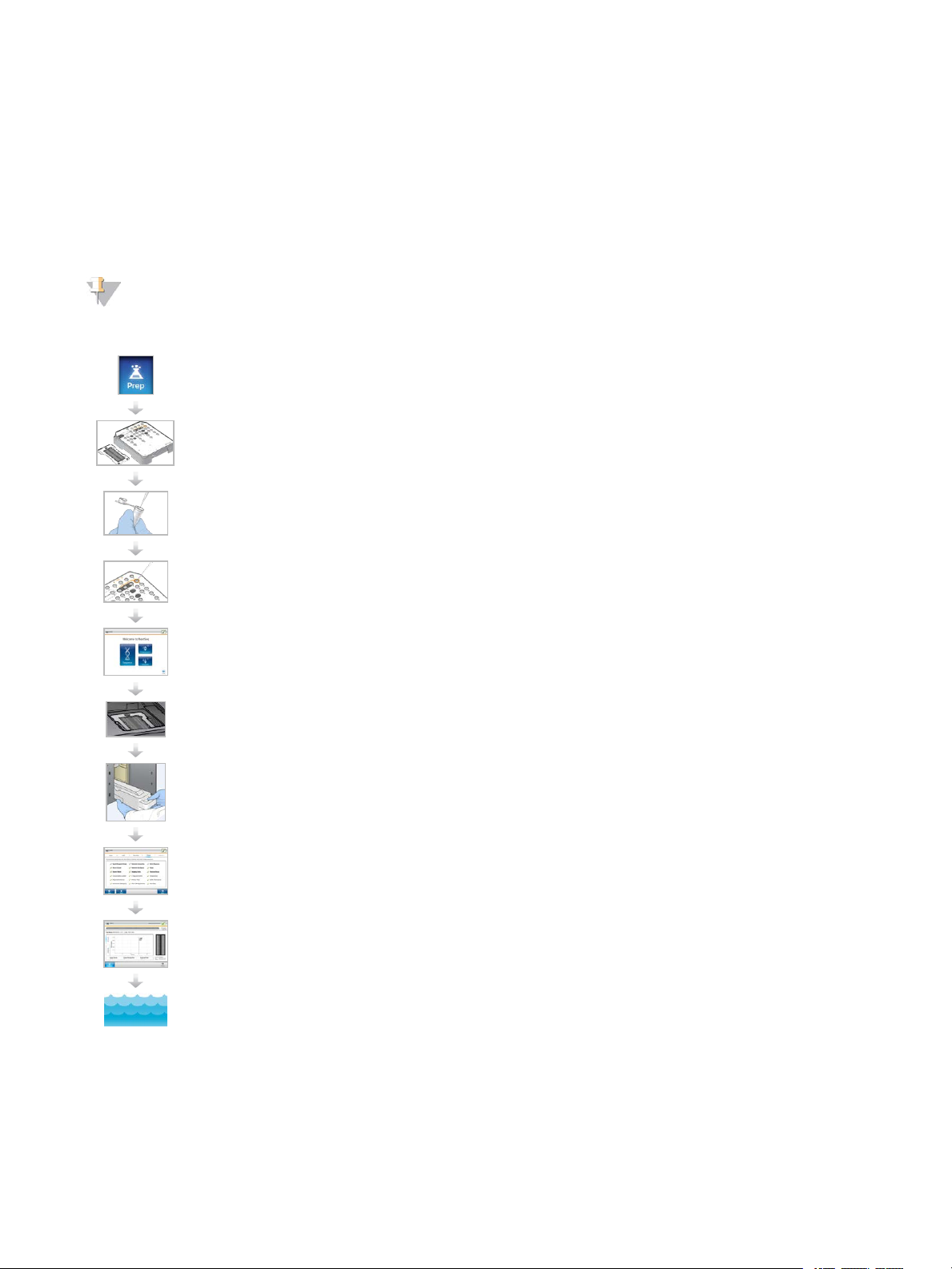

Sequencing Workflow

When using NextSeq v2.5 Reagents kit, make sure the NextSeq Control Software is version 2.2, or newer,

before beginning preparation of samples or consumables. For sub sequent software upd ates, make sure the

instrument is upd ated prior to preparing consumables for the NextSeq 500 workflow.

NOTE

NextSeq ControlSoftware Version 2.2 is required to read NextSeq v2.5 RFID.

Make sure that you complete all steps in the NextSeq 500 workflow in the specified order.

For conf igurations using Illumina Base Spac e or Ba se Spac e Onsite : Set up the run on the BaseS pace Prep

tab. S ee the

Pre pare a n ew re agent cartridge : thaw a nd in spe ct.

Pre pare a n ew flow ce ll: bring to room tempera ture, unwrap, a nd in spe ct.

BaseS pa ce help ( help.ba se spa ce.illumina.com)

.

Den ature and dilute libraries (doe s n ot apply to a ll libra ry types). See

Ne xtS eq Syste m (docu me nt # 15048776)

Load the libra ry dilution onto the rea ge nt cartridge in reservoir #10.

From th e software inte rfa ce, se le ct Sequenc e to begin the run setu p steps.

Load the flow c e ll.

Empty an d re load the spent reagents con ta iner.

Load the buffe r c artridge and reage nt cartridge.

Revie w run parameters and automa tic che ck results. Selec t Start.

Mon itor the run from the control software interface , from the Run tab on Base Space , or from a ne tworked

compu ter using Se quen cing Analysis Vie we r.

.

Den aturing and Diluting Libraries for the

An instrumen t wash begins automatica lly whe n sequ enc ing is c omplete.

Prepare the Reagent Cartridge

1 Remove thereagent cartridge from -25°C to -15°C storage.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

13

NextSeq 500 System Guide

2 Thaw in a room temperature water b ath untilthawed (~60 minutes). Do not submerge the cartridge.

3 Gently tap on the bench to dislodge water from the base, and then dry the base.

NOTE

[Alternate method] Thaw reagents overnight at 2°C to 8°C. Reagents require a minimum of 18 hours to

thaw. At this temperature, reagents are stable up to 1 week.

4 Invert the cartridge 5 times to mix reagents.

5 Inspect positions 29, 30, 31, and 32 to make sure that reagents are thawed .

6 Gently tap on the bench to reduce air bubbles.

WARNING

This set of reagents contains potentially hazardous chemicals. Personal injury can occur through

inhalation, ingestion, skin contact, and eye contact. Wear protective equipment, including eye

protection, gloves, and laboratory coat appropriate for risk of exposure. Handle used reagents as

chemical waste and discard in accordance with applicable regional, national, and local laws and

regulations. For additional environmental, health, and safety information, see the SDS at

support.illumina.com/sds.html.

Prepare the Flow Cell

1 Remove a new flow cell package from 2°C to 8°C storage.

2 Set the unwrapped flow cell package aside at room temperature for 30 minutes.

NOTE

If the foil package is intact, the flow cell can remain at room temperature up to 12 hours. Avoid repeated

cooling and warming of the flow cell.

3 Remove the flow cell from the foil package.

Figure 9 Remo ve from Fo il Package

4 Open the clear plastic clamshell p ackage and remove the flow cell.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

14

NextSeq 500 System Guide

Figure 10 Remov e from Clamshell Packag e

5 Clean the glass surface of the flow cell with a lint-free alcohol wipe. Dry the glass with a low-lint lab tissue.

Prepare Libraries for Sequencing

The library volume and loading concentration differ depending on the version of NCS you are running.

Cont rol Soft war e Versi on Library Volume Library Concentr at ion

NC S v1.3, or later 1.3 ml 1.8 pM

NC S v1.2, or ea rlier 3 ml 3 pM

Denature and Dilute Libraries

Denature and dilute your libraries to a loading volume of 1.3 ml and a loading concentration of 1.8pM for high

output kits and 1.5 pM for mid output kits. In practice, loading concentration can vary depending on library

preparation and quantification method s. For instructions, see the

Libraries Guide (document # 15048776)

.

NextSeq System Denature and Dilute

Load Libraries onto the Reagent Cartridge

1 Clean the foil seal covering reservoir #10 labeled Load Library Here using a low-lint tissue.

2 Pierce the seal with a clean 1 ml pipette tip.

3 Load 1.3 ml of prepared 1.8 pM libraries into reservoir #10 labeled Load Library Here. Avoid touching the

foil seal as you dispense the libraries.

Figure 11 Load Libraries

Set Up a Sequencing Run

1 From the Home screen, select Sequence.

The Sequence command opens the imaging compartment door, releases consumables from a previous

run, and opens the series of run setup screens. A short delay is normal.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

15

NextSeq 500 System Guide

If the instrument is configured for BaseSpace, you are prompted to log in to BaseSpace. If the instrument

is configured for standalone mode, the next step is loading the flow cell.

Log in to BaseSpace

1 Enter your BaseSpace user name and password.

2 Select Next.

Load the Flow Cell

1 Remove the used flow cell from a previous run.

2 Align the flow cell over the alignment pins and place the flow cell on the stage.

Figure 12 Load the Flow Cell

3 Select Load.

The door closes automatically, the flow cell ID appears on the screen, and the sensors are checked.

4 Select Next.

Empty the Spent Reagents Container

1 Remove the spent reagents container and discard the contents in accordance with applicable

standards.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

16

NextSeq 500 System Guide

Figure 13 Remov e the S pent Reagents Cont ainer

NOTE

As you remove the container, place your other hand underneath for support.

WARNING

This set of reagents contains potentially hazardous chemicals. Personal injury can occur through

inhalation, ingestion, skin contact, and eye contact. Wear protective equipment, including eye

protection, gloves, and laboratory coat appropriate for risk of exposure. Handle used reagents as

chemical waste and discard in accordance with applicable regional, national, and local laws and

regulations. For additional environmental, health, and safety information, see the SDS at

support.illumina.com/sds.html.

2 Slide the empty spent reagents container into the buffer compartment until it stops. An audib le click

indicates that the container is in position.

Figure 14 Load the Empt y Spent Reagents Container

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

17

NextSeq 500 System Guide

Load the Buffer Cartridge

1 Remove the used buffer cartridge from the upper compartment.

2 Slide a new buffer cartridge into the buffer compartment until it stops.

An audible click indicates that the cartridge is in position, the buffer cartridge ID appears on the screen,

and the sensor is checked.

Figure 15 Load the Buffer Cartridge

3 Close the buffer compartment door, and select Next.

Load the Reagent Cartridge

1 Remove the used reagent cartridge from the reagent compartment. Dispose of unused contents in

accordance with applicable standards.

WARNING

This set of reagents contains potentially hazardous chemicals. Personal injury can occur through

inhalation, ingestion, skin contact, and eye contact. Wear protective equipment, including eye

protection, gloves, and laboratory coat appropriate for risk of exposure. Handle used reagents as

chemical waste and discard in accordance with applicable regional, national, and local laws and

regulations. For additional environmental, health, and safety information, see the SDS at

support.illumina.com/sds.html.

NOTE

To facilitate safe disposal of unused reagent, the reservoir in position 6 is removable. For more

information, see

2 Slide the reagent cartridge into the reagent compartment until the cartridge stops, and then close the

reagent compartment door.

Remove Used Reservoir from Position #6

on page 19.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

18

NextSeq 500 System Guide

Figure 16 Load Reagent Cartridg e

3 Select Load.

The software moves the cartridge into position automatically (~30 seconds), the reagent cartridge ID

appears on the screen, and the sensors are checked.

4 Select Next.

Remove Used Reservoir from Position #6

1 After you have removed the

cover over the slot next to position #6.

Figure 17 Remov able P osit ion #6

A Protective rubber cover

B Position #6

2 Press down on the clear plastic tab and push towards the left to eject the reservoir.

3 Dispose of the reservoir in accordance with applicable standards.

used

reagent cartridge from the instrument, remove the protective rubber

Specify Run Parameters

The steps on the Run Setup screen differ b ased on system configuration:

u BaseSpace or BaseSpace Onsite—The Run Setup screen lists runs that were set up using the

BaseSpace Prep tab. If the intended run does not app ear on the Run Setup screen, make sure that the

run is marked for sequencing in BaseSpace.

u Standalone—The Run Setup screen includes fields for defining run parameters.

Select Available Run (BaseSpace Configuration)

1 Select a run name from the list of available runs.

Use the up and down arrows to scroll through the list or enter a run name in the Search field.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

19

NextSeq 500 System Guide

2 Select Next.

3 Confirm run parameters.

u Run Name—Name of the run as assigned in BaseSpace.

u Library ID—Name of the pooled libraries as assigned in BaseSpace.

u Recipe—Name of the recipe, either NextSeq High or NextSeq Mid depending on the reagent

cartridge used for the run.

u Read Type—Single Read or Paired End.

u Read Length—Number of cycles for each read.

u [Optional] Custom Primers, if applicable.

4 [Optional] Select the Edit icon to change run parameters. When finished, select Save.

u Run parameters—Change the number of read s or number of cycles per read.

u Custom primers—Change the settings for custom primers. For more information, see

Custom Primers Guide (document # 15057456)

u Purge consumables for this run—Change the setting to purge consumab les automatically after the

.

NextSeq

current run.

5 Select Next.

Enter Run Parameters (Standalone Configuration)

1 Enter a run name of your preference.

2 [Optional] Enter a library ID of your preference.

3 From the Recipe drop-down list, select a recipe. Only compatible recipes are listed.

4 Select a read type, either Single Read or Paired End .

5 Enter the number of cycles for each read in the sequencing run.

u Read 1—Enter a value up to 151 cycles.

u Read 2—Enter a value up to 151 cycles. This value is typically the same number of cycles as Read 1.

u Index 1—Enter the number of cycles required for the Index 1 (i7) primer.

u Index 2—Enter the number of cycles required for the Index 2 (i5) primer.

The control software confirms your entries using the following criteria:

u Total cycles do not exceed the maximum cycles allowed

u Cycles for Read 1 are greater than the 5 cycles used for template generation

u Index Read cycles do not exceed Read 1 and Read 2 cycles

6 [Optional] If you are using custom primers, select the checkbox for the primers used. For more

information, see

u Read 1—Custom primer for Read 1.

u Read 2—Custom primer for Read 2.

u Index 1—Custom primer for Index 1.

u Index 2—Custom primer for Index 2.

NextSeq Custom Primers Guide (document # 15057456)

.

7 [Optional] Select the Edit icon to change run parameters. When finished, select Save.

u Output folder location—Change the output folder location for the current run. Select Browse to

navigate to a network location.

u Purge consumables for this run—Change the setting to purge consumab les automatically after the

current run.

u Use run monitoring for this run—Change the setting to use run monitoring in BaseSpace.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

20

NextSeq 500 System Guide

8 Select Next.

Review Automated Check

The software performs an automated check of the system. During the check, the following indicators appear

on the screen:

u Gray checkmark —The check has not b een performed yet.

u Progress icon—The check is in progress.

u Green checkmark—The check passed.

u Red X —The check did not pass. For any items that d o not p ass, an action is required before you can

proceed. See

Resolve Automatic Check Errors

on p age 30.

To stop an automated check in progress, select the icon in the lower-right corner. To restart the check,

select the icon. The check resumes at the first incomplete or failed check.

To view the results of each individual check within a category, select the icon to expand the category.

Start the Run

When the automated check is complete, select Start. The sequencing run begins.

To configure the system to start the run automatically after a successful check, see

Set Run Setup Options

on p age 9.

Monitor Run Progress

1 Monitor run progress, intensities, and quality scores as metrics app ear on the screen.

Figure 18 Sequencing Run Pro gress and Metrics

A Run progress—Shows the current step and number of cycles completed for each read. The progress

bar is not proportional to the run rate of each step. Use the time remaining in the upper-right corner to

determine actual duration.

B Q-Score—Shows the distribution of quality scores (Q-scores). See

C Intensity—Shows the value of cluster intensities of the 90thpercentile for each tile. Plot colors indicate

each base: red is A, green is C, blue is G, and black is T. Colors match base indicators used in the

Sequencing Analysis Software (SAV).

D Cluster Density (K/mm²)—Shows the number of clusters detected for the run.

Quality Scoring

on page 41.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

21

NextSeq 500 System Guide

E Clusters Passing Filter (%)—Shows the percentage of clusters passing filter. See

Clusters Passing Filter

on page 41.

F Estimated Yield (Gb)—Shows the number of bases projected for the run.

G Flow cell image—Shows the current process on each lane pair. One lane pair is imaging when the other

lane pair is in a chemistry step.

NOTE

After you select Home, it is not possible to return to view run metrics. However, run metrics are accessible on

BaseSpace or viewable from a standalone computer using the Sequencing Analysis Viewer (SAV).

Cycles for Run Metrics

Run metrics appear at different points in a run.

u During the cluster generation steps, no metrics appear.

u The first 5 cycles are reserved for template generation.

u Run metrics appear after cycle 25, includ ing cluster density, clusters passing filter, yield, and quality

scores.

Data Transfer

Depending on the analysis configuration selected, an icon appears on the screen d uring the run to indicate

the data transfer status.

Status Illumina

Base Sp ace

Conn ecte d

Base Sp ace

Onsit e

Stand al one

Ins trument

Conn ecte d and transfe rrin g

data

Disc onne cted

If data transfer is interrupted during the run, data are stored temporarily on the instrument computer. When

the connection is restored, data transfer resumes automatically. If the connection is not restored before the

run ends, manually remove data from the instrument computer before a subsequent run can begin.

Run Copy Service

The NextSeq System Software Suite includes a Run Copy Service. RTA v2 req uests the service to copy files

from a source location to a destination location and the service processes copy requests in the order

received. If an exception occurs, the file is requeued for copy based on the number of files in the copy queue.

Sequencing Analysis Viewer

The Sequencing Analysis Viewer software shows sequencing metrics generated during the run. Metrics

appear in the form of plots, graphs, and tables b ased on data generated by RTA and written to InterOp files.

Metrics are updated as the run progresses. Select Refresh at any time during the run to view updated

metrics. For more information, see the

Sequencing Analysis Viewer User Guide (part # 15020619)

.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

22

NextSeq 500 System Guide

The Sequencing Analysis Viewer is included in the software installed on the instrument computer. You can

also install Sequencing Analysis Viewer on another computer linked to the same network as the instrument to

monitor run metrics remotely.

Automatic Post-Run Wash

When the sequencing run is complete, the software initiates an automatic post-run wash using the wash

solution provided in the buffer cartridge and NaOCl provided in the reagent cartridge.

The automatic post-run wash tak es approximately 90 minutes. When the wash is complete, the Home b utton

becomes active. Seq uencing results remain visible on the screen during the wash.

After the Wash

After the wash, the sippers remain in the down position to prevent air from entering the system. Leave the

cartridges in place until the next run.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

23

Chapter 4 Maintenance

Introduction 24

Perform a Manual Wash 24

Software Updates 26

Shut Down the Instrument 27

Introduction

Maintenance procedures include manual instrument washes and system software updates when available.

u Instrument washes—An automatic post-run wash after each sequencing run maintains instrument

performance. However, a manual wash is required periodically under certain conditions. See

Manual Wash

u Software updates—When an updated version of the system software is available, you can install the

on p age 24.

update automatically through a connection to BaseSpace or manually after downloading the installer from

the Illumina website. See

Software Updates

on p age 26.

Preventive Maintenance

Illumina recommends that you schedule a preventive maintenance service each year. If you are not under a

service contract, contact your Territory Account Manager or Illumina Technical Support to arrange for a

billable preventive maintenance service.

Perform a

Perform a Manual Wash

Manual washes are initiated from the Home screen. Wash options include the Quick Wash and the Manual

Post-Run Wash.

Was h Types Descri pti on

Quick Wash

Dur at ion: 20 mi nut es

Manual Pos t-Run Was h

Dur at ion: 90 mi nut es

A manual wash requires the reagent wash cartridge and buffer wash cartridge provided with the instrument,

and a used flow cell. A used flow cell can be used up to 20 times for instrument washes.

Figure 19 Reagent Was h Cartridge and Buffer Wash Cartridg e

Flushes the system with a user-supplied wash solution of laboratory-grade water and

Twe e n 20 ( buffer wash cartridge).

Required eve ry 14 da ys tha t th e instrumen t is idle or afte r a shutdown.

Flushes the system with a user-supplied wash solution of laboratory-grade water and

Twe e n 20 ( buffer wash cartridge) and 0.12% sodium h ypoch lorite(rea gent wash

ca rtridge).

Required if the au tomatic post-run wash was not performe d.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

24

NextSeq 500 System Guide

Prepare for a Manual Post-Run Wash

Us er-Sup p lied Consumables Vol ume and D es cr ipt ion

• Na OC l 1 ml, diluted to 0.12%

• 100% Twee n 20

• La bora tory-gra de wa te r

NOTE

Always use a fresh dilution of NaOCl prepared within the last 24hours. If you make a volume larger than 1ml,

store the remaining dilution at 2°C to 8°C for use within the next 24 hours. Otherwise, discard the remaining

dilution of NaOCl.

1 Combine the following volumes in a microcentrifuge tube to result in 1 ml 0.12% NaOCl:

u 5% NaOCl (24µl)

u Laboratory-grade water (976 µl)

2 Invert the tub e to mix.

3 Add 1 ml of 0.12% NaOCl to the reagent wash cartridge. The correct reservoir is equivalent to position

#28 on the prefilled cartridge.

Loade d onto the rea ge nt wa sh ca rtridge (po sition #28)

Used to make 125 m l 0.05% Twee n 20 w ash solution

Loade d onto the buf fe r wash c a rtridge (cen ter reservoir)

Figure 20 Load NaOCl

4 Combine the following volumes to result in a 0.05% Tween 20 wash solution:

u 100% Tween 20 (62 µl)

u Laboratory-grade water (125 ml)

5 Add 125 ml wash solution to the center reservoir of the buffer wash cartridge.

6 Select Perform Wash, and then select Manual Post-Run Wash.

Prepare for a Quick Wash

Us er-Sup p lied Consumables Volume and Descri pti on

• 100% Twee n 20

• La bora tory-gra de wa te r

Used to make 40 ml 0.05% Tween 20 wash solution

Loade d onto buffe r wash ca rtridge (c ente r re se rvoir)

1 Combine the following volumes to result in a 0.05% Tween 20 wash solution:

u 100% Tween 20 (20 µl)

u Laboratory-grade water (40 ml)

2 Add 40 ml wash solution to the center reservoir of the buffer wash cartridge.

3 Select Perform Wash, and then select Quick Wash.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

25

NextSeq 500 System Guide

Load a Used Flow Cell and the Wash Cartridges

1 If a used flow cell is not present, load a used flow cell. Select Load, and then select Next.

2 Remove the spent reagents container and discard the contents in accordance with applicable

standards.

WARNING

This set of reagents contains potentially hazardous chemicals. Personal injury can occur through

inhalation, ingestion, skin contact, and eye contact. Wear protective equipment, including eye

protection, gloves, and laboratory coat appropriate for risk of exposure. Handle used reagents as

chemical waste and discard in accordance with applicable regional, national, and local laws and

regulations. For additional environmental, health, and safety information, see the SDS at

support.illumina.com/sds.html.

3 Slide the empty spent reagents container into the buffer compartment until it stops.

4 Remove the used buffer cartridge from the previous run, if present.

5 Load the buffer wash cartridge containing wash solution.

6 Remove the used reagent cartridge from the previous run, if present.

7 Load the reagent wash cartridge.

8 Select Next. The prewash check begins automatically.

Start the Wash

1 Select Start.

2 When the wash is complete, select Home.

After the Wash

After the wash, the sippers remain in the down position to prevent air from entering the system. Leave the

cartridges in place until the next run.

Software Updates

Software updates are packaged in a software bund le called the System Suite, which includes the following

software:

u NextSeq Control Software (NCS)

u NextSeq recipes

u RTA2

u NextSeq Service Software (NSS)

u Sequencing Analysis Viewer (SAV)

u BaseSpace Broker

You can install software updates automatically using an internet connection or manually from a network or

USB location.

u Automatic updates—For instruments connected to a network with internet access, an alert icon

appears on the Manage Instrument button on the Home screen when an update is available.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

26

NextSeq 500 System Guide

u Manual updates—Download the System Suite installer from the NextSeq 500 support page on the

Illumina website.

Automatic Software Update

1 Select Manage Instrument.

2 Select Software Update.

3 Select Install the upd ate already downloaded from BaseSpace.

4 Select Update to begin the update. A dialog box opens to confirm the command.

5 Follow the prompts in the installation wizard:

a Accept the licensing agreement.

b Review the release notes.

c Review the list of software included in the update.

When the upd ate is complete, the control software restarts automatically.

NOTE

If a firmware update is included, an automatic restart of the system is required after the firmware is updated.

Manual Software Update

1 Download the System Suite installer from the Illumina website and save it to a network location.

Alternatively, copy the software installation file to a portable USB drive.

2 Select Manage Instrument.

3 Select Software Update.

4 Select Manually install the update from the following location.

5 Select Browse to navigate to the location of the software installation file, and then select Update.

6 Follow the prompts in the installation wizard:

a Accept the licensing agreement.

b Review the release notes.

c Review the list of software included in the update.

When the upd ate is complete, the control software restarts automatically.

NOTE

If a firmware update is included, an automatic restart of the system is required after the firmware is updated.

Shut Down the Instrument

1 Select Manage Instrument.

2 Select System Power Options.

3 Select Shut Down.

The Shut Down command safely shuts down the software and turns off instrument power. Wait at least

60 seconds before turning on the instrument again.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

27

NextSeq 500 System Guide

CAUTION

Do not

relocate the instrument. Moving the instrument improperly can affect the optical alignment and

compromise data integrity. If you have to relocate the instrument, contact your Illumina representative.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

28

Appendix A Troubleshooting

Introduction 29

Troubleshooting Files 29

Resolve Automatic Check Errors 30

Spent Reagents Container is Full 31

Rehybridization Workflow 31

Custom Recipes and Recipe Folders 33

System Check 33

RAID Error Message 35

Configure System Settings 35

Introduction

For technical questions, visit the NextSeq 500 sup port pages on the Illumina website. The support pages

provide access to documentation, downloads, and frequently asked questions.

Log in to your MyIllumina account for access to support bulletins.

For run quality or performance problems, contact Illumina Technical Support. See

page 50.

Consider sharing a link to the run summary in BaseSp ace with Illumina Technical Support to facilitate

troub leshooting.

Technical Assistance

on

Troubleshooting Files

An Illumina Technical Support representative might req uest copies of run-specific or scan-specific files to

troub leshoot issues. Typically, the following files are used for troubleshooting.

Key Fil e Fold er Des crip tion

Run information file

(RunInfo.xml)

Run parameters file

(RunPa rameters.xml)

RTA configu ration file

(RTAC onfiguration.xml)

Inte rOp files (*.bin) Inte rOp Binary reporting f iles used for Seque nc in g Ana lysis Viewe r.

Log file s Log s Log f iles desc ribe eac h step pe rformed by the instrument for e ach cycle,

Error log file s

(* ErrorLog* .txt)

Global log file s

(* GlobalLog*.tsv)

La ne log f ile s

(* La neL og*.txt)

Root folde r Contains the following informa tion:

• Run na me

• Nu mbe r of cyc le s in the run

• Nu mbe r of cyc le s in e a ch re ad

• Whether the read is an indexed read

• Nu mbe r of swaths and tile s on the flow cell

Root folde r Contains informa tio n abou t ru n para me ters a nd run com pon ents.

Informa tion inc ludes the RFID, seria l number, pa rt n umber, a nd expiration

date.

Data\ Intensities Contains the RTA configu ration settings for th e run.

The RTAC on figuration.xml file is crea te d a t the beginn in g of the run.

Inte rOp files are upda te d throu gh out the run.

an d list software and firmw are v ersion s u sed with the run. The file named

[In strumentN a me ]_Curren tH ardware.csv lists the serial numbers of

instrumen t c om pon ents.

RTALogs Log of RTA errors.

Error log file s a re update d whene ve r a n error occ urs.

RTALogs Log of a ll RTA events.

Global log file s a re update d throughout the run.

RTALogs Log RTA proce ssing events.

La ne log f ile s are upda te d throu ghout the run.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

29

NextSeq 500 System Guide

RTA Errors

To troubleshoot RTA errors, first check the RTA error log, which is stored in the RTALogs folder. This file is not

present for successful runs. Include the error log when reporting issues to Illumina Technical Sup port.

Resolve Automatic Check Errors

If errors occur during the automatic check, use the following recommended actions to resolve the error.

If a pre-run check fails, the reagent cartridge RFID is not locked and can be used for a subsequent run.

However, the RFID is locked after the foil seals have been pierced.

Syst em C hecks R ecommend ed Acti on

Doors Closed Make sure tha t the compa rtment doors a re close d.

Consu ma bles Loa ded Consumable sensors do not re gister. Make sure that eac h consu ma ble is properly

loa de d.

On the run setup screens, selec t Bac k to retu rn to th e loading step, a nd repe at run

setup.

Required Softwa re Critic al c omponen ts of the software are missing.

Instrume nt Disk Spac e The instrument hard drive doe s not h ave sufficient disk spac e to pe rform a run. It is

Ne twork C on ne ction The ne twork c onne ction ha s been inte rrupted. C he ck network status and the physic al

Ne twork Disk Spac e Either the BaseSpace acc ou nt is full or the network server is fu ll.

Pe rform a ma nua l software update to re store all software componen ts.

possible that data from a pre vious run did n ot transfe r.

Clea r ru n data from the instrumen t h ard drive.

ne twork conne ction .

Temperature Re commende d Action

Tempe rature Conta ct Illumina Te chnical Support.

Tempe rature Se nsors Conta c t Illumina Tec hn ic al S upport.

Fa ns Conta c t Illumina Tec hn ic al S upport.

Imagi ng Sy stem Recomme nded Act ion

Imagin g Limits Conta c t Illumina Tec hn ic al S upport.

Z Steps-a nd-Se ttle Contact Illum ina Tec hnic al S upport.

Bit Error Rate C on tact Illum ina Tec hnic al S upport.

Flow Cell Registra tion It is possible that th e flow c ell is not properly seated.

Reagent Deliv er y Recommend ed Act ion

Valve Response Conta c t Illumina Tec hn ic al S upport.

Pump Conta c t Illumina Tec hn ic al S upport.

Buf fe r Mec han ism Contac t Illumina Tec hnica l Support.

Spe nt Re agents Empty Empty the spent reagents con tainer and reload the empty con ta iner.

• On the run setup screen s, selec t Bac k to retu rn to the flow c ell step. The ima ging

compa rtment door opens.

• Unlo ad and reload the flow c e ll to make sure tha t it is sea te d properly.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

30

NextSeq 500 System Guide

Spent Reagents Container is Full

Always begin a run with an empty spent reagents container.

If you begin a run without emptying the spent reagents container, system sensors trigger the software to

pause the run when the container is full. System sensors cannot pause a run during clustering, paired-end

resynthesis, or the automatic p ost-run wash.

When the run pauses, a dialog box opens with options to raise the sippers and emp ty the full container.

Empty Spent Reagents Container

1 Select Raise Sipp ers.

2 Remove the spent reagents container and discard the contents app ropriately.

3 Return the empty container to the buffer compartment.

4 Select Continue. The run resumes automatically.

Rehybridization Workflow

A rehybridization run might be necessary if metrics generated during the first few cycles show intensities

below 2500. Some low-diversity libraries can show intensities below 1000, which is expected and cannot be

resolved with rehybridization.

NOTE

The End Run command is final. The run cannot be resumed, run consumables cannot be reused, and

sequencing data from the run are not saved.

When you end a run, the software performs the following steps before the run ends:

u Places the flow cell in a safe state.

u Unlocks the flow cell RFID for a later run.

u Assigns a rehybridization expiration d ate to the flow cell.

u Writes the run logs for completed cycles. A delay is normal.

u Bypasses the automatic post-run wash.

When you start a rehybridization run, the software performs the following steps to perform the run:

u Creates a run folder based on a unique run name.

u Checks that the flow cell rehybridization date has not expired.

u Primes reagents. A d elay is normal.

u Skips the clustering step.

u Removes the previous Read 1 primer.

u Hybridizes a fresh Read 1 primer.

u Continues through Read 1 and the remainder of the run based on specified run parameters.

Points to End a Run for Rehybridization

Later rehybridization is possible only if you end the run at the following points:

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

31

NextSeq 500 System Guide

u After cycle 5—Intensities app ear after template registration, which requires the first 5 cycles of

sequencing. Although it is safe to end a run after cycle 1, ending after cycle 5 is recommended. Do not

end a run during cluster generation.

u Read 1 or Index 1 Read—End the run

saved for later rehybridization after p aired-end resynthesis begins.

before

paired-end resynthesis b egins. The flow cell cannot be

Required Consumables

A rehybridization run requires a new NextSeq reagent cartridge and buffer cartridge regardless of when the

run was stopped.

End the Current Run

1 Select End Run. When prompted to confirm the command, select Yes.

2 When promp ted to save the flow cell, select Yes. Saving the flow cell does not ensure that the current run

will be salvageable. Note the expiration date for rehybridization.

3 Remove the saved flow cell and set aside at 2°C to 8°C until you are ready to set up the rehyb ridization

run.

NOTE

You can store the flow cell up to 7 days at 2°C to 8°C in the plastic clamshell case

package. For best results, rehybridize the saved flow cell within 3 days.

without

the desiccant

Perform a Manual Wash

1 From the Home screen, select Perform Wash.

2 From the Wash Selection screen, select Manual Post-Run Wash. See

24.

NOTE

If you have not removed the reagent cartridge and buffer cartridge from the stopped run, you can use them

for the manual wash. Otherwise, perform the manual wash with the reagent wash cartridge and buffer wash

cartridge.

Perform a Manual Wash

on p age

Set Up a New Run on the BaseSpace Prep Tab

1 If the instrument is configured for BaseSpace or BaseSpace Onsite, set up a new run on the Prep tab

using the same parameters as the original run.

TIP

Click the Pools tab, select the appropriate Pool ID to retain the previous run settings, and then assign a

unique name for the new run.

Set Up a Run on the Instrument

1 Prepare a new reagent cartridge.

2 If the saved flow cell was stored , allow it to reach room temperature (15–30 minutes).

3 Clean and load the saved flow cell.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

32

NextSeq 500 System Guide

4 Remove the spent reagents container and discard the contents app ropriately, and then reload the

empty container.

5 Load the new buffer cartridge and reagent cartridge.

6 From the Run Setup screen, select from the following options:

u BaseSpace or BaseSpace Onsite—Select the run and confirm run parameters.

u Standalone—Enter the name of the run and specify the same parameters as the original run.

7 Select Next to proceed to the pre-run check and start the run.

Custom Recipes and Recipe Folders

Do not modify original recipes. Always make a copy of the original recipe with a new name. If an original

recipe is modified, the software updater can no longer recognize the recipe for later updates, and newer

versions are not installed.

Store custom recipes in the appropriate recipe folder. Recipe folders are organized as follows.

Custom

High—Customized recipes used with a high-output kit.

Mid—Customized recipes used with a mid-output kit.

High—Original recipes used with a high-output kit.

Mid—Original recipes used with a mid-output kit.

Wash—Contains the manual wash recipe.

System Check

A system check is not required for normal operation or instrument maintenance. However, an Illumina

Technical Sup port representative might ask you to perform a system check for troubleshooting purposes.

NOTE

If an instrument wash is due, perform the wash before starting a system check.

Starting a system check automatically closes the control software and launches the NextSeq Service

Software (NSS). The service software launches and opens to the Load screen, which is configured to use the

advanced loading option.

Figure 21 Available Sy stem Checks

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

33

NextSeq 500 System Guide

Inactive checkb oxes on the Select screen indicate tests that require assistance from an Illumina field

representative.

Perform a System Check

1 From the Manage Instrument screen, select System Check. When prompted to close the control

software, select Yes.

2 Load the consumables as follows:

a If a used flow cell is not already on the instrument, load a used flow cell.

NOTE

Illumina recommends using a high output flow cell for system check purposes.

b Empty the spent reagents container and return it to the instrument.

c Load the buffer wash cartridge containing 120 ml laboratory-grade water in the center reservoir.

d Load the reagent wash cartridge. Make sure that the reagent wash cartridge is empty and clean.

3 Select Load. The software moves the flow cell and reagent wash cartridge into position. Select Next.

4 Select Next. The system check begins.

5 [Optional] When the system check is complete, select View next to the check name to view the values

associated with each check.

6 Select Next. The system check report opens.

7 Select Save to save the report to a zipped file. Navigate to a network location to save the file.

8 When finished, select Exit.

9 When promp ted to close the service software and restart the control software, select Yes. The control

software restarts automatically.

Motion Checks

Syst em C heck Descrip tion

BSM Checks the gain a nd distanc e of the Bottle Straw Mechanism ( BSM) to confirm tha t the module

is w orkin g properly.

FC LM & FAM Chec ks the gain and distan ce of the Flow Cell L oa d Mec ha nism (FCL M) an d F lu id Automa tion

Module (FAM) to confirm tha t the modu le s a re working properly.

Sta ge Te sts C hec ks the travel limits and performa nce of the XY -sta ge and 6 Z-stages, 1 for each camera .

Optics Check

Syst em C heck Descrip tion

Flow Cell

Registration

Measure s flow ce ll tilt on an optic al plan e, te sts ca me ra functiona lity, tests the ima ging modu le ,

an d verifies registration of the flow cell in th e correc t imagin g position.

Document # 15046563 v04

For Researc h Use Only. Not for use in diagnostic procedure s.

34

NextSeq 500 System Guide

Fluidics Checks

Syst em C heck Descrip tion

Valve Response Checks the ac curacy of the valv e and pu mp move me nts, and tests the pump syringe ran ge of

movem ent.

Pre ssure Decay Che cks th e lea k ra te of a sealed fluidic s syste m, which c on firms that the flow cell is properly

mou nted in the sequ enc ing position.

Flow Rate Chec ks the func tiona lity of the bubble sensors, which a re use d to de te ct the prese nce of air in

the reagen t line s. Measures th e flow ra tes to ch eck for occ lusions or leaks.

Thermal Checks

Syst em C heck Descrip tion

Fa ns Chec ks the speed of system f ans in pulse per minute (P PM) to c on firm th at fan s a re functionin g.

Fa ns tha t a re not functionin g return a negative valu e.

Thermal Probes C hec ks th e avera ge tempe rature of ea ch thermal se nsor. The rma l sensors that a re not

func tioning return a negative value.

RAID Error Message

The NextSeq computer is equipped with 2 hard drives. If a hard drive begins to fail, the system generates a

RAID error message and suggests that you contact Illumina Technical Support. Usually, a hard drive

replacement is required.

You can proceed with the run setup steps and normal op eration. The purpose of the message is for