Ilford ILFOLAB 1250 RC Operating Manual

IL882

VARIABLE SPEED PRINT DRYER

FOR HIGH QUALITY

BLACK AND WHITE PRINT DRYING

50/60 Hz

OPERATING MANUAL

ILFORD

ILFOLAB

12 5 0 R C

1st Proof rev A - March 1997

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

SAFETY PRECAUTIONS

Your photographic equipment is powered by mains electricity,

and is designed to comply with international electrical safety

standards. However, basic safety precautions must always be

followed when operating electrical equipment, including the

following, where applicable:

Read and understand all instructions and equipment labels.

Close supervision is necessary when the equipment is being used

by inexperienced personnel.

Take care to avoid burns. Some internal parts of the equipment

can become very hot with continuous use.

Do not operate equipment that has been dropped or damaged,

or has damaged electrical leads. Have the equipment examined

by qualified personnel.

Do not allow any electrical lead to touch hot surfaces.

Ensure the leads are arranged such that they cannot be pulled or

tripped over.

Ensure extension leads are of a suitable current rating to prevent

the lead overheating.

Always unplug or isolate the equipment when it is not in use.

Never pull plugs out by holding the lead.

For equipment connected to the electrical mains supply by a plug

and socket arrangement, ensure the socket is installed near to the

equipment and is easily accessible at all times.

Do not touch electrical components with wet or damp hands.

Ensure the air flow through the vents is not obstructed when

equipment is switched on.

Do not dismantle the equipment unless you are qualified to do

so. Incorrect assembly can cause hazards both to yourself and to

the equipment.

All equipment, no matter how well made, can break down and,

therefore, must not be left unattended for long periods of time

while it is switched on.

Always unplug or isolate the equipment before connecting or

disconnecting any plugs supplying electrical power to or from the

equipment.

Always obey local codes of practice, particularly for installation

requirements.

Do not destroy these instructions

CONTENTS

1

2

2.1

2.2

2.3

2.4

3

3.1

3.2

3.3

3.4

4

5

6

6.1

6.2

6.3

6.4

6.5

7

8

1

PICTOGRAMS 2

INTRODUCTION 5

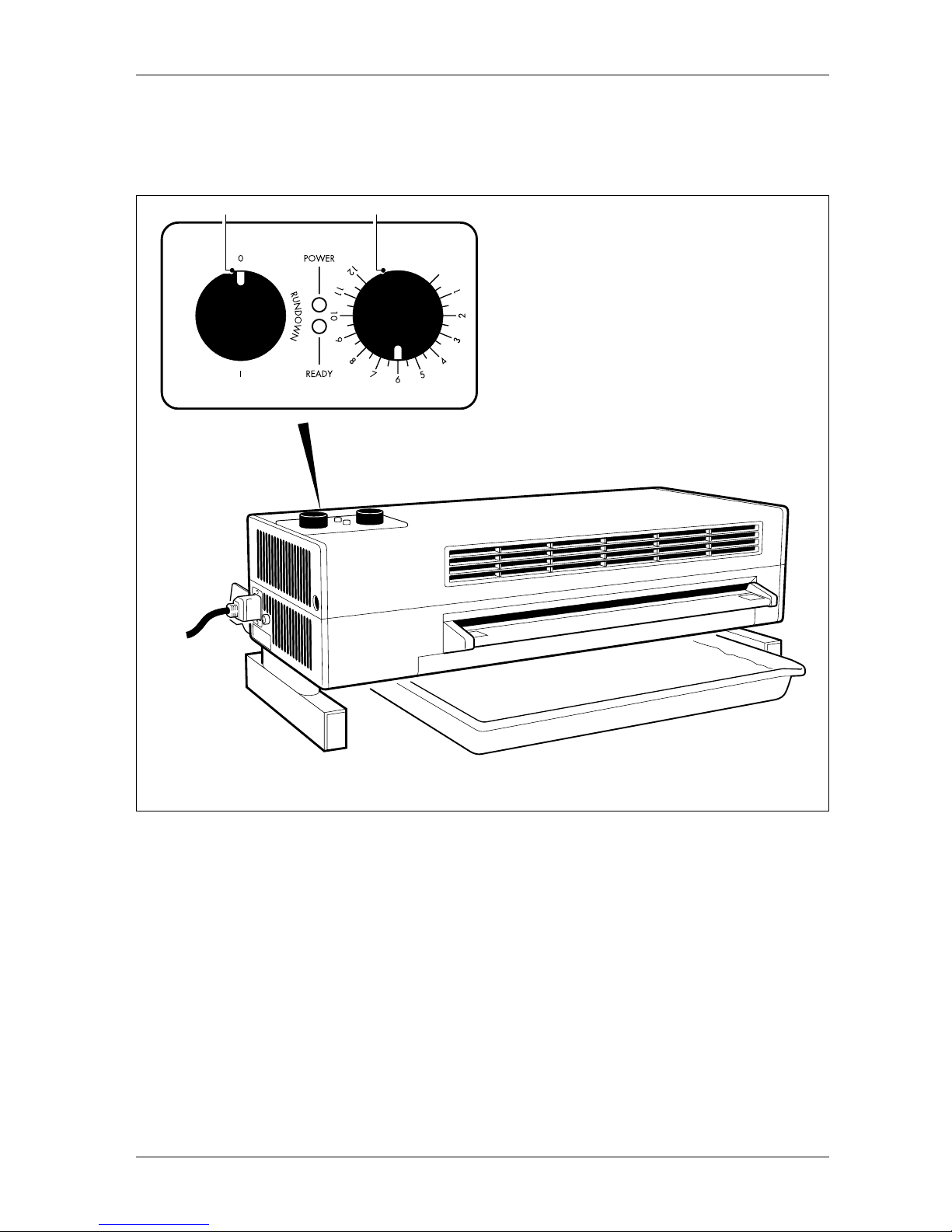

CONTROLS AND INDICATORS 7

‘POWER’ light 7

‘READY’ light 7

Dryer control 7

Speed control 7

INSTALLATION 9

Print receive tray 9

Location 9

Electricity supply 9

Removing yellow transit wedges 9

DRYING PRINTS 10

SWITCHING OFF 11

CLEANING AND SIMPLE REPAIRS 13

Daily routine 13

Cleaning the front roller assembly 13

Replacing a mains fuse 14

Replacing a roller tension spring 14

Removing rear rollers/adjusting print exit guide 15

FAULT FINDING 18

SPECIFICATION 21

INSERTS

94031.2A.GB Wall chart - Operating

PICTOGRAMS

2

The following pictograms are used on labels fixed to the dryer.

Please ensure you understand their meaning.

Electrical hazard - refer to manual

Caution moving rollers

IL895

3

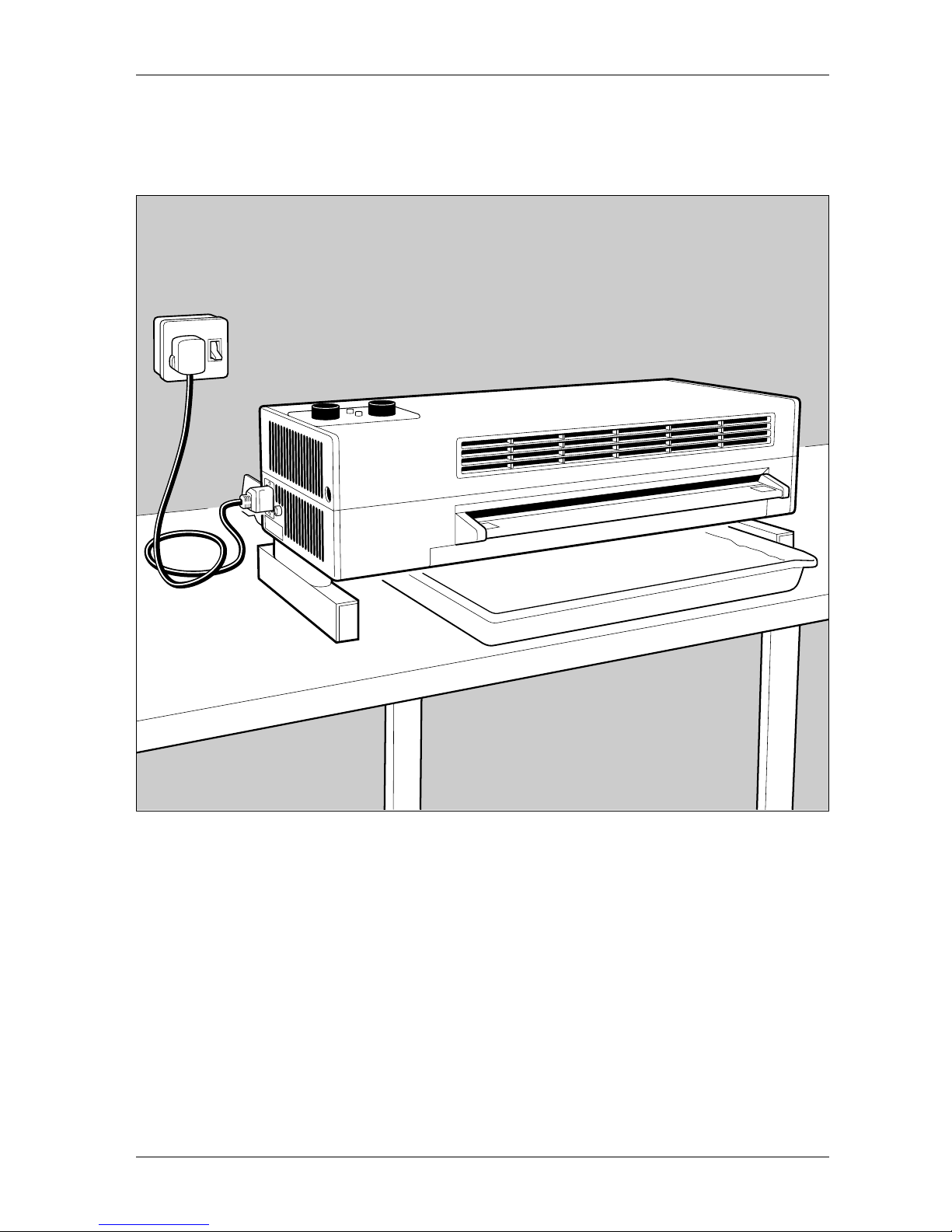

Figure 1.1

ILFOLAB 1250RC dryer - typical installation

ILFOLAB

1250 RC

ILFORD

IL883

4

1

INTRODUCTION

5

See figure 1.1.

The ILFOLAB 1250RC variable speed dryer is designed to dry

ILFORD black and white resin coated papers to a very high

standard. The dryer will dry up to 380 20.3x25.4cm

(8x10 inches) prints per hour, and has a maximum feed width of

50.8cm (20 inches).

For uniform drying and greater efficiency, prints are dried by

infra-red, fan assisted heaters. The print transport speed is

variable for precise control of a wide range of drying conditions

and materials.

This manual gives full instructions for installing and operating the

ILFOLAB 1250RC dryer. For ease of description, it is assumed

the left and right hand sides of the dryer are determined when

facing the dryer at the paper feed (front) end.

Figure 2.1

Controls and indicators

IL884A

ILFOLAB

1250 RC

ILFORD

1

2

6

Loading...

Loading...