PATENT PENDING

Precision Positioning Table

Precision Positioning Table

CAT-57178

June 2010 Overseas Dept.

s

Light table made of high-strength aluminum alloy

s

Assures high-precision positioning with precision-ground ball screws

s

Built-in C-Lube for long-term maintenance-free service

s

Excellent cost performance

Precision Positioning Table

TE86TE86

Line up of seven models

86 mm wide, 46 mm high,

and 340 to 940 mm long

TE60TE60

Line up of six models

60 mm wide, 33 mm high,

and 150 to 600 mm long

1 2

Precision Positioning Table

Precision Positioning Table TE is a light-weight compact positioning table featuring

that its main components are made of high-strength aluminum alloy and the slide table is

placed inside a U-shaped bed.

Its driving mechanism adopts a precision-ground ball screw to assure high reliability

high-precision positioning.

A C-Lube lubrication part built in the linear motion rolling guide and the ball screw

enables long-term maintenance-free operation. This can reduce your time-consuming

for lubrication.

You can freely select ball screw leads, motor types, sensor installation, and other

specifications so that you can build up optimum positioning tables fit for your need.

Precision Positioning Table TE is fit for various types of equipment for

machining, assembling, inspecting, and transferring parts ranging from equipment

that requires high positioning accuracy to general transferring equipment.

TE

Structure of Precision Positioning Table TE

Features of Precision Positioning Table TE

Light-Weight, Low-Cross Section,

and Compact

Light-weight and compact positioning table using high-strength aluminum

alloy for its main components.

Low cross-section (33 mm high for TE60 and 46 mm high for TE86) due to

optimum designing of linear guides and ball screws.

No sensor rail for mounting sensors, which contributes to space saving.

Comparison in sectional heights Precision Positioning Tables TE and TUBetween

TE60 TU60 TE86 TU86

End bracket

Motor bracket

Table

Motor attachment

Ball screw

Motor

60

33

60

60

86

Comparison in weights Precision Positioning Tables TE and TUBetween

Size Type

TE

Stroke length

mm

300

(1)(

60

TU

TE

290

540

86

1

Notes: (

(

A value for TE indicates the length of bed and a value for TU indicates the length of track rail.

)

2

This value indicates the entire weight of a single standard table.

)

The mass of the motor is not included.

High positioning accuracy

TU

Higher precision positioning by one rank due to a combination of unique linear

motion rolling guide technology and precision-ground ball screws.

490

46

Mass

kg

1.3

3.3

4.2

10.9

70

86

2

)

Mass/100mm

kg

0.43

1.14

0.78

2.22

Bed

Maintenance free

Amazing low prices

3 4

Long-term maintenance free operation due to unique C-Lube lubrication part

built in the linear motion rolling guide and the ball screw.

This can reduce labor time for lubrication and increase the reliability of the equipment.

Excellent cost performance thanks to adoption of less components and improvement in

parts shapes.

1 N = 0.102kgf = 0.2248lbs.

1 mm = 0.03937inch

S

S

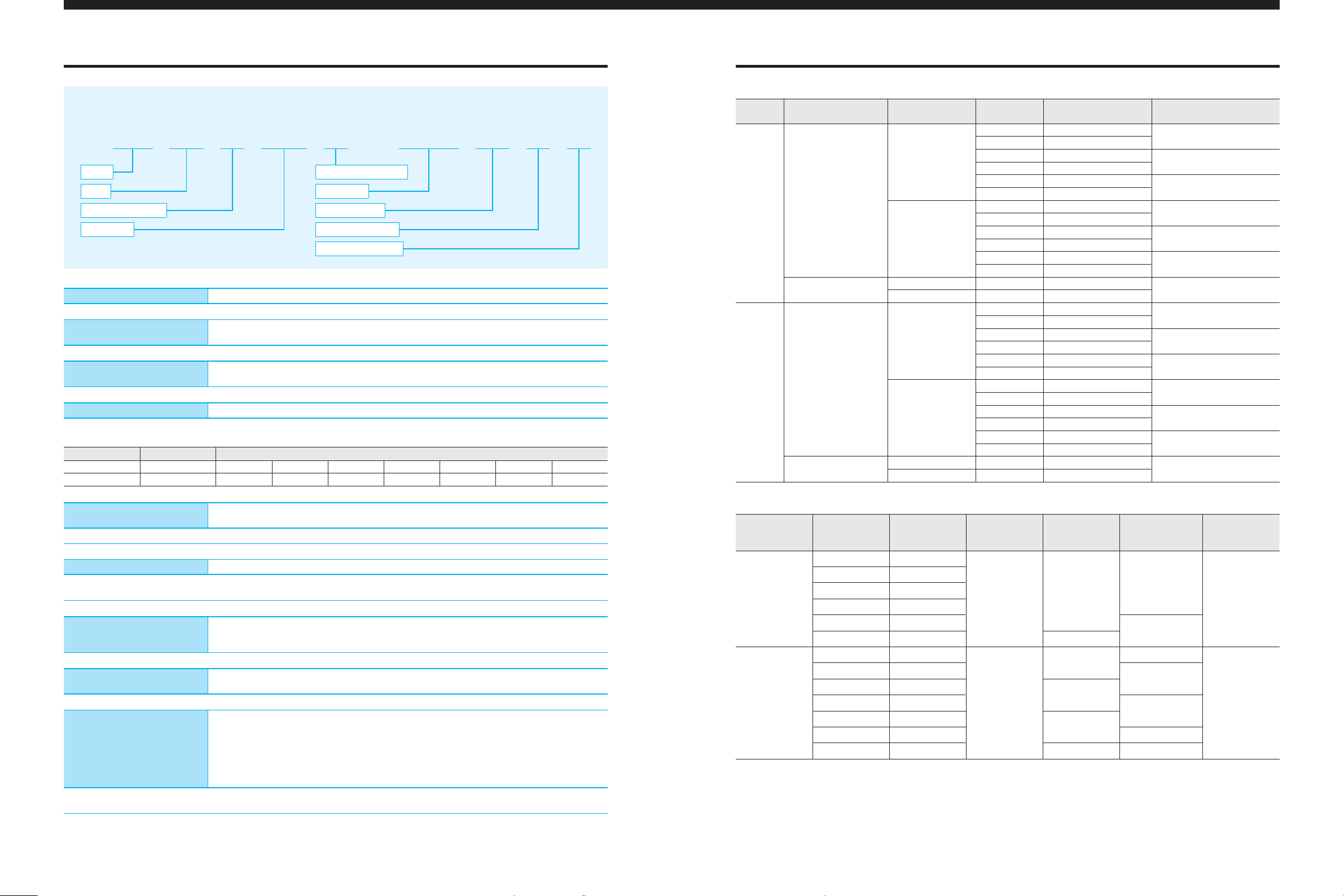

Identifi cation Number・Characteristics

Example of identification number

TE 60 F 600 A / Y048 10 C 3

●1Type ●5With or without motor

●2Size ●6Motor type

●3Shape of slide table ●7Ball screw lead

●4Bed length ●8Cover specification

●9Sensor specification

●1Type

●2Size

●3Shape of slide table

●4Bed length

Table 1 Bed length and stroke length

Type and size Bed width Bed length(stroke length)

TE60 60 150( 50) 200(100) 300(200) 400(300) 500(400) 600(500)―

TE86 86 340(200) 440(300) 540(400) 640(500) 740(600) 840(700) 940(800)

TE:Precision positioning table TE

60:Bed width 60mm

86:Bed width 86mm

S:Standard table

F:Flange type standard table

Select applicable bed length in Table 1

unit:mm

Identifi cation Number・Characteristics

Table 2 Motor type

Type and

size

TE60

TE86

Motor type

AC servo motor

Stepper motor

AC servo motor

Stepper motor

With or without

brake

Without brake

With brake

Without brake V009 PK566AE

With brake V010 PK566AEM

Without brake

With brake

Without brake V011 PK569AE

With brake V012 PK569AEM

Motor code Model number Remark

Y028 SGMAH-01AAA21-E

Y048 SGMJV-01A3A21

P002 MSMA012A1A

P012 MSMD012S1A

J002 HC-KFS13

J012 HF-KP13

Y033 SGMAH-01AAA2C-E

Y050 SGMJV-01A3A2C

P007 MSMA012A1B

P017 MSMD012S1B

J007 HC-KFS13B

J017 HF-KP13B

Y029 SGMAH-02AAA21-E

Y059 SGMJV-02A3A21

P003 MSMA022A1A

P013 MSMD022S1A

J003 HC-KFS23

J013 HF-KP23

Y034 SGMAH-02AAA2C-E

Y060 SGMJV-02A3A2C

P008 MSMA022A1B

P018 MSMD022S1B

J008 HC-KFS23B

J018 HF-KP23B

Yaskawa Electric

Panasonic

Mitsubishi Electric

Yaskawa Electric

Panasonic

Mitsubishi Electric

Oriental motor

Yaskawa Electric

Panasonic

Mitsubishi Electric

Yaskawa Electric

Panasonic

Mitsubishi Electric

Oriental motor

●5With or without motor

When the motor is prepared by customer, specify “without motor” (no symbol).

●6Motor type

When “without motor” (no symbol)is selected in item

“No symbol” when you need neither the motor attachment nor the coupling.

●7Ball screw lead

●8Cover speci cation

●9Sensor speci cation

When 2, 3, or 4 sensors are selected, they are mounted on the sensor mounting groove along the side of the bed and two shielding plates are mounted

on the slide table.

No symbol:Without motor

A

Select motor shown in Table 2

5:Lead 5mm(Applicable to TE60)

10:Lead 10mm(Applicable to TE60 and 86)

20:Lead 20mm(Applicable to TE86)

0:Without cover

C:With bridge cover(Applicable to TE…F)

0:Without sensor

2:Two sensors(limit sensors)

3:Three sensors(limit and pre-origin sensors)

4:Four sensors(limit, pre-origin and origin sensors)

5:Two sensors(limit sensors)are appended to the product.

6:Three sensors(limit and pre-origin sensors)are appended to the product.

7:Four sensors(limit, pre-origin, and origin sensors)are appended to the product.

:

With motor

5

, the motor attachment and coupling applicable to the speci ed motor will be mounted. Select

●

Table 3 Accuracy

Type and size Bed length Stroke length Repeatability

150 50

200 100

TE60

TE86

Remark:The precision standard is evaluated according to the

300 200

400 300

500 400

600 500 0.025

340 200

440 300

540 400

640 500

740 600

840 700 0.014

940 800 0.035 0.016

S

±

0.002

±

0.002

inspection standards.

Positioning

accuracy

0.020

0.020

0.025

0.030

Parallelism in

table operation B

0.008

0.010

0.008

0.010

0.012

unit:mm

Backlash

0.003

0.003

5

1 N = 0.102kgf = 0.2248lbs.

1 mm = 0.03937inch

6

S

1

1

Characteristics

S

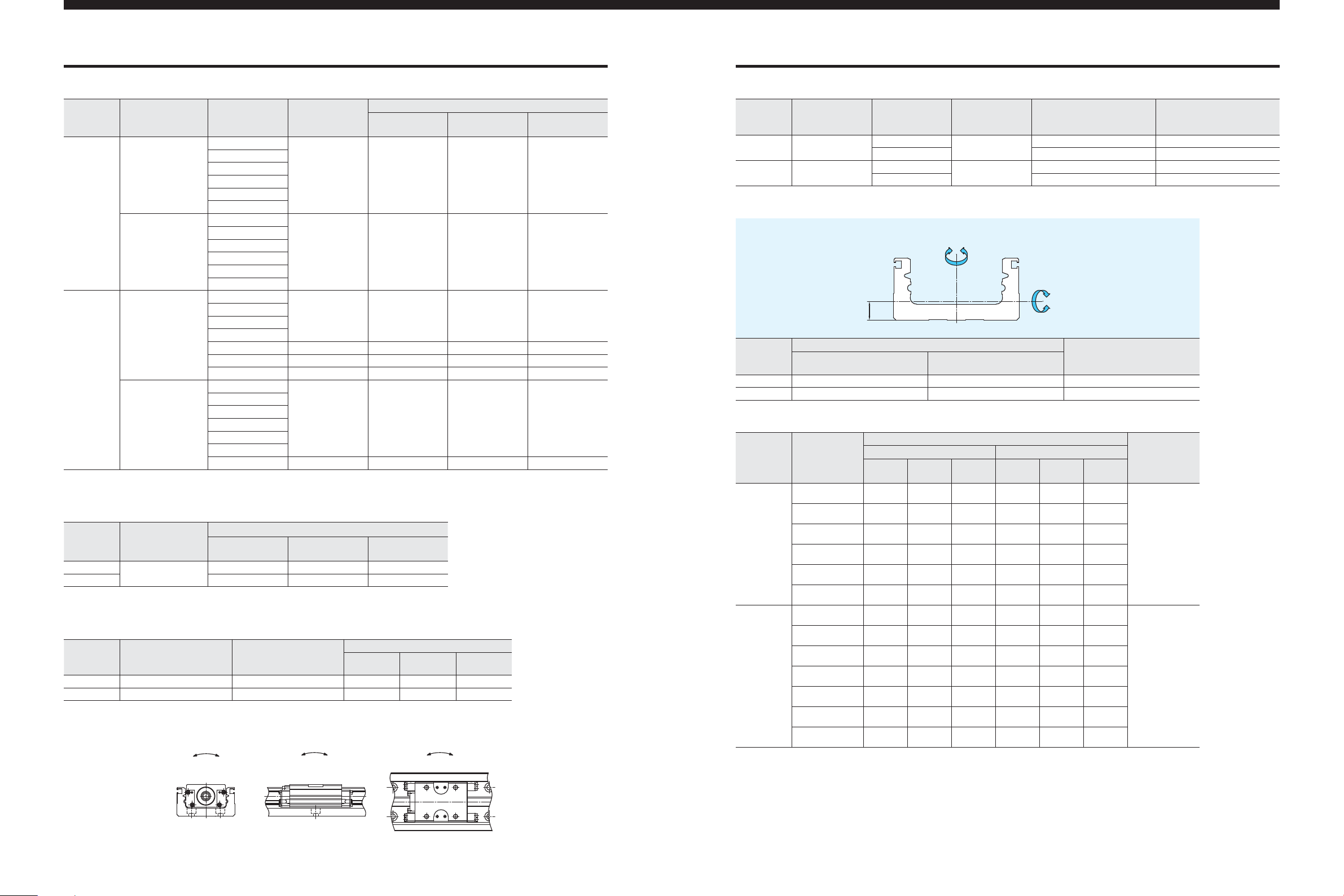

Table 4 Maximum speed

Type and

size

Motor type

Bed length

mm

Motor speed

r/min

Lead

5mm

150

200

AC servo motor

300

400

3000 250 500 −

500

TE60

600

150

200

Stepper motor

300

400

1800 150 300 −

500

600

340

AC servo motor

440

540

640

3000 − 500 1000

740 2700 − 450 900

840 2100 − 350 700

TE86

940 1680 − 280 560

340

440

Stepper motor

540

640

1800 − 300 600

740

840

940 1680 − 280 560

Remark: The values of the maximum speed are applicable when the standard motor is used. The actual maximum operation speed must be determined by

examining the operating pattern for the motor used, load conditions, etc.

Maximum speed mm/s

Lead

10mm

Lead

20mm

Table 7 Speci cation of ball screw

Size

Type of

ball screw

TE60 Ground screw

TE86 Ground screw

Lead

mm

5

10 1720 2745

10

20 2300 3920

Table 8 Moment of inertia of sectional area

e

Moment of inertia of sectional area mm

Size

TE60 4.7×10

TE86 2.0×10

1

X

4

5

Table 9 Table inertia and starting torque

Model

Bed length

mm

150 0.13 0.17 − 0.14 0.20 −

Standard table Flange type standard table

Lead

5mm

Lead

10mm

Shaft dia.

mm

10

12

Y axis

3.2×10

1.3×10

Table inertia J

Lead

20mm

4

Y

5

6

×105kg・m

T

Lead

5mm

Basic dynamic load rating

C

N

2730 4410

2300 3920

X axis

Barycentric point

e

mm

9.1

13.0

2

Starting torque

Lead

10mm

Lead

20mm

Basic static load rating

C

0

N

T

0

N・m

Table 5 Maximum loading mass

Type and

size

TE60

TE86 − 40 30

Remark 1:Values are those set when the standard motor is used.

2:The maximum load mass is for a motor speed of 3000rpm.

Acceleration/

deceleration

G

0.5

Maximum loading mass kg

Lead

5mm

Lead

10mm

30 30 −

Lead

20mm

Table 6 Load rating of Linear motion rolling guide

Type and

size

Basic dynamic load rating

C

N

Basic static load rating

C

0

N

TE60 12400 17100 354 151 151

TE86 26800 35900 1110 472 472

T

0

T

X

Static rated moment N・m

T

0

T

X

T

Y

200 0.19 0.23 − 0.20 0.26 −

300 0.26 0.30 − 0.27 0.33 −

TE60

0.03

400 0.33 0.36 − 0.34 0.40 −

500 0.40 0.44 − 0.41 0.47 −

600 0.47 0.51 − 0.48 0.54 −

340 − 0.73 1.19 − 0.81 1.50

440 − 0.88 1.35 − 0.95 1.64

T

Y

TE86

540 − 1.03 1.50 − 1.11 1.80

640 − 1.18 1.64 − 1.25 1.95

0.05

740 − 1.33 1.79 − 1.41 2.10

840 − 1.48 1.94 − 1.56 2.25

940 − 1.63 2.10 − 1.71 2.40

7

1 N = 0.102kgf = 0.2248lbs.

1 mm = 0.03937inch

8

S

S

System confi gurationSensor specifi cation

Table 10 Speci cations of sensors

Type

Item

Type

Power supply

voltage

Current

consumption

Output

Output

operation

Operation

indicator

Circuit

diagram

Note (1):If PNP type is required, please consult

Limit, pre-origin Origin

proximity sensor(NPN type

DC12〜24V ±10%

10mA or less

Open collector

・Max. current:100mA

・Applied voltage:DC 30V or less

Residual voltage:1.0V or less at 100mA in- ow current

・

0.4V or less at 16mA in- ow current

When approaching:OFF When approaching:ON

LED(orange)

(OFF when the sensor senses)

Main

circuit

(ON when the sensor senses)

Table 12 Sensor timing chart

OFF

D

(1)

LED(orange)

VCC

OUT1

OUT2

GND

R

.

Stroke length+2

Table 11 Speci cations of connectors

Pin

Signal name

No.

)

1 Origin

2 Pre-origin

3 CW limit

4 CCW limit

5 Power input

6 GND

Note (1):Other side connector shall be prepared by customer.

Remark 1:Manufactured by Tyco Electronics AMP Co., Ltd.

2: The origin signal wire is not provided when an AC servo motor is

used. Use the encoder origin signal output from the driver as the

origin signal.

Sensor-side

connector type

Cap housing

172160-1

Contactor

170365-1

Opposite-side

connector type

Plug housing

172168-1

Contactor

170363-1

(1)

Optimum electric equipment systems are available to Precision Positioning Table TE according to the types of motors. An exam-

ple of system configuration is shown below. For ordering, use model number in Table 13.

■AC servo motor

Precision Positioning Table TE

Teaching box

●❻

TAE10M5-TB

programmable controller

●

❺

2

)

(

DC24V power supply

Power cord

CTN480G

(1)

●❼

Power cord

(1)

●

❸

Driver

❷

❹

●❶

Fig.1 System con guration of the table with AC servo motor

Note (1):The power cable should be prepared by customer.

2

(

):The 24-VDC power supply should be prepared by customer.

Table 13 Electric equipment system of the table with a Yaskawa motor (made by Yaskawa Electric Corp.)

Name Model number

❶Precision Positioning Table TE TE60

Motor code Y028 Y048

❷Motor cord

TAE20G2-AM□□

(TAE20G1-AM□□)

JZSP-CSM01-□□-E

(JZSP-CSM21-□□-E)

Motor code Y033 Y050

❷Motor cord

TAE20G4-AMB□□

(TAE20G3-AMB□□)

TAE20G6-EC□□

(TAE20G5-EC□□)

JZSP-CSM11-□□-E

(JZSP-CSM31-□□-E)

JZSP-CSP01-□□-E

(JZSP-CSP21-□□-E)

CW CCW

Motor without

brake

Motor with

(1)

brake

❸Driver SGDH-01AE-E SGDV-R90A01A

❹Encoder cord

Name Model number

❶Precision Positioning Table TE TE86

A

Motor without

brake

ON

Origin

Motor with

(1)

B

OFF

C

E

Pre-origin

CCW limit

OFF

CW limit

Mechanical stopper

brake

❸Driver SGDH-02AE-E SGDV-1R6A01A

❹Encoder cord

Note (1):Motor with brake requires an additional unbraking power supply.

Remark 1:The cord in( )have high bending resistance.

2: Specify the length(3m, 5m, 10m, or 20m)of the motor encoder cord by model number□□.

The length under 10m is also selected by two digits.(Example of 3m:TAE20G2-AM03.)

Motor code Y029 Y059

❷Motor cord

TAE20G2-AM□□

(TAE20G1-AM□□)

JZSP-CSM02-□□-E

(JZSP-CSM22-□□-E)

Motor code Y034 Y060

❷Motor cord

TAE20G4-AMB□□

(TAE20G3-AMB□□)

TAE20G6-EC□□

(TAE20G5-EC□□)

JZSP-CSM12-□□-E

(JZSP-CSM32-□□-E)

JZSP-CSP01-□□-E

(JZSP-CSP21-□□-E)

unit:mm

Model Ball screw lead ABCDE

TE60

TE86

5

10 7

10

20 14

44

51

3

7

21 8.5 8

21 11 10

9

Table 14 Electric equipment system of the table with a Yaskawa motor (made by Yaskawa Electric Corp.)

and a programmable controller CTN480G

Name Model number

Motor code Y028, Y029, Y033, Y034, Y048, Y050, Y059, Y060

❺Programmable controller CTN480G

❻Teaching box TAE10M5-TB

❼Pulse limit cord

Remark 1:The cord in( )have high bending resistance.

2: The lengths of limit cord of pulse limit cord can be speci ed by increments of 1 m up to 20 m maximum in model number □□.

The length under 10m is also selected by two digits.(Example of 3m:TAE10M7-LD03)

3:The length of pulse cord of pulse limit cord is 1.5m.

TAE10M7-LD□□

(TAE10M8-LD□□)

1 N = 0.102kgf = 0.2248lbs.

1 mm = 0.03937inch

10

S

S

System confi guration

Table 15 Electric equipment system of the table with a Panasonic motor (made by Panasonic Corp.)

Name Model number

❶Precision Positioning Table TE TE60

Motor without

brake

Motor with

(1)

brake

❸Driver MSDA015A1A MADDT1205

❹Encoder cord

Motor code P002 P012

❷Motor cord

Motor code P007 P017

❷Motor cord

Brake cord

(2)

TAE20G8-AM□□

(TAE20G7-AM□□)

TAE20H0-AMB□□

(TAE20G9-AMB□□)

− MFMCB0□□0GET

TAE20H2-EC□□

(TAE20H1-EC□□)

MFMCA0□□0EED

MFMCA0□□0EED

MFECA0□□0EAD

Name Model number

❶Precision Positioning Table TE TE86

Motor without

brake

Motor with

(1)

brake

❸Driver MSDA023A1A MADDT1207

❹Encoder cord

Note (1):Motor with brake requires an additional unbraking power supply.

2

(

):An additional brake cord is required.

Remark 1:The cord in( )have high bending resistance.

2: Specify the length(3m, 5m, 10m, or 20m)of the motor brake and the encoder cord by model number□□.

The length under 10m is also selected by two digits.(Example of 3m:TAE20G8-AM03)

Motor code P003 P013

❷Motor cord

Motor code P008 P018

❷Motor cord

Brake cord

(2)

TAE20G8-AM□□

(TAE20G7-AM□□)

TAE20H0-AMB□□

(TAE20G9-AMB□□)

− MFMCB0□□0GET

TAE20H2-EC□□

(TAE20H1-EC□□)

MFMCA0□□0EED

MFMCA0□□0EED

MFECA0□□0EAD

Table 16 Electric equipment system of the table with a Panasonic motor (made by Panasonic Corp.)

and a programmable controller CTN480G

Name Model number

Motor code P002, P003, P007, P008 P012, P013, P017, P018

❺Programmable controller CTN480G

❻Teaching box TAE10M5-TB

❼Pulse limit cord

Remark 1:The cord in( )have high bending resistance.

2: The lengths of limit cord of pulse limit cord can be speci ed by increments of 1 m up to 20 m maximum in model number □□.

The length under 10m is also selected by two digits.(Example of 3m:TAE10M9-LD03)

3:The length of pulse cord of pulse limit cord is 1.5m.

TAE10M9-LD□□

(TAE10P0-LD□□)

TAE10V2-LD□□

(TAE10V3-LD□□)

Table 17 Electric equipment system of the table with a Mitsubishi motor (made by Mitsubishi Electric Corp.)

Name Model number

❶Precision Positioning Table TE TE60

Motor without

brake

Motor with

(1)

brake

❸Driver MR-J2S-10A MR-J3-10A

❹Encoder cord

Motor code J002 J012

❷Motor cord

Motor code J007 J017

❷Motor cord

Brake cord

(2)

TAE20H4-AM□□

(TAE20H3-AM□□)

TAE20H6-AMB□□

(TAE20H5-AMB□□)

−

TAE20H8-EC□□

(TAE20H7-EC□□)

MR-PWS1CBL□M-A1-L

(MR-PWS1CBL□M-A1-H)

MR-PWS1CBL□M-A1-L

(MR-PWS1CBL□M-A1-H)

MR-BKS1CBL□M-A1-L

(MR-BKS1CBL□M-A1-H)

MR-J3ENCBL□M-A1-L

(MR-J3ENCBL□M-A1-H)

Name Model number

❶Precision Positioning Table TE TE86

Motor without

brake

Motor with

(1)

brake

❸Driver MR-J2S-20A MR-J3-20A

❹Encoder cord

Note (1):Motor with brake requires an additional unbraking power supply.

2

(

):An additional brake cord is required.

Remark 1:The cord in( )have high bending resistance.

2: Specify the length (2m, 5m, or10m) of the motor brake and the encoder cord by model number□□ or □.

*In model number□□, the length under 10m is also selected by two digits.(Example of 2m:TAE20H4-AM02)

*In model number□, when the length under 10m is selected by one digit or two digits when the length is 10m.

(Example of 2m:MR-PWS1CBL2M-A1-L)

Motor code J003 J013

❷Motor cord

Motor code J008 J018

❷Motor cord

Brake cord

(2)

TAE20H4-AM□□

(TAE20H3-AM□□)

TAE20H6-AMB□□

(TAE20H5-AMB□□)

−

TAE20H8-EC□□

(TAE20H7-EC□□)

MR-PWS1CBL□M-A1-L

(MR-PWS1CBL□M-A1-H)

MR-PWS1CBL□M-A1-L

(MR-PWS1CBL□M-A1-H)

MR-BKS1CBL□M-A1-L

(MR-BKS1CBL□M-A1-H)

MR-J3ENCBL□M-A1-L

(MR-J3ENCBL□M-A1-H)

Table 18 Electric equipment system of the table with a Mitsubishi motor (made by Mitsubishi Electric Corp.)

and a programmable controller CTN480G

Name Model number

Motor code J002, J003, J007, J008 J012, J013, J017, J018

❺Programmable controller CTN480G

❻Teaching box TAE10M5-TB

❼Pulse limit cord

Remark 1:The cord in( )have high bending resistance.

2: The lengths of limit cord of pulse limit cord can be speci ed by increments of 1 m up to 20 m maximum in model number □□.

The length under 10m is also selected by two digits.(Example of 3m:TAE10P1-LD03)

3:The length of pulse cord of pulse limit cord is 1.5m.

TAE10P1-LD□□

(TAE10P2-LD□□)

TAE10V4-LD□□

(TAE10V5-LD□□)

11

1 N = 0.102kgf = 0.2248lbs.

1 mm = 0.03937inch

12

S

System confi guration Specifi cations of motor and driver

S

■Stepper motor

Precision Positioning Table TE

●

Teaching box

●❺

TAE10M5-TB

programmable controller

●

❹

2

)

(

DC24V power supply

Power cord

CTN480G

(1)

❻

Power cord

(1)

●

❸

Driver

❷

❶

Fig.2 System con guration of the table with stepping motor

Note (1):The power cable should be prepared by customer.

2

(

):The 24-VDC power supply should be prepared by customer.

Table 19 Electric equipment system of the table with a Oriental motor (made by Oriental Motor Co., Ltd.)

Name Model number

❶Precision Positioning Table TE TE60 TE86

Motor code V009 V011

Motor without

brake

❷Motor cord

TAE20R8-SM□□

(TAE20R9-SN□□)

TAE20R8-SM□□

(TAE20R9-SN□□)

❸Driver RKD514L-A RKD514L-A

Motor code V010 V012

Motor with

(1)

brake

❷Motor cord

TAE20S1-SMB□□

(TAE20S2-SNB□□)

TAE20S1-SMB□□

(TAE20S2-SNB□□)

❸Driver RKD514LM-A RKD514LM-A

Note (1):Motor with brake requires an additional unbraking power supply.

Remark 1:The cord in( )have high bending resistance.

2: The lengths of motor cord can be speci ed by increments of 1 m up to 10 m maximum in model number □□.

The length under 10m is also selected by two digits.(Example of 3m:TAE20R8-SM03)

Table 20 Electric equipment system of the table with a Oriental motor (made by Oriental Motor Co., Ltd.)

and a programmable controller CTN480G

Name Model number

Motor code V009, V010, V011, V012

❺Programmable controller CTN480G

❻Teaching box TAE10M5-TB

❼Pulse limit cord

Remark 1:The cord in( )have high bending resistance.

2: The lengths of limit cord of pulse limit cord can be speci ed by increments of 1 m up to 20 m maximum in model number □□.

The length under 10m is also selected by two digits.(Example of 3m:TAE10S3-LD03)

3:The length of pulse cord of pulse limit cord is 1.5m.

TAE10S3-LD□□

(TAE10S4-LD□□)

■ AC servo motor and driver by Yaskawa Electric Corp. (RoHS compatible)

φD

□W

LE

LM

LR

φd

2-M

φ

P

Speci cations of motor

Motor

code

Model

Y028 SGMAH-01AAA21-E

Power

voltage

V

Rated

voltage

Rated

torque

W

N ・ m

100 0.318 0.955

Maximum

momentary

torque

N ・ m

Y029 SGMAH-02AAA21-E 200 0.637 1.91 0.106 1.1

Y033 SGMAH-01AAA2C-E 100 0.318 0.955 0.0449 0.8

Y034 SGMAH-02AAA2C-E 200 0.637 1.91 0.164 1.6

Y048 SGMJV-01A3A21 100 0.318 1.11 0.0665

200

Y050 SGMJV-01A3A2C 100 0.318 1.11 0.0812 0.7

Y059 SGMJV-02A3A21 200 0.637 2.23 0.259 0.9

Y060 SGMJV-02A3A2C 200 0.637 2.23 0.323 1.5

Dimension of motor

Motor

code

Y028 40× 94.5 25 2.5 8 30 46 φ4.3

Y029 60× 96.5 30 3 14 50 70 φ5.5

Y033 40×135.0 25 2.5 8 30 46 φ4.3

Y034 60× 80 30 3 14 50 70 φ5.5

Y048 40× 82.5 25 2.5 8 30 46 φ4.3

Y050 40×127.5 25 2.5 8 30 46 φ4.3

Y059 60× 80 30 3 14 50 70 φ5.5

Y060 60×120 30 3 14 50 70 φ5.5

□W×L

M

LR LE d D P M

Rated

number of

revolution

r/min

3000

unit:mm

Motor inertia J

×104kg・m

0.0364

M

Encoder type

2

Incremental 13 bit

(8192pulse/rev)

20 bit Absolute

or incremental

(1048576pulse/rev)

Speci cations of driver

Driver type

Item

Applicable motor code Y028, Y033 Y029, Y034 Y048, Y050 Y059, Y060

Power supply voltage 200V 200V 200V 200V

Rated output of applicable motor 100W 200W 100W 200W

Feedback Serial encoder

Command input pulse

Type of command input pulse Line driver or Open collector

Maximum input pulses

Main circuit power supply voltage

Control circuit supply voltage Single phase AC200〜230V −15〜10% 50/60Hz

Continuous output current Arms 0.91 2.1 0.91 1.6

Maximum output current Arms 2.8 6.5 2.9 5.8

Ambient temperature in operation 0〜55℃

Ambient temperature in storage −20〜85℃

Ambient humidity(use and storage) Less than 90% RH(No condensation)

Mass kg 0.8 0.9 0.9 0.9

SGDH-01AE-E SGDH-02AE-E SGDV-R90A01A SGDV-1R6A01A

Selection one from symbol with pulse line, CCW or CW with pulse line, two phase pulse with 90-degree difference

Line driver:500kpps

Open collector:200kpps

Single phase AC200〜230V −15〜10% 50/60Hz

Triphase AC200〜230V −15〜10% 50/60Hz

Line driver:4Mpps

Open collector:200kpps

Mass

kg

0.5

0.4

13

1 N = 0.102kgf = 0.2248lbs.

1 mm = 0.03937inch

14

S

S

Specifi cations of motor and driver

■ AC servo motor and driver by Panasonic Corp. (RoHS compatible)

□W

φD

LE

LM

LR

φd

4-M

φ

P

Speci cations of motor

Motor

code

P002 MSMA012A1A

P003 MSMA022A1A 200 0.64 1.91 0.17 1.0

P007 MSMA012A1B 100 0.32 0.95 0.066 0.76

P008 MSMA022A1B 200 0.64 1.91 0.20 1.4

P012 MSMD012S1A 100 0.32 0.95 0.051

P013 MSMD022S1A 200 0.64 1.91 0.14 0.82

P017 MSMD012S1B 100 0.32 0.95 0.054 0.68

P018 MSMD022S1B 200 0.64 1.91 0.16 1.3

Model

Power

voltage

V

200

Rated

voltage

Rated

torque

W

N ・ m

100 0.32 0.95

Maximum

momentary

torque

N ・ m

Dimension of motor

Motor

code

P002 38×103 25 3 8 30 45 φ3.4

P003 60× 94 30 3 11 50 70 φ4.5

P007 38×135 25 3 8 30 45 φ3.4

P008 60×127 30 3 11 50 70 φ4.5

P012 38× 92 25 3 8 30 45 φ3.4

P013 60× 79 30 3 11 50 70 φ4.5

P017 38×122 25 3 8 30 45 φ3.4

P018 60×115.5 30 3 11 50 70 φ4.5

□W×L

LR LE d D P M

M

Rated

number of

revolution

r/min

3000

unit:mm

Motor inertia J

×104kg・m

2

0.062

M

Encoder type

Incremental

(10000pulse/rev)

17 bit Absolute

or incremental

(131072pulse/rev)

Speci cations of driver

Driver type

Item

Applicable motor code P002, P007 P003, P008 P012, P017 P013, P018

Power supply voltage 200V 200V 200V 200V

Rated output of applicable motor

Feedback Incremental encoder Serial encoder

Command input pulse

Type of command input pulse

Maximum input pulses

Main circuit power supply voltage

Control circuit supply voltage

Rated output current 1.0 1.6 1.1 1.6

Maximum output current 4.3 6.9 4.7 6.9

Ambient temperature in operation

Ambient temperature in storage

Ambient humidity(use and storage)

Mass kg 1.0 1.0 0.8 0.8

MSDA015A1A MSDA023A1A MADDT1205 MADDT1207

100W 200W 100W 200W

Selection one from symbol with pulse line, CCW or CW with pulse line,two phase pulse with 90-degree difference

Line driver or Open collector

Line driver:500kpps

Open collector:200kpps

Single/Three phase AC200〜230V −15〜10% 50/60Hz

Single phase AC200〜230V −15〜10% 50/60Hz

0〜55℃(No freezing)

−20〜65℃(No freezing)

Less than 90% RH(No condensation)

Single phase AC200〜240V −15〜10% 50/60Hz

Single phase AC200〜240V −15〜10% 50/60Hz

Line driver:2Mpps

Open collector:200kpps

Mass

kg

0.56

0.47

■ AC servo motor and driver by Mitsubishi Electric Corp. (RoHS compatible)

P

φD

□W

LE

LM

LR

φd

2-M

φ

Speci cations of motor

Motor

code

J002 HC-KFS13

J003 HC-KFS23 200 0.64 1.9 0.420 0.99

J007 HC-KFS13B 100 0.32 0.95 0.087 0.89

J008 HC-KFS23B 200 0.64 1.9 0.470 1.6

J012 HF-KP13 100 0.32 0.95 0.088

J013 HF-KP23 200 0.64 1.9 0.240 0.94

J017 HF-KP13B 100 0.32 0.95 0.090 0.86

J018 HF-KP23B 200 0.64 1.9 0.310 1.6

Model

Power

voltage

V

200

Rated

voltage

Rated

torque

W

N ・ m

100 0.32 0.95

Maximum

momentary

torque

N ・ m

Dimension of motor

Motor

code

J002 40× 96.5 25 2.5 8 30 46 φ4.5

J003 60× 99.5 30 3 14 50 70 φ5.8

J007 40×124.5 25 2.5 8 30 46 φ4.5

J008 60×131.5 30 3 14 50 70 φ5.8

J012 40× 82.4 25 2.5 8 30 46 φ4.5

J013 60× 76.6 30 3 14 50 70 φ5.8

J017 40×123.5 25 2.5 8 30 46 φ4.5

J018 60×116.1 30 3 14 50 70 φ5.8

□W×L

M

LR LE d D P M

Rated

number of

revolution

r/min

3000

unit:mm

Motor inertia J

×104kg・m

2

0.084

M

Encoder type

17 bit Absolute

or incremental

(131072pulse/rev)

18 bit Absolute

or incremental

(262144pulse/rev)

Speci cations of driver

Driver type

Item

Applicable motor code J002, J007 J003, J008 J012, J017 J013, J018

Power supply voltage 200V 200V 200V 200V

Rated output of applicable motor

Feedback Serial encoder

Command input pulse

Type of command input pulse Line driver or Open collector

Maximum input pulses

Main circuit power supply voltage

Control circuit supply voltage Single phase AC200〜230V −15〜10% 50/60Hz

Rated output current 0.71 1.1 0.8 1.4

Maximum output current 2.2 3.4 2.4 4.2

Ambient temperature in operation

Ambient temperature in storage

Ambient humidity(use and storage)

Mass kg 0.7 0.7 0.8 0.8

MR-J2S-10A MR-J2S-20A MR-J3-10A MR-J3-20A

100W 200W 100W 200W

Selection one from symbol with pulse line, CCW or CW with pulse line, two phase pulse with 90-degree difference

Line driver:500kpps

Open collector:200kpps

Three phase AC200〜230V −15〜10% 50/60Hz

or Single phase AC230V −15〜10% 50/60Hz

0〜55℃(No freezing)

−20〜65℃(No freezing)

Less than 90% RH(No condensation)

Three phase AC200〜230V −15〜10% 50/60Hz

or Single phase AC200〜230V −15〜10% 50/60Hz

Line driver:1Mpps

Open collector:200kpps

Mass

kg

0.53

0.56

15

1 N = 0.102kgf = 0.2248lbs.

1 mm = 0.03937inch

16

S

S

Precautions on useSpecifi cations of motor and driver

■ Stepper motor and driver by Oriental Motor Co., Ltd. (RoHS compatible)

φD

□W

LE

M

L

φd

LR

4-M

□B

Speci cations of motor

Motor

code

V009 PK566AE

V010 PK566AEM 0.83 4.4 1.1

V011 PK569AE 1.66 5.6 1.3

V012 PK69AEM 1.66 7.2 1.6

Model Step angle

0.72

Dimension of motor

Motor

code

V009 60×59.5

V010 60×99.5

V011 60×89

V012 60×129

□W×L

LR LE d D B M

M

24 1.5 8 36 50 φ4.5

Maximum holding

torque N ・ m

0.83

Current

A-phase

1.4

unit:mm

Motor inertia J

×105kg・m

2

2.8 0.8

M

Mass

kg

◆Precision Positioning Table TE is a precision device. Giving an excessive load or shock to it will lower the accuracy and damage

its components. Take extreme care when handling it.

◆Make sure that there is no dust or harmful projection on the mating table mounting surface.

◆The flatness of the mounting base for Precision Positioning Table TE will affect the positioning accuracy. It must be less than 30

μm.

◆Grease is applied to Linear Motion Rolling Guides and ball screws incorporated in Precision Positioning Table TE.

Do not admit dust or foreign matters into Precision Positioning Table. If foreign matters enter it, remove them and polluted grease

completely, and then apply clean grease again.

◆Lubrication of Precision Positioning Table TE varies depending on the operating conditions. Generally, relubricate grease every 6

months. In the case of use involving long-distance reciprocating motion at all times, remove the old grease every 3 months, and

then apply clean grease again.

◆Precision Positioning Table TE is worked, assembled, and adjusted with high accuracy. Do not disassemble or modify this product.

◎The appearance, specifications and other details of the products are subject to change without prior for improvement.

■Duration and scope of warranty

The period of warranty for the precision positioning table and related electrical devices is set at one year after delivery.

If a failure occurs while the product is correctly being used and the failure is clearly attributable to its manufacture, the product will

be repaired at no cost within the warranty period.

A warranty here means the guarantee of the precision positioning table itself as a single unit.

It shall be a fare-paying service if field service is required.

When the trouble is not obviously judged by our product deficiency as a result of our investigation, the customer shall be responsible

for the repair cost. Secondary damage that occurs on the product breakdown or use is out of our warranty.

When disposing of the products, treat them as ordinary industrial waste.

Speci cations of driver

Driver type

Item

Applicable motor code V009, V011 V010, V012

Exitation type Micro step

Command input pulse Selection one from CW/CCW signal, Pulse/Rotational direction signal

Type of command input pulse Photo coupler input, input resistance 220Ω, Input current 10〜20mA

Main circuit power supply voltage Single phase 100〜115V ±15% 50/60Hz 4.5A

Ambient temperature in operation 0〜50℃(No freezing)

Ambient humidity in operation Less than 85% RH(No condensation)

Mass kg 0.85 0.85

RKD514L-A RKD514LM-A

17

1 N = 0.102kgf = 0.2248lbs.

1 mm = 0.03937inch

18

S

S

R

TE60S

Precision Positioning Table TE

2×n-

L

30

8

(76)

φ5.5

54

A

A

11

4-M3 depth 6 4-M5 depth 7.5

φ9.5 counterbore, depth 5.4

S/2 S/2

32

100

CB C

R

Precision Positioning Table TE

TE60F

58

9(AC servo motor)

8(Stepper motor)

L

M

(2)

43.5

21

11

4-M3 depth 6

(back side)

68

S/2 S/2

43.5

100

CB C

L

30

8

(76)

54

4-M5 depth 7.5

A

A

58

×n-φ5.5

2

φ9.5 counterbore, depth 5.4

9(AC servo motor)

8(Stepper motor)

L

M

(2)

43.5

21

Section A-A

40.6

30

3.1

30

15

60

33

30

78

With sensors

31.6

Bed length Stroke length Bed mounting hole Mass

LSBCn

150 50 100 25 2 0.9

200 100 100 50 2 1.0

300 200 200 50 3 1.3

400 300 300 50 4 1.6

500 400 400 50 5 1.9

600 500 500 50 6 2.2

Note (1):The mass of the motor is not included.

2

):See “Speci cations of Motor and Driver”

(

Remark 1:In motor code J002 or J007 is selected, some part of motor may protrude from the bottom line of table body.

2:In motor code V009 or V010 is selected, motor and motor attachment protrude from the bottom line of table body.

(1)

kg

unit:mm

(Ref.)

Section A-A

86

74

64

46

3.1

15

30

60

48

30

78

With sensors

33

Bed length Stroke length Bed mounting hole Mass

LSBCn

150 50 100 25 2 1.1

200 100 100 50 2 1.2

300 200 200 50 3 1.5

400 300 300 50 4 1.9

500 400 400 50 5 2.2

600 500 500 50 6 2.5

Note (1):The mass of the motor is not included.

2

):See “Speci cations of Motor and Driver”

(

Remark 1:In motor code J002 or J007 is selected, some part of motor may protrude from the bottom line of table body.

2:In motor code V009 or V010 is selected, motor and motor attachment protrude from the bottom line of table body.

(1)

kg

unit:mm

(Ref.)

19

1 N = 0.102kgf = 0.2248lbs.

1 mm = 0.03937inch

20

S

S

R

TE86S

Precision Positioning Table TE

13

4-M3 depth 6 4-M6 depth 9

2×n-

φ11 counterbore, depth 6.5

S/2 S/2

45

100

L

46

8

(109)

φ6.6

81

A

A

B

R

Precision Positioning Table TE

TE86F

L

M

70 11

7070

(2)

13

4-M5 depth 10 4-M6 depth 12

4-M3 depth 6

(back side)

S/2

61

31

61

100

L

46

30

8

81

S/2

A

A

70

2×n-φ6.6

φ11 counterbore, depth 6.5

L

M

(2)

61

31

Section A-A

61.2

46

4.5

46 20

86

42.5

46

103.6

With sensors

44.3

Bed length Stroke length Bed mounting hole Mass

LS Bn

340 200 200 3 3.1

440 300 300 4 3.7

540 400 400 5 4.2

640 500 500 6 4.7

740 600 600 7 5.2

840 700 700 8 5.7

940 800 800 9 6.3

Note (1):The mass of the motor is not included.

2

(

):See “Speci cations of Motor and Driver”

Remark:In motor code J003 or J008 is selected, some part of motor may protrude from the bottom line of table body.

(1)

kg

unit:mm

(Ref.)

112

100

88

86

B

68

42.5

2046

103.6

With sensors

46

70 70

Section A-A

66

4.5

Bed length Stroke length Bed mounting hole Mass

LS Bn

340 200 200 3 3.7

440 300 300 4 4.3

540 400 400 5 4.9

640 500 500 6 5.5

740 600 600 7 6.1

840 700 700 8 6.7

940 800 800 9 7.2

Note (1):The mass of the motor is not included.

2

(

):See “Speci cations of Motor and Driver”

Remark:In motor code J003 or J008 is selected, some part of motor may protrude from the bottom line of table body.

(1)

kg

unit:mm

(Ref.)

21

1 N = 0.102kgf = 0.2248lbs.

1 mm = 0.03937inch

22

Maintenance free for 20,000km or 5 years

Maintenance Free & Interchangeable

CAT-5510

C-Lube Linear Way

C-Lube Linear Roller Way

The Capillary system that has developed

is a new method of lubrication. The Lube-body is

formed by sintering fine resin powder to act as

reservoir and the open pores are impregnated

with a large amount of lubrication oil.

The capillary action deposits the appropriate

amount of lubrication on the rolling elements to

protect the raceways for long periods.

Steel Ball

-

Lube

C

Steel Ball

Capillary Action

Oil Film

Surface Tension

-

Lube

C

Interchangeable series is available.

C-Lube slide units can be supplied by themselves

not with rails, and can be matched, replaced and

added freely to the interchangeable track rail.

This feature is useful in machine design, facilitating standardization of product specification and

quick changes of specification.

Maintenance FreeMaintenance Free

Efficiency of lubrication is maintained for a long term allowing to

reduce the cost of lubrication management and control.

Ecology

As C-Lube technology minimizes the amount of lubricant required

that contributes to the global environment protection.

Compact

Unlike attached-on external lubrication parts, there is no increase in

carriage length.

No loss of available stroke length when replacing standard units.

Smooth

Light and smooth running is achieved by the improvement of internal

design. C-Lube is designed not to have direct contact with the track

rail allowing very smooth operation.

Miniature type ML series Compact ME series

U-shaped track rail

MUL series

Linear Roller Way

High load capacity

MX series

MH series

23 24

World Network of

Head office : 19-19 Takanawa 2-chome Minato-ku

Tokyo 108-8586, Japan

Phone : +81 (0)3-3448-5850

Fax : +81 (0)3-3447-7637

E-mail : ntt@ikonet.co.jp

URL : http://www.ikont.co.jp/eg/

Plant : Gifu, Kamakura

NIPPON THOMPSON CO., LTD.

ASEAN REPRESENTATIVE OFFICE

Level 8, #1 Silom Road, Silom

Bangrak, Bangkok

Thailand 10500

Phone: +66 (0)2-231-8278

Fax: +66 (0)2-231-8121

E-mail: ntar@ikonet.co.jp

IKO-THOMPSON (SHANGHAI) LTD.

1402-1404 Sunyoung Center

28 Xuanhua Road, Shanghai

People's Republic of China 200050

Phone: +86 (0)21-3250-5525

Fax: +86 (0)21-3250-5526

E-mail: ntc@ikonet.co.jp

IKO INTERNATIONAL, INC.

http://www.ikont.com/ http://www.ikont.eu/

East coast

91 Walsh Drive

Parsippany, NJ 07054

U.S.A.

Phone: +1 973- 402-0254

Toll Free : 1-800-922-0337

Fax: +1 973- 402-0441

E-mail: eco@ikonet.co.jp

Midwest

500 East Thorndale Avenue

Wood Dale, IL 60191

U.S.A.

Phone: +1 630-766-6464

Toll Free : 1-800-323-6694

Fax: +1 630-766-6869

E-mail: mwo@ikonet.co.jp

West coast

20170 South Western Avenue

Torrance, CA 90501

U.S.A.

Phone: +1 310-609-3988

Toll Free : 1-800-252-3665

Fax: +1 310-609-3916

E-mail: wco@ikonet.co.jp

Southeast

2150 Boggs Road, Suite 100

Duluth, GA 30096

U.S.A.

Phone: +1 770- 418-1904

Toll Free : 1-800-874-6445

Fax: +1 770- 418-9403

E-mail: seo@ikonet.co.jp

Southwest

8105 N. Beltline Road

Suite 130, Irving, TX 75063

U.S.A.

Phone: +1 972-929-1515

Toll Free : 1-800-295-7886

Fax: +1 972-915-0060

E-mail: swo@ikonet.co.jp

NIPPON THOMPSON EUROPE B.V.

The Netherlands

Sheffieldstraat 35-39

3047 AN Rotterdam

The Netherlands

Phone: +31 (0)10- 4626868

Fax: +31 (0)10- 4626099

E-mail: nte@ikonet.co.jp

Germany

Mündelheimer Weg 56

40472 Düsseldorf

Germany

Phone: +49 (0)211- 414061

Fax: +49 (0)211- 427693

E-mail: ntd@ikonet.co.jp

Im Gewerbepark D 30

93059 Regensburg

Germany

Phone: +49 (0)941-206070

Fax: +49 (0)941-2060719

E-mail: ntdr@iko-nt.de

Gruben Str.95c

66540 Neunkirchen

Germany

Phone: +49 (0)6821-999-860

Fax: +49 (0)6821-999-8626

E-mail: ntdn@iko-nt.de

UK

2 Vincent Avenue, Crownhill

Milton Keynes Bucks MK8 0AB

United Kingdom

Phone: +44 (0)1908-566144

Fax: +44 (0)1908-565458

E-mail: sales@iko.co.uk

Spain

Autovia Madrid-Barcelona, Km. 43,700

Polig. Ind. AIDA, A-8, Ofic. 2, 1

19200-Azuqueca de Henares

Guadalajara, Spain

Phone: +34 949-263390

Fax: +34 949-263113

E-mail: nts@ikonet.co.jp

France

Roissypole Le Dôme

2 rue de La Haye

BP 15950 Tremblay en France

95733 Roissy C. D. G. Cedex

France

Phone: +33 (0)1-48165739

Fax: +33 (0)1-48165746

E-mail: ntf@ikonet.co.jp

Recognizing that conservation of the global environment is the

top-priority challenge for the world’ s population, will

conduct its activities with consideration of the environment as

a corporate social responsibility, reduce its negative impact on

the environment, and help foster a rich global environment.

ISO 9001 & 14001 Quality system

registration certificate

25 26

Loading...

Loading...