Ikegami HDK-55, FA-55 Operation Manual

HDK-55

(

FA-55

HIGH DEFINITION CAMERA SYSTEM

OPERATION MANUAL

)

OUTLINE

1

HDK-55

(

FA-55

HIGH DEFINITION CAMERA SYSTEM

OPERATION MANUAL

)

NAME and FUNCTION

INSTALLATION and

CONNECTION

OPERATION

CAMERA SETTINGS and

ADJUSTMENT

TROUBLE SHOOTING and

MAINTENANCE

SPECIFICATIONS

2

3

4

5

6

7

1206 Edition (U)

CHANGING INFORMATION

Copyright © 2012 Ikegami Tsushinki Co., Ltd.

We reserve the copyright on the software we create.

No part of this publication may be modified or reproduced in any form, or by any means, without prior written per mission from

Ikegami Tsushinki Co., Ltd.

PRODUCTS CONFORMING TO RoHS DIRECTIVE

PRODUCTS CONFORMING TO RoHS DIRECTIVE

Following products described in this manual are products conforming to RoHS directive.

· HDK-55 Color Camera

· VF421HD, VF13XHD, VFL912HD, VFL200HD Viewfinder

· BSF-55 Base Station

· OCP-200 Operation Control Panel

· MCP-200 Maintenance Control Panel

· CPH-200 Control Panel Hub

· BSH-200 Base Station Hub

Products conforming to RoHS directive include products that do not contain specified hazardous substances such as lead, mercury,

cadmium, hexavalent chromium, polybrominated biphenyl (PBB) and polybrominated diphenyl ether (PBDE) in electrical and

electronic equipment excluding following exemption applications based on the EU directive (Directive2002/95/EC).

* About RoHS Directive

The RoHS directive stands for "the Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment"

and is one of environmental directives in Europe. This directive restricts the use of specified hazardous substances in electrical and

electronic equipment.

Applications exempted from RoHS directive compliance

●

Followings applications are permitted as exemptions from RoHS directive compliance.

1. Mercury in compact fluorescent lamps not exceeding 5mg per lamp

2. Mercury in straight fluorescent lamps for general purposes not exceeding:

· halophosphate 10mg

· triphosphate with a normal lifetime 5mg

· triphosphate with a long lifetime 8mg

3. Mercury in straight fluorescent lamps for special purposes

4. Mercury in other lamps not specifically mentioned in this Annex

5. Lead in the glass of cathode ray tubes, electronic components and fluorescent tubes

6. Lead as an alloying element in steel containing up to 0.35% lead by weight, aluminum containing up to 0.4% lead by weight

and as a copper alloy containing up to 4% lead by weight

7. Lead in following items

· Lead in high melting temperature type solders (i.e. tin-lead solder alloys containing more than 85% lead)

· Lead in solders for servers, storage and storage array systems

· Lead in solders for network infrastructure equipment for switching, signaling, transmission as well as network

management for telecom munication

· Lead in electronic ceramic parts (e.g. piezoelectronic devices)

8. Cadmium plating except for applications banned under Directive 91/338/EEC amending Directive 76/769/EEC relating to

restrictions on the marketing and use of certain dangerous substances and preparations

9. Hexavalent chromium as an anti-corrosion of the carbon steel cooling system in absorption refrigerators

10. Lead used in compliant pin connector systems

11. Lead as a coating material for the thermal conduction module C-ring

12. Lead and cadmium in optical and filter glass

13. Lead in solders consisting of more than two elements for the connection between the pins and the package of microprocessors

with a lead content of more than 80% and less than 85% by weight

14. Lead in solders to complete a viable electrical connection between semiconductor die and carrier within integrated circuit Flip

Chip packages

15. Decabrominated diphenyl ether (Deca-BDE) in polymeric applications

HDK-55 1206 VER1 (U)

i

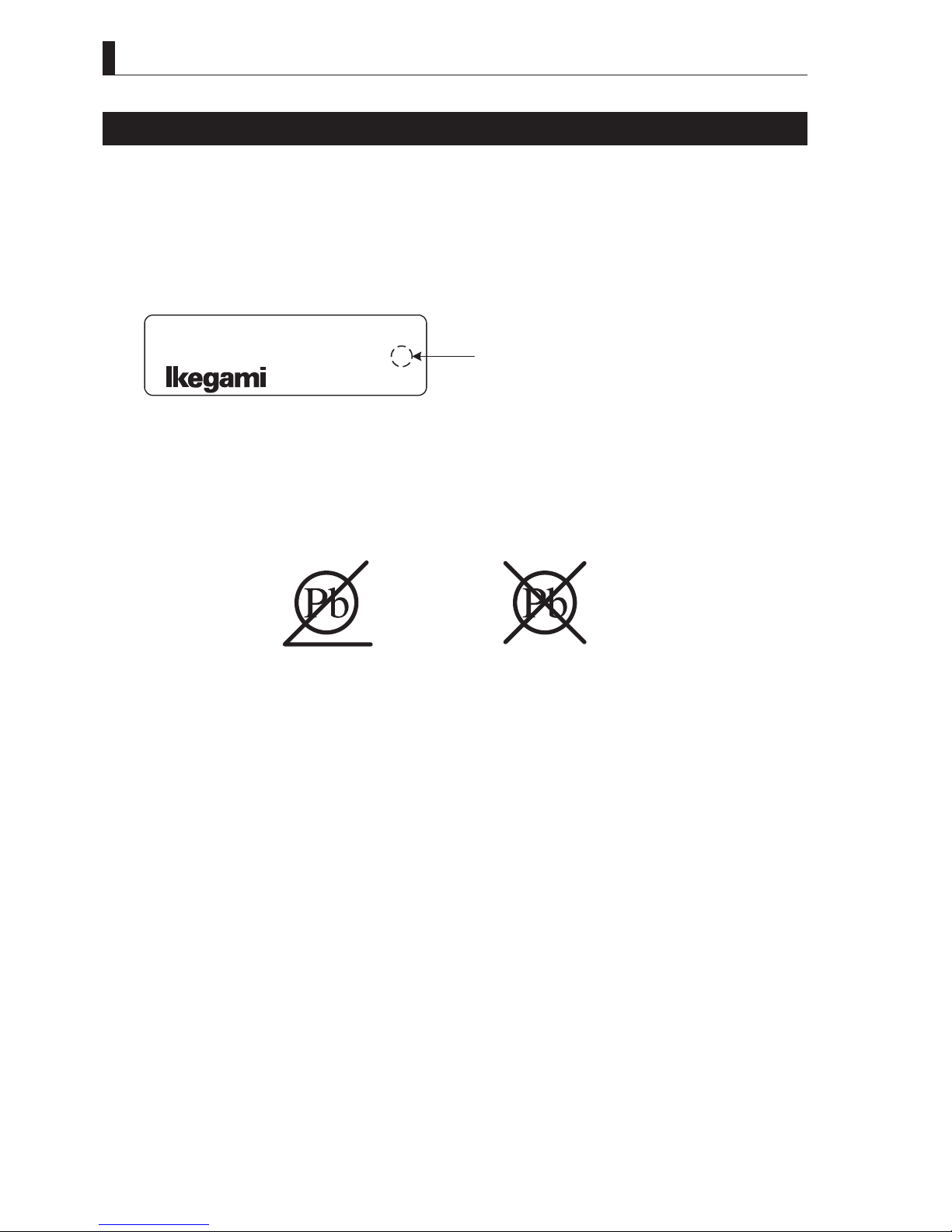

MAINTENANCE OF PRODUCTS CONFORMING TO RoHS DIRECTIVE

MAINTENANCE OF PRODUCTS CONFORMING TO RoHS DIRECTIVE

Work with care about followings for maintenance of products conforming to RoHS directive.

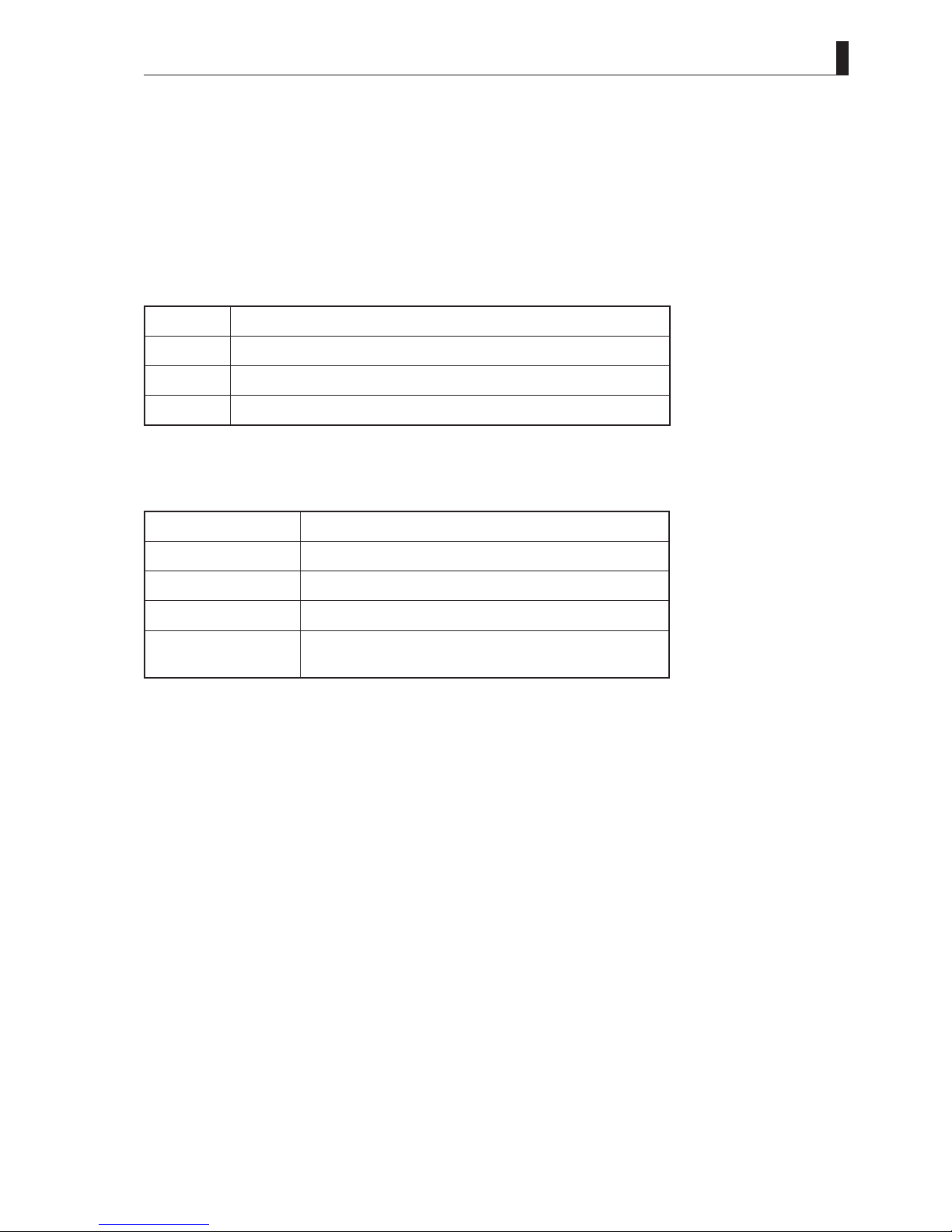

1. Identification

· For products conforming to RoHS directive, the letter "E" is appended at the end of the serial number on the label. For models

that the letter cannot be appended to the serial number, the letter "E" will be described in a distinguishable position on the

label. A description example on a main label is shown below.

MODEL HDK-55

SERIALNo. AA123456 E

Label

· Print-circuit board of the products conforming to RoHS directive is manufactured by following methods.

[1] Blue resist ink is used for the print-circuit board. (The color of conventional print-circuit board is green.)

[2] Either one of the following marks is indicated by a serigraph or label.

Product conforming to RoHS directive

Phase 3A Phase 3

2. Soldering

Since the melting point of lead-free solder used for the products conforming to RoHS directive is 20 to 45 degrees Celsius higher

than that of conventional solder with lead (Sn-Pb eutectic solder), a high temperature needs to be set to a soldering iron. Taking

allowable temperature limit of the parts and stable work into consideration, use a soldering iron with excellent thermal recovery

characteristics.

· Recommended solder composition is "Sn/3.0Ag/0.5Cu" or equivalent.

· Separate the soldering iron exclusively for RoHS products and the soldering iron for conventional use.

· Set the temperature of the soldering bit to 350 to 370 degrees Celsius.

The temperature may need to be adjusted according to the size of the copper foil land on the print-circuit board and the tip

width of the soldering bit.

· Finish by a lead-free solder looks dull or whitish compared to conventional solder with lead.

· If the customer mixed the lead-solder with the main body wiring or the circuit board, it becomes guarantee off the subject.

Ikegami doesn't guarantee to do the repair work. Because the solder polluted with lead cannot be removed.

3. Parts

Be sure to use parts conforming to RoHS directive.

ii

HDK-55 1206VER1 (U)

INFORMATION TO THE USER

INFORMATION TO THE USER

1. This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instr uction manual, may cause har mful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required

to correct the interference at his own expense.

Changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to

operate the equipment.

2. Declaration of conformity

The CE mark means that the following products will meet the Directive 2004/108/EC,2006/95/EC and the Standards EN55103-

1 E4-E5, EN55103-2 E4-E5 (for EMC), EN60950-1 (for LVD).

For European customer.

3. Rated current value of the camera when BSF-55 are used for the system operation is shown below.

Rated current value

· BSF-55 DC180V : 0.8A

HDK-55 1206 VER1 (U)

iii

SAFETY PRECAUTIONS

N

SAFETY PRECAUTIONS

This manual describes the precautions using various pictorial symbols for you to use the product safely. Please read these

precautions thoroughly before use. The symbols and meanings are as follows:

The following hazard alert symbols are used to indicate the level of impact on the body or property

when you do not follow the precautions.

WARNING

CAUTIO

The following symbols are used to indicate the expected injury or hazards when you do not follow

the precautions.

The following symbol is used to indicate other precautions to prevent damage or hazard from

occurring:

Indicates that mishandling of the product by ignoring this label may lead to a danger resulting in a

serious injury or death.

Indicates that mishandling of the product by ignoring this label may lead to a danger resulting in an

injury or property damage.

Indicates general cautions on such matters as safe work, procedure, and installation location.

Mishandling may not directly lead to death, injury, or property damage.

Indicates that mishandling may cause an electric shock.

Indicates that mishandling may cause a fire.

Indicates that mishandling may cause injury.

Indicates prohibited action.

iv

HDK-55 1206 VER1 (U)

䂓

N

Handling Precautions

WARNING

Regarding the Product

SAFETY PRECAUTIONS

Regarding the Power

CAUTIO

Regarding the Product

Do not disassemble or modify the product which is not described in this manual. Doing so may

cause fire, electric shock, or injury.

When you disconnect the cable, be sure to hold the plug and pull. Failure to do so may cause a fire

or electric shock due to a damaged cable.

To inspect or operate on the inside of the equipment, tur n off the power and wait for one or two

minutes before starting work. High voltage is present in some modules and connectors of this

product.

When you want to intercept a power supply surely, I pull a fiber cable of the camera side, or, please

pull an AC plug of the BS/CCU side.

Do not lift or hold the camera by the projection parts.

If you lift or hold the camera by the viewfinder or the lens, you are prone to dropping it. Moreover,

the connection parts between the camera and the viewfinder, or the camera and the lens may be

exposed to unnecessary pressure, which may cause equipment damage.

Always install the accessories or connect the cables after placing the camera on a fixed position.

When installing such accessories as lens or microphone, fix the camera on a stable place (e.g. on a

table, a tripod, etc.).

Avoid use or storage in the following conditions:

- Extremely high/low temperature

- In direct sunlight for a long time, or near a heater

- High humidity or dusty

- Exposed to water or other liquid

- Strong vibration or shock

- Strong magnetic field or radio waves

- lightning

- In rain without the rain cover

HDK-55 1206 VER1 (U)

v

SAFETY PRECAUTIONS

Regarding the Product

Be sure to hold the plug and pull when you disconnect the cable.

Failure to do so may cause a fire or electric shock due to a broken cable.

Avoid moving the equipment suddenly from an extremely cold place to a warm place.

Condensation may occur in the Charged Couple Device (CCD) or other parts.

Do not drop or insert a metal object such as a pin or a foreign object into the equipment.

Do not spread or spill water or other liquid on the equipment.

Do not subject the equipment to a strong shock or vibration.

Doing so may cause damage or malfunction of the equipment.

Since a CCD is adopted as the image sensor in picture elements, no burning occurs in ordinary

operation. However, when shooting a subject which emits an excessive amount of light (such as the

sun) for long hours, take great care for temperature increase inside of the CCD.

Laser beams may damage the CCDs. If you shoot a scene that includes a laser beam, be careful not

to let a laser beam become directed into the lens of the camera.

Before connecting a VTR or accessories, make sure that the camera and equipment to be connected

are powered off. Also, be sure to use dedicated cables.

Excessive sound pressure from the headset may cause a hearing loss.

Regarding the Power and the Lithium Battery

Use the product in compliance with the rating of the fuse within the product and that within the

Camera Control Unit (BS). Otherwise, a fault can occur.

Do not use an unspecified battery.

Wrong usage of batteries may cause liquid leak, explosion, and heat, and at worst injur y or fire.

When changing or discarding a battery, please contact Ikegami's sales and service centers.

Risk of explosion if battery is replaced by an incorrect type. Dispose of used batteries according to

the instructions.

Regarding the Fiber Connector and the Fiber Optic Cable

Fiber optic cable connectors are quite similar to each other in shape. Before connecting fiber optic

cables, thoroughly check male or female, the diameter, type and manufacturer of connectors.

If the ferrule is dirty, wipe the dirt off with cotton swabs soaked in alcohol.

The fiber optic cable supplies DC180V power from the BS to the camera.

Although safety measures are fully taken such as the safety circuit that stops the power supply

from the BS within a short time after an optical fiber cable is removed or short-circuited, never

force to bend, twist, or damage the cable, and take great care when handling.

vi

HDK-55 1206 VER1 (U)

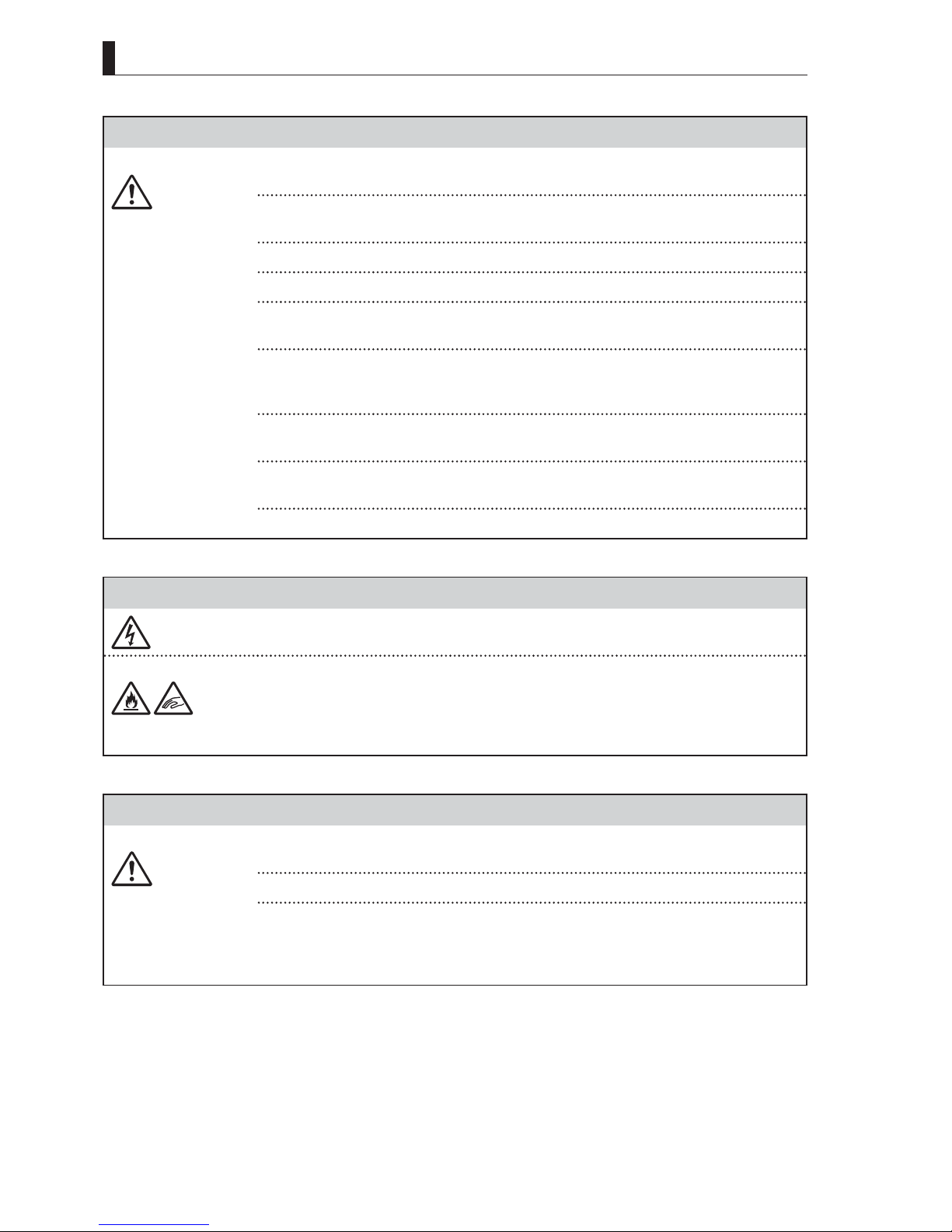

Regarding the Fiber Connector and the Fiber Optic Cable

Take care for the following:

- When disconnecting the fiber optic cable from the camera or from the BS, always hold the fiber

connector (plug) and not the cable.

- Do not crush the cable.

- Since there can be various obstacles (such as a corner of a building, glass, rough ground surface)

in places where the cable is connected, do not drag the cable without winding.

- Turn off the power before removing the fiber optic cable.

- The allowable radius of curvature of fiber optic cables is approximately six times of the outer

diameter of cables (approx. 60 mm for a φ9.2mm-wide cable). Do not force to wind less than

specified. Forcible winding can break fiber leads within the cable.

- When connecting a fiber optic cable to a fiber connector, anchor the fiber optic cable with a cable

clamp.

Radius

Approx. 60mm

Fiber Optic Cable

SAFETY PRECAUTIONS

CAMERA CABLE Clamp

Optical Fiber Cable

CAMERA CABLE Clamp

(optional)

HDK-55 1206 VER1 (U)

vii

SAFETY PRECAUTIONS

䂓

Environmental Cautions

Regarding the product

When continuously operating the product in a rainy, cold or hot conditions, use a rain cover, coldweather cover, and shade cover respectively.

Avoid storing the product in a dusty place for a long time. If unavoidable, use a dustproof cover.

When shooting in places such as airports, militar y bases or transmitting stations where magnetic

and radio fields are excessively strong, completely shield the camera by covering it with aluminum

foil.

䂓

Maintenance

Regarding the product

Before performing maintenance on the product, be sure to turn off the power for safety and for

protection against malfunction.

Clean the product using a dry and soft cloth.

If the stain is hard, soak the cloth with water or detergent, wring well and wipe. If you use

detergent, wipe off the detergent with a cloth that is soaked in just water and wrung well.

䂓

Notice for Use

- When car rying or storing the product, always use a carrying case.

- Before shooting important subjects, take test shots to obtain the desired effect.

- After using the product, always turn off the power.

䂓

Regular Maintenance Recommended

This product includes parts that wear out and have a limited life even in proper use or storage. Therefore, regular maintenance is

recommended to extend the life and safe use of this product for a long time. Please contact Ikegami's sales and service centers for

the regular maintenance and repair of our products.

viii

HDK-55 1206 VER1 (U)

HOW TO READ THE OPERATION MANUAL

HOW TO READ THE OPERATION MANUAL

This page explains general notes on reading the HDK-55 Operation Manual, and the symbols and notations used in the manual.

䂓

Notes on the Manual

- This manual is written for readers with a basic knowledge of handling broadcast cameras.

- The contents of this manual are subject to change without notice in the future.

䂓

Symbols

The symbols used in this manual are as follows:

CAUTION:

Things you have to be careful during operation. Be sure to read.

Note:

Reference:

Ter m :

䂓

Notations

The following notations are used in this manual.

This product, camera Indicates HDK-55. (Including FA-55)

BS Indicate BSF-55 Base Station.

OCP Basically indicates OCP-200 Operation Control Panel.

MCP Basically indicates MCP-200 Maintenance Control Panel.

" " - " " - " " Indicates the items enclosed by double quotes (") are to be

䂓

Illustrations and Displays

The illustrations and displays in the text are provided for explanation and may be slightly different from the actual equipment or

image.

Supplementary information or guidance

Sections where related information is available

Explains the meaning of a term you need to know.

selected and confi rmed in the order shown.

䂓

Related Manuals

- BSF-55 Base Station Operation Manual

- OCP-200 Operation Control Panel Operation Manual

- MCP-200 Maintenance Control Panel Operation Manual

- CPH-200 Control Panel HUB / BSH-200 Base Station Hub Setup Manual

HDK-55 1206 VER1 (U)

ix

HOW TO READ THE OPERATION MANUAL

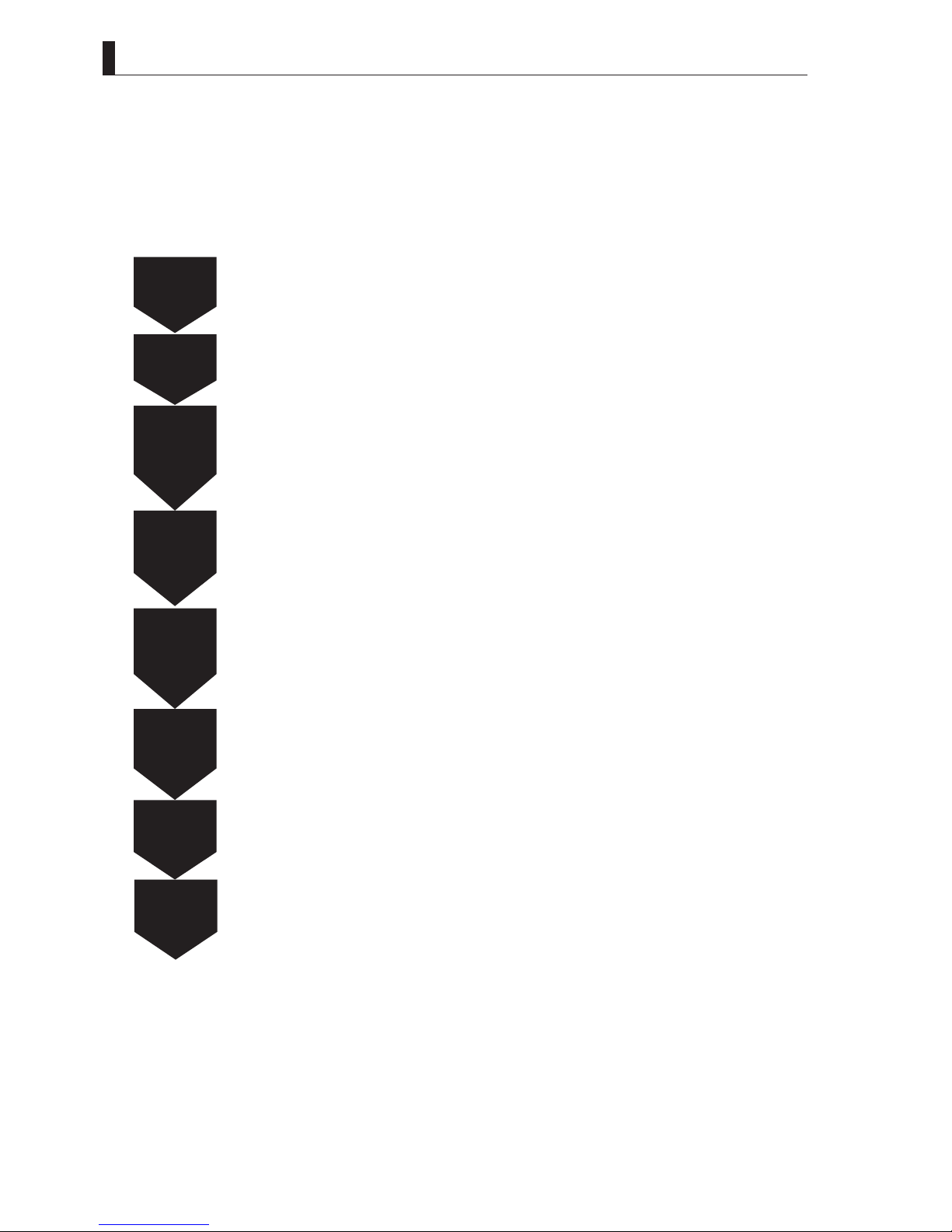

Structure of Operation Manual

䂓

HDK-55 High Definition Camera System Operation Manual is intended to both safely and smoothly operate the HDK-55.

The Operation Manual consists of seven chapters. By reading it in sequence, you can smoothly perform a series of steps, from

connection to operation. Furthermore, by combination use of BSF-55 (base station), this product enables not only stand-alone

VTR location shooting but also various shooting styles such as studio shooting and field shooting as a system camera. Refer to

other manuals such as for the BSF-55.

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Chapter 5

OUTLINE

Explains the features and the main operating systems of this product.

If you are not familiar with HDK-55 High Definition Camera System, please start with this chapter.

NAME and FUNCTION

Explains the name and function of each part of the Camera.

INSTALLATION and CONNECTION

Explains how to mount this product, lens, and viewfinder.

Taking examples of studio shooting, stand-alone shooting, and VTR location shooting, explains how

to connect this product to the peripheral equipment.

OPERATION

Explains setup before shooting.

Before shooting for the first time, read this chapter and check that this product is operating nor mally.

CAMERA SETTINGS and ADJUSTMENT

This product realizes detailed settings to support a wide range of operations and various video

expressions through the menu window. This chapter explains switch settings, menu settings, and DIP

switch settings on the modules inside of the Camera.

Chapter 6

Chapter 7

TROUBLE SHOOTING and MAINTENANCE

When the alarm lamp lights during the operation of this product, read here to know the problem. This

chapter also explains the regular maintenance such as cleaning of connectors and resetting of breaker.

SPECIFICATIONS

Explains the specifications of this product.

CHANGING INFORMATION

Contains revision information of design revision or customer-specific specification requested

by customers. Read by comparing with the main text of the operation manual. ("CHANGING

INFORMATION" may be sent to you later on.)

x

HDK-55 1206 VER1 (U)

HDK-55

CONTENTS

(

FA-55

High Definition Camera System

Operation Manual

PRODUCTS CONFORMING TO RoHS DIRECTIVE. . . i

MAINTENANCE OF PRODUCTS CONFORMING

TO RoHS DIRECTIVE ........................ii

INFORMATION TO THE USER .................. iii

SAFETY PRECAUTIONS .......................iv

HOW TO READ THE OPERATION MANUAL ....... ix

Chapter 1 OUTLINE

1.1 Features of This Product ................. 3

1.2 Operating Systems ...................... 5

1.3 Connection Diagram. . . . . . . . . . . . . . . . . . . . . 9

Chapter 2 NAME and FUNCTION

2.1 Camera and Viewfinder ................. 13

Camera Right View .................... 13

Camera Left View ...................... 17

Camera Front View ..................... 19

Camera Rear View ..................... 21

Viewfinder (VF421HD) .................. 25

2.2 Displays in the Viewfinder ............... 27

LED Indicator ......................... 27

Center Marker, Safety Marker, Frame Marker

Zebra Indicator ........................ 27

Side Mask Function .................... 28

Display Mode ......................... 28

Viewfinder Display ..................... 28

Chapter 3

INSTALLATION and CONNECTION

3.1 Preparation ...........................33

Product Use Environment ............... 33

Make sure the Power Switch is OFF ....... 33

Connection Example for Each Operating

System .............................. 33

3.2 Camera and Peripheral Installation and

Connection ........................... 39

Mounting/Removing the Camera on/from the

Tripod ............................... 39

Mounting and Removing the Lens ......... 41

Mounting and Removing the Viewfinder .... 43

Attaching the Microphone ............... 45

Connecting the Headset ................. 46

Attaching the Shoulder Belt .............. 46

.. 27

)

3.3 Power Connection ..................... 47

Power Supply from POWER .............. 47

Power Supply from BS .................. 48

3.4 Monitor Connection .................... 51

Connecting Camera and Monitor .......... 51

3.5 BS Connection ........................ 52

Connecting Camera and BS ............. 52

Chapter 4 OPERATION

4.1 Operating Procedures .................. 57

4.2 Switch Position Check .................. 58

4.3 Turning ON Power ..................... 60

Power Supply from POWER .............. 60

Power Supply from BS .................. 60

4.4 Viewfinder Adjustment .................. 62

Diopter Adjustment and Screen Adjustment . . 62

Display Mode Check ................... 62

4.5 Output Signal Check ................... 63

Color-Bar Signal Check ................. 63

Test Pulse (CAL Signal) Check ........... 64

External Chart Check ................... 64

4.6 Auto Setup ........................... 65

Auto White Balance .................... 66

Auto Black Balance .................... 67

Auto Black Shading ....................68

4.7 Preparation for Shooting in Particular

Environment .......................... 69

Chapter 5

CAMERA SETTINGS and ADJUSTMENT

5.1 Settings Using Switches on the Camera .... 73

Adjusting Headset Volume ............... 73

Selecting Shutter Speed .................74

Enhancing the Vertical Resolution

(Super-V Function) ..................... 76

Switching the GAIN .................... 77

Allocating Functions to the P.FUNC Switch . . 78

Screen Detail Enhancement (DTL) ........ 79

5.2 Settings from the Menu ................. 80

Basic Operation of the Menu ............. 80

Menu Configuration and content .......... 83

5.3 Using the Memory Card ................. 95

HDK-55 1206 VER1 (U)

xi

CONTENTS

Chapter 6

TROUBLE SHOOTING and MAINTENANCE

6.1 Alarm Lamp on the OCP or MCP

Flashes ON and OFF .................. 101

6.2 "TEMP!!" or "FAN!!" Appears

on the VF Screen ..................... 102

6.3 Initializing the Settings of this Product ..... 103

6.4 Cleaning Camera Connectors ........... 105

6.5 Reset the Breaker ..................... 109

Chapter 7 SPECIFICATIONS

7.1 HDK-55 Specifications ..................113

7.2 External Dimensions Diagram ............115

7.3 External Connections ...................119

7.4 Scene File ........................... 132

CHANGING INFORMATION ................... 133

xii

HDK-55 1206 VER1 (U)

OUTLINE

1

2

HDK-55 1206 VER1 (U)

HDK-55

■

This product realizes high quality pictures and advanced functions using the intelligent

digital technique nurtured in the HDK series. Furthermore, we succeeded to create a

small, light-weighted camera system whose weight and balance has been sought for the

improvement of the portable camera operation.

- A 16-bit (65,535 gradation) A/D converter produces pictures with a broader range of

gradation from darker par ts to highlighted parts.

1.1 Features of This Product

1.1 Features of This Product

Fusion of High Quality CCD and Superb Image Processing Techniques

■

2.3 Million pixel new interlace 3CCD

A 2.3-million pixel 2/3-inch AIT type 1080i CCD is employed to achieve superb picture

quality with a horizontal resolution of 1,000 TV lines and an S/ N ratio of more then 60dB.

■

Newly developed digital process IC

16-bit A/D conversion and new digital processing (computation) within the camera digitizes

not only video signals but also nonlinear image processing used for the white shading

correction and Gamma correction. This always achieves high quality pictures, advanced

functions, and high reliability with stability.

Support of Various Picture Expressions

■

DTL Correction

Includes a horizontal and vertical DTL correction circuit in which red, green and blue video

are independently digitally processed.

You can obtain the full resolution HDTV picture quality with little noise even in the standalone VTR shooting.

11

OUTLINE

■

Wideband Digital DTL

Includes an advanced digital DTL circuit to improve reproduction, including texture

and sheen. Furthermore, improves richer reproduction of details with little noise in dark

background and details in skin tone.

■

Focus Assist Function

A focus assist area is provided in the VF image to aid the cameraman in finding the focus.

The focus assist area can only be displayed during focusing when operation of the lens

focus ring or operation of the focus switch, etc. act as a trigger.

■

Six-axis + Two-axis Color Corrector

Includes a color corrector f unction that enables you to adjust hue and saturation of six

primary colors (R, G, B, cyan, yellow, magenta).

Also, includes a color corrector function to adjust two selected colors.

■

Super KNEE

Includes a super KNEE function which produces the KNEE process with less saturation

loss, and without changing the hue of the highlighted parts. Produces a more natural

highlight appearance, rather than washing out the color.

HDK-55 1206 VER1 (U)

3

1.1 Features of This Product

Pursuit for Superb Operation and Ease of Use

■

Application of Conventional Standard 2/3-inch Lenses

As the lens mount, BTA S-1005B is used. You can use not only HD lenses but also SD

camera lenses for SDTV portable cameras as they are.

■

High Performance Viewfinders

Employs a magnifying eye-piece in the 2-inch B/W viewfinder to improve the visibility

of fine picture detail. It is also possible to choose a 2-inch color viewfi nder, 5-inch high

precision B/W viewfinder or a 9-inch liquid cr ystal color viewfinder.

■

Low Center of Gravity, Light Weight, and Excellent Balance

Designed with a low center of gravity, light weight, and excellent balance, in consideration

of the balance when shooting on the shoulder and holding at various angles.

■

On-Line Diagnostics

An on-line diagnostic system enables monitoring the status of circuits including video,

control, fiber optic transmission, pulses and power supply. This enables you to always grasp

the status information of the camera.

■

Rotating Camera Cable Connection

Employs a rotating fiber camera cable connector. This enables studio shooting and field

shooting at various angles.

■

Return Switch

A switch to choose RET-1 or RET-2 is also equipped on the handle grip of the camera to

easily switch when low angle shooting.

Peripheral Equipment to Support a Wide Range of Purposes

■

SE-H700 System Expander

By using an SE-H700 system expander, you can use a 9-inch viewfi nder and full studio

lenses. The light weight portable camera is converted into a full facility studio camera.

Equipped with Various Interfaces

- The camera includes HD-SDI signal output.

- The camera has an interface for return video in HD-SDI signal form. (RET HD-SDI signal

transmission)

- When the camera is connected to the BSF-55, you can use the data trunk channel (RS-422)

for virtual studio applications.

- An 8-core composite fiber optic camera cable (two single-mold fibers, four power

leads, two control signal leads) connects between the camera and the BSF-55, and the

transmission complies with BTA S-004A (Japan standard) and SMPTE292M (International

standard). The distance of signal transmission and power supply allows up to 3,000 m

by multiple connections (up to 12 connections) of composite fiber optic cables (9.2 mm

diameter).

- DC12V can be supplied from the camera.

Support Function for Data Setup

The level adjustment and settings of each menu for the camera can be easily set up by

calling up the ENGINEER SET FILE that is set by user engineer or the FACTORY SET

FILE that is set at shipment according to environment or shooting conditions where the

camera system is used. This enables to initialize the camera status quickly even though the

settings are changed due to causes such as wrong operation of the menu.

4

Reference:

Refer to "6. TROUBLE

SHOOTING and

MAI NTENANCE", "Initializing

the Settings of this Product"

(page 103) for the ENGINEER

SET FILE and FACTORY SET

FILE.

HDK-55 1206 VER1 (U)

1.2 Operating Systems

1.1 Features of This Product

This product is equipped with functions which interface with a control panel and a control

unit. If you use BSF-55, this product can support not only stand-alone VTR shooting but

also various shooting styles such as studio shooting and field shooting as a system camera.

Furthermore, you can choose and operate each control panel to be connected to the BS, for

your purpose.

■

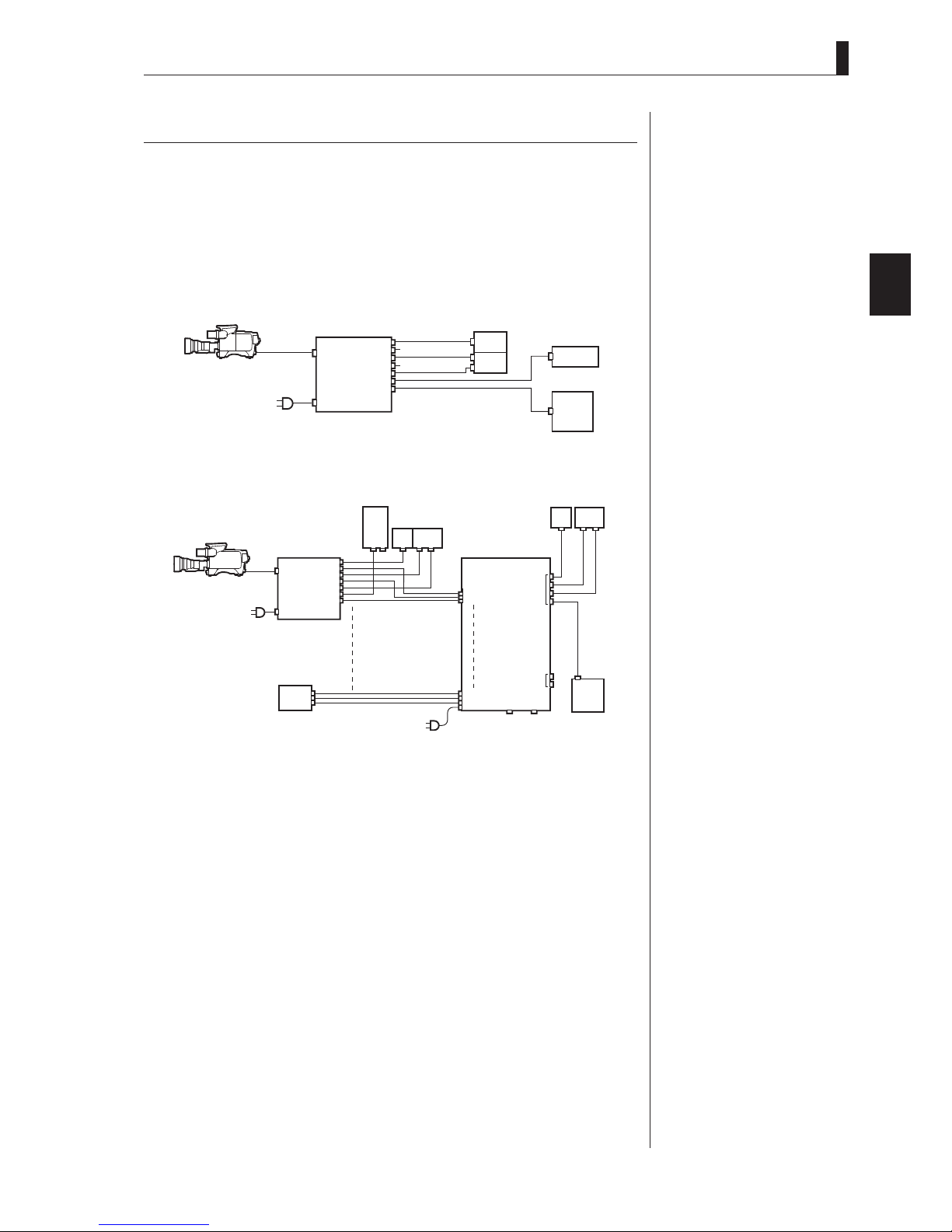

Example of Minimum Configuration of System Camera (1 camera, 1 OCP, 1 MCP)

Camera Head

BS

■

Example of System Camera Configuration (Up to 8 cameras, 1 MCP)

Camera Head

PM

BS-1

WFM

COMM

BS-8

PM

WFM

COMM

OCP

PM, WFM, COMM

PM

WFM

WFM CONT

PM WFM

WFM, COMM

WFM

CONT

PM

BS-1

BS-8

PM

WFM

CSU

OUT

OCP

MCP

PM WFM

PM

WFM

WFM CONT

COMM

IN

MCP

Note:

By using an SE-H700 system

expander together, this product

can operate as a full-scale studio

camera equipped with a 9-inch

viewfinder and a full studio lens.

Note:

For Minimum operating System,

no MCP needed when OCP-200

is used.

Ter m :

OCP (Operation Control

Panel)

This control panel is used for

normal operation. Typically one

OCP is dedicated to one camera

chain.

Ter m :

MCP (Maintenance Control

Panel)

This control panel is used for

the maintenance and precise

adjustment of the camera in

studio shooting. By using a

memory card, you can save the

shooting condition on memory

and make setup easily. By using a

CSU together with an MCP, you

can maintain up to 32 cameras.

Ter m :

CSU (Camera Select Unit)

Used when controlling multiple

cameras. With using a MCP,

one CSU can control up to 8

cameras, and contains terminals

through which video is output

on the monitor from the selected

camera.

11

OUTLINE

HDK-55 1206 VER1 (U)

5

1.2 Operating Systems

■

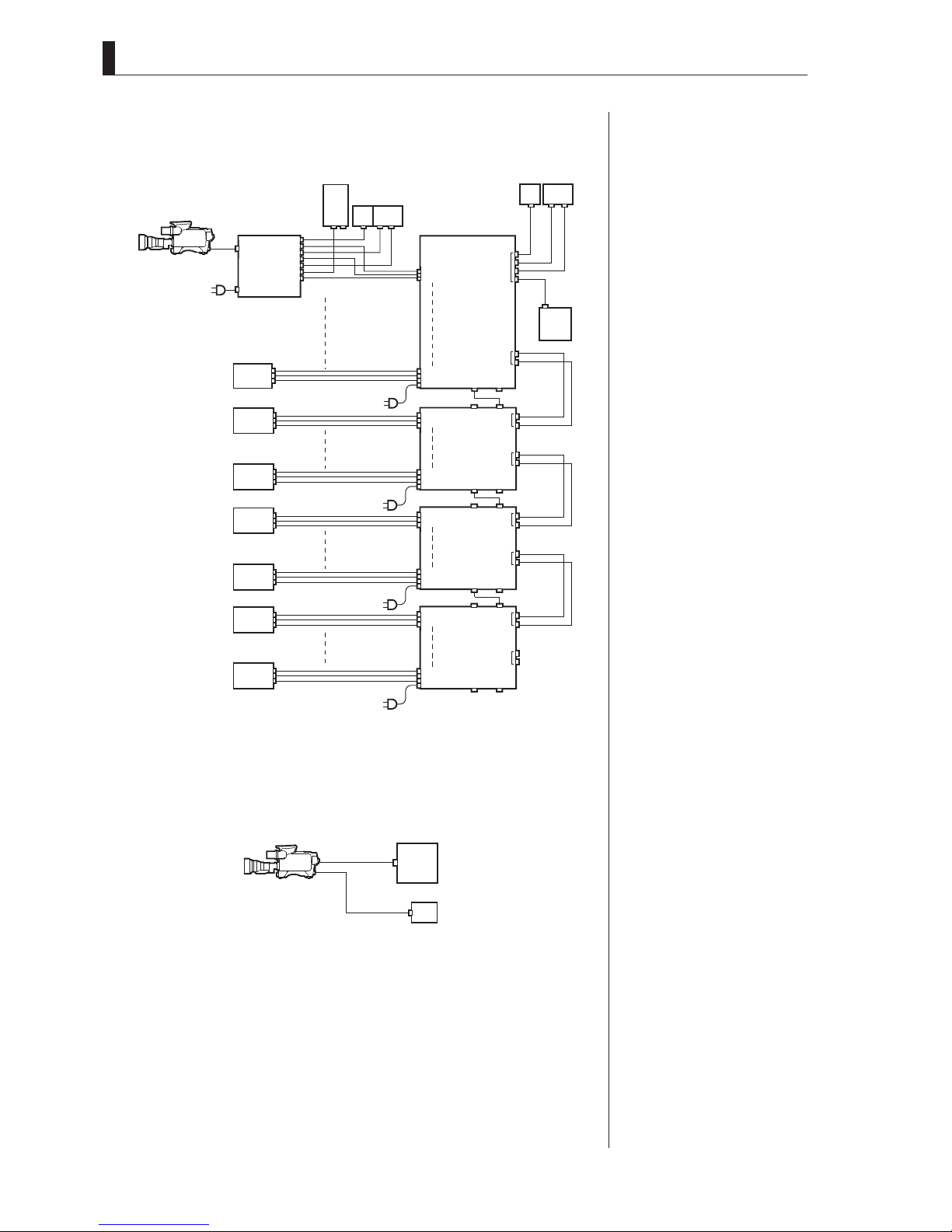

Example of Minimum Configuration of System Camera

(Up to 32 cameras and 1 MCP)

Camera Head

BS-1

BS-8

BS-9

BS-16

BS-17

BS-24

BS-25

BS-32

PM

WFM

COMM

PM, WFM, COMM

OCP

PM WFM

WFM

CONT

WFM, COMM

PM

BS-1

CSU-1

BS-8

CSU MCP

BS-9

CSU-2

BS-16

CSU MCP

BS-17

CSU-3

BS-24

CSU MCP

BS-25

CSU-4

BS-32

OUT

OUT

OUT

OUT

IN

IN

IN

IN

PM WFM

PM

WFM

COMM

MCP

PM

WFM

PM

WFM

PM

WFM

WFM CONT

■

Example of VTR Location Configuration

(Minimum Configuration of Camera, VTR, and PM)

Camera Head

HD

VTR

PM

6

HDK-55 1206 VER1 (U)

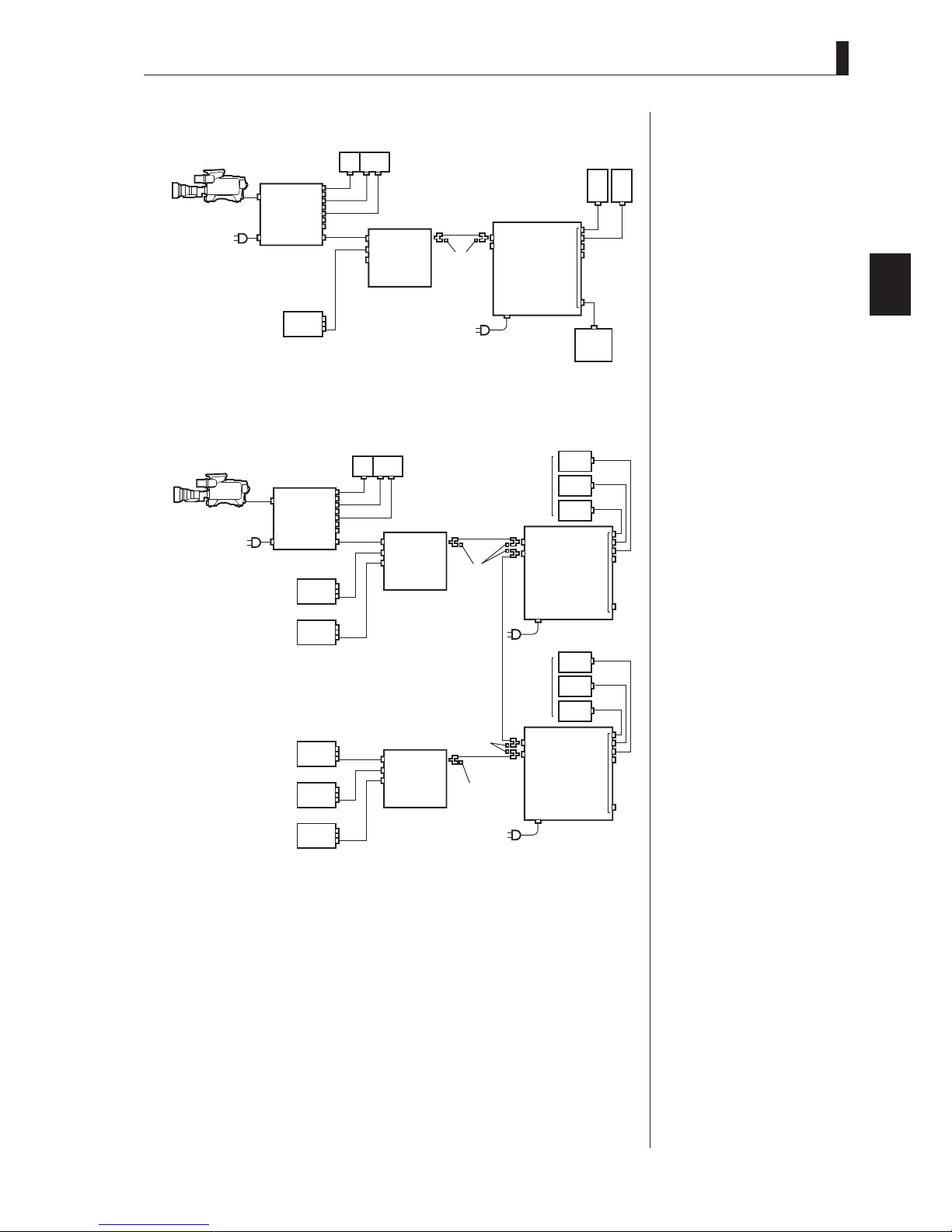

■

Network Connection (Basic bus connection)

1.2 Operating Systems

Camera Head

BS-1

OCP/

CCP

BS-2

■

Network Connection (Expansion bus connection)

Camera Head

BS-1

PM

WFM

BS-2

PM

WFM

OCP/

CCP

PM WFM

CP cable

CP cable

BS/

CCU

BSH-200

PM WFM

BS/

CCU

ARC1

ARC2

ARC3

ARC1

ARC2

ARC3

BSH-200

Coaxial cable

75Ω

termination

Coaxial cable

75Ω

termination

ARC1

ARC2

CPH-200

OCP-200

ARC1

ARC2

CPH-200

CP

OCP-200

CP cable

MCP-200

CP cable

CP

Note:

- The OCP/CCP connector and

MCP/CCP connector on the CCU

cannot be used with the network

connector at the same time in

this configuration.

Ter m :

CPH (Control Panel Hub)

The hub for network used with

connecting to a network-adaptive

control panel.

Ter m :

BSH (Base Station Hub)

It is designed as the HUB unit

of which employs command

converter for Ikegami's nonnetwork capable camea head/

BS/CCU to use under network

control system.

Note:

- The OCP/CCP connector and

MCP/CCP connector on the CCU

cannot be used with the network

connector at the same time in

this configuration.

11

OUTLINE

BS-3

BS-4

BS-5

BS-6

CP cable

BS/

CCU

BSH-200

Coaxial cable

75Ωtermination

ARC1

ARC2

ARC3

75Ωtermination

Coaxial cable

OCP-200

ARC1

ARC2

CP cable

CP

CPH-200

HDK-55 1206 VER1 (U)

7

1.2 Operating Systems

8

HDK-55 1206 VER1 (U)

1

OUTLINE

9

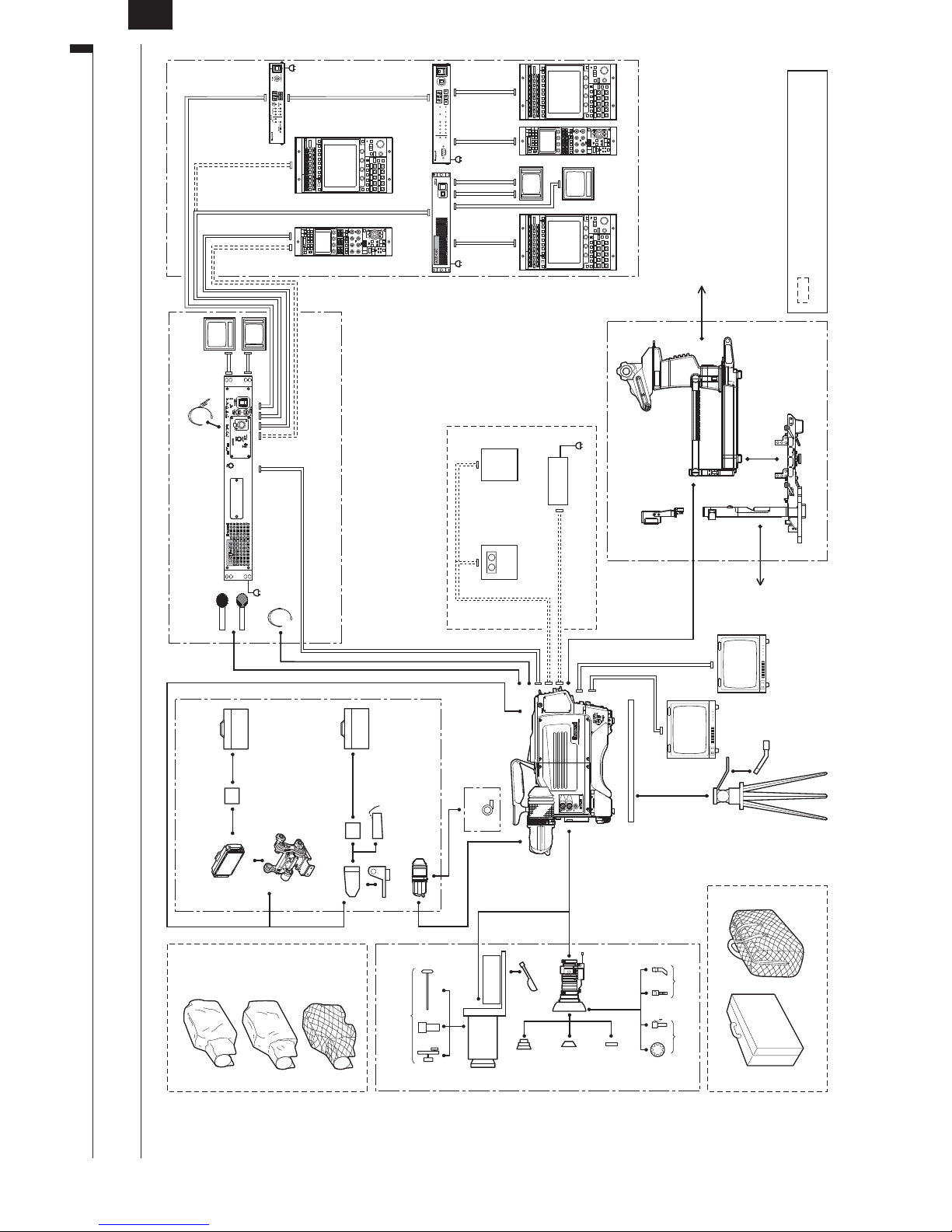

AC

Coaxial Cable CP Cable Max. 300m

CP Cable Max. 30m

MCP-200OCP-200

BSH-200E

1.3 Connection Diagram

BSH-200

CPH-200

CPH-200

AC

MCP-200

CP Cable Max.300m

CP Cable Max.80m (*Note 1)

Headset

BSF-55

PM

Base Station

MIC-1

MIC-2

WFM

AC

Max.300m (*Note 1)

Power Cont Cable

Headsets

(PROD/ENG)

Fiber Cable Max.3000m

OCP-200

(*Note 1)

CSU

AC

CP Cable

Max.300m

CP Cable Max. 50m

Coaxial Cable

WFM Cont Cable

Coaxial Cable

(*Note 2)

Max.10m

MCP Cable

HD

VTR

WFM

RCP-50B

POWER

Coaxial Cable

PM

AC

DC Power Cable

DC 11 to DC16V

length is 300m at the maximum.

When OCP-200 is used, the POWER CONT cable cannot

be used.

(*Note 2)

MCP-200

cable length is 30m at the maximum.

Note 1: When any OCP other than OCP-200 is used, the CP cable

Note 2: When any MCP other than MCP-200 is used, the MCP

- 9"LCD VF (VFL912HD (COLOR))

- Script Lamp

- RET SW Box

- Pedestal/Tripod System

SE Main Body

Tally Box

SE-H700

System Expander

- Lens

Coaxial Cable

Multi Video Cable (Analog)

Coaxial Cable (HD SDI)

HD

Monitor

(COLOR)

- Lens Accessory

Equipment inside the dotted frame is mainly

used for stand-alone/VTR location shooting.

Lens Supporter

1.3 Connection Diagram

9-inch LCD VF

VF System

Cover

Studio Hood

(VFL912HD)

Dust Proof

Cover

Carrying Case

Rain Proof

Cover

Attachment

5-inch VF

(VF13XHD)

Cold Weather

Cover

Studio Hood

Carrying Case

Field Hood

Attachment

Lens

Standard VF

Manual Control

Mic Holder

2-inch VF (VF421HD, VFL200HD)

Adaptor

Prompter

Zoom Lens

FA-55

Teleside

Converter

Script

Lamp

HDK-55

Zoom Lens

Wide

12Pin

Attachment

W/Diascope

or

W/O Diascope

Filter

Tripod Mount Plate

HD

(B/W)

Monitor

Remote Zoom

Control Set

Remote Focus

Control Set

Tripod

Case

Zoom Remote

Control Box

Camera Carrying Case Soft Carrying Case

HDK-55 1206 VER1 (U)

NAME and FUNCTION

2

12

HDK-55 1206 VER1 (U)

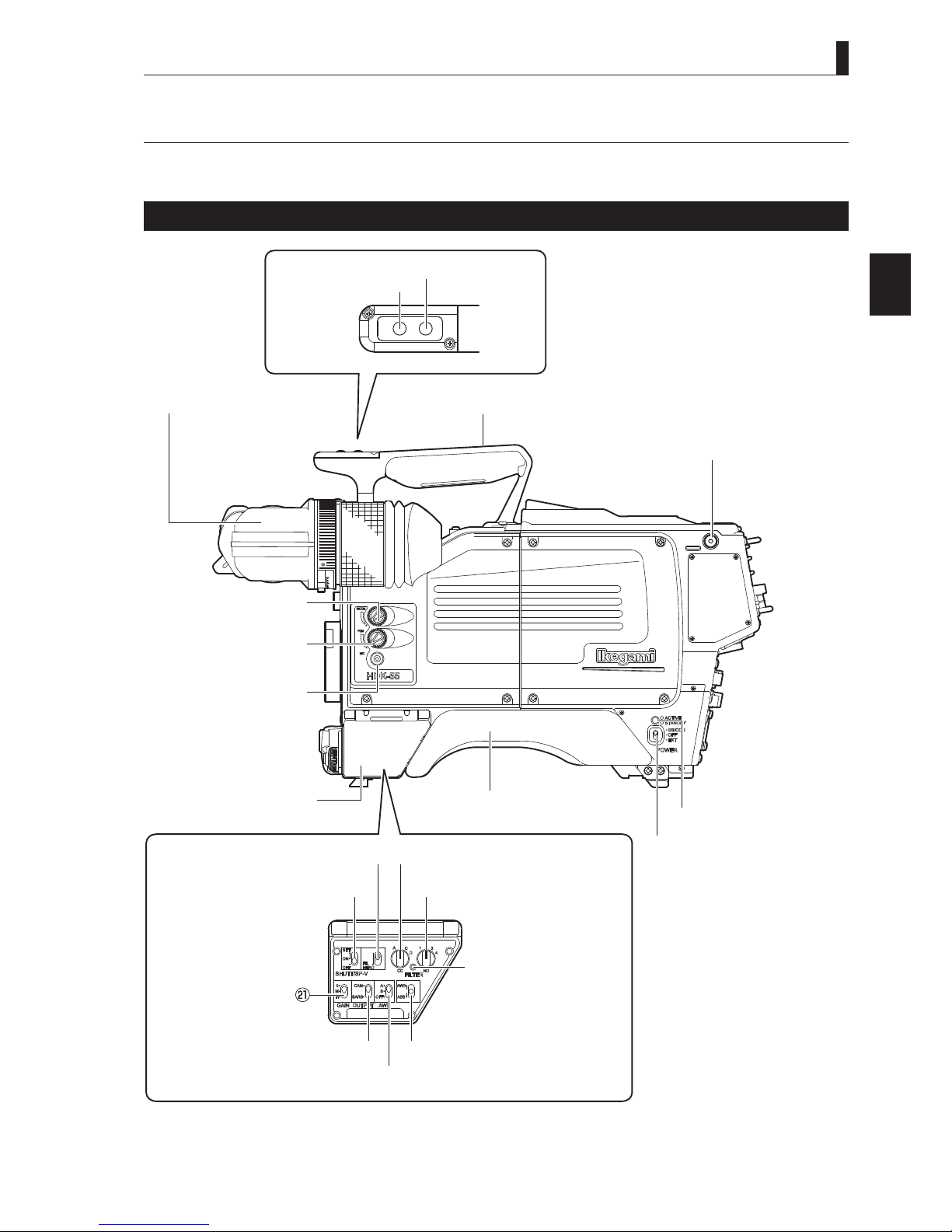

2.1 Camera and Viewfinder

This section explains the names and functions of the parts on the camera and viewfinder.

Camera Right View

2.1 Camera and Viewfinder

RET-2/MIC button ③

① Viewfinder(VF)

INCOM PHONE ⑪

control knob

INCOM PGM ⑩

control knob

INCOM MIC button ⑨

④ RET-1 button

/+%

4'6

4'6

2

NAME and FUNCTION

② Handle

⑤ Shoulder belt hook

Switch control ⑫

panel cover

FILTER HEAD switch ⑭

SHUTT/SUP-V switch ⑬

GAIN SELECT switch

OUTPUT SELECT switch ⑳

⑧ Shoulder pad

⑮ CC FILTER switch (ECC)

⑯ ND FILTER switch

⑰ FILTER local indicator

⑱ AWB/ABB switch

⑲ AWB SELECT switch

HDK-55 1206 VER1 (U)

⑥ POWER indicator

⑦ POWER switch

13

2.1 Camera and Viewfinder

Viewfinder (VF)

①

Displays camera image, return image, various characters and markers. A 2" viewfi nder, an

optional 5" high definition B/W viewfinder, and an optional 9" LCD color viewfinder are

available.

Handle

②

Grip this handle to carry the camera.

RET-2/MIC button

③

The RET-2 switch function or INCOM MIC switch function is allocated to this button. The

button selects the function or turns ON/OFF the function.

When set to RET-2

●

The viewfinder image is switched from the camera image to RET-2 image while this button

is pressed.

When set to INCOM MIC

●

Turns the intercom microphone ON/OFF when the INCOM FRONT VR SELECT switch on

the rear of the camera is set to "ENG" or "PROD". The intercom microphone is turned ON

while this button is pressed.

RET-1 button

④

Switches the viewfi nder image from the camera image to RET-1 image. The viewfinder

image is switched to the RET-1 image while this button is pressed.

Shoulder belt hook

⑤

Attaches the optional shoulder belt.

POWER indicator

⑥

Displays the stat us of power supply to the camera

Green LED : Indicates power is on

Red LED : Indicates power is in standby

POWER switch

⑦

Turns ON/OFF the power of the camera or switches the power supply.

BS/CCU : Supplies power from the BS to the camera via fiber cable.

OFF : Turns power OFF.

EXT : Supplies power from external power supply. Set the POWER switch to EXT

when power is supplied from exter nal power through DC IN connector in the

self-contained or VTR location operation.

Reference:

The functions are allocated using

the menu. Refer to "5. CAMERA

SETTINGS and ADJUSTMENT",

"Menu Configuration and

content" (page 83) for setting.

Shoulder pad

⑧

Put the shoulder pad on your shoulder when you carry the camera on your shoulder.

INCOM MIC button

⑨

Turns the intercom microphone ON/OFF when the INCOM FRONT VR SELECT switch on

the rear of the camera is set to "ENG" or "PROD". The intercom microphone is turned ON

while this button is pressed.

INCOM PGM control knob

⑩

Controls the PGM volume of the intercom when the INCOM FRONT VR SELECT switch

on the rear of the camera is set to "ENG" or "PROD".

INCOM PHONE control knob

⑪

Controls the volume of the intercom when the INCOM FRONT VR SELECT switch on the

rear of the camera is set to "ENG" or "PROD".

Switch control panel cover

⑫

Protects the switch control panel.

14

HDK-55 1206 VER1 (U)

Loading...

Loading...