Page 1

SERVICE MANUAL

NO. S1998E01

September 22, 1998

A901HT

Copyright

IIYAMA ELECTRIC CO., LTD.

710-1 Kitaowaribe, Nagano-shi 381-0014 JAPAN

Page 2

[ Revision Record ]

Rev. Section Contents

Page 3

CONTENTS

SAFETY PRECAUTION.............................................................................

1. SET-UP ADJUSTMENTS...............................................................................

Page

i-ii

1-15

2. TIMING CHART..............................................................................................

3. IC APPLICATION...........................................................................................

4. CIRCUIT DESCRIPTION.................................................................................

5. SERVICE PARTS LIST...................................................................................

6. EXPLODED VIEW.........................................................................................

7. DIAGRAMS...................................................................................................

16

17-19

20-27

28-53

54-61

62-64

NOTICE

The information in this document is subject to change without notice.

Page 4

1. SET-UP ADJUSTMENTS

The following adjustments should be made when a complete realignment is required or a new picture tube is

installed.

<Required measuring equipment>

Signal generator (Programmable video generator)........................ Leader 1604A

DC voltmeter (300V DC range)

Note: Digital multimeter can also be used.

High voltage probe (0-30kV DC)

Color analyzer.......................................................................... Minolta CA-100

Photometer............................................................................. Minolta LS-100

Electric field meter.................................................................... Combinova EFM 100

Scale (Two 50cm scales put together so that no visual aberration occurs.)

Frequency counter

Digital wattage meter

Landing meter........................................................................... LSS LND-070 or 072

Degausser

Interface adapter (Iiyama handmade)

Short-connector (Iiyama handmade)

<Preparation>

Place the monitor without tilting.

1.

Connect the signal cable from the signal generator to the monitor.

2.

Face the CRT screen to east so as not to be influenced by magnetic force.

3.

4.

Turn ON the Power Switch, and degauss the entire screen with degausser. è See "EXTERNAL DEGAUSS".

5.

Perform adjustment by setting the brightness to center and the contrast to maximum, except where

specifically indicated.

6.

Receive MODE 5 and turn ON the Power Switch. Perform adjustment after a warm-up of at least an

hour.

7.

Adjustment data is automatically saved in the memory when the on screen display disappears, when

another signal is received, or pressing the Menu and – Buttons at the same time.

Note: This monitor should be checked and adjusted by connecting it to a signal generator, then entering

and running the timing charts both below and of Chapter 2.

Comp

–

–

–

–

O

–

–

–

Sync

on

green

–

–

–

–

O

–

–

–

40.27

36.76

31.778

30.30

21.00

9.09

8.68

8.47

fH

(kHz)

24.8

27.3

31.5

33.0

47.6

110.0

115.0

118.0

The resolutions are only for your reference when using Leader 1604A.

*

Resolution*

640×400

608×420

640×400

712×419

1024×720

384×1152

400×666

400×1200

Sync polarity

H

V

N

N

N

N

N

P

N

N

N

N

P

P

P

P

P

P

Horizontal (µsec)

B

A

3.04

4.41

3.813

2.01

2.00

0.80

0.89

0.87

C

3.99

2.21

1.907

0.99

2.36

1.48

1.14

1.13

- 1 -

D

30.39

27.94

25.422

26.96

15.76

6.41

6.38

6.22

E

2.85

2.20

0.636

0.34

0.88

0.40

0.27

0.25

O

17.719

16.652

14.268

16.665

16.695

11.108

6.249

10.660

Vertical (msec)

P

0.322

0.074

0.064

0.061

0.084

0.027

0.026

0.025

Q

1.007

0.771

1.112

3.636

0.420

0.582

0.416

0.455

R

16.108

15.439

12.711

12.696

15.115

10.472

5.781

10.171

S

0.282

0.368

0.381

0.272

1.076

0.027

0.026

0.009

Page 5

ADJUSTMENT MODE

ADJ.MODE

E2PROM

S1

PWB-RS

Short-connector

There are two different modes available to adjust the monitor as described below. The adjustment with ‘o’ in front

of the title are only available under User Mode. The adjustments with ‘n’ in front of the title are only available under

Factory Mode. You can perform the other adjustments by either User or Factory Mode. Please change the mode

as required.

USER MODE:

Turn ON the Power Switch and you are in the User Mode.

FACTORY MODE: There are two ways to enter the Factory Mode.

1. Turn OFF the Power Switch. Connect the Iiyama short-connector to the RS connector on the PWBMAIN and set S1 switch on the PWB-RS of the short-connector to ADJ.MODE side. Turn ON the Power

Switch and you are in the Factory Mode. The following menu appears on the screen when you press the

MENU Button. Turn OFF the Power Switch and remove the short-connector from the RS connector to exit.

RS connector

PWB-MAIN

CRT

CRT face

2. Turn ON and OFF the Power Switch while pressing the MENU Button. Turn ON the Power Switch again while

pressing the – Button and you are in the Factory Mode. The following menu appears on the screen when you

press the MENU Button. Turn OFF the Power Switch to exit.

DF DP

The menu items in the Factory Mode are as follows:

Contrast

Brightness

V-size

V-position

H-size

H-position

Pin-cushion

Trapezoid

Parallelogram

Side-pin-balance

Side-pin-corner

Cushion-side

DEGAUSS

Uniform-VCENT

Uniform-V-TB

Uniform-HCENT

Uniform-H-RL

Landing-TL

Landing-TR

Landing-BL

Landing-BR

N-S RRC

DBF-Para

DBF-Phase

H-moire

H-convergence

V-convergence

Tilt-dy

V-linear-S

V-linear-C

Auto-da-test1

Auto-da-test2

Auto-da-test3 *

CRT Check

* Auto-da-test3 helps you to perform H/V-BLANKING and H/V-CONVERGENCE confirmations in this

SET-UP ADJUSTMENTS. The following items are displayed automatically in turn.

1. H/V-convergence è 2. Tilt-dy è 3. N-S RRC è 4. Landing-TL/TR/BL/BR è 5. H/V-blanking

- 2 -

Page 6

EXTERNAL DEGAUSS

Make sure you disable the Landing-TL/TR/BL/BR and N-S RRC settings before performing the external degauss.

Follow the procedure below depending on the adjustment mode you are in.

PROCEDURE

USER MODE

o

1) Select Degauss and press the MENU Button so that the Landing-TL/TR/BL/BR and N-S RRC will be

disabled.

2) Degauss the entire screen with degausser while the Degauss is activated (approx. 6 seconds).

FACTORY MODE

n

1) Select CRT Check and press the MENU Button so that the Landing-TL/TR/BL/BR and N-S RRC will

be disabled.

2) Confirm that the OSD stays displayed on the screen.

Note: If the OSD disappears, restart from 1).

3) Degauss the entire screen with degausser.

4) Press the MENU Button twice to turn off the OSD.

LOCK OUT FACILITY

User adjustable items can be restricted to the following three lock out types by setting the lock out facility as

described below.

Lock out type

A

B

C

PROCEDURE

1.To make the lock out facility available

1) Minimize the contrast with the front buttons.

2) Turn OFF and ON the Power Switch.

3) When degaussing starts, press the MENU, – and + Buttons in turn so that the lock out facility is activated.

Lock out type is switched in alphabetical order when you repeat the button operation.

2. To cancel the lock out facility

1) Minimize the contrast with the front buttons.

2) Turn OFF and ON the Power Switch.

3) When degaussing starts, press the MENU, + and – Buttons at the same time. Then, press the MENU, –

and + Buttons in turn so that the lock out facility is canceled.

Note: This button operation should be performed while degaussing.

Menu * / Adjustment item available

Menu 1

Menu 1, 3, 5

Contrast, Brightness

* It shows the number of the standard menu page.

- 3 -

Page 7

1-1. 80V-ADJ adjustment [PWB-MAIN]

Receive a cross-hatch inverted signal of MODE 5 when applying the AC

1)

voltage of 110±10V.

Connect the DC voltmeter between CONNECTOR TP and GND (chassis).

2)

Adjust the voltage to DC 80±0.5V with VR930 (+B ADJ).

3)

1-2. ANODE VOLTAGE adjustment [PWB-MAIN]

WARNING !

VR501 (HV-ADJ) has been carefully factory-adjusted for each unit in order

to satisfy regulations regarding X-radiation.

Further adjustment on VR501 shall not be performed.

In case of adjustment, the adjusted position of VR501 must be fixed by a

soldering iron to prevent it from rotating.

1)

Receive a cross-hatch inverted signal of MODE 5.

2)

Turn OFF the Power Switch.

3)

Connect a high-voltage probe between CRT anode and GND (chassis).

4)

Turn ON the Power Switch.

5)

Adjust the high-voltage to 27.0±0.1kV with VR501 (HV-ADJ).

Voltage

VR930

Voltage

+B ADJ

6)

Confirm the variation of high-voltage is within ±0.2kV when receiving MODE

1 and MODE 6 respectively.

7)

Turn OFF the Power Switch and remove the high-voltage probe.

1-3. SCREEN VOLTAGE adjustment [PWB-MAIN]

1)

Receive a cross-hatch inverted signal of MODE 5.

2)

Turn ON the Power Switch.

3)

Connect a high-voltage probe between LEAD-CONNECTOR SC on the

PWB-MAIN / CONNECTOR SC on the PWB-VIDEO and GND (chassis).

4)

Adjust the screen voltage to 630±10V with SCREEN VR located lower of

T501 (FBT).

Note: SCREEN VR should not be turned after the adjustment above.

VR501

T501(FBT)

HV-ADJ

Voltage

E

R

E

C

S

N

- 4 -

Page 8

1-4. POWER FACTOR CIRCUIT confirmation [PWB-MAIN]

1)

Receive a cross-hatch inverted signal of MODE 5.

2)

Turn OFF the Power Switch.

3)

Connect the DC voltmeter between TP4 and TP0.

4)

Turn ON the Power Switch.

5)

Confirm that the voltage is DC 400±10V.

6)

Remove the DC voltmeter.

1-5. TEMPERATURE SENSOR confirmation

n

1)

Receive a cross-hatch inverted signal of MODE 5.

2)

Select CRT Check and press the MENU Button.

3)

Confirm that respective temperature of fan and monitor front displayed

on the screen is as follows: actual temperature ±5°C.

1-6. FREE-RUNNING adjustment

n

1)2)Receive a cross-hatch inverted signals of fH 27.3kHz and 115.0kHz

respectively.

CRT Check

····

|||||

30

Fan

····

···········

30

Monitor front

Confirm that FREE-RUNNING adjustment is automatically performed.

1-7. FH-LIMITER confirmation

n

1)

Receive a cross-hatch inverted signal of fH 24.8kHz.

2)

Confirm that the picture disappears. Also, make sure the horizontal

oscillation frequency is within the specified range: 55-70kHz.

3)

Receive fH 27.3kHz and confirm that the picture is synchronized.

4)

Receive fH 118.0kHz and confirm that the picture disappears. Also, make

sure the horizontal oscillation frequency is within the specified range above.

5)

Receive fH 115.0kHz and confirm that the picture is synchronized.

6)

Turn OFF the power of signal generator and confirm that the picture

disappears. Also make sure the horizontal oscillation frequency is within

the specified range above.

7)

Remove the frequency counter.

1-8. H-SIZE LIMIT adjustment

n

1)2)Receive a cross-hatch inverted signals of fH 33.0kHz and 110.0kHz

respectively.

Adjust the horizontal size (H-size) to make it full-scan.

- 5 -

Page 9

Picture

Picture

Raster rolling

Raster tearing

1-9. H-BLANKING confirmation

n

1)

Receive a cross-hatch inverted signal of MODE 5.

2)

Minimize the horizontal size (H-size) with the front buttons.

3)

Select Auto-da-test3 and press the MENU Button so that the automatic

confirmation program starts.

4)

Confirm that X of the right hand side figure is as follows: X </= 3.0mm.

5)

Adjust the horizontal size roughly with the front buttons.

1-10. V-BLANKING confirmation

n

1)

Receive a cross-hatch inverted signal of MODE 5.

2)

Adjust the vertical size and position (V-size and V-position) of the picture

roughly with the front buttons.

3)

Select Auto-da-test3 and press the MENU Button so that the automatic

confirmation program starts.

4)

Confirm that the back-raster is not rolling or tearing at the top.

5)

Confirm that no retrace line is over the picture.

Raster rolling

x

Picture

1-11. V-LIN adjustment

n

1)

Receive a cross-hatch inverted signal of MODE 5.

2)

Adjust the vertical size so that the size is 270±4mm.

3)

Adjust the vertical linear corner (V-linear-C), so that difference between A

and B of the right hand side figure is as follows: | A–B | </= 0.5mm

4)

Adjust the vertical linear side (V-linear-S), so that A, B and C are almost

equal.

1-12. H-CENT adjustment [PWB-MAIN]

n

1)

Receive a cross-hatch inverted signal of MODE 5.

2)

Adjust the horizontal size and position of the picture roughly with the front

buttons.

3)

Maximize the brightness so that the back-raster appears on the screen.

4)

Set S501 to the right, center or left so that A and B in the right hand side

figure are almost equal.

5)

Return the brightness to center indication.

S501

Right

Back-raster

A

Picture

Bezel

A

C

B

Left

B

n

1-13. TILT-DY adjustment

1)2)Receive a cross-hatch inverted signal of MODE 5.

Adjust the tilt deflection yoke (Tilt-dy) with the +/– Buttons so that X of the

right hand side figure is as follows: | X | </= 0.5mm.

X

- 6 -

Page 10

1-14. PICTURE SIZE, POSITION AND DISTORTION adjustment (Criteria)

n

1)

Receive a cross-hatch inverted signal of MODE 4.

2)

Adjust the picture size and position to the specified setting below.

H-size: 360±4mm

V-size: 270±4mm

3)

Correct the side distortion with the front buttons so that X of the right hand

H-position: | A–B |<4mm

V-position: | C–D |<4mm

side figure is as follows: | X | </= 0.5mm/30mm when selecting the most

remarkable distortion with the naked eye.

Pin-cushion

Trapezoid

Side-pin-balance

1-15. PICTURE SIZE, POSITION AND DISTORTION adjustment

n

1)

Receive a cross-hatch inverted signal of fH 31.5kHz.

2)

Adjust the picture size, position and distortion roughly with the front buttons

Parallelogram

Side-pin-corner

Cushion-side

to the reference settings below.

H-size: 360±10mm

V-size: 270±10mm

H-position: | A–B |<8mm

V-position: | C–D |<8mm

| X | </= 1.0mm/30mm when selecting the most remarkable

distortion with the naked eye.

A

30mm

C

Picture

D

X

Pin-cushion

Trapezoid

B

Bezel

Picture

Note: The picture should be within the bezel.

3)

Receive a cross-hatch inverted signal of all preset modes respectively.

4)

Adjust the picture size and position to the specified setting below.

H-size: 360±4mm

V-size: 270±4mm

5)

Correct the Pin-cushion and Trapezoid distortion with the front buttons so

that X of the right hand side figure is as follows: | X | </= 0.5 mm/30mm

when selecting the most remarkable distortion with the naked eye.

Note: No other adjustment items for distortion than the above should be

adjusted.

1-16. RESET confirmation

o

1)

Receive a cross-hatch inverted signal of MODE 5.

2)

Change the horizontal position (H-Position) roughly with the front buttons.

3)

Perform Reset.

4)

Confirm that the adjustment data above is reset to the factory setting.

H-position: | A–B |<4mm

V-position: | C–D |<4mm

Side-pin-balance

Parallelogram

Side-pin-corner

Cushion-side

- 7 -

Page 11

1-17. Automatic COLOR adjustments

n

WARNING:

Do not change the horizontal and vertical sync signal or the frequency

while the automatic COLOR adjustments are underway.

Color analyzer setting:

Luminance unit switch: cd/m

l

B.P.S. DIP switch: 9600 (1000)

l

Turn ON the color analyzer switch and press 0-CAL switch before use.

l

1)

Be sure to enter the Factory Mode by using the short-connector.

2)

Connect the interface adapter from RS-232C of the color analyzer to the

PWB-RS of the short-connector.

3)

Select BNC for the signal input and receive a white window signal of MODE 4.

4)

Turn OFF the R, G and B outputs on the signal generator.

5)

Apply a color analyzer probe to the center of the screen.

6)

Turn ON the Remote Switch of the color analyzer so that “G” will appear

on the screen to inform that automatic CUT-OFF adjustment starts.

7)

Turn ON the R, G and B outputs on the signal generator when “GBRIN”

appears on the screen so that the COLOR TEMPERATURE and

CONTRAST LIMIT adjustments start automatically.

cd/m²

2

Luminance unit switch

1

0

B. P. S. DIP switch

fL

<COLOR TEMPERATURE>

The X and Y specified readings of the color analyzer are as follows:

CT 1 (9300K)

X: 0.283±0.006

Y: 0.297±0.006

CT 2 (6500K)

X: 0.313±0.006

Y: 0.329±0.006

CT 3 (5000K)

X: 0.345±0.006

Y: 0.352±0.006

<CONTRAST>

The specified contrast range is 120±6cd/m2.

Note: “G” appears again on the screen to indicate the contrast is not

within the specified range above. In that case, repeat 4) to 7).

8)

“END” appears on the screen to inform that the adjustments are completed.

9)

Turn OFF the Remote Switch of the color analyzer.

Note: The adjustments above can be repeated by turning OFF and ON the

Power Switch.

1-18. GRAY SCALE confirmationn

1)2)Receive a 16-gradation gray scale signal of MODE 4.

Make sure the 15th gradation on the gray scale is barely visible when the

16th gradation (back raster) is not visible at all.

- 8 -

Page 12

n

1-19. BRIGHTNESS adjustment [PWB-MAIN]

1)

Receive an entire white raster signal of MODE 4.

2)

Apply a photometer to the screen center.

3)

Adjust VR502 (ABL-ADJ) so that photometer reads 105±5cd/m2.

1-20. SYNC SIGNAL INPUT confirmation

n

1)

Receive a cross-hatch inverted signal of fH 47.6kHz.

2)

Select composite and sync on green signal inputs respectively by the

signal generator.

3)

Confirm that the picture is displayed normally.

1-21. SIGNAL SELECT confirmation

1)

Receive a cross-hatch inverted signal of MODE 5.

2)

Switch the signal input to BNC and D-SUB respectively.

3)

Confirm that the picture is displayed normally.

Brightness

VR502

ABL-ADJ

1-22. POWER MANAGEMENT confirmation

o

1)

Turn OFF the Power Switch and connect a digital wattage meter.

2)

Turn ON the Power Switch.

3)

Receive a cross-hatch inverted signal of MODE 5.

4)

Turn OFF the R, G and B outputs on the signal generator.

5)

Disconnect the H/HV and V cables.

6)

Confirm that the input wattage is 5W or less and the Power Indicator turns

to orange.

7)

Connect the H/HV and V cables and confirm that the picture appears.

8)

Turn OFF the Power Switch and remove the digital wattage meter.

9)

Turn ON the Power Switch.

1-23. H-CONVERGENCE confirmation

n

1)

Receive a cross-hatch inverted signal of MODE 5.

2)

Select Auto-da-test3 and press the MENU Button so that the automatic

confirmation program starts.

3)

Confirm that the horizontal line is diverged.

- 9 -

Page 13

1-24. V-CONVERGENCE confirmation

n

1)

Receive a cross-hatch inverted signal of MODE 5.

2)

Select Auto-da-test3 and press the MENU Button so that the automatic

confirmation program starts.

3)

Confirm that the vertical line is diverged.

1-25. RASTER REGULATION (DYNAMIC) confirmation

n

1)

Receive an entire white signal of MODE 5.

2)

Set the input signal by the signal generator as follows:

V-DISP-TIME: 150 V-POSI-TIME: 450

3)

Maximize the brightness or set the signal level to 0.9Vp-p by the signal

generator.

4)

Confirm that <W of the right hand side figure is 1.0mm or less when

turning the luminance volume on the signal generator to the maximum

and “1” respectively.

5)

Return the brightness to center indication.

Back-raster

Picture

W

FOCUS-B

FOCUS-A

1-26. FOCUS [PWB-MAIN]

n

1)

Receive a green cross-hatch signal of MODE 5.

2)

Adjust FOCUS-A VR of T501 (FBT) to make the vertical lines sharpest at

points L, M and R as shown in Fig 1.

3)

Adjust FOCUS-B VR of the T501 to make the horizontal center line

sharpest at points L, M and R as shown in Fig. 1.

4)

If the focus at points T and M is as shown in Fig. 2, adjust VR503 (V-DBF)

to make the horizontal lines have the same thickness at points T, M and

B. And adjust the FOCUS-B VR again to make the horizontal lines sharpest

at points T, M and B. (VR503 should not be adjusted when focus at points

T and M is optimum.)

5)

If the focus at points L and M is as shown in Fig. 3 or vice versa, adjust

DBF-Para to make the horizontal center line have the same thickness at

points L, M and R. And adjust the FOCUS-B VR again to make the

horizontal center line sharpest at points L, M and R. (DBF-Para should

not be adjusted when focus at points L and M is optimum.)

6)

Repeat 2) to 5) until the focus is optimum.

7)

Confirm no focus variation on the entire screen.

8)

Check the focus with red and blue respectively.

9)

Receive a H-character signal and repeat 7).

10)

Repeat the FOCUS adjustments until the focus with red, green and blue

is optimum.

SCREEN

Focus

VR503

L

Fig.1

Fig.2

L

Thin

Thick

T501(FBT)

V-DBF

M

T Thin

M Thick

B Thin

M

Thick

R

R

- 10 -

Fig.3

Page 14

1-27. LUMINANCE DIFFERENCE adjustment

n

1)

Receive an entire white signal of MODE 5.

2)

Apply a photometer to C (center), T (top), B (bottom), L (left) and R (right)

in the right hand side figure.

3)

Confirm that the luminance difference between C and T, C and B, C and L,

C and R is within ±10cd/m2 respectively.

4)

If the luminance difference is not within the specified range above, perform

the following adjustments:

<Point T or B>

1. Adjust Uniform-VCENT first to increase the brightness of T and B.

T

L

C

B

R

2. Adjust Uniform-V-TB so that the luminance difference between C and

2

T or C and B is within ±10cd/m

.

<Point R or L>

1. Adjust Uniform-HCENT first to increase the brightness of point L and R.

2. Adjust Uniform-H-RL so that the luminance difference between C and

L or C and R is within ±10cd/m

2

.

1-28. LUMINANCE DIFFERENCE confirmation

1)

Receive an entire white signal of MODE 5.

2)

Apply a photometer to the two points where the luminance difference is

remarkable with the naked eye.

3)

Confirm that the luminance difference is 22.5cd/m2 or less.

TL

T

L

C

B

TR

R

BRBL

- 11 -

Page 15

1-29. TCO requirement

1-29-1. VLF adjustment [PWB-MAIN]

Note: The VLF adjustment requires the precise measuring conditions. Make

sure the adjustment is carried out in the following environment.

1.

All metal parts should be attached to the monitor.

2.

All the electrical equipment used for the adjustment including the

monitor should be grounded to the same outlet.

Set the monitor and the electric field meter with tilt of zero degree at

3.

a distance of 29.5±0.5cm so that the CRT face will be parallel to the

electric field meter.

No other monitors should be placed in the area with a radius of 1.5m

4.

behind the center of monitor, between the monitor and the electric

field meter and 1.0m behind the electric field meter.

Keep at least 20cm between the monitors.

5.

The VLF level of background should be 0.3V/m or less when the

6.

monitor power cable is disconnected.

Receive a H-character inverted signal of MODE 6.

1)

Adjust the contrast so that the brightness at screen center is 60±5cd/m2.

2)

Set the brightness to center indication.

3)

Turn VR5T2 (VLF-2) fully counterclockwise.

4)

Adjust VR5T1 (VLF-1) so that the electric field meter reads the VLF level

5)

0.95V/m or less.

Monitor

Electric field meter

Monitor

20cm

VLF level

VR5T1 VLF-1

VR5T2 VLF-2

1.5m

29.5+0.5cm

1.0m

In case that the VLF level is not within the specified range above, adjust

6)

VR5T2.

In case that the VLF level is still not within the specified range above, turn

7)

VR5T2 fully clockwise and adjust VR5T1.

In case that the VLF level is still not within the specified range above,

8)

adjust VR5T2.

- 12 -

Page 16

1-30. ITC (Integrated Tube Component) adjustments

n

The following ITC adjustments should be made only when a new picture tube is installed, or convergence is poor.

All set-up adjustments above-mentioned must be completed before any further ITC adjustment is attempted.

Receive an entire white raster signal and turn ON the Power Switch. Perform adjustment after a warm-up of at least

an hour.

Perform the following adjustments by setting H-convergence and V-convergence to center indication.

Notes: See Chapter 5 concerning parts list for the ITC adjustments.

* PURITY MAGNET should not be turned during the ITC adjustments.

< Top view > < Side view >

PURITY MAGNET*

4-POLE MAGNET

6-POLE MAGNET

LOCKING RING

BOW MAGNET

Y

Y

V

X

CRT face

HC

Y

H

Y

VS

V

DIFFERENTIAL

COIL

X

V

DEFLECTION

YOKE

SEPARATOR

1-30-1. LANDING correction

Landing meter setting:

Mode Select Switch: Monitor Normal

l

Note: Mode Select Switch should be set before turning on the power switch of the landing meter.

Volt: 2V

l

Time: 50ms

l

Gain: 7

l

Unit: % for LND-070, 0.8µm (1%=0.8µm) for LND-072

l

1)

Face the CRT screen to east and set it vertically.

Degauss the entire screen with degausser. è See "EXTERNAL DEGAUSS".

2)

3)

Select DEGAUSS and press the MENU Button.

Receive an entire green signal.

4)

Adjust the horizontal size to make it full-scan.

5)

Apply the landing meter to TL (top-left), TR (top-right), BL (bottom-left) and

6)

BR (bottom-right) in the right hand side figure.

Confirm that "H" reading of the landing meter is within ±20% at each point.

7)

Adjust N-S RRC with the front buttons so that the "H" reading difference

8)

between T (top) and B (bottom) in the right hand side figure is as follows:

| T-B | = ±3%.

TL

BL

T

B

20mm

TR

BR

20mm

Adjust Landing-TL, TR, BL and BR respectively with the front buttons so

9)

that "H" reading of the landing meter at each point is as follows:

TL: –8 to –2% TR/BL: 0 to +6% BR: –6 to 0%

- 13 -

Page 17

1-30-2. Yvs adjustment

Notes: 1. This adjustment should be performed only when the picture

distortion in the right hand side figure is permitted.

2. Be sure to perform the 1-30-6. YV adjustment after this

adjustment because the convergence adjusted by YV volume

is changed at the same time during this adjustment.

1)

Receive a cross-hatch inverted signal.

2)

Adjust the specified Yvs volume so that the picture distortion is corrected.

1-30-3. STATIC CONVERGENCE adjustment

Receive a red and blue cross-hatch signal.

1)

Adjust the 4-POLE MAGNET so that red and blue beams converge on the

2)

center cross lines.

Add green to the red and blue cross-hatch signal.

3)

Adjust the 6-POLE MAGNET so that red and blue beams converge with

4)

green beam on the center cross lines.

Repeat the adjustment until red, blue and green beams converge each

5)

other.

Fix the 4-POLE MAGNET and the 6-POLE MAGNET by turning the

6)

LOCKING RING.

Bezel

Picture

R

B

G

R,B

R,G,B

Picture

B

R,B

Picture

R

G

R,G,B

Mark the 4-POLE MAGNET and the 6-POLE MAGNET with paint marker

7)

(090Z029A01) so that adjusted position is understandable.

1-30-4. BOW MAGNET adjustment

1)

Receive a red and blue cross-hatch signal.

2)

Adjust the BOW MAGNET so as to straighten an arched horizontal line.

Note: Must be careful not to misconverge vertical lines by this adjustment.

3)

Perform the 1-30-3. STATIC CONVERGENCE adjustment so as to converge

the red and blue lines.

4)

Fix the BOW MAGNET with paint (090Z020A01).

1-30-5. DIFFERENTIAL COIL adjustment (XV adjustment)

1)2)Receive a red and blue cross-hatch signal.

Adjust the DIFFERENTIAL COIL so that the horizontal cross line converge

each other.

R

B

B

R

R

B

R,B

- 14 -

Page 18

R

B

R,B

B

R

1-30-6. YV adjustment

1)

Receive a red and blue cross-hatch signal.

2)

Adjust the specified YV volume so that red and blue beams converge

each other at the upper and lower edges of the horizontal line.

B

R

R

B

R,B

R,B

1-30-7. YH adjustment

1)

Receive a red and blue cross-hatch signal.

2)

Adjust the specified YH volumes so that vertical cross lines converge

each.

1-30-8. SCREEN-CORNER MISCONVERGENCE correction

Receive a red and blue cross-hatch signal.

1)

Affix a *ferrite sheet (890Z003A02/890Z003A03) between SEPARATOR

2)

and CRT corresponding to the partially misconverged areas.

Note: Must be careful not to affect distortion by this correction.

Fix the ferrite sheet with ACETATE-TAPE (890P306A10).

3)

10

Y HYHC

R

B

B

R

B

R

R

B

10

Ferrite

100

70

(890Z003A02)

(890Z003A03)

(in mm)

*Ferrite sheet

- 15 -

Page 19

P

Q

R

S

O

V-parameters

O: Total period

P: Sync.width

Q: Back porch

R: Active video

S: Front porch

Video

Sync

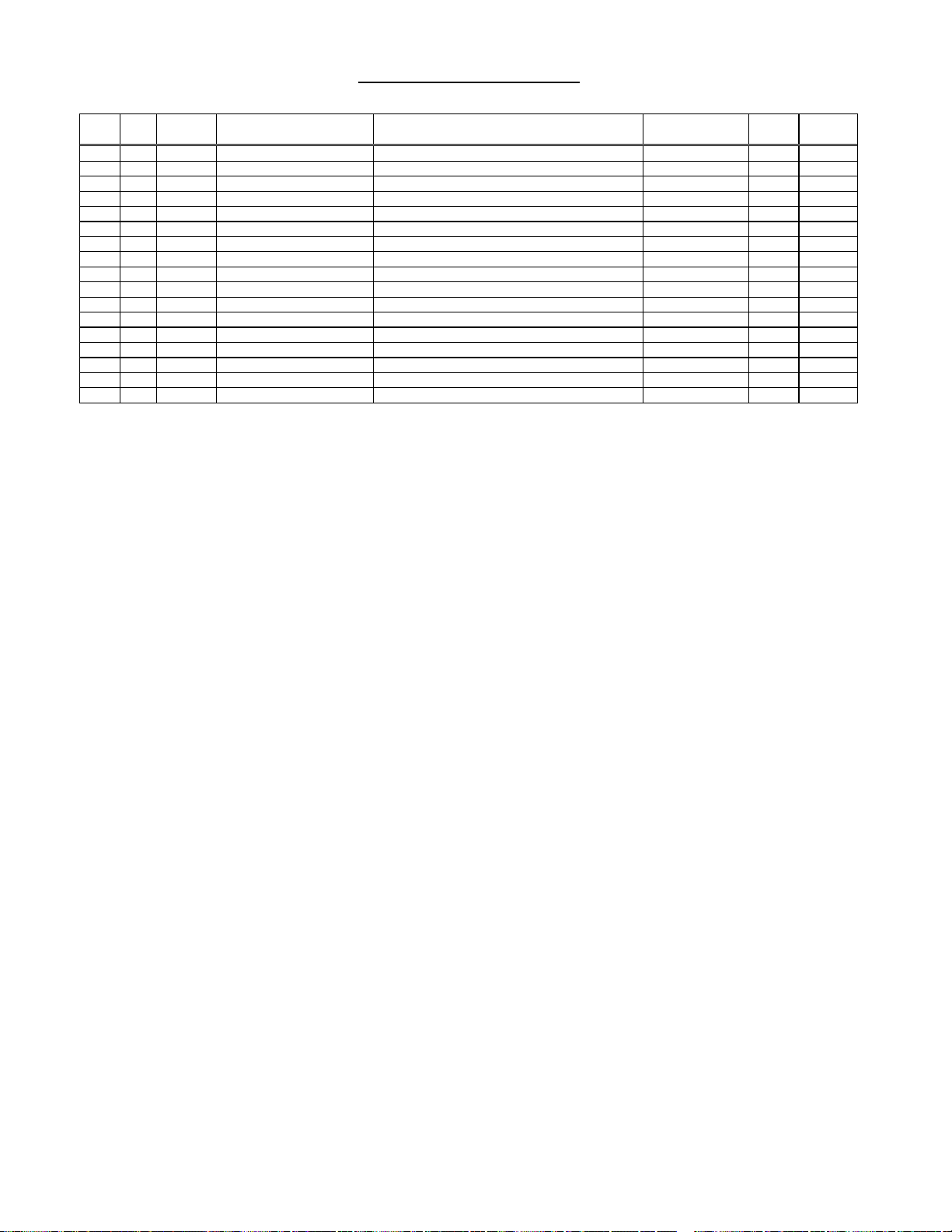

2. TIMING CHART

- 16 -

Mode

VESA Timing Name

640×480

1

640×480

2

800×600

3

1024×768

4

B

@ 60Hz

@ 85Hz

@ 85Hz

@ 85Hz

C

fH

(kHz)

31.469

43.269

53.674

68.677

D

A

fV

(Hz)

59.940

85.008

85.061

84.997

E

Sync polarity

H

V

Comp

N

N

N

N

P

P

P

P

H-parameters

A: Total period

B: Sync.width

C: Back porch

D: Active video

E: Front porch

Sync

on

green

–

–

–

–

31.778

–

23.111

–

18.631

–

14.561

–

Horizontal (µsec)

A

B

3.813

1.556

1.138

1.016

C

1.907

2.222

2.702

2.201

D

25.422

17.778

14.222

10.836

E

0.636

1.556

0.569

0.508

O

16.683

11.764

11.756

11.765

Vertical (msec)

P

0.064

0.069

0.056

0.044

1.048

0.578

0.503

0.524

Q

R

15.253

11.093

11.179

11.183

S

0.318

0.023

0.019

0.015

1280×1024

5

6

1600×1200

@ 85Hz

@ 85Hz

91.146

106.250

85.024

85.000

P

P

–

P

P

–

10.971

–

9.412

–

1.016

0.837

1.422

1.325

8.127

6.972

0.406

0.279

11.761

11.765

0.033

0.028

0.483

0.433

11.235

11.294

0.011

0.009

Page 20

3. IC APPLICATION

Ref No. Description

Deflection circuit

IC350 UPC1884CT

IC401 LA7840L Vertical output

IC502 SLA5041 FET array

IC503 324

IC205 7805 5V regulator

IC206 PQ6RD083

IC304 7805 5V regulator

IC351 7812 12V regulator

IC702 7812

IC709 7805 5V regulator

IC930 3842 Main power control

IC931 MIP0223SY Sub power control

IC932 MC34262/

MC33262

IC960

IC961

IC962

IC211 M62393P D/A converter

IC301 741Z610-10 Main microprocessor

IC302 M51951BSL Power voltage watcher

IC303 24C08 E2PROM

7812 12V regulator

3842 Variable B control

UPC1093J/

KIA431

H&V synchronous signal processor

with geometrical compensation, H&V

oscillator

Amplifier (H-size, Distortion

control)

Power circuit

6.3V regulator (to CRT heater voltage)

12V regulator

Power factor control

Over voltage, Arc and X-ray protect

control

Microprocessor circuit

Application

Ref No. Description

Sub microprocessor circuit

IC701

IC703

IC501

IC101 M52755SP

IC102

IC201

IC202

IC203

IC207

IC210

IC704

IC705

IC706 LA6510/

IC707

IC708

741Z611-10

M62393P D/A converter

High voltage circuit

MSPAD104

24LC21

M52742ASP Video amplifier

LM2403T Video output

M35045 On screen display control

M52759SP Uniformity control

324 Amplifier (Cut-off control)

LA6510/

TA8410AK

LA6510/

TA8410AK

TA8410AK

LA6510/

TA8410AK

TMC3000NF

Application

Sub microprocessor

High voltage control

Video circuit

Signal switch

DDC

CRT circuit

Power amplifier

(TILT+/–, NS+/–)

Power amplifier

(H-CONV+/–, V-CONV+/–)

Power amplifier

(TL+/–, BL+/–)

Power amplifier

(TR+/–, BR+/–)

Terrestrial magnetic sensor

Note: Specifications of Main microprocessor and Sub microprocessor are on next page.

- 17 -

Page 21

Main microprocessor specifications

Pin

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Name

H-LIN2

H-LIN1

DRIVE

SW

S.O.G.

GND

N.C.

N.C.

N.C.

500KHz

84-SDA

84-SCL

GND

GND

GND

GND

Vss

+ KEY

GND

GND

GND

GND

GND

– KEY

MENU

GND

CLAMP

DEG

PS1

LED-O

LED-G

Vss

H-LIN2 switching signal output

H-LIN1 switching signal output

DRIVE switching signal output

BNC/D-SUB switching signal

S.O.G.

GND

N.C.

N.C.

N.C.

CLOCK signal output for 1884 counter

1884 DATA input/output terminal

1884 CLOCK terminal

GND

GND

GND

GND

GND

Front-key signal input terminal

GND

GND

GND

GND

GND

Front-key signal input terminal

Front-key signal input terminal

GND

CLAMP

Degauss control signal output

POWER-SAVE control signal output 1

LED control signal output (Orange)

LED control signal output (Green)

GND

Function

Pin

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

Name

Avref.

AVDD

EP-SDA

EP-SCL

CS6

CS5

CS4

CS3

CS2

CS1

GND

GND

GND

GND

X1

X2

VDD

RxD

TxD

DIAG

V-SYNC

RESET

GND

S.O.G.

D/A-SCL

OSD-CS

OSD-SCL

SUB-SCL

SUB-SDA

SUB-SDA

Pre-SCL

Pre-SDA

Function

5V Vcc

5V Vcc

E2PROM DATA terminal

2

E

PROM CLOCK terminal

Cushion-S switching signal 6

Cushion-S switching signal 5

Cushion-S switching signal 4

Cushion-S switching signal 3

Cushion-S switching signal 2

Cushion-S switching signal 1

GND

GND

GND

GND

X'TAL 8MHz

X'TAL 8MHz

5V Vcc

Automatic adjustment DATA output terminal

Automatic adjustment CLOCK terminal

Automatic adjustment DATA input terminal

IIC-BUS reference signal input terminal

Main microprocessor RESET signal input terminal

GND

S.O.G.

D/A CLOCK output terminal

OSD SELECT signal output terminal

OSD CLOCK input/output terminal

Sub E2PROM CLOCK terminal

Sub E2PROM DATA input terminal

Sub E2PROM DATA output terminal

Pre-Amp CLOCK output terminal

Pre/OSD/DA-DATA output terminal

- 18 -

Page 22

Sub microprocessor specifications

Pin

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Name

DA-SDA

DA-SCL

N.C.

N.C.

GND

RESET

X0

X1

GND

N.C.

M-SDA

M-SDA

M-SCL

N.C.

Function

D/A DATA input/output terminal

D/A CLOCK output terminal

N.C.

N.C.

GND

Sub microprocessor RESET signal input

terminal

X'TAL 4MHz

X'TAL 4MHz

GND

N.C.

2

Main E

Main E2PROM DATA input terminal

Main E2PROM CLOCK terminal

N.C.

PROM DATA output terminal

Pin

28

27

26

25

24

23

22

21

20

19

18

17

16

15

Name

ON-TIME

Temp.

AD-Vref

5V

N.C.

N.C.

GND

GND

GND

X

Y

N.C.

N.C.

N.C.

Function

5V Vcc

N.C.

POWER-ON time detection

Temperature detection

N.C.

A/D reference voltage 5V

GND

GND

GND

Magnetism sensor detection

Magnetism sensor detection

N.C.

N.C.

N.C.

- 19 -

Page 23

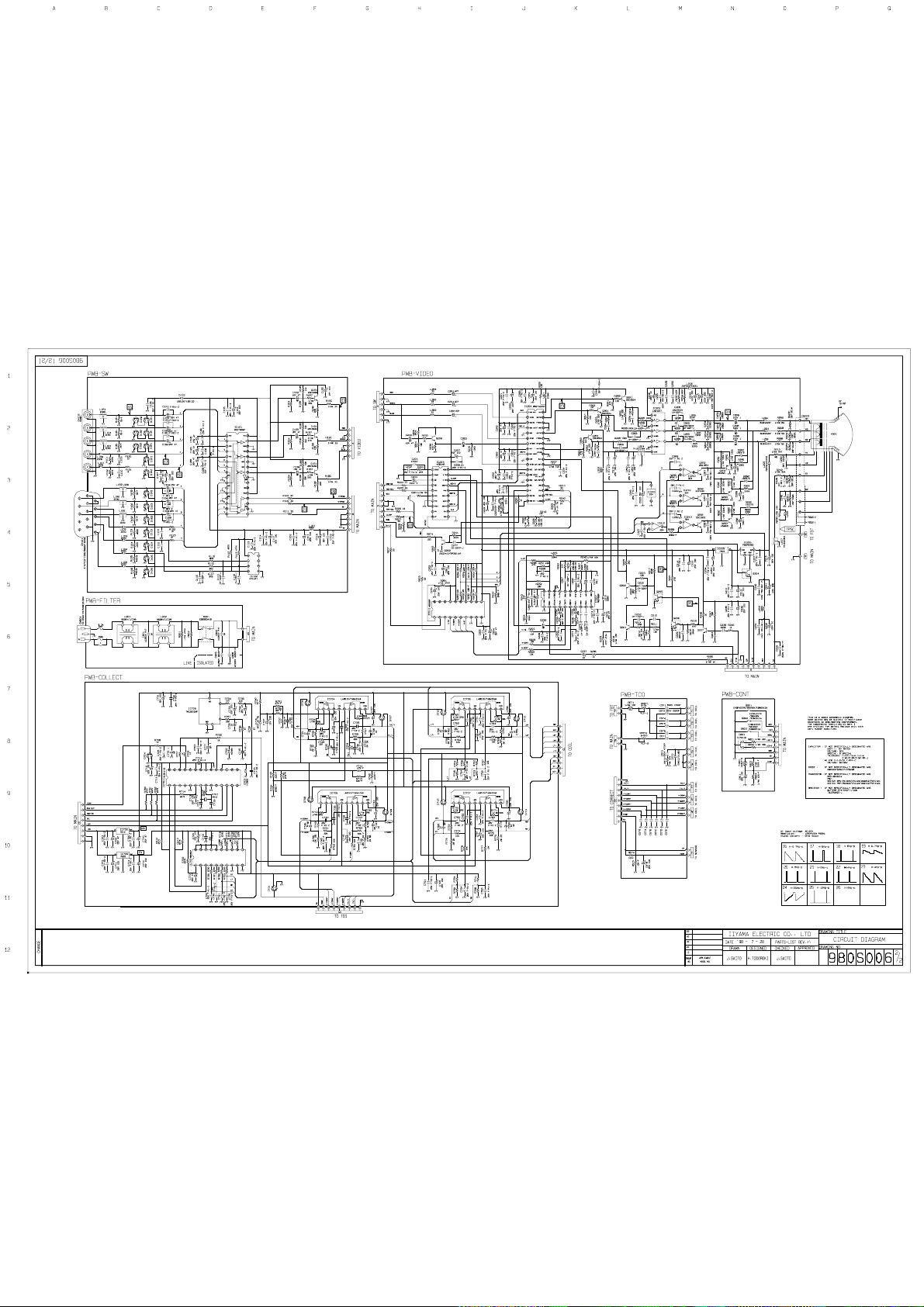

4. CIRCUIT DESCRIPTION

4-1. POWER FACTOR circuit

Q The full-wave rectified voltage waveform from D942 and smoothed voltage waveform from C926 are multiplied and

compared to R the voltage waveform from current detect resistor R925 of Q934. Q934 is turned off when R

exceeds Q, and is turned on when R is 0V. The above repetition is to change input current to substantially

sinusoidal waveform and it corrects harmonic distortion. The switching frequency is not constant as Q934 is turned

on or off by monitoring input voltage and load current. Therefore, this circuit is not synchronized with the MAIN

POWER circuit.

Switching frequency is minimum when input voltage is low and load current is maximum, in other words, the

switching frequency is maximum when input voltage is high and load current is minimum. (Switching frequency is

approx. 20-250kHz)

This circuit is operated by the voltage supplied to IC932 from the SUB POWER circuit so that it is not activated at

power management state.

0V

AC

90-132/

198-264V

D942

T932

IC932

5

D943

7

Q934

To pin 1

of IC932

R925

POWER FACTOR circuit

C926

0V

R926

R927

R928

+400V

DC

0V

- 20 -

Page 24

4-2. MAIN POWER circuit

400V is supplied to this circuit from the POWER FACTOR circuit. This circuit is fly-back type circuit which includes

IC930 controls PWM (Pulse Width Modulation) CONTROL circuit. The T930 secondary provides the following DC

voltages:

Q 80V line: Supplied to the DBF (Dynamic Beam Focus), HIGH VOLTAGE OUTPUT CONTROL,

and the CUT-OFF CONTROL circuits and the VIDEO OUTPUT IC as power source.

R 28.5V line: Supplied to the HORIZONTAL DEFLECTION OUTPUT (Variable B voltage control) and the

HORIZONTAL DRIVE circuits as power source.

S 16V line: Supplied to the VERTICAL DEFLECTION OUTPUT circuit as power source.

Divided 16V line is regulated to 12V by IC960 and supplied to the HORIZONTAL DEFLECTION

OUTPUT and HIGH VOLTAGE OUTPUT CONTROL and VIDEO SIGNAL PROCESSING circuits,

regulated to 12V by IC351 and supplied to the CONTROL SYSTEM circuit, regulated to

12V by IC702 and supplied to the CRT CORRECTION circuit and TERRESTRIAL MAGNETIC

SENSOR (IC708), regulated to 5V by IC709 and supplied to SUB MICROPROCESSOR

(IC701), D/A CONVERTER (IC703) and TEMPERATURE SENSOR as power source.

T –12V line: Supplied to the VERTICAL DEFLECTION OUTPUT and the CRT CORRECTION circuits as

power source.

U B9 voltage: The 28.5V line is pressured up to B9 voltage by the PWM CONTROL circuit which includes

(35-155V) IC961 and Q962. The voltage from the D973 cathode is supplied to the HORIZONTAL

DEFLECTION OUTPUT and the HIGH VOLTAGE OUTPUT circuits as power source.

This circuit is controlled by the voltage supplied from the SUB POWER circuit and it is not activated at power

management state. Therefore, no secondary provides the DC voltages.

AC

90-132/

198-264V

D942

IC930

POWER FACTOR

circuit

6

Q930

R932

T930

2

3

1

28.5V

16V

80V

IC961

4

–12V

L961

6

D973

Q962

R966

5

IC702

IC709

IC960

IC351

B9 (35-155V)

12V

5V

12V

12V

16V

- 21 -

Page 25

4-3. SUB POWER circuit

IC931 included in this circuit consists of the POWER MOS-FET and the CONTROL circuits and modulates the

pulse width. The current fed back from pin 9 of T931 is input to the control terminal of IC931. The T931 primary

provides the DC voltage (approx. 20V) to the POWER FACTOR and the MAIN POWER circuits as power source.

The T931 secondary provides the DC voltage (approx. 8.5V). Divided 8.5V line is regulated to 5V by IC304 and

supplied to the MAIN MICROPROCESSOR (IC301), IC350, VIDEO SIGNAL SWITCHING (IC101), DDC (IC102)

and TEMPERATURE SENSOR, regulated to 6.3V by IC206 and supplied to the CRT heater voltage, also regulated

to 5V by IC205 and supplied to the VIDEO AMPLIFIER (IC201), OSD CONTROL (IC203) and D/A CONVERTER

(IC211) as power source. The voltage at pin 1 of IC931 is 5.7V generally. This circuit is not synchronized with MAIN

POWER circuit as the oscillation frequency is fixed to approx. 100kHz.

400V

5.7V

1

POWER FACTOR and

MAIN POWER circuits

To

IC931

20V

T931

3

D964

8.5V

IC304

IC206

IC205

5V

CRT heater

5V

4-4. PROTECTION circuit

To prevent damage to the monitor, X-ray radiation etc., the POWER FACTOR and the MAIN POWER circuits stop

in the following cases:

+16V line: The voltage exceeds 23V.

+8.5V line: The voltage exceeds 15V.

+400V line: The voltage exceeds 460V.

Variable B voltage line: The voltage exceeds 200V.

X-ray protection circuit: The voltage exceeds 30kV.

Arc limit circuit: The beam current exceeds 2.9mA.

4-5. DISPLAY POWER MANAGEMENT circuits

(1) Stand-by / Suspend state:

When receiving no video signal and no horizontal or vertical sync signal for 6 seconds, pin 29 of IC301 turns to

5V from 0V. PC930 is turned on to stop power supply to the POWER FACTOR and the MAIN POWER circuits.

The power consumption is 10W or less.

(2) Active-off state:

When receiving no video signal and no horizontal and vertical sync signals for 6 seconds, pin 29 of IC301 turns

to 5V from 0V. Also, pin 16 of IC301 turns to 5V from 0V so that IC204 is turned on. The output from IC206 stops

and the heater voltage is turned off. The power consumption is 6W or less.

4-6. DEGAUSS circuit

As K930 is turned on when the power on, the degauss current flows through degauss coil and PR930 to degauss

the CRT. After approx. 6 seconds from power on, K930 is turned off automatically. As for manual degauss by the

adjustment item of Degauss, the degauss is performed in the same way.

- 22 -

Page 26

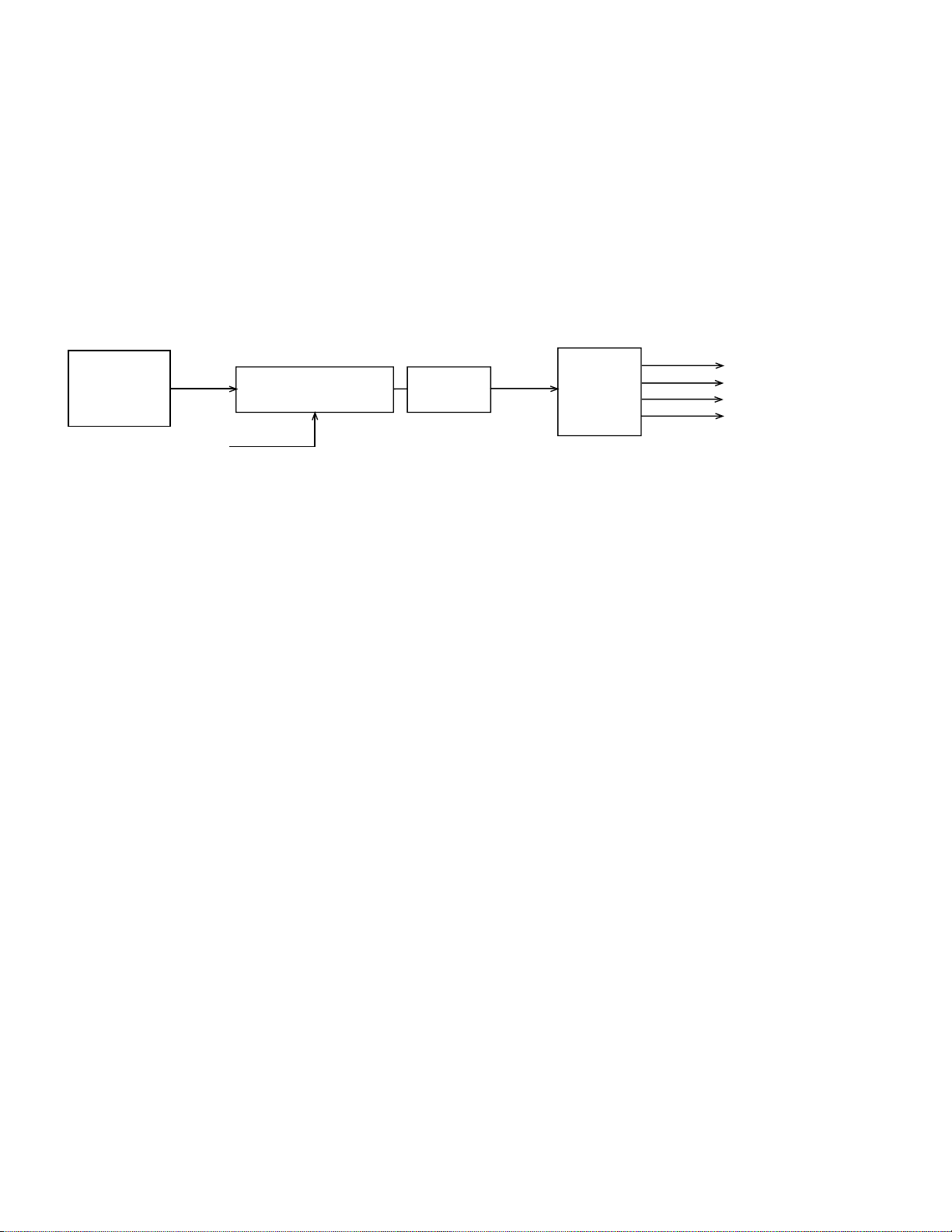

4-7. SIGNAL PROCESSING circuit

500kHz

Pin 29 of IC350

Input signal from D-SUB or BNC connector is converted to the waveform by IC101. The input signal is applied to pin

17 of IC101 from the MAIN MICROPROCESSOR (IC301) and then switched to D-SUB when pin 17 of IC101 is

“HIGH” level (5V), or to BNC when pin 17 of IC101 is “LOW” level (0V). When only one of the two signal inputs is

connected to the signal source, the one connected is automatically selected. When both of the signal inputs are

connected to the signal source, the latest one connected just before power off is selected. The adjustment item of

Signal Select also selects D-SUB or BNC. The selected input signal is converted to the waveform by IC101. The

sync signal is input to IC350 and the video signal is input to IC201.

4-8. SYNC SIGNAL PROCESSING circuit

The input sync signal to IC350 is processed inside IC350

as follows:

Q Detect the input sync signal presence

R Discriminate the input sync signal type: Separate /

Composite / Sync On Green

S Discriminate the sync polarity: Positive / Negative

T Count the frequency

500kHz clock signal supplied to pin 29 of IC350

counts the frequency. The frequency is sent to the

MAIN MICROPROCESSOR (IC301) to store Q-

T in the E2PROM as a read data.

H/V

INPUT

MAIN MICROPROCESSOR

SWITCHING

IC301

4-9. CONTROL SYSTEM circuits

4-9-1. H-SIZE and DISTORTION CORRECTION CONTROL

VIDEO

SIGNAL

IC101

IIC-BUS

H/V

H&V SYNCHRONOUS

SIGNAL PROCESSOR

H&V OSCILLATOR

IC350

The parabolic wave output from pin 9 of IC350 is adjusted and converted to the waveform by IC503 and then input to

pin 2 of IC961.

a (Approx. 8V): DC bias....H-size control

b (Approx. 1Vp-p): AC amplitude....Distortion control

b

a

0V

Pin 9 of IC350

The parabolic wave input to pin 2 of IC961 is added to the PWM waveform from pin 6 of IC961. The V-parabolic wave

modulates the variable B voltage to perform distortion correction.

c

c: H-size adjustment level

0V

Variable B voltage waveform

(D973 cathode)

- 23 -

Page 27

4-9-2. HORIZONTAL OSCILLATION

A drive pulse output from pin 17 of IC350 is amplified by Q350 and then applied to Q504 gate of the DRIVE circuit.

0.7V

0.2V

0V

Pin 17 of IC350 Inversion-amplified

waveform by Q350

12Vp-p

4-9-3. VERTICAL OSCILLATION

The sawtooth-wave is output from pin 8 of IC350 and applied to the VERTICAL DEFLECTION OUTPUT circuit.

a (Approx. 6.5V): AC amplitude....V-size control

b (Approx. 3.5V): DC bias....V-position control

a

Pin 8 of IC350

Reference voltage 5V

(Pin 23 of IC350)

b

4-10. HIGH VOLTAGE OUTPUT CONTROL circuit

The AFC waveform is output from pin 6 of L501 and applied to IC501. The duty-controlled voltage waveform is output

from pin 1 of IC501 and amplified by Q521 and then applied to T501. The applied voltage is amplified by T501 and

supplied to the CRT as anode voltage.

4-11. HORIZONTAL DEFLECTION OUTPUT circuit

The drive pulse is output from pin 17 of IC350 and amplified by Q350. The drive pulse is supplied to Q503 base via

HORIZONTAL DEFLECTION circuit and current-amplified.

4-12. VERTICAL DEFLECTION OUTPUT circuit

The sawtooth wave from pin 8 of IC350 is supplied to pin 5 of IC401 and amplified, and then supplied to the vertical

DY as sawtooth wave current. Vertical deflection is performed by the magnetic field generated when supplying the

current to the vertical DY.

+15V

Reference voltage 1.7V

Pin 2 of IC401

–10V

- 24 -

Page 28

4-13. DYNAMIC BEAM FOCUS circuit

The H-parabolic wave from pin 13 of IC350 is amplified by 18 times by Q518 and Q519 respectively. The amplified

parabolic wave is pressured up to 500vp-p by T503 and combined with V-parabolic wave and then added to pin 13

of T501.

5V

2V

0V

Pin 13 of IC350

V-parabolic wave from pin 12 of IC350 is amplified by Q520 and combined with H-parabolic wave.

5V

3V

0V

Pin 12 of IC350

4-14. SWITCHING SIGNAL circuit (CS SWITCHING POINTS)

Each switching point performs horizontal linear and distortion correction as follows:

IC301 output pin

CS6

DRIVE

H-LIN1

fH (kHz)

23.5 - 28.0

28.1 - 34.0

34.1 - 41.0

41.1 - 45.0

45.1 - 49.0

49.1 - 59.0

59.1 - 66.0

66.1 - 73.0

73.1 - 84.0

84.1 - 88.5

88.6 - 97.0

97.1 - 115.0

CS1

(Pin 55)

LOW

LOW

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

CS2

(Pin 56)

LOW

HIGH

LOW

LOW

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

CS3

(Pin 57)

LOW

LOW

LOW

HIGH

LOW

LOW

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

CS4

(Pin 58)

LOW

LOW

LOW

LOW

LOW

HIGH

LOW

LOW

HIGH

HIGH

HIGH

HIGH

CS5

(Pin 59)

LOW

LOW

LOW

HIGH

LOW

LOW

LOW

HIGH

LOW

HIGH

HIGH

HIGH

(Pin 60)

HIGH

HIGH

HIGH

HIGH

HIGH

LOW

LOW

LOW

HIGH

LOW

LOW

HIGH

(Pin 3)

LOW

LOW

LOW

LOW

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

(Pin 2)

LOW

LOW

LOW

LOW

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

H-LIN2

(Pin 1)

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

LOW

LOW

LOW

- 25 -

Page 29

4-15. VIDEO and ON SCREEN DISPLAY CONTROL circuits

The video signal from CN101 or CN102 is terminated to 75Ω. The video signal is switched to D-SUB or BNC by the

VIDEO SIGNAL SWITCHING circuit that is controlled by the MAIN MICROPROCESSOR (IC301). The adjustment

item of Signal Select selects D-SUB or BNC. The selected video signal is amplified by IC201. The OSD signal from

IC203 is combined with the video signal by IC201. The OSD signal is controlled by the MAIN MICROPROCESSOR.

The V-sawtooth wave from pin 8 of IC350 and V-bias voltage from pin 4 of IC211 are combined by IC207. The AFC

pulse wave and H-bias voltage from pin 7 of IC211 are also combined by IC207. The H and V-parabolic waves are

combined and input to IC201 to correct UNIFORMITY. The combined signal adds H/V blanking signal and is applied

to IC202. Then the video signal is amplified to approx. 50Vp-p by IC202, and then fed to the respective CRT

cathodes, KR, KG, and KB.

CN101

CN102

FRONT KEY

R

G

B

R

G

B

VIDEO

SIGNAL

SWITCHING

IC101

IIC-BUS

OSD CONTROL

OSD-CS

OSD-SCL

OSD-SDA

MAIN MICROPROCESSOR

IC301

V

Pin 19 of IC201

OSDR/G/B/BLK

IC203

DA-LD

DA-SCL

DA-SDA

R

G

B

CONVERTER

VIDEO

AMPLIFIER

IC201

BLK

CLAMP

D/A

IC211

5V

2V

0V

R

G

B

R/G/B/BRIGHTNESS

V-bias/V-gain/V

PH/

Pin 27 of IC201

VIDEO

OUTPUT

IC202

CUT-OFF

CONTROL

IC210

H-bias/H-gain

5Vp-p

R

G

B

CRT CATHODE

UNIFORMITY

IC207

IC350

V-SAW

AFC

4-16. RED, GREEN, BLUE CUT-OFF and BRIGHTNESS CONTROL circuits

The DC voltages (0-5V) from pins 12, 13, 14 and 15 of IC211 are amplified by IC210, Q2R2, Q2G2 and Q2B2

respectively. The respective amplified voltages control the DC voltage level of CRT cathode by automatic adjustments

of RED, GREEN, BLUE CUT-OFF and BRIGHTNESS.

- 26 -

Page 30

4-17. LANDING CORRECTION circuit

This circuit detects the followings to correct LANDING discoloration.

• Magnetic field.....TERRESTRIAL MAGNETIC SENSOR (IC708) detects the magnetic field.

• SWITCH ON DRIFT.....TH801 detects surrounding temperature. Thermistor attached to the funnel detects the

temperature of funnel.

• Surrounding temperature.....TH801 detects surrounding temperature.

When the above condition is changed, the SUB MICROPROCESSOR (IC701) informs the change to the D/A

CONVERTER (IC703). The output signal from IC703 is amplified by IC704, IC706 and IC707 to correct LANDING

discoloration automatically by the coils N-S RRC, TL, TR, BL and BR.

The LANDING correction also can be performed with the front buttons.

H-CONV

V-CONV

TERRESTRIAL

MAGNETIC

SENSOR

IC708

Vx-OUT

VY-OUT

TEMP

SUB MICROPROCESSOR

IC701

IIC-BUS

D/A

CONVERTER

IC703

NS RRC

TILT

TR/TL

BR/BL

POWER

AMPLIFIER

IC704

IC705

IC706

IC707

NS RRC +,–

LANDING-TL/TR/BL/BR

TILT

H/V-CONVERGENCE

- 27 -

Page 31

5. SERVICE PARTS LIST

The components identified by “ ! ” in this manual are critical

for safety.

Replace only with part number specified .

Abbreviations and Marks.......................................................................................

WARNING !

<CONTENTS>

-Page29

FAMILY-TREE..................................................................................................

ASSY-PWB-MAIN...............................................................................................

ASSY-PWB-VIDEO.............................................................................................

SUB-MATERIAL..................................................................................................

Structure

FAMILY-TREE

ASSY-PACKING

ASSY-MONITOR

ASSY-PWB-MAIN

30

30ASSY-PACKING.............................................................................................

31ASSY-MONITOR.................................................................................................

32-41

42-52

53

- 28 -

ASSY-PWB-VIDEO

SUB-MATERIAL

Page 32

ELECTRICAL PARTS LIST

Abbreviations in PART section

Abbreviation Meaning

R-C

R-MB

R-CE

R-FUSE

C-C

C-E

C-PP

C-MF

D

ZD

TR

PHC

PTH

HDT

FBT

VR

SW

SWT

Resistor-Carbon

Resistor-Metal

Resistor-Cement

Resistor-Fuse

Capacitor-Ceramic

Capacitor-Electrolytic

Capacitor-Polypropylene

Capacitor-Multilayer Metallized Polyester Film

Diode

Zener Diode

Transistor

Photo Coupler

Positive Thermistor

Horizontal Drive Transformer

Flyback Transformer

Variable Resistor

Switch

Switching Transformer

Marks in DESCRIPTION section

<Resistor> <Capacitor>

Mark

F

J

K

Tolerance

± 1%

± 5%

±10%

- 29 -

Mark

H

J

K

M

P

Z

Tolerance

± 3%

± 5%

± 10%

± 20%

+100%

– 0%

+ 80%

– 20%

Page 33

Q'TY

REV.

REF.NO.

PART

DESCRIPTION

PART NO.

PRICE

REMARK

Q'TY

REV.

REF.NO.

PART

DESCRIPTION

PART NO.

PRICE

REMARK

121ATTENTION-SHEET

870Z031-01

123SIGNAL-CABLE

242Z013-01

127PACKING-CASE

800T048-05

128PACKING-BAG

831V005-11

129BUNDLE-SOFT

886Z030-01

132CUSHION-TOP

803S051-01

133CUSHION-BOTTOM

803S051-02

137CARTON-TAPE

NO.3201/4266

096Z466A70

238SELLO-TAPE

NO.252/CT07

830Z003A01

144AC-CORD

(LNN)

500Z006-02

145AC-CORD

(HNE)

500Z005-02

146AC-CORD

(HNB)

500Z007-02

DWG. TITLE : FAMILY-TREE

1 ASSY-PACKING (LNN) T985S046-20

1 ASSY-PACKING (HNE) T985S046-30

1 ASSY-PACKING (HNB) T985S046-40

1 ASSY-MONITOR T950R089-20

1 ASS-PWB-MAIN T950T051-10

1 ASSY-PWB-VIDEO T950T052-10

1 SUB-MATERIAL 951V001-10

DWG. TITLE : ASSY-PACKING

1 15 RATING-PLATE (JF) 706V162-02 !

1 15 RATING-PLATE (EY) 706V162-03 !

1 16 SERIAL-LABEL 851T013-24 !

1 20 OPERATION-MANUAL 870Z062-01 !

!

!

!

!

!

!

!

- 30 -

Page 34

Q'TY

REV.

REF.NO.

PART

DESCRIPTION

PART NO.

PRICE

REMARK

122BACK-COVER

700R056-21

127SHAFT-POWER

704T025-01

129ASSY-FRAME-CRT

590T081A01

131FRAME-MAIN

590R130-01

132STAY-PWB

590T082A01

134FRAME-BACK

590R133A02

135SHIELD-COVER-A

590R131-02

136SHIELD-COVER-B

590R132-02

638SPRING

590V090-01

141COIL-DEGAUSSING

409Z039-01

142COIL-CANCEL

409Z040B01

143COIL-CANCEL

409Z041A01

144COIL-CANCEL

409Z041A02

145CRT

M46LPE01X11

251Z062A01

447SCREW

STV-SEMS-W3*8MC-S

632Z421B08

3648SCREW

STV-SEMS-W3*10MC-S

632Z421B10

649SCREW

STV3*8MC-S

632Z121B08

150SCREW

MHA-SEMS-B4*8GR-S

630Z344C08

451SCREW

BTV3*8MC-S

631Z121B08

252SCREW

BTF3*8AB-S

631Z113B08

253SCREW

82007-0300

666Z003A01

454SCREW

BTB-SEMS-C4*10MC-S

631Z731C10

255SCREW

BTB4*55NI-S

631Z135C55

256SCREW

STB4*10NI-S

632Z135C10

257SCREW

BTV4*8MC-S

631Z121C08

459WASHER

S-W8MC-S

668Z211A08

460NUT

H1-8MC-S

669Z111A08

168INSULATION-SHEET

222V026-01

970CABLE-TIES

GT-100M/TSL-100-M/YJ-100

540Z089A01

1272CLAMPER

DGC-8.5-19

540Z093A01

473CLAMPER

DGC-6.5-19

540Z093A02

574CLAMPER

SHK-12

540Z080A01

275CLAMPER

STL-250-3-01

540Z037A02

376SPACER

KGLS-4S/LCBS-4-01

540Z088A01

278EDGING-SADDLE

EWSE-1-01

540Z043A02

182LEAD-CONNECTOR

246T076-01

183LEAD-CONNECTOR

246T076-02

184LEAD-CONNECTOR

246T076-03

185LEAD-CONNECTOR

246T076-08

186LEAD-CONNECTOR

246T076-09

187LEAD-CONNECTOR

246T076-10

388LEAD-CONNECTOR

246T076-11

189LEAD-CONNECTOR

246T076-13

190LEAD-CONNECTOR

246T076-18

191LEAD-CONNECTOR

246T076-15

192THERMISTOR

103JT-050

744Z003A10

193LEAD-CONNECTOR

246T076-14

194LEAD-WIRE

246V021-03

195LEAD-WIRE

246V021-04

196LEAD-WIRE

242Z026-02

199GLASS-TAPE

NO.188UL

096Z001A01

1

102

LABEL-WARNING

851V109-01

2

SPOILER

C (ITC ADJUSTMENTS)

890Z003A03

DWG. TITLE : ASSY-MONITOR

1 19 FRONT-CABINET 700R062-21

1 25 ASSY-TILT-STAND 770T020A21

2 64 FERRITE-CORE KR16CC16/KRCBC16/ZCAT2032 755Z803J20

4 65 FERRITE-CORE KRCBC13/ZCAT1518/E1314MRC 755Z802E20

1 66 FERRITE-CORE BP53RB/FSOB162RN/E1620MRT 755Z902E10

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

3 100 ACETATE-TAPE NO.570F (ITC ADJUSTMENTS) 890P306A10

# MAGNET 138D (ITC ADJUSTMENTS) 890Z010A01

2 SPOILER B (ITC ADJUSTMENTS) 890Z003A02

1 DF-TAPE #575 (ITC ADJUSTMENTS) 890P329A10

!

!

!

!

!

- 31 -

Page 35

Q'TY

REV.

REF.NO.

PART

DESCRIPTION

PART NO.

PRICE

REMARK

117RADIATOR

590V091A01

218RADIATOR

590V097A01

120SHIELD-IC

590T075B01

322SPACER

TCBS-8/STBS-8

540Z042A01

323CLAMPER

STL-450-12-01

540Z037A13

124CLAMPER

STL-600-12-01

540Z037A17

125CLAMPER

WSLT-01A-01

540Z087A01

226CABLE-TIES

GT-100M/TSL-100-M/YJ-100

540Z089A01

328SCREW

BTV3*10MC-S

631Z121B10

1529SCREW

MP-SEMS-W3*10MC-S

630Z401B10

131LEAD-CONNECTOR

246T076-19

132LEAD-CONNECTOR

246T076-04

133LEAD-CONNECTOR

246T076-05

134LEAD-CONNECTOR

246T076-07

135LEAD-CONNECTOR

246T076-12

137LEAD-CONNECTOR

246T076-21

139COOL-SHEET

222V024A01

240COOL-SHEET

M-20/TC-20AG

222Z001A01

141COOL-SHEET

222V025A01

142COOL-SHEET

M-20

222Z001A02

1

C301

C-E

25V 100M-M

460Z101A43

1

C302

C-C

25V F-R1M-Z

142Z919A23

1

C303

C-E

6R3V 3300M-M

460Z332A17

1

C304

C-C

25V F-R1M-Z

142Z919A23

1

C305

C-E

25V 100M-M

460Z101A43

1

C306

C-C

25V F-R1M-Z

142Z919A23

1

C307

C-E

25V 100M-M

460Z101A43

1

C308

C-C

25V F-R1M-Z

142Z919A23

1

C309

C-C

50V B-1000P-K

142Z372A21

1

C311

C-E-NP

10V 100M-M

462Z101A23

1

C312

C-C

50V CH-27P-J

410Z270A23

1

C313

C-C

50V CH-22P-J

410Z220A23

1

C314

C-C

50V CH-22P-J

410Z220A23

1

C350

C-E

25V 100M-M

460Z101A43

1

C351

C-C

50V F-R01M-Z

142Z433A23

1

C355

C-E

100V 2R2M-M

460Z229A83

1

C356

C-E

50V 2R2M-M

460Z229A63

1

C357

C-MF

50V 1000P-J

420Z102A43

1

C358

C-E

50V 10M-M

460Z100A63

1

C359

C-E-NP

16V 33M-M

462Z330A33

1

C360

C-E

25V 33M-M

460Z330A43

1

C361

C-MF

50V 6800P-J

420Z682A43

1

C362

C-E

16V 470M-M

460Z471A33

1

C363

C-C

50V F-R01M-Z

142Z433A23

1

C364

C-E

25V 100M-M

460Z101A43

1

C365

C-C

50V F-R01M-Z

142Z433A23

1

C366

C-E

25V 100M-M

460Z101A43

1

C367

C-C

25V F-R1M-Z

142Z919A23

1

C368

C-MF

50V R82M-J

420Z824A13

1

C369

C-MF

50V R068M-J

420Z683A13

1

C370

C-C

50V F-R01M-Z

142Z433A23

1

C371

C-E

25V 47M-M

460Z470A43

1

C372

C-C

25V F-R1M-Z

142Z919A23

1

C373

C-E

100V 1M-M

460Z109A83

1

C401

C-C

25V F-R1M-Z

142Z919A23

1

C402

C-E

25V 1000M-M

460Z102A47

1

C403

C-C

25V F-R1M-Z

142Z919A23

1

C404

C-E

25V 100M-M

460Z101A43

1

C405

C-C

25V F-R1M-Z

142Z919A23

1

C406

C-E

25V 1000M-M

460Z102A47

1

C407

C-MF

100V R22M-J

420Z224A23

1

C408

C-E

35V 100M-M

460Z101A53

1

C409

C-MF

50V R039M-J

420Z393A13

DWG. TITLE : ASSY-PWB-MAIN

1 15 RADIATOR-M 590S109-02

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

- 32 -

Page 36

Q'TY

REV.

REF.NO.

PART

DESCRIPTION

PART NO.

PRICE

REMARK

DWG. TITLE : ASSY-PWB-MAIN

1

C411

C-MF

50V R01M-J

420Z103A43

1

C413

C-MF

50V 4700P-J

420Z472A43

1

C501

C-PP

1800/2000V2000P-H

424Z202B47

1

C502

C-PP

1800/2000V1800P-H

424Z182B47

1

C504

C-PP

250V 2R2M-K

425Z225A17

1

C505

C-C

2KV 3300P-K

414Z332A36

1

C507

C-C

50V B-4700P-K

142Z380A21

1

C508

C-E

250V 10M-M

471Z100E23

1

C509

C-C

500V B-680P-K

141Z354A21

1

C510

C-PP

250V 1R5M-J

422Z155A47

1

C511

C-PP

250V R68M-J

422Z684A47

1

C512

C-PP

250V R39M-J

422Z394A47

1

C513

C-PP

250V R24M-J

422Z244A47

1

C514

C-PP

250V R18M-J

422Z184A47

1

C515

C-PP

400V R1M-J

422Z104A37

1

C516

C-PP

400V R1M-J

422Z104A37

1

C517

C-E

100V 10M-M

470Z100A83

1

C518

C-MF

100V R47M-J

420Z474A23

1

C519

C-E

100V 1M-M

460Z109A83

1

C521

C-E-NP

25V 10M-M

462Z100A43

1

C522

C-C

500V B-470P-K

411Z471A33

1

C523

C-E

450V 1M-M

461Z109A63

1

C524

C-PP

1000/1250V1000P-J

423Z102C27

1

C525

C-E

100V 100M-M

470Z101A83

1

C527

C-PP

1000/1250V8200P-J

423Z822C27

1

C528

C-E

25V 1000M-M

460Z102A47

1

C529

C-E

100V 1M-M

460Z109A83

1

C530

C-E

160V 10M-M

470Z100A93

1

C531

C-E

50V R1M-M

460Z108A63

1

C532

C-E-NP

25V 10M-M

462Z100A43

1

C533

C-PP

200V R1M-J

421Z104A27

1

C534

C-C

25V F-R1M-Z

142Z919A23

1

C535

C-E

50V 4R7M-M

460Z479A63

1

C536

C-E-NP

50V 1M-M

472Z109A63

1

C537

C-C

500V B-1000P-K

141Z358A21

1

C539

C-E

50V 10M-M

460Z100A63

1

C541

C-E

25V 2200M-M

460Z222A47

1

C542

C-C

25V F-R1M-Z

142Z919A23

1

C543

C-C

25V F-R1M-Z

142Z919A23

1

C544

C-C

500V E-R01M-P

141Z418A44

1

C545

C-C

25V F-R1M-Z

142Z919A23

1

C546

C-E

25V 47M-M

460Z470A43

1

C550

C-PP

100V 2R2M-K

425Z225A07

1

C551

C-C

50V F-R01M-Z

142Z433A23

1

C552

C-C

50V F-R01M-Z

142Z433A23

1

C553

C-C

50V F-R01M-Z

142Z433A23

1

C554

C-C

50V F-R01M-Z

142Z433A23

1

C555

C-C

50V F-R01M-Z

142Z433A23

1

C556

C-C

50V F-R01M-Z

142Z433A23

1

C557

C-PP

250V R068M-J

422Z683A47

1

C559

C-E

25V 100M-M

460Z101A43

1

C561

C-C

50V F-R01M-Z

142Z433A23

1

C922

C-PP

630V 1M-K

425Z105B27

1

C923

C-MF

50V 4700P-J

420Z472A43

1

C924

C-MF

50V R22M-J

420Z224A13

1

C925

C-MF

50V 470P-J

420Z471A43

1

C926

C-E

450V 220M-M

467Z618C34

1

C928

C-E

100V 10M-M

460Z100A83

1

C929

C-C

50V F-R01M-Z

142Z433A23

1

C930

C-PP

630V R047M-K

425Z473A27

1

C931

C-C

2KV B-220P-K

155Z170B61

1

C932

C-E

50V 10M-M

460Z100A63

1

C933

C-MF

50V 560P-J

420Z561A43

1

C934

C-MF

50V 2200P-J

420Z222A43

!

!

!

- 33 -

Page 37

Q'TY

REV.

REF.NO.

PART

DESCRIPTION

PART NO.

PRICE

REMARK

DWG. TITLE : ASSY-PWB-MAIN

1

C935

C-MF

50V R047M-J

420Z473A43

1

C936

C-E

50V 10M-M

460Z100A63

1

C937

C-C

25V F-R1M-Z

142Z919A23

1

C938

C-E

100V 10M-M

460Z100A83

1

C939

C-C

2KV 100P-K

414Z101A36

1

C940

C-MF

50V 6800P-J

420Z682A43

1

C941

C-MF

50V R022M-J

420Z223A13

1

C943

C-E

100V 10M-M

460Z100A83

1

C945

C-E

25V 47M-M

460Z470A43

1

C946

C-C

AC250V 2200P-M

510Z001A36

1

C947

C-MF

50V R1M-J

420Z104A43

1

C948

C-C

50V F-R01M-Z

142Z433A23

1

C949

C-C

1KV E-R01M-Z

155Z210A31

1

C962

C-C

2KV B-220P-K

155Z170B61

1

C964

C-C

1KV B-1000P-K

413Z102A26

1

C965

C-E

100V 470M-M

460Z471A87

1

C966

C-E

50V 1000M-M

460Z102A67

1

C967

C-E

35V 2200M-M

460Z222A57

1

C968

C-E

25V 1000M-M

460Z102A47

1

C969

C-C

25V F-R1M-Z

142Z919A23

1

C970

C-E

25V 1000M-M

460Z102A47

1

C971

C-E

25V 100M-M

460Z101A43

1

C972

C-E

25V 1000M-M

460Z102A47

1

C973

C-E

16V 100M-M

460Z101A33

1

C974

C-C

25V F-R1M-Z

142Z919A23

1

C977

C-C

500V B-330P-K

411Z331A33

1

C978

C-MF

50V 1000P-J

420Z102A43

1

C979

C-MF

50V R01M-J

420Z103A43

1

C980

C-MF

50V 560P-J

420Z561A43

1

C981

C-E

50V 10M-M

460Z100A63

1

C982

C-MF

50V 1000P-J

420Z102A43

1

C983

C-E

50V 100M-M

460Z101A63

1

C984

C-C

25V F-R1M-Z

142Z919A23

1

C985

C-MF

50V 6800P-J

420Z682A43

1

C987

C-MF

100V 6800P-J

420Z682A53

1

C990

C-C

25V F-R1M-Z

142Z919A23

1

C991

C-C

50V F-R01M-Z

142Z433A23

1

C992

C-C

25V F-R1M-Z

142Z919A23

1

C993

C-C

25V F-R1M-Z

142Z919A23

1

C995

C-C

500V E-R01M-P

141Z418A44

1

C997

C-C

50V F-R01M-Z

142Z433A23

1

C998

C-C

25V F-R1M-Z

142Z919A23

1

C999

C-E

25V 100M-M

460Z101A43

1

C9A1

C-MF

50V 560P-J

420Z561A13

1

D301D1SS133

742Z029A11

1

D302D1SS133

742Z029A11

1

D303D1SS133

742Z029A11

1

D304D1SS133

742Z029A11

1

D305D1SS133

742Z029A11

1

D306D1SS133

742Z029A11

1

D350ZDMTZ-J13A

742Z401A41

1

D401DEM01Z/D1N60

742Z019A11

1

D402D1SS133

742Z029A11

1

D403DRB441Q

742Z026A11

1

D501D5VUZ47

742Z018A37

1

D503ZDHZT33-01

264P043A1

1

D504DEM01Z/D1N60

742Z019A11

1

D506ZDP6KE82/Z2082U

742Z403A21

1

D507D1SS133

742Z029A11

1

D508D1SS133

742Z029A11

1

D511D5VUZ47

742Z018A37

1

D512DRG2/S2L40

742Z021A17

1

D513D1SS133

742Z029A11

1

D514D1SS133

742Z029A11

!

!

- 34 -

Page 38

Q'TY

REV.

REF.NO.

PART

DESCRIPTION

PART NO.

PRICE

REMARK

DWG. TITLE : ASSY-PWB-MAIN

1