IHP BarcelonaLights36ZEN, VRE4660ZEN, VRE4636ZEN, BarcelonaLights48ZEN, BarcelonaLights72ZEN Installation And Operation Instructions Manual

...

C

LISTED

S

P900861-00

P/N 900861-00 REV. NC 10/2017

Ce manuel est disponible en francais,

simplement en faire la demande. Numéro

de la pièce 900861-01.

U

R

U

L

Report No. MH# 60069

Installation and Operation Instructions

OUTDOOR DECORATIVE GAS FIREPLACE

This is a Single-Sided fireplace with the option of converting it into a See-Through fireplace

Models

BarcelonaLights36ZEN

VRE4636ZEN

BarcelonaLights48ZEN

VRE4648ZEN

BarcelonaLights60ZEN

VRE4660ZEN

INSTALLATION PRECAUTION: This fireplace requires a minimum

18-square inches (per side) of cross ventilation. Failure to provide

proper ventilation can void the warranty.

BarcelonaLights72ZEN

VRE4672ZEN

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

Installateur : Laissez cette notice avec l’appareil.

Consommateur : Conservez cette notice pour consultation ultérieure.

WHEN USED AS AN OUTDOOR APPLIANCE

CARBON MONOXIDE WARNING

DANGER

• This appliance can produce

carbon monoxide which has

no odor.

• Using it in an enclosed space

can kill you.

• Never use this appliance in

an enclosed space such as a

camper, tent, car or home.

WARNING: Do not store gasoline or other flammable vapors and liquids in the vicinity of this or any other appli-

ance. An LP-cylinder not connected for use shall not be stored in the vicinity of this or any other appliance.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause injury or property damage.

Read the installation, operating and maintenance instructions thoroughly before installing or servicing this equipment.

WARNING:

AVERTISSEMENT:

WARNING: For Outdoor Use Only.

DANGER

IF YOU SMELL GAS:

1. Shut off gas to appliance.

2. Extinguish any open flame.

3. If odor continues, keep away from the appliance and

immediately call your gas supplier or fire department.

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could

result in serious injury, death, or property damage.

- Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Leave the building immediately.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the

fire department.

- Installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

RISQUED’INDENDIE OU D’EXPLOSION

Le non-respect Des avertissements de sécurité pourrait

d’entraîner des blessures graves, la mort ou des dommages matériels.

- Ne pas entreposer ni utilizer d’essence ni d’autres vapeurs

ou liquides inflammables dans le voisinage de cet appareil

ou de tout autre appareil.

- QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ:

• Ne pas tenter d’allumer d’appareil.

• Ne touchez à aucan interrupteur. Ne pas vous servir des

téléphones se trouvant dans le bâtiment où vous trouvez.

• Sortez immédiatement de bâtiment.

• Appelez immédiatement votre fournisseur de gaz depuis

un voisin. Suivez les instructions du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de gaz, appelez

le service des incindies.

- L’installation et l’entretien doivent être assurés par un

installateur ou un service d’entretien qualifié ou par le

fournisseur de gaz.

TABLE OF CONTENTS

Safety ........................................................................................2-3

Local Codes ................................................................................. 3

Installation Precautions ........................................................... 4-6

Gas Line and Cross Ventilation Requirements ......................... 5

Hard piping and High Elevation ................................................ 6

Fireplace Specifications .............................................................. 7

Single-Sided Fireplace Application ........................................8-10

Dimensions; Combustible Clearances; Mantel Clearances ........ 9

Framing with Metal Studs ....................................................... 10

See-Through Fireplace Application ...................................... 11-14

Converting Fireplace to a See-Through Model ........................ 12

Dimensions; Combustible Clearances; Mantel Clearances ...... 13

Framing with Metal Studs ....................................................... 14

LED Lighting Installation ......................................................15-22

Wiring Diagrams ................................................................... 20-22

Final Preparation .................................................................. 23-27

Installing Pilot Covers in Burner Pan ....................................... 23

Installation of Media in Burner Pan/Trough ............................. 24

Windshield Location and Pilot Operation ................................ 25

Installation of Hoods and Windshield ...................................... 26

Flame Height ........................................................................... 27

Operation .................................................................................... 28

Lighting Instructions ............................................................... 28

Product Reference Information ............................................... 28

Fireplace Maintenance .............................................................. 29

Troubleshooting .................................................................... 30-31

Optional Accessories ................................................................ 31

Gas Conversion Instructions ................................................. 32-35

Replacement Parts ................................................................36-38

Warranty .................................................................................... 39

Outdoor Decorative Gas Fireplaces

Models Barcelona Lights Series and VRE4600 Series

SAFETY

IT IS IMPORTANT TO READ THROUGH THE ENTIRE

INSTALLATION MANUAL BEFORE BEGINNING INSTAL-

LATION OF THIS FIREPLACE!!

This fireplace ships from the factory as a single-sided

fireplace with the option of removing the back panels

to convert it into a see-through fireplace. Your specific application, single-sided or see-through will

determine how you install and frame this fireplace.

Carefully read through this manual to understand.

DESCRIPTION: These Outdoor fireplace models come ready to op-

erate with HI/LO capabilities once installation is complete. They use

an electronic ignition that runs off a 7.5VDC adaptor. In addition,

each fireplace is equipped with LED lighting as a standard feature.

Each model can operate the LED lights with or without the fireplace

operating. The LED lights run off of a 12-volt DCV adaptor.

These are radiant fireplaces only and do not have a fan option.

Do not burn real wood or other combustible materials in these

fireplaces. Use only approved media. All models are shipped as

Natural Gas but can be converted to Propane Gas by ordering the

optional conversion kit (see Page 31). There is no top or rear venting required for this fireplace, however, it is mandatory to provide

adequate clearances according to this manual and cross ventilation in the enclosure. The burner assembly is removable for service.

NEVER obstruct the front opening(s) of the fireplace.

ALWAYS USE CAUTION WHEN USING THE FIREPLACE

Extra caution should be taken when lighting a fireplace when heavy

rains, high humidity and moisture are present. Light the fireplace

and leave the area while the heat dissipates any moisture out of the

media. We strongly recommend that during this drying out time

that you monitor the fireplace from a distance. This drying out period should be no less than 30 minutes. Continue monitoring the

flame from a safe distance to ensure that all popping has ceased

before fully enjoying the fire.

1. This appliance is configured from the factory only as Natural

gas. This appliance can be converted to LP gas.

2. Do not place Propane (LP) supply tanks inside any structure.

Locate propane tanks outdoors.

2

IHP.us.com

900861-00NC

SAFETY

Continued

3. This fireplace is to be used only outdoors in a well ventilated

space and shall not be used in a building, garage, or any

other enclosed area.

4. Do not use this fireplace as a wood burning fireplace. Use

only high temperature media approved for use with this fireplace.

5. Do not use this fireplace to cook or burn paper or other objects.

6. Do not use if exposed to or under water. Immediately call

a qualified service technician to inspect the fireplace and

replace any part of the control system and any gas control

which has been under water.

7. Turn fireplace OFF and let cool before servicing. Only a qualified service person should perform service.

8. To prevent performance problems in Propane (LP) fireplaces,

do not use a Propane tank less than 100lbs. capacity.

LOCAL CODES

WARNING

• Do not leave unattended during use.

• Do not use for cooking.

• Follow all gas leak procedures in this manual prior to operation.

WARNING

PROPANE TANKS ARE AT PRESSURES THAT WILL CAUSE

DAMAGE TO VALVE COMPONENTS. VERIFY THAT THE TANKS

HAVE STEP DOWN REGULATORS TO REDUCE THE PRESSURE

TO SAFE LEVELS.

WARNING

Fuels used in gas fired appliances, and the products of combustion such as fuels, contain chemicals known to cause cancer,

birth defects and/or other reproductive harm. This warning is

issued pursuant to the California Health and Safety Code Sec.

25249.1.

Install and use fireplace with care. Follow all local codes. In the absence of local codes, use the National Fuel Gas Code, ANSI Z223.1/

NFPA 54 (USA) - latest edition.

Available from:

American National Standards Institute, Inc.

25 West 43rd Street, 4th floor

New York, NY 10036

National Fire Protection Association, Inc.

1 Batterymarch Park

Quincy, MA 02169-7471

CODES AND STANDARDS

These fireplaces comply with National Safety Standards and are tested and listed by Underwriters Laboratories (Report No. MH#60069)

to ANSI Z21.97, CSA 2.41 in both USA and Canada, as outdoor decorative gas appliances. The installation must conform to local codes

or, in the absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1/ NFPA 54 (USA) - latest edition or CAN/CGA-B149.1

Natural gas and propane installation code (Canada) - latest edition.

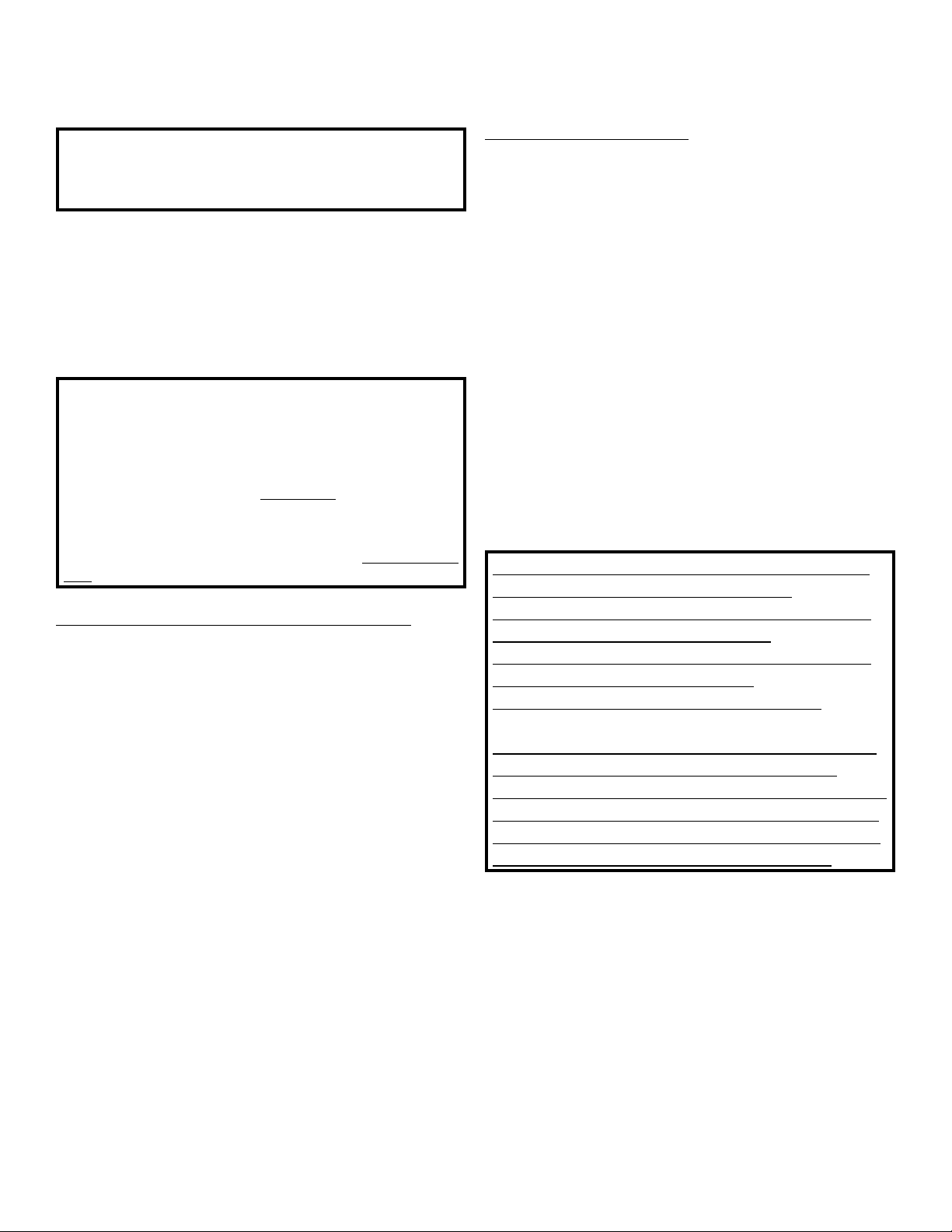

AN OUTDOOR SPACE IS DEFINED AS FOLLOWS PER ANSI Z21.97:

Outdoor spaces - An appliance is considered to be outdoors if installed

with shelter no more inclusive than:

(a) With walls on all sides, but with no over-head cover;

(b) Within a partial enclosure which includes an overhead cover and no

more than two side walls. These side walls may be parallel, as in a

breezeway, or at right angles to each other; or

(c) Within a partial enclosure which includes an overhead cover and

three sidewalls, as long as 30% or more of the horizontal periphery

of the enclosure is permanently open.

Massachusetts Requirements

These appliances are approved for installation in the US state of Massachusetts if the following additional requirements are met:

• Un-vented Room Heaters shall be installed in accordance with 527

CMR 30.

• Installation and repair must be done by a plumber or gas fitter licensed in the Commonwealth of Massachusetts.

• The flexible gas line connector used shall not exceed 36 inches (92

centimeters) in length.

• The individual manual shut-off must be a T-handle type valve.

• Unvented appliances may NOT be installed in bedrooms or bathrooms.

• A working smoke detector must be installed in the area where ventfree appliances are installed.

Seller of unvented propane or natural gas-fired supplemental room

heaters shall provide to each purchaser a copy of 527 CMR 30 upon

sale of the unit.

900861-00NC

IHP.us.com

3

INSTALLATION PRECAUTIONS

INSTALLATION PRECAUTION:

This fireplace requires a minimum 18-square inches

(per side) of cross ventilation. Failure to provide proper ventilation can void the warranty.

11. Only non-combustible materials (i.e. metal studs and cement

board) should come in direct contact with any part of the fireplace. Underneath area should be non-combustible or a flat

level combustible surface according to the clearances specified

in this manual. Bend out nailing flanges on ends of fireplace

and secure to metal studs.

1. These fireplaces are designed for outdoor use only. Not approved for any indoor use.

2. We recommend using 3/4” black iron pipe; however please refer to the National Fuel Gas Code, ANSI Z223.1/ NFPA 54 (USA)

- latest edition or CAN/CGA-B149.1 Natural Gas And Propane

Installation Code (Canada) - latest edition for proper pipe sizing

when exceeding 20-feet in length for fireplaces .

3. Determine which fireplace you are preparing to install, singlesided or see-through (refer to Page 8 or 11).

4. This fireplace is not a “load bearing” fireplace. All finishing

materials must be supported by the surrounding structure

and not rely on the fireplace itself.

5. Follow the local code requirements for the gas type being used.

This fireplace should be installed in accordance with local

codes and ordinances or in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1/ NFPA 54 (USA) - latest

edition or CAN/CGA-B149.1 Natural Gas And Propane Installation Code (Canada) - latest edition.

6. Fireplaces create high temperatures, it is very important to

have any combustibles at a safe distance.

12. This fireplace is designed to have glass media covering the

burner trough, so the burner tube is not visible. Use only the

media provided with the appliance or listed in the accessory

section of this manual (Page 31). DO NOT COVER THE IGNI-

TION HOOD WITH THE GLASS MEDIA. See Figures 33 and 34

on Pages 24 and 25 for details.

13. Gas lines and fittings must be installed in to the non-combustible structure. All gas connections must be leak tested before

installation of the fireplace. Leak detection is required before

regular use of the fireplace.

14. Do not use alternative media that will absorb moisture over

time and will not release this moisture quickly. Moisture can

boil in this media and can rapidly break apart and cause property damage or personal injury.

15. Never leave any other combustible material on top of the fireplace. This could cause unsafe operation of this system and

damage to the component that will not be covered under our

warranty.

16. It is recommended to wear gloves when moving the fireplace

into position and watch for sharp edges when handling the fireplace.

7. Fireplace should never be left unattended while in operation. It

should always be a safe distance from all trees and combustible landscape materials.

8. The fireplace must be installed on a flat, level, stable, non-combustible surface. Exception: It is permissible to place one layer

of 1/2” cement board underneath the entire fireplace, then it

may sit on a flat, level, stable, combustible surface. Drainage

is critical to ensure that water does not damage gas valve and

components. Never install the fireplace system below grade.

9. CAUTION: A minimum of 18 square inches of cross ventilation

(per side) is required to keep the inside of the enclosure dry.

Install the supplied VENT-KIT-6x12 (cat. no. F3535) approximately 3 to 4 inches from the floor centered on each end of the

fireplace (See Figure 3, Page 5).

10. Never fill the cavity under and around the valve box with any

material, this is air space necessary for ventilation.

WARNING

These appliances are not designed or intended to be used for

cooking. Do not barbecue, heat food, or roast marshmallows

in this appliance. Doing so could damage the appliance and

cause injury.

WARNING

These fireplaces are gas fireplaces. Do not burn wood or other

material in these appliances.

4

IHP.us.com

900861-00NC

INSTALLATION PRECAUTIONS

B

ur

n

e

r

Fireplace Side Wall

B

u

r

n

e

r

P

a

n

B

o

t

t

o

m

E

n

d

B

u

r

n

e

r

P

a

n

P

i

l

ot

C

o

v

e

r

Continued

CAUTION: BEFORE BEGINNING INSTALLATION CAREFULLY REMOVE THE GLASS

WINDSHIELDS, PARTS BOX AND ANY PACKING MATERIALS FROM FIREPLACE AND SET

ASIDE FOR LATER USE.

FRAMING: After framing is complete, slide the fireplace into position and secure it with the side nailing flanges. Next install cement

board, securing it to the metal studs and fireplace. The framing provides for a flush fit up to the opening of the fireplace. DO NOT PRO-

TRUDE INTO THE FIREPLACE OPENING WITH CEMENT BOARD.

GAS LINE: The gas line must have a predetermined location to en-

able it to be installed. Figure 1 shows one example of an inlet gas

line with a gas shut off at the fireplace. This allows a technician to

shut the inlet gas supply OFF and remove the burner for servicing.

It is imperative that the flex line from the gas shutoff be long

enough to lift out burner pan for service. Ensure you follow the

local and state gas codes per your installation.

LED LIGHTING: LED lighting must be installed before finish materials are completed on this fireplace. Ensure electricity is run before

fireplace is installed. See Pages 15 - 22. Ensure you follow local

and state codes per your installation.

IMPORTANT: It is permissible to reverse the burner pan in the field

to enable a closer gas line connection if necessary.

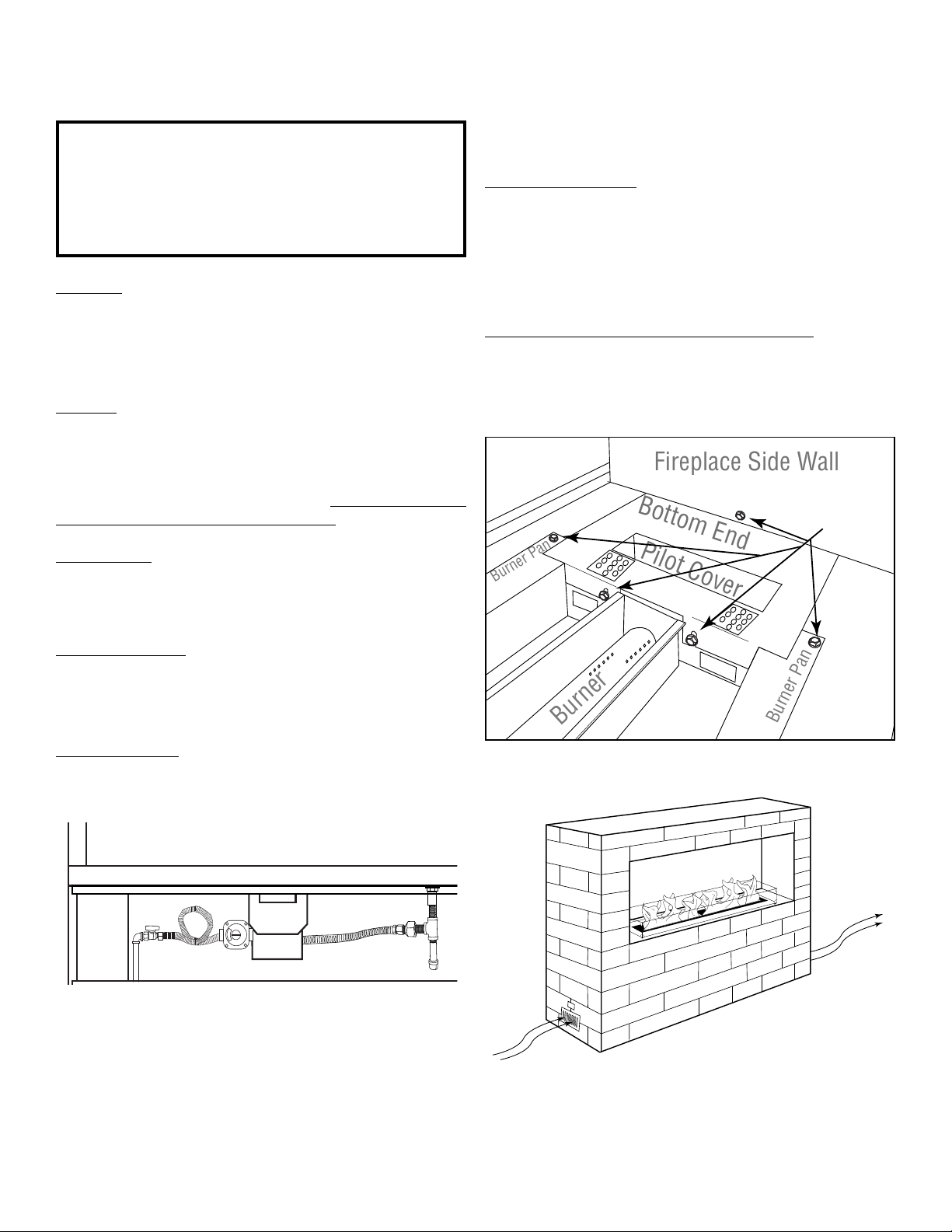

BURNER PAN REMOVAL

The burner pan is secured in the fireplace with five (5) screws on

each end. Two (2) screws are located on the outer edge of the burner pan and three (3) screws are located securing the bottom end

(see Figure 2). Remove all five (5) screws on each end to lift the

burner pan up. Use Figure 22 on Page 17 as a reference to remove

the bottom end.

VENTILATION FOR NON-COMBUSTIBLE ENCLOSURE

Fireplaces are subjected to many outdoor elements such as rain,

snow, wind, heat or cold. A minimum of 18 square inches of cross

ventilation (2 sides) is required to keep the components in good

working order. Use Figure 3 as a guide.

Remove Screws

RECOMMENDATION: Once the gas line is established it is recommended to remove the burner pan from the firebox until the fireplace is in the final stages and ready for the burner installation. See

Burner Pan Removal in Figure 2.

GAS CONVERSION: If you are converting the fireplace to LP gas

convert it while the burner pan is out of the fireplace. See Pages

31-33 for conversion instructions.

Figure 1 - Close up view of inlet gas connection with shutoff valve

Figure 2 - Removal of burner pan screws.

Figure 3 - Cross ventilation example providing minimum of

18-square inches per side using the Cross Ventilation Kit,

VENT-KIT-6x12 (Cat. No. F3535), provided.

900861-00NC

IHP.us.com

5

INSTALLATION PRECAUTIONS

Continued

WARNING: Proper clearances from combustible, construction

materials must be maintained from all sides, top and bottom of

this appliance. See specifications listed on Pages 8-10 for a single-sided fireplace and Pages 11-14 for a see-through fireplace.

The fireplace must be installed on a flat, level, stable, non-combustible surface. If one layer of 1/2” cement board is installed underneath the entire fireplace, it may sit on a flat, level, stable, combustible surface. Install fireplace according to the clearances specified

in this manual. NOTE: Do not place fireplace directly on grass, dirt,

or rocks as this may prevent proper ventilation. Ensure proper water drainage is also incorporated under the fireplace enclosure.

IMPORTANT

Installation of Natural or Liquid Propane Gas should be done by a

qualified installer, service agency or gas supplier.

The appliance and its appliance main gas valve must be disconnected

from the gas supply piping system during any pressure testing

of that system at test pressures in excess of 1/2 psi (3.5 kPa).

The appliance must be isolated from the gas supply piping system

by closing its equipment shutoff valve during any pressure testing

of the gas supply piping system at test pressures equal to or less

than 1/2 psi (3.5 kPa).

HARD PIPING TO FIREPLACE WITHOUT GAS PROXIMITY

NOTE: We recommend using 3/4” black iron pipe; however please

refer to the National Fuel Gas Code, ANSI Z223.1/ NFPA 54 (USA)

- latest edition or CAN/CGA-B149.1 Natural Gas And Propane In-

stallation Code (Canada) - latest edition for proper pipe sizing when

exceeding 20-feet in length for fireplaces rated above 100,000 BTU.

HIGH ELEVATION INSTALLATION

This appliance is listed for elevations from 0 to 4500 feet (0-1372

meters) in Canada and the U.S. If elevation exceeds 4500 feet it may

be necessary to decrease the input rating by changing the existing

burner orifice to a smaller size. Input should be reduced 4% for

each 1000 feet beyond the 4500 feet above sea level. Check with

your local gas utility for assistance in determining the proper orifice

in your location. In some cases the heating value may already be

reduced and downsizing the orifice may not be necessary.

Deration - At higher elevations, the amount of BTU fuel value delivered

must be reduced by either:

• Using gas that has been derated by the gas company.

• By changing the burner orifice to a smaller size as regulated by the

local authorities having jurisdiction and by the (USA) National Fuel

Gas Code NFPA 54/ANSI Z223.1—latest edition or, in Canada, the

CAN/CSA-B149.1 codes—latest edition.

Install the appliance according to the regulations of the local authorities having jurisdiction and, in the USA, the National Fuel Gas Code

NFPA 54 / ANSI Z223.1—latest edition or, in Canada, the CAN/CGAB149.1—latest edition.

PAY CLOSE ATTENTION TO THE FOLLOWING PAGES. THIS FIREPLACE IS SHIPPED AS A

SINGLE-SIDED FIREPLACE, HOWEVER YOU HAVE

THE OPTION TO CONVERT IT INTO A

SEE-THROUGH FIREPLACE. READ THE HEADERS

CAREFULLY TO ENSURE YOU ARE

FOLLOWING THE CORRECT INSTALLATION.

1. Turn OFF gas supply system. NOTE: All gas connections (except

for brass to brass) require the following: Clean pipe threads using either a wire brush or steel wool. Apply pipe sealant to the

fittings before making any connection. BE CAREFUL! Ensure all

gas connections are snug, but do not over tighten!

2. Extend the gas supply using minimum of 3/4” black iron pipe or

an approved flexible gas line from existing house supply. This

can be accomplished by teeing off or tapping into a gas line

connection. Install necessary pipe for the distance required and

then install a manual shutoff valve at the exterior house wall. If

pipe is to pass through a foundation or house wall, make sure

to re-seal the area around the pipe with weather sealant.

3. The primary gas shutoff (supplied) will require a 1/2” male

flared fitting to enable connection of the stainless steel flex gas

line supplied with the fireplace (See Figure 1, Page 5).

6

IHP.us.com

UNLESS SPECIFIED, ALL OTHER PAGES ARE COMMON FOR THESE FIREPLACES. REVIEW THE

INSTALLATION PRECAUTIONS BEFORE INSTALLING

ANY OF THESE MODELS. IF YOU HAVE ANY QUESTIONS PLEASE CONTACT YOUR DEALER OR GO TO

IHP.US.COM FOR REFERRAL INFORMATION.

The bottom support fin seen in several figure drawings on Pages 9

to 14 has pre-punched holes on inside edge to secure the fireplace

into position before attaching cement board.

900861-00NC

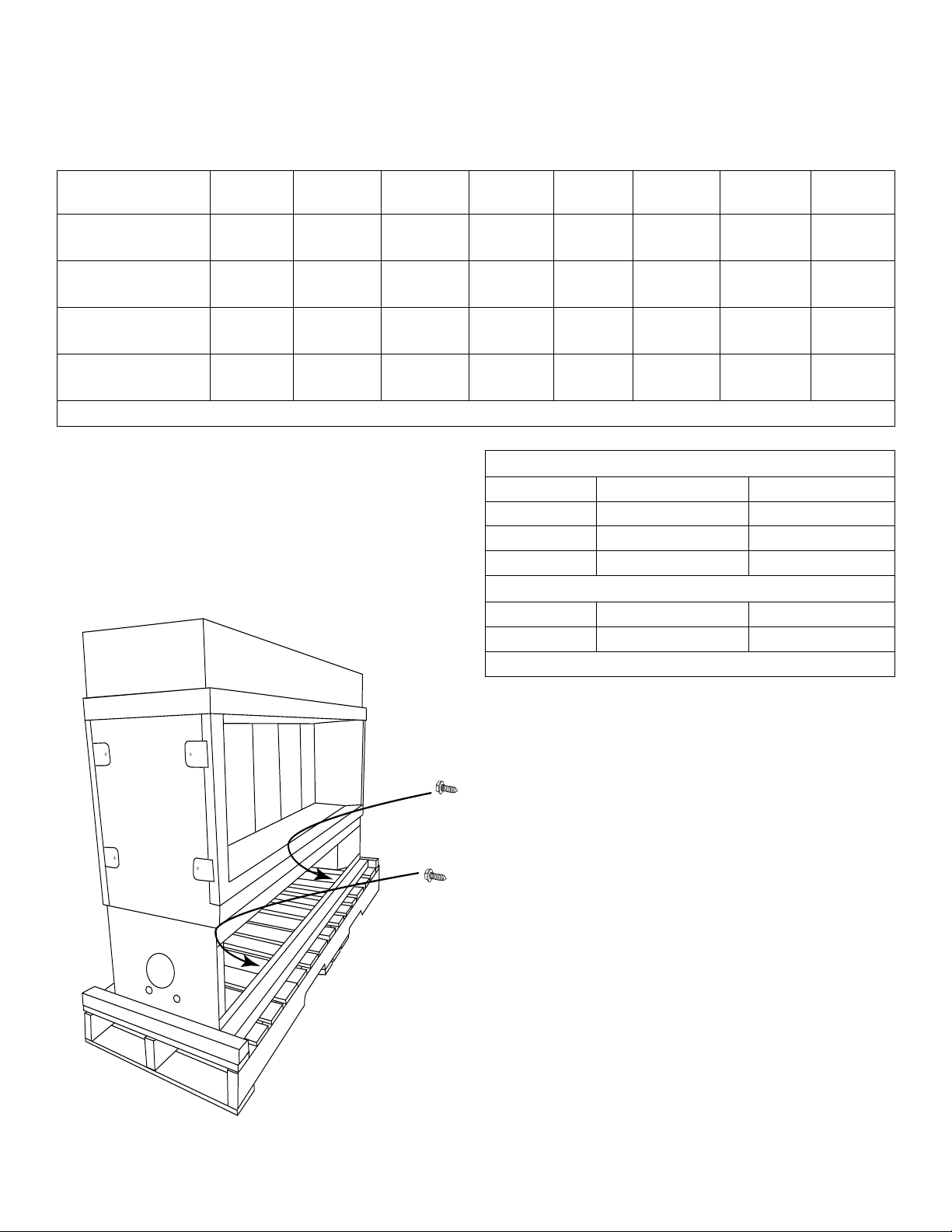

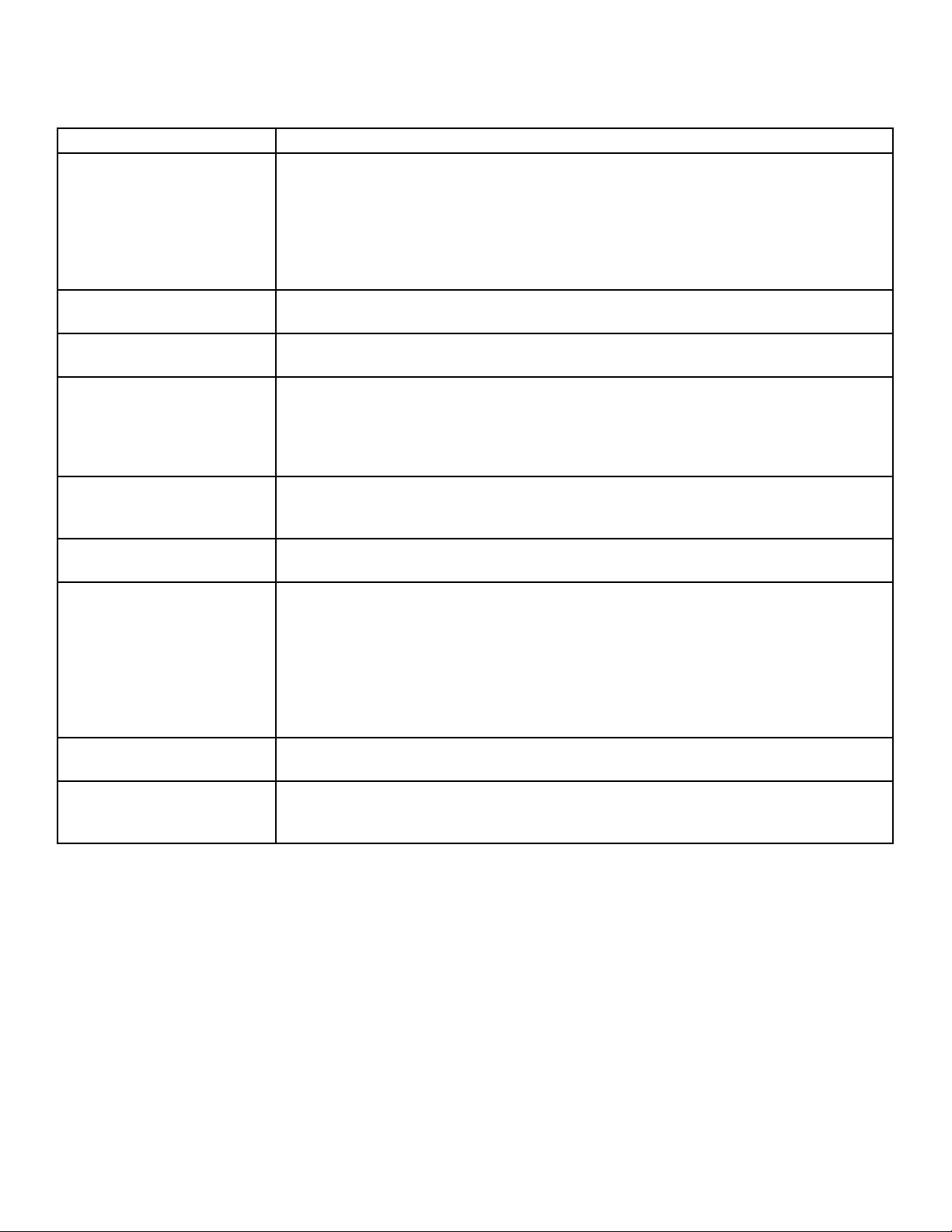

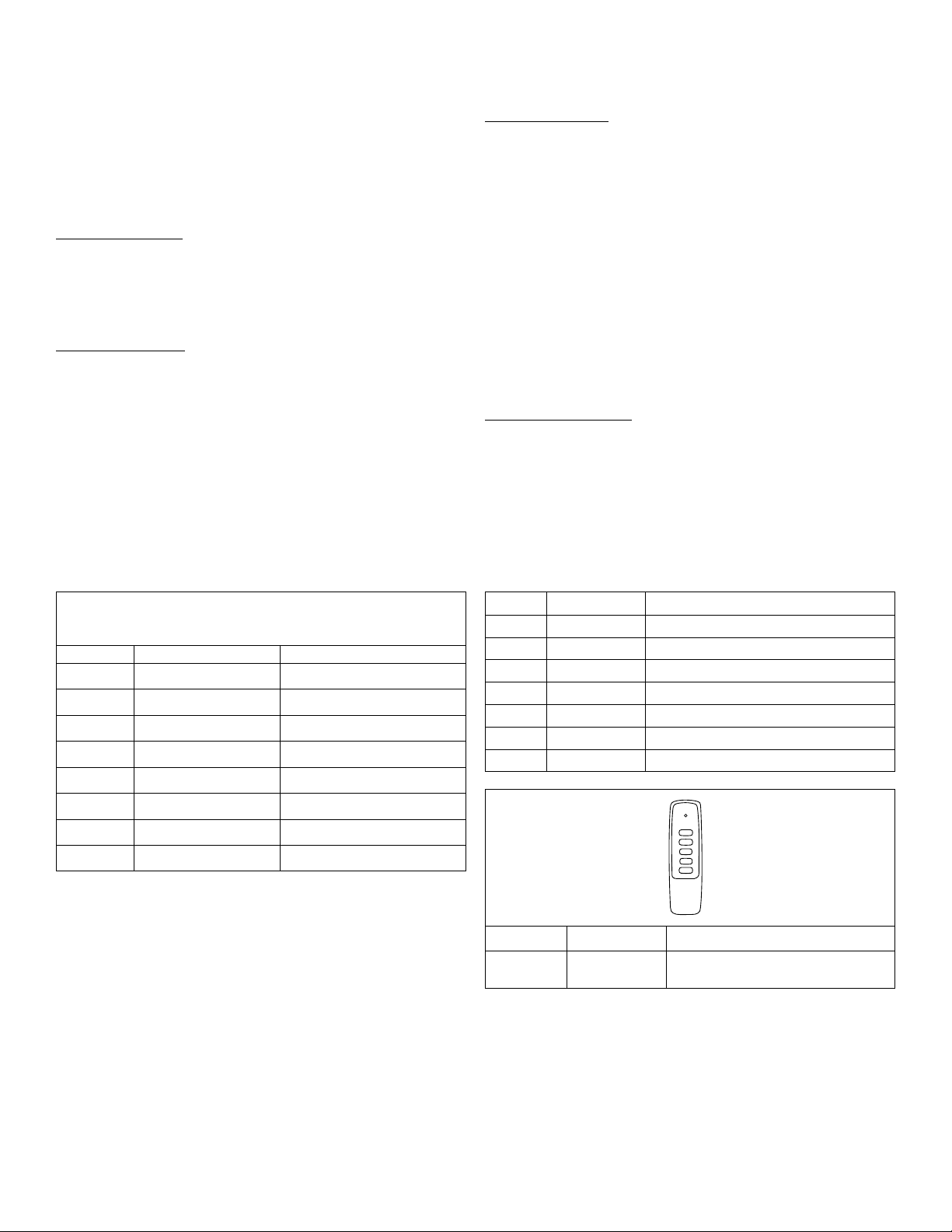

SPECIFICATIONS

NOTE: These fireplaces come shipped as Natural Gas models only. There is a conversion kit available as an accessory. Ensure you order

the specific conversion kit for your model fireplace. Table 1 shows the applicable information if converting to Liquid Propane (LP) gas.

IMPORTANT: It is permissible to reverse the burner pan in the field to enable a closer gas line connection if necessary.

FRAMING FIREPLACE

Model:

BarcelonaLights36ZEN

and VRE4636ZEN

BarcelonaLights48ZEN

and VRE4648ZEN

BarcelonaLights60ZEN

and VRE4660ZEN

BarcelonaLights72ZEN

and VRE4672ZEN

Table 1 - Fireplace Input Specifications

Disclaimer: BTU listings are based on 7.0” WC for Natural Gas at

the inlet side of gas valve. Flex line size and proper gas pipe sizing

will also affect BTU’s. As a result your BTU’s may vary slightly from

Table 1 specifications.

The fireplace ships on a wooden skid. Remove the screws as shown

in Figure 4 and lift fireplace off of skid.

NG Factory

Orifice

#41

#32

#30

#25

NG BTU’s

High

31,000

(9.08 kWh)

43,500

(12.75 kWh)

50,000

(14.65 kWh)

65,000

(19.05 kWh)

NG BTU’s

Low

18,500

(5.42 kWh)

24,500

(7.18 kWh)

36,000

(10.55 kWh)

42,000

(12.31 kWh)

NG Low

Rate Screw

#44 #52

#34 #48

#27 #44

#18 #42

LP Factory

Orifice

LP BTU’s

High

30,000

(8.79 kWh)

42,500

(12.46 kWh)

50,000

(14.65 kWh)

60,000

(17.58 kWh)

LP BTU’s

Low

19,500

(5.72 kWh)

29,000

(8.50 kWh)

36,000

(10.55 kWh)

45,000

(13.19 kWh)

LP Low

Rate Screw

Inlet Gas Pressure

Natural Gas (NG) Propane (LP)

Minimum Inlet 5.0” WC (1.24 kPa) 10.5” WC (2.61 kPa)

Maximum Inlet 10.5” WC (2.61 kPa) 13.0” WC (3.23 kPa)

Normal Inlet 7.0” WC (1.74 kPa) 11.0” WC (2.74 kPa)

Manifold Gas Pressure

Natural Gas (NG) Propane (LP)

Normal Manifold 4” WC (1.00 kPa) 10.0” WC (2.49 kPa)

Table 2 - Gas Pressures

#52

#46

#42

#35

Figure 4 - Remove Fireplace from Skid

900861-00NC

NOTE: Number of screws

vary with model size.

IHP.us.com

7

SINGLE-SIDED FIREPLACE DIMENSIONS AND CLEARANCES

NOTE: Preparation for the LED lighting and the inlet gas line must be

planned before the fireplace is installed. See Page 5, Figure 1 for inlet

gasline and Page 15 for LED lighting.

SINGLE-SIDED FIREPLACE

DIMENSIONS, FRAMING

AND CLEARANCES SECTION

This fireplace comes with various boxes prepackaged inside the fireplace. Do not discard any boxes unless notes to

do so. Read the list below for the contents.

Component Parts Box Contents:

(1) RGB Control Assembly (includes switches and LED dimmer)

(1) 12VCD Adaptor (used for LED lighting)

(1) 7.5VCD Adaptor (used for valve system)

(2) Pilot Covers (used inside burner pan area)

(2) 6x12 Black Vents (used to ventilate enclosure)

(12) Black Screws, Nuts & Washers for 6x12 vents

(1) Installation manual for vent kit

(1) 24-inch LED wire harness

(1) 10-foot valve system (module) wire harness

(1) LED 10-foot controller wire harness

Windshield Parts Box Contents:

(2) Glass Windshields (inside firebox)

(4) LED Retainer Clips (2 for singled-sided; 4 for see-through fireplace)

(8) Glass Windshield Clips (4 for singled-sided; 8 for see-through fireplace)

(2) Stainless Steel Hoods (1 for singled-sided; 2 for see-through fireplace)

LED Assemblies Box Contents:

(1) LED Tray Assembly Left

(1) LED Tray Assembly Right

(4) LED Glass Retainer Clips & Pan Head Screws

(8) Windshield Clips & Pan Head Screws

Glass Media Box Contents:

(3-5) bags of diamond crystal media depending on model size (See Table 7 and Figure 33 on Page 24 for reference)

8

IHP.us.com

900861-00NC

FRONT VIEW

TOP VIEW

END VIEW

E

E

C

F

D

A

B

G

Bottom Finish Fin

Hood

1/2”

(13mm)

(Typ. Each Side)

6”

(153mm)

20”

(508mm)

1/2”

(13mm)

(Typ. Each Side)

I

H

END VIEW

SIDEWALL

CEILING

FLOOR

11-1/2”

(292mm)

SINGLE-SIDED FIREPLACE DIMENSIONS AND MINIMUM CLEARANCES TO COMBUSTIBLES

Continued

Model:

Natural Gas (NG)

BarcelonaLights36ZEN

and VRE4636ZEN

BarcelonaLights48ZEN

and VRE4648ZEN

BarcelonaLights60ZEN

and VRE4660ZEN

BarcelonaLights72ZEN

and VRE4672ZEN

A

Overall

Length

40”

(1016mm)

52”

(1321mm)

64”

(1626mm)

76”

(1931mm)

B

Inside

Opening

36”

(915mm)

48”

(1219mm)

60”

(1524mm)

72”

(1829mm)

C

Overall

Height

37-1/2”

(953mm)

37-1/2”

(953mm)

37-1/2”

(953mm)

37-1/2”

(953mm)

D

Opening

Height

16”

(407mm)

16”

(407mm)

16”

(407mm)

16”

(407mm)

E

Overall

Depth

16-1/4”

(413mm)

16-1/4”

(413mm)

16-1/4”

(413mm)

16-1/4”

(413mm)

F

Leg

Height

11-1/2”

(292mm)

11-1/2”

(292mm)

11-1/2”

(292mm)

11-1/2”

(292mm)

G

Valve

Box Depth

8-3/4”

(222mm)

8-3/4”

(222mm)

8-3/4”

(222mm)

8-3/4”

(222mm)

H

Clearance To

Combustible Side Wall

6”

(153mm)

6”

(153mm)

6”

(153mm)

6”

(153mm)

Table 3 - Fireplace dimensions and clearances. Ensure you follow the proper clearances during installation.

I

Clearance To

Combustible Ceiling

42-1/2”

(1080mm)

42-1/2”

(1080mm)

42-1/2”

(1080mm)

42-1/2”

(1080mm)

Figure 6 - Single-sided fireplace clearance to combustibles

(See Table 3)

900861-00NC

Figure 5 - Fireplace dimensions; refer to Table 3.

IHP.us.com

Combustible

Material Permitted

Combustible

Shelf

Metal Studs

Non-Combustible

Facing Material

TOP OF

12”

(305mm)

6”

(153mm)

18”

(457mm)

12”

(305mm)

FIREPLACE

END VIEW

Figure 7 - Open front fireplace mantel clearances

9

A

B

Metal Studs Metal Studs

*

Metal studs shown in gray.

Bottom Support Fin

Hood

C

Metal Studs

Metal Studs

Top view showing 1/2” lip using

non-combustible facing material at front face

(Front)

SINGLE-SIDED FRAMING DIMENSIONS WITH METAL STUDS

Model:

Natural Gas (NG)

BarcelonaLights36ZEN or VRE4636ZEN

BarcelonaLights48ZEN or VRE4648ZEN

BarcelonaLights60ZEN or VRE4660ZEN

BarcelonaLights72ZEN or VRE4672ZEN

Table 4 - Fireplace framing dimensions.

NOTE: This outdoor fireplace is not a

“load bearing” fireplace. All finishing

materials must be supported by the

surrounding structure and not rely on

the fireplace itself.

A

Width

40-1/2” (1029mm) 37-3/4” (959mm) 16-1/4” (413mm)

52-1/2” (1334mm) 37-3/4” (959mm) 16-1/4” (413mm)

64-1/2” (1638mm) 37-3/4” (959mm) 16-1/4” (413mm)

76-1/2” (1943mm) 37-3/4” (959mm) 16-1/4” (413mm)

B

Height

C

Depth

Top view showing 1/2” (13mm) lip using

non-combustible facing material at front face

NOTE: This fireplace requires metal

studs for framing. Wood studs are not

permitted.

Figure 8 - Framing dimensions using all non-combustible materials for single-sided fireplace; refer to Table 4.

10

IHP.us.com

900861-00NC

SEE-THROUGH FIREPLACE DIMENSIONS AND CLEARANCES

NOTE: Preparation for the LED lighting and the inlet gas line must be

planned before the fireplace is installed. See Page 5, Figure 1 for inlet

gasline and Page 15 for LED lighting.

SEE-THROUGH FIREPLACE

DIMENSIONS AND

CLEARANCES SECTION

This fireplace comes with various boxes prepackaged inside the fireplace. Do not discard

any boxes unless notes to do so. Read the list below for the contents.

Component Parts Box Contents:

(1) RGB Control Assembly (includes switches and LED dimmer)

(1) 12VCD Adaptor (used for LED lighting)

(1) 7.5VCD Adaptor (used for valve system)

(2) Pilot Covers (used inside burner pan area)

(2) 6x12 Black Vents (used to ventilate enclosure)

(12) Black Screws, Nuts & Washers for 6x12 vents

(1) Installation manual for vent kit

(1) 24-inch LED wire harness

(1) 10-foot valve system (module) wire harness

(1) LED 10-foot controller wire harness

Windshield Parts Box Contents:

(2) Glass Windshields (inside firebox)

(4) LED Retainer Clips (2 for singled-sided; 4 for see-through fireplace)

(8) Glass Windshield Clips (4 for singled-sided; 8 for see-through fireplace)

(2) Stainless Steel Hoods (1 for singled-sided; 2 for see-through fireplace)

LED Assemblies Box Contents:

(1) LED Tray Assembly Left

(1) LED Tray Assembly Right

(4) LED Glass Retainer Clips & Pan Head Screws

(8) Windshield Clips & Pan Head Screws

900861-00NC

Glass Media Box Contents:

(3-5) bags of diamond crystal media depending on model size (See Table 7 and Figure

33 on Page 24 for reference)

IHP.us.com

11

BACK VIEW REAR PANEL INSTALLED

BACK VIEW REAR PANEL REMOVED

Bottom Finish Fin

Side View Detail for Removal Rear Panel Screws

SEE-THROUGH FIREPLACE DIMENSIONS AND CLEARANCES

Continued

If you have determined to install the fireplace as a see-through model then you will need to remove the rear back panel to convert it.

Before removing the rear back panel be sure to remove the contents

out of the firebox area. NOTE: The fireplace is shipped with glass

windshields and parts prepackaged inside the firebox area that can

interfere with removal of the rear panel.

CAUTION: WATCH FOR SHARP EDGES.

CAUTION

SHARP EDGES - WATCH YOUR FINGERS

Wear gloves to guard against any

sharp metal edges.

Use the following steps:

NOTE: The numbers of screws to remove will vary with each fireplace model.

Step 1. Look at the back side of the fireplace. Around the outer perimeter area of the frame or back wall are several screws to remove

(See the shaded area in Figure 9). Only remove the top and bottom

screws on the rear panel.

Step 2. The back panel will not be used again in the see-through

application. Discard back panel and screws.

NOTE: When converting to the see-through fireplace the glass

windshield clips will need to be installed. See Figures 18 and 19

on Page 16. The clips will be packaged with the glass windshields.

The see-through fireplace requires windshields on both sides for

proper operation.

Figure 9 - Removing back wall to convert to see-through model.

12

IHP.us.com

900861-00NC

FRONT VIEW

TOP VIEW

END VIEW

E

E

C

F

D

A

B

Bottom Finish Fin

Hood

1/2”

(13mm)

(Typ. Each Side)

6”

(153mm)

20”

(508mm)

G

1/2”

(13mm)

(Typ. Each Side)

I

H

END VIEW

SIDEWALL

CEILING

FLOOR

11-1/2”

(292mm)

SEE-THROUGH FIREPLACE DIMENSIONS AND MINIMUM CLEARANCES TO COMBUSTIBLES

Continued

This fireplace ships from the factory as a single sided fireplace, but by removing the back panels you can convert it into a see-through fireplace. Your

specific application, single sided verses see-through, will determine your installation. Ensure you follow the proper clearances during installation.

Model:

Natural Gas

(NG)

BarcelonaLights36ZEN or VRE4636ZEN

BarcelonaLights48ZEN or VRE4648ZEN

BarcelonaLights60ZEN or VRE4660ZEN

BarcelonaLights72ZEN or VRE4672ZEN

A

Overall

Length

40”

(1016mm)

52”

(1321mm)

64”

(1626mm)

76”

(1931mm)

Inside

Opening

(915mm)

(1219mm)

(1524mm)

(1829mm)

Table 5 - Fireplace dimensions and clearances.

B

36”

48”

60”

72”

C

Overall

Height

37-1/2”

(953mm)

37-1/2”

(953mm)

37-1/2”

(953mm)

37-1/2”

(953mm)

D

Opening

Height

16”

(407mm)

16”

(407mm)

16”

(407mm)

16”

(407mm)

E

Overall

Depth

16”

(407mm)

16”

(407mm)

16”

(407mm)

16”

(407mm)

F

Leg

Height

11-1/2”

(292mm)

11-1/2”

(292mm)

11-1/2”

(292mm)

11-1/2”

(292mm)

G

Valve

Box Depth

8-3/4”

(222mm)

8-3/4”

(222mm)

8-3/4”

(222mm)

8-3/4”

(222mm)

H

Clearance To

Combustible Side Wall

36”

(915mm)

36”

(915mm)

36”

(915mm)

36”

(915mm)

I

Clearance To

Combustible Ceiling

42-1/2”

(1080mm)

42-1/2”

(1080mm)

42-1/2”

(1080mm)

42-1/2”

(1080mm)

Figure 10 - Fireplace dimensions; refer to Table 5

Figure 11 - See-through fireplace clearance to combustibles

(See Table 5)

900861-00NC

Combustible Shelf

12”

(305mm)

Combustible

Material

Permitted

6”

(153mm)

Combustible Shelf

Non-combustible

facing material

Metal Studs

TOP OF

FIREPLACE

END VIEW

Figure 12 - See-through fireplace mantel clearances

IHP.us.com

12”

(305mm)

6”

(153mm)

18” TYP.

(457mm)

12”

(305mm)

13

SEE-THROUGH FRAMING DIMENSIONS WITH METAL STUDS

A

B

Metal Studs Metal Studs

*

Metal studs shown in gray.

Bottom Support Fin

Hood

C

Metal Studs

Metal Studs

Top view showing 1/2” (13mm) lip using

non-combustible facing material at front face

(Front)

Model:

Natural Gas (NG)

BarcelonaLights36ZEN or VRE4636ZEN

BarcelonaLights48ZEN or VRE4648ZEN

BarcelonaLights60ZEN or VRE4660ZEN

BarcelonaLights72ZEN or VRE4672ZEN

Table 6 - Fireplace framing dimensions.

NOTE: This outdoor fireplace is not a

“load bearing” fireplace. All finishing

materials must be supported by the surrounding structure and not rely on the

fireplace itself.

A

Width

40-1/2” (1029mm) 37-3/4” (959mm) 15” (381mm)

52-1/2” (1334mm) 37-3/4” (959mm) 15” (381mm)

64-1/2” (1639mm) 37-3/4” (959mm) 15” (381mm)

76-1/2” (1943mm) 37-3/4” (959mm) 15” (381mm)

B

Height

Top view showing 1/2” (13mm) lip using

non-combustible facing material at front face

C

Depth

NOTE: This fireplace requires metal studs

for framing. Wood studs are not permitted.

Figure 13 - Framing dimensions using all non-combustible materials for see-through fireplace; refer to Table 6.

14

IHP.us.com

900861-00NC

Burner Pan

Support leg under fireplace

B

o

t

to

m

su

pp

o

r

t

f

i

n

GFCI Outlet installed in a double

outlet NEMA 3R enclosure

(Bring electrical up

from underneath

the fireplace)

GFCI Outlet installed in a double

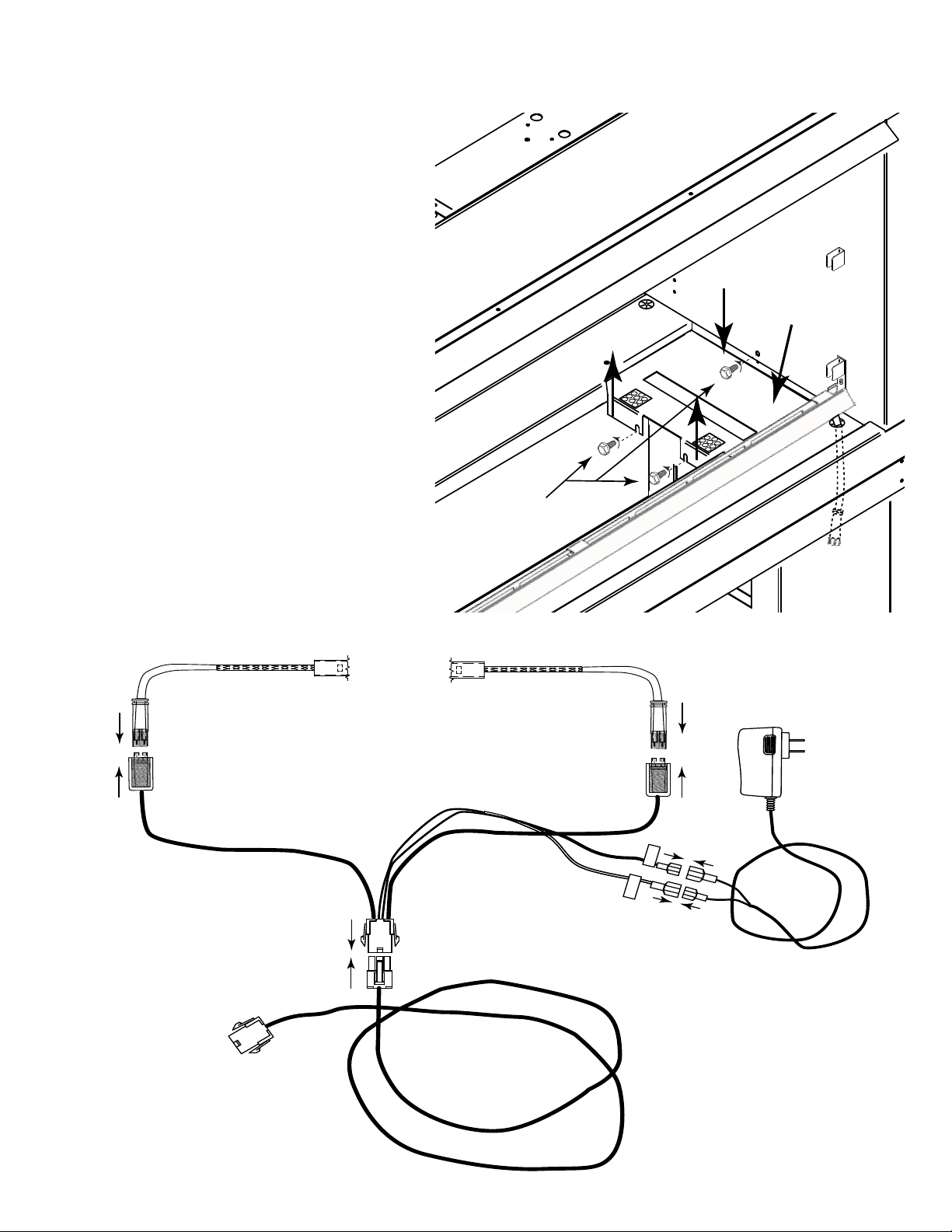

outlet NEMA 3R enclosure

36” Model = 13” (330mm)

48“ Model = 18” (457mm)

60“ Model = 24” (610mm)

72” Model = 30” (762mm)

5”

11-1/2”

(292mm)

TYP

Electrical Area (GFCI)

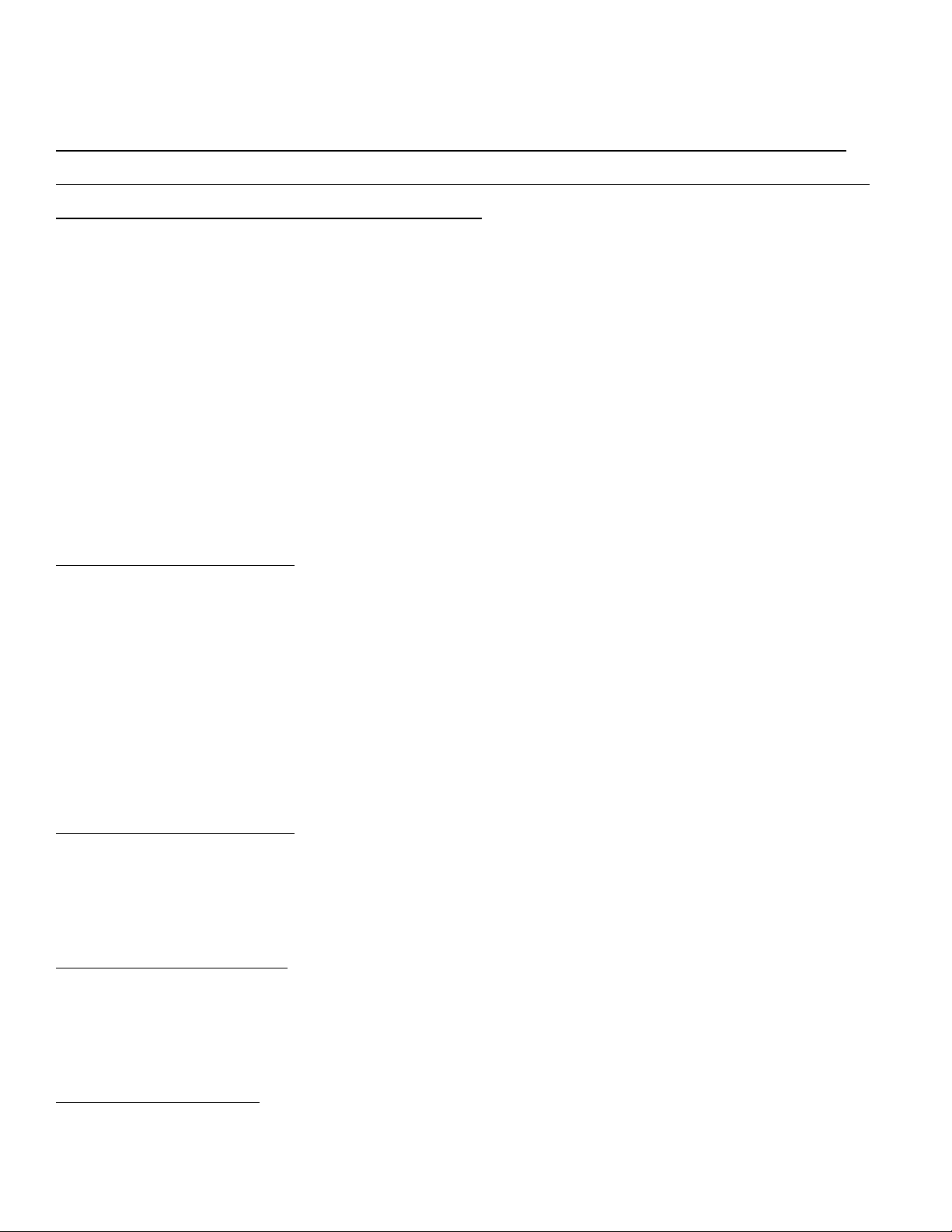

The electric junction box (GFCI) with a weatherproof cover must be installed in the

shaded area shown below. Ensure the j-box is close to the floor area where the

fireplace is sitting and not touching the burner pan.

LED LIGHTING INSTALLATION

This fireplace is equipped with LED lighting. Preparation for the LED lighting a must be planned before the fireplace finish materials

are installed. After the fireplace is set in its final location the LED lighting will need to be installed and tested before finishing materials are

applied. You will need to provide the following:

(1) 120VAC GFCI outlet double gang junction box with a weatherproof cover. Provides power to LED lights. Must be accessible for service.

Follow local electrical codes for installation.

A triple gang junction box with switches is provided with the fireplace. It must be installed within the framing parameters of the fireplace.

Step 1: Install the GFCI outlet double

gang junction box with a weatherproof

cover on the opposite side of the inlet

gas supply.

NOTE: This is not a requirement; however, with the gang box on the opposite

side of inlet will create more room for

LED installation.

Figure 16 shows GFCI gang box installed.

Figure 14 - Electrical Placement

Step 2: Find mounting location for the GFCI gang box. Figure 15 shows flat area underneath burner pan. Mount box underneath the burner

pan, below the square (cutout) hole area. Figure 16 shows the GFCI outlet double gang junction box with a weatherproof cover mounted

underneath the fireplace.

Figure 15 - GFCI box location under fireplace

900861-00NC

Figure 16 - Show GFCI box mounted in fireplace

IHP.us.com

15

LED LIGHTING INSTALLATION

Continued

Step 3: Locate the wire grommets inside the firebox. See Figure 17. Directly above them will be a series of mounting holes for the wind-

shield and LED retainer clips. Prepare the fireplace by installing the LED retainer clips. The retainer clips have two holes in them. Install

one (1) clip on the left and one (1) clip on the right side of the inner fireplace side wall. Install as shown in Figure 18.

NOTE: If you are preparing a see-through fireplace you will install a total of (4) retainer clips, two on open side.

Wire Grommets

LED Retainer Clip

Figure 17 - Locating wire grommets

Step 4: Install the four (4) windshield clips, two on each side, one at the top and one with the LED retainer clip as shown in Figure 19.

NOTE: if you are preparing a see-through fireplace you will install a total of (8) windshield clips, four on each open side.

PRECAUTION: When installing windshield clips do not secure the

screws tight. They need to be loose enough to allow the clip to

move slightly and spin around. Loose clips provide windshield to

be easily installed.

Figure 18 - Shows clip installed on right side of fireplace

16

Figure 19 - Installing windshield clips

IHP.us.com

900861-00NC

B

o

t

to

m

E

n

d

B

o

t

to

m

E

n

d

LED LIGHTING INSTALLATION

Continued

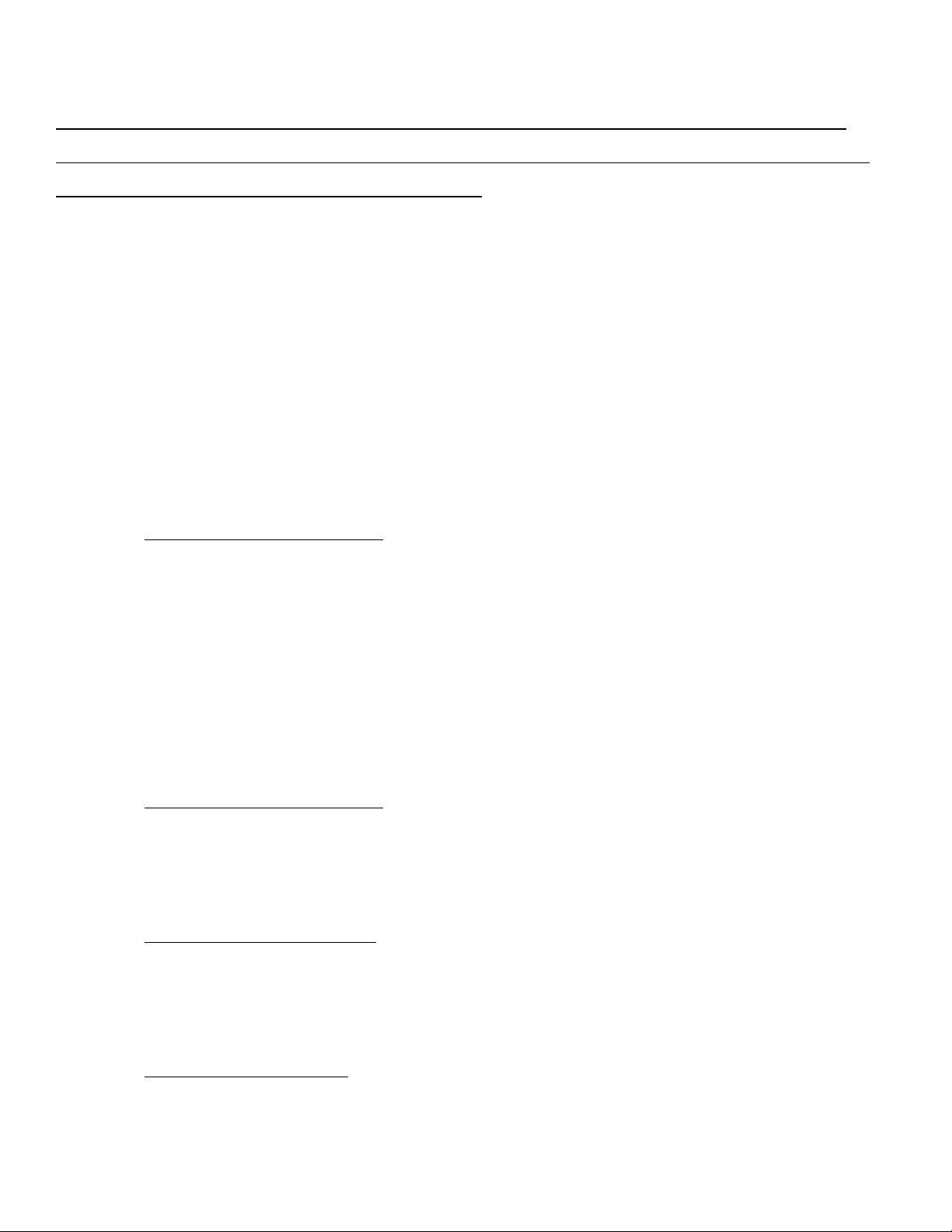

Step 5: Remove the LED right channel assembly from the carton (The front of the channel has a shield facing the front with the LED wire

hanging on the right side). See Figure 20 and Figure 21 for details. NOTE: If you are installing into a see-through fireplace you will install

both right and left channels assemblies.

Figure 20 - Shows LED right channel

Step 6: Carefully push the LED channel assembly connector through the wire grommet. As you push it through the grommet sit the channel into the retainer clip. Ensure the other end of the channel is also sitting inside the other retainer clip. See Figures 21 and 22 as a reference. NOTE: If you are installing into a see-through fireplace install the other LED light strip and channel the same direction.

LED Channel

Assembly

t

e

mm

o

Gr

e

r

i

W

Figure 21 - Installing LED lights and channel

LED Channel Assembly

Installed in retainer clip

Figure 22 - LED installed in retainer clip inside fireplace

900861-00NC

IHP.us.com

17

Bottom End

1. Remove Screws

2. Lift up

3. Push down

V+

LED Lights

Male

Female

Female

Male

LED Lights

From

Fireplace

Inside Fireplace

LED Light Connection

12-volt adaptor;

6-foot long

Cat. No. F3481

24-inch LED Wire Harness,

Cat. No. F3499

10-foot LED Controller Wire

Harness, Cat. No. F3500

Connects to RGB Control Assembly

(dimmer and switches)

Female

Male

Female

Male

Male

Female

LED LIGHTING INSTALLATION

Step 7: Remove the (3) screws from the “bottom end” of

the burner pan area. The bottom end part fills the space

between the burner pan and the fireplace side panel. It is

held into place with three (3) screws. See Figure 23.

First remove the two inside screws, then the screw securing the side wall. Lift up the area where the two screws

were and push down where the single screw was, then lift

the bottom end out of the fireplace.

Step 8: With bottom end removed, wire part, Cat. No.

F3499 (LED Wire Harness) female connectors to the LED

male connectors protruding through the wire grommets.

The male end of the LED connector will lock into the female

connector in one direction only. Once locked in position,

screw the threaded cap of the female connector securely

to the male connector. NOTE: If you are only using one set

of LED lights the other female connector of Cat. No. F3499

will not be used. See Figure 24.

Step 9: After connecting the LED lights into the LED Wire

Harness insert the 12-volt adaptor (1/4” terminals) into the

(red and black wires) of LED wire harness. Plug the 12volt adaptor into the 120VAC GFCI box with weather proof

cover.

Continued

Figure 23 - Removing bottom end

Figure 24 - LED Wire Connection

18

IHP.us.com

900861-00NC

LED LIGHTING INSTALLATION

RGB DIMMER

Cover Plate Surrounding Switch Plate

Remove screws to mount switch plate

Remove screws to mount switch plate

LED

ON/OFF

ON/OFF

LOW

HIGH

LEARN

CONT.

PILOT

RGB DIMMER

Mounting plate under switch cover

LED

ON/OFF

ON/OFF

LOW

HIGH

LEARN

CONT.

PILOT

5-5/8”

(143mm)

5-5/8”

(143mm)

Continued

Step 10: Remove the RGB control box from the components parts

carton. The fireplace is supplied with 10-feet of wiring for the RGB

control box (switches and dimmer) installation. Find a suitable location within a close proximity of the fireplace for convenience of

operation and mount the control box upright and level as shown in

Figure 27. Use Figures 25 and 26 for dimensional reference.

CAUTION: ENSURE ALL SWITCHES ARE IN THE OFF POSITION.

“I” INDICATES IGNITE/ON AND “O” INDICATES OFF. LEARN BUTTON DOES NOT APPLY.

Step 11: Remove the four (4) outer screws from each corner in-

side the cover plate and lift off. See Figure 25. This will expose

the mounting plate. See Figure 26. CAUTION: DO NOT REMOVE

THE TWO CENTER SCREWS FROM THE COVER PLATE. THIS WILL

RELEASE THE ENTIRE SWITCH BOX WIRING FROM INSIDE THE

JUNCTION BOX AND MAKE IT DIFFICULT TO REINSTALL.

Take note of the 8-PIN and 6-PIN wire connectors. These are labeled LED lights (6-PIN) and Control Module (8-PIN) connections.

These will be the final connection to the fireplace and crucial to the

operation.

Step 12: Mount the RGB control box into the desired location.

CAUTION: AVOID USING EXCESSIVE FORCE WHEN INSTALLING

ANY CONNECTORS.

Step 13: Remove the 8-PIN module wire harness (Cat. No. F3501)

from the components part box. Locate the 8-PIN male connector

from the valve box (under the fireplace) and connect it to the 8-PIN

female end of the wire harness. Connectors only attach one way;

press together until it snap locks into place. See Figure 27 for details.

Step 14: Feed the other end of the wire harness through the square

access hole underneath the fireplace and pass the GFCI box, outside

the fireplace to the RGB control box and connect. Connectors only

attach one way; press together until it snap locks into place.

Step 15: Locate the two 1/4” male terminals from the valve box

and connect the AF-4000ADP24 adaptor (Cat. No. F3482). Plug the

7.5VDC adaptor into the 120VAC GFCI box.

Step 16: Locate the 6-PIN wire harness (Cat. No. F3500) for the

LED lights and feed the wire harness up to the RGB control box and

attach. Connectors only attach one way; press together until it snap

locks into place. See Figure 27.

Figure 25 - RGB Control Box with 8-3/4” x 8-3/4” Cover Plate

900861-00NC

Figure 26 - RGB Control Box Mounting Plate

IHP.us.com

19

Switch Cover

LED ON/OFF

ON/OFF

HI/LOW

LEARNIPI/CONT PILOT

RGB DIMMER

ID# AF4000ADP48EXT

(order Remote Wire Harness

[F2690], if needed)

ID# 77113

(order RGB Control Box

[F3483], if needed)

Cat. No. F3482

Cat. No. F3481

Cat. No. F3501

ID# 77115

(order RGB Control Box

[F3483], if needed)

LED LIGHTING INSTALLATION

Continued

Figure 27 - Overview of fireplace wiring

20

IHP.us.com

900861-00NC

(Under glass panels)

LED LIGHT STRIPS

weatherproof box)

Cat. No. F3481

(12VDC adaptor inside a

gas valve system)

Cat. No. F3482

(7.5VCD adaptor powers

(Inside valve box)

VCS-ECOMOD

Continued

LED LIGHTING INSTALLATION

Cat. No. F3501

Cat. No. F3499

BLUE TERMINAL

R

B

R

B

BL

G

R

B

R

B

BL

G

RED TERMINAL

[F3483] if needed)

ID# 77115

(order RGB control box

Cat. No. F3501

BL

BR

BL

BR

LED CONTROLLER BOX

B

Y

INSIDE FIREPLACE

REPRESENTS COMPONENTS

B

Y

G = Green

R = Red

Y = Yellow

900861-00NC

G

INPUT OUTPUT

[F3483] if needed)

ID# 77112

(order RGB control box

BL

B

R

R

RGB DIMMER

REPRESENTS COMPONENTS INSIDE

G

BL

B

R

Red

R

B

LED

ID# 77113

Brown

ON/OFF

[F3483] if needed)

(order RGB control box

Blue

ON/OFF

[F3483] if needed)

ID# 77114

(order RGB control box

HI/LOW

Yellow

BR

IPI/

Y

BL

CONT

B

PILOT

Wiring Color Code

Black

LEARN

B = Black

BL = Blue

BR = Brown

Figure 28 - This wiring diagram shows the LED circuit in relationship to the IPI gas valve control system. Each is independent of the other.

21

LED LIGHTING INSTALLATION

VALVE SAFETY WIRE

(V-Wire)

CAT. NO. F3482

ADAPTOR PLUGS INTO

WEATHERPROOF BOX

VCS-ECOMOD

(Control Module)

1/2 PSI

SPAIN

INLET

OUTLET

PILOT TUBE

S

I

SWITCHES

POWER

MOTOR COMM.

BATT

V

BRONZE INSULATED WIRE

BLACK WIRE

BRASS WIRE

(GROUND)

MOTOR DRIVE WIRES

TO

120VAC

POWER

SWITCHES MOUNTED

IN RGB CONTROL

ASSEMBLEY

LOW RATE

SET SCREW

Continued

These Fireplaces are equipped with an electronic gas valve and has an IPI//CPI electronic ignition system. The IPI/CPI switch allows

the pilot to be switched from intermittent mode to continuous mode:

• (IPI) Intermittent Mode—The pilot is extinguished when the fireplace is OFF.

• (CPI) Continuous Mode—The pilot stays ON when the fireplace is OFF.

Figure 29 - This wiring diagram shows the components inside the valve box. The dotted line box shows the components external of

the valve box.

22

IHP.us.com

900861-00NC

Fireplace Side Wall

P

i

l

o

t

C

o

v

e

r

B

ur

n

e

r

B

ur

n

e

r

E

n

d

FINAL PREPARATION

When the fireplace is framed into position and the gas line is run in

place it is recommended to burn test the fireplace before the finish

work is complete. This will ensure proper operation and enables the

installer to check for any gas leaks at the fireplace.

NOTE: The pilot covers have a plastic film that must be removed

before installing.

REMOVE PLASTIC FILM

FROM PILOT COVER

No media allowed

in shaded area

Once the burner pan assembly is secured into position, the pilot covers must be installed (one on each side). After you have removed the

plastic film install the pilot covers into the open slot of each burner

end (spacers that center the burner) with the open side of pilot cover

facing toward the fireplace side wall (See Figures 30 and 31).

NOTE: Even though there is no pilot on the opposite end the other

pilot cover provides combustion air evenly to the burner for operation.

No media allowed

in shaded area

Figure 30 - Installing pilot cover

900861-00NC

Figure 31 - Pilot cover installed

IHP.us.com

23

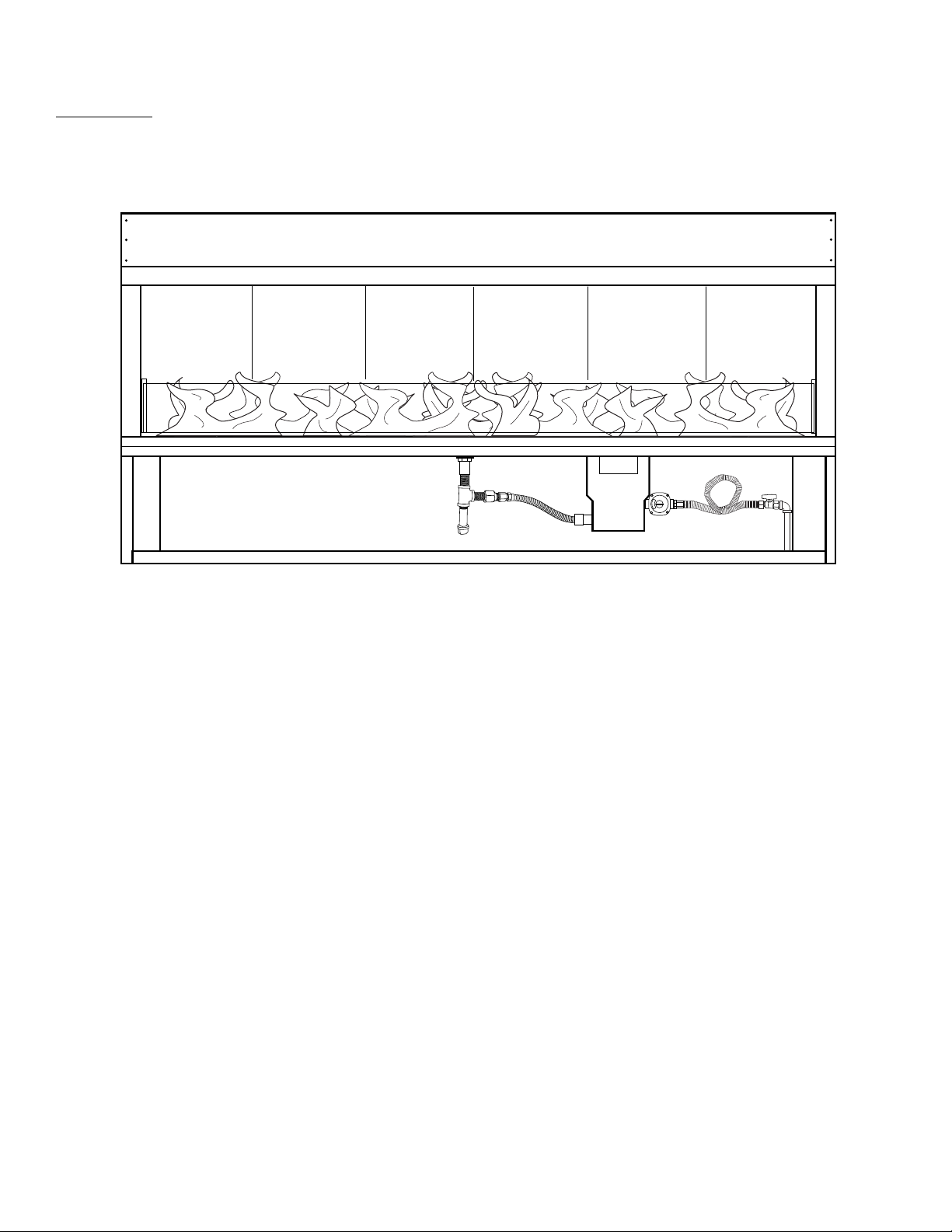

FINAL PREPARATION

BURNER PAN ASSEMBLY

Pilot

(Hidden Underneath)

Burner

Tube

Ignition

Hole

Continued

PILOT OPERATION & TEST FIRE

The pilot assembly is located at the end of the burner hidden underneath a pilot cover. Ensure the pilot flame is passing through the

ignition hole in the burner pan for proper ignition. Use the Figure

32 as a guide.

Test fire the fireplace before installing media. At the same time

this is a good time to double check for any gas leaks or electrical

connections before finalizing the installation by installing the glass

media.

INSTALLING MEDIA

Open the media box and install the glass media as shown is Figures

33 and 34. Place media fireglass into the trough area first as shown

in Figure 33. Use the remaining media to fill the burner pan equally

on both sides. After filling the trough reinstall the mesh hood overtop of the pilot area.

Keep media in burner pan the same level as the trough to allow the

burner area to appear as one complete burner pan.

Figure 32 - Proper pilot flame through ignition hole

1/2” to 3/4”

Glass Media

IMPORTANT: Media can only be placed in the trough and burner

pan area. No media is to be place into the shaded area shown in

Figure 35.

CAUTION: Ensure there is no media in the ignition hole area. The

burner tube gas ignites in this area to light the fireplace. Media in

this area could cause delayed ignition.

The fireplace requires 1/2”-3/4” large broken fireglass to be installed into the burner trough and burner pan. Use the table below

to assist in determining the amount of media needed for your specific model.

Large Broken Glass

Model # Burner pan & Trough

36”

48”

60”

72”

Qty 3 (5# bags)

Qty 4 (5# bags)

Qty 5 (5# bags)

Qty 5 (5# bags)

Table 7 - Media specifications. Requires 1/2” - 3/4” fireglass

(burner pan media amount does not include the trough)

Burner Trough

Figure 33 - Installing media into the fireplace.

24

Cat. No. Model Description

Table 8 - Glass Media

IHP.us.com

F3507 GLO-BLACK Black Onyx Glass Media, 5lb

F3508 GLO-CRYSTAL Diamond Crystal Glass Media, 5lb

F3509 GLO-LT BLUE Sapphire Blue Glass Media, 5lb

900861-00NC

CAUTION

HOT SURFACE

DO NOT TOUCH

FINAL PREPARATION

GLASS WINDSHIELD

Glass Clips

Burner Pan End View Showing Media Placement

Proper Media Height

Burner Tube

Continued

No Media in

Shaded Areas

Figure 34 - End view of burner with media

NOTE: Media amounts listed in Table 7 are guides and can vary

depending on media used. Ensure not to cover more than 1/2-inch

above the actual burner tube and keep all media within the burner

pan area (see Figures 33, 34, and 35).

CAUTION: It is important to ensure proper glass media placement

per instructions in this manual. Verify the pilot flame is not obstructed.

No Media on Igni

tion Hood

Figure 35 - Covering the entire fireplace floor is NOT permitted in

the shaded area

-

Large Broken Glass in

Burner Trough and

Burner Pan

Figure 36 - Windshield clips location

900861-00NC

WARNING: During operation of the fireplace the

glass will get hot! Hot glass will cause burns.

DO NOT TOUCH glass until cooled.

NEVER allow children to touch the glass.

IHP.us.com

25

FINAL PREPARATION

GLASS WINDSHIELD

Side View

Installing Glass

Rotate top

clip to a 45°

angle

Glass Windsheid

Installed

1

2

3

Side View

Rotate Top Clip

LED Channel

Cover

Continued

INSTALLING HOOD(S)

The fireplace requires hoods to be installed into the upper opening of the firebox. If you are installing a single-sided fireplace you only install one (1) hood. NOTE: If you are installing a see-through fireplace a hood is required on both sides of the fireplace opening. All models

require five (5) screws to secure the hood to the fireplace except the 72-inch model, which uses seven (7) screws to secure the hood. The

hood protrudes 1-inch from fireplace opening.

Figure 37 Shows hole location and installation process for hood installation. The protruding area of the hood is to be angled downward

for proper installation, see Hood Detail below.

Hood Screw Locations

Figure 37 - Installing hood(s) on the fireplace

FRONT VIEW

SIDE VIEW

Hood

End View

(Deflector Facing Downward)

INSTALLING WINDSHIELD(S)

Before installing the windshields first rotate the top windshield clip

to approximately 45°. See Figure 38. Next while holding the glass

panel horizontally slide the bottom end on each side into the top

windshield clip. Then slide the entire windshield down into the lower

clip and rest on top of the LED channel cover.

Hood Detail

Figure 38 - Installing glass windshield into fireplace

26

IHP.us.com

900861-00NC

FINAL PREPARATION

Continued

FLAME HEIGHT

Proper flame height (Figure 39) should be at the top edge of glass windshield (peaking above at times) while on HI setting. The LO setting

will be at least half of the height of HI or maybe lower. There can be a variance in flame height between Natural gas and Liquid Propane

(LP) gas models.

Figure 39 - Proper flame height

900861-00NC

IHP.us.com

27

OPERATION

RGB DIMMER

Mounting plate under switch cover

LED

ON/OFF

ON/OFF

LOW

HIGH

LEARN

CONT.

PILOT

5-5/8”

(143mm)

5-5/8”

(143mm)

CAUTION: Children and adults should be alerted to the hazards

on high surface temperatures and should stay away to avoid

burns or clothing ignition. Young children should be carefully supervised when they are in the area of the appliance.

WARNING: Do not use this appliance if any part has been under

water. Immediately call a qualified service technician to inspect

the appliance and to replace any part of control system and any

gas control, that has been under water.

SAFETY WARNINGS

1. Never leave the fireplace unattended during operation.

2. Clothing or other flammable materials should not be hung

from the appliance or placed on or near the appliance.

3. Any guard or other protective device removed for servicing

the appliance must be replaced prior to operating the appliance.

4. Installation and repair should be done by a qualified service

person. The appliance should be inspected before use and at

least annually by a qualified service person. More frequent

cleaning may be required as necessary. It is imperative the

control compartment, burners and circulating air passageways of the appliance be kept clean.

5. Inspect the fuel supply connection before each use of the appliance.

6. Temporary storage of this appliance indoors is permissible

only if it has been disconnected from its fuel supply (Natural

or L.P. gas line).

is purged). During this time, an “Ignition In-Process” beeping

pattern will take place. (e.g. one short beep, pause, three short

beeps, pause; repeated until ignition occurs). NOTE: Beeping

pattern may be difficult to hear outdoors.

3. The main flame ignites (defaults) in the HIGH position. Press

the “I” on the LOW/HIGH button to adjust to the LOW setting.

4. A continuous pilot flame can be turned ON or OFF with the continuous pilot button.

5. Push the “I” on the LED ON/OFF switch. LED’s will turn ON. Adjust the intensity of the lighting by turning the knobs clockwise

on each dimmer knob. There is infinite color combina-

tions by adjusting the dimmer knobs to personal taste.

HOW TO TURN OFF

1. To turn OFF the fireplace press the “O” position on the ON/OFF

switch. This will turn OFF the fireplace. NOTE: Fireplace must

be OFF for 5-minutes before relighting.

To turn OFF the LED lights in the fireplace press the “O” position

on the LED ON/OFF switch. This will turn OFF the LED lights.

The LED lights are independent of the fireplace and can be used

when the fireplace is not in operation.

WARNING

1. This appliance is hot when operated and can cause severe

burns if contacted.

2. Do not burn any solid fuels in this appliance.

3. These appliances are not designed or intended to be used for

cooking. Do not barbecue, heat food, or roast marshmallows

in this appliance. Doing so could damage the appliance and

cause injury.

4. These appliances are not designed or intended to be used for

cooking. Do not barbecue, heat food, or roast marshmallows

in this appliance. Doing so could damage the appliance and

cause injury.

LIGHTING INSTRUCTIONS

READ ALL WARNING AND SAFETY INFORMATION ABOVE BE-

FORE ATTEMPTING TO LIGHT FIREPLACE

1. Turn ON main gas supply and check all fittings and connections

for leaks with a soap and water solution.

HOW TO TURN ON

2. Push the “I” on the ON/OFF switch to turn ON (System will take

approximately 7-10 seconds before ignition after the gas line

Figure 40 - Control panel

28

IHP.us.com

900861-00NC

FIREPLACE MAINTENANCE

WARNING

• Turn off gas and any electrical power before servicing

the appliance.

• Let fireplace completely cool before cleaning.

• Failure to keep the primary air opening(s) of the

burner(s) clean may result in sooting and property

damage.

• Burner Flame Pattern - If yellow tipping occurs, your

fireplace could produce increased levels of carbon

monoxide. Do not mistake orange flames with yellow

tipping. Dirt or other fine particles enter the fireplace

and burn causing brief patches of orange flame.

CAUTION

You must keep control areas, burner and circulating air

passageways of fireplace clean. Inspect these areas of

fireplace before each use. Have fireplace inspected yearly

by a qualified service person.

Inspect Burner Assembly. If it is evident that the burner is damaged, the burner must be replaced with one specified by the

manufacturer before the appliance is put into operation.

Inspect Burner Flame and Pilot Flame Appearance Periodically do a visual check of the burner flame and the pilot flame.

Ensure that the burner flame appearance resembles the flame

shown in Figure 39, Page 27. Refer to Figure 35 on Page 25 for

more information about the pilot flame appearance. Contact a

qualified service technician at once if any abnormal condition

is observed.

Verify proper operation after servicing.

S’assurer que l’appareil fonctionne adéquatement une fois

l’entretien terminé.

1. The fireplace should be inspected and cleaned before first use

at the beginning of each season by a qualified field service person.

2. Any component that is found faulty must be replaced with an

approved component.

3. Any tampering with or modifying the fireplace is dangerous and

voids all warranties.

4. During winter months in cold climates and various seasons

operation the fireplace may be affected by weather conditions.

It is recommended to use a weather proof cover overtop for

your fireplace to protect it from humid/rainy weather conditions when not in use. Heavy rains/downpours could affect

the fireplace operation if not covered; if this occurs ensure you

allow the fireplace time to dry out before attempting to operate.

NOTE: If a combustible type cover is used over the fireplace

when not in use be sure to remove it before operation to prevent a severe safety hazard.

5. Carbon (soot) may build up on the metal interior during heavy

use. Sooting may also occur periodically under the pilot cover.

CAUTION: Ensure fireplace is cool to touch and gas is turned

OFF. To clean, mix several drops of dish washing liquid into a

bucket of hot water. The dish soap assists in breaking up the

soot and removing it from the metal.

1. Dip a scrubbing sponge into the soapy water and wipe it

back and forth over the soot deposits. This breaks off the

majority of the soot from the metallic surface.

2. Spray any remaining soot deposits with a combination of

warm water and white vinegar mixed in a spray bottle in a

half-and-half solution. White vinegar is slightly acidic and

this helps break up the soot and cleans the metal effectively.

3. Run a nylon scrub brush against any stubborn soot to re-

move it from the metal. Avoid using a metal scrub brush

since this can result in scratching.

4. Buff the metal with a damp rag to remove any remaining

soap or vinegar and then dry it with a dry rag.

6. Over time stainless steel parts can discolor when heated, usually a golden or brown hue. This discoloration is normal and

does not affect the performance of the appliance.

900861-00NC

IHP.us.com

29

GENERAL TROUBLESHOOTING

Symptom Remedy

Fireplace Won’t Light 1. Bleed gas line.

2. Ensure all gas lines are turned ON.

3. Ensure there is not too much media overtop the burner, it can inhibit the gas flow. Too little or no

media can also contribute to non-lighting.

4. Ensure adaptor is plugged in.

5. Verify 120VAC power at junction box under burner pan.

6. Media blocking pilot hole. See Figure 35 on Page 25.

No Spark to Ignite 1. Visually look at igniter for any physical damage.

2. Ensure adaptor is plugged in and reads 7.5VDC

Continues to Spark after Lighting 1. Thermocouple out of alignment.

2. Check connection of thermocouple at “S” terminal on control module to ensure it is connected.

Low Flame 1. Use only glass media provided with appliance or listed in the accessory section of this manual

(see Page 31). Ensure that the media is no more than 1-inch over top of burner.

2. Ensure all shutoff valves are is fully open (see Page 5, Figure 1).

3. Check for spider webs inside burner orifice.

4. Check gas pressure.

Water in my Fireplace 1. Excess dust/sand material from media may be blocking the weep holes to relieve water. Remove

all media and unplug weep holes. Clean or install new media free of dust and dirt.

2. Ensure fireplace has proper drainage for water and proper ventilation to dry out.

Whistling Noises 1. Check media to ensure it is not too tightly packed around the burner tube.

2. Ensure a non-whistling flex connector is being used.

Fireplace Won’t Stay Lit 1. Check alignment of pilot flame through ignition hole on Page 25, Figure 35.

2. Thermocouple reading should be between 10-20mV. Test at the brass ground lead on gas valve

and the gold lead at “S” terminal on the control module. If no minimum millivolts are maintained

replace the TC. Must test with pilot running to obtain readings.

3. Check continuity of thermocouple. Using a volt meter remove the TC test lead “S” from the con-

trol module and the brass fork terminal from the gas valve. Test for continuity. If no continuity

then replace the TC.

4. Ensure thermocouple is clean and free of any debris. Excessive soot can be an issue.

Low Flame Height 1. Wrong media installed into the burner trough.

2. Too much media installed overtop of the trough (See Page 24 for details).

Sooting 1. Incorrect gas for the fireplace. Ensure rating label has proper model number for gas being used.

2. Too much media can cause sooting.

3. Wrong media being used. (See Page 24 for details).

30

IHP.us.com

900861-00NC

ERROR CODE TROUBLESHOOTING

Error Codes

The control module has the ability to detect problems with the

valve kit system and will initiate error codes when they occur.

The error codes listed below will guide you to solving troubleshooting issues.

Ignition Safety Error: One short beep every one second.

Cause: Pilot did not light within the trial period of 50-60 seconds

therefore step motor will turn gas valve to OFF position.

Corrective Action: Press OFF button to clear. Wait 30 seconds and

try again.

Recycle Safety Error: Two short beeps every one second.

Cause: 1. Pilot automatically lights and drops out 3-times within

2-minutes causes step motor to turn gas valve to OFF position. 2.

Someone has pressed the ON/OFF button 6-times within 2-minutes

causing the step motor to turn gas valve to OFF position.

Corrective Action: Press OFF button to clear. After 5-minutes the

beeping will stop then retry.

PRODUCT REFERENCE INFORMATION

Sensor Safety Error: Four short beeps every one second (constant

beeping).

Cause: Pilot flame sensor voltage too high, ground circuit not properly connected, pilot ground wire loose or not connected, or motor

not plugged into control module; therefore, step motor will turn gas

valve to OFF position.

Corrective Action: Press OFF button to clear. Wait 30-seconds to

thermocouple to cool down. If persist, then check other possible

causes and retry.

Thermal Safety: Four short beeps every two seconds.

Cause: System has overheated and exceeded 170°F internal temperature limit and the step motor will turn gas to OFF.

Corrective Action: Internal temperature must cool down to below

160°F then press the OFF button to clear and retry.

Communication Safety: One short beep every four seconds.

Cause: Transmitter and module are not communicating properly.

Could be related to distance greater than 20-feet away from each

other or weak/dead batteries in one or the other.

Corrective Action: Module must receive a signal from transmitter.

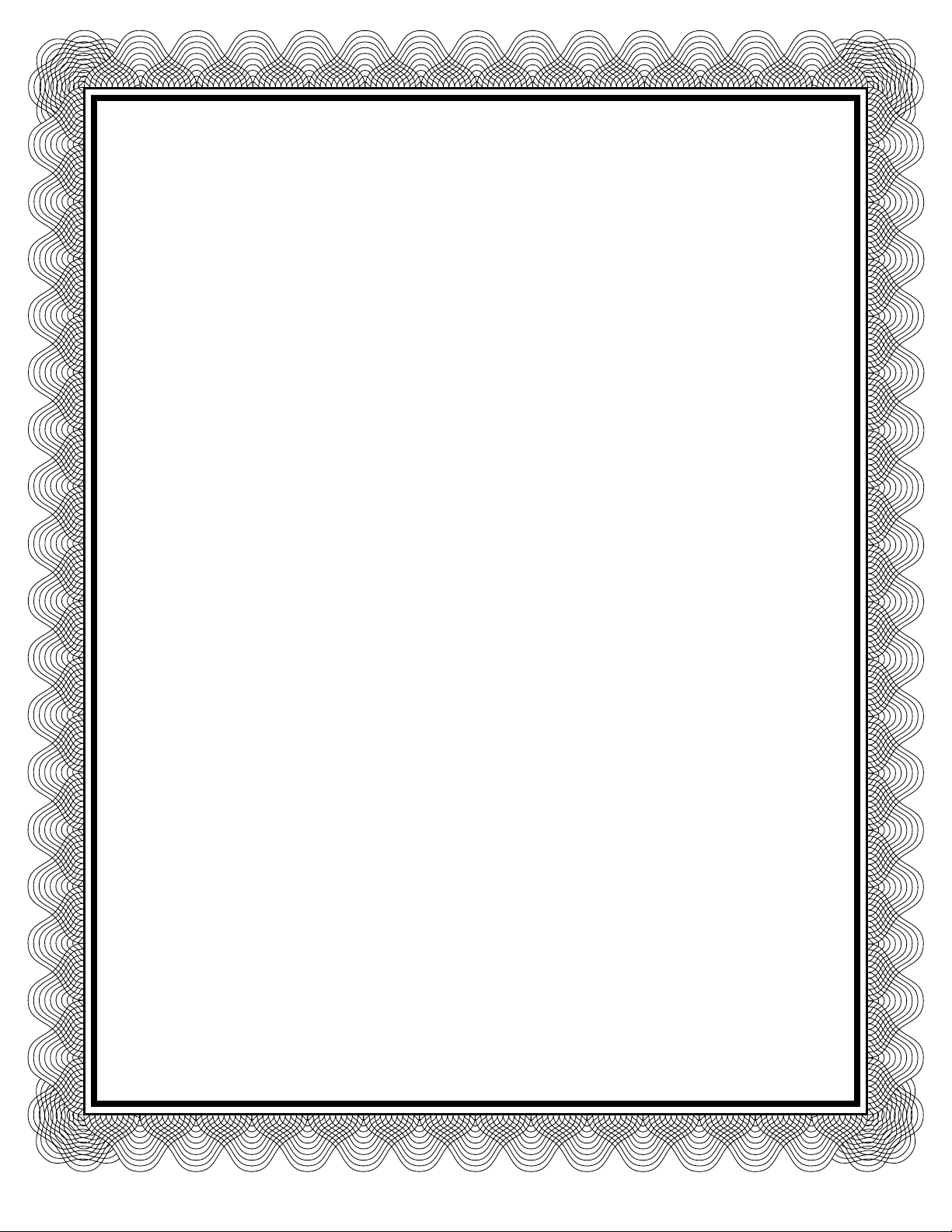

OPTIONAL ACCESSORIES

Product Reference Information

Linear Electronic VF Outdoor Fireplaces

Cat. No. Model Description

F3442 BarcelonaLights36ZEN Astria®, 36”, Natural Gas

F3443 BarcelonaLights48ZEN Astria, 48”, Natural Gas

F3444 BarcelonaLights60ZEN Astria, 60”, Natural Gas

F3445 BarcelonaLights72ZEN Astria, 72”, Natural Gas

F3446 VRE4636ZEN Superior

F3447 VRE4648ZEN Superior, 48”, Natural Gas

F3448 VRE4660ZEN Superior, 60”, Natural Gas

F3449 VRE4672ZEN Superior, 72”, Natural Gas

®

, 36”, Natural Gas

Cat. No. Model# Description

F3502 LPK 1 LP Conversion kit for 36-inch outdoor fireplace

F3503 LPK 2 LP Conversion kit for 48-inch outdoor fireplace

F3504 LPK 3 LP Conversion kit for 60-inch outdoor fireplace

F3505 LPK 4 LP Conversion kit for 72-inch outdoor fireplace

F3507 GLO-BLACK Black Onyx Glass Media, 5lb

F3508 GLO-CRYSTAL Diamond Crystal Glass Media, 5lb

F3509 GLO-LT BLUE Sapphire Blue Glass Media, 5lb

ON

OFF

HI

Remote Control Kit

LO

PILOT

Continuous

Cat. No. Model# Description

F2687 EF-BRCK

Remote Control, Manual ON/OFF operation,

Off / Continuous pilot feature

900861-00NC

IHP.us.com

31

NATURAL GAS TO PROPANE GAS CONVERSION

WARNING

This conversion kit shall be installed by a qualified service

agency in accordance with the manufacturer’s instructions

and all applicable codes and requirements of the authority

having jurisdiction. If the information in these instruction

is not followed exactly, a fire, explosion or production of

carbon monoxide may result causing property damage,

personal injury or loss of life. The qualified service agency

is responsible for the proper installation of this kit. The

installation is not proper and complete until the operation of the converted appliance is checked as specified

in the manufacturer’s instructions supplied with the kit.

The qualified service agency performing this installation

assumes responsibility for this conversion.

AVERTISSEMENT

Cette trousse de conversion doit être installée par un

technicien agréé, selon les instructions du fabricant et

selon toutes les exigences et tous les codes pertinents

de l’autorité compétente. Assurez-vous de bien suivre les

instructions dans cette notice pour réduire au minimum

le risque d’incendie, d’explosion ou la production de

monoxyde de carbone pouvant causer des dommages

matériels, des blessures ou la mort. Le tecnicien agréé

est responsable de l’installation de cette trousse.

L’installation n’est pas adéquate ni complète tant que

le bon fonctionnement de l’appareil converti n’a pas été

vérifié selon les instructions du fabricant fournies avec

la trousse. Le fournisseur de service qualifié ayant

réalisé l'installation assume les responsabilités liées à

la conversion.

KIT CONTENTS

(1) OAS-LP# (brass orifice) and

(1) ECO-LSS# (brass low rate set screw),

(1) LP Conversion Label (placed next to blank space on rating label),

(1) Installation Instruction Sheet

CAUTION: THE GAS SUPPLY SHALL BE SHUT OFF PRIOR TO DISCONNECTING THE ELECTRICAL POWER, BEFORE PROCEEDING

WITH THE CONVERSION.

ATTENTION: AVANT D’EFFECTUER LA CONVERSION,

COUPEZ D’ABORD L’ALIMENTATION EN GAZ, ENSUITE, COUPEZ

L’ALIMENTATION ÉLECTRIQUE.

READ ALL THE STEPS BEFORE STARTING THE CONVERSION. INSTALLER