igus drylin dryve D3 User Manual

dryve D3 DC motor control system

Manual V 0.0

Motion Plastics

Operating Instructions of the dryve D3 V0.0 1/15

Table of contents

Table of contents

1

Safety instructions, protective measures and guidelines ............................ 3

1.1

1.2

1.3

1.4

1.4.1

1.5

1.6

2

Product overview ............................................................................................. 5

2.1

2.1.1

2.1.2

2.1.3

2.1.4

Important instructions ........................................................................ 3

Qualified personnel ........................................................................... 3

Maintenance ...................................................................................... 3

Safety instructions ............................................................................. 4

Classification of information .............................................................. 4

Electromagnetic compatibility (EMC) ................................................. 4

EC Declaration of Conformity ............................................................ 4

Technical data ................................................................................... 5

Dimensions ....................................................................................... 5

Mechanical data ................................................................................ 5

Electrical data .................................................................................... 5

Environmental conditions .................................................................. 5

3

Installation ........................................................................................................ 6

3.1

3.2

3.2.1

3.2.2

4

Initial operation ................................................................................................ 8

4.1

4.2

4.3

4.4

4.5

4.5.1

4.5.2

4.5.3

4.5.4

4.5.5

4.5.6

4.5.7

5

Troubleshooting ..............................................................................................15

Mechanical installation ...................................................................... 6

Electrical installation .......................................................................... 6

General information about the electrical installation .......................... 7

Terminal assignment ......................................................................... 7

Control elements ............................................................................... 8

Motor rotation direction ...................................................................... 9

Limit switch ........................................................................................ 9

External directional switch ................................................................10

Basic settings ...................................................................................10

Operating modes ..............................................................................10

Limit switch control ...........................................................................11

Acceleration type and ramps ............................................................11

Motor settings ...................................................................................13

Table Basic Settings.........................................................................13

Speed ...............................................................................................14

Force setting ....................................................................................14

6

Accessories .....................................................................................................15

7

Service .............................................................................................................15

Operating Instructions of the dryve D3 V0.0 2/15

Safety instructions, protective measures and guidelines

1 Safety instructions, protective measures and guidelines

1.1 Important instructions

Read this manual carefully before operating the dryve D3 motor control system. Familiarise yourself with the safety instructions

and ensure that the required safety measures are followed.

This manual was created according to the best of our knowledge and belief. It is used for technical documentation and for assisting the user during the initial operation. The warnings, cautions and instructions issued by igus regarding the dryve D3 motor

control system must in any case be passed on to the end user if the dryve D3 motor control system is used as part of an overall

system.

The company igus undertakes guarantees only for igus products in accordance with the standards, norms and specifications

given in this manual. The guarantee covers only the replacement or repair of a defective dryve D3 motor control system. There

is no liability for consequential damage and consequential errors. The igus GmbH does not take any responsibility for the integration of the dryve D3 motor control system into the overall system. The responsibility for it lies with the plant designer or the

end user. Please observe the instructions under "Qualified Personnel". The company igus assumes no responsibility for personal injury or damage to property resulting from misuse or unauthorised technical modification of the dryve D3 motor control

system.

The igus GmbH reserves the right to make changes and improvements to the product or the technical documentation

at any time without prior notice.

The dryve D3 motor control system must only be used if:

- All information and safety instructions in this manual have been observed.

- No changes have been made to the dryve D3 motor control system and it is in a technically

flawless condition.

- The operating limits that are specified in Technical data are complied with.

- Necessary measures, if called for, have been taken for radio interference suppression depending on the operating

environment.

- All used connecting cables have been relieved of strain.

1.2 Qualified personnel

The operation of the product must only be carried out by qualified personnel.

Personnel must:

- Have read and understood this manual and documentation on the installed motor, axis and accessories.

- Be familiar with all relevant applicable standards, provisions and accident prevention regulations.

- Be able, due to their training, to anticipate or recognise any hazards that may arise when using the control system.

- Ensure the safety of persons and objects when using the motor control system in the overall

system.

1.3 Maintenance

The dryve D3 motor control system is maintenance-free.

Never open the housing of the dryve D3 motor control system independently, even in the event of a malfunction.

Opening the housing annuls the guarantee.

Operating Instructions of the dryve D3 V0.0 3/15

Safety instructions, protective measures and guidelines

A disregard of the notice

inevitably

leads to a

serious or even fatal accident

.

Failure to observe this notice is

likely

to result in a

serious or fatal accident

or

property damage

.

Failure to comply with the notice may

possibly

result in an

accident

or

property damage

.

Disregard of the notice may

possibly

result in

property damage

.

Failure to

follow these instructions can result in death, serious injury, or material damage

1.4 Safety instructions

1.4.1 Classification of information

The degree and type of hazard are assigned to one of the following classes.

DANGER

Safety instructions marked with DANGER indicate an imminently hazardous situation.

WARNING

Safety instructions marked with WARNING indicate a potential hazardous situation.

CAUTION

Safety instructions marked with CAUTION indicate potential danger.

NOTE

Safety instructions marked with NOTE indicate a potential hazardous situation.

!

!

!

1.5 Electromagnetic compatibility (EMC)

WARNING!

• Risk of injury due to interference with signals and devices

Disturbed signals can cause unforeseen device reactions.

Carry out the wiring in accordance with the EMC measures.

Device assembly Use cable clamps for the shield support, con-

nect metal parts over a large area.

Switching devices such as contactors, relays or

solenoid valves with interference suppression

units or spark suppressors (e.g. diodes, varistors, RC elements)

Wiring Keep cables as short as possible. Avoid capacitive and inductive interference.

Connect the shield of all shielded cables to the

housing via cable clamps over a large

area.

Measures for EMC Effect

Good conductivity due to surface contact.

Reduce mutual interference couplings.

Reduce emissions.

1.6 EC Declaration of Conformity

Hereby the igus GmbH declares

that the following device

dryve D3 DC motor control system

complies with the relevant provisions of the following directives:

EMC guideline 2014/30/EU

RoHS -2 guideline 2011/65/EU

Applied harmonized standards:

EN 61000-6-2 : 2005

EN 61000-6-3 : 2007 + A1: 2011

Cologne, March 2018

Operating Instructions of the dryve D3 V0.0 4/15

Product overview

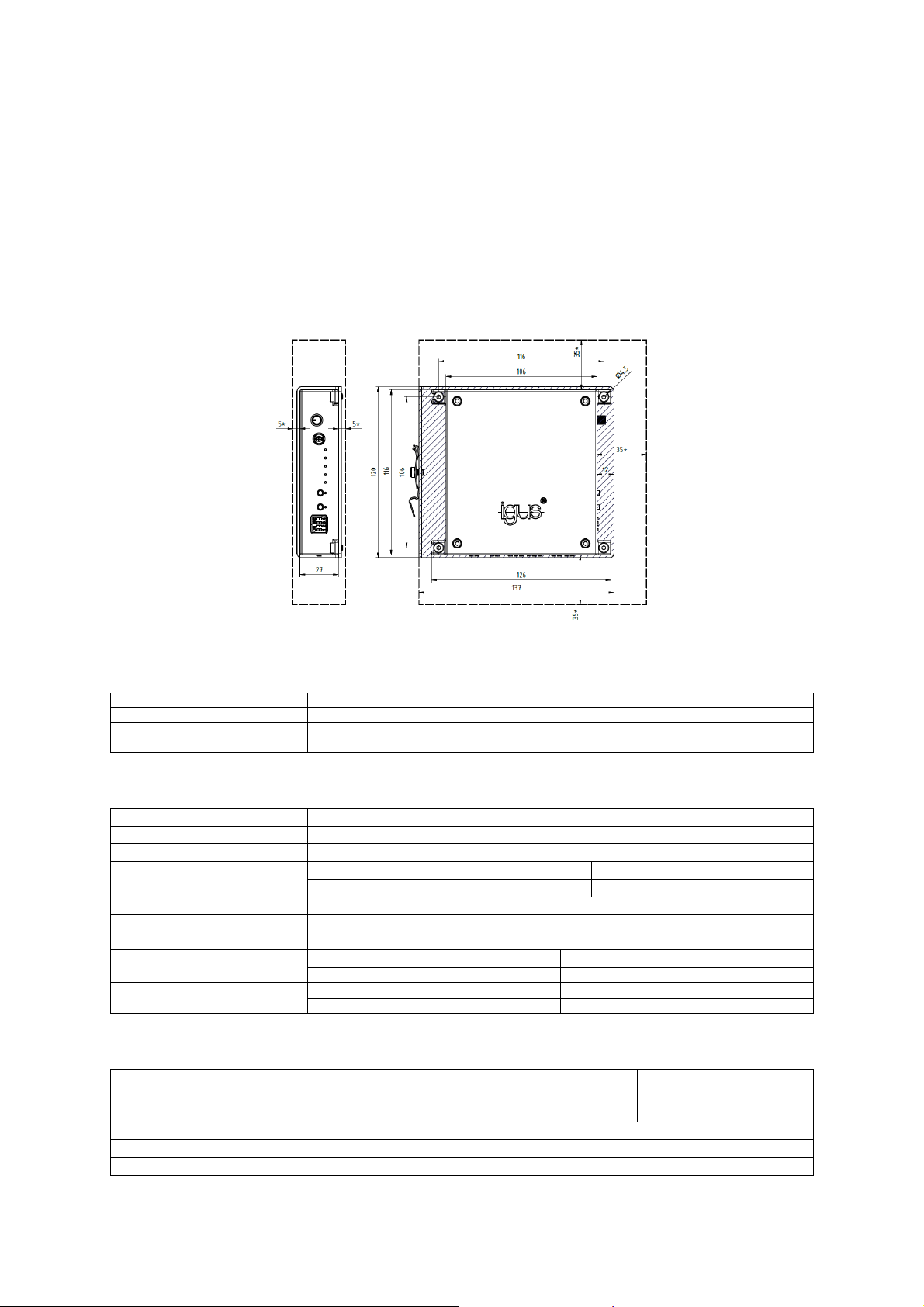

D x W x H dryve D3 in mm

116 x 27 x 126

Weight

150 g

D x W x H angle adapter in mm

Weight

Current

Max. 10 mA

Current

5mA

2 Product overview

Ready to use immediately

Connect the voltage source and the motor: you are ready to start. No complicated software installation or complex wiring of various additional switches and sensors.

Easy control

The intuitively operated rotary elements allow you to set the speed and force limit of the connected motor without prior

knowledge. A travel movement can be started by the two buttons on the front of the dryve D3.

2.1 Technical data

2.1.1 Dimensions

The shading indicates the distance for neighbouring components.

2.1.2 Mechanical data

2.1.3 Electrical data

Voltage supply 24 V, ± 2 V

Motor types DC motor

Continuous motor current Max. 2.5 A

Motor output frequency Switch 4 off 8 kHz

Switch 4 on 1 KHz

Power output Max. 60 W

Cable lengths Max.3 m

Cable cross-sections 0.34 mm² to 1.5 mm²

Limit switch

External travel movement Voltage 5 V

Voltage UB at X2.1

2.1.4 Environmental conditions

Ambient temperature Operation -20 °C to +45 °C

Transport -40 °C to +60 °C

Bearing -40 °C to +60 °C

Relative humidity ≤ 90 %, non-condensating

Protection class IP 30

Degree of soiling according to EN 61010 1

Operating Instructions of the dryve D3 V0.0 5/15

Loading...

Loading...