igus DryLin User Manual

61.1

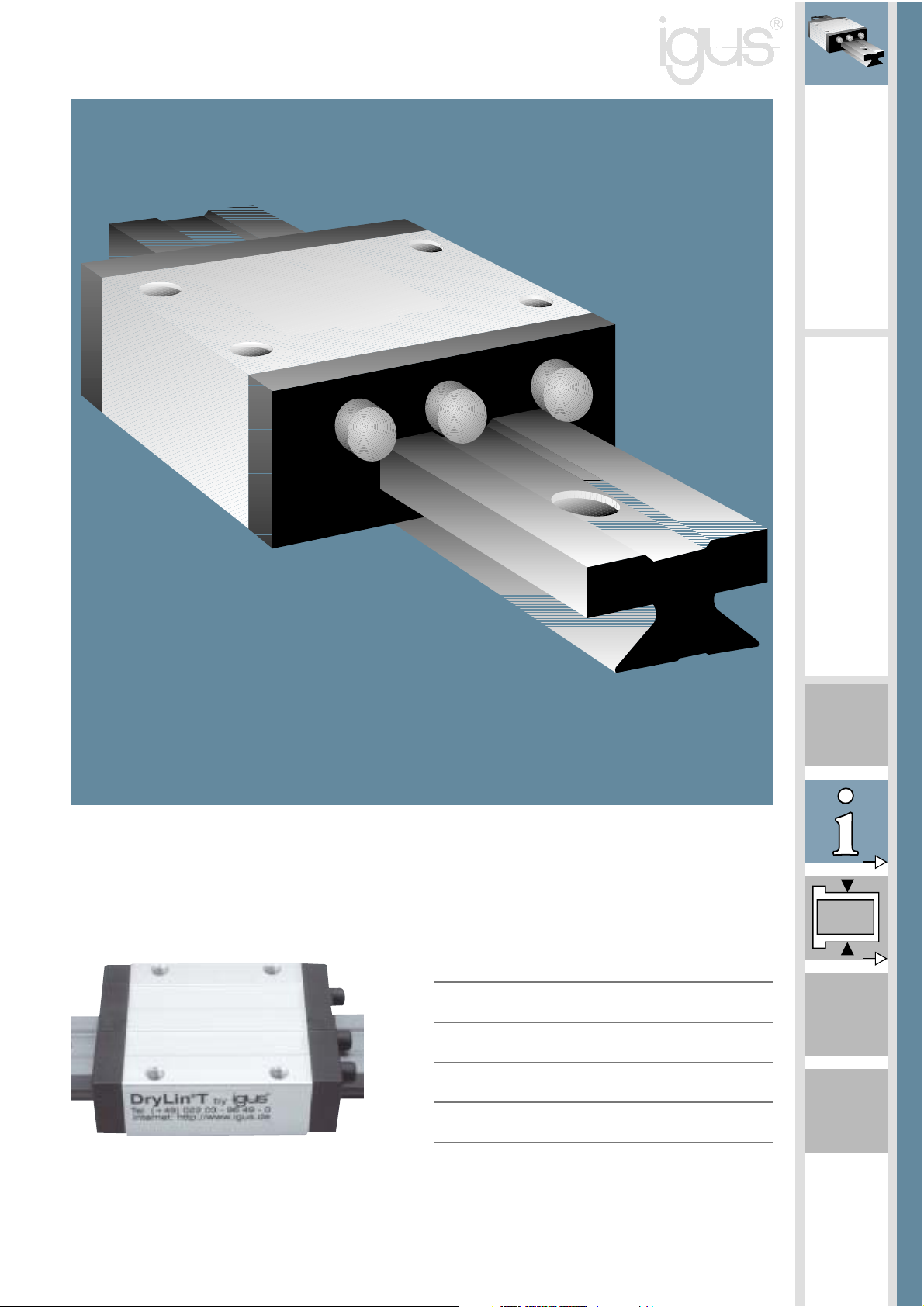

DryLin®T Linear Guide System –

Maintenance-Free, Adjustable and Quiet

Corrosion resistant

Wear resistant

Low coefficient of friction

Extremely quiet operation

No lubrication necessary

DryLin

®

T

Phone +49 - 22 03 - 96 49-145

Fax +49 - 22 03 - 96 49-334

mm

61.2

DryLin

®

T

Internet www.igus.de

E-mail info@igus.de

Phone +49 - 22 03 - 96 49-145

Fax +49 - 22 03 - 96 49-334

igus

®

GmbH

51147 Cologne

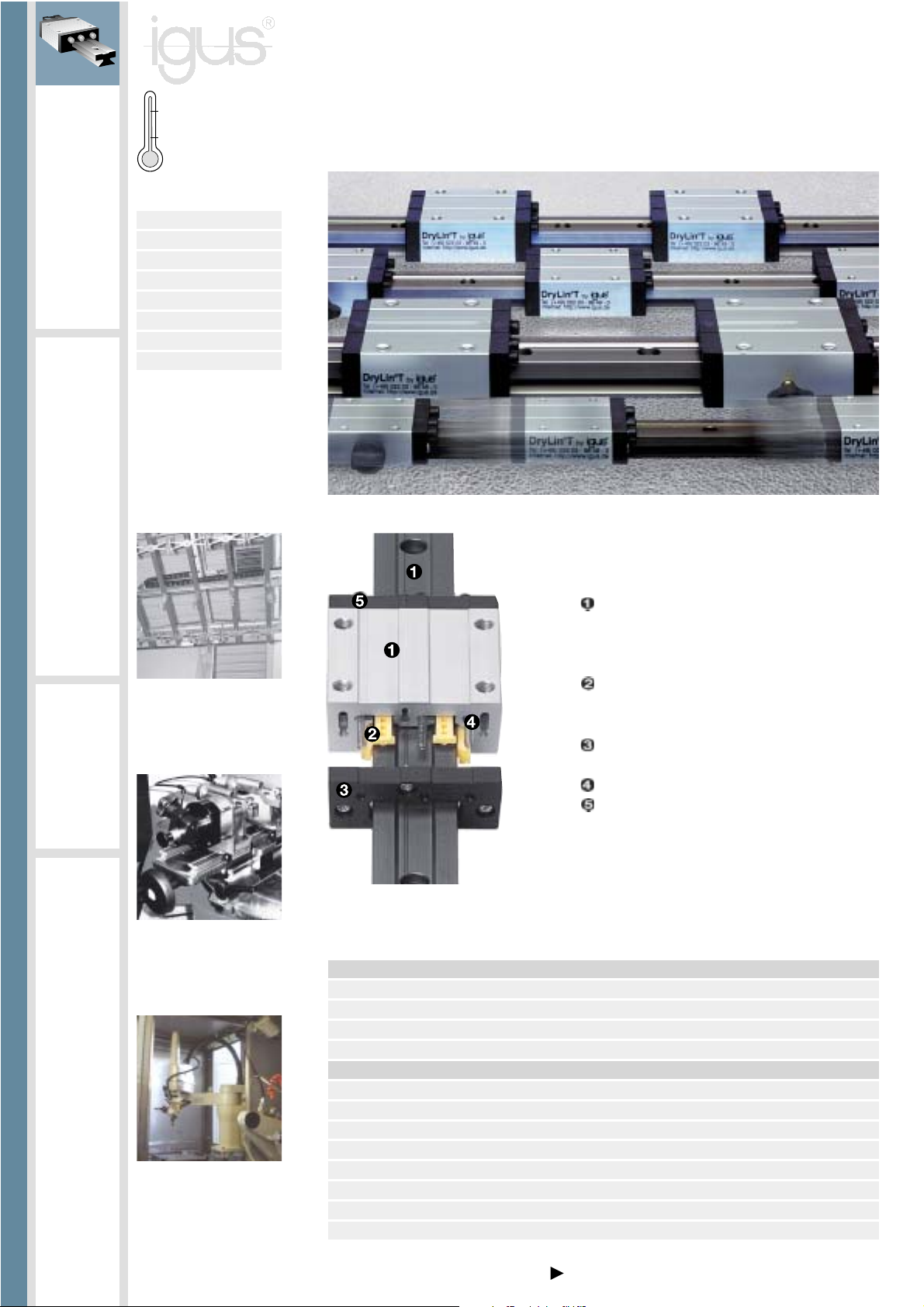

Valve machining produces

an extreme environment

DryLin®linear guide system

in a treatment machine

DryLin®T linear guide system in pneumatic doors of

tool changers

DryLin®T – Linear Guide System

DryLin®T linear guide systems were originally developed for applications in both automation and

materials handling. The goal was to create a high performance, maintenance-free linear guide for

use in the most diverse, even extreme environments.

Technical Data

Sliding elements:

Maintenance-free

Material:

iglidur®J*

Max. surface speed:

15 m/s

Temperature range:

-40 °C to +90 °C

* Other materials upon request

Profile rails and base structures of the carriages

manufactured from aluminium Al Mg Si 0.5

The rail is hard anodized, the aluminium housing of the

carriage is clear anodized

6 sliding iglidur

®

J/J200 elements act as guide bear-

ings, which are set in pairs opposite each other and

act as three guide bearings altogether

Each of the three guide bearings can be adjusted

manually or automatically

All steel parts are galvanized or of stainless steel

The end plate is solid plastic

Technical Data

Guide rails

Material Aluminium, extruded section

Substance Al Mg Si 0,5

Coating Hard anodized aluminium, 50 μm

Hardness 500 HV

Sliding carriage

Base structure Aluminium, extruded section

Material Al Mg Si 0,5

Coating Anodized aluminium

Sliding elements Maintenance-free plain bearing iglidur

®

J

Bolts, springs Stainless steel, galvanized steel

Cover Plastic

Max. surface speed 15 m/s

Temperature range -40 °C to +90 °C

Lifetime calculation, CAD files and much more support www.igus.de/en/DryLinT

+90º

–40º

61.3

0X

C

0

C

0Z

0Z

C

0(-Y

)

0Y

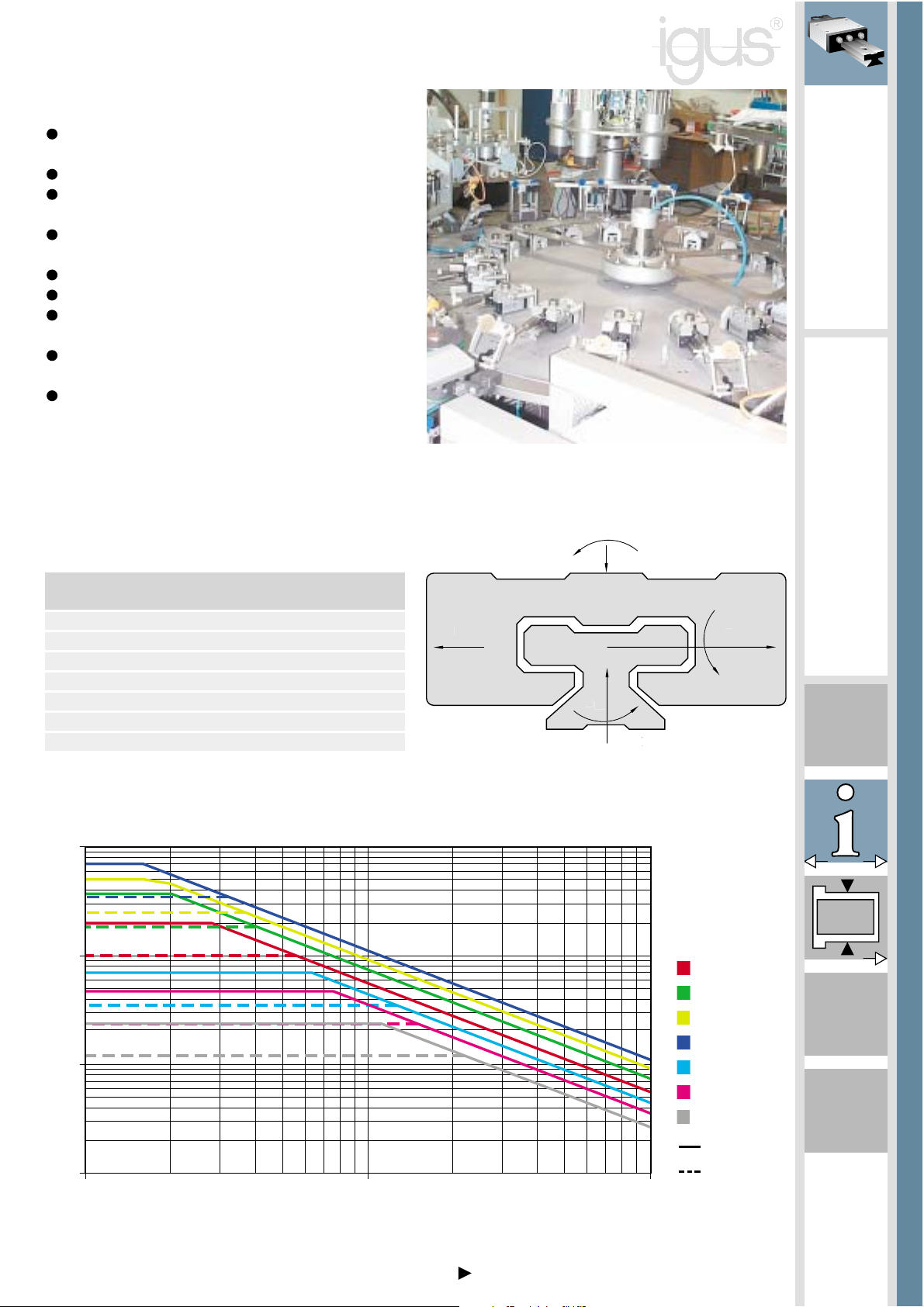

10000

1000

100

10

0,1 1 10

04-09 0,48 0,48 0,24 3,4 1,8 1,8

04-12 0,96 0,96 0,48 9,2 4,4 4,4

04-15 1,4 1,4 0,7 17 8 8

01-15 4 4 2 32 25 25

01-20 7,4 7,4 3,7 85 45 45

01-25 10 10 5 125 65 65

01-30 14 14 7 200 100 100

DryLin

®

T

Phone +49 - 22 03 - 96 49-145

Fax +49 - 22 03 - 96 49-334

TK-01-15

TK-01-20

TK-01-25

TK-01-30

TK-04-15

TK-04-12

TK-04-09

y-direction

z-direction

Lifetime calculation, CAD files and much more support www.igus.de/en/DryLinT

Type C0YC

0(-Y)C0ZM0XM0YM0Z

[kN] [kN] [kN] [Nm] [Nm] [Nm]

Table 3.2: DryLin

®

T-01 – Permissible static load capacity Graph 3.3: Designation of load directions

DryLin

®

T in demanding use in the packaging industry

Speed v [m/s]

Load F [N]

Graph 3.2: DryLin®T – Permissible dynamic load

Special properties

With a low rate of inertia, high accelerations and short term extreme

speeds up to 30 m/s are possible

DryLin

®

T linear guide systems run dry. Dirt cannot settle in lubricants

Recommended for use in food, medical, and clean room technolo-

gies, since no lubricants are present

DryLin

®

T linear guide systems are also suited for underwater use

due to corrosion resistance

High pressure washdown does not damage the system

Vibration dampening and extremely quiet operation

The aluminium rail provides good thermal dissipation. The aluminium

only retains heat at continuously high speeds

The combination of aluminium and iglidur

®

J results in a low initial

breakaway force

DryLin

®

T is dimensionally interchangeable with the standard ball

bearing systems

DryLin®T – Technical Information

Y

mm

61.4

DryLin

®

T

Internet www.igus.de

E-mail info@igus.de

Phone +49 - 22 03 - 96 49-145

Fax +49 - 22 03 - 96 49-334

igus

®

GmbH

51147 Cologne

Lifetime calculation, CAD files and much more support www.igus.de/en/DryLinT

DryLin®T – Guide Rails

DryLin®T – Variations

The DryLin®T system can be delivered with extended manual

clearance adjustment, automatic version or in the miniatureprofile design.

DryLin®T – Adjustable clearance

DryLin®T is delivered preset. The user can adjust the clearance

manually. Therefore, it is possible to compensate for height differences

in the position of the mating surfaces.

DryLin®T – Automatic

After mounting, DryLin®T Automatic carriages are self-adjusting. In

operation, the clearance of this type of carriage can be automatically

reduced again, when the applied load is relieved.

DryLin®T – Manual clamping

The DryLin®T series with manual clamping was developed for simple

functions. A clamped polymer has a tendency to creep which causes

a decrease in clamping force over time (up to 70%). Therefore, applications for DryLin

®

T with a clamp are restricted. Please contact our

technical experts if you need other alternatives for clamping DryLin

®

linear systems.

DryLin®T – Heavy Duty

The Heavy Duty series is used with most extreme conditions like dirt,

sticking arrears, splinters, mud etc. The Polymer sliding elements of

iglidur

®

J are fixed by the metal end caps and cannot be lost.

This system is compatible with many standard ball bearing systems

and is available in the following sizes: TW-01-20, TW-01-25, and

TW-01-30.

DryLin®T – Miniature

The clearance of DryLin®T miniature systems is not adjustable. The

sliding elements are mounted with positive locking (form-fitted) into

the chromated zinc slide carriages. This simple, effective design makes

the rails robust and at the same time cost-effective.

Loading...

Loading...