Conductivity limiter FLB1

for use with the level probes

EL 18 or EL22 or EL23

D-08-B-39272-EN-0.doc

Edition10/2017

Foreword – Product Philosophy

You have purchased a high quality IGEMA-GmbH product and we thank you for your trust.

Measurement and control systems have been developed, produced and distributed

worldwide for over 90 years under the IGEMA trademark. True to the motto “Steam is our

passion”, we offer you a complete program for the safe and economical operation of your

plant, in particular in the steam and condensate sector. We take care of both the

modernization of steam boilers that are equipped with mature mechanical technology and

of new systems that are operated with innovative, future-orientated electronic solutions.

So that your product can be reliably operated, please read these installation and operating

instructions carefully.

In addition to the information on assembly and operation, you will also find important tips

on the maintenance, care, safety and value retention of your measurement and control

system.

1

Table of contents

Content

1. Risks and Safety Precautions ................................................................................................................................ 3

1.1 General safety instructions ........................................................................................................................... 3

1.2 Device-specific safety instructions.............................................................................................................. 3

1.3 Exclusion of liability ........................................................................................................................................ 4

2. Contents of the packaging .................................................................................................................................... 5

3. Schematic diagram ................................................................................................................................................. 5

4. System description .................................................................................................................................................. 5

4.1 Application ........................................................................................................................................................ 5

4.2 Function ............................................................................................................................................................. 6

5. Design and installation FLB1 ................................................................................................................................ 6

5.1 Installation dimensions and descriptions ................................................................................................. 6

5.2 Installation ........................................................................................................................................................ 7

5.3 Electrical connection ...................................................................................................................................... 7

5.3.1 Wiring diagram ....................................................................................................................................... 8

5.3.2 Procedure ................................................................................................................................................. 9

6 Fitting the probe .................................................................................................................................................... 10

6.1 EL22 ................................................................................................................................................................. 11

6.2 EL23 ................................................................................................................................................................. 12

6.3 EL18 ................................................................................................................................................................. 13

7. Calibration .............................................................................................................................................................. 14

7.1 Zero calibration............................................................................................................................................. 14

7.2 Sampling ........................................................................................................................................................ 14

7.3 Temperature calibration ............................................................................................................................. 15

8. Limit setting (maximum value) ......................................................................................................................... 16

8.1 Setting the FLB1 ........................................................................................................................................... 16

9. Technical Data ....................................................................................................................................................... 16

9.1 Device data - Evaluator ............................................................................................................................... 16

9.2 Device data - Contacts ................................................................................................................................ 16

2

1. Risks and Safety Precautions

1.1 General safety instructions

Avoidance of risks to persons

• Observe accident prevention regulations and system-specific safety instructions.

• Only use the device supplied in accordance with the intended planning.

• Do not add to or modify the device without the approval of IGEMA GmbH.

• Read and observe fitting and operating instructions.

• The device must only be fitted and put into operation by appropriate trained persons.

Limitations of use

• The device must only be used in accordance with the instructions in this operating manual or for the

parameters agreed in the supply contract (see data plate) and the applications.

• Approval for this device loses its validity if modifications not agreed with us have been made.

• The safety of the whole boiler system into which this device is fitted lies in the responsibility of the installer of

the system.

• If this device is inserted incorrectly the function/protection expected from this device may be impaired.

Avoidance of risks and damage

• The installation and operating instructions are an integral part of the device and must be sent to the

departments responsible for "Goods in, transport, assembly, commissioning and maintenance". They must be

kept in such a way that the technical staff have access to these documents at all times.

• If this device is passed on to third parties, these installation and operating instructions in the relevant language

of the country must accompany it.

• Read and observe the installation and operating instructions carefully and keep them in a safe place.

• Take note of and follow the safety instructions in the individual sections of these operating instructions!

• When transporting, avoid e.g. knocks and putting down heavily, this can lead to damage.

• For intermediate storage, the unit must be stored dry and protected from damage.

•

This device must

not

be used in potentially explosive atmospheres.

1.2 Device-specific safety instructions

• The fitting is under pressure during operation!

When flange connections, screw plugs or glands are released, hot water or steam will escape.

•

Make sure the system pressure is

zero

before carrying out installation or maintenance work!

• The fitting is hot during operation! Severe burns may be sustained on hands and arms. Make

sure the system is cold before carrying out installation and maintenance work!

• Severe burns may be sustained over the whole body!

• When opening and dismantling the device, residue of the medium may escape; even with the system not

under pressure, fumes can escape.

• Installation work on the device must only be carried out by qualified and trained persons with the power to the

device switched off.

• Sharp-edged interior parts may cause cuts to the hands! Wear work gloves when working!

Danger

Danger

3

1.3 Exclusion of liability

IGEMA GmbH Mess- und Regelsysteme will assume no liability if the above-mentioned regulations,

instructions and safety precautions are not noted and followed.

Danger

This symbol and signal word refer to a potentially

hazardous situation which could result in death or

injuries if ignored.

Caution electrical voltage

This symbol and signal word indicate live parts with

an immediate danger of death from electric shock.

Caution hot

This symbol and signal word refer to a potentially

hazardous situation where extremely severe burns

and scalds may be suffered over the whole body.

Caution

This symbol and signal word refer to a potentially

hazardous situation which could result in personal

injury, property and environmental damage if

ignored.

Caution

This symbol and signal word refer to a potentially

hazardous situation which could result in damage to

the equipment or incorrect functioning if ignored.

Info

This symbol refers to useful information and

recommendations and to measures extending the

value retention of your measurement and control

system.

4

2. Contents of the packaging

1 TDS limiter FLB1

1 probe EL22 or EL18 or EL23

1 set of installation and operating instructions

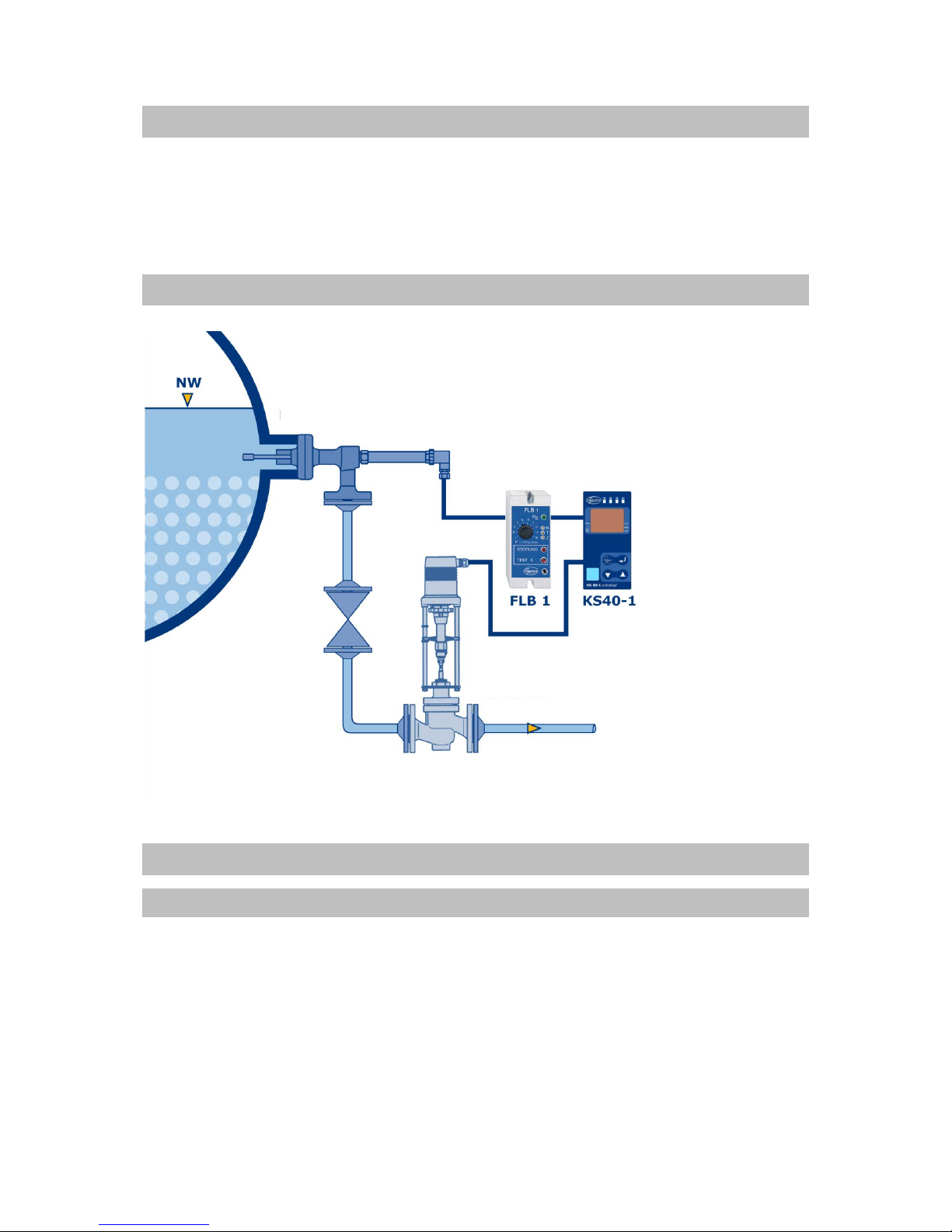

3. Schematic diagram

4. System description

4.1 Application

The TDS limiter FLB1 is used for continuous monitoring of the conductivity of liquids.

The conductivity is measured using a measuring cell. This consists of a special conductivity

electrode and tank wall or protective tube.

The requirements of EU Directive 2014/68/EU, standards EN 12952-11 and EN12953-9,

waterlevel 100 (Wasserstand 100) are taken into account.

Level probe EL22

TDS-valve ASV2

5

Probes for use with the FLB1:

4.2 Function

If a conducting liquid is in the measuring cell, the feeding triangular voltage drives a current

through the liquid. The value of this current is proportional to the conductivity of the liquid in the

measuring cell. This value is detected by the evaluation unit and converted into the 4-20 mA

interface. The current is simultaneously converted into a voltage. This voltage is amplified

depending on the position of the limit switch and compared with a reference. If the result of the

comparison is greater than or equal to the reference, the relay is de-energised and the contacts

open the burner chain. The warning light "Fault" (Störung) lights up. If the conductivity of the

liquid drops below 78% of the set limit, the relay is energised again. The warning light "Fault" is

extinguished.

This function can be checked by pressing and holding down the "Test K" key. If there are

malfunctions of the system, e.g. due to power failure or a short circuit, the evaluation unit reacts as

if the conductivity has exceeded the limit value.

The warning light "U B"

indicates that the operating voltage is present.

5. Design and installation FLB1

The device is supplied in a plastic plug-in housing for fitting into switch cabinets. The housing is

designed for quick fitting with a spring catch for the DIN EN 50022 standard 35 mm carrier rail and

for screw fixing on a mounting plate.

5.1 Installation dimensions and descriptions

Trimmer N for zero calibration

Trimmer T for temperature compensation

Trimmer Z for cell constant

1 = Conductivity limit setting

2 = Jack plug Ø 3.6 mm, for connection of a

measuring device for setting

Name PS TS Connection Feature

Type EL18 32 bar 239°C G ½“ Piping-with flange mounting

EL22 32 bar 239°C G ½“ frquently fitted with T-piece

EL23 80 bar 296°C G ½“ protective tube installation

1

2

Cable feedthroughs

Base with

connecting terminals

Front view

Side view

Base Hood

Screws for loosening the Snap fastening for

Hood from the lower part for carrier rail

6

5.2 Installation

Secure with protection class in accordance with current regulations

With top-hat DIN rail mounting for standard DIN46277 35 mm carrier rail

• Snap the device on the standard carrier rail.

• Loosen the fastening screws and remove the hood from the base.

• Connect to power supply (see Section 5.3).

Without top-hat DIN rail mounting

• Loosen the fastening screws and remove the hood from the base.

• Loosen screws and remove the DIN rail adapter.

• Drill the marked points in the base with a Ø4.3 mm drill.

• Fit base on base plate with 2 M4 screws.

• Connect to power supply (see Section 5.3).

5.3 Electrical connection

The device terminal strip is live during operation!!

Before working on the device disconnect it from the mains!!

The device must be protected mains-side by the operator with a max. 2A fuse!

If inductive consumers are connected, voltage peaks occur when switching

off. For this reason, connected inductive consumers (e.g. contactors) must be

provided additionally with an RC circuit: e.g. 0.1µF / 100Ω.

Caution electrica l voltage

Caution

Caution electrica l voltage

7

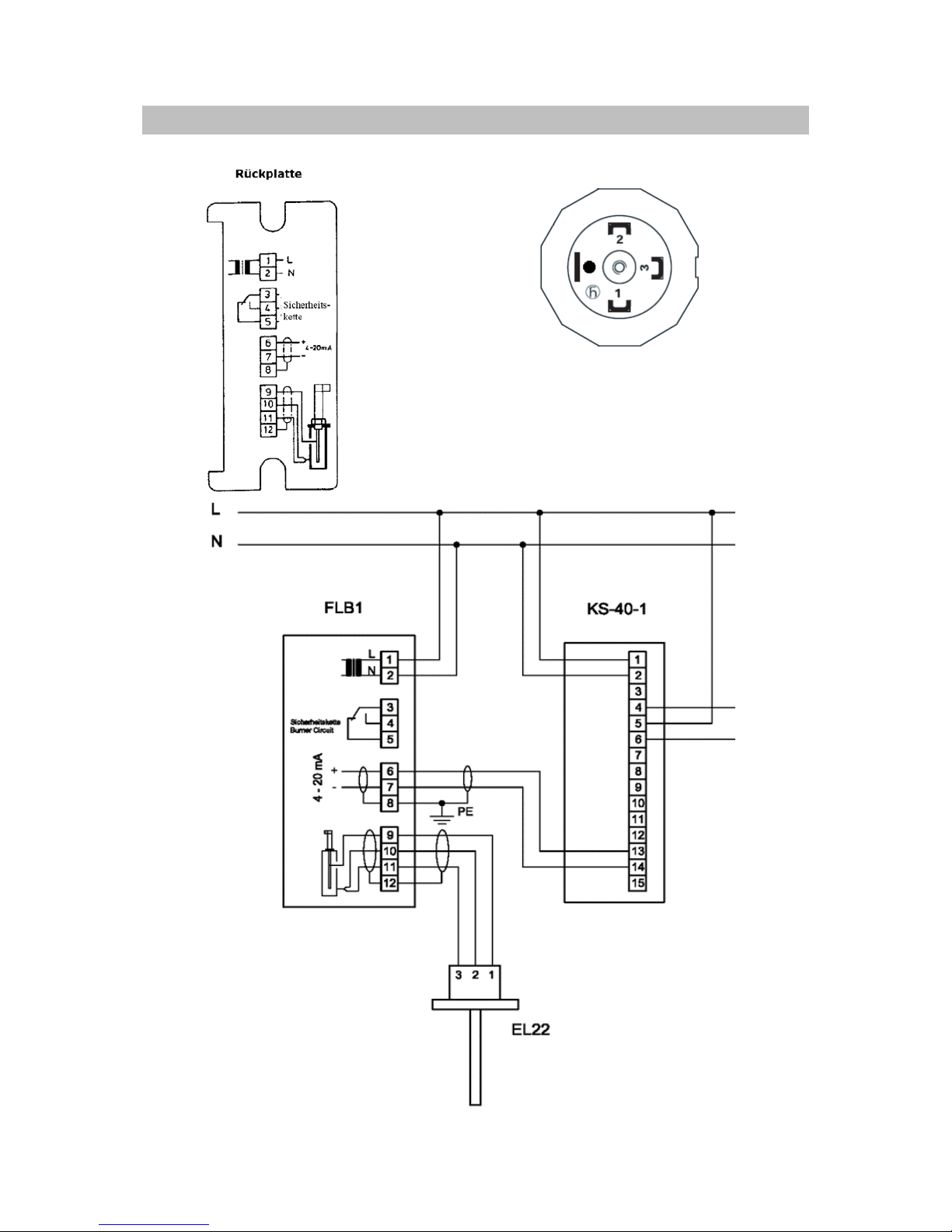

5.3.1 Wiring diagram

Probe plug

1 Electrode rod

2 GND

3 GND

● -

Back plate

Safety

chain

8

5.3.2 Procedure

Connect according to wiring diagram (5.3.1).

• Pierce or pull out cable feedthrough and feed connection cable through.

• Check supply voltage. See name plate for permissible voltage.

• Use a shielded connection cable for the probe: e.g. LIYCY min. 0.75 mm² up to a max.

length of 50 m. LIYCY min. 1.5 m² up to a max. length of 100 m (see note).

• Use a shielded cable for the current output (see note).

• Only connect shielding on the FLB1 control unit (terminal 12).

• After connecting to the power supply – with the device disconnected – place the hood on

the base and tighten the fastening screws.

• Fit electrode according to separate assembly instructions and connect as in the wiring

diagram.

When installing it, check whether the cables used are UV-resistant and that UV

protection is ensured on the installation side if necessary.

The cable must not come into contact with heat-conducting parts.

For aligning the probe plug to the local circumstances, the upper nut can be released (∅ 33.5mm).

In doing so, take care not to move the plug in the probe!! (SW24).

The contact carrier can be carefully turned into the correct position.

On refitting ensure that the seal is correctly seated! Retighten the upper nut without moving the

plug in the probe.

The connector plugs must be wired according to the wiring diagram.

Caution

9

6 Fitting the probe

It is essential to remove the cardboard protective tube for transport before

installation!

If several probes are screwed into one flange, the probe plug and the associated

probe should be labelled to prevent confusion!

Screwing in the probe

• Unscrew the probe plug

• Clean and check sealing surfaces

• Insert (new) sealing ring

• Grease the thread with heat-resistant solid lubricant (e.g. graphite).

• Screw in and tighten the probe, max. tightening torque Md = 140 Nm.

• Fit into the boiler before connecting the power.

Do not seal thread with PTFE tape or the like!

When commissioning the boiler, check the probe screw connection in the flange

for leaks and retighten if necessary!

Caution

Caution

Caution

10

6.1 EL22

This probe is fitted horizontally into the boiler as standard using a T-piece.

This enables the concentrated water, which is measured, to be directly discharged.

In order to determine the length, note that there should be a free space of 40mm around the

measuring tip.

11

6.2 EL23

This probe is fitted as standard using a protective tube.

12

6.3 EL18

This probe is fitted as standard using a flange in a pipe. With intermittent flow, a measurement can

then be carried out and TDS reduction can be started.

13

7. Adjustment

Do not carry out adjustment until all the system components are installed.

Switch on the mains voltage, the green warning light "U B"

lights up.

Measuring instruments required for calibration:

• Multimeter (preferably digital multimeter)

• Conductivity measuring device (preferably with temperature compensation)

7.1 Zero calibration

Requirement: The measuring tip of the conductivity electrode is not in contact with the water.

Depending on the installation of the electrode, lower the water level in the boiler or empty the

measuring line.

Connect the multimeter to the Ø3.6 mm jack socket (8) or to the terminals (6 and 7) and set a

current of 4 mA with the potentiometer "N".

• Turning the potentiometer clockwise gives larger values.

• If the value “4 mA” cannot be set – check the electrical lead for compliance with

the specifications in the wiring diagram.

7.2 Sampling

Requirement:

• Boiler in operating mode

• Measuring tip of the dedicated measuring electrode is surrounded by boiler water

Remove boiler water via the sampling cooler and determine the conductivity "K

actual

" in μS/cm

relative to 25°C using a conductivity meter.

Caution

14

7.3 Temperature calibration

Requirement:

• Boiler in operating mode

• Measuring tip of the dedicated measuring electrode is surrounded by boiler water

• Calculate the current to be set according to the equation

I = 4 + 16 x K

actual

[mA] / K

max

.

Example: K

actual

= 2000 μS / cm; see point 5.2 Sampling

K

max

= 10000 μS/cm; see scale value [K x 1000 μS/cm] on the front of the device.

I = 4 mA + (16 mA x 2000 / 10000) = 7.2 mA

Connect the multimeter to the Ø3.6 mm jack socket (8) or to the terminals 6 and 7 and set the

calculated current with the potentiometer "T".

• Turning the potentiometer clockwise results in smaller values.

• Up to 20 revolutions in one direction may be necessary.

If the calculated current cannot be set, the factory-set cell constant on the device is to be

corrected: set the calculated current via the potentiometer “Z”. Then carry out the calibration

again as described under points 5.1, 5.2 and 5.3.

If, in spite of following the above steps, calibration is not possible, the following error eliminations

are to be checked in addition:

• Press the "TEST K" key.

If the circuit is interrupted at the terminals of the connection block (3 and 4), a fault in the

FLB1 can be excluded.

• Check the correct fitting of the conductivity electrode according to the operating

instructions and the electrical connection according to the wiring diagram.

Do not remove the hood until the device has been disconnected from the

mains.

The capacity of the cable must not exceed 50 nF.

• To extend the contact life of the relays we recommend the use of commercial RC

combinations or an appropriate varistor when using inductive consumers (e.g. 0.1

µF/100 Ohm oder S07k275 varistor).

• See data sheet for further information.

Caution electrical voltage

Caution

15

8. Limit setting (maximum value)

Standards 12953-10 and 12952-12 contain requirements for the boiler water and the feedwater

according to the permissible operating pressure.

8.1 Setting the FLB1

Set the desired limit value for maximum conductivity with the limit switch “K” taking into account

the applicable directives.

9. Technical Data

9.1 Device data - Evaluator

Component identification mark: TÜV ID: 0000006175

CE identification number: 0035

Power supply: 230 V ± 10% / 50-60 Hz

Power consumption: approx. 4.5 VA

Device fuse: 80 mA/T

Protection type as per DIN EN 60529: IP 40*

All. ambient temperature: 0 – 60°C

* in accordance with the German regulation VdTÜV-Wasserstand 100, 4.90, IP 54 protection class must be

ensured in the boiler area.

9.2 Device data - Contacts

Burner shutdown: Protection voltage: max. 250 V AC

Switching current: max. 5 A resistive

Power interface: 4 – 20 mA

Electrical conductivity of the liquid: 0 μS / cm ≤ æ ≤ 10,000 μS / cm

0 μS / cm ≤ æ ≤ 1,000 μS / cm

Adjustable limit value "K" at 25°C: 1,000 μS / cm ≤ æ ≤ 10,000 μS / cm

100 μS / cm ≤ æ ≤ 1,000 μS / cm

16

Warranty

We accord a warranty period of 24 months on our products. A condition for that is

appropriate treatment according to these installation and operating instructions. The

warranty for wear and spare parts is restricted to material defects and construction faults.

Level probes are wear parts and are

not

subject to warranty.

IGEMA GmbH

Antwerpener Str. 1

D-48163 Münster

Germany

Tel.: +49 25 01 9 24 24 0

Fax.: +49 25 01 9 24 24 99

info@igema.com

www.igema.com

This high quality IGEMA product has been designed, manufactured and tested

using the

QM System specifications in accordance with DIN EN ISO 9001: 2000.

If the device supplied shows transport damage or gives cause for complaint in

spite of our final quality control please contact our SERVICE department by return.

Telephone

+49 (0)241- 5687-0.

17

Loading...

Loading...