Triton House

Crosby Street

Stockport

SK2 6SH

England

TOCSIN i700

INSTALLATION

AND

USER INSTRUCTIONS

Tel: +44 (0)161 483 1415

Fax: +44 (0) 161 484 2345

Email: sales@internationalgasdetectors.com

Website: www.internationalgasdetectors.com

FS646773

EMS696504

REF: ROS 66-8 V10.1

Table of Contents

Specification

CE Declaration

Overview

Interface Wiring

19" Rack Systems

Addressable relay Cards

Wiring Relay Outputs

Powering 3rd Party Devices

Operating System

Accepting and Resetting Alarms

User Menu (Password 100)

Zero & Calibrate Command

Setting Alarm Levels

Copy Alarms

Common Alarms

Engineering Menu (Password 50)

Channel Setup

FIND Command

Test Addressable Sensors

Testing Addressable Relays

Test FIRE Input Channels

Production Menu (Password 200)

Alarm Actions

Mimic Panels

Highway Splitting

Integrated Battery Backup

Battery Backup Run Time

Modbus

3

4

5

6

16

17

18

19

20

21

24

26

27

28

30

31

34

36

39

40

41

42

43

44

45

46

49

51

Page 2 of 52

This product must be earthed in accordance with local safety regulations.

The Control Panel leaves the factory configured for the supply voltage stated on the customers order.

Standard voltage and frequency range is:-

AC Mains Powered 230V AC (176 to 264V AC) 47 to 63 Hz

Switch Selection Option 110V AC (88 to 132V AC) 47 to 63Hz

DC Low Voltage Powered 18 to 30V DC

NOTE: Operation on an incorrectly selected supply voltage will damage the controller

Should the control panel be used in conjunction with portable generating equipment, care should be taken to ensure that

the electrical supply is within the tolerance band described above. The control panel may be stored at temperatures

between 0 C and 55 C. If stored at low temperatures and then brought into a warmer environment, condensation may

form on some components. In such a situation , this condensation should be allowed to evaporate prior to use of the

equipment. If stored at high temperature, care should be taken to ensure that humidity condensation does not enter

critical electrical components, for example the power supply. The Control Panel is designed to operate within

specification for ambient temperature between 0 C and 55 C, relative humidity up to 95% ( non-condensing ).

On installation alarms will need to be configured to signal when monitored gas levels have breached safe limits. The

control panel will be shipped in a semi-configured state which must be checked and configured during commissioning to

match the applications cause and effect requirements. Failure to do so will result in an ineffective system.

Who should read this manual.

0 0

o o

!Warning !

This manual is intended for use by trained installers of gas detection systems who are technically competent and

have all necessary tools to undertake installation and maintenance on this type of equipment.

Failure to install and maintain the equipment properly can render the detection system ineffective.

You should not undertake any of the procedures in this manual if you do not have access to the correct equipment,

have not undertaken training on this or similar equipment or are not technically qualified to install this equipment.

Calibration gases and test equipment is available from IGD.

Power Source 88 to 132V AC (110V AC Selected) or 176 to 264V AC (230V AC Selected)

47 to 63 Hz 150 Watts DC Option Available

Display 2 x 16 backlight LCD

Operating Temperature 0°c to 55°c

Operating Humidity Up to 95% non-condensing

Resolution 0.00% or ppm Range Dependant

Update Rate 1 Second

Size (mm) 255 (H) x 265 (W) x 100 (D)

Protection Standard IP54

Inputs Up to 4 or up to 8 x 4-20mA loops

8 analogue 4-20mA loopsInputs

2 x RS485 data highways for up to 64 detectors (700+)

Outputs (Standard)

3 x configurable SPCO relays (7 Amp non conductive load)

1 x fault SPCO relays (7 Amp non conductive load)

1 x solid state audio/sounder 24VDC

1 x solid state visual/flasher 24VDC

Outputs (Optional)

Additional 8 way relay cards, I/O Nodes

Gas Detectors

Check ratings for maximum I/O from PSU

Optional Equipment Battery backup 1.2Ah or 2.4Ah

CE Declaration BS EN61000-6-4 EMC Compatibility 'Emissions'

BS EN 61000-6-2:2001 EMC Compatibility 'Immunity'

BS EN 61010-1: 2001 Safety requirements, electrical equipment

Weight 3.65 KG

Page 3 of 52

Issuers name and address:

EC Declaration of Conformity

Oliver IGD Limited of

Triton House

Crosby St,

Stockport, SK2 6SH

Declares that the product listed as:

TOCSIN i700

Addressable & analogue Gas Detection Control Panel

United Kingdom

Are in conformity with the provisions of the following European Directive(s) when installed, operated, serviced and maintained

in accordance with the installation and operating instructions contained in the product documentation.

2004/108/EC EMC Directive

2006/95/EC Low Voltage Equipment Directive (note not applicable to 24V DC Powered Versions)

And that the standards and/or technical specifications referenced below have been applied or considered.

EN 61779-1:2000

Electrical apparatus for the detection and measurement of flammable gases, general

requirements and test methods.

EN 50271:2001

Electrical apparatus for the detection and measurement of combustible gases, toxic gases or

Oxygen: requirements and tests for apparatus using software and or digital technologies.

Excluding requirements for SIL

EN 61000-6-2: 2005

EN 61000-6-4: 2007

EN 61000-3-2/A2: 2009

EN 61000-3-3: 2008

EMC Generic standards. Immunity for industrial environments

EMC Generic standards. Emission standard for industrial environments

EMC Limits. Limits for harmonic current emissions (equipment input current ≤ 16 A per phase)

EMC Limits. Limitation of voltage changes, voltage fluctuations and flicker in public low-voltage

supply systems, for equipment with rated current ≤ 16 A per phase

Technical File Reference

T700-TF9

Oliver IGD Limited Operate an

Independently assessed ATEX/IECEX

QAN.

EMC Tested by:

TUV - SUD

Quality Assurance Certificate Number

16PQAN0014

Quality Assurance Notification Number:

2585

Units 16-18 Abenbury Way,

Wrexham Industrial Estate,

Wrexham, LL13 9UZ

United Kingdom

Oliver IGD Limited operate an independently

assessed ISO9001:2015 Quality Management and

ISO14001:2015 Environmental Management System

Certificate Numbers

FS0646773 & EMS696504

BSI Assurance UK LTD,

London, W4 4AL

United Kingdom

Octagon House

Concorde Way

PO 15 5RL Fareham

Certificate Number

E8N 15 02 91327 001

TUV Certificates and reports can be checked on-line at

https://www.tuev-sued.de/industry_and_consumer_products/certificates

Select Oliver IGD when prompted on the website to view certificates

Issued by: Oliver IGD Limited, Stockport, SK2 6SH , United Kingdom

Signature: Declaration of Conformity in accordance with EN ISO/IEC 17050-1:2004

Name: Andrew J Collier M.I.O.D

Position: Managing Director Date: 1.January 2019 Declaration Ref: I700-DEC-1

Page 4 of 52

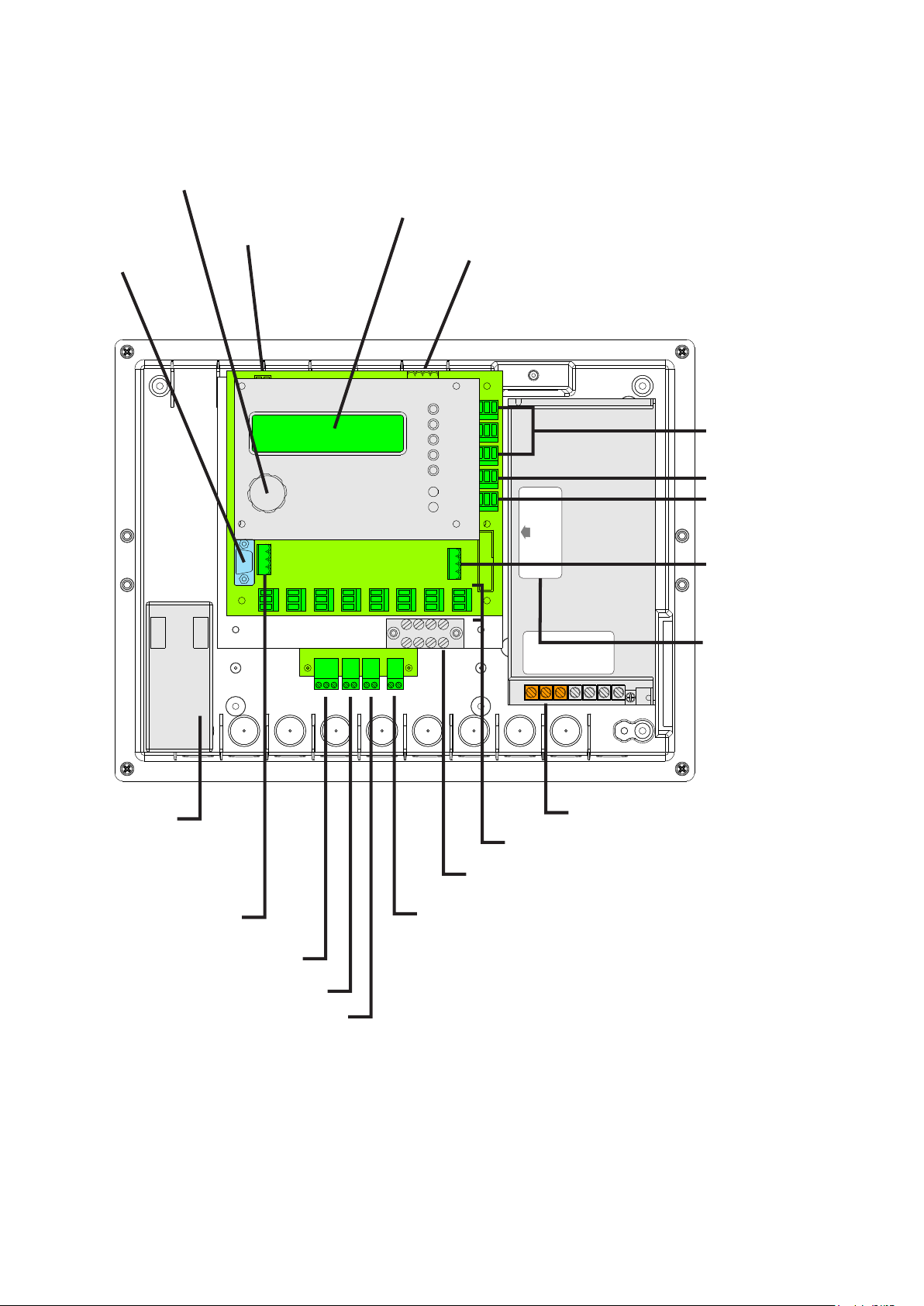

Tocsin 700 Panel Overview

Jog Wheel

24V DC Panel Power

RS232 Comm

Port

2 x 16 LCD Display

Digital Inputs

3 off Configurable

Relay Outputs

With Activation

Indication Lamps

Backup Battery

RS 485 Detector

Data Highway

Connector Port 2 ‘C2’

(Addressable Versions)

Battery Connector

PSU SET TO 230V AC

Fault Relay Outputs

Sounder/Flasher

Outputs

RS 485 Detector

Data Highway

Connector Port 1

‘C1’

(Addressable Versions)

L N E

Label Indicates

Voltage Input as

Shipped From Factory

By Default 230V AC

Use Switch to Change

if Necessary

Mains/DC Input

(Check Supply Option Before Use)

8 off 4-20mA Loop Inputs

Grounding Points

Volt Free Contact Opens On Loss of Mains Power

Power to Main PCB

24V PSU Input

IMPORTANT

Control panels are usually shipped pre-configured with a basic alarm strategy. Before installation check the

documentation provided to ensure the programmed cause and effect matches the site requirement. If it does

not then the system will need to be re-programmed by the installer using the embedded panel software or

PC based T700 setup software.

When first powering systems which include an IGD battery backup the batteries MUST be connected first for

correct operation. During initial startup the panel software will check the battery condition, if mains power is

applied first then the batteries cannot be functionally checked and the panel will report an error.

Page 5 of 52

In all Cases:

Tocsin 700 Interface wiring

VISUAL

OUTPUT

OUTPUT

+24V DC

B

A

0V

0V DC

4-20mA IN

+24V DC

GND

COM

NO NC

GND

AL1

AL2

AL3

24V DCAUDIO

Relay contact ratings.

7A @ 250V AC Non-Inductive

7A @ 30V DC Non-Inductive

Spike suppression must be fitted

Note that FAULT relays are normally

energised on power up.

These 3 relays can be assigned,

named, zoned etc using the Tocsin

700 operating software.

Dedicated fault relay output, this output

is energised in normal operation

SOUNDER O/P

Sounder Alarm

24V DC

Max Current

150mA 24V DC

WARNING LAMP O/P

Note Flasher on

with alarm level 1.

Buzzer on with

alarm level 2.

1.5mmSQ See Panel

for recommended cable

types. Typical max cable

run 1000M.

1.5mmSQ See Panel

for recommended cable

types. Typical max cable

run 1000M.

Addressable control panel versions only.

See 'Addressable Sensors' Section

TOCSIN 102/A

Enclosure

Ground

Blue

Red

TOXIC GAS

DETECTORS

TOCSIN 102IR

Enclosure

Ground

Black

Red

Blue

FLAMMABLE GAS/

CO2 DETECTORS

Page 6 of 52

Tocsin 700 Interface wiring...continued

0V DC

4-20mA IN

+24V DC

GND

1.5mmSQ See Panel

for recommended cable

types.Max cable

run 1000M.

Common

Active

Compensator

P Y W

CHASS

ZERO

CAL

24V DC

B

A

GND

mA

360

mA+360CONC0V mA-

FAULT

T106P Pellistor

Flammable Gas

Detectors

Page 7 of 52

Tocsin 700 Interface wiring...Digital Port

Located at the top edge of the Tocsin

700 card is a 4 way connector used to

allow digital interface to the Tocsin 700

operating system as follows:

1 2 3 4

0V common

Reset Alarms

Password Inhibit

Inhibit Alarms

Page 8 of 52

Tocsin 700 Interface wiring...continued

Tocsin 700 to Tocsin 103 2 wire Detector Series

0V DC

4-20mA IN

+24V DC

GND

4-20mA Toxic

And Oxygen Gas

Detectors

Enclosure

Ground

24V DC

SCREEN

4-20mA

1.5mmSQ See Panel

for recommended cable

types. Typical max cable

run 500M.

Page 9 of 52

Tocsin 700 Interface wiring...continued

Tocsin 700 to Tocsin 103 3 wire Detector Series

Cable Guidance Panel

It is imperative to use cabling which suits

the environment in which the T700 and its

sensors are to be used. The following is intended

as a guide.

Fit 1.5mm SQ cable for analogue systems

Fit 2.5mm SQ cable for addressable systems

Use

Pirelli LSX type cable for office/light commercial

un-zoned installations

Steel Wire Armored or CY cable for medium/heavy

industrial un-zoned installations

0V DC

4-20mA IN

+24V DC

GND

GND

Mineral Insulated Pyro cable for all hazardous

area zoned installations.

Note in all cases the T700 Panel must be installed outside

of any hazardous area and must be supplied via

a fused spur.

Enclosure

Ground

Screen

0V DC

24V DC

4-20mA

1.5mmSQ See Panel

for recommended cable

types. Max cable

run 1000M.

4-20mA Flammable

And CO2 Gas

Detectors

Page 10 of 52

Tocsin 700 Interface wiring...continued

0V DC

4-20mA IN

+24V DC

DIP Switches For Relay O/P

And Sounder O/P Enable

GND

T103 FREON Gas

Detectors

Enclosure

Ground

NO

COM

NC

0V DC

24V DC

4-20 OUT

1.5mmSQ See Panel

for recommended cable

types. Typical max cable

run 500M.

Sensitivity Adjustment

Factory Preset

Do Not Adjust

Page 11 of 52

Tocsin 700 Interface wiring...continued

4-20mA IN

+24V DC

GND

FIRE AND SMOKE INPUTS (FACTORY OPTION)

NOTE THESE DETECTORS ARE RESET BY

INTERRUPTION OF THE POWER SUPPLY. THE

TOCSIN 700 WILL DO THIS IF THE CHANNEL IS

SELECTED AS A ‘FIRE’ AS A GAS TYPE, RELAY

OUTPUTS MUST BE SET AS LATCHING. NOTE

THAT THE POWER IS SUPPLIED TO THE INPUT

CONNECTORS IN BANKS OF FOUR. IF MIXING

WITH GAS DETECTORS SEGREGATE THE FIRST

FOUR INPUTS AS GAS DETECTORS AND THE

SECOND FOUR INPUTS AS SMOKE DETECTORS.

THIS IS A FACTORY FIT OPTION AND MUST BE

REQUESTED WHEN ORDERING THE CONTROL

PANEL. CHANNEL HARDWARE CONFIGURATION

IS DIFFERENT TO STANDARD 4-20mA INPUTS

INTERFACING TO FIRE AND SMOKE DETECTOR

DIODE BASES.

NOTE IF SUPPLIED IN THIS FORMAT THE INPUT

CONNECTORS INCORPORATE PROTECTION

DIODE. DO NOT USE WITHOUT THIS

CONNECTOR/DIODE

ASSEMBLY

NOTE LAST DEVICE IN LINE TO BE FITTED WITH

5K6 RESISTOR AS INDICATED

3

4SD DIODE BASE

1

6

5

4SD DIODE BASE

1

3

3

4SD DIODE BASE

5

6

1

6

NOTE: TYPE INDICATED IS TYPICAL OF NITTAN ST-I

CONVENTIONAL OPTICAL SMOKE OR HEAT DETECTORS. OTHER

MANUFACTURER CONNECTIONS MAY VARY.

5

Page 12 of 52

Tocsin 700 Interface wiring...continued, Addressable Systems.

+24V DC

B

A

GND

GND

2.5mm SQ Cable See Previous Note

120 Ohm Termination

Resistor on the Last

Detector in Line

Local Comms

Connector For

Palm Connection

B

24V

SCREEN

A

0V

24V

Red

Rx

White

Yellow

Tx

4-20

Blue

B

24V

SCREEN

0V

Black

B

24V

A

0V

24V

Red

Rx

Tx

White

Yellow

Blue

A

0V

SCREEN

Local Comms

Connector For

Palm Connection

24V

SCREEN

4-20

0V

Black

B

A

0V

Tocsin 102 Addressable

Series Detector Head

Use Junction Boxes Suitable for Area Classification

Tocsin 102 Addressable

Series Detector Head

Page 13 of 52

Tocsin 700 Interface wiring...continued, Addressable Systems Cont.....

+24V DC

B

A

GND

GND

2.5mm SQ Cable See Previous Note

360

mA

GND

A

B

24V DC

CHASS

Compensator

ZERO

CAL

FAULT

P Y W

Common

Active

mA+360CONC0V mA- mA+360CONC0V mA-

360

mA

GND

A

B

24V DC

CHASS

Compensator

ZERO

CAL

FAULT

P Y W

Common

Active

mA+360CONC0V mA-

360

mA

GND

A

B

24V DC

CHASS

Compensator

ZERO

CAL

FAULT

P Y W

Common

Active

Use Junction Boxes Suitable for Area Classification

Page 14 of 52

Tocsin 700 Interface wiring...continued, Addressable Systems Cont.....

+24V DC

B

A

GND

GND

2.5mm SQ Cable See Previous Note

Addressable Relay Outputs

These come equipped with two volt

free contacts which can be set as

normally open or normally closed action

Use for beacon/sounders etc

Mix on the same loop as addressable detectors

MUTE ALARM MUTE ALARM

CHASS

24V DC

Set Address

B

A

4301

GND

mA

PWR M EN Al COMM

PALM

CHASS

24V DC

Set Address

B

A

4300

GND

mA

PWR M EN Al COMM

PALM

Use Junction Boxes Suitable for Area Classification

Page 15 of 52

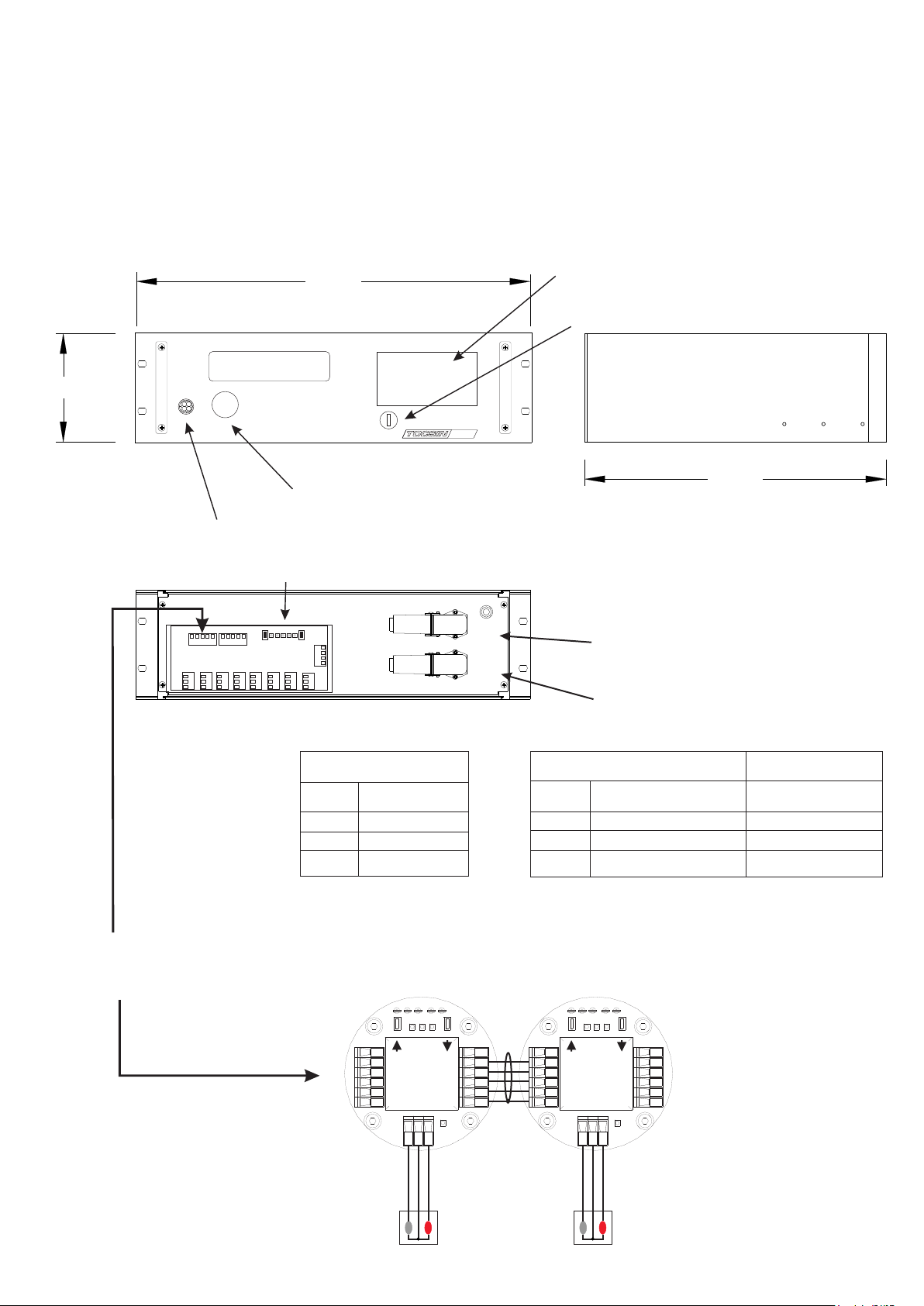

19" Rack Mount systems

Tocsin 700R 19" rack versions of the control panel are 24V DC powered and only interface as addressable

systems. The systems are shipped with an addressable relay card mounted to the rear which can be remote

mounted if required. Note that detectors are connected via the relay card connector shown below.

133.4

483.0

ADVA NCE D GA S DE TEC TI ON S YST EM

Jog Wheel

Alarm Sounder

External Addressable Relay Card

4208

4209

4210

4211

4212

4213

4214

4215

4216

70 0

RS485 to HUB

RS485 to HOST

or HMI PANEL

Optional Event Panel Printer

Optional Keyswitch

240.0

Connection to Addressable Gas

Detectors and Addressable Relays

Power and Modbus Connection

Detector Connector:

Pin 1 24V DC

Pin 2 Comm B

Pin 3 Comm A

Pin 4 0V DC

Power Connector: Cable

Pin 1 Comm B Grey

Pin 2 Comm A Green/Yellow

Pin 3 24 V DC Brown

Pin 4 0V DC Black

Addressable Gas Detectors and Addressable interface modules connect here

in the same manner described previously.

mA+360CONC0V mA-

ZERO

CAL

360

mA

GND

A

B

4101 41024102

FAULT

24V DC

CHASS

P Y W

Common

Active

Compensator

mA+360CONC0V mA-

360

mA

GND

A

B

24V DC

CHASS

Compensator

ZERO

CAL

FAULT

P Y W

Common

Active

Tocsin 106 Pellistor Flamable

Gas Detectors Shown

Page 16 of 52

Addressable Relay Card

Power out for

use in

conjunction

with relays

0V DC

24V DC

Relay status LED,

ON when Energised

In all Cases:

Relay contact ratings.

7A @ 250V AC Non-Inductive

7A @ 30V DC Non-Inductive

Spike suppression must be fitted

Note that FAULT relays are normally

energised on power up.

24V DC

A2

A1

Base Address set up

LED's and interface

for the relay card

Highways Connection

Pin 1 0V DC

Pin 2 Comm A

Pin 3 Comm B

Pin 4 24 V DC

Pin 1 0V DC

Pin 2 Comm A

Pin 3 Comm B

Pin 4 24 V DC

Highways Connection

Example fit

protection

diodes when

0V DC

switching

external DC

loads.

~

A1

~

A2

Example fit protection

supressors when

switching external AC

loads typical device

Farnell Ref 1438460

Normally Closed

Common

Normally Open

Relay Terminals

First Relay on

The Card (relays

number from

this one).

Page 17 of 52

TOCSIN i700 Relay Outputs

There are four relays directly fitted to the Tocsin i700 controller. These can be configured by the user to

activate on different alarm levels. One of the relays, is a dedicated system fault relay. See later programming

details regarding alarm and fault relays.

Switching DC Loads

Normally Closed

Common

Normally Open

Example fit protection

diodes when switching

external DC loads.

Switching AC Loads

Normally Closed

Common

Normally Open

Example fit protection supressors

when switching external AC loads

typical device IGD Part Number

5438601

24V DC

~

A1

A1

A2

0V DC

~

A2

In all Cases:

Relay contact ratings.

7A @ 250V AC Non-Inductive

7A @ 30V DC Non-Inductive

Spike suppression must be fitted

Note that FAULT relays are normally

energised on power up.

In all cases switched loads should have appropriate EMC protection as indicated in the diagram above.

Loads should be fused. DC inductive loads should not be powered from the controller PSU. Inductive

loads such as solenoids or motors can have high in-rush currents well above the steady state current

indicated on data sheets. These high in-rush currents can interfere with the correct operation of the

controller and so powering from the control panel is to be avoided.

Page 18 of 52

Powering Third Party Devices

In general third party devices should only be switched and NOT powered from the

Tocsin 700, (with the exception of beacons and sounders).

The Tocsin 700 controller has been extensively third party tested to ensure electrical

safety and EMC compliance in a number of installation formats.

Connecting third party devices which may place unknown power demands on the Tocsin

700 can result in damage and/or unintended operation and so is NOT recommended.

The requirement to power gas shut off solenoid valves is common and so has been

tested. The following tables and wiring arrangement will allow a suitable solenoid to

operate correctly from the control panel.

Note this connection is

direct from the 700

PSU. Incorrect

connection can

damage the 700 and

power supply. Check

polarity before

powering

Example fit

protection

diodes when

switching

external DC

loads.

Tocsin 700 Model Max Solenoid

Load @ 24VDC

60W PSU Version with

8 Detectors 1.5A

150W Version with

50 Detectors 1.5A

0V

24V

A2

A1

Do note exceed the ratings listed on this data sheet. Also note that some solenoid

valves can have significant in-rush current which may adversely affect operation and

overload the power supply.

Page 19 of 52

Operating System

Operating System Overview

2 Line x 16 Character LCD Display

Output Relay 1 Lamp

Output Relay 2 Lamp

Output Relay 3 Lamp

System Fault Lamp

Power On

Jog Wheel

Rotate the jog wheel to move

up and down the system

menus.

Press the jog wheel to make

a selection or to accept/silence

an alarm

The Tocsin 700 series gas detector control panels are designed to be as flexible in operation as

possible. The system software allows the owner/installer to configure the following functions:-

Configure input type, not only the selection of pre-programmed input gases but also the option

to define an input type and scale the incoming 4-20mA signal to match. For example,

pressure, temperature, distance etc

Decide alarm levels for each input and decide, rising,falling or latching alarms and which relay

to asign to which inputs to allow, zoning etc

Logical naming of inputs, for example 'boiler 1' (max 8 characters)

Set the display scan rate

Zero and calibrate each channel from the control panel.

In addition the Tocsin 700 control panel can be 'hooked up' to a PC or PALM device via its serial

programming link to allow system configuration using Oliver IGD software. This allows not only preconfiguration of the panel prior to commissioning but also a record of how the system was set up.

+Always refer to the shipping manifest and test schedule for confirmation of the shipped

configuration.

Page 20 of 52

Accepting and Reseting Alarms

For most of its operating life the Tocsin 700 control panel and associated sensors will monitor for

whichever hazard it is configured for. The only requirement from the plant operator is to have the

system regularly calibrated, typically every 3 or 6 months depending on the nature of the gas

hazard. This section describes what happens at the control panel should the system detect a hazard

and go into alarm and how to accept the alarm and reset the control panel.

Step 1. The panel detects a gas hazard

Panel indicates which channel is in alarm

Panel indicates which alarm level has tripped

Panel indicates how many alarms in total have tripped

CH1 AL 1 TOTAL 2

CH1 AL 1 TOTAL 2

BOILER 1 AREA 3

BOILER 1 AREA 3

Relay outputs will activate dependant on the

system configuration

Alarm outputs (beacons and sounders) are active

if fitted.

The user programmed description for the sensor is displayed

Step 2. Operator Accepts The Alarms

Pressing the jog wheel will accept the indicated alarm. If there is more than one alarm tripped then

the next alarm is indicated on the display. Note that the total number of active alarms is indicated in

the top right of the display.

Once all alarms have been accepted the sounder output from the panel is de-activated, if a sounder

has been fitted it will silence. The relay outputs associated with the active alarms will still be

energised until the gas hazard has been cleared and the panel reset.

Once all active alarms have been accepted the display will read as follows:

WARNING

CH1 AL 1 TOTAL 2 OF 4

CH1 AL 1

It is important to have a site health and safety

PRESS RESET ALL

response in place in the event of alarm activation.

Gas detection systems are an indication that a

problem may exist but should not be relied on as a

f a i l s a f e s y s t e m . .

Pressing the jog wheel at this stage will reset the system. This de-activates any energised alarm relays

depending on the panel user alarm programming and the 'beacon' output. If the gas hazard is still present

then it will not be possible to reset the alarm.

Page 21 of 52

Tocsin 700 Menu System

1. Start up

12:23:01

OLIVER IGD LTD

2. Warming Up

Time 12:23:01

WARMING UP 01:49

Time in 24 hour format.

Company name is programmable in

EPROM Memory.

Warmup is displayed for the set period

3. Normal Display Mode

Normal display mode.

1 FLAM 0 % LEL

BOILER 1

In normal display mode the display will

auto scroll through all installed channels

at a user settable time. The time is

settable from 1 to 240 minutes.

Time is user programmable in seconds

and is programmed in the engineering

mode.

Normal display shows current channel in top left corner. Current channels measurement gas, reading

and measurement units.

The gas types are pre-programmed in the Tocsin 700 operating system. 23 Gas Types are preprogrammed and a further 4 gas types can be added by the user.

There are three pre-configured measurement types.

%LEL PPM %VOL.

Again the user can add a further two measurement types.

Page 22 of 52

4. Pre-configured Measurement Types

Display with %LEL (Lower Explosive Limit) Display

1 FLAM 0 % LEL

BOILER ROOM 1

Display with %VOL (% by Volume) Display

1 O2 0 % VOL

N2 STORE 1

Display with ppm (Parts Per Million) Display

1 CO 12 PPM

CAR PARK LEVEL 1

The second line displays the channels

description, up to eight characters long this is

editable using the Tocsin 700 menu system.

5. Menu System

The menu system is accessed by firstly selecting a channel. This is done by rotating the Jog Wheel.

Clockwise increases the channel indicated. Anti clockwise decreases the channel indicated. When the

switch is rotated the back light illuminates and the unit stops it's auto scrolling function. If no channel is

selected or if the button is not rotated within a minute then the unit returns to it's normal auto scrolling

mode. In auto scrolling mode each channel fitted to the control panel is sequentially displayed for a

fixed time period.

To select a channel to work on the Jog Wheel is pressed. This takes the user into the main menu.

The channel selected is shown on the top line. This information updates with the users commands.

The gas concentration also updates in this mode, this aids the user in calibration.

Channel Number

Gas Type

Current Reading

Units

1 O2 0 % VOL

`

Note these

ZERO

configuration

menu’s are

password protected

Current Command Option

Pressing the jog wheel will

activate this command.

Page 23 of 52

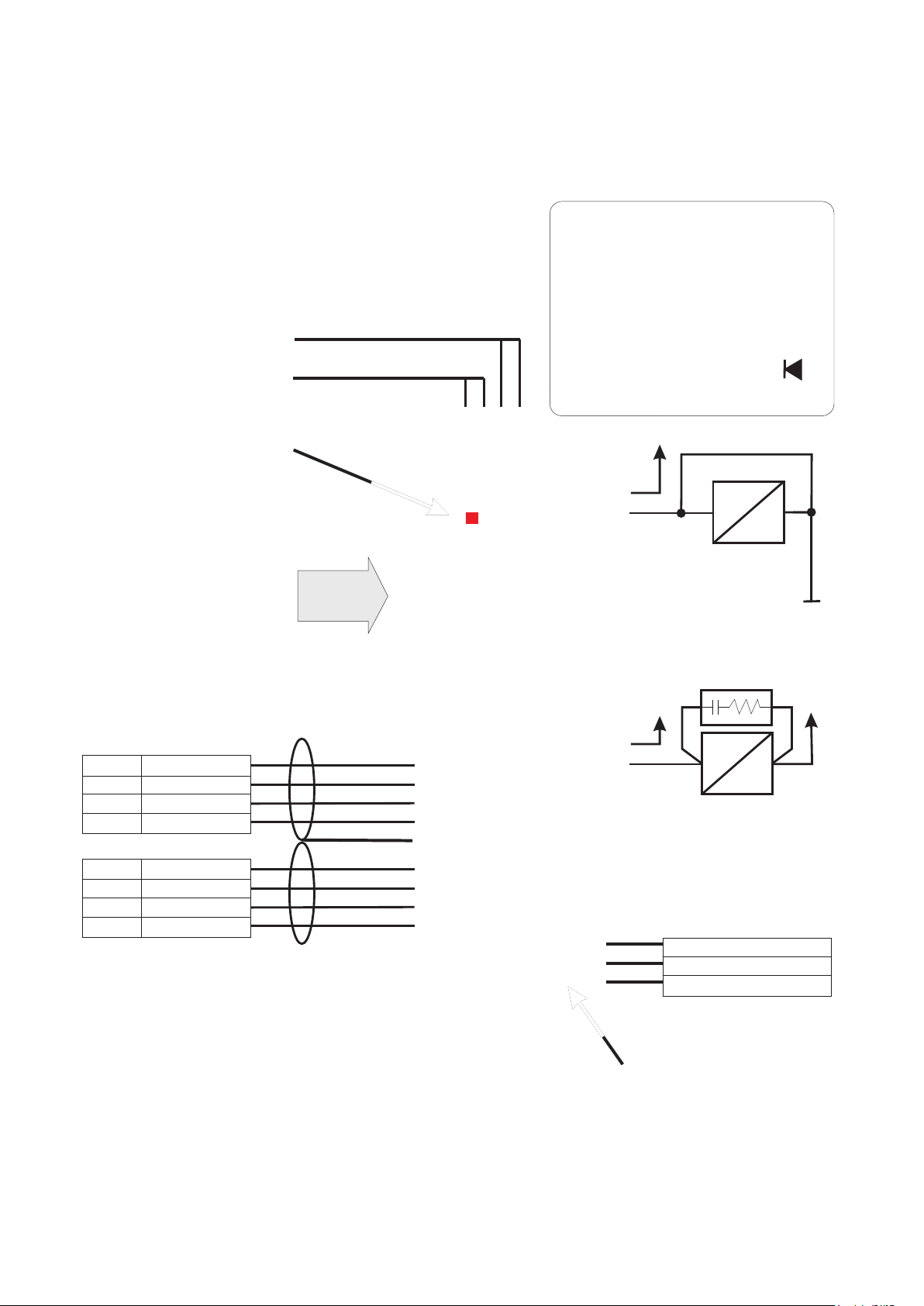

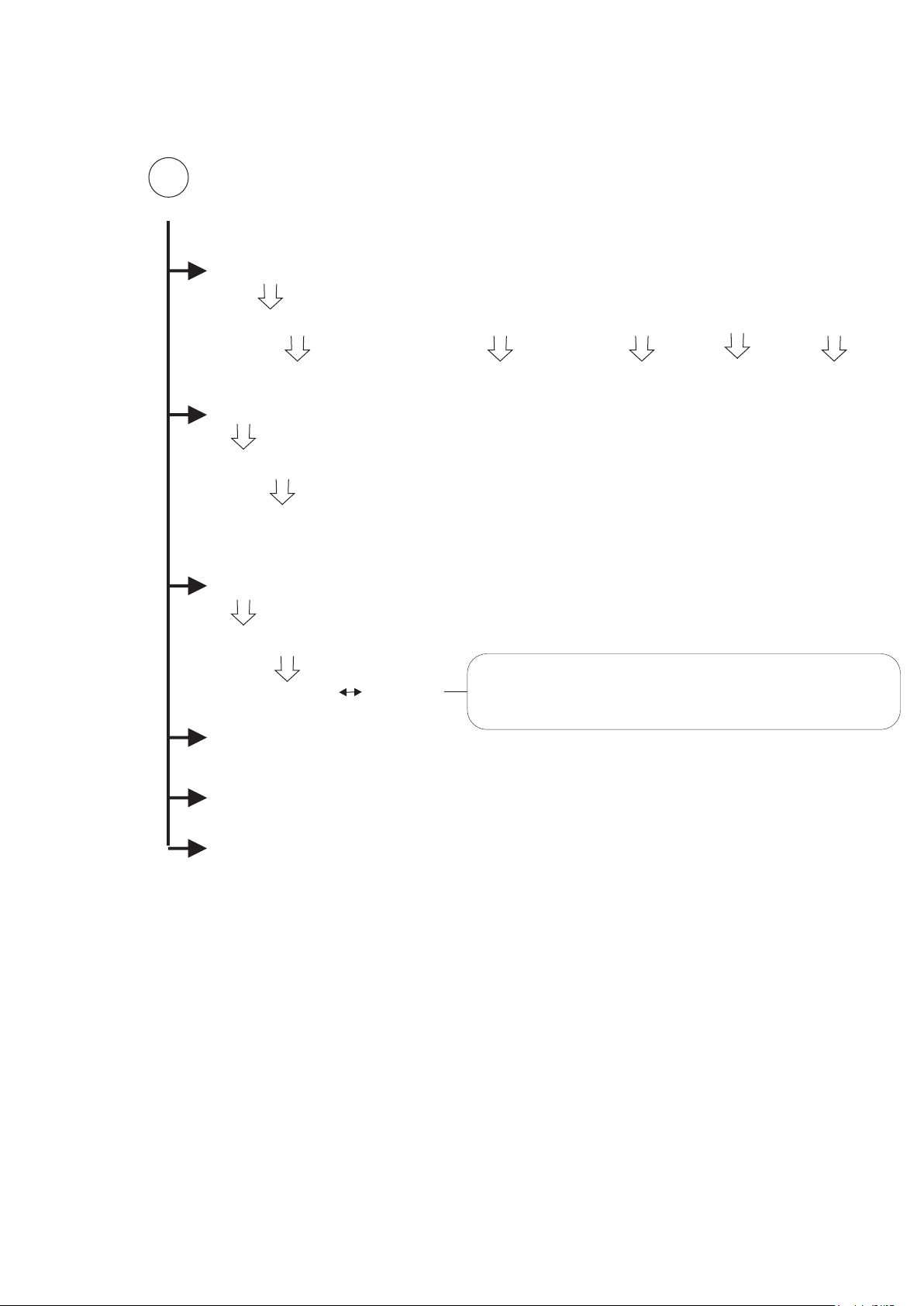

7. Menu System Overview Setup Menu’s (User Menu)

Press and hold down the jog wheel. The system will

1 O2 0 % VOL

ZERO

request a password. Once entered correctly the following

menu sequence will be displayed.

Rotate to move down a menu. Pressing the button selects the sub menu one column

to the right

ZERO

ABORT CONTINUE

CALIBRATE

ABORT CONTINUE

ALARM 1 SETUP

PASSWORD CODE

100

SELECT SENSOR SET ALARM TYPE SET LEVEL CABLE ACTION SET RELAY OP

1 to 64 Rising

Falling

Rising Latch

Falling Latch

rotate

jog wheel

to set

Select

I/O

Cable 1

or 2

Set ‘N’

For Normal

Operation

or

1 to 37

or

address

Set ‘M’

ALARM 2 SETUP

For To Allow

Muting Action

SELECT SENSOR SET ALARM TYPE SET LEVEL CABLE ACTION SET RELAY OP

1 to 64 Rising

Falling

Rising Latch

Falling Latch

rotate

jog wheel

to set

Select

I/O

Cable 1

or 2

Set ‘N’

For Normal

Operation

or

1 to 37

or

address

Set ‘M’

ALARM 3 SETUP

For To Allow

Muting Action

SELECT SENSOR SET ALARM TYPE SET LEVEL CABLE ACTION SET RELAY OP

1 to 64 Rising

Falling

Rising Latch

Falling Latch

rotate

jog wheel

to set

Select

I/O

Cable 1

or 2

Set ‘N’

For Normal

Operation

or

1 to 37

or

address

Set ‘M’

COPY ALARM SETUP

For To Allow

Muting Action

2

COPY FROM CH (select from 1 to 64)

TO RANGE CH (select from 1 to 64) - (select from 1 to 64)

Page 24 of 52

7. Menu System Overview Setup Menu’s Continued

2

COMMON ALARMS

SELECT GROUP FROM CHANNEL TO CHANNEL ALARM SET RELAY OP

PASSWORD CODE

100

1 to 16

DESCRIPTION

SELECT CHANNEL (1 to 64)

use jog wheel to enter up to 8 character description

DISABLE CHANNEL

SELECT CHANNEL (1 to 64)

ENABLE DISABLE

CHANGE CHANNEL

ENGINEER MENU

Select the from to range

for the channel alarms

to be grouped

Note the display option shows what you are about

to change the option to. Therefore if the channel is

already ENABLED then the option shows DISABLE

AL1,

AL2

or AL3

1 to 37

or

address

EXIT

Page 25 of 52

The bottom line of the display shows the command available for selection and is altered by

rotating the jog wheel.

5.1 The Zero Command

With the panel in normal display mode,

rotate the jog wheel to the desired

1 O2 0 % VOL

ZERO

channel and press the jog wheel. Now

rotate the jog wheel until the bottom line

of the display reads zero. At this stage

apply zero gas to the gas head and allow

the reading to stabilise.

1 O2 0 % VOL

Once the reading has stabilised

press the jog wheel and the bottom

line will change to read zeroing. The

Tocsin 700 now averages the

incoming signal for a few seconds

before applying any necessary zero

correction. Once complete the

bottom line of the display changes to

read ‘PASSED’ or ‘FAILED’ . If the

zero operation passed the zero

correction is applied.

5.2 The Calibrate Command

1 O2 0 % VOL

CALIBRATE

1 O2 0 % VOL

SET CAL BOTTLE

ZEROING

This function allows the user to calibrate a channel.

As in the case of the zero function, select a channel to

be calibrated and rotate the jog wheel until the

'Calibrate' option appears on the bottom line of the

display.

The display set bottle will appear

for a few seconds to prompt the

input of the calibration gas set

point.

1 O2 0 % VOL

The bottom line of the display now changes to

100

allow the input of the calibration gas value. The

display will indicate the last value used to

calibrate the channel. Rotate the jog wheel:

Clockwise to increase the value.

Anticlockwise to decrease the value.

With the calibration gas applied to the gas head allow the reading

to stabilise then press the jog wheel. The display will change to

'calibrating' for a few seconds as the reading is averaged and new

calibration constants calculated. PASSED or FAILED will be

displayed and once complete the display will return to step A.

1 O2 0 % VOL

CALIBRATING

Page 26 of 52

5.3 Set Alarm Level Setup for Alarm Levels 1,2 and 3

Select the ALARM 1 SETUP from the user

menu. And the following display will be

shown. Note you are now editing alarm

level 1 settings. By changing the channel

number you can check and set all alarm

detector

channel

number

level 1 settings for each channel

connected. Press and hold the jog wheel to

exit the screen then select ALARM 2 and

ALARM 3 SETUP’s.

Gas

Relay Action as:

Rising

Falling

Rising Latching

Falling Latching

Set Alarm Level

As you enter this menu screen

the channel number will be

flashing.

Press the jog wheel to move

sequentially around the screen.

With the item you want to change

flashing rotate the jog wheel to

alter levels or options.

01 RIS&L L = 19

C1 N RELAY = 1

Cable Number (1 or 2) For

Addressable Detectors and

Relays. Note this is not

relevant for Analogue

Detectors or On-board

Relays

1

2

3

PSU SET TO 230V AC

L N E

Relay Action.

Set as N for Normal

Operation or Set as

M if you want the

relay to De-activate

when the jog wheel

is pressed to Mute

an active alarm,

Mute Action

Relay Number To

Activate When Alarm

Level Exceed

Note relay numbers 1

to 3 are included on

the main panel

located as shown here

01 RIS&L L = 50

C1 M RELAY = 4201

Relay outputs can also be added onto the addressable highway

along with gas detectors to provide local relay outputs for

sounders/beacons and small solenoids etc.

These outputs start their numbering from 4201. Up to 32

addressable relay output nodes can be added to either

addressable cable 1 or 2 (C1,C2).

This example shows an alarm set once 50ppm is exceeded

on channel 01. The relay activated if this occurs is on the

addressable highway at address 4201 connected to port 1 (C1).

The alarm is Rising and Latching in operation and so must be

manually reset at the Tocsin 700 panel (RIS&L). If the T700 jog

wheel is pressed the alarm will Mute (De-activate) as the action

is set to M.

Page 27 of 52

Copy Alarm Setup Command

Select the COPY ALARM SETUP if you want to copy the complete alarm setup from one channel to

multiple others. This can be used to speed setup where there are many sensors/channels that are to

have the same alarm levels set. Each channel can then have any minor amendments made after

copying the majority of the setup thus speeding up the setting up process of the control panel.

Select the COPY ALARM SETUP menu item

1

and the following setup screen is displayed.

COPY FROM 01

TO RANGE C02 TO CO2

Note the COPY FROM channel number is

flashing. This is the channel who’s setup you

wish to copy to other channels. Rotate the jog

wheel if you wish to select a different channel

to be copied from. Once the selection is

correct press the jog wheel

2

COPY FROM 01

The first of the copy to channel numbers is

now flashing. Again rotate the jog wheel until

the first channel number in the range you

TO RANGE C02 TO CO2

wish to copy to is displayed. Press the jog

wheel when the first channel in the range to

copy to is indicated.

2

COPY FROM C01

The second of the copy to channel numbers

is now flashing. Again rotate the jog wheel

until the last channel number in the range you

TO RANGE C02 TO CO8

wish to copy to is displayed. Press the jog

wheel when the last channel in the range to

copy to is indicated.

In this example the alarm setup from channel

one will be copied to channels two through

eight.

Page 28 of 52

5.6 Editing The Channel Description

1 O2 0 % VOL

DESCRIPTION

Select DESCRIPTION from the user menu.

This allows the user to edit the description shown

when the unit is in normal display mode. This

description is also used in Alarm indication to

show alarm locations.

1 O2 0 % VOL

Rotating the jog wheel causes the current

ROOM 3

character to change. Once the desired

character is displayed press the jog wheel

to accept it and move on to the next

character to be edited. Once the desired

text string is complete press and hold in the

jog wheel. The display will flash to indicate

the end of text edit mode. Release the jog

wheel and the newly edited text string is

accepted.

1 O2 0 % VOL

ROOM 3

5.7 Change Channel

Allows the user to change channel being edited. This allows the user to stay in the menu system

rather than going out and coming back in. Press the jog wheel until the desired channel number is

displayed. Press the jog wheel to then move to that channel.

5.75 Common Alarms

This function allows the alarm activation of a relay output from a number of grouped channel

alarms (AL1,2 or 3).

In this example for common

alarm group 1 any Alarm

level 1 that activated for

channels 1 to 6 on the

control panel will activate

relay output 4201 (this

Common Alarm

group Number

up to 16 groups

can be stored

Range of channels Selected

01 FROM = 1 TO =6

AL1 RELAY = 4201

would be an addressable

Alarm Level for the

range of selected

relay output in this

instance).

channels

Relay Output (in this example

an addressable relay output)

Note relays used in grouped functions should ideally not

be used elsewhere in the setup for individual alarm

outputs.

Page 29 of 52

PASSWORD CODE

100

5.8 Common Alarms

The common alarm menu provides another method to

01 FROM =1 TO =1

AL1 RELAY = 0

When using common alarms there are some restrictions to bear in mind when planning both the

layout of the channels and alarms:

activate alarm outputs. The menu option provides a

method to ‘group’ together channel alarms to a common

alarm output.

As an example if channels 1 to 6 on the control panel all

need to activate a beacon sounder on first alarm: then

this is simpler to set using the common alarms menu

rather than programming on each channel alarm.

This also free’s up the channel alarms for other outputs.

1: Common alarms work best with consecutive channels so if there is a requirement for a common

alarm output to work with a number of detectors in an area, make sure the detectors are on

consecutive channels.

2: If you use a relay output on a common alarm DON'T also use that relay on a normal channel

alarm. doing so runs the risk that a channel in the common alarm group can be trying to ‘set’ a relay

whilst an individual normal channel alarm can be trying to reset the same relay. This can result in

unpredictable alarm operation and is to be avoided.

3: There are 16 common alarms

4: If using addressable relay outputs or nodes, these must be on Cable Highway 1

Programming Example

Common alarm number 3

03 FROM =1 TO =6

AL1 RELAY = 4219

From channel 1 to channel 6 any AL1 on these channels activates addressable relay 4219

5.9 EXIT

Returns user to normal display. Auto scrolling initiates and back light turns off after 1 minute.

Page 30 of 52

PASSWORD CODE

50

8. Menu System Overview Engineers Menu

CHANNEL SETUP

CHANNEL SELECT GAS SELECT RANGE UNITS CABLE TYPE ADDRESS

1 TO 64

COPY CH SETUP

FLAM

CO

NO

NO2

CL2

HCL

HCN

NH3

O2

H2S

SO2

H2

O3

CO2

FIRE

CFC

VAC

PRES

TEMP

HF

EthO

SiH4

BCL3

CUST

1

5

10

25

50

100

200

500

1000

2000

3000

%LEL

PPM

%VOL

Select

I/O

Cable 1

or 2

102

102IR

1 TO 16 For

analogue inputs

4100 to 4200

For Digital

Inputs

COPY FROM CH (select from 1 to 64)

TO RANGE CH (select from 1 to 64) - (select from 1 to 64)

FIND ADD SENSORS

EDIT LOW ADDRESS (enter start address)

EDIT HIGH ADDRESS (enter end address)

FIND ADD RELAYS

2

Reports which cables will be checked based on setting for Cable C2

Found = 4

1 of 4 = 4201 (C1)

Each jog wheel press shows the next found relay. Note

the cable number its is found on is also reported. This

function is for information only.

Page 31 of 52

PASSWORD CODE

50

22

SENSOR DIAG

rotate jog wheel to select sensor/channel

press jog wheel to view

CONCENTRATION mA ZERO CAL BOTTLE RANGE

SENSOR ADJUST

SELECT CHANNEL (1 to 64)

SELECT TO ADJUST ZERO AND SPAN GAIN

OF A DETECTOR. (Addressable detectors only)

ZERO ALL SENSORS

CHANGE ADDRESS

WARNING ABORT OR CONTINUE

SET CURRENT ADDRESS (4100 TO 4200)

SET NEW ADDRESS (4100 TO 4200)

SET TIME

HOUR (rotate jog wheel to change press jog wheel when correct)

MINUTE (rotate jog wheel to change press jog wheel when correct)

SET DATE

DAY (rotate jog wheel to change press jog wheel when correct)

MONTH (rotate jog wheel to change press jog wheel when correct)

YEAR (rotate jog wheel to change press jog wheel when correct)

ADD CHANNELS

3

TEL FOR NEW SEED (contact Oliver IGD to obtain code to change the number of

42038 connected channels)

Page 32 of 52

PASSWORD CODE

50

3

REMOTE PORT

MODBUS (J17) EVENT PRINTER SENSORS RS485

SET RELAY BOARDS

SET NUM BOARDS (0 to 4)

SET 4-20mA BOARDS

SET NUM BOARDS (0 to 4)

4-20OUT ADDRESS

4-20OUT CH1

4-20OUT ZERO

4-20OUT CAL

TEST 4-20mA OUT

TEST 4-20mA OUT

TEST ADD SENSORS

TEST ADD RELAYS

TEST ADD RELAYS2

TEST RELAYS

TEST FIRE

CHANGE CHANNEL

USER MENU

EXIT

Page 33 of 52

5.3 Detector Channel Setup

Select the CHANNEL SETUP from the

ENGINEER menu. And the following

display will be shown. By changing the

channel number you can check and set all

channels connected. Press and hold the

jog wheel to exit the screen.

Note that channels for addressable

detectors will be automatically configured

by using the FIND command (see later)

As you enter this menu screen

the channel number will be

flashing.

Press the jog wheel to move

sequentially around the screen.

With the item you want to change

flashing rotate the jog wheel to

alter levels or options.

Cable Number (1 or 2) For

AddresNote this is not relevant for

Analogue Detectors.

Gas

detector

channel

number

01 FLAM 100 PPM

Gas Type

(see previous list)

Range

Units

C1 102IR 4100

Detector Address

Note address numbers 1

to 8 are included on the

main base panel located

as shown here

Digital

addressable

detectors wired to

port C1 and C2

have addresses

PSU SET TO 230V AC

starting at 4100.

Up to 32

detectors can be

wired on each

C1C2

port.

1 2 3 4 5 6 7 8

L N E

As mentioned above, addressable detectors can be automatically installed by using the FIND

command described later in this manual.

Analogue channels must be set up manually. The control panel accepts input from any 4-20mA device,

not necessarily gas detectors. For flexibility the channel setup function allows the gas type, range and

units to be configured. Most standard gas types, ranges and units can be selected from the preconfigured lists. However if the required gas type, range or units are not present on the preprogrammed lists then up to four user configurable types can be added. Adding user types is detailed

later in this manual. Note that channel setups can be copied to speed set up in a similar manner to the

way alarm setups are copied.

Page 34 of 52

Copy Alarm Setup Command

Select the COPY CHANNEL SETUP if you want to copy the complete channel setup from one channel

to multiple others. This can be used to speed setup where there are many sensors/channels that are to

have the same detector inputs set and scaled. Each channel can then have any minor amendments

made after copying the majority of the setup thus speeding up the setting up process of the control

panel.

Select the COPY CHANNEL SETUP menu

1

item and the following setup screen is

displayed.

COPY FROM 01

TO RANGE C02 TO CO2

Note the COPY FROM channel number is

flashing. This is the channel who’s setup you

wish to copy to other channels. Rotate the jog

wheel if you wish to select a different channel

to be copied from. Once the selection is

correct press the jog wheel

2

COPY FROM 01

The first of the copy to channel numbers is

now flashing. Again rotate the jog wheel until

the first channel number in the range you

TO RANGE C02 TO CO2

wish to copy to is displayed. Press the jog

wheel when the first channel in the range to

copy to is indicated.

2

COPY FROM C01

The second of the copy to channel numbers

is now flashing. Again rotate the jog wheel

until the last channel number in the range you

TO RANGE C03 TO CO7

wish to copy to is displayed. Press the jog

wheel when the last channel in the range to

copy to is indicated.

In this example the channel setup from

channel one will be copied to channels three

through seven.

Page 35 of 52

The FIND Command

If addressable gas detectors are cabled to either port 1 or 2 of the control panel then the FIND

command can be used to automatically install these detectors onto the panel. Note this option is usually

only run the first time detectors are connected and will already have been run if factory configuration

has been requested and undertaken. Running the FIND command again will overwrite any previously

stored information. This will include any alarm level set up as a newly installed detector will have default

alarm levels set automatically as part of the FIND function.

Select the FIND ADD SENSORS menu item

1

and the following setup screen is displayed.

FIND ADD SENSORS

EDIT LOW ADD 4100

Use the jog wheel to enter the first address in

the sequence you expect to find (usually

4100)

Note the low address number will be flashing.

Once correctly set press the jog wheel to

move to the next setting.

2

FIND ADD SENSORS

EDIT LOW HIGH 4100

Now use the jog wheel to enter the highest

address you expect to find. Once set press

the jog wheel.

The system now checks through each

3

possible address in the range selected and

tries to communicate to each address in turn.

FINDING 4105

FOUND 2 SENSORS

The top line of the display indicates the

current address being searched for and the

bottom line of the display shows the total

number of detectors found so far

Page 36 of 52

The FIND Command Continued.......

4

FOUND 10 SENSORS

ACCEPT ?

5

SENSOR 1 OF 6

ADDRESS = 4101

The system now advises how many detectors

have been found. You now have the option to

press the jog wheel and ACCEPT these

detectors into the panel setup or select

ABORT to exit the FIND option and make no

changes

If you select to ACCEPT the found detectors

the system will indicate sequentially each

address that has been found. At this stage

these should be noted down on a setup sheet

to keep a record of which channel is which

detector address. Press the jog wheel to

display each detector address in turn.

Page 37 of 52

The FIND ADD RELAYS Command

If addressable Tocsin 107 series I/O Nodes are cabled to either port 1 or 2 of the control panel then the

FIND ADD RELAYS command can be used to check that the Tocsin 700+ can communicate to them.

The function first checks if port C2 is set for SENSORS option, if not it is ignored. The function then

interrogates the highways and reports how many addressable relays have been discovered and what

addresses and cable numbers (C1 or C2) they are on.

Select the FIND ADD RELAYS menu item

1

and the following setup screen is displayed.

REMOTE PORT NOT

SENSORS (J16)

The function first checks the selection on port

C2. If the PORT setting is SENSORS then it

is checked, if not then it is ignored (as in this

example).

2

TEST RELAYS ON

CABLE C1 ONLY

The system now checks through each

3

possible address in the range 4200 to 4299

and tries to communicate to each address in

FOUND = 4

turn.

1 of 4 = 4201 (C1)

The top line of the display now indicates the

number of relay addresses found and the

bottom line indicates each address in turn

and its cable location as the jog wheel is

pressed

4

On the final press of the jog wheel the system

NO CHANGES MADE

reports ‘NO CHANGES MADE’ as this is an

information only option.

The display then advises set up of the relays

on AL1,2 or 3 manually as no auto set up is

possible.

Note that 8 way relay extender boards can

also be discovered using this option.

Page 38 of 52

The TEST ADD SENSORS command

This function can be used to check correct communication is in place when commissioning or

testing addressable gas detectors.

The top line of the display indicates the

current channel under test. The system

will step through each detector in turn.

In this mode of operation the detectors

CHANNEL 1 OF 7

are run 10 times faster than normal to

exercise the communication circuits

ERRORS = 0.0%

The bottom line of the display shows

the percentage of errors detected. Errors

can be of two types. If a data packet is corrupt

it will be discarded. If a detector takes too

long to reply to a request for data then this

will also be an error. Ideally for a newly

installed system all channels will show zero

errors. Greater than 0.5% errors indicates an

‘electrically noisy’ industrial environment or

potentially faulty detector or cable terminations.

Up to 0.5% errors can be tolerated.

Normally errors can be traced to poor

electrical terminations.

The TEST ADD RELAYS command

Similar to the TEST ADD SENSORS this function can be used to check correct communication is in

place when commissioning or testing addressable relay output nodes.

The top line of the display indicates the

current relay under test. The system

will step through each detector in turn.

In this mode of operation the detectors

are run 10 times faster than normal to

1 Add=4201 C1

exercise the communication circuits

Tx=1059 E = 0.0%

The bottom line of the display shows

the percentage of errors detected. Errors

can be of two types. If a data packet is corrupt

it will be discarded. If a detector takes too

long to reply to a request for data then this

will also be an error. Ideally for a newly

NOTE

installed system all channels will show zero

errors. Greater than 0.5% errors indicates an

This test is a communications test

only and does not power the actual

relay outputs. To test the relays use

the TEST ADD RELAYS2 function.

‘electrically noisy’ industrial environment or

potentially faulty detector or cable terminations.

Up to 0.5% errors can be tolerated.

Normally errors can be traced to poor

electrical terminations.

Page 39 of 52

The TEST ADD RELAYS2 command

This function can be used to check relay operation when commissioning or testing addressable

relay output nodes.

When this mode is selecting this display

is shown.

Rotate the jog wheel to select a relay to test.

1 of 3 ADD= 4201

RELAY = OFF C1

The bottom line of the display shows

the relay output that relates to the

address shown on the top line of the display.

Press the jog wheel to change the relay status.

Note that the relay status set will remain

until you exit engineer mode.

It should also be noted that the relay action

(normally open or normally closed) is set on

the Tocsin 107 module software. If a Tocsin 107

module is set as normally closed then switching it

on here to test it will energise it to be normally

open and vice versa.

The TEST RELAYS command

This function can be used to check relay operation for relays 1 to 3 on the Tocsin 700 and relays 4

to 36 on any add-on relay cards that may be present.

RELAY TEST

RELAY AL1

Select the mode and the following

display is shown. Pressing the

jog wheel will energise each relay

output in turn AL1 to AL3 and also

the fault relay, Sounder and

Beacon Output

Page 40 of 52

The TEST FIRE command

Factory configured versions of the Tocsin 700 are available with the capability to operate analogue

thermal rate of rise and optical smoke detectors. This mode can be used when commissioning such

detectors and provides a walk around test function.

In this mode of operation the following

display is indicated with a 30 minute

count down timer indicated on the

bottom line of the display.

TEST FIRE

Checking (29:32)

Whilst in this mode the panel will

automatically reset any fire alarm

input after 5 seconds. This allows

a commissioning engineer to walk a

site triggering detector heads to

bump test them during test and

commissioning of a system.

After the 30 minute period the panel returns

to the ENGINEERS menu.

Press the jog wheel to exit ths mode

The CHANGE CHANNEL command

This function can be used to move from one channel to another without exiting the ENGINEERS

menu.

06 FLAM 5% LEL

CHANGE CHANNEL

Select the mode and press the jog

wheel to move sequentially

between channels.

Page 41 of 52

Menu Overview Production Menu

1

LCD CONTRAST

WARMUP MINS

T90 (Secs)

FAULT THRESHOLD

ALARM THRESHOLD

MUTE MESSAGE

MUTE TIME

MODBUS ADDRESS

MODBUS BAUD RATE

MODBUS DATA BITS

Set Display Brightness (1 to 10)

Set The Number of Minutes The panel is in Warm up Mode For (2 to 240)

Set the 4-20mA input Filter Level (0 to 100 Secs to T90)

Set the Level for Fault Detection on the Addressable Comm’s Ports

(8 to 99 consecutive errors communicating to a sensor before

reporting a system fault)

Set the number of seconds the gas level must exceed the set

alarm level for before setting the alarm relay.

Display ‘PRESS TO MUTE ALARM’ message on bottom line of display

when an alarm is active (ENABLE or DISABLE option). If disabled then

channel tag is displayed.

Set the time period for which an alarm will stay muted before

returning to its alarm condition

Set the Modbus address default is 100

Set the Modbus baud rate default is 19200

Set the Modbus data bits default is 8 bits

MODBUS PARITY

MODBUS STOP BITS

CUSTOM GAS

CUSTOM GAS1

CUSTOM GAS2

CUSTOM GAS3

CUSTOM GAS4

CUSTOM UNITS1

CUSTOM UNITS2

RESET TO DEFAULTS

REPROGRAM

Set the Modbus parity default is none

Set the Modbus stop bits default is 1

Select to add a custom gas type to the selectable list of

gases. Input and store any 4 digit reference and it is added

to the list of gas types that can be selected (i.e FLAM, CO etc)

Select to add a custom UNIT to the selectable list of

UNITS (for example PPM, %VOL etc. Input and store any 3 digit reference

and it is added to the list of unit types that can be selected

Reset the control panel to its default values and settings.

Select this option when updating the Tocsin 700 firmware using the

Tocsin 700 PC Set up software. Note connect to the control panel

first then enter factory settings mode and select REPROGRAM.

EXIT

WARNING

DO NOT ALTER THESE SETTINGS WITHOUT TRAINING OR

GUIDANCE FROM OLIVER IGD. IMPROPER SETTING OF

THESE PARAMETERS MAY RESULT IN UNINTENDED

OPERATION

Page 42 of 52

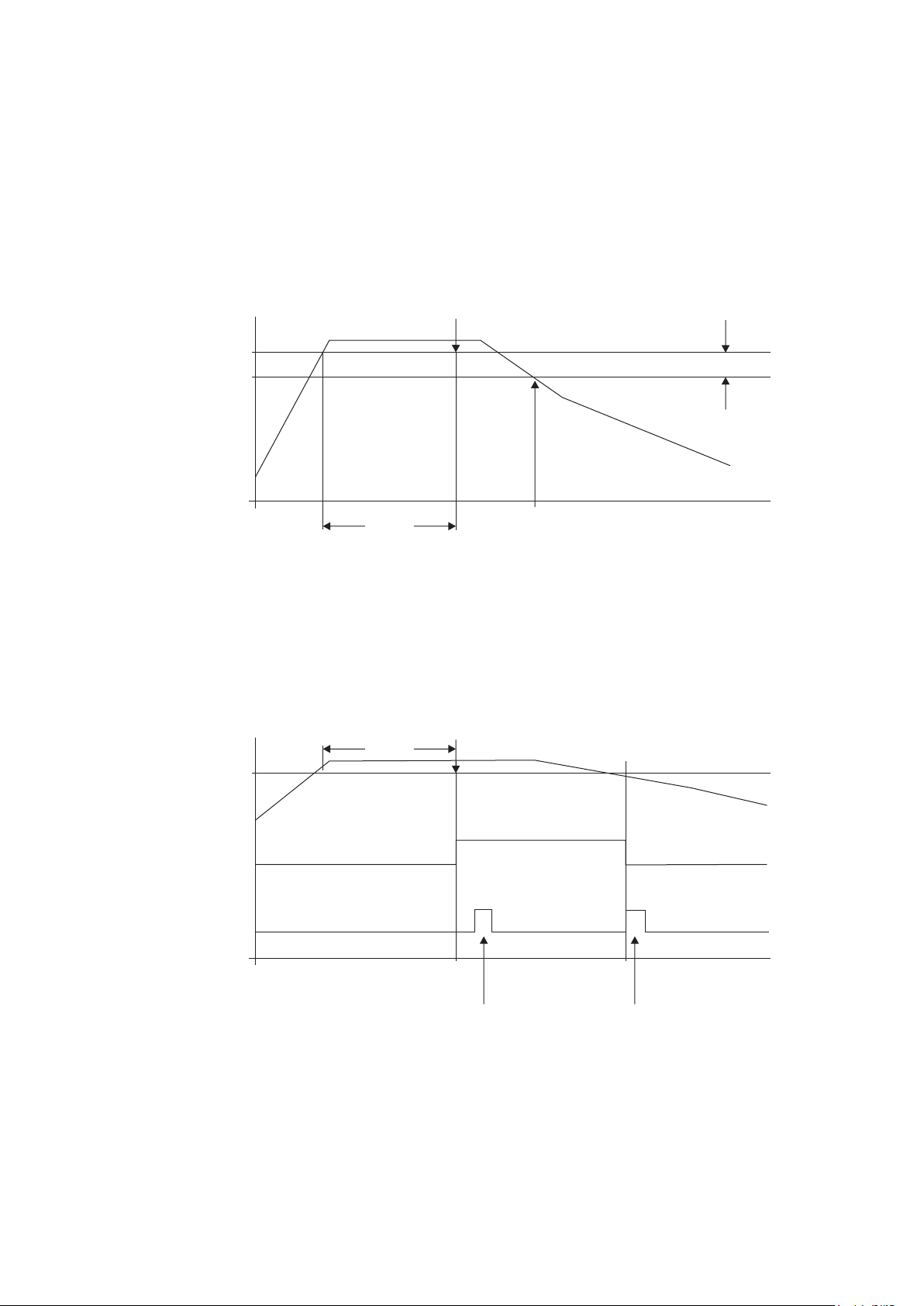

11. Alarm Output Action

Rising and Falling Non Latching Alarms

Alarm Set Point

5% of Alarm Set PointAlarm Activates

10 Seconds

(Software Adjustable)

Rising and Falling Latching Alarms

10 Seconds

Alarm Set Point

Alarm O/P On

Alarm O/P Off

Re-Set Input On

Re-Set Input Off

Alarm Resets

Alarm Activates

Indicates pressing the front

panel ‘jog wheel’ to cancel

the alarm

Page 43 of 52

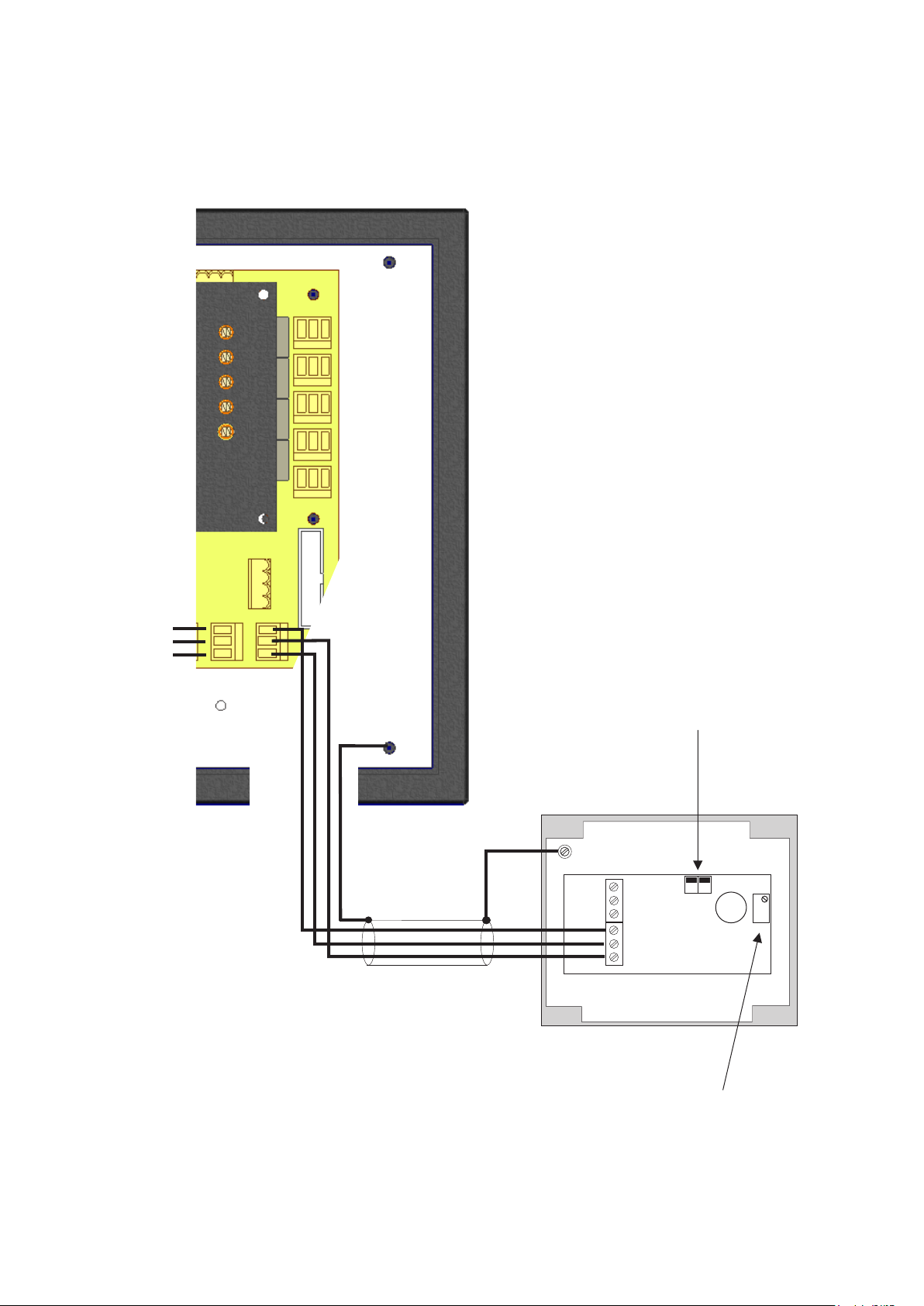

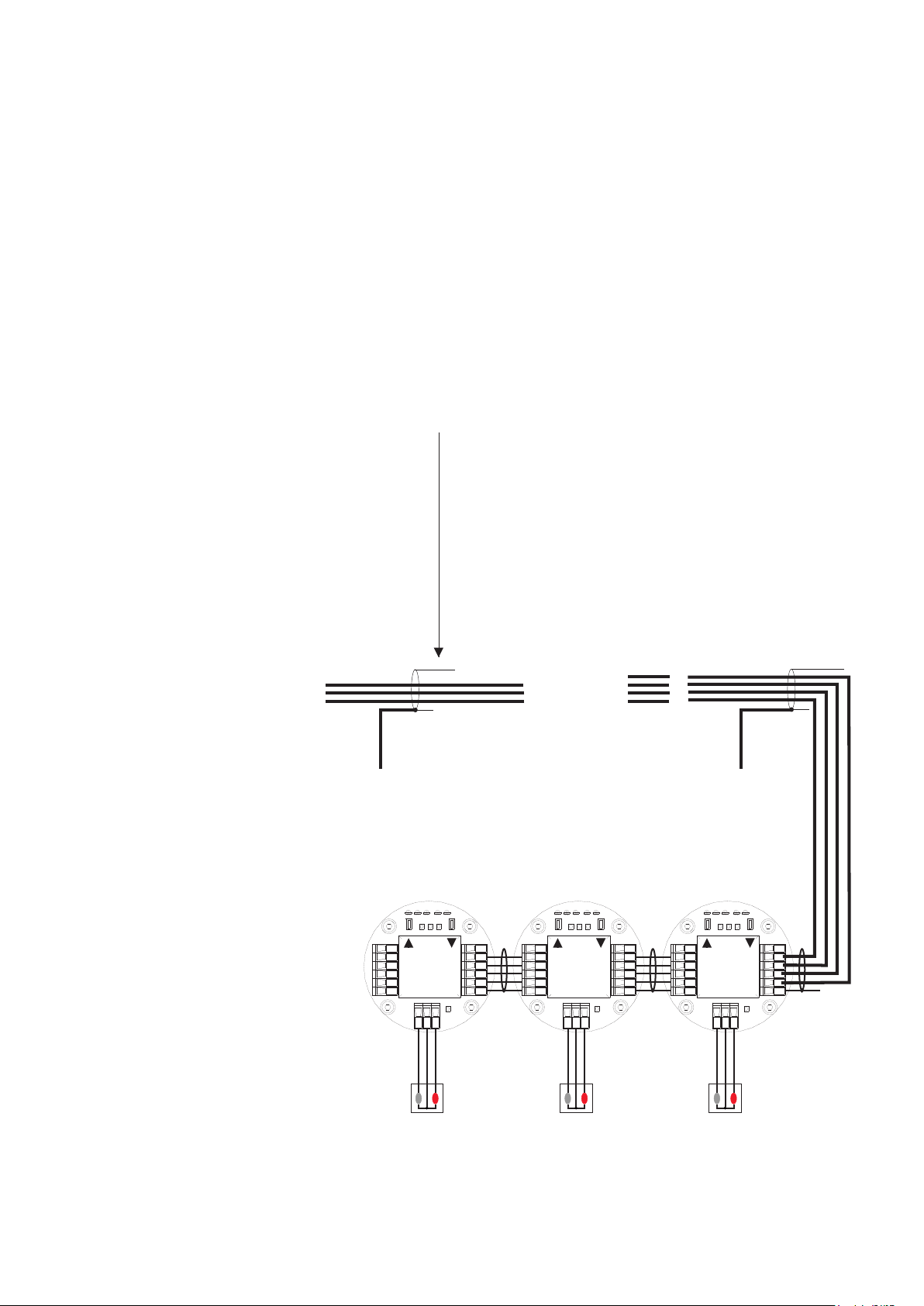

USING REMOTE ‘MIMIC’ PANELS

It is possible to connect two Tocsin 700 control panels to the same detectors. This allows you to

have the flexibility to provide local and remote display and control. The following schematic and

notes show the system requirement.

CABLING REQUIREMENTS.

Comms link between panels use min 1.5mm

SQ screened 3 core cable for up to 1KM

distance between panels. As indicated

connect A,B and GND (0V) only.

Master Control PanelMimic Panel

+24V DC

B

A

GND

Note that the detectors in this

example are communicating

with both panels (the master

panel is transparent to the

mimic). Alarms are set on the

control panel and so can be set

up to be the same or different to

meet the requirement.

+24V DC

B

A

GND

+24V DC

GND

B

A

Set C2 Remote Port as RS485 Option

Detectors Connected to Master Panel

mA+360CONC0V mA- mA+360CONC0V mA-

ZERO

CAL

360

mA

GND

A

B

24V DC

CHASS

Compensator

P Y W

Common

Active

FAULT

360

mA

GND

A

B

24V DC

CHASS

Compensator

ZERO

CAL

P Y W

Common

Active

FAULT

2.5mm SQ Cable See Previous Note

GNDGND

mA+360CONC0V mA-

ZERO

CAL

360

mA

GND

A

B

FAULT

24V DC

CHASS

P Y W

Common

Active

Compensator

Page 44 of 52

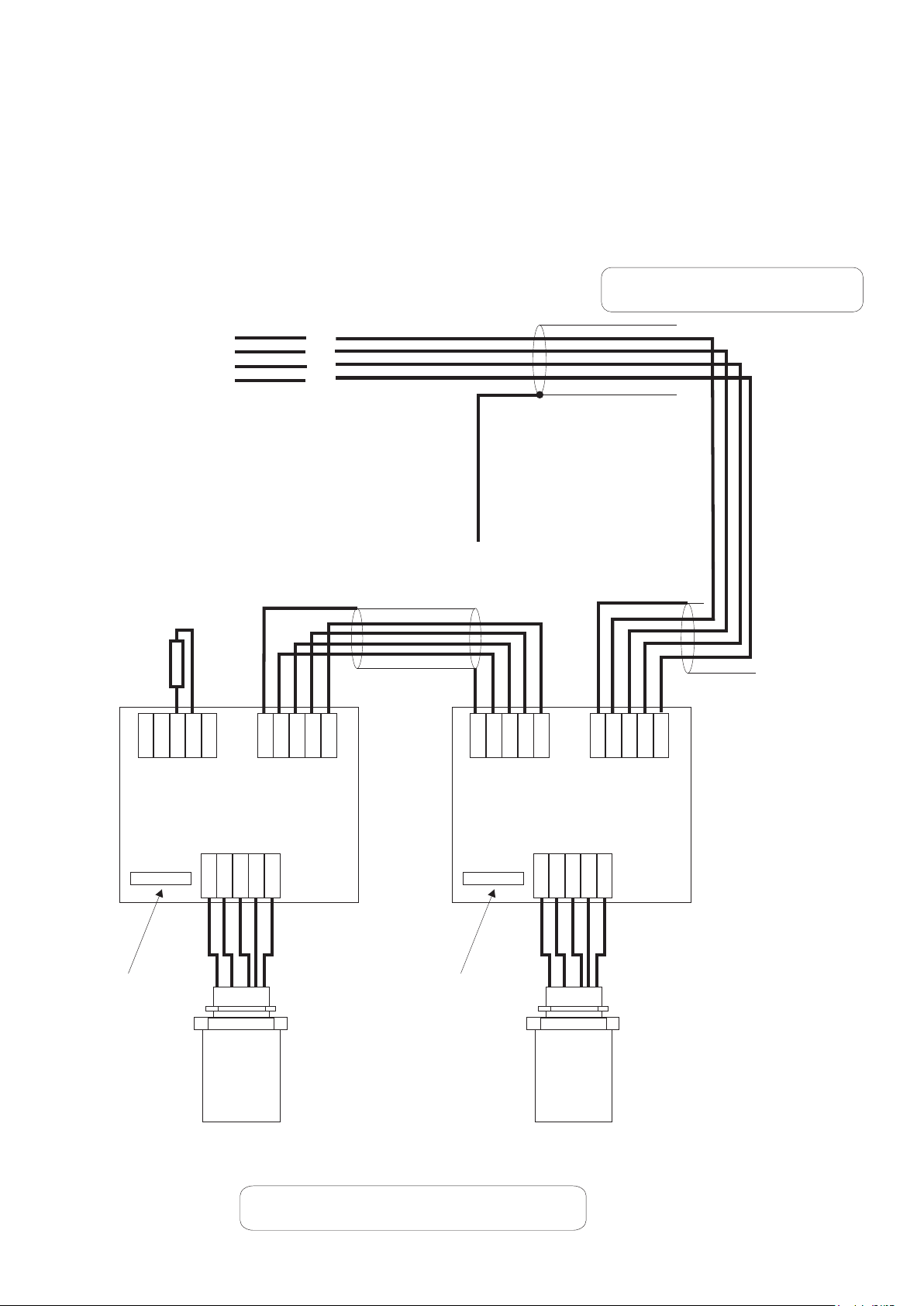

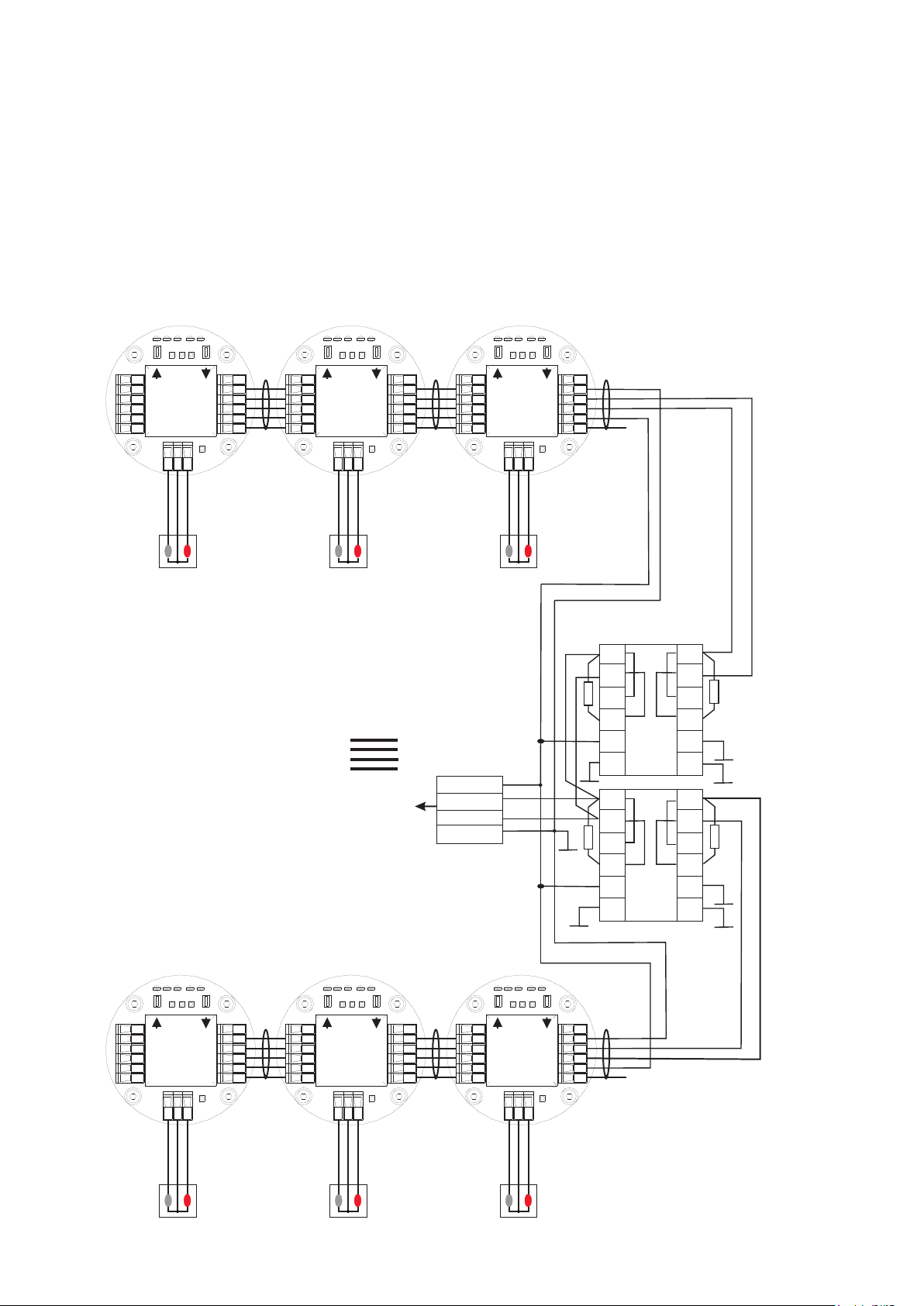

USING THE 485RPT MODULE TO SPLIT THE MAIN DATA HIGHWAY

In some circumstances more than one data highway may be required as well as a host Modbus

connection. This can be achieved by fitting 485RPT modules to the main highway port. If this is

to be implemented then one 485RPT module will be required per extra highway. The Tocsin 700

operates in the normal manner but it should be noted that there is still a limitation of 32 devices.

CABLING REQUIREMENTS.

mA+

360

CONC0V0V

mA+

360

CONC0V0V

mA+

360

CONC0V0V

mA-

mA-

mA-

mA

GND

A

B

24V DC

CHASS

W

mA

GND

A

B

24V DC

CHASS

W

Tocsin 700+ Control Panel

+24V DC

B

A

GND

+24V DC

GND

B

A

+24V DC

GND

mA

GND

A

B

24V DC

CHASS

W

G

K

H

L

J

M

B

A

G

K

H

L

J

M

D

A

E

B

F

C

485RPT

D

A

E

B

F

C

485RPT

All resistors

120 Ohms

mA+

mA-

360360

mA

GND

A

B

24V DC

CHASS

CompensatorCompensator

360

CONC

ZEROZERO

CALCAL

FAULTFAULT

PPYYW

CommonCommon

ActiveActive

mA+

mA-

360360

mA

GND

A

B

24V DC

CHASS

CompensatorCompensator

360

CONC

ZEROZERO

CALCAL

FAULTFAULT

PPYYW

CommonCommon

ActiveActive

mA+

mA-

360360

mA

GND

A

B

24V DC

CHASS

CompensatorCompensator

360

CONC

ZEROZERO

CALCAL

FAULTFAULT

PPYYW

CommonCommon

ActiveActive

Page 45 of 52

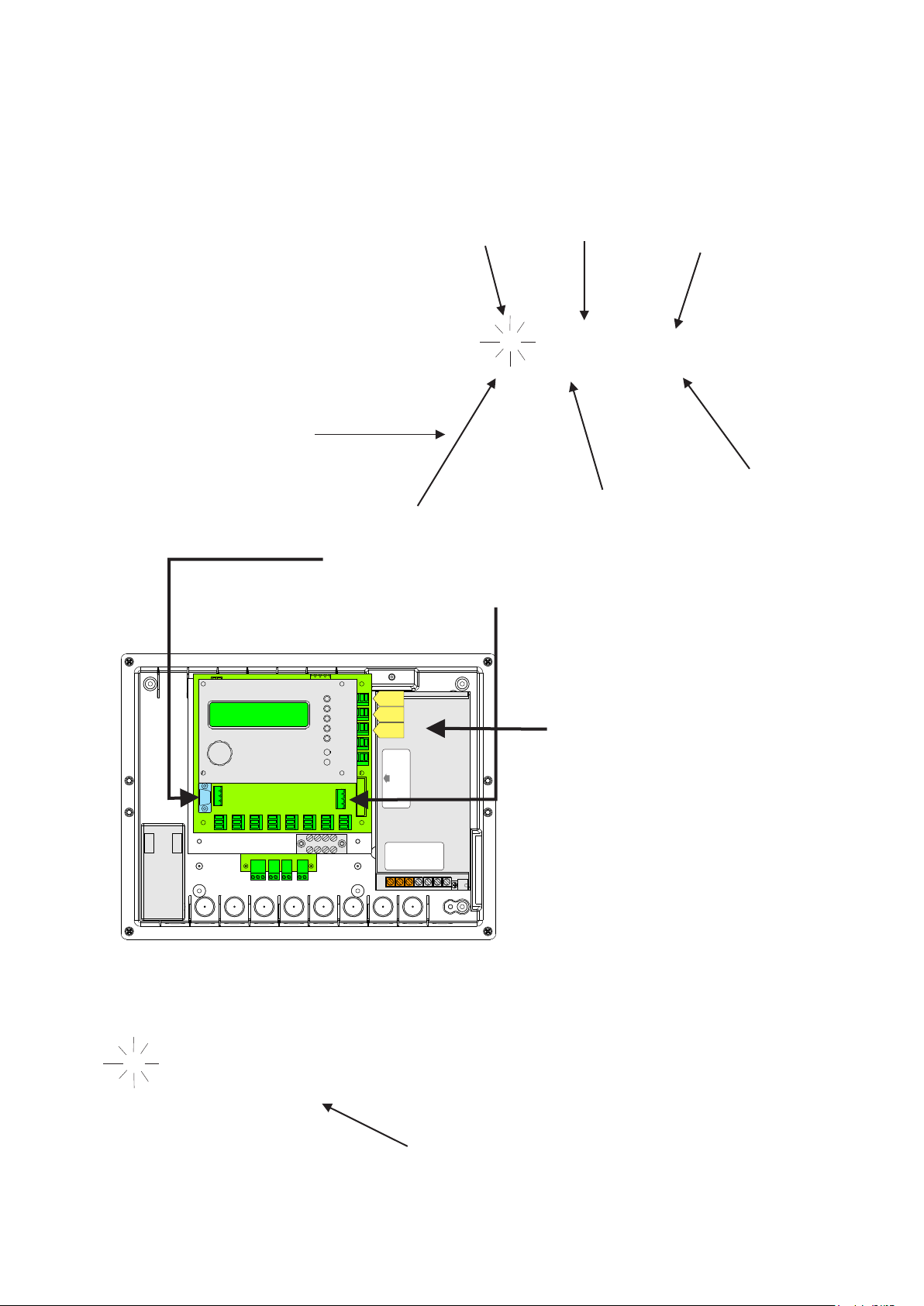

Integrated Battery Backup

The standard i700 is shipped with a 1.2AH Battery Backup Module

The battery is shipped separate from the control panel. Locate the battery in the panel once it is

mounted as indicated in the overview diagram. The batteries are shipped ready charged for

operation. Connect the battery to the charge management PCB with the cable provided

If required an additional 1.2AH battery pack can be fitted. This is supplied with a specific IGD

cable set to add the battery in parallel to the existing battery. Third party units must not be used.

additional battery module part number I700-BAT-2

Status LED’s

Note these are duplicated

on the controller front panel

DIP Switch for

Function Setup

Charge Control PCB

0V DC

12V DC

0V DC

12VDC

0V DC

24V DC

0V DC

24V DC

NC

NC

Test Points

The Single Pole relay changes state when mains power is

lost and the Tocsin 700 runs on the battery pack. It can

therefore be used to remotely indicate mains power loss.

The relay is rated at 7A 250V Non Inductive. Note the

relay is powered in normal operation and opens on alarm

or power loss.

Page 46 of 52

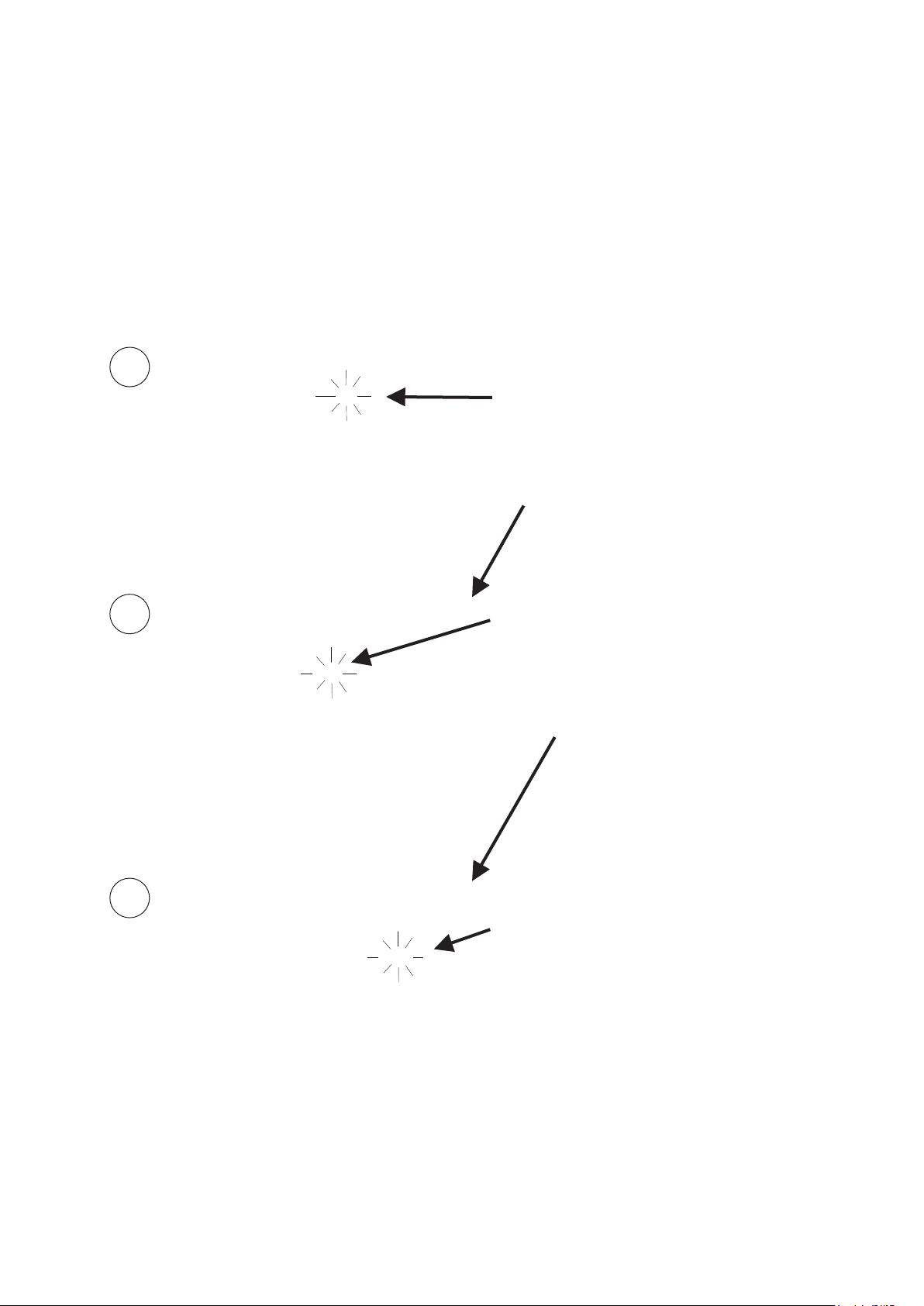

Front Panel Status LED’s

Mounted on the front panel of the battery backup module are two status LED’s. The Following

table indicates their operation.

The Mains power LED will be on when the unit

is operating from 110/230V AC. In this mode

the battery backup module is inactive and

being charged if required. The LED’s will

indicate the charge level as the battery is

being re-charged.

If the Mains power LED is off, then the battery

pack is active and providing backup power to

the TOCSIN 700 controller and associated

detectors. In this mode of operation the charge

level indicator LED’s indicate remaining

battery power.

The battery pack will automatically switch into

operation once the incoming 24V DC power

rail drops below 22V.

Once battery power drops below 20V DC the

controller determines that the battery pack is

exhausted and power to the TOCSIN 700

controller will be turned off.

MAINSOKBATTERY

OK

Status LED’s

> 50 % CHARGE

< 50 % CHARGE

0 % CHARGE

BATTERY FAULT

Battery Not Charging or

Battery Over Temp (>70°C)

Battery Under Temp (<0°C)

Note that the status LED’s take up to one

minute to show correct status.

Both LED’s will flash at start up as the

controller makes an assessment of the

battery and mains power status.

As soon as mains power is restored the

controller will start re-charging the battery

pack. The charge status will be indicated on

the charge LED’s. Typical re-charge time from

flat will be approximately 5 hours.

Oliver IGD Ltd reserve the right to amend product specifications in the interests of product

development and improvement without prior notice

Page 47 of 52

PCB DIP Switch Selection.

The DIP switches fitted to the charge control PCB, control

some of the operational features of the controller as

follows:

By default all switches are in the OFF position.

DIP switch 1 is used to set battery size, set to OFF for

1.2Ah batteries. Set to on for 7Ah batteries

DIP switch 2 sets the charge rate. set to OFF for max

300mA charge, this is the default max. Set to ON for

100mA charge, this setting is typically used in conjunction

with the TOC-625 controller fitted with more than 4

detectors to limit the battery charge rate due to the smaller

size of the TOC-625 PSU.

Note that the DIP switch setting is only read at power up.

The system must be powered on and off (batteries

disconnected) before the new setting takes effect.

For a new installation.

4

3

2

1

On Off

1. Connect the batteries allow system to power up on battery power

2. Switch on the mains power to the control panel

During this process observe the LED status and see the battery charge status

then the switch over from battery power only to mains and battery charge.

Page 48 of 52

Assessing A typical System For Battery Life

Use a table similar to the one indicated below to make an assessment of the system power

requirement.

System Component Alarm Mode Current Quantity Totals

Tocsin 700 0.25Amps 1 0.25Amps

Tocsin 920 0.5Amps NA NA

Tocsin 102 IR HC Detector 0.05Amps 4 0.2Amps

Tocsin 102 Pellistor HC Detector 0.13Amps 0 0

Tocsin 102 Toxic Gas Detector 0.02Amps 5 0.1Amps

Audible Alarm (Typical Example)** 0.12A 0 0

Visual Alarm (Typical Example)** 0.15A 1 0.15Amps

Additional Relay Units (8 Per Card)* 0.01A/Relay 0 0

Total System Current 0.7 Amps

The batteries used are 1.2AH units so using the previously indicated de-rating factors the

expected battery life will be as follows:-

Expected Operating Battery Life= Battery Capacity x de-Rating Factor

Total System Current

= 1.2AH x 0.75 = 1.3 Hours

0.7A

Note that in this example whilst the de-rating factor indicated was just 10% of battery capacity the

next de-rating factor up was chosen.

Values indicated in the system component table are those for alarm condition to take account of

the greatest possible current draw.

Page 49 of 52

Assessing Battery Life

Battery back up life is dependant on the power consumption of the main control panel and the

consumption of the detectors connected to it. The following table indicates how to assess the likely

back up period for a system. Other factors can have an influence particularly how many

charge/discharge cycles the batteries have been subjected to and the age of the batteries. It is

recommended that batteries are replaced every two years as a matter of course.

System Component Power Consumption.

System Component Monitor Mode Alarm Mode

Tocsin 700 0.21Amps 0.25Amps

Tocsin 920 0.38Amps 0.5Amps

Tocsin 102 IR HC Detector 0.05Amps NA

Tocsin 102 Pellistor HC Detector 0.13Amps NA

Tocsin 102 Toxic Gas Detector 0.02Amps NA

Audible Alarm (Typical Example)** NA 0.12A

Visual Alarm (Typical Example)** NA 0.15A

Additional Relay Units (8/16 Per Card)* NA 0.01A/Relay

* Additional Relay Outputs Available In Blocks Of 8 For The Tocsin 700 System And

Tocsin 920 System. Note when Making Power Assessments Only consider Active

Relay outputs.

** Examples Only Check Supplied Data Sheets for chosen Products.

Battery De-Rating Factors

It is normal practice to de-rate battery performance with increasing current draw. The

following table indicates the de-rating factors recommended to be applied in

calculating the time any given system will run on battery battery power.

Power Level Drawn De-Rating Factor

<10% 0.87

>10%<30% 0.75

>30% 0.58

Page 50 of 52

MODBUS INTERNAL MEMORY MAP ADDRESSES

Command

Function

Register

Sensor

Returned Word

Read Sensor Conc

04

30,001 to 30,999

1 to 999

Max = 1200 (110% LEL)

Min = 0 (-10% LEL)

Resolution = 0.1%

Read Sensor Volts

04

31,001 to 31,999

1 to 999

Max = 500 (5.00V)

Min = 0 (0.00V)

Resolution = 0.01V

Read Area Status

(T700 = Common

Alarms)

04

32,001 to 32,999

1 to 999

AREA

Bit4 = Sensor Disabled

Bit5 – Bit15 = Spare

Bit0 = AL1

Bit1 = AL2

Bit2 = AL3

Bit3 = Fault

Read Sensor Status

04

33,001 to 33,999

1 to 999

Bit0 = AL1

Bit2 = AL3

Bit3 = Fault

Bit4 = Sensor Disabled

Bit5 = Sensor Fault

Bit6 = Under Range Fault

Bit7 = Over Range Fault

Bit9 = Spare

Bit10 = Spare

Bit11 = Spare

Bit12 = Spare

Bit1 = AL2

Bit13 = AL1 Muted

Bit14 = AL2 Muted

Bit8 = Comms Fault

Bit15 = AL2 Muted

Mute all Alarms

051ALL

Pass = 0

Fail = 1

Reset all Alarms

052ALL

Fail = 1

Pass = 0

Disable Sensor

05

1,001 to 1,999

1 to 999

Pass = 0

Fail = 1

Enable Sensor

05

2,001 to 2,999

1 to 999

Pass = 0

Fail = 1

Zero Sensor

05

3,001 to 3,999

1 to 999

Pass = 0

Fail = 1

Set Add. Relay = On

05

4,201 to 4,232

4201 to

4232

Pass = 0 Fail = 1,2,3

(1=Timeout, 2=Already Used,

3=Not Implemented)

Set Add, Relay = Off

05

5,201 to 5,232

4201 to

4232

Pass = 0 Fail = 1,2,3

(1=Timeout, 2=Already Used,

3=Not Implemented)

FUNCTIONS:

Page 51 of 52

MODBUS INTERNAL MEMORY MAP ADDRESSES

Parameter

Setting

1: Modbus Mode

RTU Mode Only

2: Operating Mode

Slave Mode Only

#1

3: Response Time

Maximum = 100mS

(5s for Zero Command)

4: Requests

Maximum = 32 per Second

5: Panel Address

100 to 131 (100=default)

6: Baud Rate

4800, 9600, 19200 (19200=default)

7: Start Bits

1

8: Data bits

8

9: Parity

(Odd=default. None=T700 only)

None, Odd, Even

10: Stop

1, 2 (1=default & T700 only)

11: Flow Control

None

12: Physical Interface

2 Wire RS232, 2 Wire RS485

(2 Wire RS485=Optional on T900)

13: Bit Order

Least significant bit transmitted first

14: Byte Order

Least significant byte transmitted first

15: Inter-byte spacing

Maximum = 1.5 bytes times

(781uS @ 19200 Baud)

16: Inter-packet spacing

Minimum = 3.5 bytes times

(1823uS @ 19200 Baud)

COMMAND STRUCTURE

Interfacing to the Remote Modbus Port

Master DCS/BMS Master DCS/BMS

RS485 Modbus

ScreenBA

24V DCBA

Comms Port

0V DC

Note only the A,B and 0V DC

Connections are Used. 0V DC

between master and slave should be

connected for correct operation and to

prevent damage to both master and

slave systems

RS485 Modbus

Comms Port

0V DC

Modbus 485 Option Selected

Using C2 Port

1 1

Screen

Pin 2 Rx

Pin 3 Tx

24V DC

Pin 3 Tx

Pin 2 Rx

RS232 Modbus

Comms Port

Pin 5 0V

RS232 Modbus

Comms Port

Using 9 Way D Connector Port

Pin 5 0V

Modbus 232 Option Selected

Tocsin i700 Controller (slave) Tocsin i700 Controller (slave)

Page 52 of 52

Loading...

Loading...