IGD TOCSIN 650, TOC-650-150BB, TOC-650-24, TOC-650-150, TOC-650-300 Operation And Maintenance

...

2-Wire

Addressable

Triton House

Crosby Street

Stockport

Sk2 6SH

England

TOCSIN 650 SERIES

A d d r e s s a b l e D e t e c t o r C o n t r o l P a n e l

O p e r a t i o n a n d M a i n t e n a n c e

V 3 . 1

Tel: +44 (0)161 483 1415

Fax: +44 (0) 161 484 2345

Email: sales@internationalgasdetectors.co.uk

Website: www.internationalgasdetectors.co.uk

FS646773

EMS696504

REF: T650 V3.1

Table of Contents

Specification

CE Declaration

Overall Dimensions

Interface Wiring

Highway Hub Controller Overview

Relay Card Overview

Relay Card Setup

Addressable Detector Node

Operating System

Overview

User Actions

Menu overview

Putting Into Service

New Setup Sequence

4

5

7

9

10

12

13

14

15

17

19

22

Help Section

The Sensor ZERO Function

Checking Reaction Time

The Sensor CALIBRATE Function

Troubleshooting

Standard Accessories Supplied

Accessories Available

23

25

26

27

27

28

2

Brief Introduction

The Tocsin 750 and 650 series control panels use the latest technology 2-wire addressable

highways to control gas detectors and associated accessories. Providing an extremely flexible and

low cost solution.

Main Features

750 Series

Up to 350 Detecor Nodes

Internal or External Battery Backup

2 Core Cable Connection (No Polarity)

Colour Touch Screen

650 Series

Up to 128 Detector Nodes

Cascade Panels as Master - Salve

Jog Wheel Interface

RGB Backlit Display

Service & Maintenance

It is recommended that control panels and all connected detectors are commissioned upon

installation and serviced every 6 months by an IGD trained technician. IGD can offer full training to

enable your staff to do the servicing or offer a competitive service from our fleet of service

engineers.

Warnings and Performance Statements

This product must be earthed in accordance with local safety regulations.

The Control Panel leaves the factory configured for the supply voltage stated on the customers order.

Standard options are indicated in the basic specifications on page 4

Should the control panel be used in conjunction with portable generating equipment, care should be

taken to ensure that the electrical supply is within the tolerance band described above.

The control panel may be stored at temperatures between 0 C and 55 C. If stored at low temperatures

° °

and then brought into a warmer environment, condensation may form on some components. In such a

situation , this condensation should be allowed to evaporate prior to use of the equipment. If stored at

high temperature, care should be taken to ensure that humidity condensation does not enter critical

electrical components, for example the power supply.

The Control Panel is designed to operate within specification for ambient temperature between 0 C

and 55 C, relative humidity up to 95% ( non-condensing ). Sensor specifications may differ.

o

o

Do not use a Control Panel for protection applications that has not been calibrated. If calibration seals

are missing from the control panel or have been tampered with or broken, then the control panel must

be re-calibrated and sealed by a trained engineer.

Substances and interfering gases can cause adverse effects on the performance or electrical safety of

the gas detection systems. Care should be taken to limit exposure to these poisoning substances, for

further advice and information contact head office

The response time of the entire system is determined by the time of response of all the parts of the

equipment within the gas detection system.

The relationship between the output signal and the gas concentration is linear, the control panel

interprets the signal and the gas level is displayed on the HMI or RGB backlit display. IGD hold

evidence of this linear performance which is available upon request.

We recommend users read the procedures described in BS EN 60079-29-2 for reference.

Basic Specification

150W PSU @ 110V AC Nominal

150W PSU @ 230VAC Nominal

300W PSU

Ambient Operating Temperature

Ambient Operating Humidity

Protection

Display

Displayed Detector Resolution

(Range Dependant)

Connected Hubs

Connected devices

88 to 127 V AC 50/60Hz by selection

190 to 260V AC 50/60Hz by selection

88 to 260V AC 50/60Hz by selection

0 to 55 Degrees Centigrade

5-95% RH Non-Condensing (see sensor data)

Ip54

IP ratings do not imply that the equipment will detect gas during and after exposure to these conditions.

Calibration and maintenance may be required more frequently and should be assessed based upon exposure.

2 x 8 LCD Display and Jog Wheel

1% LEL

1%Vol

0.1% Vol

1 ppm

0.1ppm

Cascade hub optional

Up to 128 Devices on single hub max 350 input channels

CE Declaration

Pressure Limits

Warm up time

Max Power Consumption

Air Velocity

EMC Compatibility

Full EC Declaration appears on Page 4

800 to 1200mBar (80 to 120kPa)

15 minutes

2 Watts

0-6M/S refer to installers guide for allowable orientation

see installer guide

4

Issuers name and address:

EC Declaration of Conformity

Oliver IGD Limited of

Declares that the product listed as:

Triton House

Crosby St,

Stockport, SK2 6SH

United Kingdom

TOCSIN 650

Addressable Gas Detection Control Panel

Are in conformity with the provisions of the following European Directive(s) when installed, operated, serviced and maintained

in accordance with the installation and operating instructions contained in the product documentation.

2004/108/EC EMC Directive

2006/95/EC Low Voltage Equipment Directive (note not applicable to 24V DC Powered Versions)

And that the standards and/or technical specifications referenced below have been applied or considered.

EN 61779-1:2000

Electrical apparatus for the detection and measurement of flammable gases, general

requirements and test methods.

EN 50271:2001

Electrical apparatus for the detection and measurement of combustible gases, toxic gases or

Oxygen: requirements and tests for apparatus using software and or digital technologies.

Excluding requirements for SIL

EN 61000-6-2: 2005

EN 61000-6-4/A1: 2011

EN 61000-3-2: 2014

EN 61000-3-3: 2013

EMC Generic standards. Immunity for industrial environments

EMC Generic standards. Emission standard for industrial environments

EMC Limits. Limits for harmonic current emissions (equipment input current ≤ 16 A per phase)

EMC Limits. Limitation of voltage changes, voltage fluctuations and flicker in public low-voltage

supply systems, for equipment with rated current ≤ 16 A per phase

Technical File Reference

T650-TF9

Oliver IGD Limited Operate an

Independently assessed ATEX/IECEX

QAN.

EMC Tested by:

TUV - SUD

Quality Assurance Certificate Number

16PQAN0014

Quality Assurance Notification Number:

2585

Units 16-18 Abenbury Way,

Wrexham Industrial Estate,

Wrexham, LL13 9UZ

United Kingdom

Oliver IGD Limited operate an independently

assessed ISO9001:2015 Quality Management and

ISO14001:2015 Environmental Management System

Certificate Numbers

FS0646773 & EMS696504

BSI Assurance UK LTD,

London, W4 4AL

United Kingdom

Octagon House

Concorde Way

PO 15 5RL Fareham

Certificate Number

E8N 15 05 91327 004

TUV Certificates and reports can be checked on-line at

https://www.tuev-sued.de/industry_and_consumer_products/certificates

Select Oliver IGD when prompted on the website to view certificates

Issued by: Oliver IGD Limited, Stockport, SK2 6SH , United Kingdom

Signature: Declaration of Conformity in accordance with EN ISO/IEC 17050-1:2004

Name: Andrew J Collier M.I.O.D

Position: Managing Director Date: 1 January 2019 Declaration Ref: T650-DEC-3

Important Notes

Gas detection systems must be correctly specified, installed and maintained in order to be effective.

Anyone undertaking elements of this work should have access to the necessary equipment and be able

to demonstrate competence. This will usually mean having passed a training competency course.

International Gas Detectors run training courses for safety survey, specification , installation and

service aspects of hazardous gas detection systems. In addition IGD can supply test equipment and

calibration gases necessary to undertake this work.

Please the following points

1. A zero grade gas usually instrument air or Nitrogen and a suitable calibration gas mixture is required.

2. The correct gas adaptors must be used to apply gases to detectors when zeroing and calibrating.

Incorrect application of gases can affect calibration results

3. Use equipment and gases traceable to a national standard. Any calibration will only be as good as

the equipment and materials used.

4. IGD supply fixed flow regulators for use with IGD calibration gas bottles which supplies gas at

0.5L/Min

Panel Options

Part Number

TOC-650-24

TOC-650-150

TOC-650-150BB

TOC-650-150B1

TOC-650-300

Description

24V DC Control Panel No Internal PSU

Standard Features inluding

2 x 8 RGB Display and Jog Wheel

4 Relays, 4 Highways

110/230V AC Control Panel 150W PSU

Standard Features inluding

2 x 8 RGB Display and Jog Wheel

4 Relays, 4 Highways

110/230V AC Control Panel 150W PSU

Standard Features inluding

2 x 8 RGB Display and Jog Wheel

4 Relays, 4 Highways

Built in 1.2AH Battery Backup

110/230V AC Control Panel 150W PSU

Standard Features inluding

2 x 8 RGB Display and Jog Wheel

4 Relays, 4 Highways

Built in 5AH Battery Backup

110/230V AC Control Panel 300W PSU

Standard Features inluding

2 x 8 RGB Display and Jog Wheel

4 Relays, 4 Highways

TOCSIN 750 Series Controller

TOCSIN 750 Series Annunciator

Options With:

Display, Relay Output, Digital or

Analogue Input, Flammable Gas Detector

TOCSIN 750 Series Detectors

Flammable Gases, Toxic Gases

Oxygen

TOC-650-300B1

110/230V AC Control Panel 300W PSU

Standard Features inluding

2 x 8 RGB Display and Jog Wheel

4 Relays, 4 Highways

Built in 5AH Battery Backup

6

TOCSIN 102 Series Detectors 2-WIRE

Flammable Gases, Toxic Gases

Oxygen For ATEX Applications

General

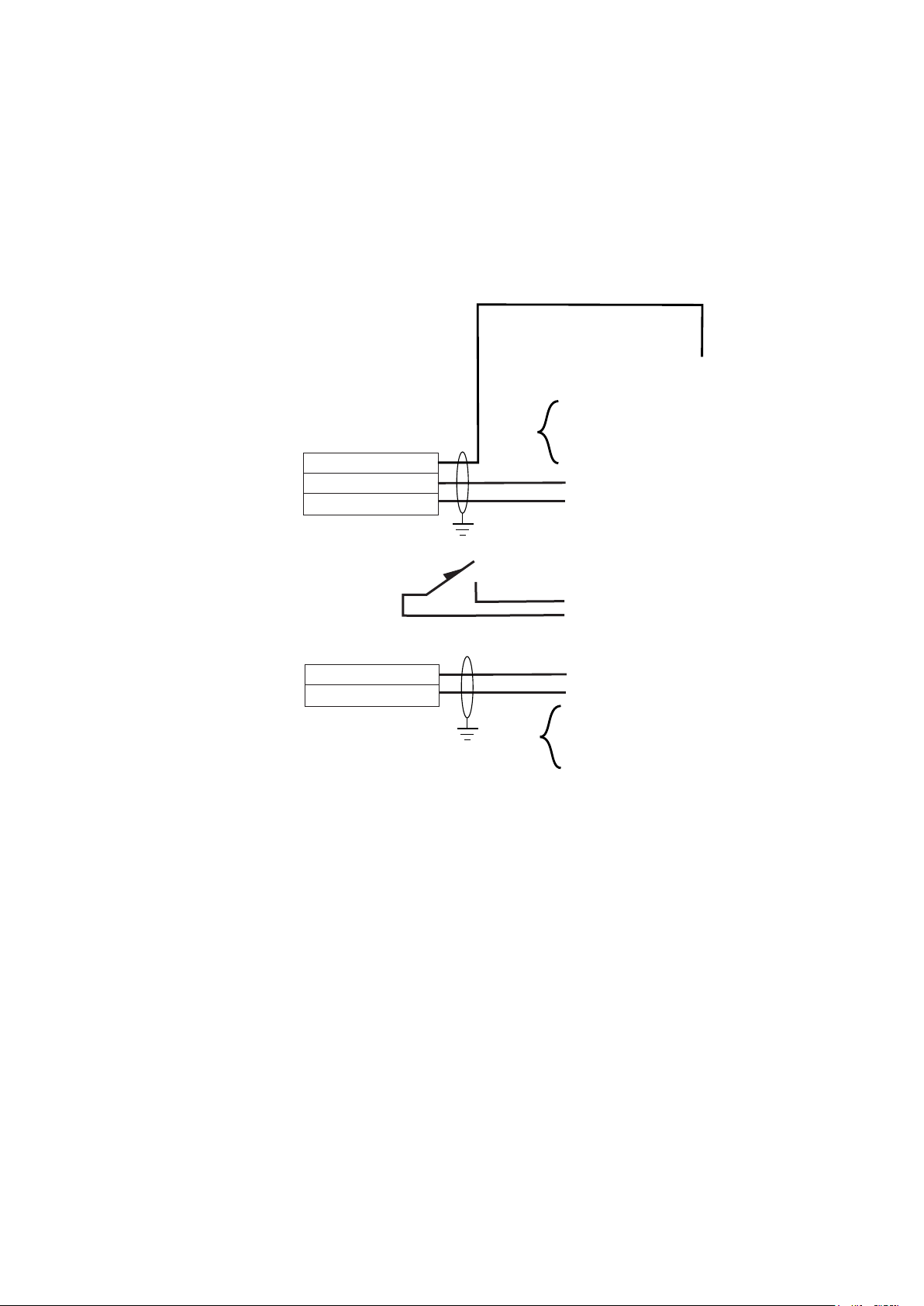

Note cables run with modules sequentially wired.

Power can be taken from system modules for small current devices such as LED beacon sounders and is

limited to 100mA per module

Highways are fused at 2A, observe load calculations when planning, use boosters where necessary

Observe interface requirements for relays, fitting freewheel diodes and snubbers as indicated

End of line terminators, supplied with panels must be fitted for correct operation

TOCSIN 650 PHYSICAL

360mm

Top Face

Front Face

10 off 20mm

Cable Entries

FRONT VIEW

382mm

30mm

56.5mm

20mm

292mm

2-Wire

Addressable

48.5mm

120.5mm

72mm

Side Face

134mm

Installation Cables

Supported Installation Cables 2 Core 1.5mmSQ or 2.5mmSQ See IGD Cable System Calculator

Typically SWA, MICC, FP200, SY, CY, System cables must be screened, refer to installers guide

Installation Guide

Your 750 Series control panel has been supplied with a separate installation guide. Please read this

before installing your system. The Installation guide provides information for correct cable selection,

how to correctly install cables and devices and ensure correct cable segregation. It is important to

read and understand this document prior to installation.

Copies of the installation guide are available in the downloads section of our website. Always check

you are using the latest versions of the supplied manuals by checking on the IGD website.

Failure to follow correct installation may result in poor performance and/or damage to system

components.

International Gas Detectors

2-Wire

Addressable

2-WIR E SYSTE MS

2 - W i r e G a s D e te c ti o n S y s t e m I ns t al l e r s G u i d e Vx x

OL IV ER

Triton House

Crosby Street

Stockport

SK2 6SH

England

IG D

Tel: +44 (0)161 483 1415

Email: sales@internationalgasdetectors.co.uk

Website: www.internationalgasdetectors.co.uk

Fax: +44 (0) 161 484 2345

Version 2.0

T750-INST

IGD-Academy

IGD’s On-Line training academy is available to support your companies activities. The Academy

features a range of CPD approved training courses and ‘how to’ videos.

The academy can be found at: https://igdacademy.internationalgasdetectors.com

Please note that some courses are only available on a request basis. If you require a request only

course please email to request your account and course.sales@internationalgasdetectors.com

8

T650 Control Panel & 2 Wire Hub Controller PCB Features

Rs485 Remote

Ethernet

(Modbus etc)

Battery Connection

For Battery Backup

Power in

24V DC

L2

L1

4 off 2 Wire Ports Each supporting 32 Devices

128 Devices in Total

L1

L2

L1

Display

Colour HMI

L2

Display TOC-650 (2x8 LCD)

Fault Relay

Inputs for E-stops/Fire

L2

L1

Direct Beacon-Sounder O/P

Hub cards can be cascaded to add more ports if

required. Note This is Polarity Sensitive And

Must be Connected L1 to L1 and L2 to L2.

Failure to observe polarity when cascading can

result in damage to the card

Alarm Relay 1

Alarm Relay 2

Alarm Relay 3

L1

Two display options, either 650 style with jog wheel

L2

or

HMI Style touch screen display

Note both displays can be fitted at the same time which can allow

the HMI display to be remote from the panel and used as a

system repeater or mimic

Tocsin 750 Addressable Relay Card Setting Relay Addresses

Each Addressable relay card must have its own unique base address. This can

be set on the card and is indicated below. The relays are then

addresses/numbered from that base address. The example below shows a card

with a default base address of 101

DOWN

BUTTON

108

Press and hold the DOWN button until all LED's are OFF. Release the button

and the address currently set will be illuminated on the bottom five LED’s.

Use the UP and DOWN buttons to alter the address set as indicated in the

table below

To exit press and hold UP or DOWN button until all LED’s are off then release.

1 2 3 4 5

107

106

A0A4

105

104

1 2 3 4 5

103

100

101

102

103

102

116

117

118

119

101

UP

BUTTON

104

105

106

107

108

109

110

111

112

113

114

115

NOTE: WHEN SETTING ADDRESSES YOU CANNOT HAVE TWO DEVICE ADDRESSES SET THE

SAME ON THE SAME ADDRESSABLE HIGHWAY or DEVICE.

10

120

121

122

123

124

125

126

127

128

129

130

131

Tocsin 650/750 Addressable I/O Card

Power out for

use in

conjunction

with relays

0V DC

24V DC

In all Cases:

Relay contact ratings.

5A @ 250V AC Non-Inductive

5A @ 30V DC Non-Inductive

Spike suppression must be fitted

Note that FAULT relays are normally

energised on power up.

Relay status LED,

ON when Energised

10 off I/O Ports

2-Wire Highway Connections

Pin 1 Line 1

Pin 2 Line 2

24V DC

A2

A1

Example fit

protection

diodes when

0V DC

switching

external DC

loads.

~

A1

~

A2

Example fit protection

supressors when

switching external AC

loads typical device

Farnell Ref 1438460

Pin 1 Line 1

Pin 2 Line 2

Base Address set up

LED's and interface

for the relay card

Normally Closed

Common

Normally Open

Relay Terminals

First Relay on

The Card (relays

number from

this one).

Tocsin 650/750 Addressable I/O Card Input Ports

Relay cards also have analogue and digital inputs that can be used to read data onto the system

from external devices. Setup of the inputs, type, range, addressing etc is controlled via IGD’s

Android Apps. Wiring options are indicated below. Note the differences between Version 1 and 2

PCB assemblies.

Typical IGD Loop Powered

4-20mA Detectors

Pellistors Based Detectors

Infra Red Based Detectors

PID Based Detectors

Thermal Conductivity

Typical IGD Loop Powered

4-20mA Detectors

Temperature

Pressure

CO

H2S

Oxygen

HCN

HCL

NO

NO2

H2

CL

SiH4

O3

3 Wire Detectors

0V DC

4-20mA Signal

24V DC

Loop Powered Detectors

4-20mA Signal

24V DC

Note 1

Note 2

10

9

8

7

6

5

4

3

2

1

Note 1

Note 2

Note 3

These Ports are designated to be digital inputs only.

These Ports are not used on version 1 PCB assemblies limiting the PCB to a maximum of 6

analogue inputs or 8 digital inputs including ports 9 and 10.

If extended 4-20mA devices are connected, they maybe floating ground type.

12

Module PCB Features

The following diagram indicates features available on the TOC-750 ‘module’ PCB. Please note

that failure to observe and make correct connections or exceed ratings may result in damage to

the PCB.

6

5

Ribbon Cable Connection For TOC-750

Annunciator Display and Options

Pellistor (Catalytic)

Flammable Gas

Connection Point For

IGD Infra-Red, Toxic, PID

or Oxygen Gas Detectors

Multi-Function I/O Port 2

Solid State Output or

4-20mA Input or

TOC-10 IP or Gas Meter

P

7

Y

W

3 3

Detector Interface

Suitable for IGD

4

Types MK3, MK6, MK7

Multi-Function I/O Port 1

Solid State Output or

4-20mA Input or

TOC-10 IP or Gas Meter

2-Wire Highway

Connection

1

To Next Device

DVM Test Point +

SPCO Relay

Output

2

And Up/Down Interface Buttons

Module PCB Basic Interface Specifications

Housing

Sealing

Environment

Temperature

Voltage

Communication

1

Relay

2

Digital Output

3

Digital Input

Analogue I/P

Pellistor Port

4

Sounder

5

Display

6

Comm Port

7

TOC-750 Series ABS or Copper Free Aluminium For ATEX Versions

IP65 (using suitable glanding & splash guard) for TOC-750, IP68 for ATEX Versions

0 -95% RH Non Condensing

0-55 Deg C

12-28V DC

IGD 2-Wire Highway Operating IGD Sentinel+ Protocol

Not Polarity Dependant

5A Non Inductive Loads 230V AC

24V DC 100mA Combined For Both Outputs Typically for LED Beacon Sounders

Suitable for use with TOC-10 Link Function, switch/call point, totalising count

4-20mA, selectable range, units and tag information

Option to Interface to MK3, MK6 or MK7 Pellistors

85dB (Option for TOC-750 Annunciators)

2 x 8 Programmable LCD with RGB Backlight (Option for TOC-750 Annunciators)

Supports IGD Infra-Red, PID, Toxic and Oxygen Gas Detectors

Local LED Indications

1

2-Wire Highway

Connection

To Next Device

DVM Test Point -

User Actions....Day to Day Operation

Once fully installed the TOC-650 controller will continuously monitor connected gas detectors and

sensors and compare current values with any set alarm thresholds. The display will cycle to display

each channel in turn.

To access the display and switch the backlight on rotate the jog wheel

Channel

Number

The back light turns on making

it easier to see the channel

information. Note that each

channel will be displayed in turn

as indicated by rotating the jog

wheel

In Alarm Condition

Alarm Level

The back light will flash red and

the display will indicate which

alarm level and which channel

is in alarm. The sounder will

also activate. Pressing the

button will silence the sounder.

If the gas is still breaching the

alarm threshold it will not be

possible to reset the alarm

Channel

Number

Gas or Reading

Type

1=FLAM

10% LEL

Current Channel

Reading

Channel

Gas Type

1=FLAM

alarm 1

In the event of alarm or fault, CALL FOR SERVICE.

The owner operator is not usually a gas engineer or competent person

as defined by Health and Safety guidelines. If there is any doubt call

your service company and get it checked.

In alarm mode the RED

alarm led will either be

flashing for alarm level 1 or

solid for alarm level 2. The

bottom line of the display will

indicate:

Alarm 1

Alarm 2

Alarm 1&2

In Fault Condition

In FAULT mode the Yellow fault led

will be on. The bottom line of the

display will indicate as follows:

FLT COM

FLT SEN

FLT OVR

FLT UND

communication

error to sensors

Sensor Error

Sensor Over Range

Sensor Under Range

Channel

Number

Channel

Gas Type

1=FLAM

FLT UND

14

Controller Interface Overview

Internal Sounder 85dB

Sounds on alarm 1 or 2 activation

and can be muted

Colour Backlit LCD Display

Flashes Red on alarm

Flashes Yellow on Fault Detection

Blue during menu operation

.

Alarm Indicator LED (Red)

Flashes on Alarm Level 1

Continuous on Alarm Level 2

Fault Detected

Indicator LED (Yellow)

Typical display during warm up

WARMUP

600s

Selector Button

Power LED (Green)

Selector Jog Wheel

• Initial power up sequence is:

o Indicate board tested status (end

user should see “PASSED” with a

green backlight)

o Display then shows Software

version, Checksum and date,

Display version, display

checksum and date, connected

sensor info

o Countdown

To Access the Display rotate the Jog Wheel

Channel

Number

Gas or Reading

Type

1=FLAMM

10% LEL

Current Channel

Reading

Data entry and menu selection using the password entry as an example.

To access the menu system press the button until the message

“Release button and enter password”

message is displayed.

Password Number You are

Entering. Rotate the jogwheel

clockwise to increment or

Anticlockwise to decrement

0

PASSWORD

With the correct password displayed

press the centre selection button

to go to the menu or function.

25

PASSWORD

INHIBIT USER MENU

Inhibit the control panel for

up to 60 minutes. Use this

option if calibrating or

accessing the connected

devices using a laptop

running IGD Configurator

software. Inhibiting the panel

means it stops

communicating to connected

devices this prevents alarms

or data clashes during PC

access.

50

PASSWORD

CALIBRATIONS & ALARMS

Zero and Calibrate Sensors.

Setup alarm levels and relay

actions.

16

100

PASSWORD

ENGINEER MENU

PANEL TEST & SETUP

Test I/O Functions, FIND

connected devices. Setup

channels, Modbus addressing etc.

TOC-650 Menu Overview

0000

PASSWORD

50

Engineer Menu Options

Provides access for control panel

set up and diagnostic functions

FIND SEN

1 of 12

FIND RLY

2 of 12

DIAG

3 of 12

SET TIME

4 of 12

SET DATE

5 of 12

SEN mS

6 of 12

RLY mS

7 of 12

CASCADE

8 of 12

Use this option to

FIND connected Input

devices.

Use this option to

FIND Relay Outputs.

Use to Access Device

Diagnostics

Set the System Time

Set the System Date

Use to check the comms

response time for sensors.

Should be less than 10mS

Use to check the comms

response time for relays.

Should be less than 10mS

Use to set hub cascading

options

100

User Menu Options

Provides access for

maintenance functions

ZERO

1 of 9

cal

2 of 9

DISABLE

3 of 9

CONTRAST

4 of 9

VIEW EV

5 of 9

CLEAR EV

6 of 9

SEN INFO

7 of 9

Use this option to

ZERO connected

devices

Use this option to

CALIBRATE

connected devices

Disable a Device

Use this option to set

the screen contrast

Select to View the

Event Log

Select to Clear the

Event Log

Select to View

Information About a

sensor

TEST RLY

9 of 12

BL. TOOTH

10 of 12

USR MENU

11 of 12

EXIT

12 of 12

Use to Energise/Deenergise relay outputs

Use to enable/Disable

Reset Bluetooth

Move to the USER

(100) Menu

Select to Exit Back to

Normal operation

ABOUT

8 of 9

EXIT

9 of 9

Use to View Software

Versions

Select to Exit Back to

Normal operation

TOC-650 Menu Overview

Provides access for control panel

set up and diagnostic functions

0000

PASSWORD

345

Production Menu Options

RESET

1 of 8

SET DFLT

2 of 8

DISP TST

3 of 8

Z CVolts

4 of 8

Z BATTERY

5 of 8

USR MENU

6 of 8

ENG MENU

7 of 8

Use this option to

Reset the Hubcard

(System Re-boot)

Reset Hubcard to

defaults

Display Self Test

Not Used

Not Used

Use to Move to the User

(100) Menu

Use to Move to the

Engineer (50) Menu

EXIT

8 of 8

Exit to Normal

Operation

18

Putting Into Service

Note that this product should be supplied via a fused spur. Ensure cables used are suitable for both

their intended area of operation and load capability. This product should only be installed by a

competent person.

Follow the 2-Wire Installation guide

This provides location as well as cabling/installation guidance.

Failure to observe correct installation can have an adverse affect on system operation

and performance

if you don't have a copy of this download it from www.internationalgasdetectors.com

To set alarm levels and programme the required cause and effect you will need to

access the controller using IGD’s Panel Setup App for Android. Download the Panel

Setup App from the Google Play Store to a suitable blue tooth enabled tablet or

Phone. Android 4.1.1 or later operating system and min 7” display recommended.

It is recommended to follow the set up sequence below when configuring and installing a control

panel from new.

Note panels are usually supplied pre-configured so this many not be necessary, check

shipping documentation

Perform a sensor FIND and automatically install detector data. Engineers Menu .... Find Option

find sen

1 of 12

Perform a Relay FIND

find rly

1 of 12

With Sensors and Relays Installed download the panel setup to IGD’s Panel Seup App to configure

the system. It will be necessary to upload this once completed and re-start the controller for it to take

effect.

Allow the system to run for at least an hour to allow detectors to fully stabilise to the site conditions.

Detectors are supplied pre-calibrated. Follow the Bump Text video on the IGD online Academy to

check both detector calibration and to prove the system programmed cause and effect. Ensure all

interfaces to third party devices and systems function as required. Note that individual relays can be

directly energised and de-energised to aid checking

TEST RLY

9 of 12

Should any detectors require re-calibration

zero

Zero each connected detector. User Menu ZERO

1 of 15

cal

Calibrate each detector. User Menu CALibrate

2 of 15

Ensure there are no indicated system errors in normal operation.

Note IGD calibration and gas adaptor kits are available and necessary to perform calibration and

bump testing. Record all results for traceability.

If you are uncertain how to zero/calibrate or locate your gas detectors and system components then

use IGD’s online training academy.

If your application is safety related you must ensure you are a competent person with demonstrable

training. If in doubt check with IGD for help and support.

Warm Up Period

With power applied the system should undertake its power up sequence and

then commence a warm up period. The warm up period is there to allow

connected detectors to stabilise before operation. Note that certain detector

types, Oxygen sensors in particular may take up to 2 hours to fully stabilise.

During the warm up period check that each connected detector or device has power and

communication. The following diagram shows the three main terminal PCB types for detectors and I/O

interface nodes and the relevant check points.

With sensors connected and after the TOC-650 controller has completed its warm up the operating

system will go to normal operation mode.

Normal Operation

In normal operation mode the TOC-650 communicates to each detector or node in turn and displays the

data on screen. Pressing the button once will activate the back light, each button press then cycles the

display through each channel.

For example a three channel system with a Flammable gas detector, a Carbon Monoxide Detector and

WARMUP

600s

an Oxygen detector would read as:

Channel Number Gas Type

1=FLAM

0% LEL

Reading Units

2 = CO

0 ppm

3 = O2

21% VOL

20

Putting into Service Test Schedule

In conclusion by following the steps discussed your checklist for putting into service should be:

1

Ensure the mains power supply is via a fused spur and installed in accordance with local

installation wiring regulations.

Check cable and glands are of suitable type for both the area of application and load carrying

capacity.

2

Ensure terminations via glands provide a positive seal.IGD Gland packs PN TOC-GLAND

achieve minimum requirements when correctly installed

Leave all interfaces unplugged and check installation cabling terminations following IGD 2-Wire

3

Installers Guide, check website for latest revisions.

4

Check the shipping TOC-650 SET UP REPORT to check how the controller and interfacing

detectors and nodes have been configured. Ensure that the detector addresses match the

document and required site locations.

Power up the system. Check that all connected devices indicate that they have power and are

5

communicating correctly.

Allow at least 1 hour for the detectors to correctly warm up and stabilise.

6

During this period, if the relay outputs are being used check the cabling then plug in and test

using the TST RLY function.

7

After warm up is complete use instrument air or Nitrogen as appropriate to check the detector

zero reading. Adjust if necessary (see later “zero and calibration function” section).

8

After warm up is complete use a suitable known calibration gas to check the detector calibration

reading. Adjust if necessary (see later “zero and calibration function” section).

9

Bump Test to check programmed cause and effect operates as required

10

Complete any site paperwork as necessary and instruct the site responsible person regarding

day to day operation (see later section “ user operation “).

11

Download the controller setup and save as a backup for the system.

In the event that the controller needs amendment to set up follow the instructions in the following

sections.

a) Adding detectors or nodes to the controller or complete set up

b) Adding or changing alarm levels

c) Assigning relay outputs

d) Zero and Calibration Function (detectors)

e) Zero and Calibration Function (analogue output)

Sequence for a Complete New Setup

If you need to perform a complete new set up

Then presuming the system is correctly installed and cabled the process would be as follows:

1. Use the FIND command to discover connected devices and install them to the controller

2. Set up the required alarm levels and relay actions

3. Test using zero and calibration gases

The following dialogues describe each function to use

The FIND Command

As previously described enter password mode and enter password 50 to gain access to the

engineers menu. The first menu option (menu option 1 of 11) is the FIND menu. To run this option

the detectors must be correctly connected to the controller and displaying green power LED function

as a minimum (some of the green power LED’s may be flashing if detectors already have

communication.) The FIND function then works in the following manner

find

1 of 11

1

Press and hold button

until prompted to

release. The system

starts discovering

connected devices

find

Release

When the discovery process is

complete the display indicates

how many sensors have been

found. The system also indicates

the first found address. Each

button press then indicates each

found device address in turn.

find

1 of 11

s=2 40%

checking

2

Display indicates devices found so far

Display indicates % progress

1 = 4101

found= 2

2 = 4101

found= 2

2 = 4101

Release

no

Release

3

To store or abort the data press and

hold the button until prompted to

release. The first option is NO to

store data, rotating the jog wheel

changes this to YES to store data

and vice versa. With the desired

option displayed press the select

button.

yes

Release

saved=2

passed

4

If the YES option to store data

was selected then the number

of saved devices is shown on

screen and passed of fail to

indicate the status of the

update

If the control panel has been shipped pre-configured then once correctly connected the system will be

operational. The controller should correctly cycle through each channel with no indicated errors.

Relay Test

The alarm relay outputs can now be connected (if they are being used). The relay outputs can be

forced on and off using the ‘test relay’ function (TEST RLY).

test rly

13 of 12

22

Gas Detector ZERO Function

All gas detectors will require periodic ZERO and CALIBRATION. The calibration interval depends on a number of

environmental factors such as: temperature variance, exposure to wind chill, rain, humidity changes and vibration

to list a few. As a guide line gas detectors should be checked at least yearly. As with any measuring instrument if

calibration is not held over the intervening interval then a shorter calibration interval may be required.

Detectors should always be zeroed first and then calibrated. Alarms should be isolated during this process. A

normal calibration sequence would consist of:

1. Assess zero reading in pre-zero condition and record by applying a zero gas typically Nitrogen or Instrument air

2. Assess calibration point by applying a known calibration gas. and record

3. If the zero and calibration points are within +/-2% of range then take no further action. zeroing and calibrating a

detector that already reads correctly will not improve its performance. If either is out then proceed to step 4.

4. Apply a suitable zero gas and zero the channel, observe and record result.

5. Apply a known calibration gas and calibrate the channel, observe and record the result.

Notes

Do not rely on the ambient environment to provide a zero point, Nitrogen or Instrument air should always be used

as appropriate. If there is a background level of the target gas and a zero is performed then the zero point will not

be correctly set.

This sequence first indicates

To Zero the detector enter password mode

as previously described and enter

password 100 to enter the user menu.

Select menu item 1 ZERO

zero

1 of 10

The top line of the display shows the

if the zero operation passed

or failed, then the new

detector reading then the

option to end and return to

the engineer menu. This

sequence effectively allows

the engineer to observe the

new detector zero point

before exiting.

Regulator to deliver a

fixed flowrate (typically

between 0.5 to 1 L/min)

current reading. The bottom line shows the

current option.

8 PPM

Abort

With zero gas flowing and the reading stable

press the button to select CONTINUE. Now

press and hold the button until prompted to

Zero

Gas

Calibration

Gas

20% LEL

Hose delivers zero gas to the

detector. Note a test gas

applicator is usually required.

In some cases weather

protection guards or the

detector itself may include a

gas applicator port. If not the

correct calibration gas

adaptor must be used.

release to action the zero request.

0 PPM

Continue

ZERO

PASSED

0 PPM

CLICK TO

Bottled Nitrogen or Instrument grade zero air

The display shows the result of the zero request, note that the actual zero and

calibration values are stored on the individual detector heads. When carrying out a

zero or calibration the controller sends the request to the detector head for action

and monitors the result. This means that detectors can be supplied pre-calibrated

The reading is now displayed so the result of the zero request can be observed.

The reading should be stable. Click the button to return to the previous menu.

Repeat the sequence if you are not within +/-2% of zero.

The Sensor ZERO Function

Zero and calibration functions should only be undertaken by trained competent

personnel. The effectiveness of a gas detection system is largely down to how well it is

maintained and this means how well it is calibrated.

Apply zero gas to the detector.

It is important that the detector zero point is correctly set. It must be considered that

there is the possibility that the gas to be detected is already present in the area of the

detector. For this reason never zero on just the ambient surroundings.

There are two possibilities

A. confirm there is no gas present by using a portable detector

B. Use a suitable ZERO gas as follows.Zero gas should have a humidity between 0-90%RH

GAS RECOMMENDED ZERO GAS

O2/CO2 NITROGEN

PELLISTOR INSTRUMENT AIR

TOXIC GASES NITROGEN

The following diagram shows a typical equipment set up.

Regulator to deliver a fixed flowrate (0.5-1 L/min)

Oliver IGD P/N 5022001

Recommended Test 750 series Gas Applicators.

Tocsin 102 Series Detector P/N 401101A

MK3 Gas Detector P/N 401101A

Cal Gas Adaptor

Ensure it is correctly

fitted

ZERO

MK5 & MK6 Gas Detector P/N 401101E

TOC-750 Series

GAS

Hose delivers cal gas to the detector. Note a test

gas applicator is usually required. In some cases

weather protection guards or the detector itself

may include a gas applicator port.

Relative response to Methane @ 4.4%

Vol = 100% LEL

Equivalent to 55% LEL N-Butane

IMPORTANT: Flow gas for a minimum of 60 Seconds. Some detectors with longer response

times may take longer to stabilise.

Procedure for check reaction time to gas

Use standard IGD professional gas introduction kit with 2M hose.

Using a stop watch turn on the calibration gas and time to 50% and 90% LEL

Note on a 20% LEL bottle T50 point is 10% LEL and T90 point is 18% LEL

on a 50% LEL bottle T50 point is 25% LEL and T90 point is 45% LEL

Ensure detector is at zero +/- 1% LEL

Connect calibration gas but do not turn on

Time to 50% should be less than 30 seconds

Time to 90% should be less than 60 seconds

replace non conforming sensors

24

Once the alarm level has been set you then need to set the Alarm TYPE and decide which relay activates

once the set alarm level is breached. The following sequence continues from the previous page and

describes the set up sequences

Scroll to change selection

LEVEL TYPE RELAY EXIT

To select an option rotate the jog

wheel and press the selection button

to select the required option

Top line indicates “select alarm type” Rotate

the jog wheel to select the desired alarm type

option. Press the selection button to select.

RIS LAT RISING FALLINGFALL LAT

Rising Latching Alarm

Latching alarms

remain set until the

button is pressed to

reset the alarm. The

gas level must be

below the alarm level

threshold for the reset

to operate. This type of

alarm is typically used

in safety applications.

Where alarm is

required in response to

rising gas levels

Rising Alarm

Rising alarms will

automatically reset

once the gas level falls

below the alarm

threshold. This type of

alarm is typically used

in control applications

where action is

required in response to

rising gas levels.

Press and hold until

prompted to release to

Falling Latching Alarm

Latching alarms remain set

until the button is pressed

to reset the alarm. For a

falling alarm the gas level

must be above the alarm

level threshold for the reset

to operate. This type of

alarm is typically used in

safety applications for

Oxygen deficiency

monitoring where you are

monitoring for a falling

Oxygen level.

select this option.

Press and hold until

prompted to release to

select this option.

Press and hold until

prompted to release to

select this option.

Select Alarm TypeSelect Alarm TypeSelect Alarm TypeSelect Alarm Type

Falling Alarm

Falling alarms will

automatically reset once

the gas level rises

above the alarm

threshold. This type of

alarm is typically used in

control applications

where action is required

in response to falling

gas level (typical in

Oxygen deficiency

applications).

Press and hold until

prompted to release to

select this option.

Rising and Falling Non Latching Alarms

Alarm Set Point

10 Seconds

If alarm devices, output contacts or alarm signal outputs are provided as part of continuous duty

gas detection equipment and are intended to operate when a potentially hazardous gas

concentration is detected, they shall be of a latching type requiring a deliberate manual action to

reset. If two or more alarm set points are provided, the lower may be non-latching - based on user

preference. Alarms shall remain in operation while the alarm condition is still present, although

audible alarms may be silenced if this audible alarm is not the only alarm.

Alarm Resets

Rising and Falling Latching Alarms

5% of Alarm Set PointAlarm Activates

Alarm Set Point

Alarm O/P On

Alarm O/P Off

Re-Set Input On

Re-Set Input Off

10 Seconds

Indicates pressing the front panel ‘jog wheel’

Alarm Activates

Gas Detector CAL Function

Gas detectors must be calibrated with known calibration gases traceable to National Standards. As previously

discussed detectors require regular calibration. Calibration gases should have values chosen that either:

a) Are at the alarm set point to get maximum accuracy at this point

or

b) Are between 50 to 90% of the range of the detector. The detector measuring range will normally be marked on

the detector.

To CAL the detector enter password mode

as previously described and enter

password 100 to enter the user menu.

Select menu item 2 CAL

CAL

2 of 8

Enter the channel number you wish to

calibrate.

1

sensor

Enter the calibration gas value, this will be

marked on the gas bottle and enter.

50

BOTTLE

The top line of the display shows the current

reading. The bottom line shows the current

option.

55 PPM

Abort

With CAL gas flowing and the reading stable

press the button to select CONTINUE. Now

press and hold the button until prompted to

release to action the zero request.

This sequence first indicates

if the zero operation passed

or failed, then the new

detector reading then the

option to end and return to

the engineer menu. This

sequence effectively allows

the engineer to observe the

new detector zero point

before exiting.

Zero

Gas

Bottled Nitrogen or Instrument grade zero air

Calibration

Gas

20% LEL

Regulator to deliver a

fixed flowrate (typically

between 0.5 to 1 L/min)

Calibration gas.

Note: the concentration marked on

the label. Ensure it is of the correct

type for the detector being

calibrated. The concentration

should typically be 50 to 90% of

the detector range.

Calibration gas should have a humidity between 0-90%RH

Refer to EN 600179-20-1 for gas concentration guidance.

55 PPM

Continue

CAL

PASSED

50 PPM

CLICK TO

Repeat this sequence if you

are not within +/-2% of the

gas bottle value.

The display shows the result of the cal request, note that the actual zero and

calibration values are stored on the individual detector heads. When carrying out a

zero or calibration the controller sends the request to the detector head for action

and monitors the result. This means that detectors can be supplied pre-calibrated

The reading is now displayed so the result of the cal request can be observed. The

reading should be stable. Click the button to return to the previous menu.

26

Troubleshooting

Fault of electric circuit Please contact IGD

Warm up is not finished Wait till warm up is finished

Sensor is overdue service

and calibration

Please contact IGD for

service and calibration

Possible fault

Possible reason

Possible solution

The detector cannot

be turned on

No power supply

Connect power supply

Panel failure

Please contact IGD

No response to the

gas

Electrical Fault

Please contact IGD

Inaccurate indication

Damaged sensor

Please contact IGD

Sensor fault indication

Sensor fault

Please contact IGD

Fault indication

Error Message

Reboot system

Error Message after reboot

Please contact IGD

Minus gas level

displayed

Gas sensor drift

Calibrate zero point

Standard accessories Supplied

1 x Terminator Set (5 off)

1 x Resistor Pack

1 x Diode Pack

1 x Snubber

Battery Care

For control panels with the internal battery backup the following battery care is recommended:

Installation: The batteries will come pre-installed but will be disconnected to prevent battery drain.

They should be connected before the panel is connected to the mains supply.

Maintenance: Batteries should be checked at each 6 monthly service visit to ensure full

functionality. Batteries have a life of approx. 5 years dependant upon usage.

Battery Backup units and Power Booster units are available.

Recommendations for maintenance after measuring range is exceeded

Allow to stabilise in clean air or use instrument air at 0.5L/Min for 4 hours. If reading is greater then

5% LEL after this period replace otherwise re-zero and calibrate

Accessories

Part Number Description

5083101 Beacon Sounder Amber/Red

508150 Beacon Sounder Red

5083160 Beacon Sounder Blue

401101B Cal Adaptor (Tocsin 103)

401101Z Cal Adaptor (Zirconia)

401103 Cal Adaptor (MK5/6)

4011109 Gas Adaptor (TOC-30, TOC-10)

401451 Splash Guard (Tocsin 103)

401452 IGD Splash Guard

401465 Protection Filter Disk

5110101 Remote Gassing Port

5134601 40mm Stop Button

5138601 Collector Cone Ring Lock

5138701 T103 Splash Guard

5138801 `Collector cone kit (MK6)

TOC-GLAND M20 Snap fit cable glad

5925801 Universal Pole Clamp

TOC-750-DIO Free wheel diode pack

TOC-750-HMI Remote HMI display

TOC-750-IO2 8 Channel Relay Card

TOC-750-SNB Contact Suppressor (Snubber)

TOC-750-TRM Terminator set

TOC-GAS-KIT Bump Test Kit

5137201 Professional Calibration Kit 1

5142301 Professional Calibration Kit 2

5124601 Professional Calibration Kit 3

28

Loading...

Loading...