Page 1

Operating instructions

UK

Safety Rope Emergency Stop Switches

ZB0050 / ZB0051

ZB0070 / ZB0071

ZB0075

7390877 / 04 05 / 2019

Page 2

Contents

1 Safety instructions ..................................................................................................... 3

2 Installation / set-up .................................................................................................... 4

2.1 Applications..........................................................................................................4

2.2 Function and electrical connection .......................................................................4

3 Operating and display elements ................................................................................ 5

4 Installation ................................................................................................................. 6

5 Function ..................................................................................................................... 8

5.1 Maintenance requirement .................................................................................... 8

6 Electrical connection .................................................................................................. 9

7 Safety characteristics .............................................................................................. 12

8 Technical data ZB0050 / ZB0051 / ZB0071 ............................................................. 13

8.1 Technical data ZB0070 / ZB0075 ....................................................................... 14

9 Scale drawing .......................................................................................................... 15

10 Accessories .......................................................................................................... 15

11 Standards .............................................................................................................. 16

12 Approvals / certificates........................................................................................... 17

2

Page 3

1 Safety instructions

Follow the operating instructions.

Non-observance of the instructions, operation which is not in accordance with use as

prescribed below, wrong installation or incorrect handling can affect the safety of

operators and machinery.

For installation and prescribed use of the product the notes in the operating

instructions must be carefully observed and the applicable technical standards

relevant for the application have to be considered.

Failure to observe instructions or standards, especially any tampering with and/or

modification to the product, will void any manufacturer’s liability.

The unit must be installed, connected and put into operation by a qualified electrician

trained in safety technology.

After installation the system must be subjected to a complete function check.

Disconnect the device externally before handling it. Also disconnect any independently

supplied relay load circuits.

For installation the requirements according to EN 60204-1 must be observed.

In case of malfunction of the unit please contact the manufacturer. Tampering with the

device can seriously affect the safety of operators and machinery. It is not permitted

and leads to the exclusion of any liability and warranty claims.

3

Page 4

2 Installation / set-up

2.1 Applications

The safety rope emergency stop switch is used to provide safety-related switching

statuses where large danger areas have to be secured and housings or covers are not

possible.

Typical applications are conveyor systems and rotating machines and large danger

areas.

The safety rope emergency stop switch meets the requirements of EN ISO 13850, IEC

/ EN 60947-5-1 and IEC / EN 60947-5-5.

The safety rope emergency stop switch can be used in applications up to performance

level e according to EN ISO 13849-1.

NOTE

2.2 Function and electrical connection

Make careful note of all information in the operating instructions of the safety rope

emergency stop switch. This document provides all required instructions concerning

installation, mounting, operation and maintenance.

Important note

The products described here are designed to be components of a safetyoriented machine or control system. A complete safety-related system normally

includes sensors, evaluation units, signalling components and concepts for safe

switch-off. It is the responsibility of each manufacturer of a machine or

installation to ensure a correct functioning of the whole system.

The manufacturer of the safety rope emergency stop switch, his subsidiaries

and affiliates are not in a position to ensure all of the characteristics of a

machine or product which was not designed by him.

The manufacturer accepts no liability for any recommendation that may be

implied or stated here. The warranty contained in the contract of sale is the sole

warranty. Any statements contained herein do not create new warranties or

modify existing ones.

Compliance with the description of the operating instructions of the safety rope

emergency stop switch is mandatory!

4

Page 5

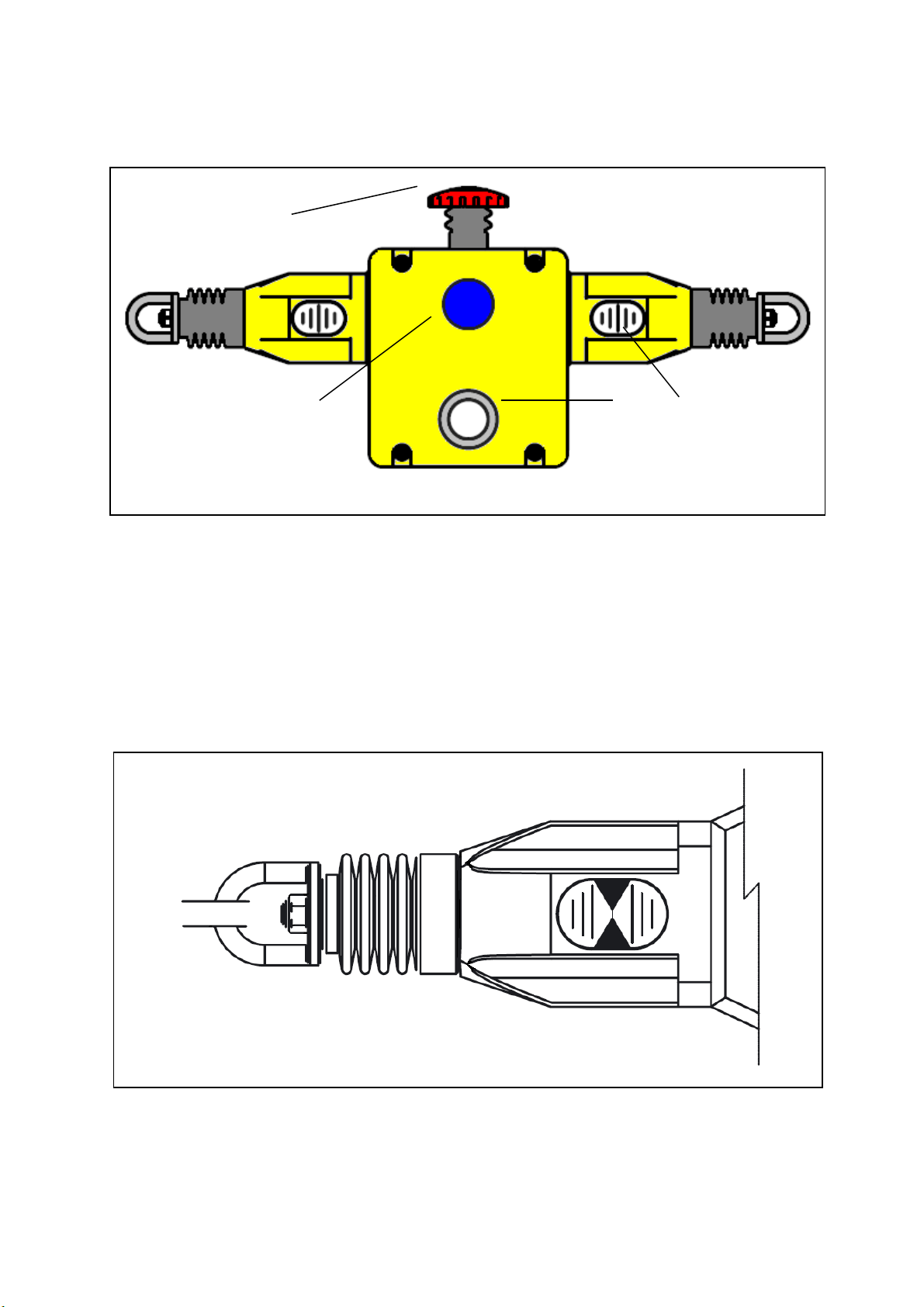

3 Operating and display elements

1: red E-stop

2: blue reset button

3: dual LED (ZB0051, ZB0070, ZB0071, ZB0075)

4: rope tension indicator

Rope tension indicator: Indicator shown with steel rope properly adjusted

5

Page 6

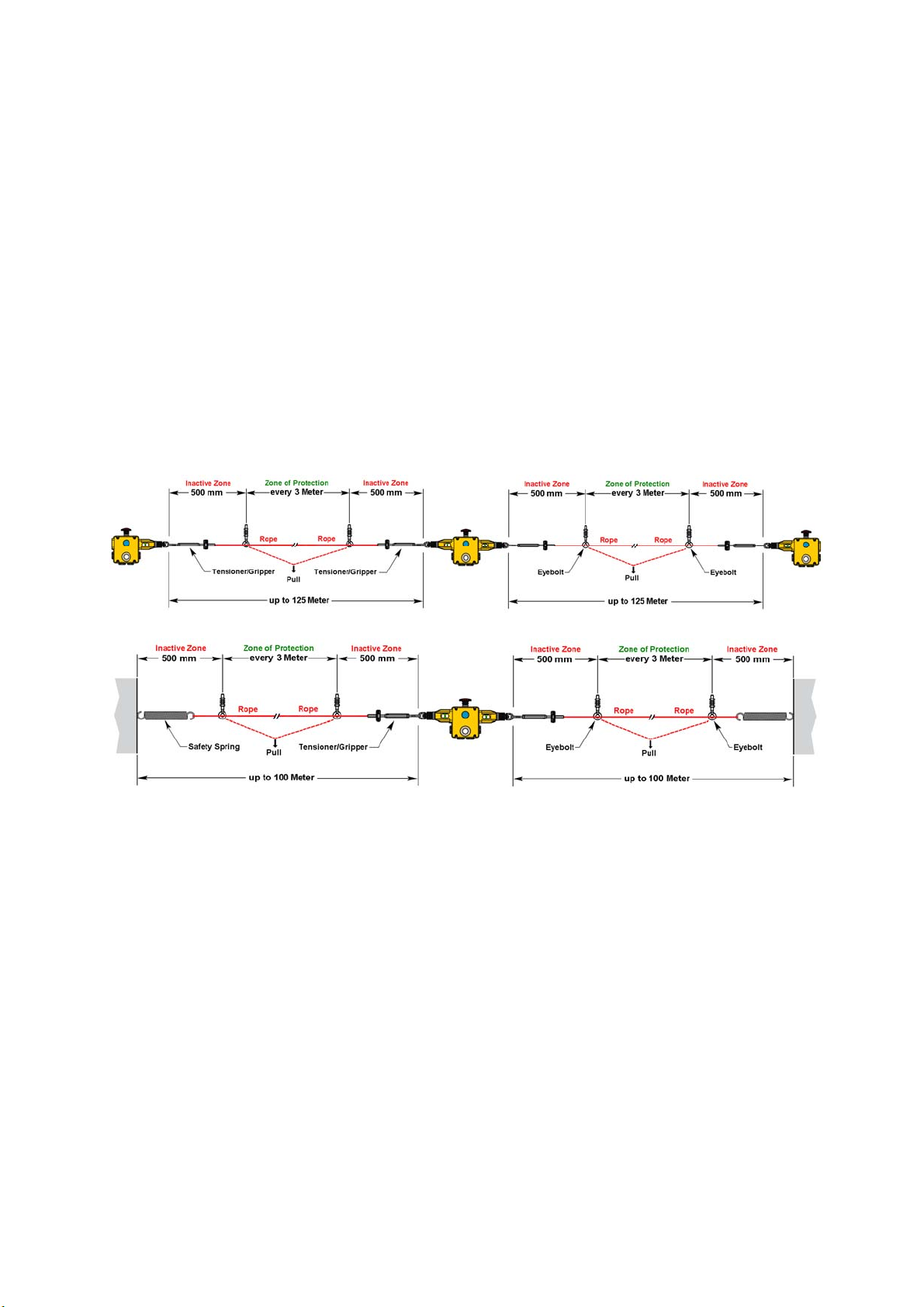

4 Installation

Installation must be carried out by authorised personnel. The safety rope emergency

stop switch is mounted using four M5 screws. The tightening torque for the fixing

screws is 4 Nm The tightening torque for the cover screws, the cable glands and cable

seals is 1.5 Nm to ensure protection rating IP 67. Only use seals of the correct size for

the cable entry and the external diameter of the cable.

The maximum vertical pull force on the rope pull is 130N until activation, the max.

travel 300mm. Enough space has to be provided so that the required actuation travel

can be reached.

Eye bolts have to be installed between the switches across the whole length of the

rope at a distance of min. 2.5m to max. 3m. The first eyebolt must be mounted at a

distance of max. 500mm of the switch eye bolt or the tension spring (if it is used). It is

important to note that the first 500mm cannot be used as part of the active protected

area (E-stop triggering).

Installation of the components

The tension of the rope is obtained by rope tensioner systems. After the installation

the tension must be set to the middle position which is indicated by green arrows in

the transparent window of the individual switches. Verify the function of all switches

and the control circuits by pulling on various spots on the rope in the active protected

area and then resetting the individual switches by pressing the blue reset button.

Ensure each time that the switches clip into place and have to be reset manually by

pressing the blue button. If necessary, increase the rope tension until the tests along

the active length of the area are satisfactory.

6

Page 7

The switches are equipped with a red, mushroom-shaped E-stop button. Check the

individual emergency stop switches and reset them to ensure proper functioning of the

control circuits.

The typical operating conditions for a successful operation of the safety rope

emergency stop system are:

max. 75N pull force and max. 150mm bending of the rope between the eye bolts for

rope support.

Rope pull systems with single direction safety rope emergency stop switches are

influenced by fluctuations of the ambient temperature!

To ensure proper function of the rope pull system it is mandatory to take into account

the dependence on the temperature when fixing the rope length and distance of the

eye bolts (every 3m).

+ 25°C

+ 22°C

+ 20°C

+ 15°C

+ 10°C

+ 7,5°C

+ 5°C

+ 3°C

Installation Temperature [°C]

- 3°C

- 5°C

- 7,5°C

- 10°C

- 15°C

- 20°C

- 22°C

- 25°C

Rope Length 15m 30m 50m 60m 75m 100m 126m

Installation Temperature in [°C] ± X [°C] = max. allowed rope length in [m]

7

Not OK

OK

Page 8

5 Function

Pulling the tensioned rope, rope breakage or impact on the E-stop cause activation of

the switching function of the safety rope emergency stop switch.

There is a window on the switch via which the correct rope tension can be monitored

during setting and maintenance. Setting, troubleshooting and maintenance are made

much easier.

After activation of the E-stop function a latching mechanism maintains the E-stop

command until it is unlocked manually by pressing the blue reset button. Before

resetting the E-stop signal the cause of the activation has to be determined. Reset is

only possible with correct rope tension (position indication in middle position).

The max. rope length also depends on the change of the ambient temperature.

Function of the safety rope emergency stop switch

5.1 Maintenance requirement

Every week:

Check proper functioning of the system at various spots along the rope length. Check

the setting of the nominal rope tension and re-adjust it, if necessary.

Every six months:

Separate the voltage supply and remove the cover. Make sure that the screws are

tight and check them for signs of penetrated moisture.

8

Damaged or faulty devices are to be replaced! Repair is not permissible.

Page 9

6 Electrical connection

Wiring is only possible if the device is disconnected from power.

Contact arrangement

0 mm 4.0 mm 15.0 mm 17.0 mm

4 NC + 2 NO Rope slack Tension range Rope pulled

11/12

21/22

33/34

41/42

51/52

63/64

contact open contact closed

Contact travels safety rope emergency stop switch

24 V DC LED:

+ 24 V DC on terminal 1 -> LED display flashing red

+ 24 V DC on terminal 3 -> LED display permanently green

9

Page 10

Installation sample:

Programming sample:

Data bits:

Data bit

In/Out

Activated input channel Bit sequence D3-D0

SI-1 XX00

SI-2 00XX

SI-1 and SI-2 0000

keiner XXXX

Activated alarm outputs Bit sequence D3-D0

O-1 XXX1

X= random

D3 D2 D1 D0

SI-2 SI-2 SI-1 SI-1/O-1

10

Page 11

110 V AC LED:

110 V AC on terminal 1 (red) -> LED display flashing red

110 V AC on terminal 3(green) -> LED display permanently green

0V on terminal 2 (black)

Installation sample:

11

Page 12

7 Safety characteristics

Characteristics Value

Performance level PL e

Category cat. 4 (with appropriate monitoring)

MTTFd

Mission time T 21 years

Annual Usage 8 cycle per hour/24hours per day/365 days

B10d 1.5 • 106 cycles at 100mA load

These calculations were made on the basis of an ambient temperature of 40 °C.

The device meets the requirements of EN ISO 13849-1: 2008 category 4 / PL e and can be

used in applications up to PL e.

For the PFD-/PFH values and the MTTF

documentation.

Explanation of the abbreviations:

PL

Cat.

T Mission time Max. service life

Performance Level Capability of safety-related parts to

Category Classification of the safety-related parts of

214 years

values of the other components see the respective

d

perform a safety function at predictable

conditions to fulfill the expected risk

reduction.

a controller as regards their resistance to

failures.

B10d

MTTFd

Number of cycles, up to 10% of the

components with dangerous failure.

Mean Time To Dangerous

Failure

12

Page 13

8 Technical data ZB0050 / ZB0051 / ZB0071

Electrical design

Safety contacts 4 NC

Auxiliary contact 2 NO

Type of contact snap-action contacts

Contact material silver

Switching capacity AC: 240 V/3 A, 120 V/6 A, inductive

DC: 24 V/2.5 A, inductive

Max. switching voltage/switching capacity 240 V/720 VA

Minimum load 5 V, 5 mA DC

Thermal current 10 A

Rated Insulation voltage 500 V

Short-circuit / overload protection external fuse 10A (FF)

Connection terminal up to 2.5 mm 2

Mechanical design

Fixing elements 4 x M5 screws

Mounting position as required

Cable entry 4 x M20

Max. rope length 125 m each side

Activation force (on rope) < 125 N

Tension force for operating position (axial) 130 N (between switches)

Switching contacts to IEC / EN 60947-5-1

Mechanical life > 1,000,000 activations

Function display

Operation LED green

Error LED red, flashing

current load LED 15 mA

Ambient temperature -25...80 °C

Protection rating IP 67

Vibration resistance 10 - 500 Hz

Shock resistance 15g 11ms

Housing material die-cast aluminium

Housing colour yellow

Weight 1320 g

13

Page 14

8.1 Technical data ZB0070 / ZB0075

Electrical design

Safety contacts 4 NC

Auxiliary contact 2 NO

Type of contact snap-action contacts

Contact material silver

Switching capacity AC: 240 V/3 A, 120 V/6 A, inductive

DC: 24 V/2.5 A, inductive

Max. switching voltage/switching capacity 240 V/720 VA

Minimum load 5 V, 5 mA DC

Thermal current 10 A

Rated Insulation voltage 500 V

Short-circuit / overload protection external fuse 10A (FF)

Connection terminal up to 2.5 mm 2

Mechanical design

Fixing elements 4 x M5 screws

Mounting position as required

Cable entry 4 x M20

Max. rope length 125 m each side

Activation force (on rope) < 125 N

Tension force for operating position (axial) 130 N (between switches)

Switching contacts to IEC / EN 60947-5-1

Mechanical life > 1,000,000 activations

Function display

Operation LED green

Error LED red, flashing

current load LED 15 mA

Ambient temperature -25...80 °C

Protection rating IP 67

Vibration resistance 10 - 500 Hz

Shock resistance 15g 11ms

Housing material Stainless steel 316

Housing colour silver

Weight 2850 g

14

Page 15

9 Scale drawing

Dimension in mm

10 Accessories

ZB0052: Safety rope e-stop switch with left sided rope connection, LED 24 V DC

ZB0053: Safety rope e-stop switch with right sided rope connection, LED 24 V DC

ZB0072: Safety rope e-stop switch with left sided rope connection, LED 110 V AC

ZB0073: Safety rope e-stop switch with right sided rope connection, LED 110 V AC

ZB0054: Rope tensioner kit, stainless steel, rope length 5 m

ZB0055: Rope tensioner kit, stainless steel, rope length 10 m

ZB0056: Rope tensioner kit, stainless steel, rope length 20 m

ZB0057: Rope tensioner kit, stainless steel, rope length 50 m

ZB0058: Rope tensioner kit, stainless steel, rope length 80 m

ZB0059: Rope tensioner kit, stainless steel, rope length 100 m

ZB0060: Rope tensioner kit, stainless steel, rope length 126 m

ZB0061: Safety spring, stainless steel, 220 mm

ZB0062: Pulley

E7015S: Safe AS-i Safety at Work PCB

E11295: M12 adapter plug to metric M20, 4 poles

E21010: M20 x 1.5 cable gland

15

Page 16

11 Standards

The following standards and directives have been applied:

• Machinery Directive 2006/42/EC

• EN ISO 13849-1: 2008

• EN ISO 13850: 2008

• AS/NSZ 4024.1 - 2014

• IEC / EN 60947-5-1: 2004: +A1: 2009

• IEC / EN 60947-5-5: 1998 + A11: 2013

• UL 508

The device must be supplied from an electrically isolated source having a secondary

UL-listed fuse rated as noted in the following table.

Overcurrent protection

Wire cross section control circuit Maximum nominal current of the protective

Evaluation unit (mm2)

equipment

ampere

26 (0.13) 1

24 (0.20) 2

22 (0.32) 3

20 (0.52) 5

18 (0.82) 7

16 (1.3) 10

Hints for AS4024.3610-3614

Information with regard to AS4024-2014:

1) Perpendicular force to operate the switches midway between eyebolt

Supports: Check <70N. rope deflection <300mm

2) Axial force - direct along rope axis: <230N (Typical 125N).

Typical parameters for successful operation of a system is less than 70N pulling force

with less than 150mm deflection of rope between eyebolt supports. This can normally

be achieved with rope switches set to the mid position between the green arrows in

the viewing window. If required, depending upon the necessary checks along the

active length of coverage, the tension can be increased further beyond the mid

position to ensure a tripping pulling force of less than 70N.

16

Page 17

12 Approvals / certificates

• EC declaration of conformity

• TÜV Rheinland (pending)

• UL (cULus)

• AS/NSZ 4024.1

17

Page 18

ifm weltweit • ifm worldwide • ifm à l’échelle internationale

http://www.ifm.com e-mail: info@ifm.com

Service hotline: 0800 / 16 16 16 4 (only Germany, Mo-Fr from 7.00 - 18.00 h)

ifm Niederlassungen • Sales offices • Agencies

D ifm electronic gmbh Vertrieb Deutschland

Niederlassung Nord • 31135 Hildesheim • Tel. 0 51 21 / 76 67-0

Niederlassung West • 45128 Essen • Tel. 02 01 / 3 64 75 -0

Niederlassung Mitte-West • 58511 Lüdenscheid • Tel. 0 23 51 / 43 01-0

Niederlassung Süd-West • 64646 Heppenheim • Tel. 0 62 52 / 79 05-0

Niederlassung Baden-Württemberg • 73230 Kirchheim • Tel. 0 70 21 / 80 86-0

Niederlassung Bayern • 82178 Puchheim • Tel. 0 89 / 8 00 91-0

Niederlassung Ost • 07639 Tautenhain • Tel. 0 36 601 / 771-0

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen

A ifm electronic gmbh • 1120 Wien • Tel. +43 16 17 45 00

AUS ifm efector pty ltd. • Mulgrave Vic 3170 • Tel. +61 3 00 365 088

B L ifm electronic N.V. • 1731 Zellik • Tel. +32 2 / 4 81 02 20

BR ifm electronic Ltda. • 03337-000, Sao Paulo SP • Tel. +55 11 / 2672-1730

CH ifm electronic ag • 4 624 Härkingen • Tel. +41 62 / 388 80 30

CL ifm electronic SpA • Oficina 5032 Comuna de Conchalí • Tel. +56 232 239 282

CN ifm electronic Co. Ltd. • 201210 Shanghai • Tel. +86 21 / 3813 4800

CND ifm efector Canada inc. • Oakville, Ontario L6K 3V3 • Tel. +1 800-441-8246

CZ ifm electronic spol. s.r.o. • 25243 Průhonice • Tel. +420 267 990 211

DK ifm electronic a/s • 2605 BROENDBY • Tel. +45 70 20 11 08

E ifm electronic s.a. • 08820 El Prat de Llobregat • Tel. +34 93 479 30 80

F ifm electronic s.a. • 93192 Noisy-le-Grand Cedex • Tél. +33 0820 22 30 01

FIN ifm electronic oy • 00440 Helsinki • Tel . +358 75 329 5000

GB IRL ifm electronic Ltd. • Hampton, Middlesex TW12 2HD • Tel. +44 208 / 213-0000

GR ifm electronic Monoprosopi E.P.E. • 15125 Amaroussio • Tel. +30 210 / 6180090

H ifm electronic kft. • 9028 Györ • Tel. +36 96 / 518-397

I ifm electronic s.a. • 20041 Agrate-Brianza (MI) • Tel. +39 039 / 68.99.982

IL Astragal Ltd. • Azur 58001 • Tel. +972 3 -559 1660

IND ifm electronic India Branch Office • Kolhapur, 416234 • Tel. +91 231-267 27 70

J efector co., ltd. • Chiba-shi, Chiba 261-7118 • Tel. +81 043-299-2070

MAL ifm electronic Pte. Ltd • 47100 Puchong Selangor • Tel. +603 8063 9522

MEX ifm efector S. de R. L. de C. V. • Monterrey, N. L. 64630 • Tel. +52 81 8040-3535

N Sivilingeniør J. F. Knudtzen A/S • 1396 Billingstad • Tel. +47 66 / 98 33 50

NA ifm electronic (pty) Ltd • 25 Dr. W. Kulz Street Windhoek • Tel. +264 61 300984

NL ifm electronic b.v. • 3843 GA Harderwijk • Tel. +31 341 / 438 438

NZ ifm efector pty ltd • 930 Great South Road Penrose, Auckland • Tel. +64 95 79 69 91

P ifm electronic s.a. • 4410-136 São Félix da Marinha • Tel. +351 223 / 71 71 08

PL ifm electronic Sp. z o.o. • 40-524 Katowice • Tel. +48 32-608 74 54

RA ROU ifm electronic s.r.l. • 1107 Buenos Aires • Tel. +54 11

ROK ifm electronic Ltd. • 140-884 Seoul • Tel. +82 2 / 790 5610

RUS ifm electronic • 105318 Moscow • Tel. +7 495 921-44-14

S ifm electronic a b • 512 60 Överlida • Tel. +46 325 / 661 500

SGP ifm electronic Pte. Ltd. • Singapore 609 916 • Tel. +65 6562 8661/2/3

SK ifm electronic s.r.o. • 835 54 Bratislava • Tel. +421 2 / 44 87 23 29

THA Sang Chai Meter Co., Ltd. • Bangkok 10 400 • Tel. +66 2 / 616 80 51

TR ifm electronic Ltd. Sti. • 34381 Sisli/Istanbul • Tel. +90 212 / 210 50 80

UA TOV ifm electronic • 02660 Kiev • Tel. +380 44 501 8543

USA ifm efector inc. • Exton, PA 19341 • Tel. +1 610 / 5 24-2000

VN ifm electronic • Ho Chi Minh City 700000 • Tel. +84-8-35125177

ZA ifm electronic (Pty) Ltd. • 0157 Pretoria • Tel. +27 12 450 0400

/ 5353 3436

Technische Änderungen behalten wir uns ohne vorherige Ankündigung vor. • We reserve the right to make technical alterations without prior notice. • Nous nous réservons le droit de modifier les données techniques sans préavis.

18

Loading...

Loading...