Page 1

Operating instructions

Control monitor

VS2000 Exi

PTB 01 ATEX 2075

7390212/01 07/03

ENGLISH

ifm electronic Ltd. • Hampton, Middlesex TW12 2HD • Tel. 0208 / 213-0000

R

1

78

13 14 15 16 17 18

19 20 21

3

2

9

+

-

Page 2

The operating instructions

... apply to all control monitors of type VS2000 Exi. The only difference between the

individual units is the height of the permissible AC or AC/DC power supply which is

indicated on the type label of the unit.

... are part of the unit. They contain information about the correct handling of the

product. Read them before use to familiarise yourself with operating conditions,

mounting and operation. Follow the safety instructions.

Contents

1. Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2

2. Function and features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

3. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

4. Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

5. Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 6

6. Function diagram flow monitoring . . . . . . . . . . . . . . . . . . . . . page 6

7. Installation and set-up / operation . . . . . . . . . . . . . . . . . . . . . page 7

8. Maintenance, repair, disposal . . . . . . . . . . . . . . . . . . . . . . . . . page 7

9. Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 7

1. Safety instructions

T

he unit must be installed, connected and put into operation by a qualified

electrician as during the installation dangerous contact voltage occurs

and the safe function of the unit and the plant is only guaranteed when

installation is correctly carried out.

B

e careful when handling the connected unit. Due to the protection rating

IP 20 this is only allowed by qualified staff.

T

he design of the unit corresponds to the protection class II except for the

terminal blocks where protection against accidental contact (safety from

finger-touch to IP20) for operation by qualified staff is only guaranteed if the

terminal screw has been completely screwed in. This is why the unit always

has to be mounted in a control cabinet of at least IP 54 which can only be

opened by means of keys.

I

n case of malfunction of the unit or uncertainties please contact the manu-

facturer. Tampering with the device can seriously affect the safety of people and equipment. This is not permitted and leads to an exclusion of liability and warranty.

Page 2

Page 3

2. Function and features

The VS2000 Exi control monitor is designed to work with flow sensors of intrinsi-

cally safe design Ex"i". It meets the requirements according to EN50014 and

EN50020 (intrinsic safety "i").

The explosion group indicated on the unit as well as special conditions have to be

taken into account according to EC type test certificate PTB 01 ATEX 2075.

Marking:

• The unit provides intrinsically safe voltage supply for the sensors, evaluates the

signals from the sensors and signals whether a preset flow value has been

reached:

• Flows of either liquids or gases can be monitored.

• In addition the VS2000 Exi monitors the sensor cable: In the case of wire break

and short circuit the monitoring relay deenergises, the red LED is on.

3. Installation

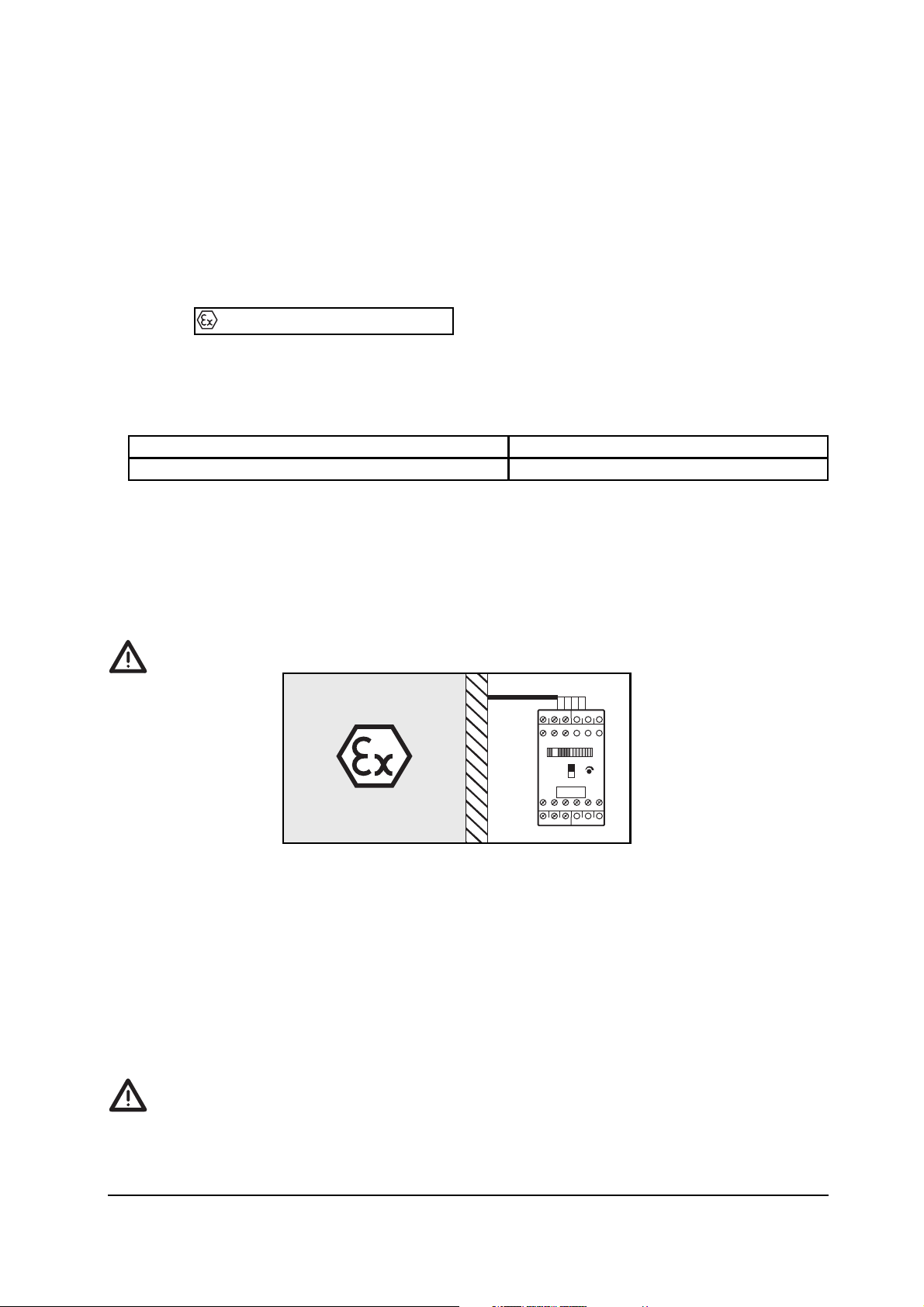

The VS2000 Exi must be mounted outside the Ex zone.

• Mount the unit in a control cabinet with a protection rating of at least IP 54 to

guarantee protection against accidental contact with dangerous contact voltages

and against atmospheric influence.

• The control cabinet should be installed in accordance with local and national rules

and regulations.

• Mount the unit on a DIN rail.

• Mount the unit vertically and leave enough space between the unit and the top

and bottom of the control cabinet to enable air circulation to avoid excessive heating.

When several units are mounted side by side the internal heating of all

units has to be considered. The ambient temperature for the individual unit

must not exceed the permissible value of +60°C.

Page 3

flow above the preset value output relay is energised

flow below the preset value output relay is deenergised

II (1) G [EEx ia] IIC

1

2

3

9

78

-

13 14 15 16 17 18

19 20 21

+

Page 4

In this case adhere to the distances between the units.

The following applies to identical VS2000 Exi units:

• Distance = 0 mm when operated with U

NOM

(see Technical data / Operating volt-

age).

• Distance = at least 10 mm when operated with U

NOM

+10%.

For units from other companies the permissible distance is to be determined by

measurements.

• Prevent the penetration of conductive or other dirt during installation and wiring.

Mounting of the sensors:

Adhere to the mounting instructions enclosed to the sensor.

4. Electrical connection

The unit must only be connected by a qualified electrician.

Isolate from mains supply before wiring!

Check if the relays are connected to voltages of external power supplies.

The rules and regulations for the installation and operation of electrical equipment

in hazardous areas must be observed.

Terminal connection:

Voltage supply

AC voltage:

According to Technical data (see page 13) / Type label ± 10% at the terminals 18 (L1)

and 17 (N), frequency range 47...63Hz.

DC voltage:

24V DC ± 10 %, at the terminals 18 (+) and 17 (-).

Page 4

Core colours:

BN = brown, BU = blue, BK = black,

WH = white, GY = grey

R1 = relay flow monitoring

R2 = relay wire monitoring

1/BN

4/BK

5/GY

2/WH

3/BU

1

2

3

7

8

9

15

13

14

16

17

18

21

19

20

R1

AC

N

L1

R2

DC

L-

L+

Page 5

Connection of sensors

Max. permissible values of the control circuits

for SN2301 ... SN2304:

Max. permissible values of the control circuits

for SR2301:

To prevent negative effects on the functions caused by noise voltages, sensor cables

and load cables should be laid separately. Maximum length of the sensor cable:

100m. Adhere to the maximum permissible values for the external inductance and

capacitance.

Output relay

Flow monitoring: terminals 13, 14, 15.

Wire monitoring: terminals 19, 20, 21.

Switching capacity: max. 250V AC, 4A (see Technical data, page 13).

The current must be externally limited to these values by taking appropriate measures.

External interference suppression of inductive loads is required.

Page 5

in the protection rating intrinsic safety

Voltage

[EEx ia] IIC and [EEx ia] IIB

Current

I

o

= 92mA / Ie= 47.2mA

U

o

= 15.8V

Power

P

o

= 680 mW

in the protection rating intrinsic safety

External inductance

[EEx ia] IIC [EEx ia] IIB [EEx ia] IIB

External capacitance 185nF

1mH

1.6µF

1mH

885nF

5mH

in the protection rating intrinsic safety

Voltage

[EEx ia] IIC and [EEx ia] IIB

Current

I

o

= 84mA / Ie= 38.5mA

U

o

= 15.8V

Power

P

o

= 680 mW

in the protection rating intrinsic safety

External inductance

[EEx ia] IIC [EEx ia] IIB [EEx ia] IIB

External capacitance 205nF

1mH

1.7µF

1mH

935nF

5mH

Page 6

5. Adjustment

1. Set the selector switch (3) to liquid or gaseous media:

= liquid, = gas.

2. Apply the operating voltage. After the power-on delay time (approx. 30 s) has

elapsed the unit is ready for operation; (during this time flow may be indicated).

3. Set the preset flow and keep it constant. Turn the setting potentiometer (4) until

a green LED lights. The farther the green LED lit is away from the yellow LED, the

safer is the adjustment (excess gain for flow or temperature fluctuations).

6. Function diagram flow monitoring

Page 6

Row of LEDs

- red LED is lit: flow below the switch point

- yellow LED is lit: relay is energised,

flow has reached the switch point

- green LED is lit: flow above the switch point

Selector switch medium (liquid/gas)

LED red

- is lit in case of wire break or short circuit

Setting potentiometer for switch point

1

3

2

4

preset flow

switch point

output relay

t1 = power-on delay time

1

2

78

3

9

1

2

3

+

-

4

13 14 15 16 17 18

19 20 21

f

t1

1

0

t

Page 7

7. Installation and set-up / operation

After mounting, wiring and setting check the safe functioning of the unit

In the case of wire break or short circuit of the sensor cable the relay "wire monitoring" is de-energised and the red LED lights. After rectification of the fault the control monitor is again ready for operation

8. Maintenance, repair, disposal

If used correctly no maintenance and repair measures are required.

Only the manufacturer is allowed to repair the unit.

After use dispose of the unit in an environmentally friendly way in accordance

with the applicable national regulations.

9. Technical data

Page 7

SN2302 SN2303 SN2304 SR2301SN2301

AC DC

230V 110V 200V 240V 24V

± 10%

5VA 125mA

-20 ... +60°C

IP 20

IP 40

plastic (noryl)

15 terminals max. 2 x 2.5mm

2

relay

max. 4A (250V AC, cos ϕ ≥ 0.7); 0.2 A (250V DC); 4A (24V DC)

Electrical design

Operating voltage

Voltage tolerance

Power/current consumption

Operating temperature

Protection terminals

Protection housing

Housing

Connection

Output

Contact rating

Loading...

Loading...