Page 1

Operating instructions

Vibration sensor

VNB211

UK

80270676/00 12/2017

Page 2

Content

1 Preliminary note ��������������������������������������������������������������������������������������������������� 4

1�1 Notes on this document ��������������������������������������������������������������������������������� 4

1�2 Symbols used ������������������������������������������������������������������������������������������������4

2 Safety instructions �����������������������������������������������������������������������������������������������4

2�1 General ���������������������������������������������������������������������������������������������������������� 4

2�2 Installation and connection ����������������������������������������������������������������������������4

2�3 Tampering with the device �����������������������������������������������������������������������������5

3 Functions and features ����������������������������������������������������������������������������������������5

4 Installation������������������������������������������������������������������������������������������������������������6

5 Electrical connection �������������������������������������������������������������������������������������������� 7

5�1 M8/USB interface ������������������������������������������������������������������������������������������7

5�2 History values ������������������������������������������������������������������������������������������������7

5�3 Real-time clock ����������������������������������������������������������������������������������������������8

6 Functions �������������������������������������������������������������������������������������������������������������8

6�1 Monitoring function ����������������������������������������������������������������������������������������8

6�2 Input function �������������������������������������������������������������������������������������������������8

6�3 Output function (switching output and analogue output) �������������������������������9

6�4 Self-test����������������������������������������������������������������������������������������������������������9

6�5 Averaging of a vibration characteristic value �������������������������������������������������9

6�5�1 Calculation �������������������������������������������������������������������������������������������� 9

6�5�2 Settings �����������������������������������������������������������������������������������������������10

6�5�3 Diagram averaging �����������������������������������������������������������������������������10

6�6 Measuring function ��������������������������������������������������������������������������������������10

7 Operating and display elements ������������������������������������������������������������������������ 11

7�1 LED display ������������������������������������������������������������������������������������������������� 11

7�2 7-segment display ���������������������������������������������������������������������������������������12

7�3 Operating mode ������������������������������������������������������������������������������������������� 12

7�3�1 Examples in the operating mode ��������������������������������������������������������12

7�4 Operating mode external process value ������������������������������������������������������ 13

7�4�1 Example display change (v

- external process value) ��������������������13

rms

8 Device configuration ������������������������������������������������������������������������������������������14

8�1 Programming via pushbuttons ��������������������������������������������������������������������� 14

8�1�1 Global VNB parameters ����������������������������������������������������������������������14

2

Page 3

8�1�2 Characteristic vibration value �������������������������������������������������������������14

8�1�3 External process value �����������������������������������������������������������������������14

9 Menu ������������������������������������������������������������������������������������������������������������������ 14

9�1 Menu structure ��������������������������������������������������������������������������������������������� 15

9�2 Main menu ��������������������������������������������������������������������������������������������������� 15

9�2�1 V1 menu ���������������������������������������������������������������������������������������������16

9�2�2 V2 menu ���������������������������������������������������������������������������������������������16

9�2�3 EV1 menu ������������������������������������������������������������������������������������������� 16

9�2�4 EV2 menu ������������������������������������������������������������������������������������������� 17

9�2�5 EP1 menu ������������������������������������������������������������������������������������������� 17

9�2�6 EP2 menu ������������������������������������������������������������������������������������������� 18

9�2�7 Ext menu ��������������������������������������������������������������������������������������������18

9�2�8 Out menu �������������������������������������������������������������������������������������������� 19

9�3 Explanation of the menu ������������������������������������������������������������������������������ 20

UK

10 Parameter setting via the pushbuttons on the unit ������������������������������������������22

10�1 Parameter setting in general ���������������������������������������������������������������������22

10�1�1 Change from menu level 1 to the sub-menu ������������������������������������23

10�1�2 Locking / unlocking ���������������������������������������������������������������������������24

11 Maintenance, repair and disposal �������������������������������������������������������������������� 24

12 Scale drawing ��������������������������������������������������������������������������������������������������24

13 Time diagrams �������������������������������������������������������������������������������������������������25

13�1 Averaging for a characteristic vibration value ��������������������������������������������25

13�2 Switching delay for the upper limit monitor ������������������������������������������������ 26

13�3 Switching delay for the lower limit monitor ������������������������������������������������28

14 Factory setting �������������������������������������������������������������������������������������������������29

3

Page 4

1 Preliminary note

Technical data, approvals, accessories and further information at www�ifm�com�

1.1 Notes on this document

This document applies to devices of the type "vibration sensor" (art� no�: VNB211)�

It is part of the device and contains information about the correct handling of the

product�

This document is intended for qualified electricians� These specialists are people

who are qualified by their training and their experience to see and to avoid

possible hazards that may be caused during operation of the device�

► Read this document before using the device�

► Keep this document during the service life of the device�

1.2 Symbols used

► Instructions

> Reaction, result

→ Cross-reference

LED on

LED flashes

Important note

Non-compliance may result in malfunction or interference�

Information

Supplementary note

2 Safety instructions

2.1 General

► Observe these operating instructions�

► Observe the warning notes in these instructions�

Non-observance of the instructions, operation which is not in accordance with use

as prescribed below, wrong installation or incorrect handling can affect the safety

of operators and machinery�

2.2 Installation and connection

The device must only be installed, connected and put into operation by a qualified

electrician as the safe function of the device and machinery is only guaranteed

4

Page 5

when installation is correctly carried out� The installation and connection must

comply with the applicable national and international standards� Responsibility lies

with the person installing the device�

This is a class A product which is intended for use in industrial applications�

The unit may cause radio interference in domestic areas� In this case it can

be necessary for the user to take appropriate measures�

2.3 Tampering with the device

Tampering with the device is not allowed and will lead to an exclusion of liability

and warranty� Tampering with the device can affect the safety of operators and

UK

machinery�

3 Functions and features

The parameters of the device are mainly set via the VES004 PC software�

The device manual can be found at www�ifm�com

Monitoring of

• 2 sensor-internal characteristic vibration values (a/v, RMS/peak)

• 2 external characteristic vibration values (a/v, RMS/peak via VNA001

accelerometer) or two external process values (current value above and/or

below limit value)

Visualisation of

• Measured values

• Switching states

• Measured data via PC software

5

Page 6

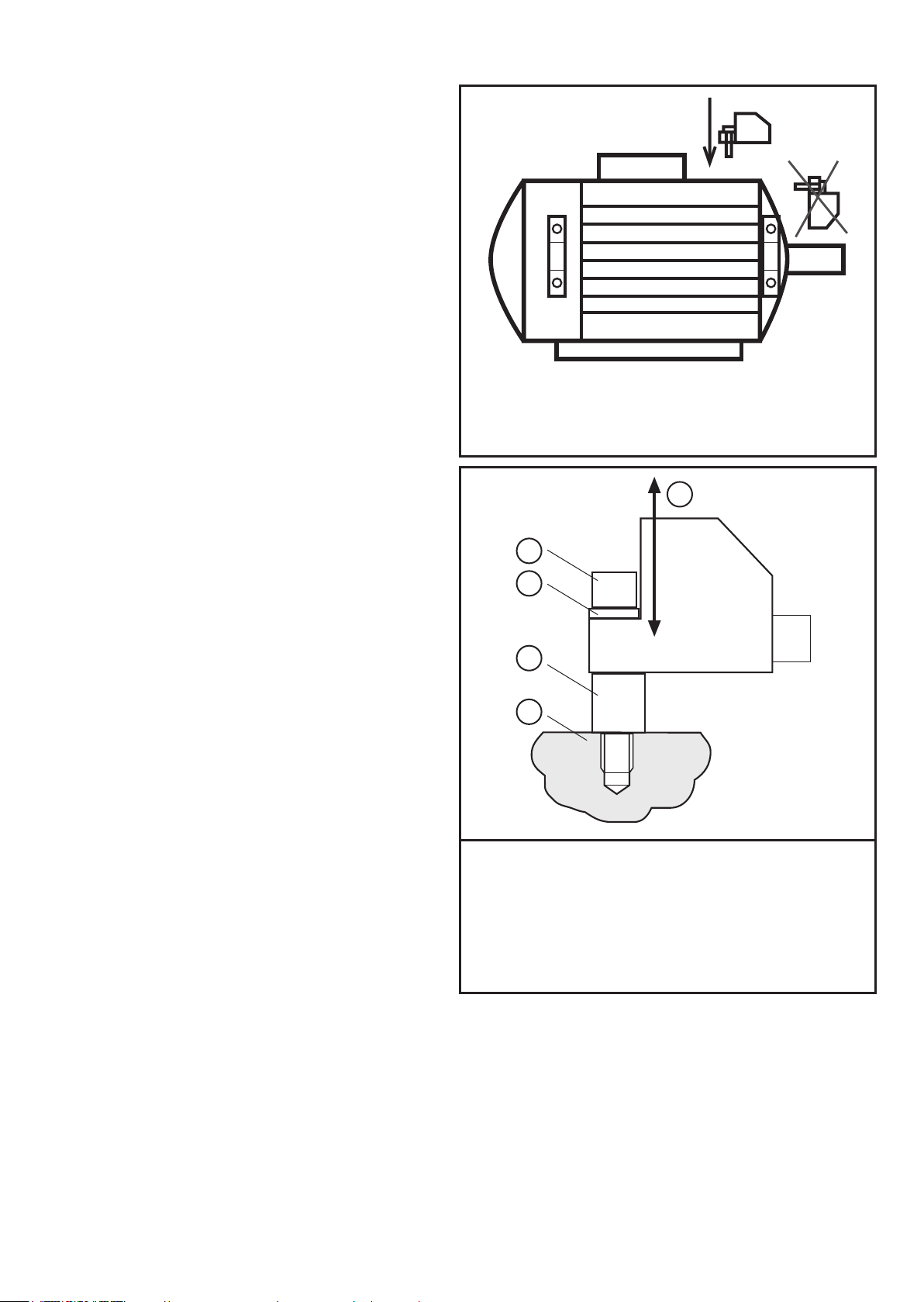

4 Installation

Please note the following points

when installing the unit:

► Mount only in a thick housing wall

(e�g� crane hook thread)�

► Mount vertically to the machine

surface using the spacer adapter

in the direction of the strongest

vibrations� This is usually the

radial direction�

► Tighten the M5 screw with a

tightening torque of 7 Nm�

► Ensure a reliable vibration

transmission� Avoid any elastic

intermediate layers�

1

2

3

4

5

1: Measurement axis

2: M5 screw

3: Spring washer

6

4: M8 x M5 adapter

5: Machine surface

Page 7

5 Electrical connection

The unit must be connected by a qualified electrician�

The national and international regulations for the installation of electrical equipment

must be adhered to�

Voltage supply to EN 50178, SELV, PELV�

Disconnect power before connecting the unit�

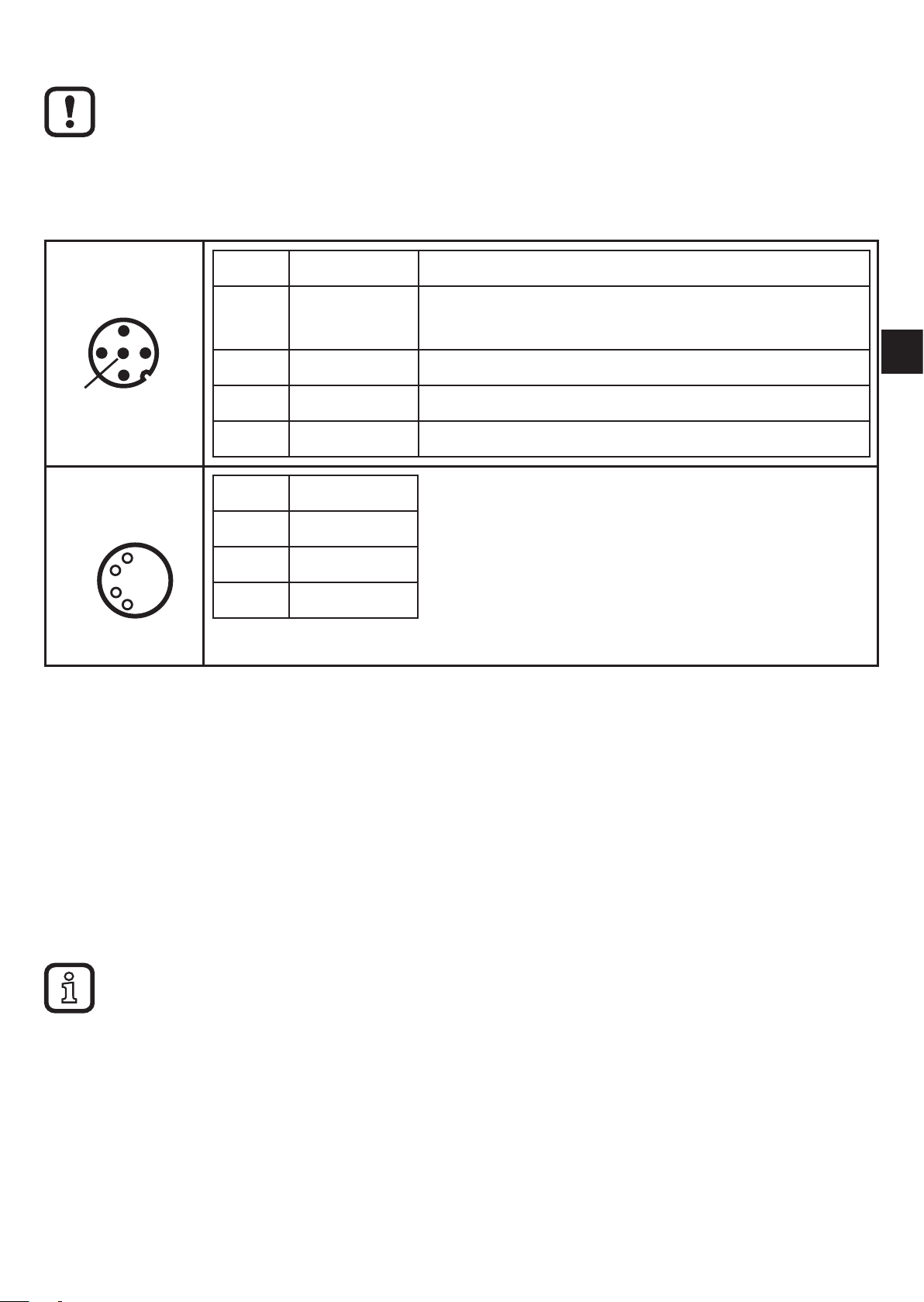

M12

M8

Pin 1: L+ 9�6���30 V DC

Pin 2: Out 1 Switching output or current output

Pin 3: L Pin 4: Out 2 Switching output

Pin 5: IN Current input 0/4���20 mA

Pin 1: VCC (5 V)

Pin 2: USB DPin 3: LPin 4: USB D+

5.1 M8/USB interface

0/4���20/22 mA (configurable)

UK

► First connect the interface cable to the device and then to the USB interface of

the computer�

• Communication with the PC software for parameter setting of the objects to be

monitored, to read and reset the history data and to visualise measured data�

• The devices have a serial number that can be read via the PC software�

• The sensor can also be supplied via the USB interface�

Switching and analogue outputs are not supported if a USB power supply is used�

5.2 History values

The unit has an internal history memory� The memory interval can be configured

for each object via the PC software (min� 1 s)� The maximum value and optionally

the average value in this interval are stored together with the time stamp in the

memory�

7

Page 8

The memory's capacity is 685,000 values; beyond this the oldest values are

overwritten (ring memory, FIFO)�

The history can be configured, read and reset via the PC software�

5.3 Real-time clock

The unit has an integrated real-time clock including a buffer battery for the time

stamp in the history memory� The time is synchronised with the system clock when

the history is reset via the PC software�

6 Functions

The basic functions of the unit are set via the PC software�

Only parameters for alarming and scaling of the signals can be set via the buttons

on the unit → 8.1 Programming via pushbuttons

6.1 Monitoring function

The VNB211 can monitor up to two internal characteristic vibration values� The

characteristic values are activated and configured via the PC software� Monitoring

can be effected in acceleration or vibration velocity in a frequency range that can

be set�

On delivery, the first characteristic value monitors the effective value of the

vibration velocity to ISO 10816 in the frequency range of 10���1000 Hz�

On delivery, the second characteristic value monitors the maximum peak of the

acceleration in the frequency range of 10���6000 Hz�

6.2 Input function

Monitoring can be extended by another vibration measuring point or a process

value via the external input of the VNB211�

For the external input it is also possible to monitor up to two characteristic

values� With an extension by a vibration measurement point (with a VNA001

accelerometer + Y cable) the same parameters can be configured as with internal

characteristic vibration values�With an extension by a process value (via an

analogue 4���20 mA current signal) the process value (e�g� a storage temperature

or pressure) can be monitored for exceeding and/or falling below the limit value�

On delivery, the first characteristic value for the external input is configured as

temperature monitoring (e�g� connection of a TT3237)�

The second characteristic value is deactivated on delivery�

8

Page 9

6.3 Output function (switching output and analogue output)

The two outputs of the VNB211 are used for the alarm (pre-alarm, main alarm)�

The first output (OU1) can be used as digital or analogue output� The switching

logic (which characteristic values are alarmed in which way) can be set only in the

PC software�

System errors (e�g� a failed self-test) are also signalled on the first output (OU1)�

If the output is used as digital output, the output pulses with a frequency of 1 Hz

in case of a fault� A current of 22 mA is provided as analogue output in case of a

system error�

UK

6.4 Self-test

The self-test checks the function of the VNB's measuring cell� The self-test

is made during power-on and can in addition be started manually via the PC

software or the buttons on the unit�

Displays on the unit:

• Self-test passed → [PASS]

• Self-test failed → [FAIL]

> LED OU1 flashes

Output OU1

- pulsing if "digital" output function (NC, NO)

- supplies 22 mA if "analogue" output function

6.5 Averaging of a vibration characteristic value

6.5.1 Calculation

Formula to determine the new diagnostic value:

("previous diagnostic value" x (1 - averaging)) + ("new measurement" x averaging)

= new diagnostic value

Example

Averaging 0�25; "previous diagnostic value" 17�3 mm/s;

"new measurement" 14�7 mm/s

(17�3 mm/s x (1 - 0�25)) + (14�7 mm/s x 0�25) = 16�65 mm/s

For the VNB211 the measurement time between "previous diagnostic value" and

"new measurement” can be configured via the PC software�

9

Page 10

6.5.2 Settings

1

1

0

10

15

20

25

30

35

5

4710 13 16 19 22 25 28 31 34 37 40 43 46 49 52 55 58 61 64 67 70 73 76 79 82 85 88 91 94 97

2

Averaging = 1: averaging deactivated

Averaging 0�01; strong averaging

6.5.3 Diagram averaging

1: Measured value

2: Averaged diagnostic value (averaging = 0�125)

6.6 Measuring function

The device can be set to the measurement mode via the VES004 software� In this

mode, you have access to the raw data (time signal) of the acceleration or of the

external input (4���20 mA)� The data can be visualised, recorded, analysed and

processed in the software�

If the device remains connected to the software, the user has to actively (manual

ly) finish the time signal monitoring� If the device is separated from the software, it

automatically returns to the monitoring function�

If the unit is in the measurement mode, there is no monitoring� "rSc3" is displayed

-

on the unit�

10

Page 11

7 Operating and display elements

7.1 LED display

10

Mode/Enter Set

11

12

1...8: LED display

UK

1: LED green a = vibration velocity a [g] or [m/s²]

2: LED green v = vibration velocity v [mm/s] or [in/s]

3: LED green d = not used

4: LED green RMS = average value

5: LED green Pk = peak value

6: LED green Ext = process value of the external transducer

7: LED yellow OU1 = pre-alarm active *)

8: LED red OU2 = main alarm active *)

*) The LED indicates the current alarm state (warning alarm, damage alarm)� The configu

ration of the corresponding output (OU1, OU2) as "normally closed" or "normally open" is

ignored�

9: 7-segment display green, yellow and red, 4 digits

- Display of the measured values

10: Points

- Lower points as decimal separators

-

11: Set button

Parameter setting mode

- Setting of the parameter values

- Change of display between the configured characteristic values

12: Mode/Enter button

- Selection of the parameters and acknowledgement of the parameter values�

11

Page 12

7.2 7-segment display

• Displays the damage level (green, yellow, red)

If the segment display changes the colour, the switch-on and switch-off delays or

the hysteresis are not considered�

• Display of the current measured value for the selected object

• Display of the configuration menu and its parameters

7.3 Operating mode

The user must know the objects configured in the vibration sensor and in the external

sensor� The display allows no indication of the unit if the external input is used for

process value monitoring�

7.3.1 Examples in the operating mode

Colour segment display: yellow

a

v

d

RMSPk

Ext

OU1

OU2

Colour segment display: red

a

v

d

RMSPk

Ext

OU1

OU2

Current measured value of the 1st object,

e�g� vibration velocity v

= 17�35 mm/s�

rms

Parameters

- Pre-alarm SP1 = 10 mm/s

- Main alarm SP2 = 20 mm/s

> Output OU1 is active

Current measured value of the 2nd object,

e�g� imbalance (v

) = 1�252 in/s

peak

Parameters

- Unit uni = in/s

- Early warning SP1 = 0�5 in/s

- Main alarm SP2 = 1 in/s

12

> Outputs OU1 and OU2 are active

Page 13

Colour segment display: red

2

a

v

d

RMSPk

Ext

OU1

OU2

Current measured value external analogue sensor,

temperature ϑ = 95 °C

Parameters

- Pre-alarm ESP1 = 50 °C

- Main alarm ESP2 = 90 °C

> Outputs OU1 and OU2 are active

The LEDs OU1 and OU2 indicate the alarm condition, not the voltage level (high,

UK

low) at the output�

The level can be inverted via the parameters OU1 and OU2 (NC, NO)�

7.4 Operating mode external process value

In the operating mode "external process value" measured values are displayed,

e�g� temperatures, pressure values or other characteristic vibration values�

The detected values are transferred via the measured value input (pin 5)�

> LED "Ext" lights�

7.4.1 Example display change (v

a

v

d

RMSPk

Ext

OU1OU

Configuration

1 characteristic vibration value + 1 external process

value

- external process value)

rms

Normal operating mode

Set

Vibration velocity 17�35 mm/s v

rms

[Set]

Operating mode external process value

e.g. temperature 42.61 °C

a

v

d

RMS

Pk

Ext

OU1

OU2

[Set]

Normal operating mode

Vibration velocity 17�35 mm/s v

rms

13

Page 14

8 Device configuration

8.1 Programming via pushbuttons

The following settings can be made via the pushbuttons on the unit�

8.1.1 Global VNB parameters

- Scaling of the input (4���20 mA, for use for the external process value)

- Scaling of the output (4���20 mA, if OU1 = analogue)

- Switching function of the outputs (NC, NO)

- Switch-on and switch-off delays

- Self-test

- Unit (mm/s, inch/s)

8.1.2 Characteristic vibration value

- Averaging

- Switchpoints (pre-alarm and main alarm)

8.1.3 External process value

- Switch points

- Hysteresis

All other settings of the sensor are made via the PC software� There it is defined

how many and which characteristic values (characteristic vibration values and/or

process values) are to be monitored → device manual.

9 Menu

Depending on the configuration of the sensor the menu level 1 is adapted via

the PC software� There are only menu items whose characteristic values were

configured via the PC software�

If the external input in the PC software is configured for an analogue current

signal, the menu items EV1) and EV2) are not available�

If the external input in the PC software is configured for an accelerometer

(VNA001), the menu items EP1) and EP2) are not available�

14

Page 15

9.1 Menu structure

9.2 Main menu

Vibration

Ext. input

Main

menu

UK

15

Page 16

9.2.1 V1 menu

9.2.2 V2 menu

9.2.3 EV1 menu

The menu for the external characteristic vibration value 1 is only available if it was

configured in the PC software�

16

Page 17

9.2.4 EV2 menu

The menu for the external characteristic vibration value 2 is only available if it was

configured in the PC software�

UK

9.2.5 EP1 menu

17

Page 18

9.2.6 EP2 menu

The menu for the external process value 2 is only available if it was configured in

the PC software�

9.2.7 Ext menu

18

Page 19

9.2.8 Out menu

UK

19

Page 20

9.3 Explanation of the menu

Menu level 1

V1 ) Sub-menu for the characteristic vibration value 1

V2 ) Sub-menu for the characteristic vibration value 2

EV1) Sub-menu for the external characteristic vibration value 1 with respective

configuration

EV2) Sub-menu for the external characteristic vibration value 2 with respective

configuration

EP1) Sub-menu for the external process value 1

EP2) Sub-menu for the external process value 2 with respective configuration

EXT) Sub-menu for the external input

in the configuration as analogue input

OUT) Sub-menu for the outputs

Uni Unit of the vibration velocity - mm/s or in/s

Test Self-test - (PASS or FAIL)

is automatically made when the sensor is switched on

Sub-menu characteristic vibration values V1) and V2)

The values indicated for the switch points SP1 and SP2 of characteristic values of the

vibration velocity change when another unit is selected�

SP1 Switch point pre-alarm

If the switch point is exceeded,

- OU1 switches, if it is digital

- the yellow LED "OU1" lights

- the measured value display changes to yellow

SP2 Switch point main alarm

If the switch point is exceeded,

- OU2 switches

- the red LED "OU2" lights

- the measured value display changes to red

AUER Averaging → chapter 6.5

20

Page 21

Sub-menu external characteristic vibration values EV1) and EV2) with respective

configuration

ESP1 Switch point pre-alarm

If the switch point is exceeded,

- OU1 switches, if it is digital

- the yellow LED "OU1" lights

- the measured value display changes to yellow

ESP2 Switch point main alarm

If the switch point is exceeded,

- OU2 switches

- the red LED "OU2" lights

- the measured value display changes to red

AUER Averaging → chapter 6.5

Sub-menu external characteristic vibration values EP1) and EP2) with respective

configuration

ESP1 Switch point pre-alarm

If the switch point is exceeded,

- OU1 switches, if it is digital

- the yellow LED "OU1" lights

- the measured value display changes to yellow

Eh1 Hysteresis pre-alarm

Absolute distance between set and reset point

ESP2 Switch point main alarm

UK

If the switch point is exceeded,

- OU2 switches

- the red LED "OU2" lights

- the measured value display changes to red

Eh2 Hysteresis main alarm

Absolute distance between set and reset point

Sub-menu external input as analogue current input

EASP Scaling of external sensor for the process value,

initial value of the measuring range at 4 mA

EAEP Scaling of external sensor for the process value,

final value of the measuring range at 20 mA

Sub-menu outputs

ou1 Switching logic OU1 (OU1 = digital)

NC, NO (normally closed, normally open)

21

Page 22

ASP1 Scaling current output with respective configuration

(OU1 = analogue), value at 4 mA

AEP1 Scaling current output with respective configuration

(OU1 = analogue), value at 20 mA

ou2 Switching logic OU2

NO, NC (normally open, normally closed)

dS1 Switch-on delay for OU1 (0���60 s)

dr1 Switch-off delay for OU1 (0���60 s)

dS2 Switch-on delay for OU2 (0���60 s)

dr2 Switch-off delay for OU2 (0���60 s)

Error message

Err1 The value to be displayed is less than -999 or greater than 9999�

► Check the scaling of the current output (ASP1, AEP1) and set again�

10 Parameter setting via the pushbuttons on the unit

During the parameter setting process the monitoring function of the unit is

maintained� It continues to monitor with the existing parameters until the parameter

setting has been completed�

10.1 Parameter setting in general

3 steps must be taken for each parameter setting:

Select parameter

1

► Press [Mode/Enter] until the reque-

sted parameter is displayed.

Mode/Enter Set

22

Page 23

Set parameter value

Mode/Enter Set

2

► Press [Set].

> The current setting value of the

parameter is displayed�

► Press [Set] for 3 s.

► Setting of the decimal point (cc�

cc) and the sign by pressing [Set]

several times�

► Press [Mode/Enter] to confirm.

► Set an individual digit with [Set] and

confirm with [Mode/Enter].

► Repeat with all digits�

Acknowledge parameter value

3

► Press [Mode/Enter].

> The parameter is displayed again�

Mode/Enter Set

The new setting value is saved�

Set other parameters

► Start again with step 1�

Change the operating mode

► Press [Mode/Enter] several times until the current measured value is displayed.

> The unit returns to the operating mode�

If no button is pressed within 30 s, the unit automatically returns to the operating mode�

UK

10.1.1 Change from menu level 1 to the sub-menu

► Press [Mode/Enter] until [EF

displayed�

► Briefly press [Set].

> The first parameter of the submenu is

displayed (here: [LFCO]).

┘

] is

Mode/Enter Set

Mode/Enter Set

23

Page 24

10.1.2 Locking / unlocking

The unit can be locked electronically to prevent unintentional settings�

► Make sure that the unit is in the

normal operating mode�

► Press [Mode/Enter] + [Set] for 10 s.

> [Loc] is displayed.

During operation: [Loc] is briefly displayed if you try to change parameter values.

For unlocking:

► Press [Mode/Enter] + [Set] for 10 s.

> [uLoc] is displayed.

On delivery: not locked�

Mode/Enter Set

Mode/Enter Set

11 Maintenance, repair and disposal

► Dispose of the device in accordance with the national environmental

regulations�

12 Scale drawing

62,4

51

36

14

5,3

6

M12x1

20

M5

24

37,6

10

4

M8x1

5,3

5

Page 25

13 Time diagrams

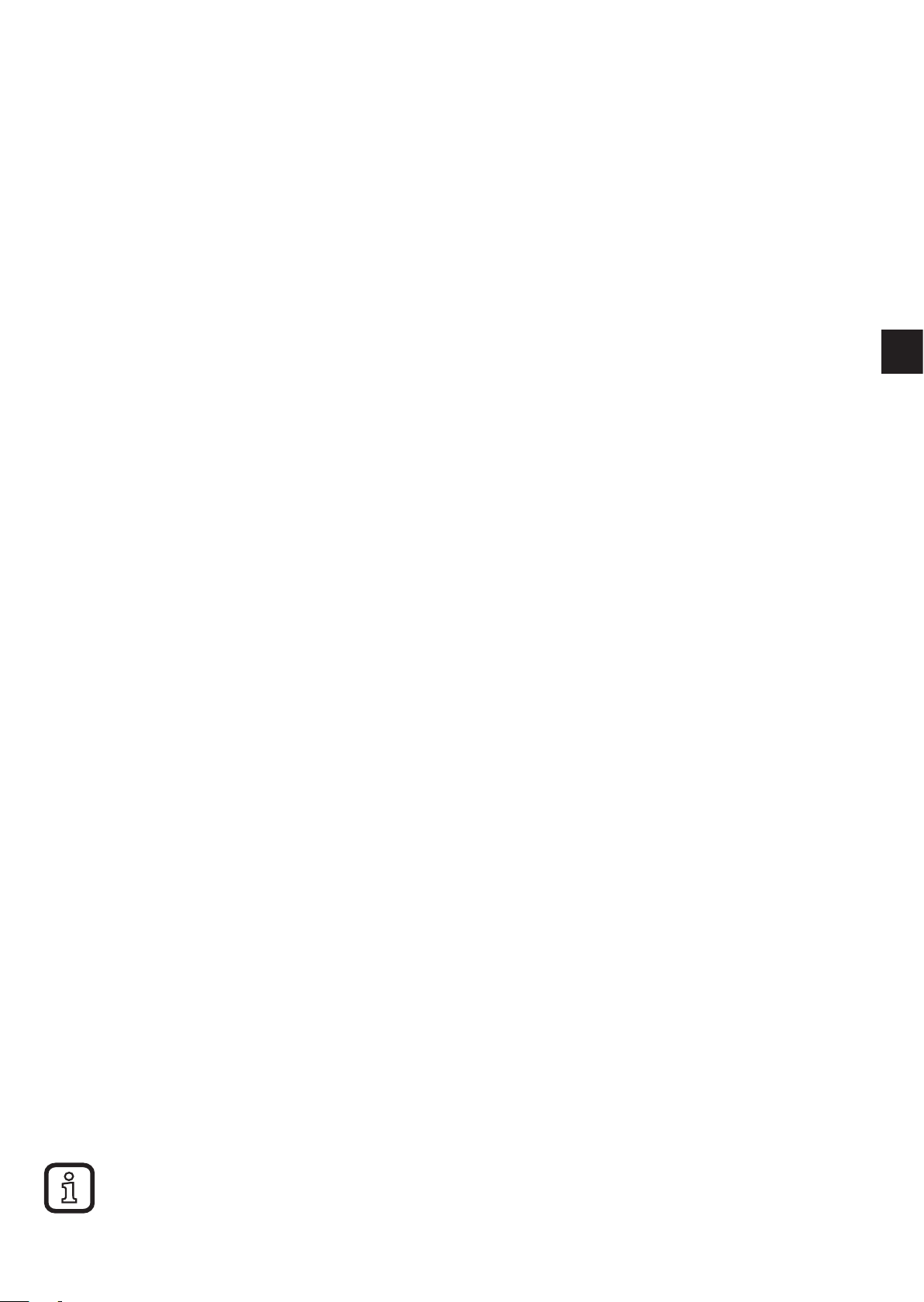

13.1 Averaging for a characteristic vibration value

The time diagram shows the effect of averaging for a characteristic vibration value�

The outputs are configured as normally open (OU1 and OU2 → NO), averaging

(AUER) = 0�25�

rms [mm/s]

v

1

SP1

SP2

24 V

0 V

OU 2 (n.o.)

ds2, dr2 = 0 s

off

OU 1 (n.o.)

10

10

on

off

on

20

20

2

UK

t [s]

t [s]

24 V

ds1, dr1 = 0 s

0 V

1: Raw signal

2: Averaged signal

off

on

10

off

on

20

t [s]

25

Page 26

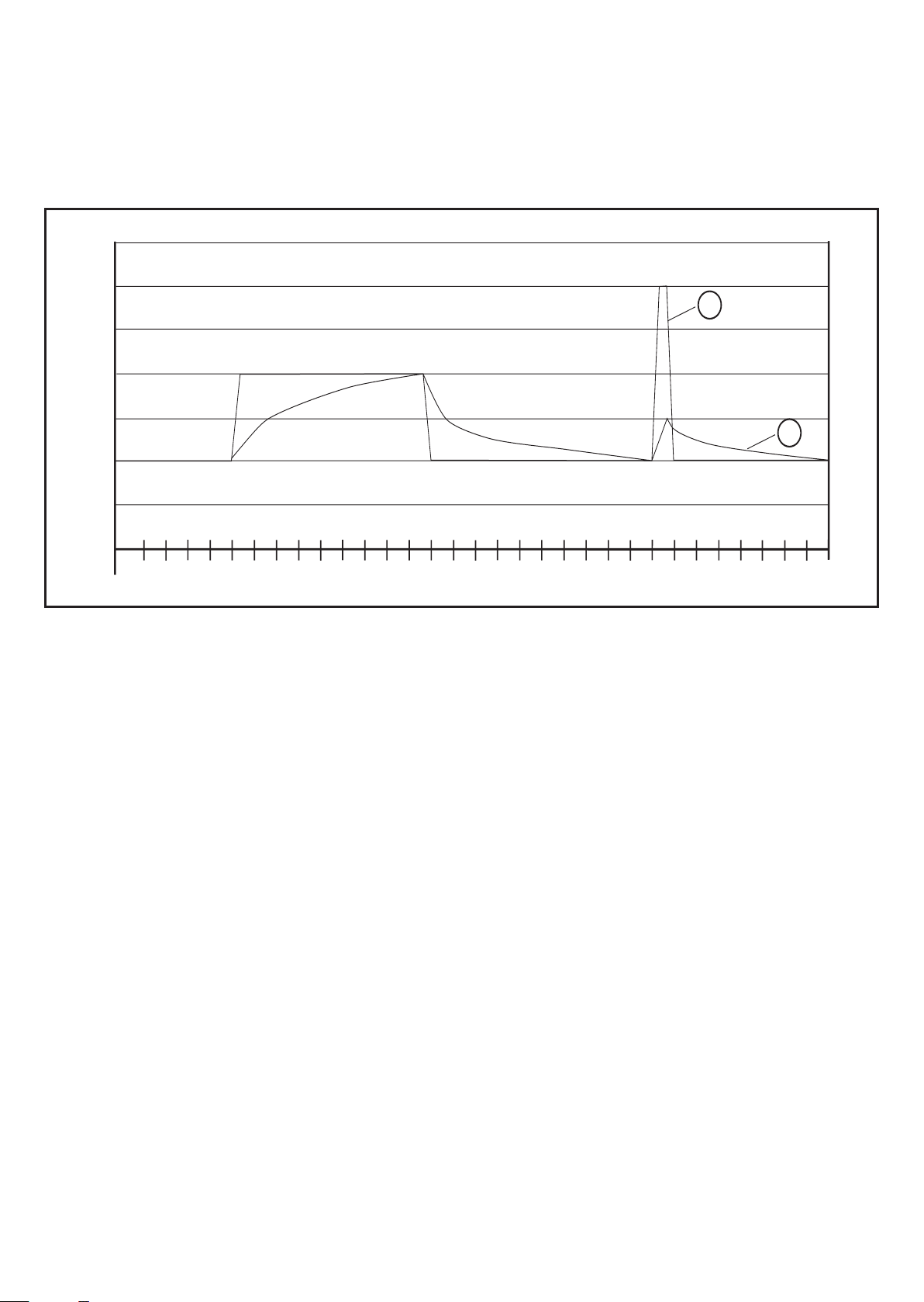

13.2 Switching delay for the upper limit monitor

The time diagram shows the effect of the switching delay on the analogue input

for an upper limit monitor (ESP1 < ESP2)� The outputs are set as normally closed

(OU1 and OU2 → NC).

Analogue In

[°C]

Eh2

Eh1

ESP2

{

ESP1

{

24 V

0 V

24 V

10

OU 1 (n.c.)

ds1, ds2, dr1, dr2 = 0 s

on

10

OU 2 (n.c.)

20

20

off

off

t [s]

off

on

t [s]

off

0 V

24 V

0 V

24 V

0 V

on

10

OU 1 (n.c.)

ds1, ds2 = 2 s / dr1, dr2 = 3 s

2 s

10

OU 2 (n.c.)

ds1, ds2 = 2 s / dr1, dr2 = 3 s

2 s

3 s

on

10

on

20

20

20

on

t [s]

off

3 s

1

t [s]

off

2

t [s]

1: Not switched off because the selected switching delay is too short (< 3 s)�

2: Not switched on because the selected switching delay is too short (< 2 s)�

26

Page 27

If the switching delays of pre-alarm and main alarm are set differently:

- main alarm already switched on, pre-alarm not yet switched on

- pre-alarm already switched off, main alarm not yet switched off

UK

27

Page 28

13.3 Switching delay for the lower limit monitor

The time diagram shows the effect of the switching delay on the analogue input for

a lower limit monitor (ESP1 > ESP2)� The outputs are set as normally closed (OU1

and OU2 → NC).

Analogue In

[°C]

{

Eh1

ESP1

Eh2{

24 V

0 V

ESP2

24 V

0 V

24 V

0 V

24 V

0 V

10

OU 1 (n.c.)

ds1, ds2, dr1, dr2 = 0 s

on

10

OU 2 (n.c.)

off

on

10

OU 1 (n.c.)

ds1, ds2 = 2 s / dr1, dr2 = 3 s

2 s

on

10

OU 2 (n.c.)

ds1, ds2 = 2 s / dr1, dr2 = 3 s

2 s

on

10

off

3 s

3 s

off

off

on

on

2 s

20

20

off

20

20

20

t [s]

off

t [s]

t [s]

off

3 s

t [s]

1

t [s]

1: Not switched on because the selected switching delay is too short�

28

Page 29

14 Factory setting

Factory setting User setting

Global settings

Input filter 10 Hz high pass

Characteristic vibration

value 1

Filter 1000 Hz low pass

Evaluation method RMS

Degree of integration Vibration velocity

Measurement time 0�25 s

History interval 300 s

History values Maximum value + average

value

Characteristic vibration

value 2

Filter 6000 Hz low pass

Evaluation method Peak

Degree of integration Acceleration

Measurement time 0�25 s

UK

History interval 300 s

History values Maximum value + average

value

External input

Usage Analogue signal

Scaling VNA (if used =

VNA)

Input filter (if used = VNA) Not used

External process value 1

Measurement time 0�5 s

Not used

29

Page 30

Factory setting User setting

History interval 300 s

History values Maximum value + average

value

External process value 2 Not used

Measurement time

History interval

History values

External

characteristic vibration

value 1

Filter

Evaluation method

Degree of integration

Measurement time

History interval

History values

External

characteristic vibration

value 2

Not used

Not used

Filter

Evaluation method

Degree of integration

Measurement time

History interval

History values

Outputs

30

Page 31

Factory setting User setting

Switching logic pre-alarm Characteristic vibration value

1 or characteristic vibration

value 2 or external process

value

Switching logic main alarm Characteristic vibration value

1 or characteristic vibration

value 2 or external process

value

UK

The following list indicates the factory settings of the parameters that can be set

via the pushbuttons on the unit:

Factory setting User setting

Characteristic vibration

value 1

SP1 (pre-alarm) 2.8 [mm/s]

SP2 (main alarm) 4.5 [mm/s]

rms

rms

AUER (averaging) 0�125

Characteristic vibration

value 2

SP1 (pre-alarm) 5 [g]

SP2 (main alarm) 7.5 [g]

peak

peak

AUER (averaging) 1

External

Not used

characteristic vibration

value 1

ESP1 (pre-alarm)

ESP2 (main alarm)

AUER (averaging)

External

characteristic vibration

value 2

Not used

31

Page 32

Factory setting User setting

ESP1 (pre-alarm)

ESP2 (main alarm)

AUER (averaging)

External process value 1

ESP1 (pre-alarm) 10

ESP2 (main alarm) 20

Eh1 (hysteresis pre-alarm) 1

Eh2

(Hysteresis main alarm)

External process value 2 Not used

1

ESP1 (pre-alarm)

ESP2 (main alarm)

Eh1 (hysteresis pre-alarm)

Eh2

(Hysteresis main alarm)

External input

EASP (4 mA) 0

EAEP (20 mA) 100

Outputs

ou1 (output 1) NC (normally closed)

ASP1

(4 mA, if ou1 = I)

Not used

AEP1

(20 mA, if ou1 = I)

ou2 (output 2) NC (normally closed)

dS1 switch-on delay prealarm

dr1 switch-off delay prealarm

Not used

0 [s]

0 [s]

32

Page 33

Factory setting User setting

dS2 switch-on delay main

alarm

dr2 switch-off delay main

alarm

Display

uni Metric

0 [s]

0 [s]

UK

33

Loading...

Loading...