Page 1

Operating instructions

Mechatronic flow sensor

SBY357

704561 / 04 09 / 2010

UK

Page 2

2

1 Safety instructions

• Please read the product description prior to set-up of the unit. Ensure that the

product is suitable for your application without any restrictions.

• Improper or non-intended use may lead to malfunctions of the unit or to

unwanted effects in your application. That is why installation, electrical connection, set-up, operation and maintenance of the unit must be carried out by

qualified personnel authorised by the plant operator.

• Check the compatibility of the product materials (see technical data) with the

media to be monitored in all applications.

• The device shall be supplied from an isolating transformer having a secondary

Listed fuse rated either

a) max 5 amps for voltages 0~20 V (0~28.3 Vpeak), or

b) 100/Vp for voltages of 20~30 V (28.3~42.4 Vpeak).

• Flow Operated Switches shall be connected only by using any R/C (CYJV2)

cord, having suitable ratings.

Contents

1 Safety instructions ...............................................................................................2

2 Functions and features ........................................................................................3

3 Installation............................................................................................................3

4 Electrical connection ............................................................................................4

5 Switch point setting ..............................................................................................4

5.1 Definition of requested value .........................................................................5

5.2 Adjustment to existing flow ............................................................................5

6 Operation .............................................................................................................6

7 Maintenance, repair and disposal ........................................................................6

8 Scale drawing ......................................................................................................7

9 Technical data .....................................................................................................8

Page 3

3

UK

2 Functions and features

The unit monitors liquid media (water, glycol solutions, oils).

It detects the volumetric flow quantity to the principle of differential pressure and

switches the output:

• Output closed (LED = ON), if volumetric flow quantity ≥ switch point.

• Output open (LED = OFF), if volumetric flow quantity < switch point.

The switch point is adjustable.

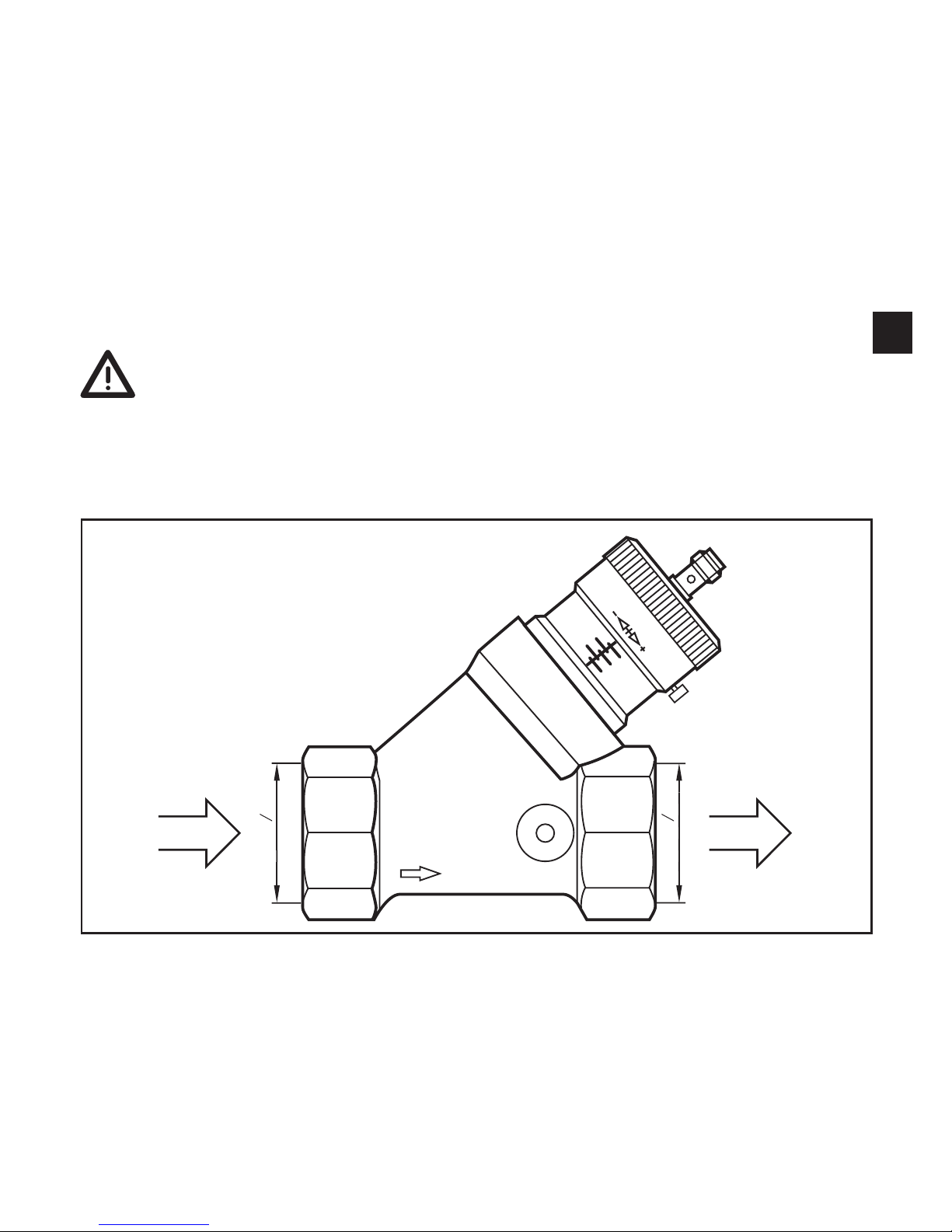

3 Installation

► Ensure that the system is free of pressure during installation.

► Ensure that no media can leak at the mounting location during installa-

tion.

► Install the unit according to the marked flow direction into a pipe RP 1½ and

tighten firmly.

Rp 1

2

1

Rp 1

2

1

IN

OUT

IN = inlet

OUT = outlet

Page 4

4

4 Electrical connection

The unit must be connected by a qualified electrician.

The national and international regulations for the installation of electrical

equipment must be adhered to.

Voltage supply to EN 50178, SELV, PELV.

► Disconnect power.

► Connect the unit as follows:

For information about available sockets/connectors see:

www.ifm.com

→ Products → Accessories

5 Switch point setting

There are 2 possibilities:

• Definition of requested value → 5.1.

• Adjustment to existing flow → 5.2.

A

B

C

D

1 2

A: LED; B: setting screw; C: lock screw; D: setting scale

Do not turn the setting screw beyond the maximum value of the setting

range (→ Technical data) to avoid faulty switching.

Page 5

5

UK

5.1 Definition of requested value

► Loosen the lock screw.

► Turn the setting screw until the requested value just becomes visible on the

setting scale. → Example in figure 2: requested value = 100 l/min.

► Tighten the lock screw.

5.2 Adjustment to existing flow

► Let the normal flow circulate in the installation.

► Loosen the lock screw.

► Set the switch point with the setting screw.

- If the LED lights before setting: turn the setting screw in the direction [+] until

the LED goes out. Then turn in the opposite direction [-] until the LED lights.

- If the LED does not light before setting: turn the setting screw in the direction

[-] until the LED lights.

► Tighten the lock screw.

Correlation between number of the turns of the setting screw (SET) and switch

point in l/min:

One complete turn corresponds to approx. 18 l/min

SET

1 2 3 4 5 6 7 8 10

0

20

40

60

80

100

Q [l/min]

120

11 12 13 14

140

160

180

200

The diagram shows the typical course of the measurement curves for water at 20 °C.

Page 6

6

6 Operation

After power on the unit is ready for operation. It detects the volumetric flow quantity and switches the output according to the setting.

Function diagram

A = requested flow; B = switch point; C = switching output

7 Maintenance, repair and disposal

In case of correct use no maintenance and repair measures are necessary.

In case of strongly polluted media: mount a filter in front of the inlet (IN). Recommendation: use a 50-micron filter.

Only the manufacturer is allowed to repair the unit.

After use dispose of the unit in an environmentally friendly way in accordance with

the applicable national regulations.

Page 7

7

UK

8 Scale drawing

56

137...146,5

121,5

121...127,5

Rp 1

2

1

Rp 1

2

1

20 20

dimensions are in millimeters

Page 8

8

9 Technical data

Setting range [l/min]..................................................................................................20...200

Flow range max. [l/min] ...................................................................................................200

Operating voltage [V] ....................................................................... 24 DC (-15 % / +10 %)

Current rating [mA] ......................................................................................................... 100

Protected against short circuits, reverse polarity and overload

Voltage drop [V] .............................................................................................................< 2.5

Current consumption [mA] ..............................................................................................< 15

Hysteresis [l/min] ..........................................................................................................5...10

Repeatability [% of value of measuring range] ....................................................................1

Accuracy [% of value of measuring range] .......................................................................± 5

Response time [s] ........................................................................................................< 0.01

Pressure loss (dP) / flow rate (Q)

dP [bar]

Q [l/min]

5

15

25

35

45

55

65

75

85

95

105

115

125

135

145

155

165

175

185

195

2050

0,1

0,2

0,3

0,4

0,5

0,6

0,7

0,8

0

Housing materials ......................brass chemically nickel-plated; aluminium anodised; POM

Materials (wetted parts) .............. stainless steel (304S15); brass; chemically nickel-plated;

POM; PPS; O-ring: FPM (Viton)

Protection ............................................................................................................... IP 67 III

Switching cycles min. ........................................................................................... 10 million

Medium temperature [°C] ........................................................................................... 0...85

Operating temperature [°C] ........................................................................................ 0...60

Pressure resistance [bar].................................................................................................. 25

Further information at www.ifm.com

Loading...

Loading...