Page 1

Device manual

Profibus encoder

RM30xx

RN30xx

UK

706355/00 06/2013

Page 2

Encoder with Profibus interface

Contents

1 Preliminary note � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

1�1 Symbols used� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

1�2 Warning signs used � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

1�3 Notes on this document � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

2 Safety instructions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

3 General information � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

3�1 1�2 Profibus technology � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

4 Functions and features � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

5 Electrical connection� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

5�1 Connection of the signal and supply cables � � � � � � � � � � � � � � � � � � � � � � � � 6

6 Installation� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

7 Installation� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

7�1 Settings in the terminal cap � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

7�1�1 Participant address � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

7�1�2 Bus termination � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

8 Device configuration � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

9 Encoder classes � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

9�1 Class 1 and Class 2 � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

9�2 Parameter setting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

9�2�1 Class 2 functionality � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

9�2�2 Commissioning diagnostics � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

9�2�3 Scaling function � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

9�2�4 Measuring steps per revolution � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

9�2�5 Total resolution � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

9�3 Data exchange during normal operation � � � � � � � � � � � � � � � � � � � � � � � � � �11

9�3�1 Transfer of the process actual value � � � � � � � � � � � � � � � � � � � � � � � � �11

9�3�2 Preset function � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

10 Profibus encoder profile Class 2� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

10�1 Parameters� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

10�1�1 Activation of the manufacturer-specific parameters � � � � � � � � � � � � 14

10�1�2 Requested measuring steps � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

10�1�3 Required resolution � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

10�1�4 Activate set-up mode � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

10�1�5 Reduced diagnosis � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

10�1�6 Software limit switch� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

10�1�7 Physical measuring steps � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

10�1�8 Encoder type � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

10�1�9 Unit of measurement velocity� � � � � � � � � � � � � � � � � � � � � � � � � � � � � 19

10�2 Data exchange during normal operation � � � � � � � � � � � � � � � � � � � � � � � � 19

10�3 Set-up mode� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 20

2

Page 3

Encoder with Profibus interface

10�3�1 Set the direction of rotation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 21

10�4 Start teach operation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 21

10�4�1 Stop teach operation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 21

10�4�2 Preset value � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

11 Diagnostic messages � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 24

11�1 Overview� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 24

11�2 Supported diagnostic messages � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

11�2�1 Extended diagnostic header� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

11�2�2 Memory error � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

11�2�3 Operating status� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

11�2�4 Encoder type � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

11�2�5 Singleturn resolution� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

11�2�6 Number of revolutions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 26

11�2�7 Operating time alarm � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 26

11�2�8 Profile version� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 26

11�2�9 Software version� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 26

11�2�10 Operating time � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 26

11�2�11 Zero point shift � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 26

11�2�12 Configured resolution � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 26

11�2�13 Configured total resolution � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 26

11�2�14 Serial number� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 27

UK

12 LED indicators � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 27

12�1 Legend � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 27

13 Configuring with STEP7 � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 28

13�1 Installation and import of the GSD file � � � � � � � � � � � � � � � � � � � � � � � � � � 28

13�2 Adding an encoder to a STEP7 project � � � � � � � � � � � � � � � � � � � � � � � � � 30

13�3 Parameter setting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 31

3

Page 4

Encoder with Profibus interface

1 Preliminary note

1.1 Symbols used

► Instruction

> Reaction, result

[…] Designation of keys, buttons or indications

→ Cross-reference

Important note

Non-compliance can result in malfunction or interference�

Information

Supplementary note

1.2 Warning signs used

NOTE

Warning of damage to property�

1.3 Notes on this document

This document applies to encoders of the following type:

RM30xx and RN30xx with Profibus interface

It is part of the device and contains information about the correct handling of the

product�

This document is intended for qualified electricians� These specialists are people

who are qualified by their training and their experience to recognise and to avoid

possible hazards that may be caused during operation of the device�

► Read this document before using the device�

► Keep this document during the service life of the device�

► Observe these operating instructions�

► Adhere to the warning notes�

2 Safety instructions

Non-observance of the instructions, operation which is not in accordance with use

as prescribed below, wrong installation or incorrect handling can affect the safety

of operators and machinery�

The installation and connection must comply with the applicable national and

international standards� Responsibility lies with the person installing the unit� Only

the signals indicated in the technical data or on the device label may be supplied

to the connections or wires�

4

Page 5

Encoder with Profibus interface

3 General information

3.1 1.2 Profibus technology

Profibus is a manufacturer-independent, open fieldbus standard determined by

the international standards EN 50170 and EN 50254�

There are 3 versions: DP, FMS and PA�

ifm encoders support the DP version and are designed for common baud rates

up to 12 Mbaud�

Besides manufacturer-specific functions the devices support the classes 1 and

2 to the encoder profile� This device profile can be ordered from the Profibus

user organisation indicating the order number 3�062�

Here you can also get further information about PROFIBUS (functionality,

manufacturers, products) as well as standards and profiles

com�

→

www�profibus�

UK

4 Functions and features

The encoder converts rotary movements into digital numerical values� Each

revolution and each angular position of the revolutions is provided as a numerical

value� These values allow angular movements to be measured and positions and

number of revolutions to be determined�

Products from ifm electronic gmbh are usually individual components of larger installations� These

applications require tests of the entire installation and do not only depend on the specification of

these components� The notes in this manual apply only to the product from ifm electronic and not to

the entire installation� If the product is used in a non-intended way, this will be at your own risk�

5

Page 6

Encoder with Profibus interface

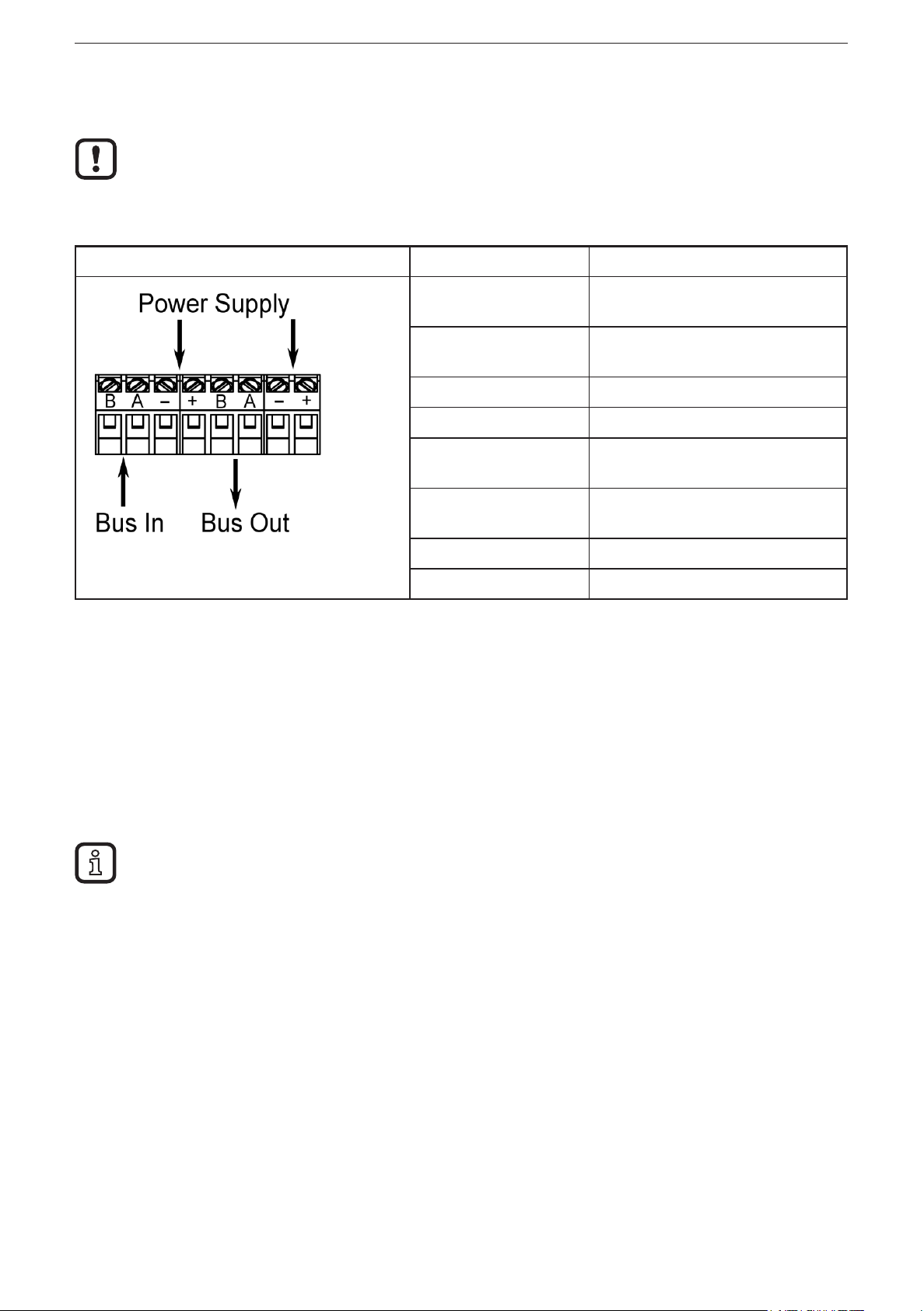

5 Electrical connection

► Disconnect power�

► Connect the device according to the indications on the type label�

5.1 Connection of the signal and supply cables

Terminal Description

B (left) Signal cable B

A (left) Signal cable A

- 0 V

+ 10���30 V

B (right) Signal cable B

Incoming bus cable

Incoming bus cable

Outgoing bus cable

A (right) Signal cable A

Outgoing bus cable

- 0 V

+ 10���30 V

6 Installation

► Disconnect power�

► Ensure that the machine stands still�

► The drive must not be started during installation�

► Do not hit the shaft; do not use a file or similar tool on the shaft� Risk of

destruction!

This product is a precision measuring device� Therefore it has to be handled with care by trained

staff� The following warnings apply to influences outside the limit values indicated in the product data

sheet�

Damage to the product can be caused by:

● electrostatic discharge while touching the electronics

● too high forces on the shaft

● humidity and chemical liquids (do not connect any cables oriented upwards)

● extreme temperatures

● too high vibrations and shocks

● short circuit or too high an operating voltage

● impact, shock or any other physical forces

6

Page 7

Encoder with Profibus interface

7 Installation

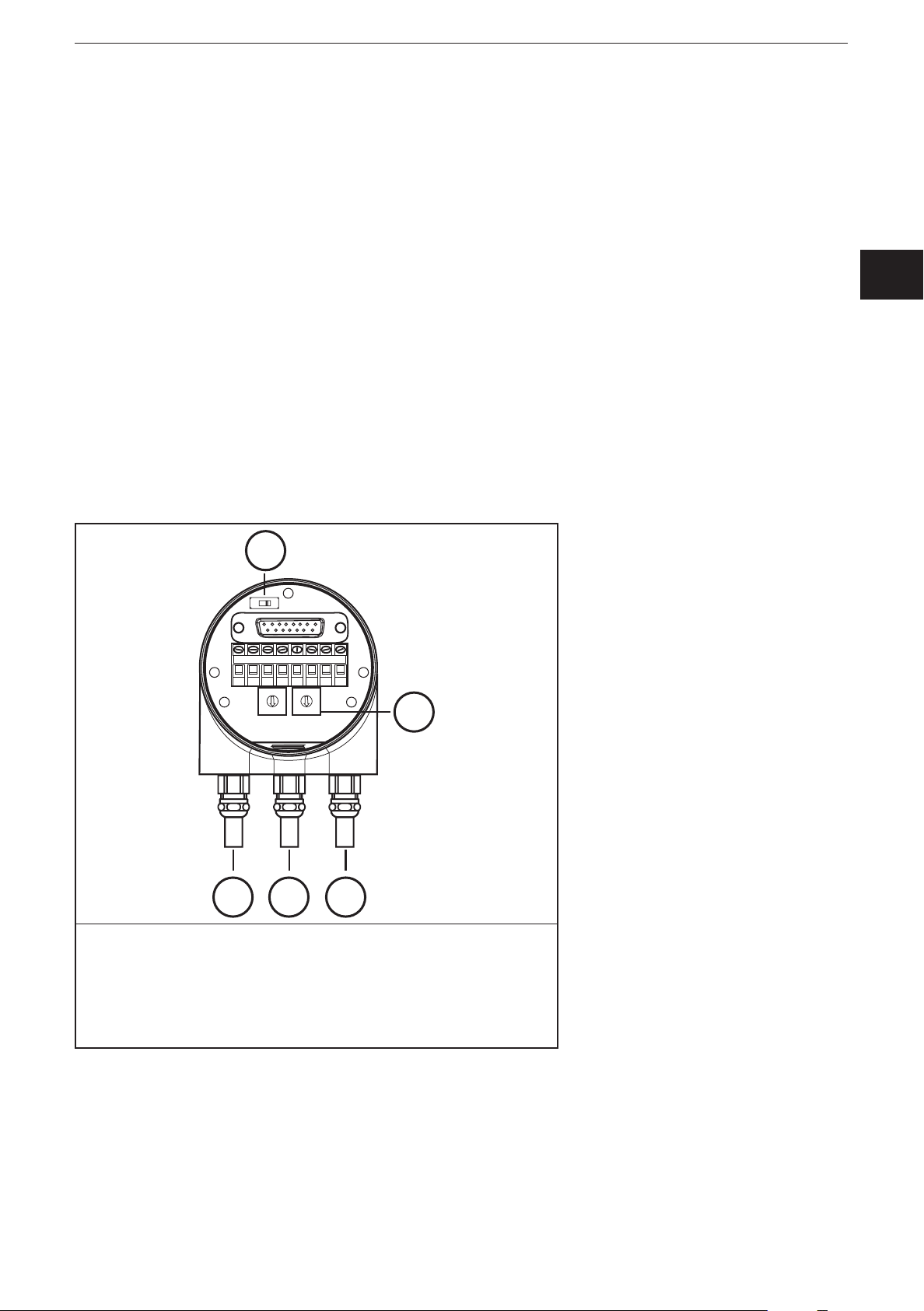

The encoder is connected via the terminal cap� It is connected to the encoder via

a 15-pole D-Sub-connector and can be removed by loosening the 2 screws on the

back of the device� Bus and supply cables are inserted in the cab via cable glands

and connected via screw terminals�

7.1 Settings in the terminal cap

7.1.1 Participant address

The Profibus participant address is set via decimal rotary switches in the terminal

cap� The positional value (x 10 or x 1) is indicated on the switch� Possible

addresses are between 1 and 99; each address must only occur in the system

once�

The device address is read when the voltage supply of the encoder is applied; a

change of address by the master [Set_Slave_Add] is not supported�

UK

Connection and setting of addressing

5

+-

BA

5

6

4

7

3

8

2

9

1

0

1

2

1: Supply +UB / - GND

2: Bus IN

3: Bus OUT

4: Addressing

5: Setting terminating resistor

BA

5

6

4

3

2

1

0

+-

7

8

9

4

3

7.1.2 Bus termination

If the encoder is installed as an end device, the terminal resistor integrated in the

device must be activated� This is done via the slide switch in the terminal cap (5)�

7

Page 8

Encoder with Profibus interface

When the terminal resistor is activated, the next bus (Bus Out) is decoupled�

The bus is only correctly connected if the encoder is installed on the terminal cap� If the encoder has

to be replaced during operation, the use of a separate active bus termination is recommended�

After the address has been set in the hardware and, if applicable, the terminating resistor has been

activated, the encoder can be put into operation�

8 Device configuration

Encoders with Profibus interface can be configured and parameterised according

to the requirements of the user�

In this respect the GSD file of the device is loaded into the projection tool� Various

encoder classes can be selected for the projection� Parameters and functionalities

of the device that can be set depend on the selected encoder class� ifm encoders

of the RM30xx and RN30xx series support all encoder classes described below�

Therefore the functionality is not restricted from the hardware side and is only

determined by the user� ifm encoders do not only provide the encoder classes

"Class 1" and "Class 2" described in the encoder profile but also encoder classes

with manufacturer-specific functions�

When configuring the device, configuration and parameter data are defined by

selecting the encoder class� This data saved in the Profibus master is transferred

once to the encoder when the system starts up (configuration and parameterising

phase – "DDLM_Set_Prm")� It is not possible to change configuration or

parameters during operation�

After the configuration and parameter data has been received, the encoder goes

into normal operation (cyclic data exchange – "DDLM_Data_Exchange mode")

in which, for example, the position value is transferred� The length and format of

the data exchanged are also defined when configuring the device by selecting the

appropriate encoder class�

9 Encoder classes

9.1 Class 1 and Class 2

The encoder classes Class 1 and Class 2 are the versions according to the

encoder profile defined by the encoder working group in the Profibus user

organisation (available from PNO indicating order no� 3�062)�

8

Page 9

Encoder with Profibus interface

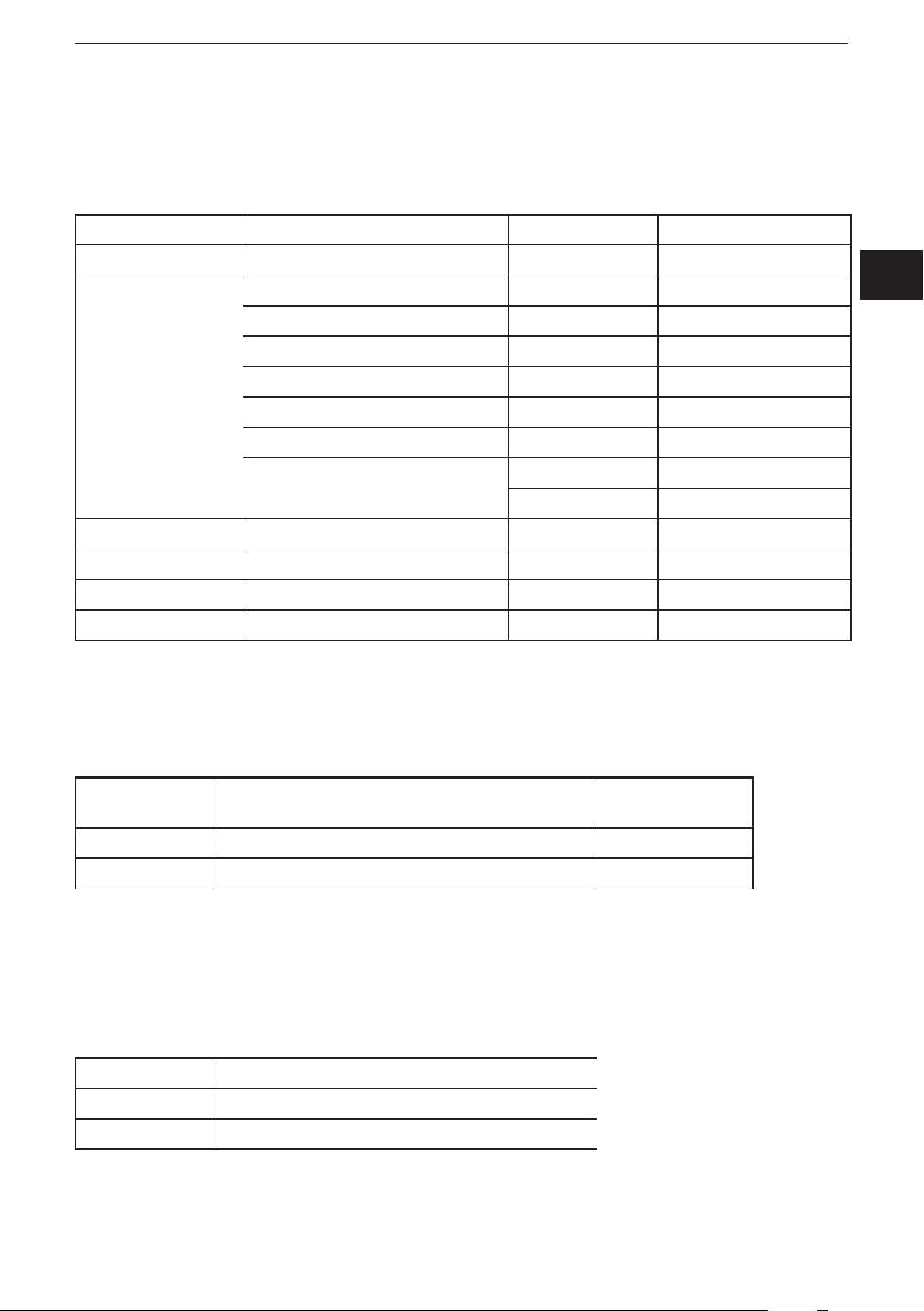

9.2 Parameter setting

The following table gives an overview of the parameters that can be set according

to the encoder profile and of the arrangement in the parameter setting telegram�

Parameters are set using input masks in the projection tool�

Octet (= byte) no. Parameters Bit no. Details

1���8 Profibus standard parameters

9 Direction of rotation 0 → Chapter 9.2.1

Class 2 functionality 1 → Chapter 9.2.2

Commissioning diagnostics 2 → Chapter 9.2.3

Scaling function 3 → Chapter 9.2.4

Reserved 4

Reserved 5

Not used for Class 1 and Class 2 6

UK

7

10���13 Measuring steps / revolution → Chapter 9.2.5

14���17 Total resolution → Chapter 9.2.6

18���25 Reserved (to encoder profile)

26��� Not used for Class 1 and Class 2

Rotational direction

The direction of rotation defines the counting direction of the process actual value

output when the shaft rotates clockwise (CW) or counter-clockwise (CCW)� The

counting direction is defined by bit 0 in octet 9�

Octet 9 bit 0 Direction of rotation when viewing the shaft Direction of

rotation

0 Clockwise (CW) Rising

1 Counter-clockwise (CCW) Rising

9.2.1 Class 2 functionality

Class 2 encoders can be limited to the functionality of Class 1; the possibility of

parameter setting is disabled� To use the function of Class 2 encoders, bit 1 is set

in octet 9�

Octet 9 bit 1 Class 2 functionality

0 Disabled

1 Enabled

9.2.2 Commissioning diagnostics

This function is of no meaning for the ifm encoder�

9

Page 10

Encoder with Profibus interface

9.2.3 Scaling function

The scaling function enables parameter setting of the resolution per revolution and

the selected total resolution� It should always be enabled if you want to use the

functions of Class 2 (or the manufacturer-specific classes)�

Octet 9 bit 3 Scaling function

0 Disabled

1 Enabled

9.2.4 Measuring steps per revolution

This parameter is used to assign a requested number of steps referred to one

revolution to the encoder�

If the value of the parameter exceeds the actual physical basic resolution of the

encoder, the output value no longer proceeds by one step�

For encoders as of the B1 generation a parameter fault is displayed in this case;

the device does not change to the cyclic data transfer�

For high-resolution encoders it may be required to split the value into high word

and low word, depending on the projection tool�

Octet 10 11 12 13

Bit 31���24 23���16 15���8 7���0

Data 2

31

to 224 223 to 2

Requested number of measuring steps per revolution

16

215 to 2

8

27 to 2

0

9.2.5 Total resolution

Octet 14 15 16 17

Bit 31���24 23���16 15���8 7���0

Data 2

31

to 224 223 to 2

Selected total resolution in measuring steps

16

215 to 2

8

27 to 2

0

This parameter enables the user to adapt the measuring range of the device� The

encoder counts up to the configured total resolution and then it starts again at 0�

Example

Selected: 100 steps per revolution, total resolution 12800, then the encoder starts

again at zero after 128 revolutions and counts again up to 12799�

With many projection tools it may be required to split the value into high word and

low word�

10

Page 11

Encoder with Profibus interface

When the [Total measuring range] parameter is entered, use the following formula:

total resolution < measuring steps per revolution x number of revolutions

(physical)

If this is not observed, the device indicates a parameter fault and does not go into the cyclic data

exchange�

The internal software routine is only effective during operation�

9.3 Data exchange during normal operation

The DDLM_Data_Exchange mode is the normal status during system operation�

On request, the encoder sends current position values to the master� Conversely,

the encoder can also receive cyclic data (e�g� the preset value with Class 2

encoders)�

UK

9.3.1 Transfer of the process actual value

The current position value of the multiturn encoder is transferred as a 32-bit value

(double word) to the master�

Word Word 1 Word 0

Function Process actual value

Bit 31���30 29���16 15���0

0 X X

11

Page 12

Encoder with Profibus interface

9.3.2 Preset function

The preset function enables adaptation of the encoder zero point to the

mechanical zero point of the system�

► Set the encoder actual value to the requested preset value�

> The requested zero point drift is calculated by the device and stored in an

EEPROM (non-volatile) which takes less than 40 ms�

The preset value is activated in the peripheral output double word by setting bit

31 (adopted with rising edge)� Setting is made automatically after transfer of the

scaling parameters, i�e� the preset value refers to the scaled actual value�

Data bits

Bit 4 31 30 29...0

Master → encoder 1 0 Transfer of the requested value

(= preset value)

Encoder → master 0 0 New = requested process actual value is transferred

Master → encoder 0 0 Reset bit 31 - normal mode

Encoder → master 0 0 New = requested process actual value is transferred

Only set the preset while the encoder shaft is at standstill� If the shaft moves

during this time, shifts are possible since runtimes occur via the bus when the

preset value is set�

Note on the singleturn version

The process can be transferred to the singleturn version – here bit 15 is used to

activate the preset value� With high-resolution singleturn encoders (16 bits) no

preset values > 32767 (15 bits) can be set in Class 2 (MSB is used to activate the

preset value)� If this function is requested, one of the manufacturer-specific ifm

classes has to be selected (transfer here also in 32-bit format for the singleturn)�

12

Page 13

Encoder with Profibus interface

10 Profibus encoder profile Class 2

Parameter setting telegram

Octet (= byte) no. Parameters Bit no. Details

1���8 Profibus standard parameter

9 Direction of rotation 0 → Chapter 9.2.1

Class 2 functionality 1 → Chapter 9.2.2

Commissioning diagnostics 2 → Chapter 9.2.3

Scaling function 3 → Chapter 9.2.4

Reserved 4

Reserved 5

UK

Activate manufacturer-specific

parameters (octet 26)

Reserved 7

10���13 Measuring steps / revolution

(Reference: octet 26 bits 0 and 1)

14���17 Total resolution → Chapter 9.2.6

18���25 Reserved

26 Reference to the requested

measuring steps

Activate set-up mode 2 → Chapter 10.1.4

Reduced diagnosis 3 → Chapter 10.1.5

Reserved 4

Activate lower software limit switch 5 → Chapter 10.1.6

Activate upper software limit switch 6 → Chapter 10.1.6

Activate parameters as from octet

27

27���30 Lower limit switch → Chapter 10.1.6

6 → Chapter 10.1.1

→ Chapter 10.1.2

0

1

7 → Chapter 10.1.1

→ Chapter 10.1.3

31���34 Upper limit switch → Chapter 10.1.6

35���38 Physical measuring steps → Chapter 10.1.7

39 Reserved 0

Encoder (singleturn or multiturn) 1 → Chapter 10.1.8

Reserved 2

Reserved 3

Selection of the measuring unit to

provide the value of velocity

Reserved 6

Reserved 7

4

5

→ Chapter 10.1.9

13

Page 14

Encoder with Profibus interface

10.1 Parameters

The manufacturer-specific parameters are described below� The parameters to the

encoder profile (also supported) are described in chapter 9�

10.1.1 Activation of the manufacturer-specic parameters

The manufacturer-specific parameter byte 26 is activated via bit 6 in octet 9�

The manufacturer-specific bytes 27���39 are activated in byte 26�

Octet 9 bit 6 Octet 26

0 Deactivated

1 Activated

Octet 26 bit 7 Octet 27...29

0 Deactivated

1 Activated

10.1.2 Requested measuring steps

The device can be programmed with the [Desired measuring units] parameter so

that any number of measuring steps referred to

– one revolution

– the entire measuring range

– any part of the measuring range

can be implemented�

Octet 10 11 12 13

Bit 31���24 23���16 15���8 7���0

Data 2

31

to 224 223 to 2

Required number of measuring steps

16

215 to 2

8

27 to 2

0

14

Page 15

10.1.3 Required resolution

Parameter selection of

– resolution per revolution

– or max� total resolution

– code sequence

Encoder with Profibus interface

– Class 2 functionality

– scaling function

UK

Selection required resolution

Resolution per revolution

The position value is scaled so that it increases by the number of the required

measuring steps during one revolution�

In addition the [Total mesuring range] parameter is evaluated via which the

measuring range can be adapted (→ chapter 9.2.5)

Resolution per max� total resolution

The requested measuring steps entered refer to the total measuring range�

The device provides the configured number of measuring steps via the total

(physical) number of revolutions�

15

Page 16

Encoder with Profibus interface

Resolution per physical measuring steps

The requested number of steps refers to the data entered via the [Physical

impulses] parameter (→ chapter 10.1.7).

This is the numerical value that is read from the coded disc inside the encoder

(e�g� 4096 steps per revolution for the standard 12-bit version)�

This option allows free setting of gearbox factors�

Reference Octet 26 bit 0 Octet 26 bit 1

Per revolution 0 0

Per max� total resolution 1 0

Per physical measuring steps

(= steps indicated in octets 35-38)

0 1

10.1.4 Activate set-up mode

Bit 2 in octet 26 is a switch for the set-up mode�

In this mode other parameters besides the preset value can be transferred to the

encoder�

With activated mode a teach operation can be carried out; the gearbox factor can

be directly determined in the system�

In this mode (green LED flashing) the direction of rotation and scaling set during

projection are ignored and the values saved in the internal EEPROM are used�

The device can be operated permanently in the set-up mode�

Recommendation:

Transfer the parameters determined in the set-up mode and then use the device in

normal mode (which enables a replacement of the device without having to repeat

the teach operation)�

Octet 26 bit 2 Set-up mode

0 Off

1 On

16

Page 17

Encoder with Profibus interface

10.1.5 Reduced diagnosis

With older Profibus masters the full number of diagnostic bytes (standard

diagnosis: 57 bytes) may lead to problems� �

With the RM30xx and RN30xx devices it is possible to reduce the number of the

diagnostic bytes provided by the encoder to 16� If the device class "Class 1" is

selected, only 16 diagnostic bytes are provided in general�

Octet 26 bit 3 Diagnostic data length

0 Standard = 57 bytes

1 Reduced = 16 bytes

10.1.6 Software limit switch

UK

2 positions can be programmed� If they are exceeded or not reached, the encoder

sets bit 27 in the 31-bit process actual value to "1"�

Between the two positions the bit is set to "0"� Both limit switch values can be set

to any value via parameter setting but they must not exceed the value of the [Total

measuring range] parameter� The limit switches are activated via bit 5 or 6 in octet

26�

With many projection tools it may be required to split the values into high word and low word�

Octet 27 28 29 30 31 32 33 34

Bit 31���24 23���16 15���8 7���0 31���24 23���16 15���8 7���0

31

Data 2

���2

24

Octet 26 bit 5 Lower limit switch

0 Off

223���2

16

215���2

8

27���2

0

231���2

24

223���2

16

215���2

Lower limit switch in measuring steps (referred to scaled value)

8

27���2

0

1 On

Octet 26 bit 6 Upper limit switch

0 Off

1 On

17

Page 18

Encoder with Profibus interface

10.1.7 Physical measuring steps

Octet 35 36 37 38

Bit 31���24 23���16 15���8 7���0

31

Data 2

24

���2

Physical measuring steps

223���2

16

215���2

8

27���2

0

This parameter is evaluated by the device if the option [Physical impulses] was

selected as reference to the requested measuring steps� By means of the physical

measuring steps a gearbox factor can be freely set� Here it is defined how many

measuring steps (requested measuring steps) are to be provided on a defined

sub-measuring range� This option is useful if "odd" scaling factors are to be

entered�

Example

The encoder is to provide 400 steps over 3 revolutions�

With the reference [Desired measuring units per revolution] this number of steps

cannot be set (the [Desired measuring units] parameter should contain the value

133�333; however only integers can be entered)�

Remedy

The physical measuring steps are selected as reference for the requested

measuring steps�

The number of the physical measuring steps over the requested measuring range

is determined on the basis of the actual (physical) resolution of the device (type

label)� For this absolute encoder with 12-bit standard resolution this would in this

case be

4096 steps/revolution x 3 revolutions = 12288 steps

This value is now entered as [Physical impulses] parameter; the actually required

number of steps of 400 is entered at [Desired measuring units]� The encoder

now provides 400 steps over a measuring range of 12288 physical steps (i�e� 3

revolutions)�

Note: With many projection tools it may be required to split the value into high

word and low word�

10.1.8 Encoder type

The type of encoder (singleturn or multiturn) is defined in bit 1 of octet 39� This

is done automatically when the encoder class is selected� The user only has to

consider this parameter if parameters are set directly in the hexadecimal code�

Octet 39 bit 1 Type

0 Singleturn

1 Multiturn

18

Page 19

Encoder with Profibus interface

10.1.9 Unit of measurement velocity

The unit for the velocity value to be provided (class ifm 2�2) can be set via this

parameter�

Unit Bit 4 Bit 5

Steps / second 0 0

Steps / 100ms 1 0

Steps/10ms 0 1

Revolutions / minute 1 1

10.2 Data exchange during normal operation

The process actual value is in general transferred as a 32-bit word (double word)

with the manufacturer-specific encoder classes ifm 2�1 and ifm 2�2� In addition to

the 25 bits that are provided for the position value 7 other bits are used as status

bits� In the (peripheral) output double word the master sends the preset value and

in addition the control bits to the encoder�

For encoders of this type more than 25-bit absolute position data may be available�

The position values < 25 bits are not supported in the ifm classes; the more

significant bits are overwritten by status bits�

If the ifm classes are to be used with encoders whose physical resolution exceeds

25 bits, the user must ensure that the physical position value is scaled to a (max�)

output value < 33554432 (via parameter setting)� If absolute values > 25 bits are

required, Class 2 has to be selected�

UK

An additional (peripheral) input word of the current velocity value is transferred

with device class ifm 2�2�

Identification

Encoder →

master

Master →

encoder

F1 hex D0 hex

Status + position actual value Velocity

Status + 2

Preset value + control bits

Control + 2

24

24223

223 - 2

- 2

16

16

215 - 2

215 - 2

8

8

27 - 2

27 - 2

0

0

215 - 2

8

27 - 2

0

19

Page 20

Encoder with Profibus interface

The status bits in the input double word have the following meaning

Bit Meaning

28 Rotational direction 0 = increasing clockwise

(seen on the shaft)

27 Software

Limit switch

26 Operating mode 0 = set-up mode 1 = normal mode

25 Readiness for operation 0 = encoder not ready for

0 = lower limit switch ≤ actual

value ≤ upper limit switch

operation

1 = increasing counter-clockwise

(seen on the shaft)

1 = actual value > upper limit

switch or actual value < lower

limit switch

1 = encoder ready for operation

10.3 Set-up mode

If the encoder is switched to the set-up mode via parameter setting, the gearbox

factors can be determined directly in the system via a teach operation�

The set-up mode is signalled by the encoder via a flashing green LED in the

terminal cap and via bit 26 in the input double word (set to 0)�

In the set-up mode the parameters set during projection (direction of rotation,

scaling) are ignored and the values saved in the internal EEPROM are used� If the

direction of rotation and gearbox factor are changed during the set-up mode, the

new values are stored in the EEPROM�

Process during the set-up mode

► Install the device in the system�

► Enable the set-up mode via parameter setting�

► Adapt the direction of rotation (if required)�

► Move the system to the starting position�

► Transmit the start command for the teach operation to the encoder�

► Move the system to the end position�

► Transfer the requested number of steps to the encoder with the "stop teach

operation" command�

► Set the preset value�

► Transfer the values determined during the teach operation to the projection

(parameters)�

► Disable the set-up mode during parameter setting�

20

Page 21

Encoder with Profibus interface

10.3.1 Set the direction of rotation

The direction of rotation cannot be changed online in the set-up mode� The current

direction of rotation is displayed via bit 28 in the input double value (0: increasing/

1: decreasing clockwise)� The direction of rotation can be changed via bit 28 in the

output double word�

Status bits Data bits

Bit 31 30 29 28 27 26 25 24���1 0

UK

Master

→ encoder

Encoder

→ master

Master

→ encoder

Encoder

→ master

0 0 0 1 0 0 0 Select the direction of rotation

via bit 28

0 0 0 0/1 0 0 1 The encoder acknowledges the new

direction of rotation in bit 0 and bit 28

0 0 0 0 0 0 0 The selection is terminated by resetting

bit 28

0 0 0 0/1 X 0 1 Output of the process actual value

with changed direction of rotation

The set direction of rotation is saved in the EEPROM non-volatilely�

10.4 Start teach operation

► Move the system to the starting position�

► Transmit the start command for the teach operation to the encoder�

> The device starts the measurement to determine the gearbox factor internally�

0/1

Status bits Data bits

Bit 31 30 29 28 27 26 25 24���0

Master

→ encoder

Encoder

→ master

Master

→ encoder

Encoder

→ master

0 1 0 0 0 0 0 Start of the teach operation by setting bit 30

0 1 0 X X 0 1 Encoder acknowledges the start of the teach

operation by setting bit 30

0 0 0 0 0 0 0 Reset bit 30

0 1 0 X X 0 1 Output of the non-processed actual value

(gearbox factor = 1, preset not active)

10.4.1 Stop teach operation

► Transfer the requested number of steps to the encoder with the "stop teach

operation" command�

► Do not exceed the physical resolution (e�g� 20000 steps on a quarter of a

revolution)�

21

Page 22

Encoder with Profibus interface

Positive and negative direction of rotation and if the zero point is possible

exceeded is considered automatically� The measuring distance covered must not

be longer than half the measuring range of the encoder (i�e� max� 2047 revolutions

for the multiturn encoder with 4096 revolutions, max� 8191 revolutions for the 14bit multiturn)�

As response to the "stop teach operation" command the encoder transmits the

total resolution calculated by the device�

► Write down the value and accept it later for the normal operation of the system

in projection / parameter setting�

After this process the device works with the new scaling factor which is stored in

the EEPROM non-volatilely�

Status bits Data bits

Bit 31 30 29 28 27 26 25 24���0

Master

→ encoder

Encoder

→ master

Master

→ encoder

Encoder

→ master

0 0 1 0 0 0 0 Number of the requested steps over the

measuring range covered

0 1 1 X X 0 1 Transfer of the total resolution for the new

gearbox factor

0 0 0 0 0 0 0 Reset bit 29

0 1 0 X X 0 1 Output actual value (included in the new

gearbox factor)

Encoder replacement without a new teach operation

► Transfer the total resolution determined by the encoder to the projection�

Enter the total resolution determined during the teach operation into the parameter

field [Desired measuring units] (→ 10.1.2) and then set the switch to [Max. total

measuring range] → 10.1.3).

During the new configuration make sure that the direction of rotation is entered

correctly - the setting in the set-up mode must also be observed during parameter

setting� Then the set-up mode can be disabled via parameter setting; the encoder

is now used in "normal operation"�

22

Page 23

Encoder with Profibus interface

10.4.2 Preset value

The preset value is set according to the procedure described in chapter 9�3�2� Only

difference: Setting of the preset value with the manufacturer-specific classes ifm

2�1 and ifm 2�2 is confirmed via a status bit�

Status bits Data bits

Bit 31 30 29 28 27 26 25 24���0

Master

→ encoder

1 0 0 0 0 0 0 Tranfer of the requested value

(= preset value)

UK

Encoder

→ master

Master

→ encoder

Encoder

→ master

1 0 0 0 0 0 1 New = requested process actual value is

transferred

0 0 0 0 0 0 0 Reset bit 31 - normal mode

0 0 0 0 0 0 1 New = requested process actual value is

transferred

23

Page 24

Encoder with Profibus interface

11 Diagnostic messages

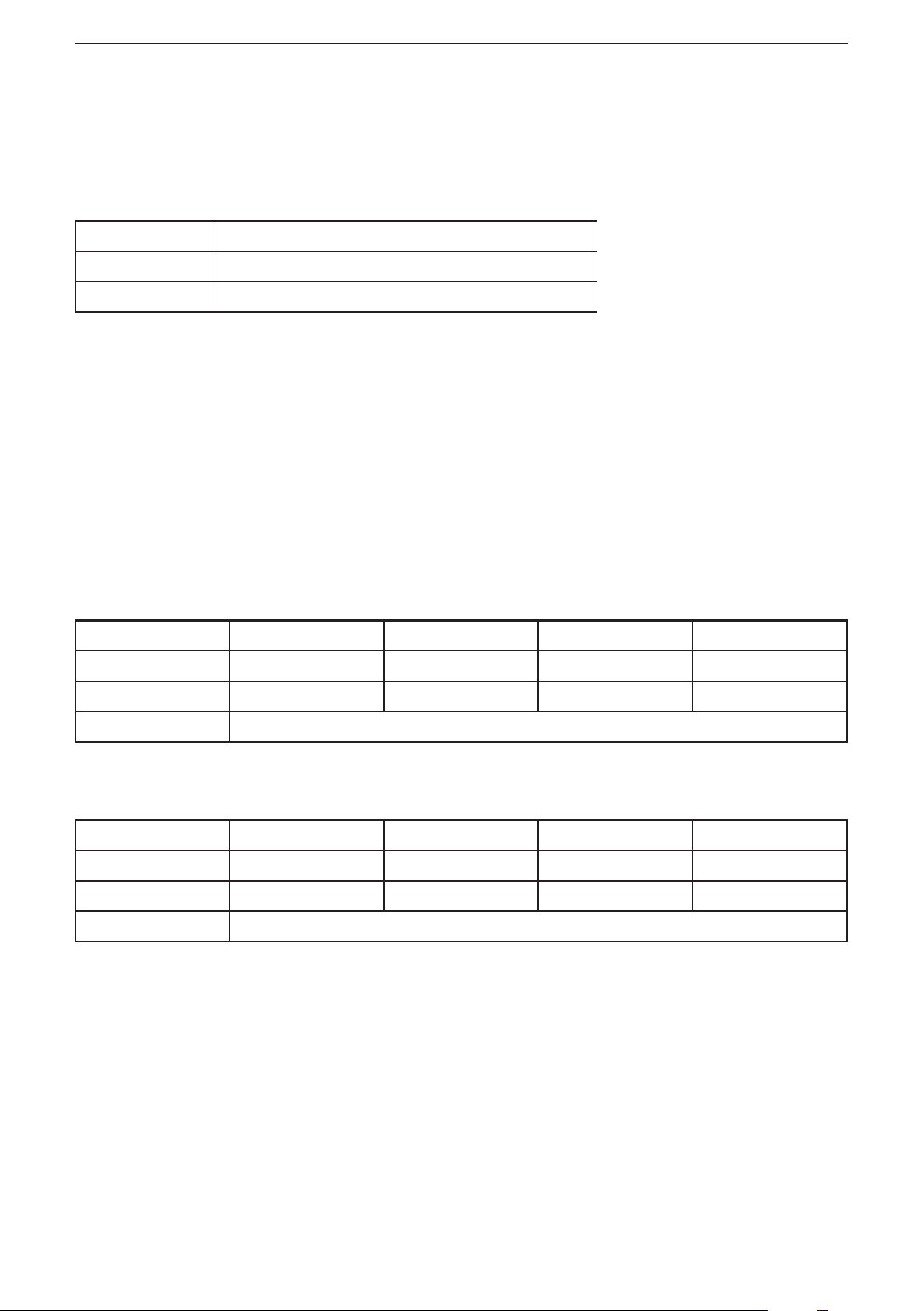

11.1 Overview

In the DDLM_Slave_Diag operating mode, diagnostic data is transferred from

the encoder to the master on request� The number of the diagnostic bytes is 57�

Exception: Reduced diagnosis� The diagnostic data is output according to the

definitions of the Profibus standard (octets 1-6) or according to the encoder profile

(starting with octet 7)�

Diagnostic function Data type Diagnosis

Octet number

Station status 1 (see: Profibus standard) Octet 1 1

Station status 2 (see: Profibus standard) Octet 2 1

Station status 3 (see: Profibus standard) Octet 3 1

Diagnostic master address Octet 4 1

PNO ID number Octet 5�6 1

Extended diagnostic header Octet string 7 1

Alarms Octet string 8 1

Operating status Octet string 9 1

Encoder type Octet string 10 1

Resolution per revolution (hardware) Unsigned 32 11���14 1

Number of revolutions (hardware) Unsigned 16 15�16 1

Other alarm messages Octet string 17 2

Supported alarms Octet string 18�19 2

Warnings Octet string 20�21 2

Encoder

class

Supported warnings Octet string 22, 23 2

Profile version Octet string 24, 25 2

Software version Octet string 26, 27 2

Operating time Unsigned 32 28���31 2

Zero point shift Unsigned 32 32���35 2

Manufacturer specific: Offset value Unsigned 32 36���39 2

Configured resolution per revolution Unsigned 32 40���43 2

Configured total resolution Unsigned 32 44���47 2

Serial number ASCII string 48���57 2

24

Page 25

Encoder with Profibus interface

11.2 Supported diagnostic messages

The individual diagnostic inputs are described in detail below�

11.2.1 Extended diagnostic header

Diagnostic byte 7 contains the length of the extended diagnosis (including the

diagnostic header)�

11.2.2 Memory error

UK

Via bit 4 in diagnostic by 8 it is indicated if a memory error has occurred�

In this case memory error means that the EEPROM of the encoder does no longer

function reliably and non-volatile storage (e�g� of the zero point shift) is no longer

ensured�

Bit Definition 0 1

4 Memory error

(Fault in

EEPROM)

No Ye s

11.2.3 Operating status

The operating parameters set via parameter setting can be enquired via diagnostic

byte 9�

Bit Definition 0 1

0 Rotational direction CW CCW

1 Class 2 functionality Off On

2 Diagnosis routine Off On

3 Scaling function Off On

11.2.4 Encoder type

The design of the encoder can be enquired via diagnostic byte 10�

Byte 10 Definition

0 Singleturn encoder

1 Multiturn encoder

11.2.5 Singleturn resolution

The physical resolution per revolution of the encoder is stored in the diagnostic

bytes 11���14�

25

Page 26

Encoder with Profibus interface

11.2.6 Number of revolutions

The physical number of the distinguishable revolutions per encoder can be

enquired via the two diagnostic bytes 15 and 16� The standard values for

singleturn is 1 and 4096 (or 16384) for multiturn�

11.2.7 Operating time alarm

The warning message for exceeding the operating time is indicated in bit 4 of

diagnostic byte 21� The bit is set after 105 hours�

11.2.8 Prole version

The profile version of the encoder is stored in the diagnostic bytes 24 and 25�

Bytes 24 25

Bit 15���8 7���0

7

Data 2

���2

0

27���2

0

Revision no� Index

11.2.9 Software version

The software version of the encoder is stored in the diagnostic bytes 26 and 27�

Octet 26 27

Bit 15���8 7���0

7

Data 2

Revision no� Index

���2

0

27���2

0

11.2.10 Operating time

The operating time of the device is recorded in the diagnostic bytes 28���31� While

the supply voltage is applied, the value (Operating time) is stored again in the

encoder in steps of 0�1 every 6 minutes�

11.2.11 Zero point shift

The zero point shift is provided in the diagnostic bytes 32���35�

11.2.12 Congured resolution

The configured resolution per revolution of the encoder is stored in the diagnostic

bytes 40���43� This value is only valid if the gearbox factor was calculated in the

parameter mask via the setting [Resolution per revolution]�

11.2.13 Congured total resolution

The configured or calculated total resolution is stored in diagnostic bytes 44���47�

26

Page 27

Encoder with Profibus interface

11.2.14 Serial number

According to the encoder profile, diagnostic bytes 48���57 are intended for a serial

number� At the moment the serial number is not stored in the device; the bytes are

pre-assigned with 2A hex�

12 LED indicators

12.1 Legend

LED on / lit The terminal cap has two LEDs that optically represent

LED flashes

LED off

Colour Status /

frequency

Red Green

Colour Status /

UK

the bus status on the encoder�

The red LED is used to display errors; the green LED to

display the status of the encoder� Each LED has three

states: off, on, flashing� Seven of the nine possible combinations are used to display a certain state�

Should there be problems during start-up of the device,

the status of the LEDs is to be checked; it often gives

information about the cause of the fault�

Description

frequency

No voltage supply

The encoder is operational but has not received any

configuration data after the voltage was applied�

Possible causes: Address incorrectly set; bus cables

incorrectly connected�

Parameter setting or configuration fault

The encoder receives configuration or parameter setting

data of an incorrect size or inconsistent data�

Possible cause: e�g� total resolution is set too high

The encoder is operational but is not addressed by the

master (e�g� incorrect address is addressed)�

The encoder does not receive any data for a longer

time (approx� 40 s) (e�g� data line interrupted)

Normal operation in the data exchange mode

Set-up in the data exchange mode

27

Page 28

Encoder with Profibus interface

13 Configuring with STEP7

In the following chapter the configuration of the ifm encoder with the configuration

tool Hardware manager STEP 7 is shown as an exemple�

In the example the STEP 7 version 5�4 SP4 and the CPU 315-2PN/DP are used�

13.1 Installation and import of the GSD file

Prior to initial configuration of the system in the hardware configurator of the

software, the GSD files of the encoder must be imported into the software�

Start the software and proceed as follows to import the above GSx files:

► Open new or existing project�

► Open hardware configurator

Copy the required GSx file via menu item [Options] → [Install GSD File...].

Importing a GSD file

The GSD file is supplied by ifm (free of charge on www�ifm�com)�

In order to display the encoder as a bitmap in STEP7 the file will be installed

automatically with the GSD file – both files must be in the same directory� The

main software release number in the GSD file and the firmware must be the same,

e�g� 4�xx�

► Select the GSD file from the according source directory�

28

Page 29

Encoder with Profibus interface

UK

Selecting the GSD file from the directory

After correct import and an update of the hardware catalogue via [Options]

→ [Update Catalog] the modules will be displayed as separate entries in the

hardware catalogue�

The exact configuration procedure can be found in the operating manual which is supplied together

with the software�

29

Page 30

Encoder with Profibus interface

13.2 Adding an encoder to a STEP7 project

To add an encoder to a project, the absolute encoder can be selected from the

hardware catalogue and added to the network� The requested device is coupled to

the bus by drag&drop (or double-click on the module with marked bus)�

When the device has been added, the participant address of the slave device is

entered� It must correspond with the address set in the terminal cap�

Adding an encoder to a STEP7 project

30

Page 31

Encoder with Profibus interface

13.3 Parameter setting

Mark the encoder to be configured in projection and then doubleclick on location

1 (table in the lower area of the station window)� The dialogue window [Properties

DP slave] appears� Here the default address of the device can be changed (if

requested)�

► Select [Parameter Assignment] in the tab to enter the parameters�

UK

Parameter setting of the encoder

31

Loading...

Loading...