Page 1

Device manual

ProfiNet encoder

RM30xx

706354/00 06/2013

UK

Page 2

Encoder with ProfiNet interface

2

Contents

1 Preliminary note � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

1�1 Symbols used� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

1�2 Warning signs used � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

1�3 Notes on this document � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

2 Safety instructions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

3 General information � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

3�1 Absolute encoder � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

3�2 ProfiNet � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

4 Functions and features � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

5 Electrical connection� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

5�1 Ethernet and power supply� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

5�2 Ethernet cables � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

5�2�1 RJ45 – M12 crossed � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

5�2�2 RJ45 – M12 straight� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

5�2�3 M12 – M12 � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

6 LED indicators � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

6�1 Legend � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

6�2 Status LEDs � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

7 Installation� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

8 Device configuration � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

8�1 Standardisation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

8�2 Encoder classes � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

8�3 Encoder functions� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

8�4 Signal list for cyclic data transmission � � � � � � � � � � � � � � � � � � � � � � � � � � � �11

8�4�1 Format of position value� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �11

8�4�2 Encoder control word (STW2_ENC) � � � � � � � � � � � � � � � � � � � � � � � � 13

8�4�3 Encoder status word (ZSW2_ENC) � � � � � � � � � � � � � � � � � � � � � � � � � 14

8�4�4 Encoder control word (G1_STW)� � � � � � � � � � � � � � � � � � � � � � � � � � � 14

8�4�5 Encoder status word (G1_ZSW) � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

8�5 Standard and vendor telegrams � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

9 Configuration principle � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

9�1 Overview of encoder functions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

9�2 Encoder functions – Data format � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

9�3 Parameters for acyclic data transmission� � � � � � � � � � � � � � � � � � � � � � � � � 19

9�3�1 Standard parameters � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 20

9�3�2 Device parameters� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 20

9�3�3 Vendor parameters � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 20

9�4 Supported parameters � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 20

9�5 Encoder function description � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

9�5�1 Code sequence � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

9�5�2 Class 4 functionality � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

Page 3

UK

Encoder with ProfiNet interface

3

9�5�3 Preset control for G1_XIST1 � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

9�5�4 Scaling function control � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

9�5�5 Alarm channel control � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 24

9�5�6 Compatibility mode � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 24

9�5�7 Preset value � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 24

9�5�8 Offset value � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 27

9�5�9 Scaling parameters � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 27

9�5�10 Maximum master sign-of-life failures � � � � � � � � � � � � � � � � � � � � � � � 27

9�5�11 Velocity measuring units� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 27

9�5�12 Velocity filter� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 28

9�5�13 Endless shaft (round axis) � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 28

9�5�14 Encoder profile version � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 29

10 Configuring with STEP7 � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 30

10�1 Installing the GSDML file � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 30

10�2 Adding an encoder to a STEP7 project � � � � � � � � � � � � � � � � � � � � � � � � � 31

10�2�1 Standard encoder without PDEV � � � � � � � � � � � � � � � � � � � � � � � � � � 32

10�3 Module Access Point parameter setup: � � � � � � � � � � � � � � � � � � � � � � � � � 37

Page 4

Encoder with ProfiNet interface

4

1 Preliminary note

1.1 Symbols used

► Instructions

> Reaction, result

[…] Designation of keys, buttons or indications

→ Cross-reference

Important note

Non-compliance can result in malfunction or interference�

Information

Supplementary note

1.2 Warning signs used

NOTE

Warning of damage to property�

1.3 Notes on this document

This document applies to encoders of the following type:

RM30xx (ProfiNet interface)

It is part of the device and contains information about the correct handling of the

product�

This document is intended for qualified electricians� These specialists are people

who are qualified by their training and their experience to recognise and to avoid

possible hazards that may be caused during operation of the device�

► Read this document before using the device�

► Keep this document during the service life of the device�

► Observe these operating instructions�

► Adhere to the warning notes�

2 Safety instructions

Non-observance of the instructions, operation which is not in accordance with use

as prescribed below, wrong installation or incorrect handling can affect the safety

of operators and machinery�

The installation and connection must comply with the applicable national and

international standards� Responsibility lies with the person installing the device�

Only the signals indicated in the technical data or on the device label may be

supplied to the connections or wires�

Page 5

UK

Encoder with ProfiNet interface

5

3 General information

3.1 Absolute encoder

The basic principle of an absolute encoder is the optical sampling of a transparent

code disc which is fixed with the shaft to be measured�

The absolute encoder has a resolution of 8,192 steps per resolution (13 bits) at

4,096 revolutions (12 bits)� This results in a maximum resolution of 33,554,432

steps (25 bits)�

For further information about the function principle and setup of a ProfiNet

network, please refer to

→ http://www.profibus.com/community/regional-pi-associations/germany

3.2 ProfiNet

ProfiNet is an industrial Ethernet standard merging plant automation with

enterprise IT resources� ProfiNet provides comparable functionality to PROFIBUS

with the additional possibility of firmware upgrades�

Established IT standards are employed as basis of communication:

UDP and IP� XML is used as description language for device profiles (GSDML

files)�

Two ways of using ProfiNet are available:

ProfiNet IO, similar to PROFIBUS DP as a distributed I/O system and ProfiNet

CBA as a modular component-based system for larger systems�

ProfiNet offers scalable communication for different applications in industrial

automation:

● ProfiNet NRT (Non Real Time) is suited for non-time-critical process

automation with clock rates of roughly 100 ms�

● ProfiNet RT (Real Time) offers a communication channel with optimised

performance (10 ms clock rate) for most factory automation tasks�

● ProfiNet IRT (Isochronous Real Rime) supports communication clock rates

around 1 ms and a jitter of less than 1 μs. This operating mode is mainly of use

for motion control applications�

ProfiNet IO uses a view of distributed controllers similar to PROFIBUS DP� IO

controllers (PLCs) run automation programs, IO devices (e�g� absolute encoders)

are remotely assigned field devices, and IO supervisors (e�g� programming

devices) are used for commissioning and diagnostics�

The setup of ProfiNet IO is done similar to PROFIBUS� The fieldbuses (e�g�

Ethernet topologies) are assigned to the control system during configuration� The

IO device is configured based on the GSDML contents�

After completion of the setup the configuration data are loaded into the IO

controller (PLC) and data exchange with the IO device takes place�

Page 6

Encoder with ProfiNet interface

6

An IO device is addressed within ProfiNet (and also possibly by external Ethernet

components) through its IP address�

Data can be transferred (process data) from the IO controller to the IO device (and

vice versa) cyclically� Apart from this, acyclic parameters can be exchanged during

setup of the IO device or by the use of PLC programming blocks during operation�

4 Functions and features

● Integrated bootloader for firmware upgrades

● Round axis functionality

● Neighbouring detection (when replacing the device)

● Device identification via LEDs

● Different filters for velocity

● ProfiNet encoder profile V4�0/V4�1

5 Electrical connection

► Disconnect power�

► Connect the device according to the indications on the type label�

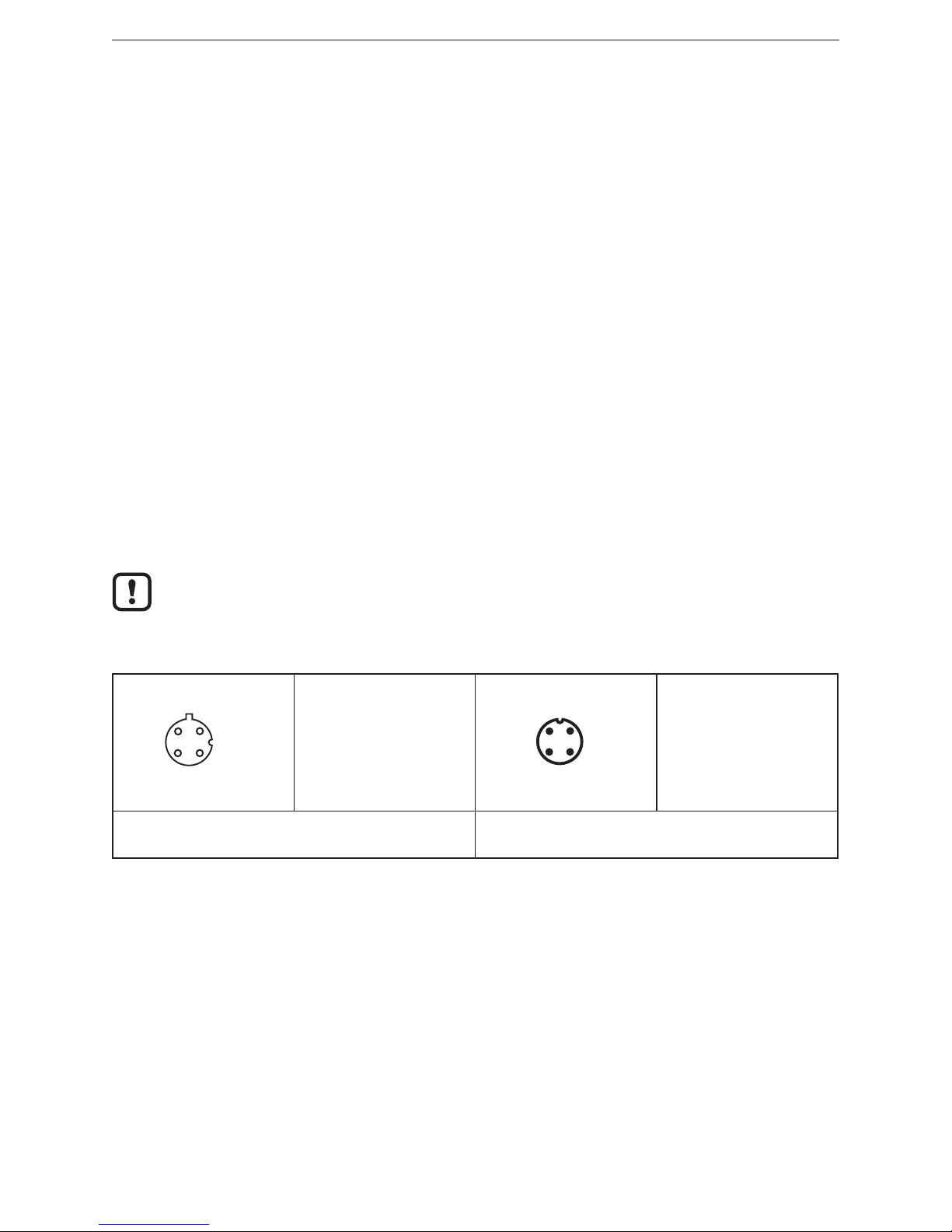

5.1 Ethernet and power supply

1

4

3

2

1: Tx +

2: Rx +

3: Tx -

4: Rx -

1: US (10 - 30 V DC)

2: not connected (n�c�)

3: GND (0 V)

4: not connected (n�c�)

Ethernet:

4 pin female, D-coded

Power supply:

4 pin male, A-coded

Page 7

UK

Encoder with ProfiNet interface

7

5.2 Ethernet cables

5.2.1 RJ45 – M12 crossed

Signal RJ45 M12

Tx + 1 2

Tx - 2 4

Rx + 3 1

Rx - 6 3

5.2.2 RJ45 – M12 straight

Signal RJ45 M12

Tx + 1 1

Tx - 2 3

Rx + 3 2

Rx - 6 4

5.2.3 M12 – M12

Signal M12 M12

Tx + 1 1

Tx - 2 2

Rx + 3 3

Rx - 4 4

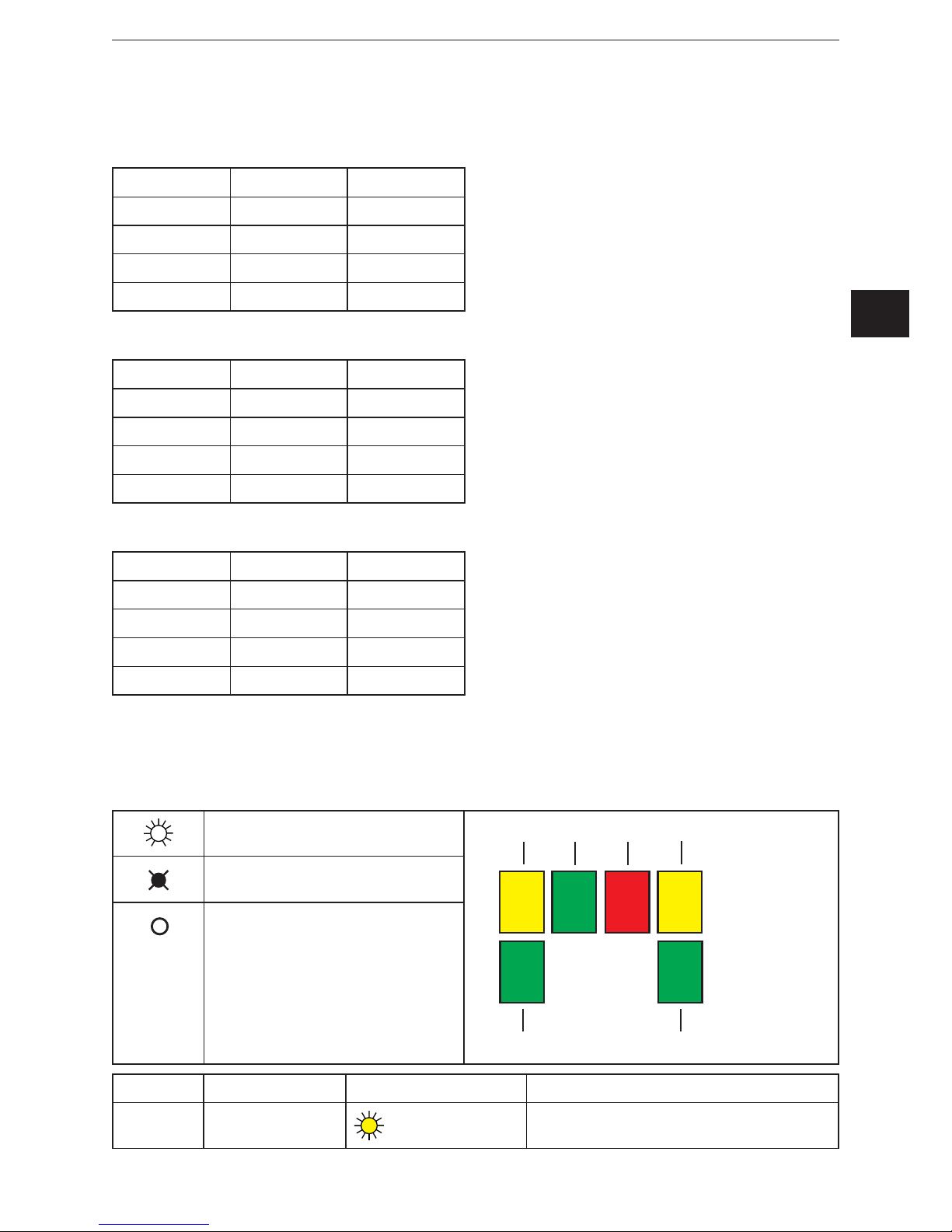

6 LED indicators

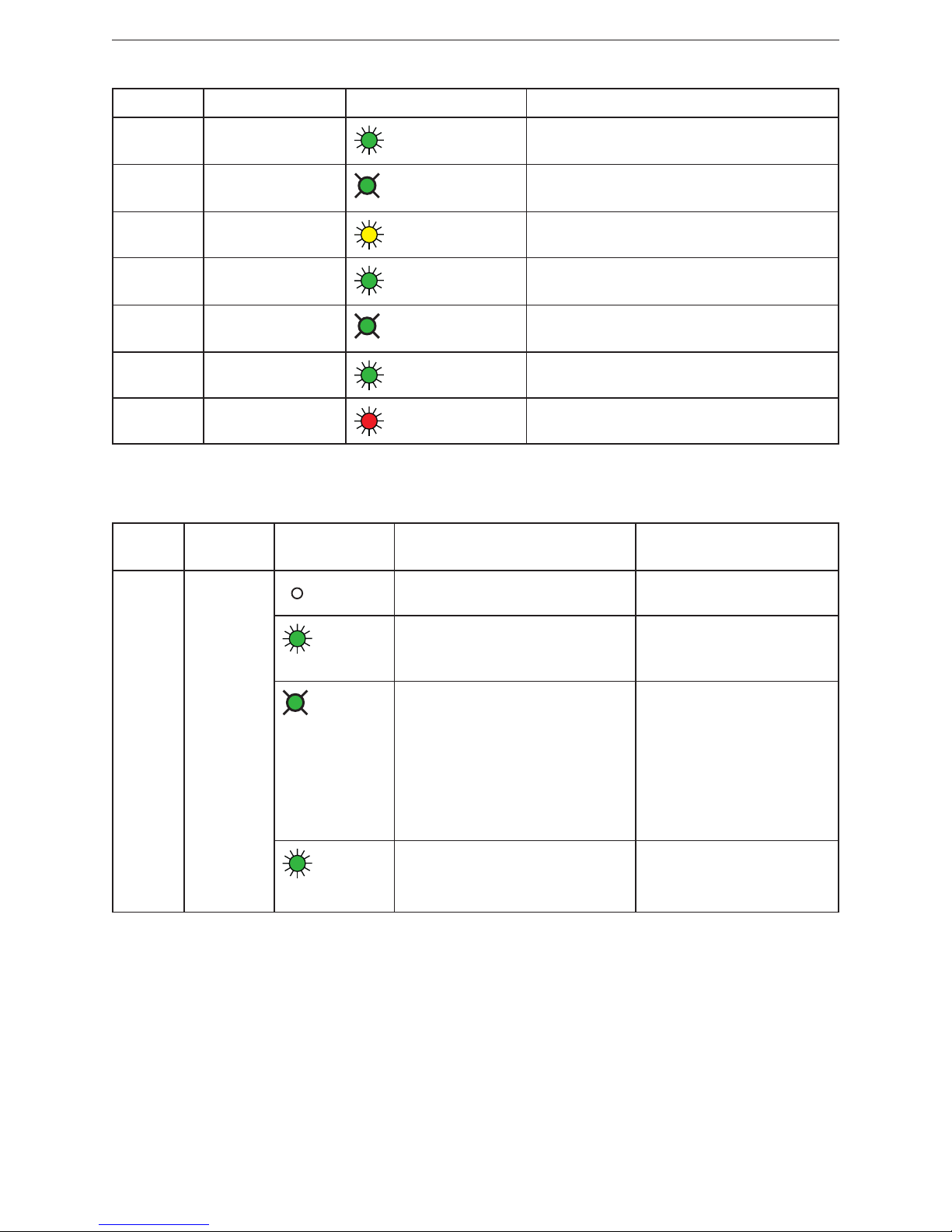

6.1 Legend

LED on / lit

Stat 1 Stat 2 Active 1

Active 2

Link 1Link 2

LED flashes

LED off

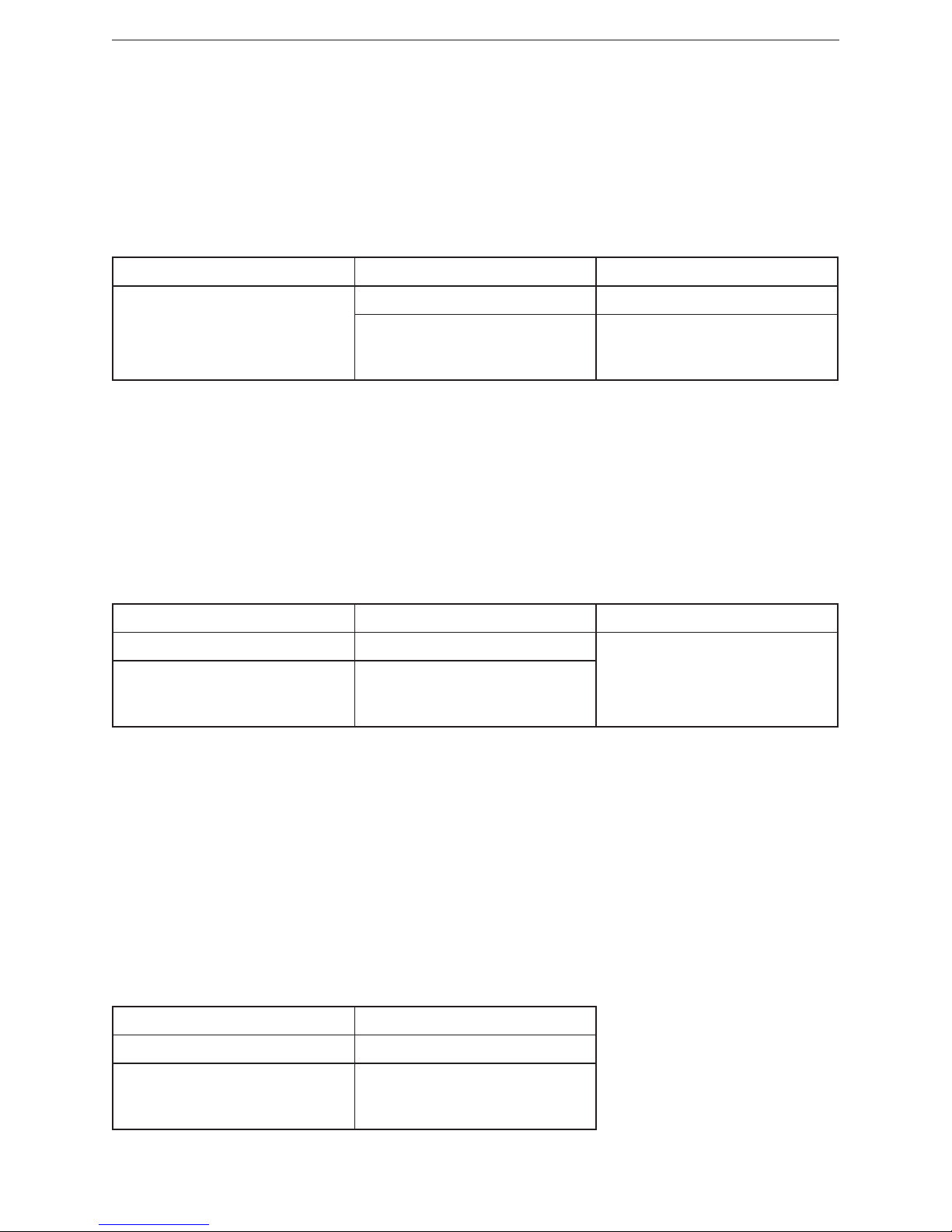

LED Colour Status / frequency Description

Active 1 Yellow

Data traffic on port 1

Page 8

Encoder with ProfiNet interface

8

LED Colour Status / frequency Description

Link 1 Green

Active link to other Ethernet components

via port 1

Link 1 Green

2 Hz

Identification call is activated and link connection is available

Active 2 Yellow

Data traffic on port 2

Link 2 Green

Active link to other Ethernet components

via port 2

Link 2 Green

2 Hz

Identification call is activated and link connection is available

Stat 1 Green

Status 1, details → Status LEDs

Stat 2 Red

Status 2, details → Status LEDs

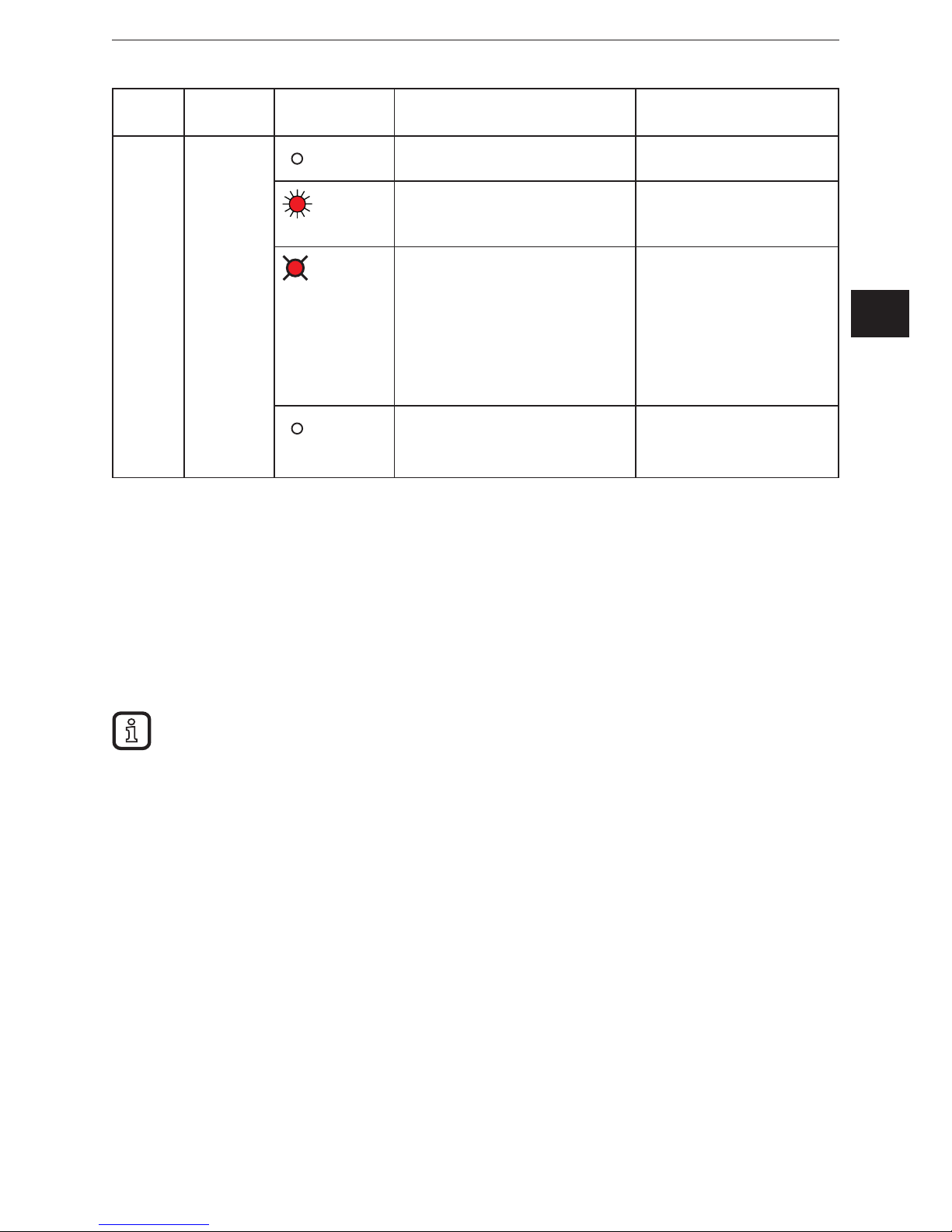

6.2 Status LEDs

LED Colour Status /

frequency

Description Cause

Status 1 Green

No power Fuse or cable defective

No connection to control unit

Criteria: no data exchange

– Bus disconnected

– IO controller not available

/ switched off

0�5 Hz

Parameterization fault, no data

exchange

Criteria: data exchange correct�

The slave did not switch to the

[data exchange] mode�

– Slave not configured yet

or wrong configuration

– Wrong station address

assigned (but not outside

the permitted range)

– Actual configuration of

the slave differs from the

desired configuration

Data exchange

Connected device and operation

OK�

Page 9

UK

Encoder with ProfiNet interface

9

LED Colour Status /

frequency

Description Cause

Status 1

(fault)

Red

No power Fuse or cable defective

No connection to control unit

Criteria: no data exchange

– Bus disconnected

– IO controller not available

/ switched off

0�5 Hz

Parameterization fault, no data

exchange

Criteria: data exchange correct�

The slave did not switch to the

[data exchange] mode�

– Slave not configured yet

or wrong configuration

– Wrong station address

assigned (but not outside

the permitted range)

– Actual configuration of

the slave differs from the

desired configuration

Data exchange

Connected device and operation

OK�

7 Installation

► Disconnect power�

► Ensure that the machine stands still�

► The drive must not be started during installation�

► Do not hit the shaft; do not use a file or similar tool on the shaft: Risk of

destruction!

This product is a precision measuring device� Therefore it has to be handled with care by trained

staff� The following warnings apply to influences outside the limit values indicated in the product data

sheet�

Damage to the product can be caused by:

● electrostatic discharge while touching the electronics

● too high forces on the shaft

● humidity and chemical liquids (do not connect any cables oriented upwards)

● extreme temperatures

● too high vibrations and shocks

● short circuit or too high an operating voltage

● impact, shock or any other physical forces

Page 10

Encoder with ProfiNet interface

10

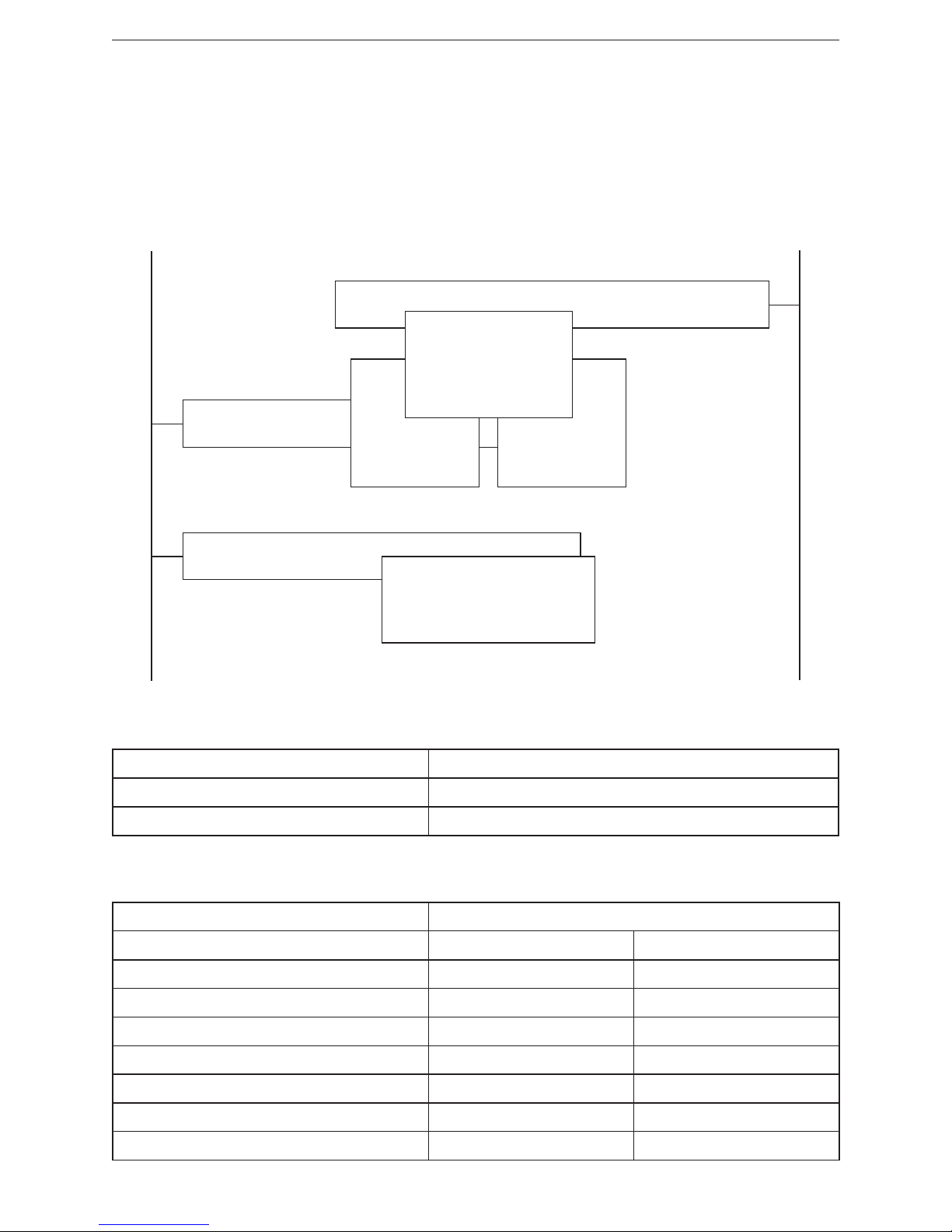

8 Device configuration

8.1 Standardisation

The current generation of ProfiNet encoders is based on the profile V4�0/V4�1

(PNO no� 3�162)� With this standardisation it is possible to substitute all products

that fulfil the specification�

PROFIBUS

Network

PROFINET

Network

PROFINET IO

PNO No. 2.332

PROFIBUS DP-V2

IEC 61158

PROFIDRIVE V4

PNO No. 3.172

I&M Functions

PNO No. 3.502

Encoder Profile V4

Class 3 and 4

PNO No. 3.162

Encoder Profile

Class 1 and 2

PNO No. 3.062

PROFIBUS DP

EN 50170

8.2 Encoder classes

Application class Description

3 Isochronous mode is not supported (RT)

4 Isochronous mode is supported (IRT)

8.3 Encoder functions

Implementation

Function Class 3 Class 4

Code sequence - / • * •

Class 4 functionality • •

G1_XIST1 preset control - / • * •

Scaling function control - / • * •

Alarm channel control • •

Preset value - / • * •

Preset value (64bit) - -

Page 11

UK

Encoder with ProfiNet interface

11

Implementation

Function Class 3 Class 4

Measuring units per revolution (32bit) - / • * •

Total resolution (32bit) - / • * •

Measuring units per revolution (64bit) - / • * •

Total resolution (64bit) - / • * •

Maximum master sign-of-life failures - / • * •

Velocity measuring unit - / • * •

Encoder profile version • •

Operating hours counter - -

Offset value - / • * •

Offset value at 64 bits - / • * •

Round axis function • •

Velocity filter • •

* If class 4 functionality is activated

8.4 Signal list for cyclic data transmission

Signal no. Meaning Abbreviation Length (bit) Sign

3 Master's sign-of-life counter STW2_ENC 16 -

4 Slave's sign-of-life counter ZSW2_ENC 16 -

6 Velocity value A NIST_A 16 •

8 Velocity value B NIST_B 32 •

9 Control word G1_STW 16 -

10 Status word G1_ZSW 16 -

11 Position value 1 G1_XIST1 32 -

12 Position value 2 G1_XIST2 32 -

13 Position value 3 G1_XIST3 64 -

8.4.1 Format of position value

Note:

G1_XIST1 and G1_XIST2 are the actual position values in binary format� The

alignment in the data-frame (left or right-aligned) is considered for each individual

resolution� For absolute encoders an example is given below�

The alignment of the output format (left or right-aligned) remains constant and affects the actual

resolution� The number of bits provided changes depending on the resolution�

Example

25 bit multiturn absolute encoder (8,192 steps per revolution, 4,096 revolutions)�

Page 12

Encoder with ProfiNet interface

12

All values are presented in binary format� If an error occurs, G1_XIST2 displays

the error telegram instead of the right-aligned value�

The shifting factors in P979 "sensor format" display the current format� P979,

subindex 4 (shift factor for G1_XIST2) = 0� The settings in the encoder parameter

data affect the position value in both G1_XIST1 and G1_XIST2�

Absolute value in G1_XIST2

31���25 24���13 12���0

M S

Distinguishable

revolutions

(multiturn value)

Pulses

(singleturn steps

per revolution)

Setting: encoder profile 4.0*

● By default, G1_XIST1 is left-aligned�

● P979, subindex 3 (shift factor for G1_XIST1) = 32 – total resolution (next binary

value)

● G1_XIST1 transmits positions values independent of bit 10 in stw2 and bit 13 in

g1_stw1�

Absolute value in G1_XIST1 for encoder profile 4�0

31���20 19���7 6���0

M S

Distinguishable

revolutions

(multiturn value)

Pulses

(singleturn steps

per revolution)

Setting: encoder profile 4.1*

● By default, G1_XIST1 is right-aligned�

● A 32-bit counter starts with the absolute position value� After increasing to the

maximum counter value, start again with 0 or decreasing from the max� counter

value to 0�

● P979, subindex 3 (shift factor for G1_XIST1) = 0

● G1_XIST1 transmits positions values independent of bit 10 in stw2 and bit 13 in

g1_stw1�

Absolute value in G1_XIST1 for encoder profile 4�1

31���13 19���0

M S

Distinguishable

revolutions

(multiturn value)

Pulses

(singleturn steps

per revolution)

Page 13

UK

Encoder with ProfiNet interface

13

* Profile 4.0 is realised with GSDML-V2.2-IFM-RM30xx+RN30xx-20130802, profile

4�1 with newer data�

G1_XIST3

For 64-bit position values G1_XIST3 is available� The binary value is output rightaligned and without shifting factor�

IO data (DWord) 1 2 3 4

Format 64-bit position value

8.4.2 Encoder control word (STW2_ENC)

4-bit counter, left-aligned� The master application starts the sign-of-life counter with

any value between 1 and 15� The master increases the counter in every cycle of

the master application�

Valid values for the master's sign-of-life counter are 1 to 15� "0" indicates an error

and is left out in normal operation�

Implementation

Bit Function Class 3 Class 4

0���9 Reserved,

currently not used

- -

10 Control by PLC • •

11 Reserved,

currently not used

- -

12���15 Sign-of-life status indication - -

Bit Value Meaning Comments

10 1 Control by PLC Control via interface,

IO data is valid

0 No control via PLC IO data is not valid, except sign-

of-life

12���15 Controller sign-of-life Continuously sends

counting values from 0 to 15

Page 14

Encoder with ProfiNet interface

14

8.4.3 Encoder status word (ZSW2_ENC)

4-bit counter, left-aligned� The slave application starts the sign-of-life counter with

any value between 1 and 15 after successful synchronisation to the clock pulse�

The counter is increased in every DP cycle of the slave application� Valid values

for the slave's sign-of-life counter are 1 to 15, "0" indicates an error and is left out

in normal operation�

Implementation

Bit Function Class 3 Class 4

0���8 Reserved,

currently not used

- -

9 Control requested Mandatory Mandatory

10���11 Reserved,

currently not used

- -

12���15 Encoder sign-of-life counter - Mandatory

Bit Value Meaning Comments

9 1 Control requested Control via interface,

IO data is valid

0 No control via PLC IO data is not valid, except sign-

of-life

12���15 Encoder

Sign-of-life counter

Continuously sends

counting values from 0 to 15

8.4.4 Encoder control word (G1_STW)

Bit Value Function Comments

0���10 Reserved,

currently not used

11 0/1 "Home position" mode Specifies if the position value

shall be set to a previously

programmed absolute value or

shifted by this value�

0: set home position / preset

(absolute)

1: shift home position / preset

(relative = offset)

12 1 Set preset /

shift request

Preset (shift) is set when changing this bit to "1" (rising edge)�

Default preset value:

(shift): 0

Warning:

After setting the preset the offset

will be saved in the EEPROM� In

these 5-10 ms the encoder will

not send position values�

Page 15

UK

Encoder with ProfiNet interface

15

Bit Value Function Comments

13 1 Request absolute value cyclically Request of additional cyclic trans-

mission of the absolute actual

position in G1_XIST2� If no other

data needs to be transferred

due to commands or errors the

absolute position value will be

transmitted automatically�

14 1 "Parking sensor" activated If the "parking sensor" bit is

activated, the encoder transmits

no error messages�

15 1 Acknowledgement of a sensor

error

Request to acknowledge / reset a

sensor error

8.4.5 Encoder status word (G1_ZSW)

Bit Value Function Comments

0���10 Reserved,

currently not used

11 Acknowledgement of a sensor

error in process

Is set if the reset of a sensor error

takes longer than one bus cycle�

12 1 Set preset value /

shift reference point executed

Acknowledgement for "set preset

/ shift reference point"

13 1 Transmit absolute value cycli-

cally

Acknowledgement for "request

absolute value cyclically"

14 1 "Parking sensor" activated If the "parking sensor" bit is

activated, the encoder transmits

no error messages�

15 1 Acknowledgement of a sensor

error

Indicates a sensor error�

A device specific error code is

shown in G1_XIST2�

8.5 Standard and vendor telegrams

Standard telegram 81

IO data

(DWord)

1 2

Setpoint STW2_ENC * G1_STW1 *

IO data

(DWord)

1 2 3 4 5 6

Actual value ZSW2_ENC* G1_ZSW1* G1_XIST1* G1_XIST2*

Standard telegram 82

IO data

(DWord)

1 2

Setpoint STW2_ENC* G1_STW1 *

Page 16

Encoder with ProfiNet interface

16

IO data

(DWord)

1 2 3 4 5 6 7

Actual value ZSW2_ENC* G1_ZSW1* G1_XIST1* G1_XIST2* NIST_A*

Standard telegram 83

IO data

(DWord)

1 2

Setpoint STW2_ENC* G1_STW1 *

IO data

(DWord)

1 2 3 4 5 6 7 8

Actual value ZSW2_ENC* G1_ZSW1* G1_XIST1* G1_XIST2* NIST_B*

Standard telegram 84

IO data

(DWord)

1 2

Setpoint STW2_ENC* G1_STW1 *

IO data

(DWord)

1 2 3 4 5 6 7 8 9 10

Actual value ZSW2_ENC* G1_ZSW1* G1_XIST3* G1_XIST2* NIST_B*

* Details on the variables → chapter 3.4

Vendor telegram 860

With this telegram it is not necessary to set special bits for a cyclic data

transmission� In its functionality, it is similar to PROFIBUS and provides for easy

configuration of the preset value during PLC operation� The velocity value uses the

format that is defined in the velocity measuring unit�

If bit 31 is set to "1", the preset value will be adopted immediately� A further preset

value can only be set if bit 31 is reset to "0"�

● No control word

● No status word

● No status indication

● Output: 32 bit-unsigned preset value (bit 31 preset control, must be less than

total resolution)

● Input: 32 bit-unsigned preset value + 32 bit-integer velocity value

Data input (from encoder to controller): 8 bytes

Position value - 32-bit unsigned Velocity value - 32-bit signed

Page 17

UK

Encoder with ProfiNet interface

17

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

MSB LSB MSB LSB

Data output (from controller to encoder): 4 bytes

Preset - 32-bit unsigned

Bit 31 Bit 30 ���������������������������������������������������������������������������������bit 0

Preset control Preset value < Total resolution

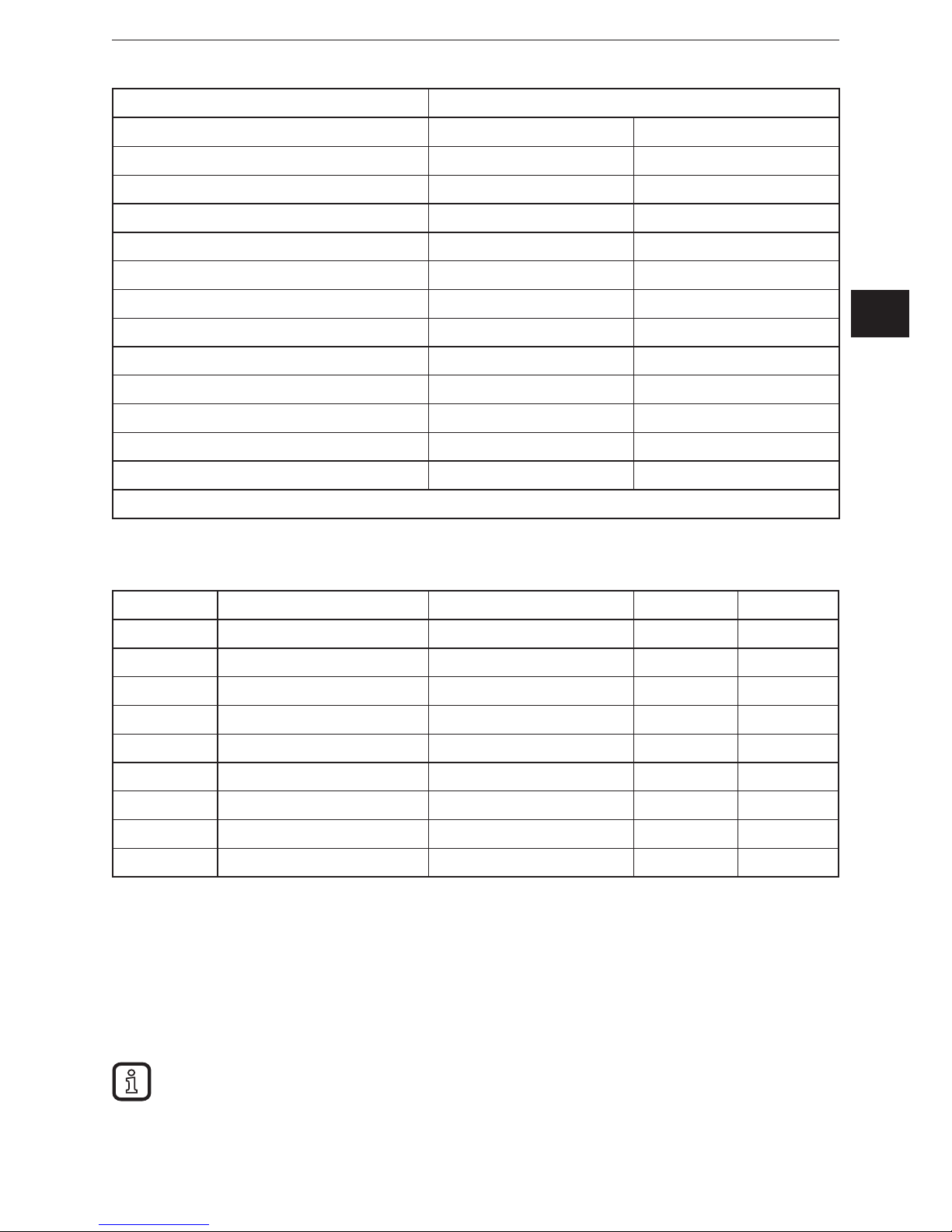

9 Configuration principle

Encoders with ProfiNet interface can be programmed according to the needs of

the user�

► The GSDML file of the encoder has to be installed in the PLC software tool�

9.1 Overview of encoder functions

Function Communication channel

Position value Cyclic input (IO device -> IO controller)

Preset Cyclic output (IO controller -> IO device)

Code sequence Acyclic input/output

Scaling function Acyclic input/output

9.2 Encoder functions – Data format

ProfiNet IO devices are set up in modules� Each module can be assigned to slot�

One sub slot can contain several cyclic input/output channels as well as acyclic

record channels (required for parameters)�

There are PLC versions from different manufacturers available� Some of them

support only one sub slot� Others, e�g� S7 400, support several sub slots� To work

with all PLCs there are two directories in the GSDML file: standard (for IRT) and

"no PDEV"�

ifm encoders offer for the standard profile one slot with one sub slot for all old

PLCs that do not support several sub slots�

Device parameters are systematically grouped together in a table� The following

tables give an overview of the ifm encoder functions�

Page 18

Encoder with ProfiNet interface

18

EncoderGSDML file

ControllerSPS project tool

1 2

1: Acyclic data transmission (parameters)

2: Cyclic data transmission (process data)

Page 19

UK

Encoder with ProfiNet interface

19

9.3 Parameters for acyclic data transmission

In the start-up phase the user parameters are sent to the encoder as data record

object for mapping of the different encoder functions in the user data section (data

record 0xBF00)� In addition to the parameter "data configuration" the encoder

supports a number of PROFIdrive parameters and encoder specific parameters via

the acyclic data exchange service�

With GSDML version GSDML-V2�2-IFM-RM30xx+RN30xx-20130802, it is

possible to change the telegram type without changing the MAP parameters�

MAP

Parameter

Access

Encoder

Functions

Parameter

Manager

Parameter

Data Base

Standard

Telegram 81.

82, 83 or 84

Sub 1Sub 2

Sub 2Sub 0

Slot 1 Standard Telegrams

Sub 0

Slot 0

Page 20

Encoder with ProfiNet interface

20

9.3.1 Standard parameters

Function Slot Sub slot Index Offset Length IO

Code sequence 1 1 0xBF00 0�0 1 bit -

Class 4 functionality 1 1 0xBF00 0�1 1 bit -

G1_XIST1 preset control 1 1 0xBF00 0�2 1 bit -

Scaling function control 1 1 0xBF00 0�3 1 bit -

Alarm channel control 1 1 0xBF00 0�4 1 bit -

Compatibility mode 1 1 0xBF00 0�5 1 bit -

Measuring units per revolution 1 1 0xBF00 1 8 bytes -

Total resolution 1 1 0xBF00 9 8 bytes -

Maximum master

sign-of-life failures

1 1 0xBF00 17 1 byte -

Velocity unit 1 1 0xBF00 18 1 byte -

9.3.2 Device parameters

Function Slot Sub slot Index Offset Length IO

Preset value 1 1 0xB02E via parameter no�

65000

-

9.3.3 Vendor parameters

Function Slot Sub slot Index Offset Length IO

Preset value 1 1 0x1000 0 1 byte -

9.4 Supported parameters

Number Parameter Read only Read/Write

922 Telegram selection • -

925 Number of tolerated sign-of-life failures - •

964 Device identification • -

965 Profile identification number • -

971 Transfer into EEPROM - •

975 DO identification • -

979 Sensor format • -

980 List of defined parameters • -

65000 Preset - •

65001 Operating status • -

Page 21

UK

Encoder with ProfiNet interface

21

Parameter model

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Request Reference Request ReferenceResponse ID Request ID

DO-ID No of Parameters DO-IDNo of Parameters

Parameter

response

Parameter

request

ParameterResponse

Data Record

0xB02E (READ)

Data Record

0xB02E (WRITE)

Controller/Supersivor

PROFIdrive

Base Mode

Parameter

response

PROFIdrive

Base Mode

Parameter

request

write

Data Record

0xB02E

read

Data Record

0xB02E

error: 1)

ErrorCode = 0xDE

ErrorDecode = 0x80

ErrorCode 1 = 0xB5

ErrorCode 2 = 0

ParameterRequest

error: 3)

ErrorCode = 0xDF

ErrorDecode = 0x80

ErrorCode 1 = 0xB5

ErrorCode 2 = 0

request

accepted

error “state

conflict”, request

not accepted

readout of

parameter

response

error “state conflict”,

no response

available

ok

ok

transfer

response to

Data Record

transfer

request to

Parameter

Manager

BlockHeader;

ParameterRequest

BlockHeader;

ParameterResponse

Parameter

Manager 2)

Parameter

Data Base

Drive / DO

PROFIdrive

Base Mode Parameter

request

PROFIdrive

Base Mode Parameter

response

Request Reference Request ReferenceResponse ID Request ID

DO-ID No of Parameters DO-IDNo of Parameters

Page 22

Encoder with ProfiNet interface

22

Example of configuration according encoder profile V4�1

9.5 Encoder function description

Implementation Description

chapter

Function Class 3 Class 4

Code sequence - / • * • 9�5�1

Class 4 functionality • • 9�5�2

G1_XIST1 preset control - / • * • 9�5�3

Scaling function control - / • * • 9�5�4

Alarm channel control • • 9�5�5

Compatibility mode • • 9�5�6

Preset value - / • * • 9�5�7

Preset value (64 bits) - - -

Measuring units per revolution (32 bits) - / • * • 9�5�9

Total measuring range (32 bits) - / • * • 9�5�9

Measuring units per revolution (64 bits) - / • * • -

Total measuring range (64 bits) - / • * • -

Maximum master sign-of-life failures - / • * • 9�5�10

Velocity unit - / • * • 9�5�11

Encoder profile version • • 9�5�14

Operating hours counter - - -

Offset value - / • * • 9�5�8

Offset value 64 bits - / • * • -

Page 23

UK

Encoder with ProfiNet interface

23

Implementation Description

chapter

Function Class 3 Class 4

Round axis functionality • • 9�5�13

Velocity filter • • 9�5�12

* If class 4 functionality is activated

9.5.1 Code sequence

The parameter "code sequence" defines the counting direction of the position

value� The value increases when the shaft is rotating clockwise (CW) or counterclockwise (CCW) (view onto the shaft)�

Code sequence Direction of rotation when viewing the shaft Code sequence

922 Clockwise (CW) Increasing

925 Counter-clockwise (CCW) Decreasing

9.5.2 Class 4 functionality

The parameter "class 4 functionality" defines that scaling, preset and code

sequence affect the position value in G1_XIST1, G1_XIST2 and G1_XIST3�

Class 4 control Class 4 function

0 (standard) Deactivated (disable)

1 Activated (enable)

9.5.3 Preset control for G1_XIST1

The parameter "preset control" defines the preset function� If parameter class 4

is activated and preset control is deactivated, then the preset value will not be

affected in G1_XIST1�

Preset control Preset function

0 (standard) Preset does not affect G1_XIST1

1 Preset affects G1_XIST1

9.5.4 Scaling function control

The parameter "scaling function control" activates / deactivates the scaling

function� If it is not activated, the physical position value is returned by the

encoder� Scaling function control is only available when class 4 control is

activated�

Scaling function control Scaling function

0 (standard) Deactivated

Page 24

Encoder with ProfiNet interface

24

Scaling function control Scaling function

1 Activated

9.5.5 Alarm channel control

The parameter "alarm channel control" defines the length of the diagnostic

telegram� If the alarm channel is deactivated, then only the first 6 bytes of the

diagnosis will be transmitted�

Alarm monitoring Alarm function

0 (standard) Deactivated

1 Activated

9.5.6 Compatibility mode

This parameter defines if the encoder should be executed in a mode compatible to

version 3�1�

Overview of functions when compatibility mode is disabled

Compatibility mode Compatibility function Meaning

0 Activated Compatible to encoder profile

V3�1

1 (standard) Deactivated No downward compatibility

Function Compatibility mode

Active (=0)

Compatibility mode

Active (=1)

Control by PLC

(STW2_ENC)

Ignored; the control word (G1_STW)

and setpoint values are always valid�

Control request

(ZSW2_ENC) is not supported and

is set to 0

Supported

User parameter

"maximum master sign-oflife failures"

Supported Not supported; one sign-of-life failure

is tolerated, P925 can optionally moni-

tor the sign-of-life counter�

User parameter "alarm

channel"

Supported Not supported; the alarm channel

function is active and

monitored by PROFIdrive parameters�

P965 - profile version 31 (V3�1) 41 (V4�1)

9.5.7 Preset value

With the preset value it is possible to adapt the encoder zero point to the zero

point of the application� When using this function the current encoder position

value is set to the desired preset value� The integrated microcontroller calculates

the internal zero point shift� It is stored in the EEPROM (~ 10 ms)�

Page 25

UK

Encoder with ProfiNet interface

25

Set preset only in standstill�

There is no preset activated when the preset value is written to the encoder�

The preset function is controlled by the bits in sensor control and status words

(G1_STW and G1_ZSW)� The preset value is used when a preset is requested by

bit 12 of the sensor control (G1_STW)�

Class 4 functionality must be enabled�

If the preset value is greater than the total resolution, then the error message 0x02

(lower or higher limit value exceeded) appears in the parameter response in base

mode�

Parameter Meaning Data type

Preset value Preset value is defined via asynchronous

data exchange�

Default value = 0

Integer 32

Page 26

Encoder with ProfiNet interface

26

Example of parameter order for preset with record read-write for SIMATIC CPU300

RecordWriteData] = {

0x00,0x02,0x00,0x01, // Header

0x10,0x00,0xFD,0xE8,0x00,0x00, // Parameter address (preset)

0x43,0x01,0x00,0x00,0x00,0x64 // Parameter value (preset value=100=0x64h)

};

Meaning:

0x00,0x02,0x00,0x01,

| | | |------- Number of parameters = 1

| | |------------- Axis no�/DO-ID = 0

| |------------------ Request ID = 2 Change value

|---------------------- Request reference

0x10,0x00,0xFD,0xE8,0x00,0x00, // Parameter address (preset)

| | | | | |--- Subindex LOW byte

| | | | |------- Subindex HIGH byte

| | | |------------ Parameter number (PNU) LOW byte

| | |----------------- Parameter number (PNU) HIGH byte

| |---------------------- Number of elements

|-------------------------- Attributes

0x01,0x00,0x00,0x00,0x64 // Parameter value (preset value=100=0x64h)

| | | | | |--- Preset value LSB

| | | | |------- Preset value

| | | |------------ Preset value

| | |----------------- Preset value MSB

| |---------------------- Number of values =1

|-------------------------- Format: 0x43= DWord or integer 32bit

SIMATIC S7:

-SFB53

-FC x:

CALL "WRREC", DB53

REQ :=M41�7 // activate sfb request

ID :=DW#16#0 // logical slot address -> adapt

INDEX :=W#16#B02E // record index number

LEN := 16 // data length in byte size of (RecordWriteData[])

DONE :=M41�1 // request finished

BUSY :=M41�2 // busy bit

ERROR :=M41�3 // error bit

STATUS:=MD46 // error number, if error bit = 1

RECORD:= RecordWriteData // record buffer address -> adapt

Page 27

UK

Encoder with ProfiNet interface

27

9.5.8 Offset value

The offset value is calculated in the preset function and exchanges the position

value for the calculated value�

9.5.9 Scaling parameters

The scaling parameters are used to change the resolution� This parameter only

refers to the output values if the scaling function is enabled�

Parameter Meaning Data type

Measuring units

per revolution

Singleturn resolution in steps Unsigned 32

Total measuring range

in measuring units

Total measuring range Unsigned 32

If the resolution per revolution is reduced, a skip in the position value may occur when crossing the

physical zero point�

Reason: The position values exceed the real total resolution�

Use the formula below to avoid this problem:

Total resolution = desired measuring steps / revolution x revolutions

9.5.10 Maximum master sign-of-life failures

With this parameter the number of allowed failures of the master's sign of life is

defined�

Parameter Meaning Value

Maximum master sign-oflife failures

Number of permissible failures

of the sign-of-life counter

0 … 255

Standard =1

9.5.11 Velocity measuring units

This parameter defines the coding of velocity measuring unit used to configure the

values NIST_A and NIST_B� Only telegrams 82-84 use the velocity outputs�

Velocity unit Value

Steps / s 0

Steps / 100 ms 1

Steps / 10 ms 2

RPM 3

N2/N4 4

Page 28

Encoder with ProfiNet interface

28

N2/N4: Velocity scaling used for PROFIdrive telegrams

The current velocity value in NIST is the share in per cent of the reference value�

The reference value can be programmed with parameter P2000�

● N2 (NIST_A), 4000 hex corresponds to a value of 100% of the reference value

● N4 (NIST_B), 4000 0000 hex corresponds to a value of 100% of the reference

value

● The value range is between -200% and +200%

MSB = 1 corresponds to a negative sign

MSB = 0 corresponds to a positive sign

9.5.12 Velocity lter

The velocity value can be used with three different exponential moving average

filter types�

Parameter Meaning Data type

Velocity filter Parameter selection: fine, normal, coarse Integer 32

Ratio between old and current velocity:

– Fine: 7:3

– Normal: 96:4

– Coarse: 996:4

9.5.13 Endless shaft (round axis)

Normally the "total resolution" / "measuring units per revolution" must be an

integer and the total resolution must fit an integer number of times into 8192 for an

encoder with 13 bits per revolution� This means that e�g� 100 or 325 revolutions

could cause troubles�

So the following equation must apply:

(4096 x measuring units per revolution) / total resolution = integer

But the ProfiNet encoder solves this problem automatically� The encoder checks

whether the parameters need the endless shaft and activates this functionality

independently�

The internal software routine only works if the encoder is in operation� If it is necessary to turn the

encoder shaft more than 1,024 revolutions without power supply this can lead to problems (the

internal routine will not work without power supply)� With this function there will be saved additional

values in the internal EEPROM�

Page 29

UK

Encoder with ProfiNet interface

29

9.5.14 Encoder prole version

The encoder profile version is implemented in the encoder� This parameter is not

affected by the compatibility settings�

Bits Meaning

0���7 Profile version, least significant number (value range: 0…99), decimal coding

8���15 Profile version, most significant number (value range: 0…99), decimal coding

16���31 Reserved

Page 30

Encoder with ProfiNet interface

30

10 Configuring with STEP7

In the following chapter the configuration of the ifm encoder with the configuration

tool Hardwaremanager STEP 7 is shown exemplarily�

In this example STEP7 version 5�4 SP4 and the CPU 315-2PN/DP or Simotion

Scout with single axis controller D410 (integrated ProfiNet controller) are used�

10.1 Installing the GSDML file

Prior to initial configuration of the system in the hardware configurator of the

software, the GSD files of the encoder must be imported into the software�

Start the software and proceed as follows to import the above GSx files:

► Open new or existing project�

► Open hardware configurator�

Copy the required GSx file to the software via menu item [Options] → [Install GSD

Files���]�

Importing a GSD file

The GSDML file is supplied by ifm (free of charge on www�ifm�com)�

In order to display the encoder as a bitmap in STEP7 the file will be installed

automatically with the GSDML file – both files must be in the same directory� The

main software release number in the GSDML file and the firmware must be the

same, e�g� 4�xx�

► Select the GSD file from the according source directory�

Page 31

UK

Encoder with ProfiNet interface

31

Selecting the GSD file from the directory

After correct import and an update of the hardware catalogue via [Options] →

[Update catalog] the modules will be displayed as separate entries in the hardware

catalogue�

The exact configuration procedure can be found in the operating manual which is supplied together

with the software�

10.2 Adding an encoder to a STEP7 project

To add an encoder to a project, drag the device [OCD-ENCODER] to an existing

ProfiNet Ethernet network (or choose the network and double-click the [OCDEncoder] icon)�

► Move the telegram to the free slot�

Encoder selection

– Standard encoder with PDEV (asynchronous + RT + IRT)

– Standard encoder without PDEV (asynchronous + RT)

Page 32

Encoder with ProfiNet interface

32

10.2.1 Standard encoder without PDEV

Asynchronous + RT communication for controllers which do not support IRT

functionality�

Standard encoder without ohne PDEV

Page 33

UK

Encoder with ProfiNet interface

33

Encoder name and IP address

Double-click the encoder icon to set the PLC communication parameters�

► Set a device name and the IP address of the encoder�

Set device name

► Click [Ethernet]�

► Also, under the [IO cycle] tab, set the desired update time�

► The device name and IP address have to be set directly in the encoder�

► Connect the PLC and the encoder to Ethernet and switch them on�

Page 34

Encoder with ProfiNet interface

34

► Click [Target system] -> [Ethernet] -> [Edit Ethernet node] and then [Browse]�

Edit Ethernet node

> A new window with the Ethernet nodes is opened�

> STEP7 will scan for devices on Ethernet and will display them in the window�

> The encoder is displayed under [IFM OCD]�

► Select this entry and click [Flash]�

> The link LEDs flash with 2 Hz�

► Click [OK] �

> The MAC address is transferred to a new window�

► Click [Use IP parameters]�

► Enter the IP address and subnet mask of the encoder�

► Click [Assign IP configuration]�

► Enter the name of the device in the text field [Device name]�

Page 35

UK

Encoder with ProfiNet interface

35

► Click [Assign name]�

If more than one encoder is used in the same ProfiNet network, each encoder must be assigned a

different name�

Browse network

Page 36

Encoder with ProfiNet interface

36

Encoder name and IP address

► Double-click the encoder icon to set the PLC communication parameters�

► Assign device name�

► Click [Ethernet] and set the IP address of the encoder�

► Set the desired update time under the [IO cycle] tab�

IO cycle

Page 37

UK

Encoder with ProfiNet interface

37

10.3 Module Access Point parameter setup:

► Double-click on the menu item [Module Access Point]�

Module Access Point

> The window with the list of parameters is opened�

Page 38

Encoder with ProfiNet interface

38

These parameters will be transmitted to the encoder on each start of the PLC�

Parameter settings

Page 39

UK

Encoder with ProfiNet interface

39

Loading...

Loading...