Page 1

System manual

ecomat 100 type R 360

Page 2

System manual ecomat 100 type R 360, April 1999

Guarantee

This manual was written with the utmost care. However, we cannot assume any guarantee for the

contents.

Since errors cannot be avoided despite all efforts we appreciate any comment.

We res erve the right to make technical alterations to the product which might result in a change of

contents of the manual.

page 2

Page 3

1. General 5

1.1. Safety instructions 5

1.2. Function and features 6

1.3. Controller configuration 7

1.4. Technical data 8

1.5. Mounting of the modules 12

1.6. Electrical connection of the modules 12

1.7. Fusing of the controller modules 12

2. The monitoring function 15

2.1. Hardware setup 15

2.2. Function of the monitoring concept 16

3. Unit I/O configuration 17

3.1. Bidirectional and diagnostic I/O channels 17

3.1.1. Bidirectional inputs/outputs 17

3.1.2. Outputs with diagnostic functions 18

3.2. Fast inputs 19

3.3. The software control configuration 19

3.4. Wiring 19

4. States and operating system 21

4.1. Operating modes 21

4.2. Status LED 22

4.3. Loading the operating sytem 22

4.3. Operating modes 25

5. Error codes and error classes 27

5.1. Reaction to system error 27

6. CAN in the ecomat R 360 29

6.1. Technical specifications 29

6.2. Exchange of data via CAN 29

6.3. CAN errors and error handling 31

6.4. The physical CAN link 33

6.5. General remarks on the CAN utilization 36

6.6. Description of the CAN function blocks 38

6.7. CANopen in the ecomat R 360 44

6.8. The ecomat R 360 as CANopen slave 48

6.9. The ecomat R 360 as CANopen master 59

6.10. Functions for CANopen I/O modules from ifm electronic 78

page 3

Page 4

7. PWM in the ecomat R 360 87

8. Fast counters in the ecomat R 360 97

9. Other functions in the ecomat R 360 101

9.1. Software reset 101

9.2. Save data in memory and read 102

9.3. Use of the serial interface 106

9.4. Reading the system time 110

9.5. Processing of variables 112

10. Closed-loop control functions 113

10.1. Adjustment rule for a controller 115

11. Functions of the ecomat tdm R 360 127

11.1. Data exchange and variable definition 129

11.2. Setting and resetting of pictures and messages 134

11.3. The unit status and the LEDs 137

11.4. Unit control 144

Annex 1. Address allocation ecomat R 360 147

Annex 1.1. Complete overview 147

Annex 1.2. Inputs 149

Annex 1.3. Outputs 150

Annex 1.4. Allocation outputs – short-circuit and wire-break bits 151

Annex 1.5. The flag range in the ecomat R 360 152

Annex 1.6. CANopen unit interface ecomat R 360 153

Annex 1.7. Object list of the ecomat R 360 154

Annex 1.7.1. Data range communication profile, index 1000 to 1FFF 154

Annex 1.7.2. Range of manufacturer-specific data, index 2000 to 5FFF 161

Annex 1.7.3. Legend to object library 161

Annex 2. Wiring 163

Annex 2.1. Type CR0015 163

Annex 2.2. Type CR0016 164

Annex 2.3. Type CR0017 165

Annex 2.4. Type CR0501 166

page 4

Page 5

1. General

1.1. Safety instructions

Observe the information of the description. Non-observance of

the notes, operation which is not in accordance with use as

prescribed below, wrong installation or handling can result in

serious harm concerning the safety of persons and plants.

The instructions are for authorised persons according to the

EMC and low voltage guidelines. The controllers must be

installed and comm iss ioned by a skilled elec tric ian ( progr ammer

or service technician).

This description is part of the unit. It contains texts and drawings

concerning the correct handling of the controller and must be

read before installation or use.

If the unit is not supplied by the mobile on-board system (24V

battery operation) it must be ensured that the external voltage is

generated and supplied according to the criteria f or safety extralow voltage (SELV) as this is supplied without further m easures

to the connected controller, the sensors, and the actuators.

The wiring of all signals in connection with the SELV circuit of

the unit must also com ply with the SELV criteria ( safe extr a-low

voltage, safe electrical separation from other electric circuits).

If the supplied SELV voltage as an external connection to

ground (SELV becomes PELV) the responsibility lies with the

user and the respective national regulations for installation m ust

be complied with. All statements in these operation instruc tions

refer to the unit the SELV voltage of which is not grounded.

The terminals m ay only be supplied with the signals indicated in

the technical data or on the unit label and only the approved

accessories of ifm electronic gmbh may be connected.

The unit can be operated within a wide temperature range

according to the technical specif ication indicated below. Due to

the additional self-heating the housing walls can have high

perceptible temperatures when touched in hot environments.

page 5

Page 6

In the case of malfunctions or uncertainties pleas e contact the

manufacturer. Tampering with the units can lead to

considerable risks for the safety of persons and plant. It is not

permitted and leads to the exclusion of any liability and warranty

claims.

1.2. Function and features

The controller modules ecomat 100 series R 360 (in the

following text ecomat R 360) are for the user under harsh

operating conditions (e.g. extended temperature range, strong

vibration, intensive EMC interference). T hey are thus suited for

direct mounting into machines in mobile and rugged

applications. Due to their specification the inputs and outputs

are especially rated for this use. Integrated hardware and

software functions (operating system) offer high protection of

the machine.

The controller ecomat R 360 is approved for safetyrelevant tasks in the field of safety of persons if the

corresponding system test routines are integrated in the

operating system and the application software. The final

classification and the release of the system (hardware an d

software) can only be done by the proper supervisory

organisations. The programmer has to obtain information

about the special characteristics of the hardware and

software in the additional documentation which can be

obtained on request.

ifm electronic gmbh

Teichstr. 4

D 45127 Essen

Tel.: 0201 / 2422-0

Fax: 0201 / 2422-303

The application software can easily be created by the user with

the ecolog 100

All software functions and programming processes

described in this documentatio n refer to the ecolog 100

plus

software.

plus

programming software the knowledge of which is required

for this description.

The user also has to obser ve the software versions (especially

the operating system of the R 360 and the function libraries) that

is used. Software levels are marked by suffixed letters in

alphabetic order in the file names ( e.g. CR0015_B.DL or TDMA.LIB). When revising existing application projects the user

should find out about incompatibilities between the old and the

new versions.

page 6

Page 7

The user is responsible for the safe functioning of the

application programs which he creates himself. If

necessary, he must additionally obtain an approval

according to the corresponding national regulations by the

relevant testing and supervisory organisations.

1.3. Controller configuration

The ecomat R 360 is a customer or application-specif ic conc ept

for series use which m eans that the control modules have the

optimum configuration to the application. If necessary, special

functions and special hardware solutions can be accomplished.

In general: All descriptions and explanations in t his manual

are generally applicable to the controller system ecomat R

360. The appropriate contro ller configuration f or the uni t in

use is to be loaded in the programming system (article

number of the unit, CRnnnn = file name controller

configuration CRnnnn_X).

Before using the controller modules you need to check the

availability of certain functions, hardware options, inputs and

outputs are available in the hardware.

page 7

Page 8

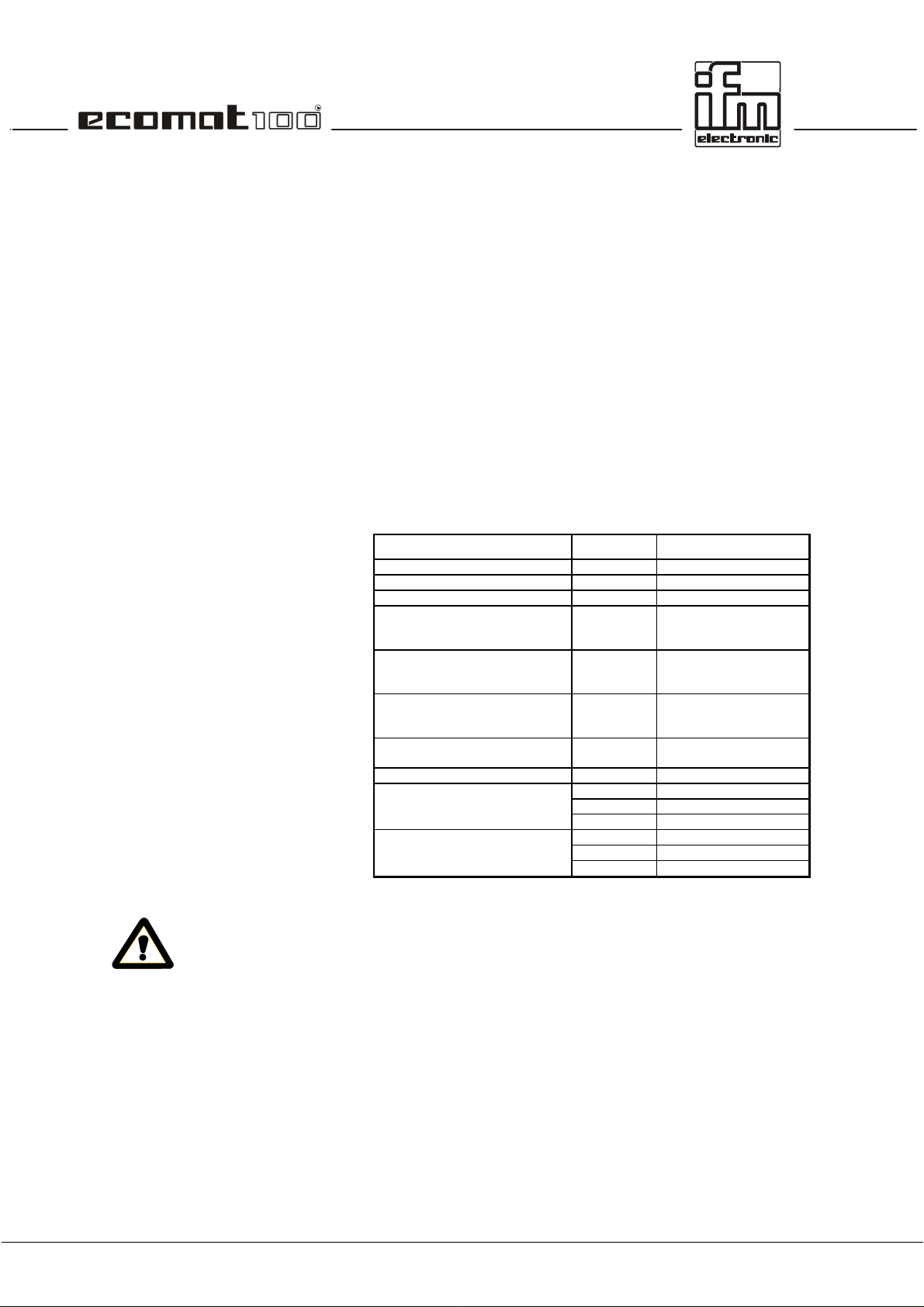

1.4. Technical data

Housing:

Housing dimensions:

Mounting position:

Connection of the unit:

Operating temperature:

Storage temperature:

Protection rating:

Protection class:

Air humidity:

Supply voltage:

closed, screened metal housing with flange fastening

225 x 153 x 43 mm (WxHxD), without connector

240 x 153 x 43 mm (WxHxD), with connector

preferably vertical, alternatively horizontal

55-pin connector, latched, protected against reverse polarity,

AMP pr Framatom type housing with crimp connection contacts

AMP junior timer 0.5/2.5 mm

2

-30°C ... +75°C

-40°C ... +90°C

IP67 (protection for connector, depending on cable version)

III

≤

90% rel. air humidity, non-condensing

U

nominal 12 or 24 V DC (-10% ... +25%)

B

See type label (reverse polarity protection through connector)

residual ripple:

≤

1.5 V

, f ≤ 50Hz

pp

Power consumption:

Processor:

Display:

Device monitoring:

Memory:

Interface:

reset in case of undervoltage 12 V unit:

reset in case of undervoltage 24 V unit:

overvoltage 12 V unit:

overvoltage 24 V unit:

≤

400 mA, without external load

≤

+ 9.6 V

≤

+12.0 V

≤

+ 17.5 V for t ≤ 10s

≤

+ 36.0 V for t ≤ 10s

CMOS microcontroller C 167C

two-colour-LED red/green for indication of status and error

8-bit microcontroller to m onitor the C 167C (extended watchdog

function)

check sum test for program and system

under and overvoltage monitoring, excess temperature

monitoring

256 kByte program memory

64 kByte data memory (volatile)

with 1 kByte data memory protected against voltage failure

(256 Byte auto-save)

CAN, Version 2.0 B (ISO/DIS-11898), 10 ... 1000 kBaud

protocol: CANopen or free communication profile

device class: CANopen master/slave; CAN: FullCAN

page 8

serial interface RS 232 C, 9,6 kBaud

number of participants: 2 (master/slave)

Page 9

Binary input

Low-Side (PNP):

Inputs IX0.0 ... IX0.7: switch-on level U

switch-off level U

≥ 10 V, I ≥ 3.3 mA

B

≤ 5 V, I ≤ 1.7 mA

B

input frequency 50 Hz

Inputs IX0.8 ... IX0.39: switch-on level 0.6 U

switch-off level 0.4 U

input frequency 50 Hz

Pulse inputs IX0.12 ... IX0.15: input frequency 50 kHz

Pulse inputs IX0.20 ... IX0.23: input frequency 50 kHz

Binary input

High-Side (NPN):

... 0.8 UB, I ≥ 6.7 mA

B

... 0.2 UB, I ≤ 1.7 mA

B

Inputs IX0.8 ... IX0.39: switch-on level 0.05 U

switch-off level 0.30 U

input frequency 50 Hz

Analog input

Low-Side:

Inputs IW9 ... IW16: input voltage +0 ... 10 V

input impedance

≥

50 k

resolution 10 Bit

accuracy

≤ ±

1.0 % FS

... 0.04 UB, I ≥ 7.7 mA

B

... 0.40 UB, I ≤ 5.1 mA

B

Ω

page 9

Page 10

Binary output

High-Side (PNP):

Outputs QX0.0 ... QX0.23: semiconductor output; short-circuit and overload protection,

diagnostic capability as an option

switching voltage 10 ... 17 V (12 V DC); 11 ... 32 V (24 V DC)

switching current 50 mA ... 2.5 A

overload current 5 A

sum current 10 A (per 8 outputs)

output frequency max. 100 Hz (depending on the load)

Outputs QX0.00 ... QX0.07 special specification as PWM output

output frequency max. 1000 Hz

PWM mark/space ratio 1 ... 99%

resolution depending on the PWM frequency

Binary output

Low-Side (NPN):

Outputs QX0.0 ... QX0.23: semiconductor output; short-circuit and overload protection,

diagnostic capability as an option

switching voltage 10 ... 17 V (12 V DC); 11 ... 32 V (24 V

DC)

switching current 50 mA ... 2.5 A

overload current 5 A

sum current 10 A (per 8 outputs)

output frequency max. 100 Hz (depending on the load)

page 10

Page 11

Input Test:

For the duration of the test operation (e.g. programming) the

connection needs to be connected to U

(supply).

B

For ”RUN” operation the input needs to be disconnected from

(supply).

U

B

Output Error (pin 13):

Relay output:

Housing drawing:

semiconductor output; short-circuit and overload protection

switching voltage 10 ... 17 V (12 V DC); 11 ... 32 V (24 V DC)

switching current 10 mA ... 100 mA

overload current 0.5 A

internal relay output

used in series with (max. 12 outputs the power supply of which

is interrupted on detection of an error by hardware or user

program

On principle, the unit should be switched load-free.

switching current 100 mA ... 15 A

overload current 20 A

no. of switching

operations (load-free)

response time

≥

≤

6

10

3 ms

page 11

Page 12

1.5. Mounting of the modules

In order to expose the controller modules to the minimum

mechanical stress they should preferably be mounted

horizontally or vertically on the mounting panel. The module

must be fixed with four scr ews to DIN 7500 or DIN 7984 (M5 x

L).

If possible, the modules s hould be mounted in such a way that

the cable entry of the plug points downwards.

1.6. Electrical connection of the modules

Before comm issioning it m ust be ens ured that the f ollowing pins

must/can be connected to the corresponding potentials.

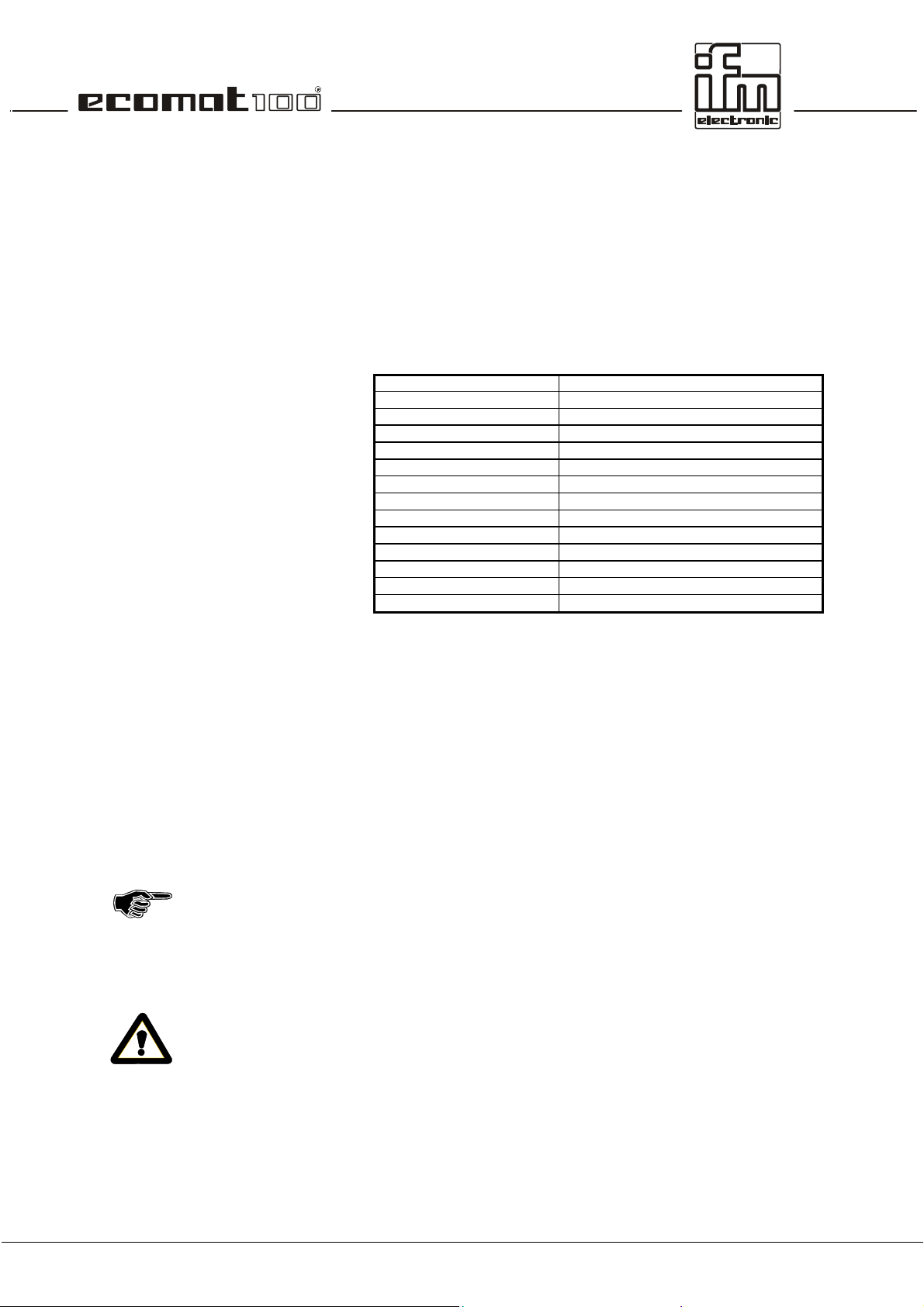

Designation Pin No. Potential

Supply voltage 23 (VBBS) + 24 V DC

Ground 01 (GNDS) GND

Analog ground 12 (GNDA) GND

Supply voltage

outputs High-Side

without monitoring relay

Supply voltage

outputs High-Side

with monitoring relay

Supply voltage

outputs Low-Side

without monitoring relay

Test input,

programming mode

Test input, operating mode 24 (Test) open

Programming interface RS 232 06 (RxD) Pin 03, PC 9pin SUB-D

CAN interface 14 (CANH) CANH further participant

05 (VBBo) + 24 V DC

34 (VBB

15 (GNDo) GND

24 (Test) + 24 V DC

07 (TxD) Pin 02, PC 9pin SUB-D

33 (CM5) Pin 05, PC 9pin SUB-D

32 (CANL) CANL further participant

33 (CM5) GND further participant

) + 24 V DC

R

page 12

To guarantee the electrical interference protection of the

controller modules, the housings must be connected to

the ground of the vehicle.

1.7. Fusing of the controller modules

In order to protect the whole system (cabling and controller ) the

individual circuits must be fused accordingly, tak ing into ac c ount

the total current of 10 A of the individual output modules (max. 8

outputs – e.g. QX0.08 ... QX0.15).

Page 13

If an output terminal receives current externally, e.g. for

bidirectional inputs and outputs, the output rail must not

be floating (i.e. open-circuit)

Reason

The supply voltage is fed back to the output rail via the

integrated protective diode in the output. If a second output

connected to the same potential is switched, the load of this

output is fed through the transistor of the first output thus

causing the first output to overload and fail.

This needs special attention when unit and output voltage

supply are fused separately and when the output rail VBB

R

switched off by the software via the integrated relay. If

necessary, the supply voltage should be monitored via the

appropriate hardware and software measures.

is

page 13

Page 14

page 14

Page 15

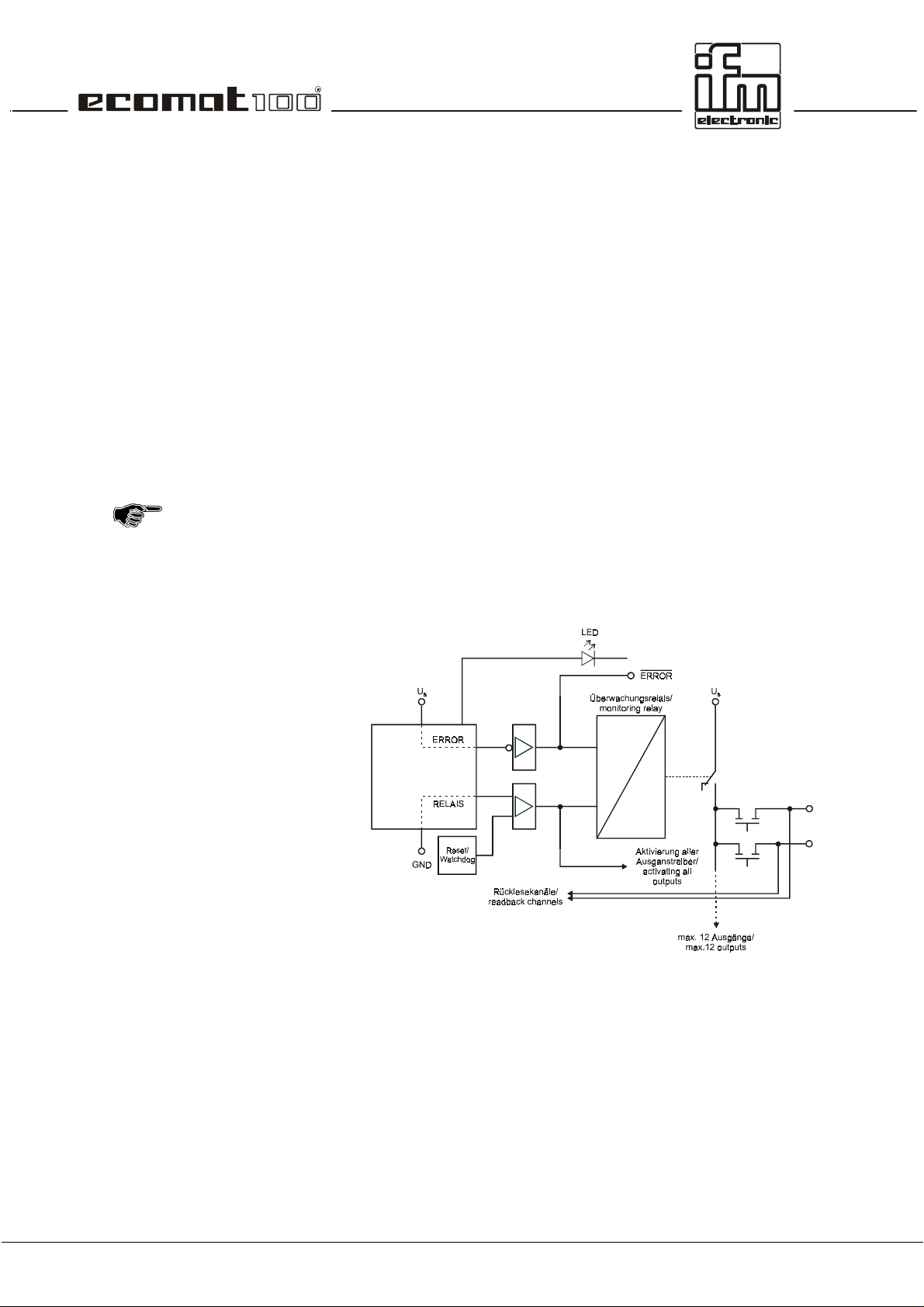

2. The monitoring function

The safe operation of the controller outputs is ensured by the

monitoring function.

2.1. Hardware setup

The relay is triggered on two channels via the µcontroller. For

this purpose the negative channel is triggered by means of an

AND link of the watchdog signal (internal µcontroller m onitoring)

and the RELAY bit with a semiconductor switch. The positive

channel is only triggered by means of the ERROR bit via a

semiconductor switch. In the activated state the outputs to be

disconnected (max. 12) are connected to the supply voltage via

the relay contact (not forced)

In addition the output signal of the semiconductor switch has the

logical effect of a release signal for all outputs. These outputs

are only switched externally after the RELAY bit has been set.

Therefore the RELAY bit has to be set even if there is no

RELAY integrated in the hardware.

Schematic of the monitoring concept.

page 15

Page 16

2.2. Function of the monitoring concept

While the progr am is running the monitoring relay is under the

complete control of the software user. A parallel contact from

the safety circuit for example can be evaluated as an input and

the monitoring relay can be switched off. For further safety the

appropriate national regulations must be applied.

If a µcontroller error occurs while the program is running the

watchdog signal switches the relay off so that important par ts of

the plant can be protected.

When creating the program the programmer has to make

sure the program is left in a safe state (so that automatic

operation is reset) in the case of an internal (e.g. watchdog)

or external error (e.g safety circuit). For this purpose the

outputs in question have to be switched off by software.

If an output to be monitored is permanently switched and the

contact of the monitoring relay is welded it is not possible to

switch off this output. However, since the relay is always

switched load-free in normal operation, the contact wear is ver y

low.

page 16

Page 17

3. Unit I/O configuration

The unit I/O configurations des cribed in the annex are available

as standard units (ex stock). They cover the required

specifications for most of the applications.

Depending on the customer’s requirements for series

applications it is possible to realise other configurations, e.g.

regarding the arrangement of inputs and outputs and the design

of the analog channels.

The software functions described in this documentation only

apply to standard configurations. For customer-specific units

the specific hardware versions and additional software

description (additional documentation) have to be observed.

3.1. Bidirectional and diagnostic I/O channels

The inputs/outputs of the R 360 can be designed as

bidirectional input/output channels or for readback functions

(diagnosis, wire-break monitoring, short-circuit monitoring). At

the terminal the input and output or the output with the

corresponding readback c hannel (readback input) are available

simultaneously.

For safety-relevant applications outputs with readback

function (diagnostic outputs) are to be used.

3.1.1. Bidirectional inputs/outputs

The connection can be used as an input or an output. The input

can be read via the software at any time.

page 17

Page 18

This function is based on the condition that in the controllers

high-side outputs are combined with low-side inputs or low-side

outputs are combined with high-side inputs so that no conf licts

can occur, i.e. short circuit via the switched output transistor and

closed switch at the input.

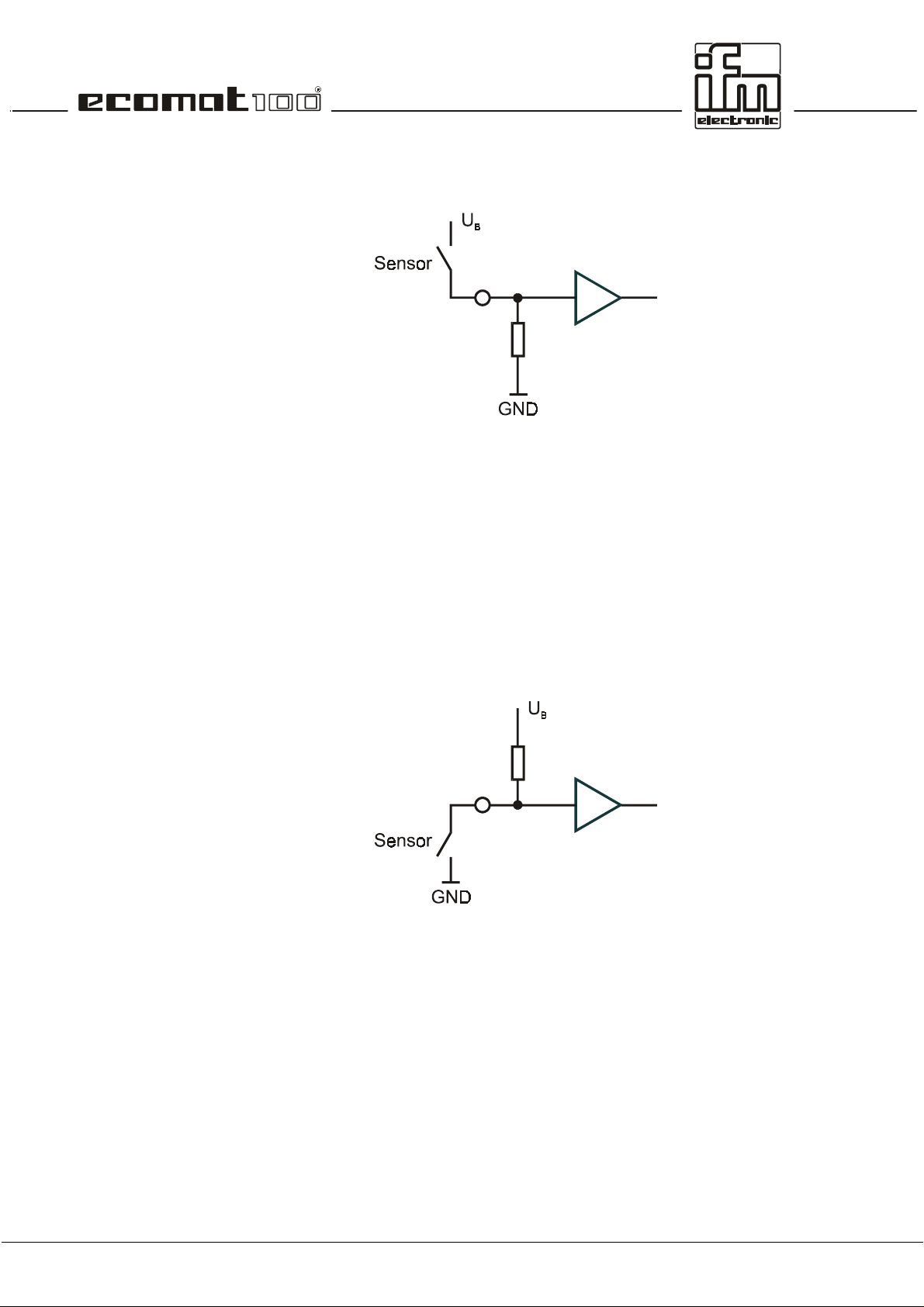

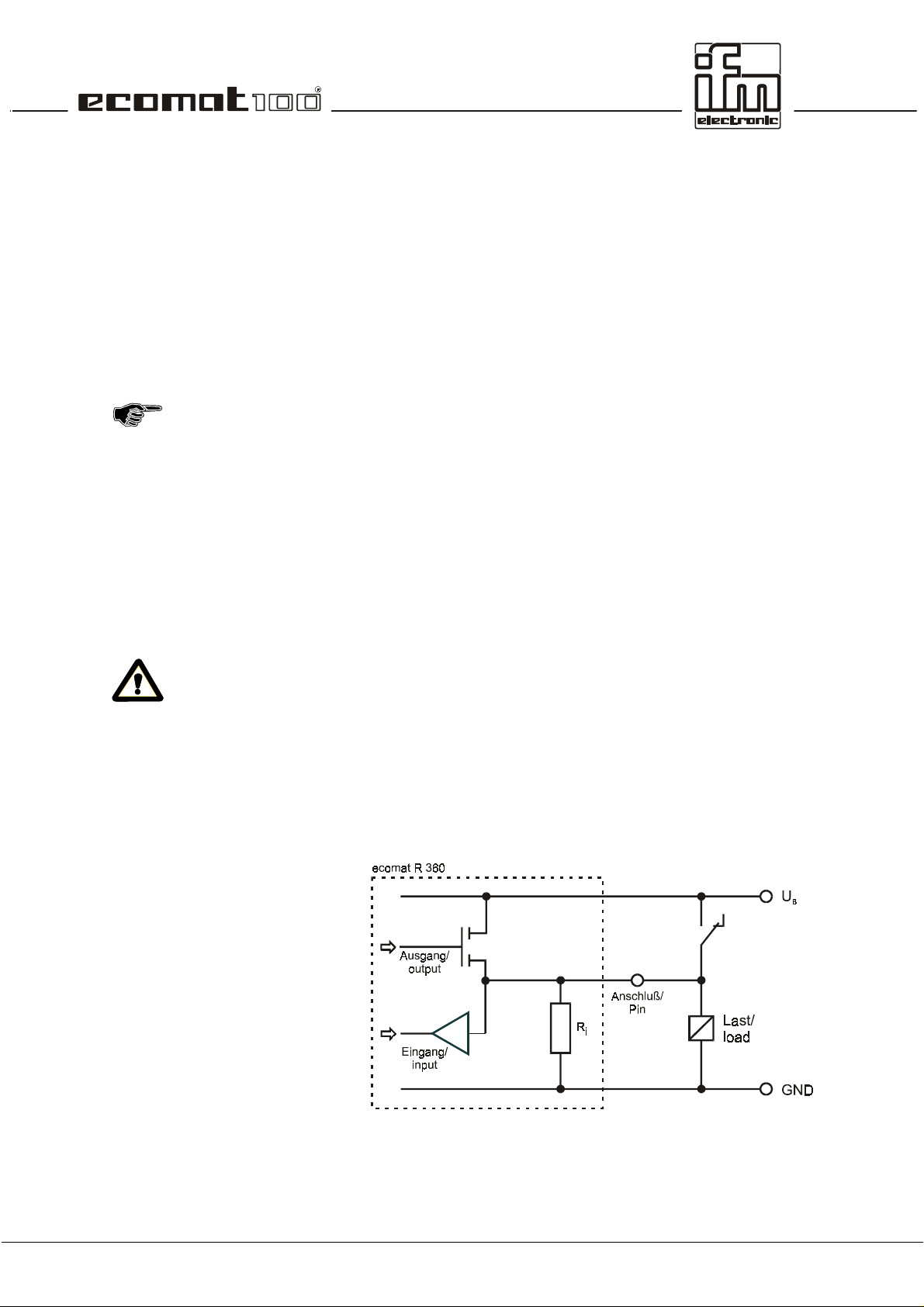

The block circuit diagram shows:

•

The load connected to the output can also be triggered

manually via the switch. The position of the switch can only

be detected when the output is blocked.

(Insert suppressor circuit via the load)

•

Short-circuit detection (overload) is also possible via the

input channel when the switch is open. The LOW (logic 0) is

read in when the output is switched.

In the case of a short circuit (overload) the output transistor

switches off automatically. For safety reasons it does not

switch on again automatically when the short circuit has been

removed. The output has to be switched off and then on

again via the software

•

Wire-break detection is not possible with this input/output

configuration.

3.1.2. Outputs with diagnostic functions

The connection can be used as an input as well as an output.

The input can be read at any time via the software.

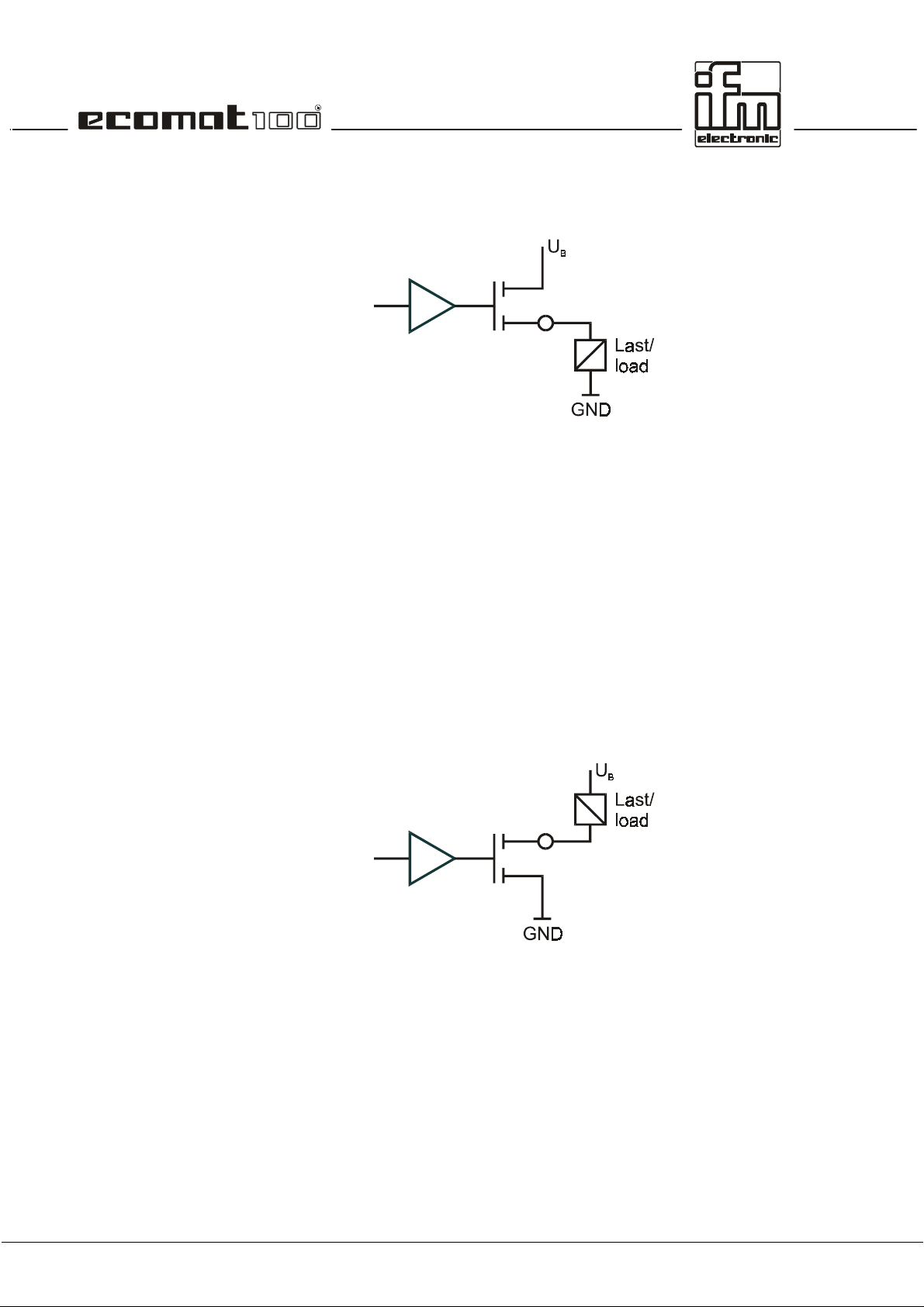

This function is based on the condition that in the controller

high-side outputs are combined with high-side inputs or low-s ide

outputs with low-side inputs.

page 18

Page 19

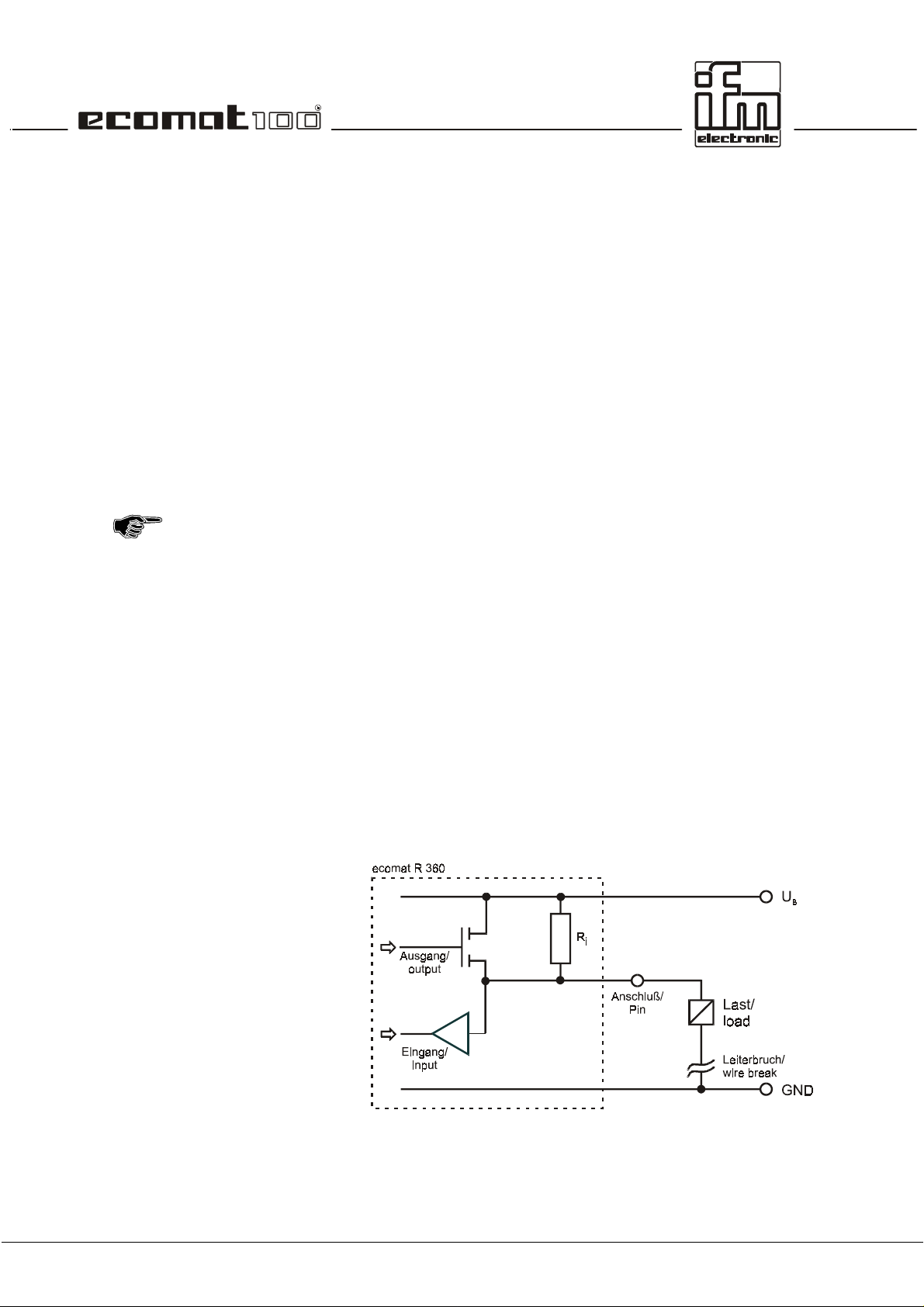

The block circuit diagram shows:

•

Short-circuit detection (overload) is possible via the input

channel. When the output is s witched the LOW (logic 0) can

be read in.

The output transistor automatically switches off in the case of

a short circuit/overload. For saf ety reasons it does not s witch

on again automatically. Therefore it has to be switched off

and then switched on again.

•

Wire- break detection is poss ible via the input channel. When

the output is blocked HIGH (logic 1) is read in as the resistor

pulls the output to HIGH potential (VBB). W ithout the wire

R

i

break the low-resistance load (R

< 10 k

L

Ω)

would force

(logic 0) LOW.

3.2. Fast inputs

In the controller modules the standard unit conf igurations have

an input frequency up to 50 kHz via 8 fast count/pulse inputs. If

e.g. mechanical switches are connected to these inputs , contact

bouncing might cause wrong signals in the controller. These

"error signals" have to be filtered out with the application

software, if required (see example program).

3.3. The software control configuration

For each hardware configuration the corresponding software

control configuration has to be loaded in the programming

system. For the programming system it repr esents the interfac e

to the hardware.

The software control configuration also provides the user with all

important system and error flags. Depending on the application

program they have to be processed and evaluated. They can be

accessed with their symbolic names or the IEC addresses.

3.4. Wiring

The wiring shown in the annex describes the standard unit

configurations. The wiring helps to assign the input and output

channels to the IEC 1131 addresses and the unit terminals.

page 19

Page 20

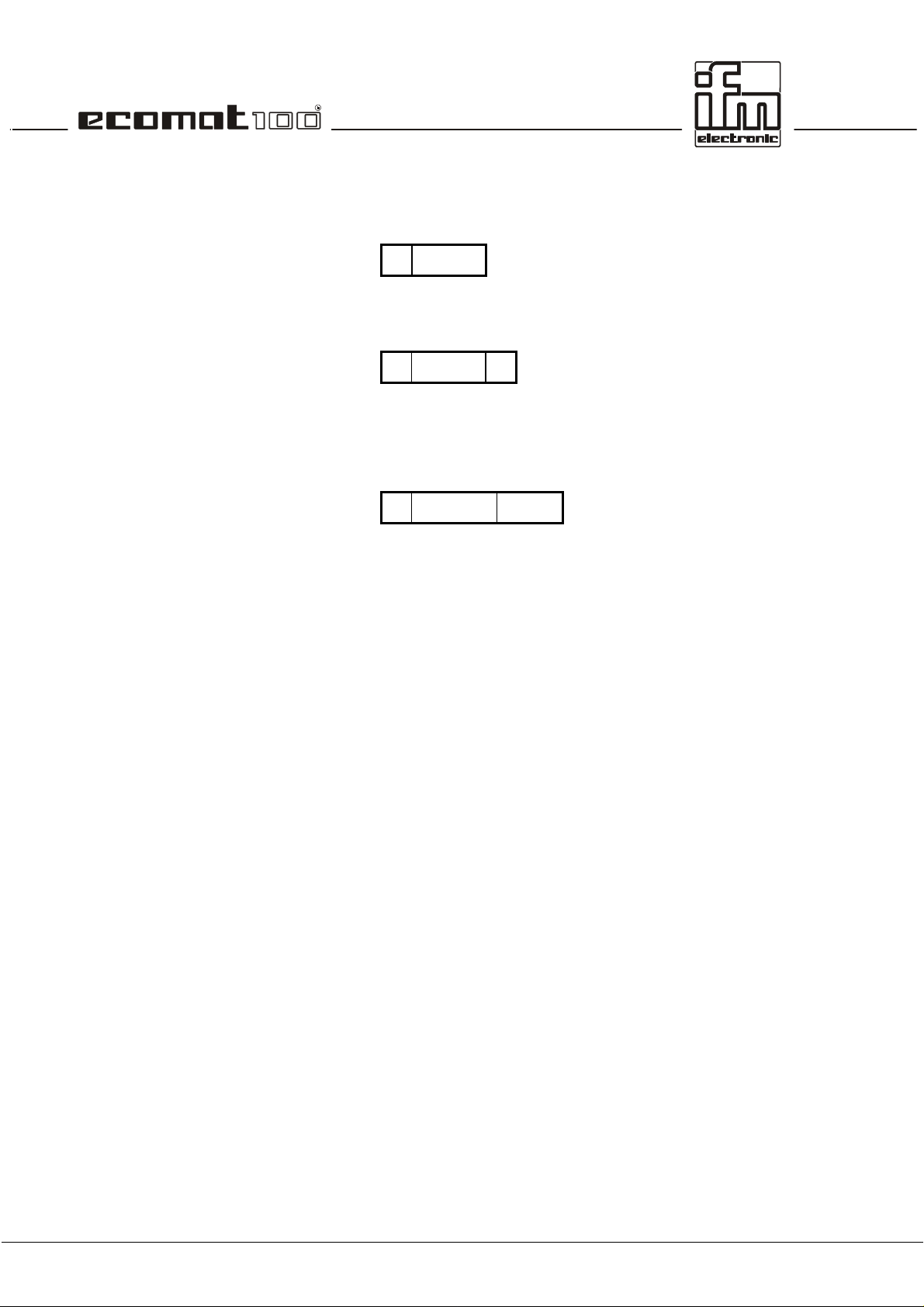

Labelling of the input/output channels:

12

GND

A

12 pin number

GND

A

pin description

30 %IX0.07 BL

30 pin number

%IX0.07 IEC address for a binary input

BL hardware design of the input

(here binary low-side)

47 %QX0.03 BH/PH

47 pin number

%QX0.03 IEC address for a binary output

BH/PH hardware design of the output

(here binary high-side or PWM high-side)

The abbreviations have the following meanings:

A analog input

BH binary input/output, high-side

BL binary input/output, low-side

PH PWM output, high-side

PL PWM output, low-side

IH pulse/counter input, high-side

IL pulse/counter input, low-side

R readback channel for an output

Allocation of the input/output channels:

Depending on the unit configuration an input and/or output is

available at a unit terminal.

Channels that can be used as inputs and outputs

simultaneously (bidirectional inputs/outputs) are highlighted

page 20

Page 21

Reset

Run

Stop

Fatal Error

No operating system

4. States and operating system

4.1. Operating modes

When the s upply voltage is applied, the controller module may

be in one of 5 possible operating modes:

This status is run through after each power-on reset. The

operating system is initialised. Diff erent checks ar e carried out.

This status is only temporary and is superseded by the run

status.

!"

The LED is lit red for a shor t time (is lit orange starting with

software version CRxxxx_G).

This status is reached:

•

from the reset status (Autostart)

•

from the stop status by means of the run command

prerequisite: test mode

•

with the CANopen NMT master via the function

PREOPERATIONAL or OPERATIONAL

!"

The LED flashes green or red (RUN with error)

This status is reached:

•

from the reset status if no program is loaded

•

from the run status by giving the stop command via the

interface

Prerequisite: test mode

•

with the CANopen NMT master via the function

PREPARED.

!"

The LED is constantly lit green or red (stop with error)

The controller passes into this status if a non-tolerable error is

found. This status can only be left via a reset.

!"

The LED is off (is lit red starting with software version

CRxxxx_G).

No operating system has been loaded, the controller is in the

bootloading status. Before loading the application software a

download of the operating system must be carried out.

!"

The LED flashes green (fast).

page 21

Page 22

4.2. Status LED

These operating states are shown with the integrated status

LED.

LED colour Flash frequency Description

LED off constantly off Fatal Error

green 5 Hz no operating system loaded

green 0.5 Hz Run, CANopen: PREOPERATIONAL

2.0 Hz Run, CANopen: OPERATIONAL

constantly on Stop, CANopen: PRERPARED

red 0.5 Hz Run w. error (CANopen: PREOPERATIONAL)

2.0 Hz Run w. error (CANopen: OPERATIONAL)

100 %

Reset checks or stop with error

The operating states STOP (PREPARED) and RUN (PREOPERATIONAL / OPERATIONAL) can be changed by the

programming system or the network master.

The user program is process ed in the RUN s tate. The controller

only takes part in the CANopen communication (PDO

processing, see chapter 6) when it is set to OPERATIO NAL. To

see the current operating state in the application program the

user can evaluate the flag COP_PREOPERATIONAL. The f lag

is TRUE when the state is PREOPERATIONAL, otherwise it is

FALSE.

4.3. Loading the operating sytem

When the unit is shipped an operating s ystem is in general not

loaded in the controller (LED flashes green at 5 Hz). In this

operating state only the boot loader is active. It provides the

minimum functions for the loading process of the operating

system (e.g. the support of the serial and the CAN interface).

In General, the download of the operating system only has to be

carried out once. The application program can then be loaded in

the controller (even several times). The advantage of this

process is that the EPROM does not need to be r eplaced for an

operating system update and that customer-specific operating

system can be realised for certain applications.

The operating system is provided together with this

documentation on a separate data carrier.

page 22

Page 23

Operating system download

New controller

Operating system update

The programmer has to ensure that the same so ftw are lev el

of the operating system (CR..._x.H86), of the controller

configuration (CR..._x.M66) and the unit library (CR..._x.LIB)

are used. If not, an error message is g enerated during the

download of the application software. Software states are

marked by suffixed letters in alphabetical order in the file

name (e.g. CR0015_B.H86). The basic file always has to be

the same.

The operating system and the application software are loaded

directly from the programming system. The download can be

carried out via the serial and via the CAN interface. The

following points have to be observed:

On delivery, the controller module does not contain an oper ating

system. When the supply voltage is applied it therefore goes

into the state "No operating system loaded". Only the bootloader

is active

!"

For downloading activate the controller configuration screen

via the button or via the menu item

Configuration.

!"

The requested controller configuration (CR..._x.M66) is

called via the menu item

!"

The connection between controller and PC can then be

established with

connection is made depends on the setting in

(serial or CAN) and the following param eterisation of

Config

the PC interface under

Parameters..

A communication connection to the controller is only

established when a project is loaded and when this is

translated without errors.

!"

The download process is started by select ing the m enu item

Extras / Load Hex file

screen

The new controller configuration file has to be used for all

application programs to be loaded in the controller.

In general, a new operating system software can be loaded in

the controller at a later time. T his process corresponds in most

parts to the one described above.

As opposed to the delivery sate of the controller, an operating

system is loaded, i.e. the controller is in the STOP or RUN

mode.

!"

The controller configuration of the operating system loaded

at current time is activated s o that the programming system

can establish the connection between controller and PC.

PLC Configuration

Online / Login

.

Insert / Firmware.

. The interface via which the

Online / Communication

and select file (CR..._x.H86) in the

.

Window / PLC

Extras / HW-

page 23

Page 24

!"

The controller configur ation sc r een is activated via the button

or via menu item

!"

The requested controller configuration (CR..._x.M66) is

called via menu item

!"

The connection between controller and PC is establis hed via

Online / Login.

connection depends on the setting in

(serial or CAN) and the subsequent param eterisation of the

PC interface under

It does not matter which project file is loaded (as long as

the project can be booted with routine PLC_PRG). The

translation processes started with the login can be

ignored. The system message:

Program has changed! Do you want to download the

Window / PLC Configuration.

Insert / Firmware

The serial interface for establishing the

Online / Communication Parameters..

.

Extras / HW Config

.

new program?

can be answered with NO.

!"

Menu item

Configuration

controller. The LED of the controller m odule flashes fast (5

Hz).

!"

Then reset the controller since the online connection

between PC and controller does no longer exist after the

operating system has been deleted.

!"

After the reset the new operating system can be loaded. T he

process is the same as for "New controller".

The new controller configuration file now has to be used f or all

application programs to be loaded in the controller from now on.

Extras / Load Hex file

deletes the current operating system in the

in the screen

PLC

page 24

Page 25

4.3. Operating modes

Independent of the operating states the controller can be

operated in different operating modes. The c ontrol bits can be

set and reset via the application software or in test operation

with the programming software ecolog 100

Variables

).

Test

To get this operating mode apply a high level (supply voltage) to

the test input. In the RUN or STOP mode the controller can now

accept commands via one of the interfaces. The state of the

user program can be queried via the flag TEST.

Serial Mode

The serial interface is available for a data exchange in the

application. Debugging of the application software is only

possible via the CAN interface.

This function is switched of f as a default (FALSE). T he state of

the user program or the progr amm ing system can be c ontrolled

and queried via the flag SERIAL_MODE.

ISO Direction

This function switches between Send data and Receive data

when the ISO 9141 interface is used..

TRUE Send data

FALSE Receive data (standard setting)

The flag ISO_DIRECTION is used to switch the ISO 9141

diagnostic interface between ´Send data´ and ´Receive data´.

The ISO interface is a special form of a serial interface that

provides communication with the diagnostic interfaces in the

vehicle.

The use of the ISO interface requires hardware and software

adaptations which are not included in the standard units.

When the ISO interface is used the serial interface is not

available for program download and debugging. Program

download and debugging are

interface

.

only

The function is only available when the test input is 'open'.

plus

(window:

possible via the

Global

CAN

page 25

Page 26

page 26

Page 27

5. Error codes and error classes

In order to ensure maxim um operational reliability the operating

system carries out internal error check s in the controller during

the start-up phase (reset phase) and during the program

execution.

The following error flags are set in the case of an error:

Error Error description

CAN_INIT_ERROR CAN module cannot be initialised

CAN_DATA_ERROR CAN inconsistent data

CAN_RX_OVERRUN_ERROR CAN overrun, received data

CAN_TX_OVERRUN_ERROR CAN overrun, transmission data

CAN_BUS_OFF_ERROR CAN not on the bus

CAN_ERROR CAN-Bus collective error bit

ERROR collective error bit (general)

ERROR_MEMORY memory error

ERROR_POWER under/overvoltage error

ERROR_TEMPERATURE excess temperature error (> 85°C)

COP_SYNCFAIL_ERROR SYNC object was not transferred

COP_GUARDFAIL_ERROR Guarding object is missing (only in the slave)

COP_GUARDFAIL_NODEID number of missing slave (only in the master)

5.1. Reaction to system error

It is the programmer's responsibility to react to error flags.

The specific err or bits should be proc essed in the user program

and then have to be reset. The error bit provides an error

description which can be further processed if required.

In the case of severe errors the ERRO R bit can be set causing

the operating LED to light red, the error output (pin 13) to be set

to LOW and the m onitoring relay (if there is one) to be switched

off. The protected outputs are de-energised.

The logic link via the relay bit ( see chapter 2) also sw itches

off all other outputs.

Depending on the application it has to be decided if the relay

and thus the outputs can be switched on again by resetting the

ERROR bit.

When using CAN for communication the function

CAN_ERRORHANDLER should be used. Thus all CAN errors

are detected as a collective error, are counted and CAN is

started again.

page 27

Page 28

Example

In addition, it is also possible to set the ERROR bit of "free

defined errors" via the user program.

In normal operation the relay should only be switched loadfree, so the function must o nly be used in an "emergency"

for a general switching-off of the outputs.

In order to reset all outputs in "normal operation" this function

should be accomplished via s uitable BIT links, not by using the

relay.

A CAN-BUS-OFF error occurs.

The operating system sets the CAN-BUS-OFF-ERROR bit.

The user program detects this state by polling the

corresponding bits.

If required the ERROR bit can be set:

As a result the operating display LED flashes red and the safety

relay is de-energised switching off all outputs. T he level of the

error output becomes low.

The error is removed by restarting CAN via the function call

CAN_RESTART. The CAN-BUS-OFF-ERROR bit is deleted

automatically.

If required the ERROR bit has to be deleted via the user

program. The relay energises again, the LED flashes green.

page 28

Page 29

6. CAN in the ecomat R 360

6.1. Technical specifications

Bus type: FULL-CAN

Physical layer: ISO/DIS 11898

Baud rate: 10 kBit/s ... 1 MBit/s

Protocol: CANopen

free protocol

2048 data objects in the system (CAN specification 2.0B)

Identifier use

System configuration

Only

The ecomat R360 is delivered with the device identifier 254 (ID

1 ... 2048 identifiers freely available for the data transfer

From these the following identifiers are reserved:

220 ... 221 reserved for the display tdm R 360

223 ... 252 device identifiers of the participants

254 device identifier of an unconfigured module

255 identifier of the download system (e.g. PC)

32) as participant 0. The download system uses this identifier

for the first communication with an unconfigured module.

one

unconfigured module may be connected with the

network. After the new participant number 1 ... 30 (corresponds

to the node identifier 1 ... 30) was assigned via the programming

software, a download or debugging can be performed and

another device can be integrated into the system (also see

section 6.5).

6.2. Exchange of data via CAN

The exchange of data via CAN is based on the internationally

standardized CAN protocol of the data link layer (level 2) of the

7-layer ISO/OSI reference model according to ISO 11898.

Each bus participant can send messages (multi-master

capability). The exchange of data operates sim ilar to r adio. Data

are sent to the bus without sender or address. The data are only

qualified by their identifier. It is the job of each participant to

receive the transmitted data and to check by means of the

identifier whether the data are relevant for this participant.

page 29

Page 30

This operation is automatically carried out by the CAN controller

in conjunction with the operating system. To avoid processing

each CAN message it is possible to only let a certain part of the

bus data reach the CAN controller by indicating a so-called

acceptance mask (CAN_ACCEPTANCE). The use of this

special function only makes sense if data are not relevant for

certain bus participants and time optim ization in a plc module is

absolutely required for CAN processing. To employ this function

hardware knowledge of the CAN controller is necessary. This

information is provided in the m anufacturer's documentation or

can be obtained from the technical support of ifm electronic

gmbh.

For the normal exchange of data via CAN the programm er only

has to inform the system of the data objec ts with their identif iers

by means of the functions CAN_RECEIVE and

CAN_TRANSMIT when designing the software. Via these

functions the RAM address of the oper ating data, the data type

and the selected identifier are combined to form a data object.

They then participate in the data exchange via the CAN bus.

The transmit and rec eive objects can be defined from all valid

IEC data types (e.g. BOOL, WORD, INT, ARRAY).

The CAN message consists of an identifier and max. 8 data

bytes. The identifier can be freely selected between 1 and 2048.

As already mentioned, it does not represent the sender or

receiver module but qualifies the message. To trans mit data it is

necessary that in the sender module a transmit object is

declared and a receiver object in

Both declarations must be assigned to the same identifier.

Receive data

Transmit data

The transmission order is rej ected if the controller is not ready

By calling the function CAN_TRANSMIT the application

In principle, the received data objects are automatically stored in

a buffer (i.e. without the user's influence).

A buffer (queue) is available f or each identifier. It is em ptied by

means of the function CAN_RECEIVE to the FIFO principle

(First In, First Out) depending on the application software. In the

queue

data transmissions can only be stored after the buffer has been

emptied. The reception of a new CAN message leads to

overflow of the queue, which is indicated to the user by the

OVERFLOW bit.

program transfers exactly one CAN message to the CAN

controller. As feedback you receive the inform ation whether the

message has been successfully transferred to the CAN

controller which then perform s the actual transfer of the data to

the CAN bus.

because it is in the process of transferring a data object. The

transmission order must then be repeated by the application

program. This inf o rmation is indicated to the user by m eans of a

bit.

max. 30

data transmissions are s tored tem porarily. More

at least one

other module.

page 30

Page 31

6.3. CAN errors and error handling

The error mechanisms described below are automatically

processed by the CAN controller integrated in the plc. This is not

influenced by the user. He must/should only react to errors

signalled in the application software.

Goal of the CAN error mechanisms:

•

Ensuring uniform data objects in the whole CAN network

•

Permanent function of the network also in case of a faulty

CAN participant

•

Distinction between temporary and permanent disturbance of

a CAN participant

•

Locating and automatic switch-off of a f aulty participant in 2

steps (error-passive, bus-off). This gives a temporarily

disturbed participant a "break".

To give the interested user an overview of the operating

characteristics of the CAN controller in case of an error, a

simple description of the error handling will be given below. After

the error detection the information is processed automatically

and is available to the programmer as CAN error bits in the

application software.

Error message

Error counters

However, in case of an error these error counters are

If a bus participant detects an error condition, it immediately

sends an error flag, thus causing the abort of the transm ission

or rejection of the correct messages already received by the

other participants. This ensures that all par tic ipants ar e provided

with correct and uniform data. Sinc e the er ror f lag is tr ansferr ed

immediately, the sender can immediately start to repeat the

disturbed message as opposed to other field bus systems

(which wait until a defined acknowledgement time has elapsed) .

This is one of the most important features of CAN.

One of the fundamental problems of the serial data transmission

is that a permanently disturbed or faulty bus participant can

block the whole system. This would be a danger especially for

the error handling method of CAN. To exclude this case, a

mechanism is required which detects a faulty participant and

switches it off from the bus, if necessary.

To do so, the CAN controller incor porates a transmission error

counter and a reception error counter. They are counted up

(incremented) for each erroneous trans m ission or r eception. If a

transmission was correct, these counters are counted down

again (decremented).

incremented more than they are decremented in case of no

error. During a certain time period this can lead to a s ubstantial

increase of the counts even if the number of undisturbed

messages is greater than the number of disturbed messages.

But longer time periods without errors reduce the c ounts again.

Thus the counts are a measure for the relative frequency of

disturbances.

page 31

Page 32

If a participant immediately detects an error it made (it is

responsible for the error), this participant is more severely

"punished" for the error than the other bus participants. To do

so, the counter is incremented by a higher amount. If the count

exceeds a certain value, it can be assu med that this par ticipant

is faulty. To prevent this participant from further disturbing the

bus communication by means of

active), it will become

error-passive

active error messages

.

(error-

Participant, error-active

Participant, error-passive

Participant, bus-off

The bus-off state can only be removed by a reset

An error-active participant takes part in the bus communication

without restriction and is allowed to signal detected errors by

sending the active error flag. As already described, this corr upts

the transferred message.

An error-passive participant is still capable of communicating

without restriction. But it is only allowed to signal an error it

detected by means of a passive error flag which does not

interfer with the bus operation. An error-passive participant

becomes again error-active if its count is again below a defined

value.

If the error count continues to increment, the participant is

switched off from the bus (bus-off) after a maximum count of

the participant has been exceeded.

(CAN_RESTART) of the CAN controller.

page 32

Page 33

But a detailed err or analysis can only be performed by means of

This is why the function CAN_ERRORHANDLER should be

used which registers all CAN error states and, if necessary,

resets the CAN controller. At the same tim e an error counter is

available to the application program. It could for example be

used to take further action depending on the c ount (e.g. error

LED).

an exact evaluation of the error bits.

6.4. The physical CAN link

The data transmission and error handling mechanisms

described in sections 6.2 and 6.3 are directly implemented in

the CAN controller. The physical link of the individual CAN

participants is described in layer 1 in ISO 11898.

Network structure

The standard ISO 11898 assumes a line-structured set-up of

the CAN network.

In addition, the line must be fitted with a terminating

resistor of 120

electronic's devices fitted with a CAN interface have no

terminating resistors.

Ideally, no spur should lead to the bus participants (node 1 ...

node n) because depending on the total cable length and the

transmission time reflections occur in the bus. To avoid this

leading to system errors, the spurs to a bus partic ipant (e.g. I/O

module) should not exceed a certain length. 2 m spurs are

considered to pose no problem. The sum of all spurs in the

whole system should not exceed 30 m. In special cases the

cable lengths of the line and the spurs must be accurately

calculated.

ΩΩΩΩ

at its two ends. In principle, ifm

page 33

Page 34

Bus level

l

Bus cable length

The CAN bus is in the inactive (recessive) state if the output

transistor pairs are switched of f in all bus par ticipants. If at leas t

one transistor pair is switched on, a bit is s ent to the bus which

then becomes active (dom inant). Thus a current flows through

the terminating resistors and generates a different voltage

between the two bus cables. The recessive and dominant states

are converted into corresponding voltages in the bus nodes and

are detected by the receiver circuits.

This differential transmission with a common return line

considerably improves the transmission safety. Interfering

voltages which affect the system externally or mass potential

offsets influence both signal lines with the same interfering

quantities. They are therefore ignored when the difference is

formed.

The bus cable length depends on the c haracteristics of the bus

connection (cable, connector), the cable resistance and the

necessary transmission rate (baud rate). As described above,

the length of the spurs mus t also be considered for the network

design. For the sake of simplicity, the following dependence

between bus length and baud rate can be assumed.

page 34

Page 35

Wire cross-sections

For the design of the CAN network the wire cross-s ection of the

bus cable used must be tak en into account. The following table

describes the dependence of the wire cross-sections on the

number of the bus participants refer red to a transmission rate of

1 Mbit/s and a maximum cable length of 40 m (cable r esistance

r = 70 mΩ/m).

Cable length 32 bus nodes 64 bus nodes 100 bus nodes

100 m

250 m

500 m

0.25 mm2 0.25 mm2 0.25 mm2

0.34 mm2 0.50 mm2 0.50 mm2

0.75 mm2 0.75 mm2 1.00 mm2

Depending on the EMC requirements the bus cables can be laid

in parallel or as a twisted pair with or without screen.

page 35

Page 36

6.5. General remarks on the CAN utilization

If in connection with the plc ecomat R 360 CAN or CANopen is

used, some points must be taken into account. They concern

the physical structure of the CAN network and the correct

software handling.

Physical network structure

Software for CAN and CANopen

The following points must be considered:

The following applies to the CAN network structure:

•

Ensure that the selected data transmiss ion rate is not higher

than needed. A low transmission rate increases the

operational reliability.

•

The cable length must match the data tr ansm ission rate. For

R 360 it is typically 400 m at 125 kBaud.

•

Lay the bus cable in a line and avoid spurs. Ensure clean

and firm terminal locations to avoid unnecessary contact

resistance. If necessar y, lay the cables as a twisted pair with

or without a screen.

•

Fit both ends of the bus cable with a terminating resistor of

120 Ω.

•

The higher the number of the partic ipants in the network , the

more carefully the network m ust be laid out (cable version,

cable length, etc.).

In principle, R 360 can directly take part in the CAN

communication (layer 2) by using the functions

CAN_TRANSMIT and CAN_RECEIVE. In the CANopen mode

the programmer is supplied with the defined services.

•

In the direct CAN mode in layer 2 the programmer is

responsible for all services. The plc is in this state after a

program download or a reset com mand by the programm ing

system.

•

For the direct CAN mode the cyclical integration of the

function block CAN_ERRORHANDLER is recommended.

Otherwise, the application program must perform a

CAN_RESTART in the case of BUS_OFF.

•

After a program download or a reset command by the

programming system the plc is not yet a CANopen device.

To change to the CANopen mode the flag CAN_OPEN mus t

be set at the start of the program. The R 360 then operates

as a CANopen slave.

•

If a R 360 slave is stopped via the pr ogramming sof tware, a

following node start command of the CANopen master is

ignored. However, a stop command of the master

(NMM_SET_PREPARED) is always executed.

page 36

Page 37

•

In case of a missing guarding reply of the R 360 slave the

master continuously sends node resets. This can lead to

problems when logging on the program ming system via the

CAN interface. In this case the master must be switched

off.If the R 360 is also to operate as a CANopen master , it

must be initialized with the function

NMM_SET_NMT_MASTER.

If the plc is stopped (via PC), it retains the CANopen

functions, but the master functions are interrupted (e.g. no

SYNC message).

•

All participants of the CAN network m ust be clearly assigned

a module ID.

Device IDs in the ecomat R 360

To communic ate with the participants in the CAN network each

must have a defined device identifier. It is of no importance

whether the plc is used as network mast er, as CANopen slave

or for the direct CAN com munication. Make also sure that the

device identifiers do not overlap with the IDs of the I/O modules.

The ecomat R 360 is supplied with the default ID 32 (under

CANopen). In the programming software ecolog 100

plus

the

node ID 32 is designated as the module ID no. 0.

Module ID

ecolog 100

plus

Node ID

CANopen

Device ID

debugger

(default) 0 (unconf.) 32 0xFE

1 1 0xDF

2 2 0xE0

3 3 0xE1

: : :

29 29 0xFB

30 30 0cFC

The device ID can be assigned online via ecolog 100

plus

.

page 37

Page 38

6.6. Description of the CAN function blocks

The CAN function block s for use in the application program will

be described below.

To utilize the full functions of CAN it is absolutely required for

To be able to set up a communication link the same

Example program

the programmer to create a precise bus c oncept before starting

to work. The number of the data objects with their identifiers

must be defined as well as a reaction to possible CAN errors.

Also, the frequency with which data must be transm itted has to

be taken into account. So the functions CAN_TRANSMIT and

CAN_RECEIVE must be called just as frequently. The

programmer must additionally monitor whether his transmission

orders have been passed on succ essfully to CAN_TRANSMIT

(bit RESULT) or must make sure that the data received are read

from the data buff er of the queue with CAN_RECEIVE and are

immediately processed in the program.

transmission rate (baud rate) must first be s et f or all partic ipants

of the CAN network. For the R 360 this is done with the function

CAN_BAUDRATE.

An example program in function block diagram (FBD) is stored

on the program diskette ec olog 100

plus

(CAN 3_66.PRO). In this

example data objects are exchanged with another CAN

participant via the identifiers 1 and 2. To do so, the other

participant must have a receive identifier for the transmit

identifier (or vice versa).

The function CAN_ACCEPTANCE is not f urther descr ibed here

because the application requires thorough hardware knowledge

of the CAN controller. Users who need this spec ial feature are

requested to contact the technical support.

page 38

Page 39

Function

Library CRxxxx.LIB

Function symbol

Purpose

Parameters

Function outputs, none

Description

CAN_BAUDRATE

Sets the transmission rate for the bus participant.

Function inputs

Name Data type Description

ENABLE BOOL TRUE: The function is processed.

BAUDRATE WORD Value of the baud rate to be set in kBit/s

With the func tion CAN_BAUDRATE the transm ission rate is set

for the plc module. To do so, the corresponding value in kBit/s is

indicated at the function input BAUDRATE. After the exec ution

of the function this new value is stored in the device and is also

available again after a power failure. The factory default for the

baud rate of the modules is 125 kBit/s.

The function should be executed only once during the

initialization in the first program cycle. After that it is disabled via

the input ENABLE.

The baud rate becomes immediately valid after the function call.

FALSE: The funct i o n i s n o t p r o c e s s e d .

(10, 20, 50, 100, 125, 250, 500, 1000 )

page 39

Page 40

Function

Library CRxxxx.LIB

Function symbol

Purpose

Parameters

Function outputs

Description

CAN_TRANSMIT

Passes a CAN data object (message) on to the CAN c ontroller

for transmission.

Function inputs

Name Data type Description

ID WORD Contains the number of the data object

RTR BYTE Not used, therefore value 0

DLC BYTE Number of the bytes to be transmitted from

DATA ARRAY The array contains max. 8 data bytes.

ENABLE BOOL TRUE: The function is processed.

Name Data type Description

RESULT BOOL TRUE: The function has accepted the

CAN_TRANSMIT is called f or each data object in the program

cycle, for long program cycles sever al times. The program mer

must ensure by evaluating the bit RESULT that his transmiss ion

order has been accepted. It can be said that for 125 kBit/s one

transmission order can be executed every 1 ms.

Via the bit input ENABLE the execution of the function can be

disabled temporarily. This can for example prevent a bus

overload. Also, several data objects can be sent quasi

simultaneously if each data object is assigned a flag used to

control the execution of the function via the ENABLE input.

identifier 0 ... 2048.

the array DATA (permitted values 0 ... 8).

FALSE: The function is not processed.

transmission order.

page 40

Page 41

Function

Library CRxxxx.LIB

Function symbol

Purpose

CAN_RECEIVE

Configures a data reception object and reads the reception

buffer of the data object.

Parameters

Function outputs

Description

Function inputs

Name Data type Description

CONFIG BOOL For the configuration of the data object the

CLEAR BOOL Deletes the data buffer (queue).

ID WORD Contains the number of the data object

Name Data type Description

DATA ARRAY The array contains max. 8 data bytes.

DLC BYTE The number of the transmitted bytes in

RTR BYTE Is not used

AVAILABLE BYTE Number of the messages received

OVERFLOW BOOL TRUE: Overflow of the data buffer.

CAN_RECEIVE must be called once for eac h data objec t dur ing

the initialization phase to inform the CAN controller of the

identifiers of the data objects.

In the further program cycles CAN_RECEIVE is called to read

the corresponding reception buff er, for long program cycles this

is done several times. The programmer must make sure by

evaluating the byte AVAILABLE that newly received data objects

are retrieved from the buffer and are further processed. Each

call of the function decrem ents the byte AVAILABLE by 1. If the

value of AVAILABLE equals 0, the buffer contains no data.

By evaluating the bit OVERFLOW an overflowing data buffer

can be detected. If the bit OVERFLOW is set, at least 1 data

object is

lost

.

bit must be set TRUE once. For data

transmission to commence the CONFIG bit

must be set to FALSE.

identifier 0 ... 2048.

the array DATA, possible values 0 ... 8.

Data loss!

FALSE: The buffer is not yet full.

page 41

Page 42

Function

Library CRxxxx.LIB

Function symbol

CAN_RESTART

Purpose

Parameters

Description

Restart of the CAN participant after "serious" transmission

errors (bus-off state).

Function inputs

Name Data type Description

ENABLE BOOL TRUE: The function is processed.

FALSE: The function is not processed.

Function outputs, none

CAN enables a distinction between a temporary and a permanent disturbance of a bus partic ipant. As desc r ibed in sec tion

6.3, three function states are available.

If a participant is

If a certain number of trans mission errors occ urs , the partic ipant

becomes

participant becomes again

If a participant is already error-passive and transm ission errors

continue to occur, it is switched off from the bus (

the error flag CAN_BUS_OFF_ERROR is set. A return to the

bus is only possible with the function CAN_RESTART. The error

flag is reset after a successful return.

The input ENABLE suppresses the execution of the function.

error-passive

error-active,

. If the error frequency is r educed, the

error-active

this is the normal state.

.

bus-off

) and

page 42

Page 43

Function

Library CRxxxx.LIB

Function symbol

CAN_ERRORHANDLER

Purpose

Parameters

Function outputs

Description

The programmer's job is to locate the precise error cause by

Minimum error routine to monitor CAN.

Function inputs

Name Data type Description

RESET BOOL Deletes the error counter.

Name Data type Description

ERRORCOUNT

CAN_ERRORCOUNT evaluates all possible CAN errors and

totals the number of the errors in the c ounter ERRORCOUNT.

In the case of a bus-off error the function tries to return the

participant to the bus. To do so, the function CAN_RESTART is

integrated.

evaluating the error counter and the error bits supplied by the

system. Via the function input RESET the counter can then be

set to 0 again.

In each application software where the CAN com munication is

utilized (also for the communication with a CAN display) at

least this function should be employed and processed

cyclically.

WORD Error counter, contains the number of the

errors occurred.

page 43

Page 44

6.7. CANopen in the ecomat R 360

The CAN layers 1 and 2 described at the beginning of chapter 6

control the physical link and the transmission of the data

between the bus participants. For a practical CAN application

this means that the program mer is responsible for the definition

of the data protocol for the special application.

To obtain a uniform protocol layer for networking the different

participants which describes the meaning of the transmitted

data the CAN Application Layer (CAL) was determined as layer

7. CANopen is based on CAL and defines which data are to be

transmitted by which CAL services. The meaning of the data f or

the corresponding device type (I/O module, drives, encoders,

etc.) is also defined. With these definitions the application

programmer can access all components with CANopen

capability independent of the manufacturer and without much

work on the protocol. CANopen participants which belong to the

same device family have organized their data the same way.

The characteristics of these device clas ses are indicated in the

"device profiles" (DS-40x).

Despite this definition the basic CAN structure which allows

each bus participant to send mess ages (data) to the network is

maintained. Only the network master ( NMT m aster) exists once

and is mainly used for running up and monitoring the system.

The mechanism s described below are to give a rough overview

of the CANopen functions. If you wish to utilise the full CANopen

functions, please contact CAN in Automation Technical Centre.

General information on CANopen

The object-oriented identifiers (11 bits) ar e called "CAN Object

In principle, each CANopen node has an object directory which

can be accessed via "Service Data Objects" (SDOs). In

addition, there are at least two "Process Data Objects" (PDOs)

for transmitting and rec eiving process data, a "Node Guarding

Object" to monitor the network as well as an "Emergency

Object" to indicate error states.

Ids" (COB IDs) under CANopen. Via the 4 most significant bits

(MSBs) they are divided into 16 groups. The rem aining 7 bits

are used to distinguish 127 CANopen nodes. This ensures a

clear assignment of the individual object types to the nodes.

This definition is a default assignment.

page 44

Page 45

The object directory

Service Data Object (SDO)

It is defined in the "predefined connection set”. Whether this

default is adhered to or not depends on the corresponding

application. To ensure a high flexibility as regards the selection

of CANopen devices from different manufacturers you should

carefully consider whether non-adherence is required.

Object Code

(binary)

NMT 0000 0000000 0 Network managem.

SYNC 0001 0000000 128 Synchronization

EMCY 0001 xxxxxxx 129 - 255 Error states

TIME STAMP 0010 0000000 256 Network time

PDO1(tx) 0011 xxxxxxx 385 - 511 Synchronous PDO

PDO1(rx) 0100 xxxxxxx 513 - 639 Synchronous PDO

PDO2(tx) 0101 xxxxxxx 641 - 767 Asynchronous PDO

PDO2(rx) 0110 xxxxxxx 769 - 895 Asynchronous PDO

SDO(tx) 1011 xxxxxxx 1409 - 1535 Master->slave SDO

SDO(rx) 1100 xxxxxxx 1537 - 1663 Slave->master SDO

Nodeguarding 1110 xxxxxxx 1793 - 1919 Node/life guarding

All node parameters are stored in the object directory of the

corresponding CANopen node. To ensure a clear identification a

directory entry is marked by an index (IDX, length 16 bits) and a

subindex (SUBIDX, length 8 bits). Depending on the param eter

type they are stored in the individual index areas. The m eaning

of the individual indexes for the communication and standard

parameters are defined for the individual device types in the

CANopen standard. In addition, an area for manufacturerspecific data is available. In this area the configuration

parameters for the I/O modules f rom ifm elec tronic gmbh are for

example stored.

Index (hex) Object

0000 Not used

0001 - 009F Data types

00A0 - 0FFF Reserved

1000 - 1FFF Area for the communication profile

2000 - 5FFF Area for the manufacturer-specific data

6000 - 9FFF Area for standard device parameters

A000 - FFFF Area for gen. IEC1131 network variables

A read and write access to the object director y is achieved via

the "Service Data Objects" (SDOs).

The SDOs are used for all data in CANopen which are not time

critical. In principle, they are only transmitted from point to point

(network master / s lave). The SDO s are c hiefly used to transm it

the configuration data of the CAN participant during the booting

phase.

COB IDs

(decimal)

Default function

page 45

Page 46

Process Data Object (PDO)

Node Guarding Object

Emergency Object

In the object direct ory of the node these err ors are s tor ed. T o do

The time critical process data are transferred by means of the

"Process Data Objects" (PDOs). T he PDOs can be exchanged

between the individual nodes in any way (PDO linking). It is also

defined whether the data exchange is event-controlled

(asynchronous) or synchronized. Depending on the type of data

to be transferred the right choice of the transmission type can

considerably relieve the amount of data transm itted on the CAN

bus. The default setting of the I/O modules from ifm electronic

gmbh specifies a synchronous transmission of analog input data

and all output data and an event-controlled transmission of

digital input data.

To detect communic ation errors in the network node guarding is

used. Each bus node is cyclically accessed by the network

master via the defined node guarding COB ID. If no reply is

given within the defined guard time, the m ast er s ignals an error .

Via the life time (life time factor * guard time) it can also be

defined after how many unsuccessful attempts the error

message is to be created.

If an internal error occurs in a bus participant (e.g. wrong

configuration parameter, short circuit at the output) an EMCY

object is created. This EMCY object is standardized and is sent

once when the error occurs and once when the error state has

disappeared.

so, the "error register", the "manufacturer-specific status

register" and the "error history" are available.

page 46

Page 47

Boot-up routine

During the boot-up routine the network master allows the

network to run up. In this process the m aster is infor med of the

most important communication parameters and, if necessary,

guarding is activated. During the boot-up routine the

configuration parameters s hould also be transferred. The node

should be in the "pre-operational" state.

State Description

6 Start remote node indication

7 Stop remote node indication

8 Enter pre-operational state indication

10 Reset node indication

11 Reset communication indication

12 Initialization finished - enter pre-operational automatically

To ensure a successful boot-up routine at least the node

number and baud rate of the CAN participant m ust be set. The

baud rate of the master must conform to this. This setting is

done via DIP switches in the node or an additional parameter

setting software. Since the plc R 360 also allows a description of

the object directory via the SDOs, setting can also be done via

the plc.

To ensure that the ecomat R 360 operat es in the CANopen

mode the flag CAN_OPEN must be set to TRUE at the

program start (during the initialization).

page 47

Page 48

Object directory

Baud rate and node number

6.8. The ecomat R 360 as CANopen slave

The ecomat R 360 can also be used as a programmable

input/output module under CANopen. It behaves like a

CANopen slave. As CANopen slave the ecomat R 360 is

classified as a "programmable device" according to CiA DS 405.

To use the R 360 as CANopen slave the system bit CAN_OPEN

must be set.

The device parameters can be accessed via the object

directory. If they are identified as read/write, they can be

changed via SDO_WRITE and by the NMT master or by an

external parameter setting system.

The object directory in the ecomat R 360 has three m ain areas.

The CANopen communication parameters are stored as from

index 1000 hex.

As from index 2000 hex the manufacturer-specific data of baud

rate and node number are stored.

As from index A000 hex starts the area for the general IEC1131

network variables. They are transferred via the PDOs. The

identifiers and the transmis sion types of the PDOs are entered

in this area.

For the exact structure of the object directory see point 1.6 in

the appendix.

The baud rate and node number are entered in the

manufacturer-specific area of the object directory from index

20F0 / 20F1 hex and 20F2 / 20F3 hex. The baud rate or node

number can be changed via a SDO by the master, a function

call or the programming system. If the change is made via

SDO_WR ITE, both entries in the obj ect directory m ust have the

same contents. The change of the baud rate only becomes valid

after a reset, that of the node ID at once.

Index Subindex Name Default value

20F0 0 Node ID 32

20F1 0 Node ID 32

20F2 0 Baud rate 3

20F3 0 Baud rate 3

On no account are two participants with the same node

number allowed in the network.

page 48

Page 49

Retentive data

PDOs

For setting the baud rate the following parameters are allowed:

Number Baud rate (kBit/s)

0 1000

1 500

2 250

3 125

4 100

5 50

6 20

7 10

Via the manufacturer-specific area of the object directory it is

possible to transfer a max. 256-byte data block to the R 360

slave by means of SDO_WRIT E. These data are stored in the

flash memory in a non-volatile way and can be further

processed in the application program via the retain addresses

%MB0 ... %MB255 (%MW0 ... %MW127). Thus this data area

is available as freely defined parameter set.

In the "predefined connection set” to CiA DS 401 the first two

RX and TX PDOs are def ined depending on the node number.

With these PDOs 16 data bytes each can be sent and received.

If more PDOs ar e required, they must be "manually" defined in

the application program by means of the functions

PDO_RX_CONFIG and PDO_TX_CONFIG. The identifiers

must then be assigned in rising order from 380 hex. If the

"predefined connection set" is not used, the CO B IDs f or PDO 1

and PDO 2 must also start f rom 380 hex. A total of 2 x 8 PDOs

can be set up.

Since the COB IDs for the PDOs are not stored (exception

PDO 1 and 2 in the "predefined connection set") they must be

once

for all PDOs in the initialization routine af ter

page 49

re-initialized

each start of the plc. In principle, the PDO IDs which are not

included in the "predefined connection set" have the same

default in all devices (RX PDOs from 380 hex, TX PDOs from

388 hex). They must therefore be reconfigured with

PDO_TX/RX_CONFIG if several R 360 slaves are used.

Otherwise there would be conflicts with the IDs.

RX-PDO ID TX-PDO ID

RX-PDO 1 pred. c. set TX-PDO 1 pred. c. set

RX-PDO 2 pred. c. set TX-PDO 2 pred. c. set

RX-PDO 3 382 hex TX-PDO 3 38A hex

RX-PDO 4 383 hex TX-PDO 4 38B hex

RX-PDO 5 384 hex TX-PDO 5 38C hex

RX-PDO 6 385 hex TX-PDO 6 38D hex

RX-PDO 7 386 hex TX-PDO 7 38E hex

RX-PDO 8 387 hex TX-PDO 8 38F hex

Page 50

PDO mapping

Via the application progr am the data relevant to the CANopen

Monitoring the PDO reception

A conventional PDO mapping is not possible in the ecomat

R 360 since this is not necessary for a plc.

network can be directly written into the PDOs or read from them.

Network variables in the area from %MW 2000 for the received

data and from %MW 2032 for the data to be transm itted can be

immediately processed by the application program (see

appendix 1.5). Thus 8 x 4 transmission words (TX-PDOs) and

8 x 4 reception words (RX-PDOs) are available to the user.

The detection whether new data have been transferred is not

supported by CANopen. If this function is required, it must be

created by the programmer. This can be done as follows:

•

Write the signature in the receive object

•

PDO contains a toggle bit or consecutive number

•

Use the function block CAN_RECEIVE

Transmission types

Node guarding

The transmission types SYNC, i.e. synchronous transmission

after a PDO SYNC object or ASYNC, i.e. transmission after a

change of the network variables (event due to a change) are

supported. The COB ID of the sync object can be configured.

The indication of an inhibit time can delay the sending of

ASYNC objects. So considerably fluctuating process values can

cause an extremely high bus load in the case of an eventcontrolled evaluation. If the inhibit time is indicated, the next

PDO cannot be sent to the bus before the time has elapsed.

If strategically important values are to be transferred in the

ASYNC mode, a single transmission m ay not be s afe enough.

Via the function block PDO_T X_REFRESH the important PDO

can be repeated from time to time.

As default setting all PDOs are transm itted after a data change

(ASYNC mode).

If an ecomat R 360 is accessed by the NMT master once by

means of a guarding object, it is fully controlled by the

NMT master by means of the cyclical node guarding. If the CAN

communication is disturbed, a guarding error message is

created in the NMT mas ter. Also, in the R 360 CANopen slave