IFM Electronic PL2058 Operating Instructions Manual

Bedienungsanleitung

Operating instructions

Notice utilisateurs

Elektronischer

Drucksensor

Electronic pressure

sensor

Capteur de pression

électronique

PL2058

R

DEUTSCHENGLISHFRANÇAIS

Sachnr. 701712/00 08/02

12

Contents

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 14

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . page 15

Installation and set-up / operation / maintenance . . . . . page 16

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 17

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . page 18

Adjustable parameters . . . . . . . . . . . . . . . . . . . . . . . . page 19

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 20

Scaling the measuring range . . . . . . . . . . . . . . . . . . . . page 21

Scale drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 32

1 Function and features . . . . . . . . . . . . . . . . . . . . . . page 13

4 Technical informations / Functioning / Parameters page 19

3 Programming / Use with EPS interface . . . . . . . . . page 17

2 Use with factory setting . . . . . . . . . . . . . . . . . . . . page 14

Safety instructions

Please read the product description prior to installing the unit.

Please check that the product is suitable for your application

without any restrictions.

If the operating instructions or the technical data are not

adhered to, personal injury and/or damage to property may

occur.

Please check in all applications that the product materials (see

Technical data) are compatible with the media to be measured.

The pressure sensor detects the system pressure and converts it into

an analog output signal (4 ... 20 mA). The measuring range can be

scaled to up to 25% of the value of the span (→ page 19, 21).

It is also indicated:

• System pressure above the measuring range: output signal > 20 mA.

• System pressure below the measuring range: output signal drops to

max. 3.2 mA (depending on the scaling).

Applications :

Avoid static and dynamic overpressure exceeding the given overload pressure.

Even if the bursting pressure is exceeded only for a short time

the unit can be destroyed (danger of injuries)!

The unit is ready for operation when delivered.

Factory preset: not scaled.

13

1Function and features

ENGLISH

Bursting

pressure

Permissible

overl. pressure

Measuring range

-12.5 ... 250.0 10000 (10 bar) 30000 (30 bar)

-1.25 ... 25.00 1000 (1 MPa) 3000 (3 MPa)

mbar

kPa

-5.0 ... 100.4 4000 12000

-125 ... 2550 102000 306000

inH2O

mmWS

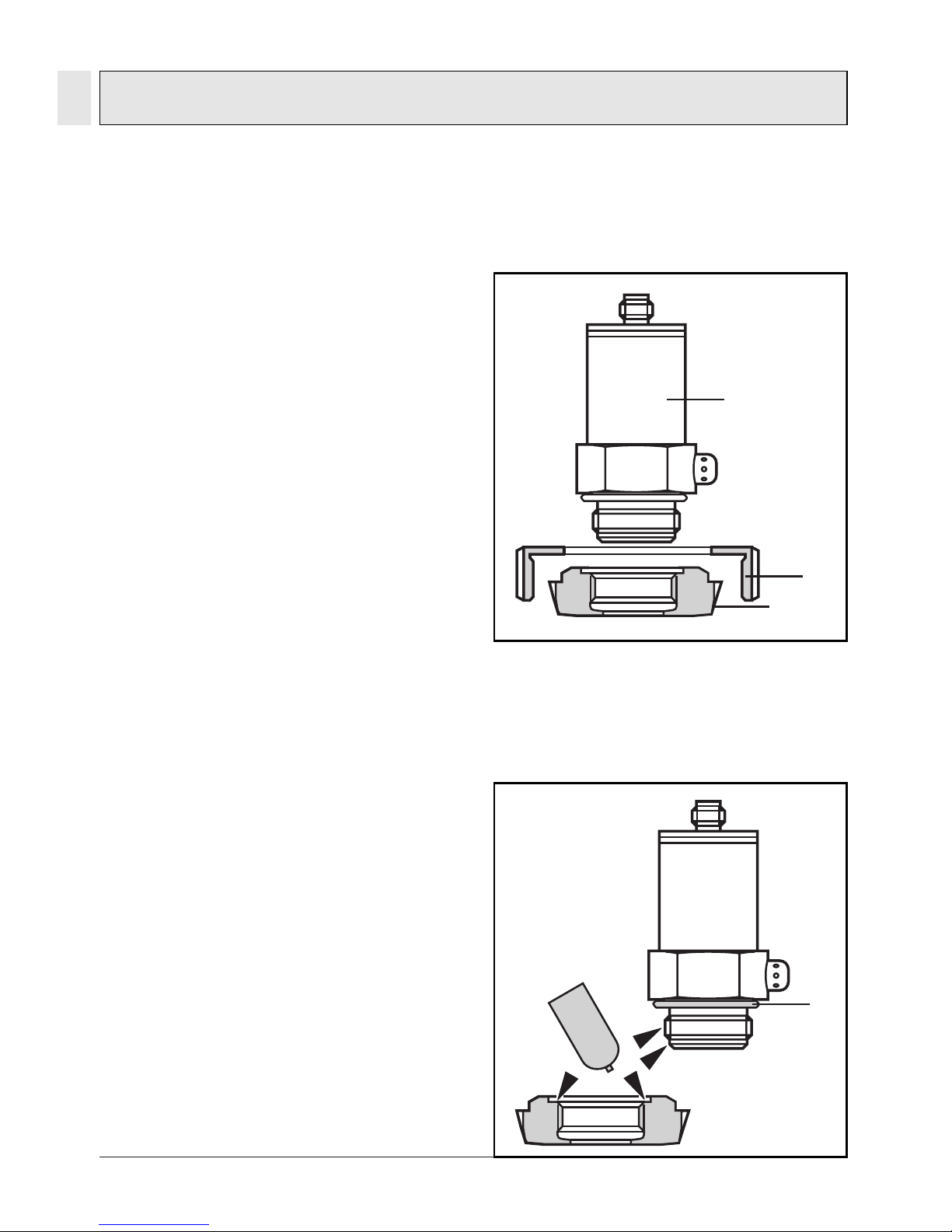

Installation

Before mounting and removing the sensor, make sure that no pressure

is applied to the system.

The unit is adaptable for various

process fittings. ifm adapters to

be ordered separately as accessories.

Mount adapter (C) to the sensor

(A) first, then sensor + adapter to

the process connection by means

of a nut, a clamping flange or

similar (B).

If it is not possible to slide the fixing element (B) down over the

top of the sensor: slide it up over

the bottom of the sensor before

the adapter is mounted.

Note: Sensor and adapter are only to be mounted once.

Mounting of the adapter

Step 1

Grease thread and sealing chamfer of the sensor and of the

adapter with the greasing paste

supplied.

The greasing paste is food-grade

(USDA-H1 84-201).

Make sure that the O-ring (D) is

correctly positioned.

14

2

A

B

C

D

Grease

Use with factory setting

Loading...

Loading...